Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Clamping meets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

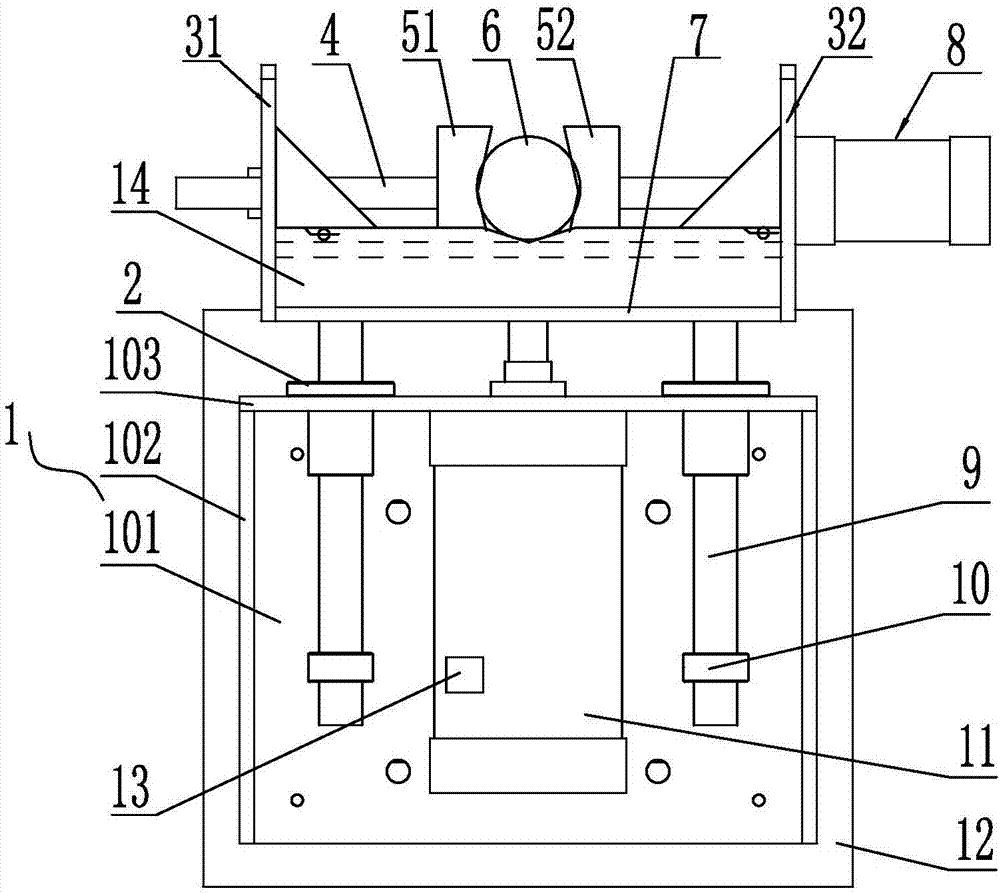

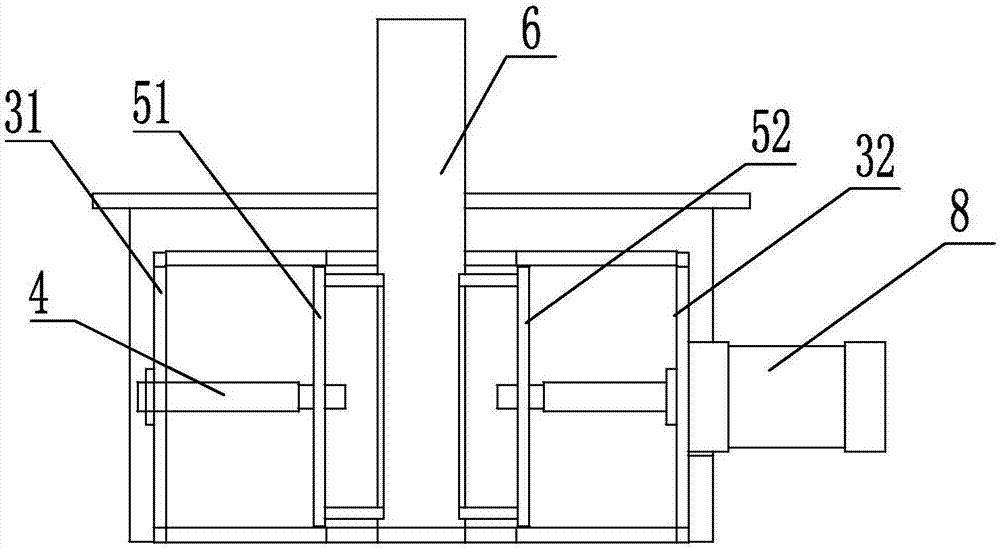

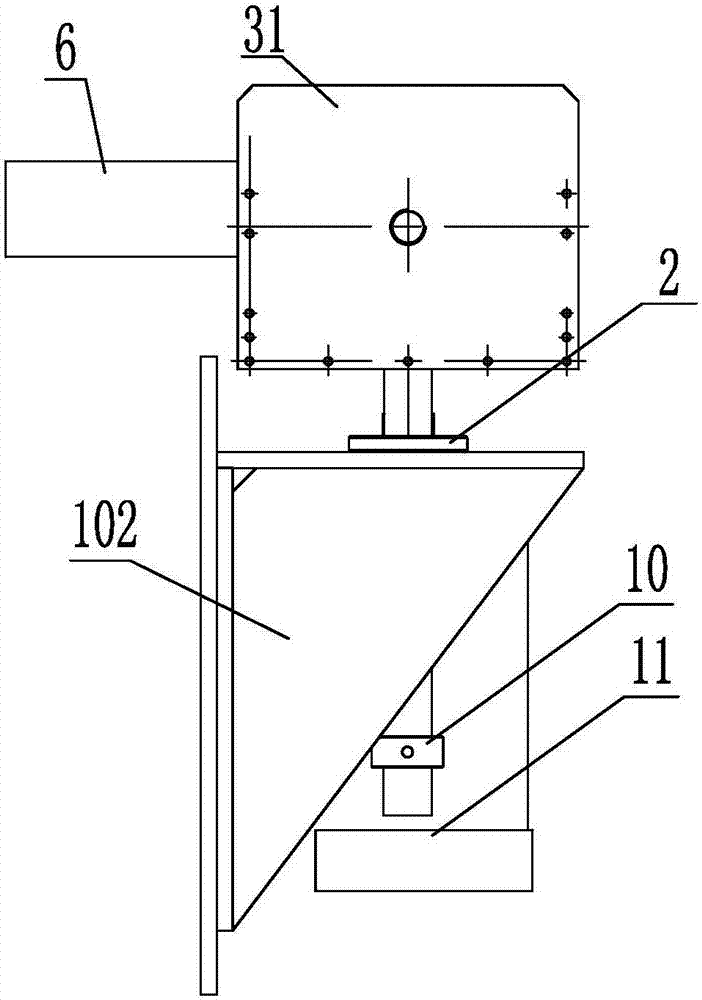

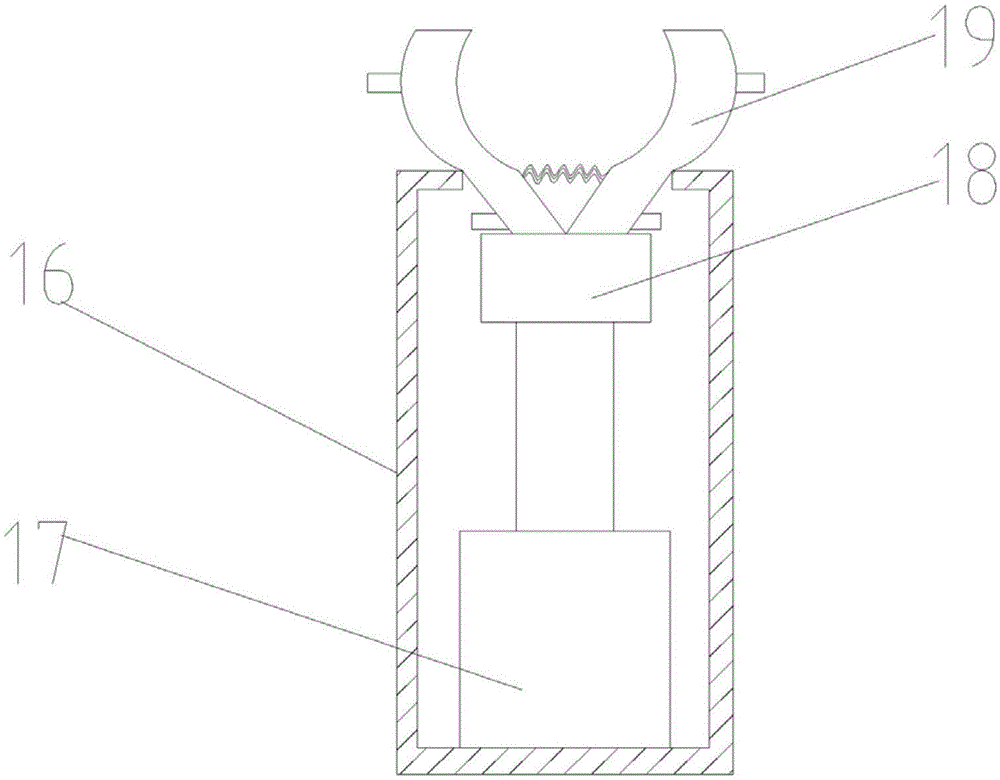

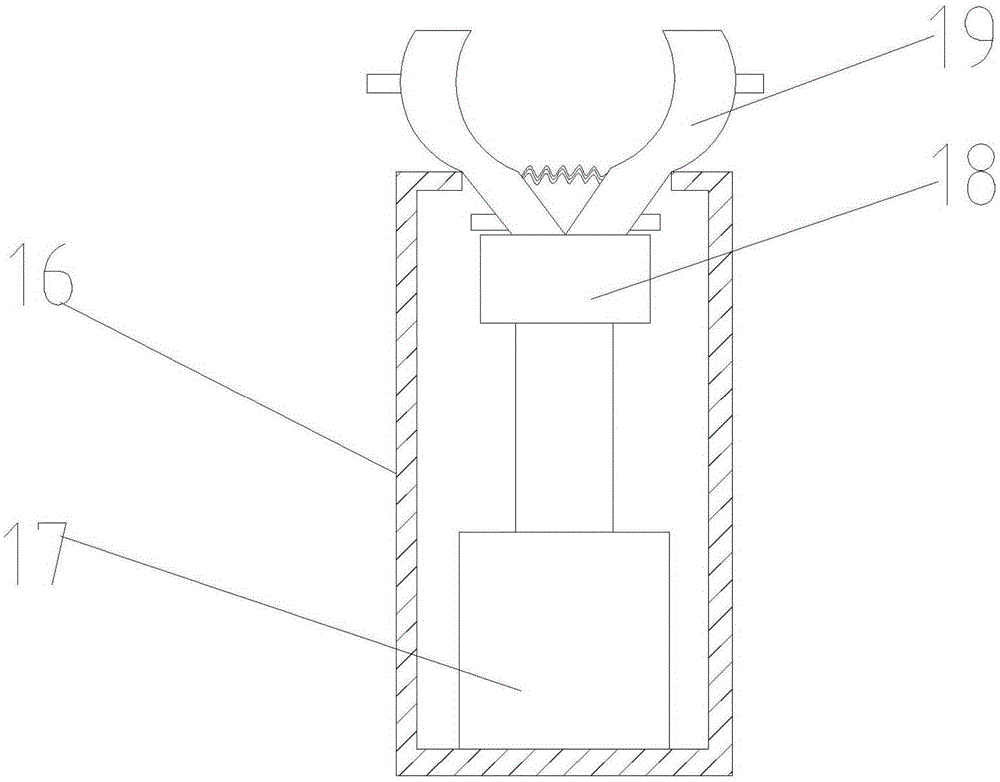

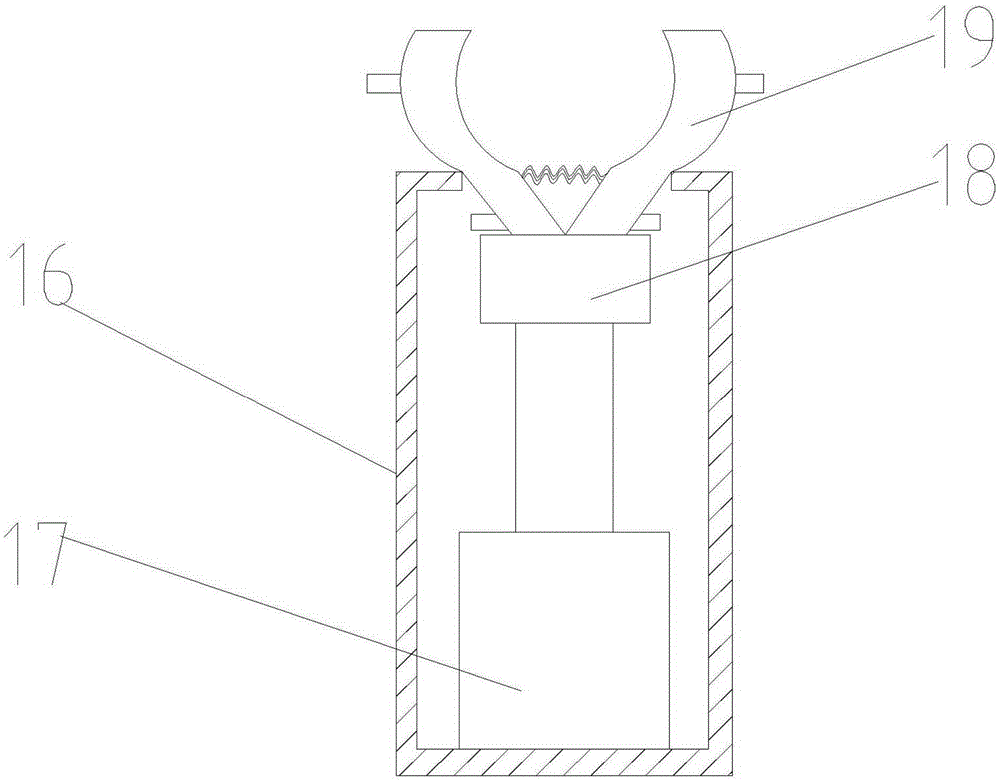

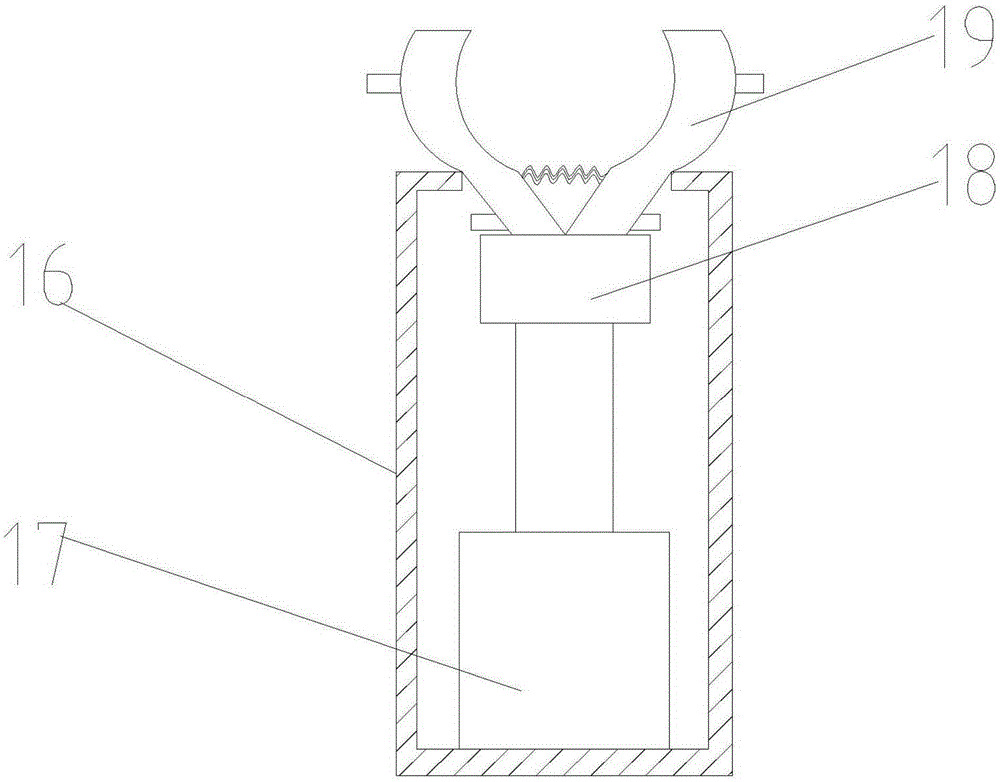

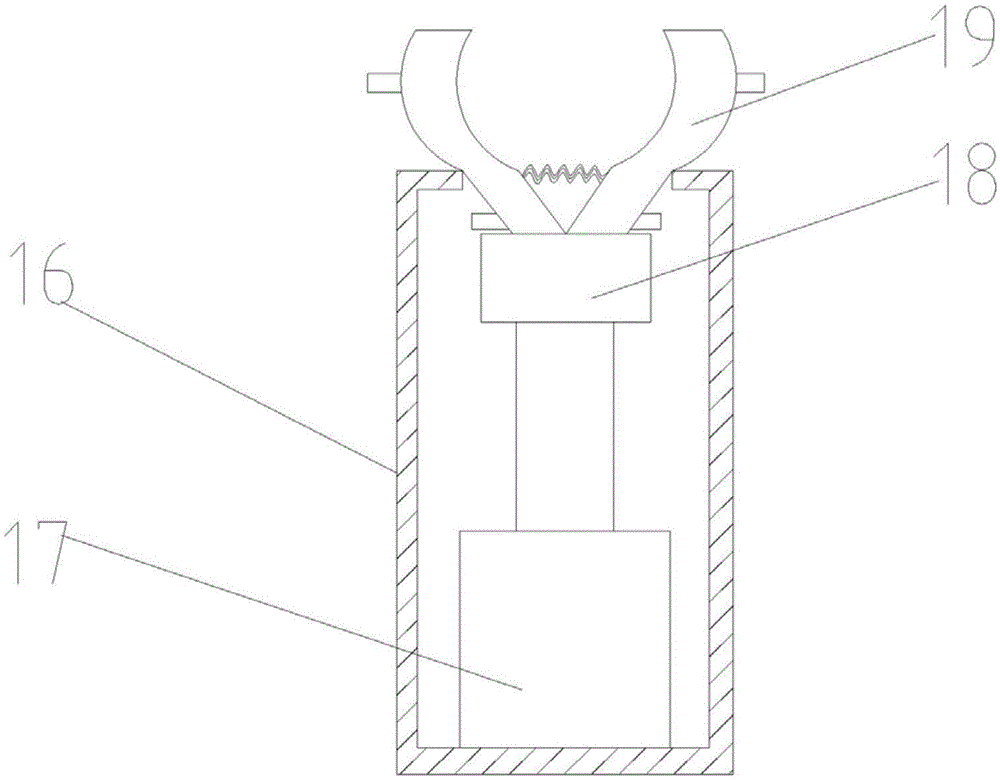

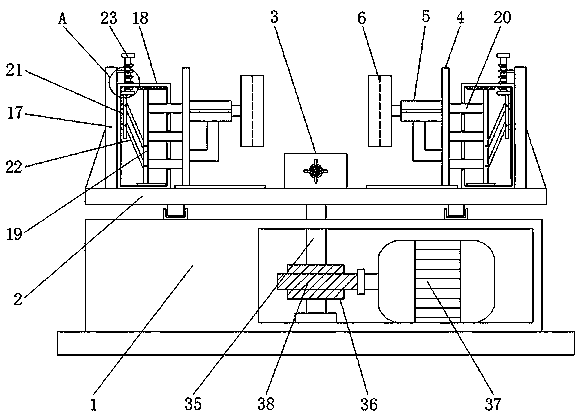

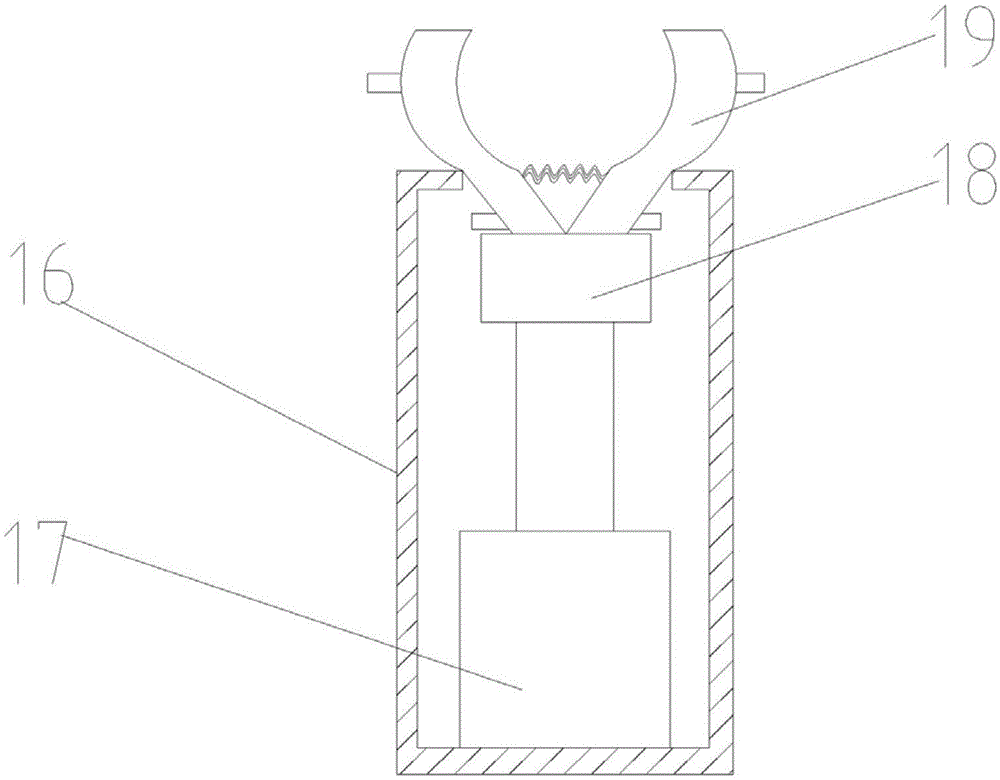

Lifting type centering clamping device and clamping method thereof

InactiveCN106975952AAchieve clampingAchieve releaseMetal working apparatusPositioning apparatusProduction lineLogistics management

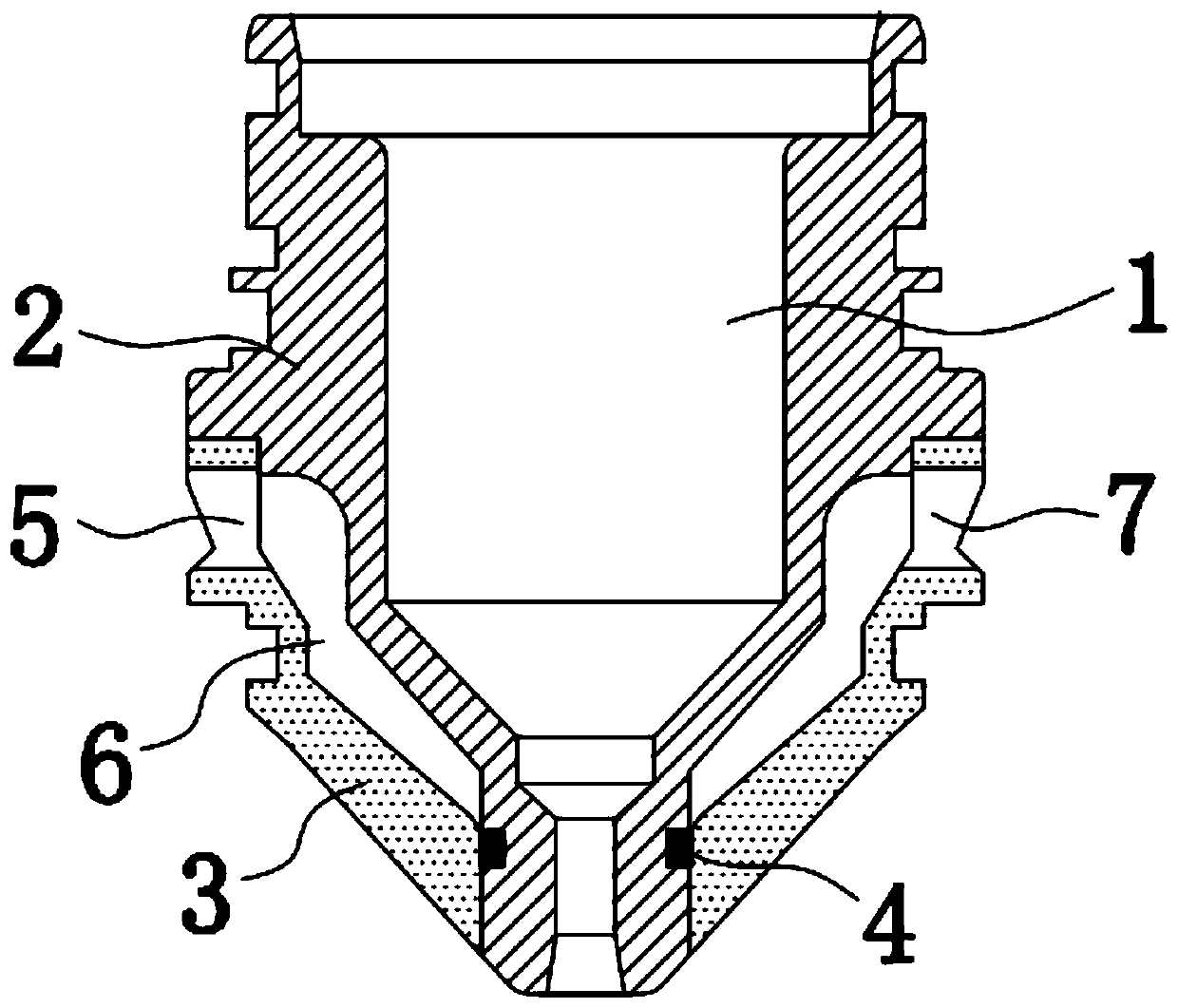

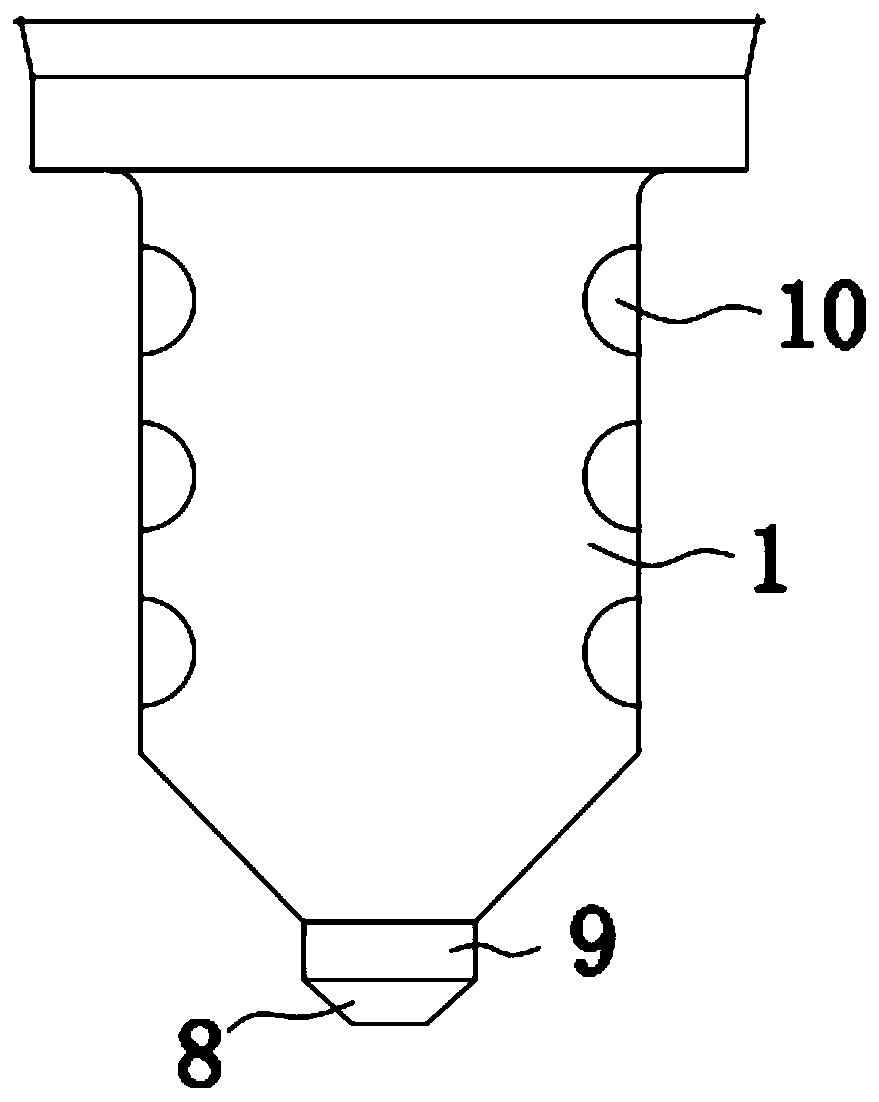

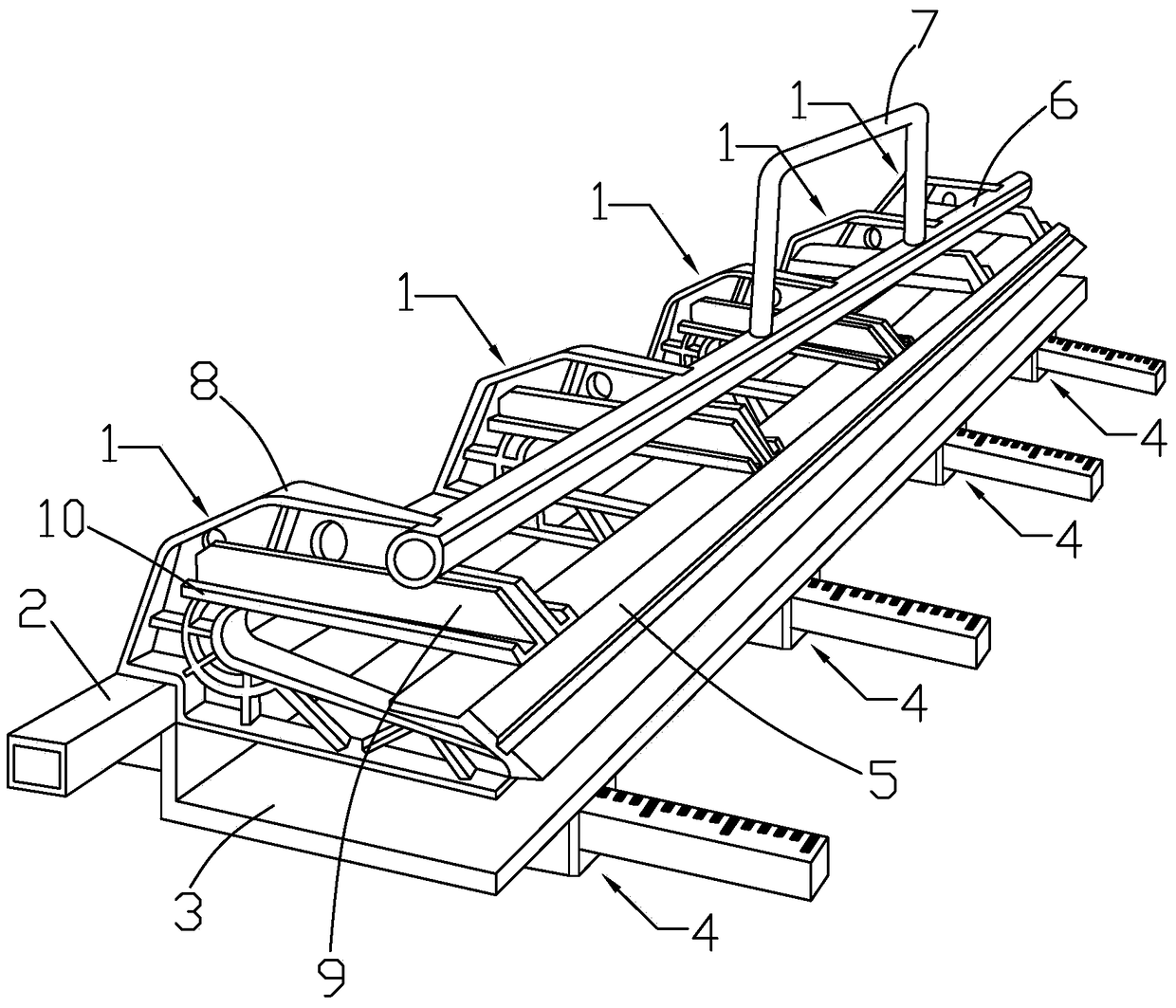

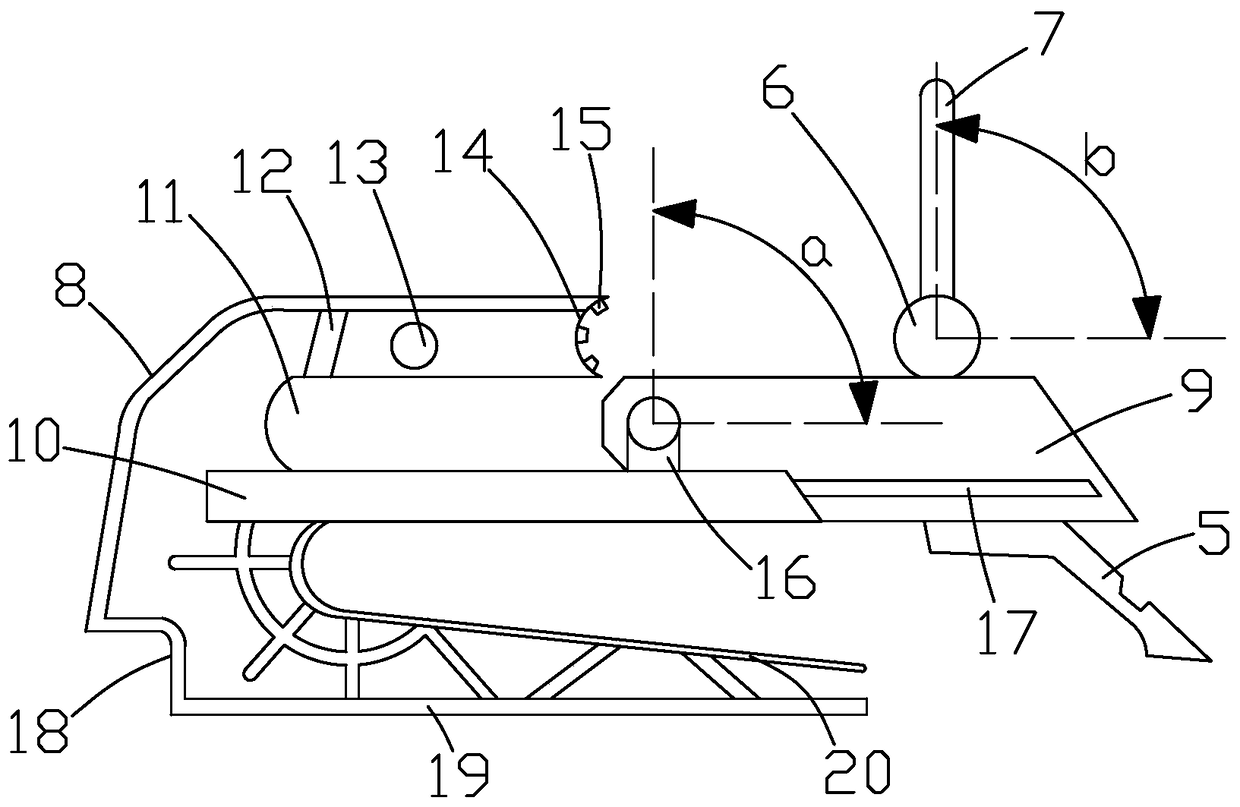

A lifting type centering clamping device comprises a centering clamping mechanism and a lifting mechanism. The centering clamping mechanism comprises a bottom plate, a clamping air cylinder, a left connecting plate, a right connecting plate, a left clamping plate and a right clamping plate, wherein the left connecting plate, the right connecting plate, the left clamping plate and the right clamping plate are sequentially and symmetrically mounted on the left and right sides of the bottom plate; the left clamping plate and the right clamping plate are oppositely mounted to form an open-ring type clamping opening; the left connecting plate is connected with the left clamping plate through a screw rod; the right connecting plate is connected with a piston rod of the clamping air cylinder stretching into the right connecting plate; and the clamping air cylinder moves to drive the right clamping plate to move towards the left clamping plate to clamp or loosen a workpiece. The lifting mechanism comprises a base and a lifting air cylinder; a piston rod of the lifting air cylinder is connected with the bottom plate of the centering clamping mechanism; and the lifting air cylinder moves to push the bottom plate to lift and drop to realize lifting and dropping of the centering clamping mechanism. A clamping method of the centering clamping device comprises the steps of initial adjustment, clamping and loosening. The device is small in size, compact in structure and easy in operation of the clamping method, can meet the clamping machining requirement of longitudinally and transversely conveying the workpiece, and can be widely used in an automatic logistics production line.

Owner:LIUZHOU OVM MASCH CO LTD

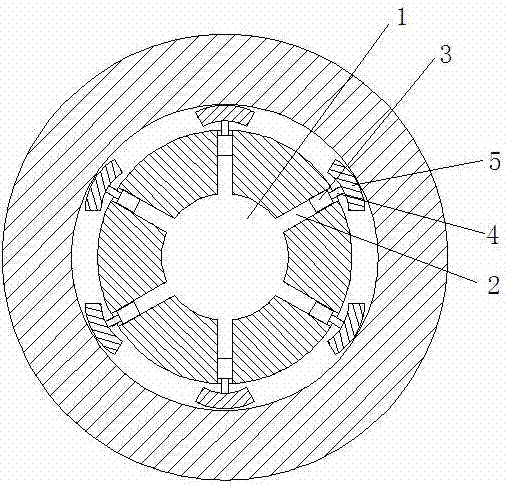

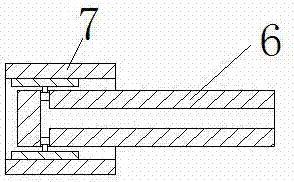

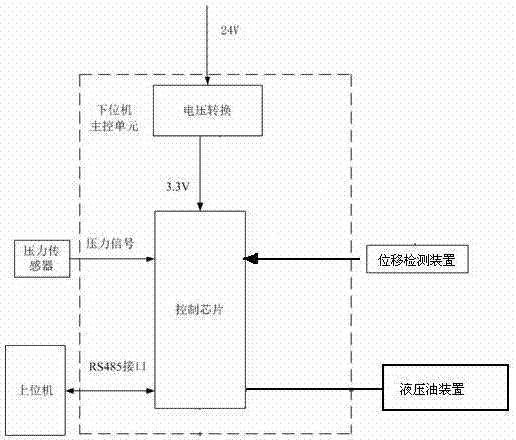

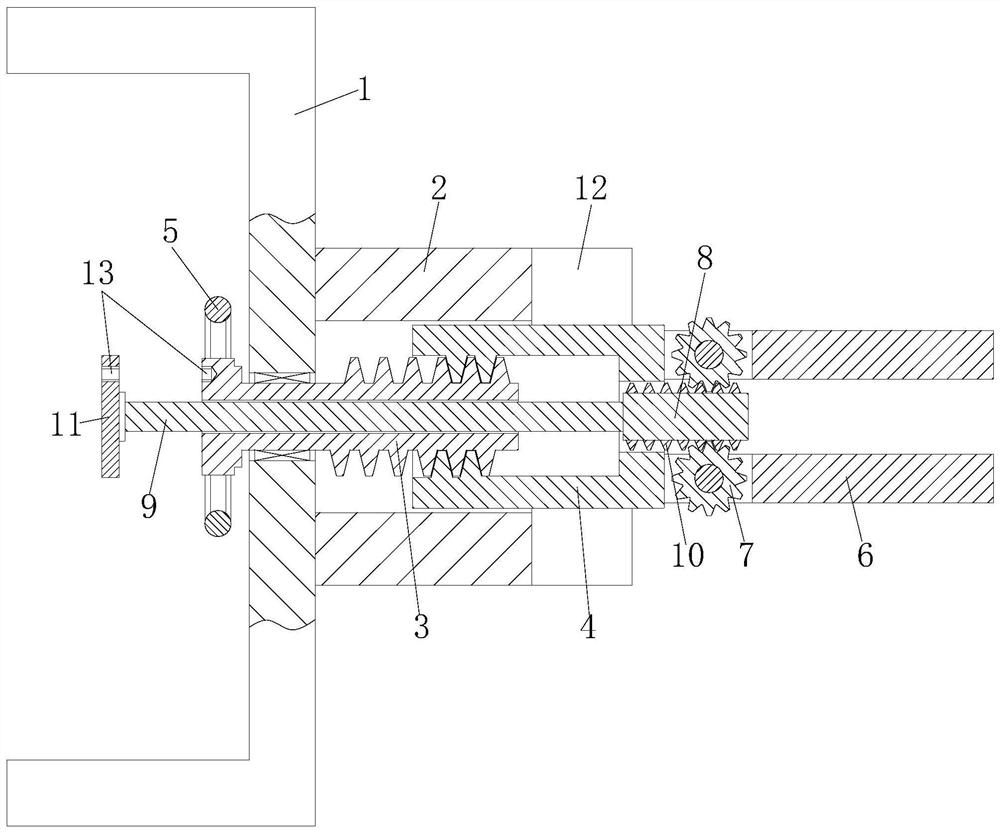

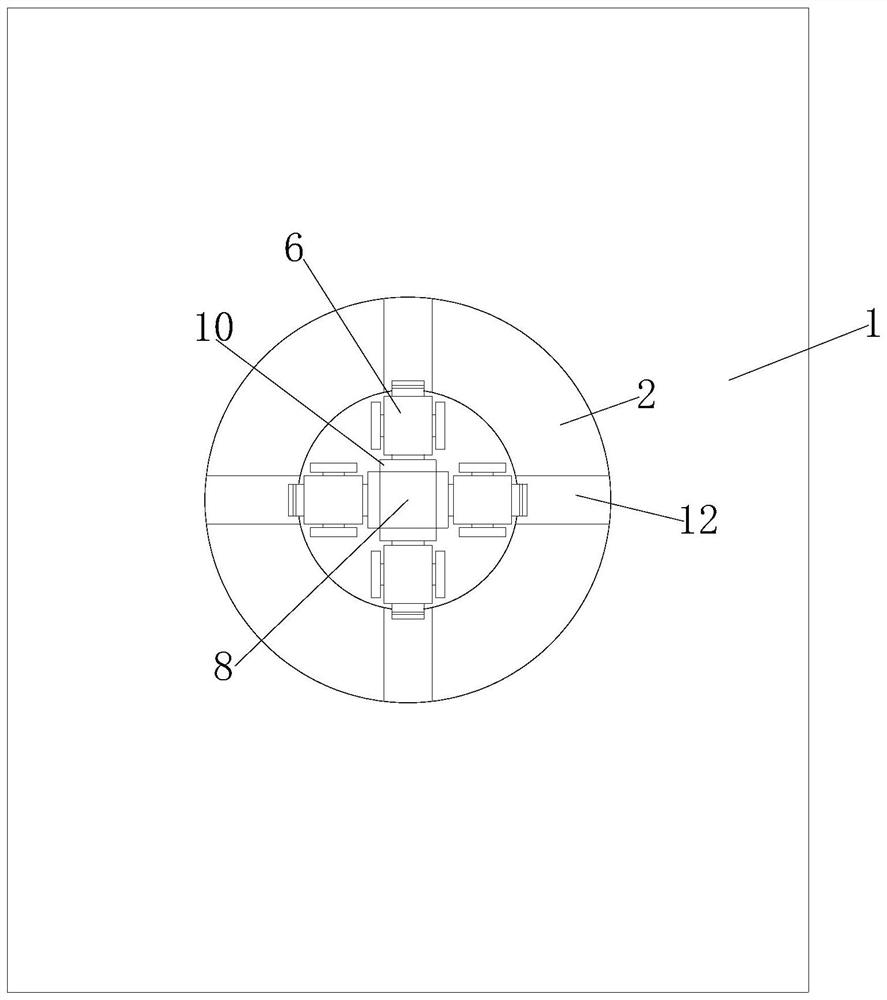

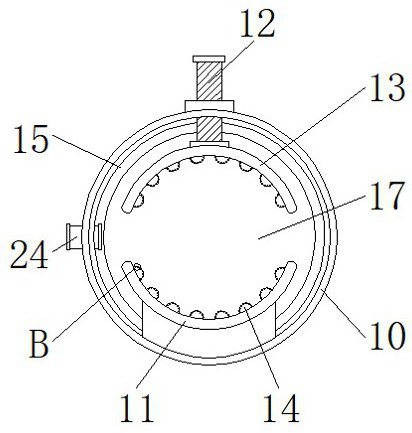

Clamping method of tube workpiece clamp

InactiveCN106903536AClamping meetsOvercome virtual contact with the workpieceWork clamping meansMeasurement/indication equipmentsEngineeringMachine tool

The invention discloses a clamping method for a pipe workpiece fixture. The clamp includes a connecting shaft, a hydraulic oil device, a hydraulic diameter expanding mechanism, a displacement detecting device, a pressure detecting device and a host computer, wherein one end of the connecting shaft is connected to the The machine tool spindle is connected, and the other end of the connecting shaft is evenly provided with multiple hydraulic diameter expanding mechanisms along the circumference of the connecting shaft on the same plane. The multiple hydraulic expanding mechanisms are supported on the inner wall of the workpiece to support and clamp the workpiece. The invention clamps the workpiece through several hydraulic diameter expanding mechanisms, and detects the workpiece through double detection mechanisms to ensure accurate clamping of the workpiece.

Owner:SUZHOU YASIKE PRECISION CNC CO LTD

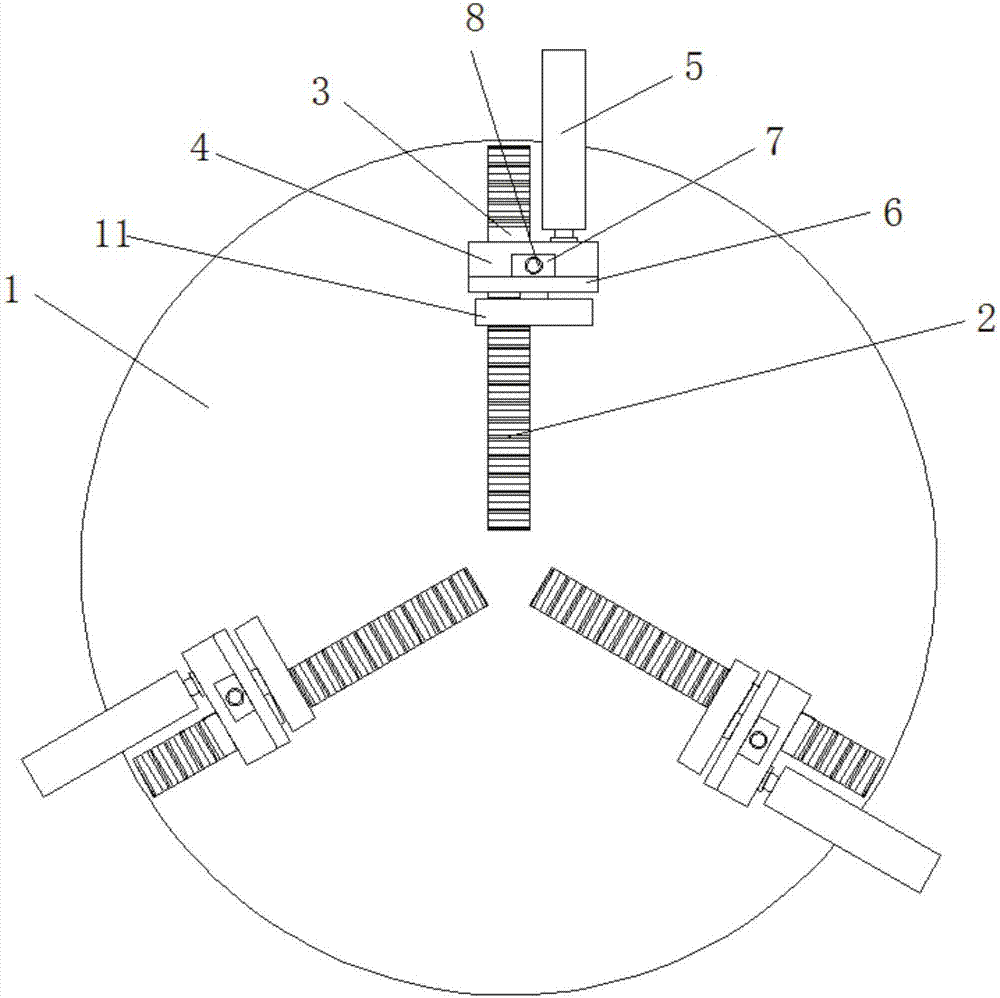

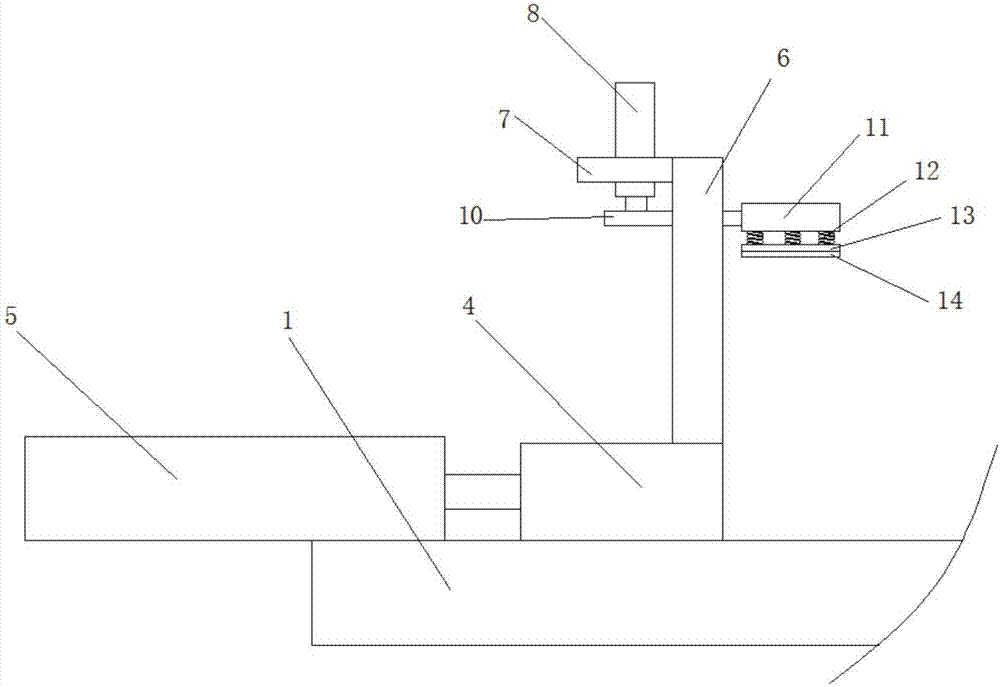

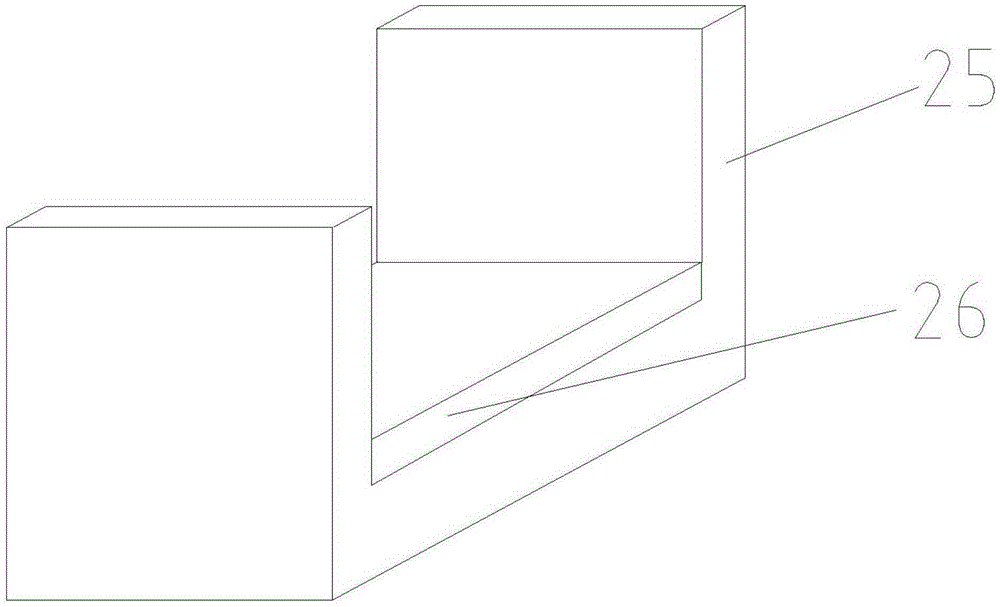

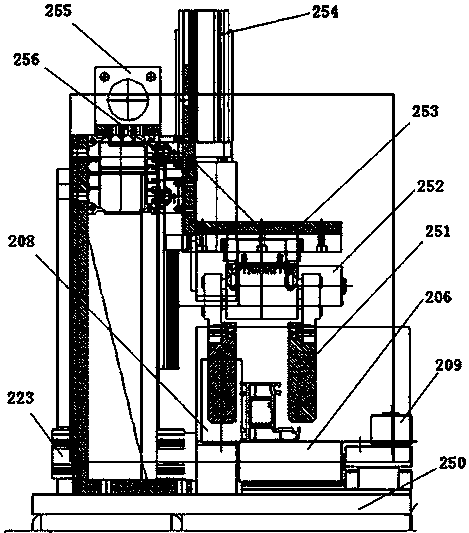

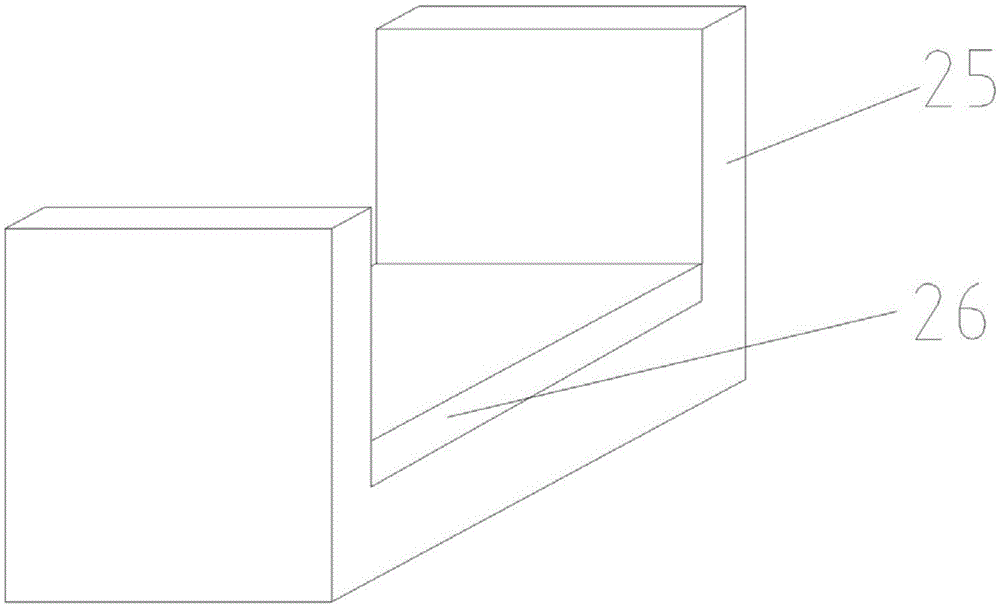

Workpiece clamping device of numerical control milling machine

PendingCN107511705AClamping meetsPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a workpiece clamping device of a numerical control milling machine. The device comprises a fixed disc; the fixed disc is fixedly mounted on the numerical control milling machine; three sets of chutes are formed in one side of the fixed disc in the radius direction at equal intervals; slide blocks are movably mounted in the chutes, and are fixedly connected with first clamping plates; the first clamping plates are tightly bonded on the surface of the fixed disc; first clamping cylinders are fixedly mounted on the fixed disc on one sides of the chutes in the length directions of the chutes; and piston rods of the first clamping cylinders are arranged towards the circle center of the fixed disc. Three sets of clamping mechanisms are arranged on the fixed disc; the clamping mechanisms can move in the chutes for adjustment; workpieces can be stably clamped through the clamping support force in three directions, and cannot be shaken even if in the machining process; and the positions of the three sets of clamping mechanisms can be adjusted to satisfy clamping of irregular workpieces so as to widen the application range of the device.

Owner:JINGYIHENGZHUN TIANJIN CNC EQUIP CO LTD

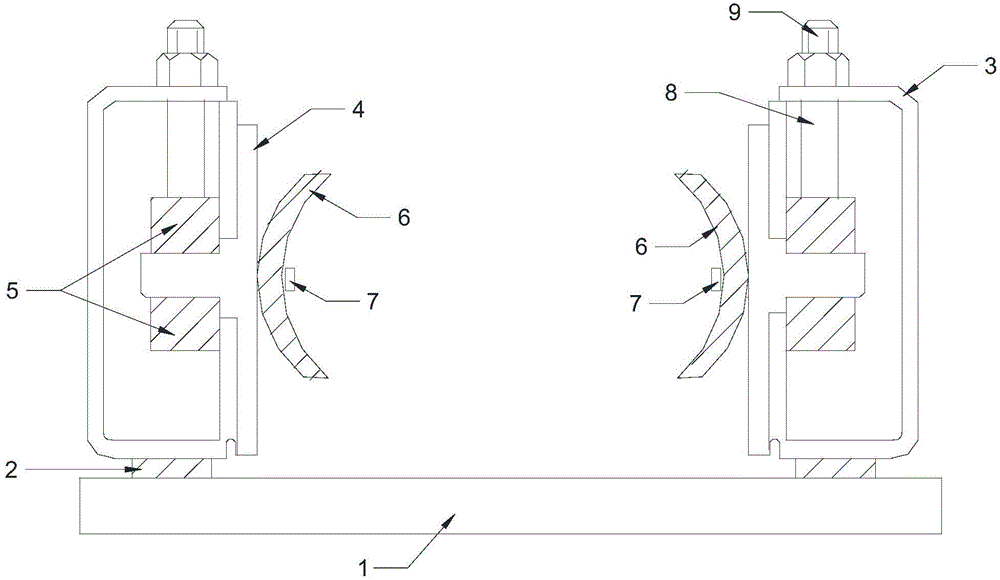

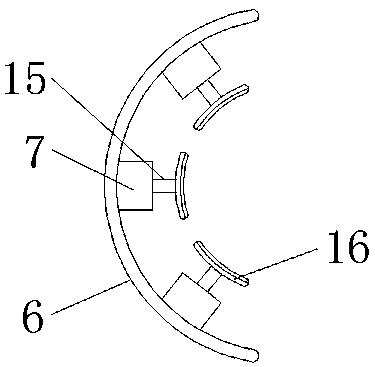

Cambered surface clamping device

InactiveCN104440260AAchieve clampingClamping meetsWork holdersPositioning apparatusEngineeringOperating table

The invention relates to the field of fittings, in particular to a cambered surface clamping device. The cambered surface clamping device comprises a horizontal operating table top, wherein plane bearings are symmetrically arranged at two ends of the horizontal operating table top; the cambered surface clamping device further comprises a rectangular framework connected with the plane bearings; a through hole is formed in the side wall, perpendicular to the horizontal operating table top, of the rectangular framework; the cambered surface clamping device further comprises a T-shaped removable plate; the vertical end of the T-shaped removable plate is inserted into the through hole and positioned in the rectangular framework; a rotating nut is arranged in the rectangular framework; the rotating nut is rotationally connected with the vertical end of the T-shaped removable plate; an arc clamping plate is arranged on the surface of the horizontal end of the T-shaped removable plate. The invention aims at providing a cambered surface clamping device which can be fit for the positioning of regular cambered surface work pieces or irregular cambered surfaces, with improved application range and practicability.

Owner:常州市品鑫除尘设备有限公司

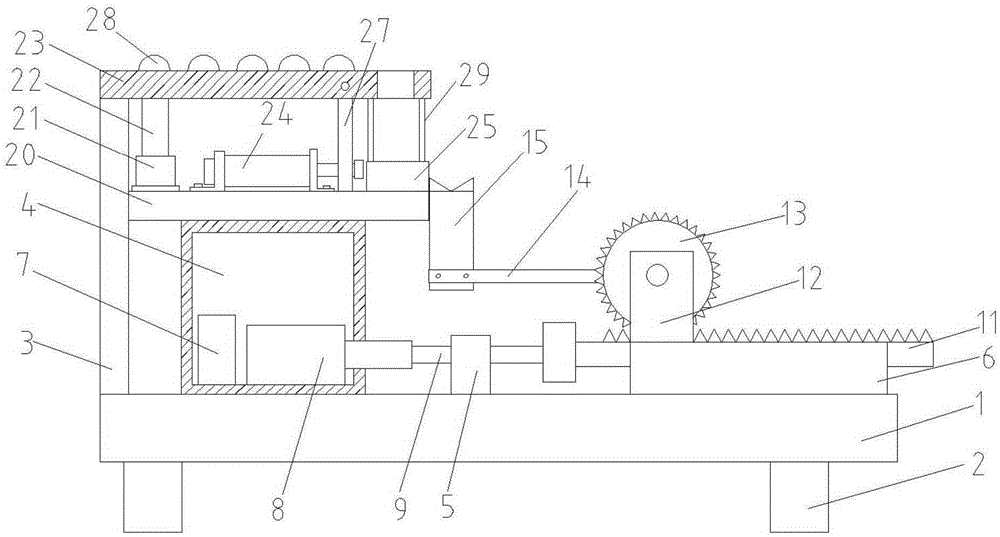

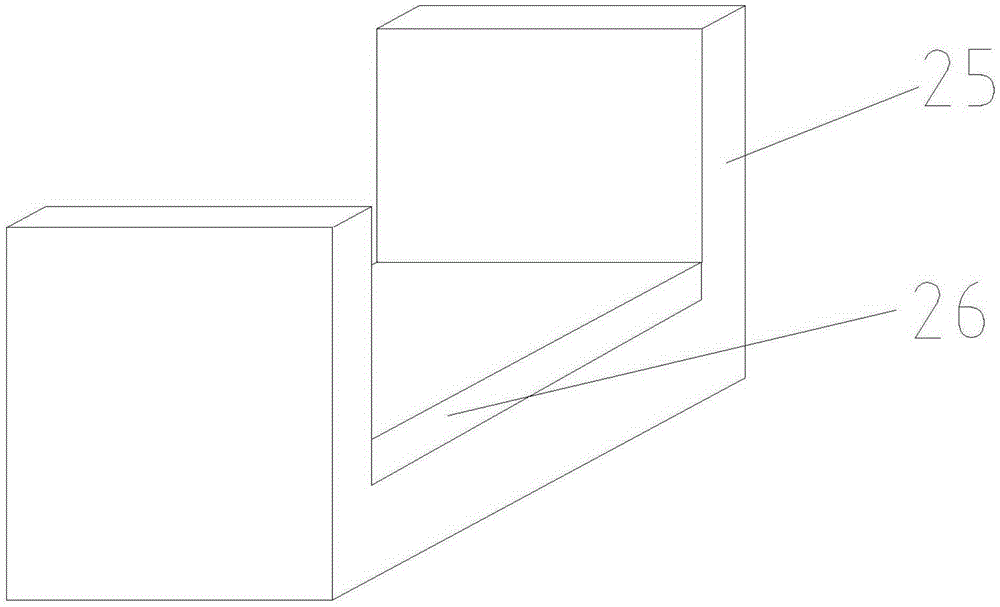

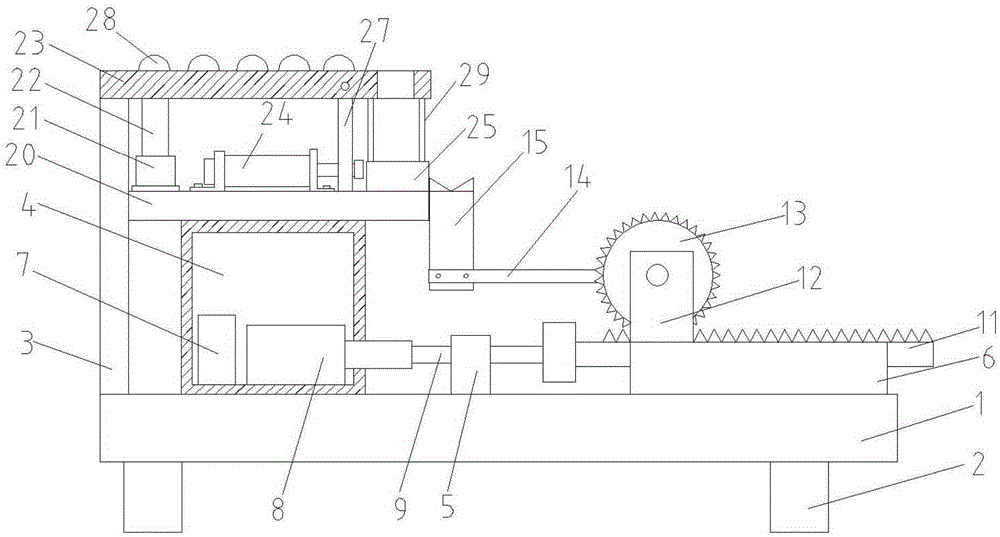

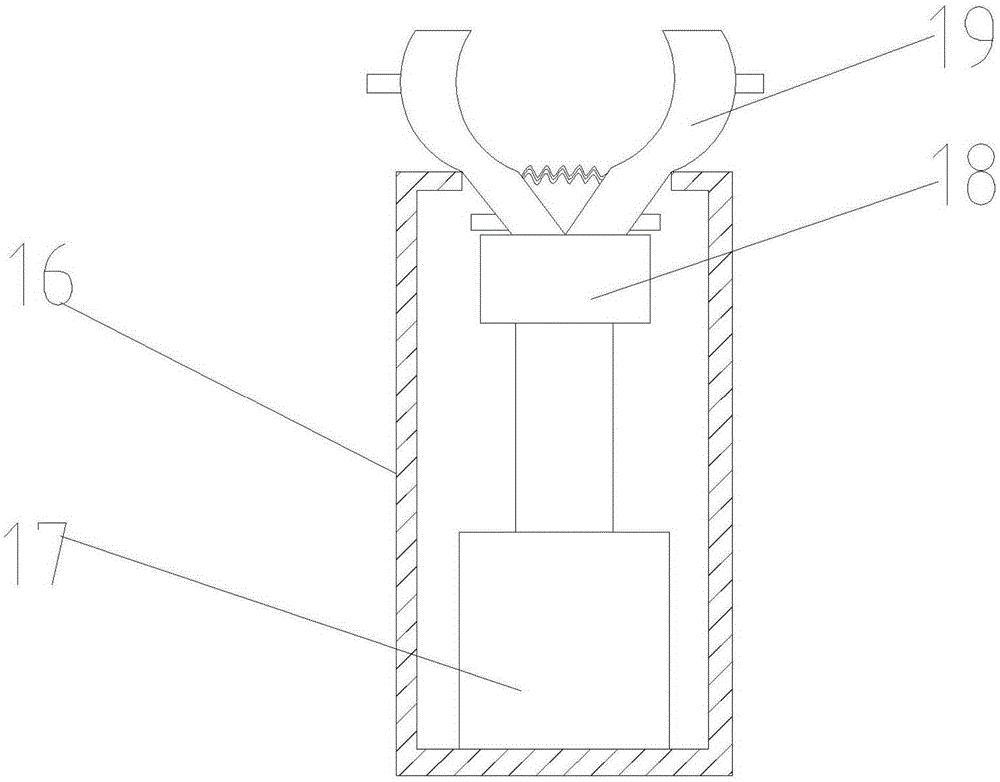

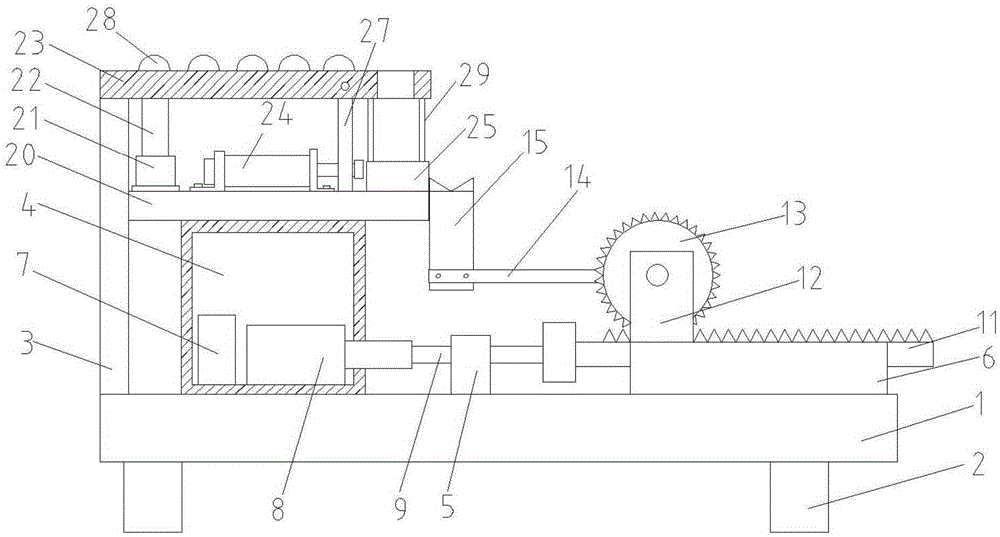

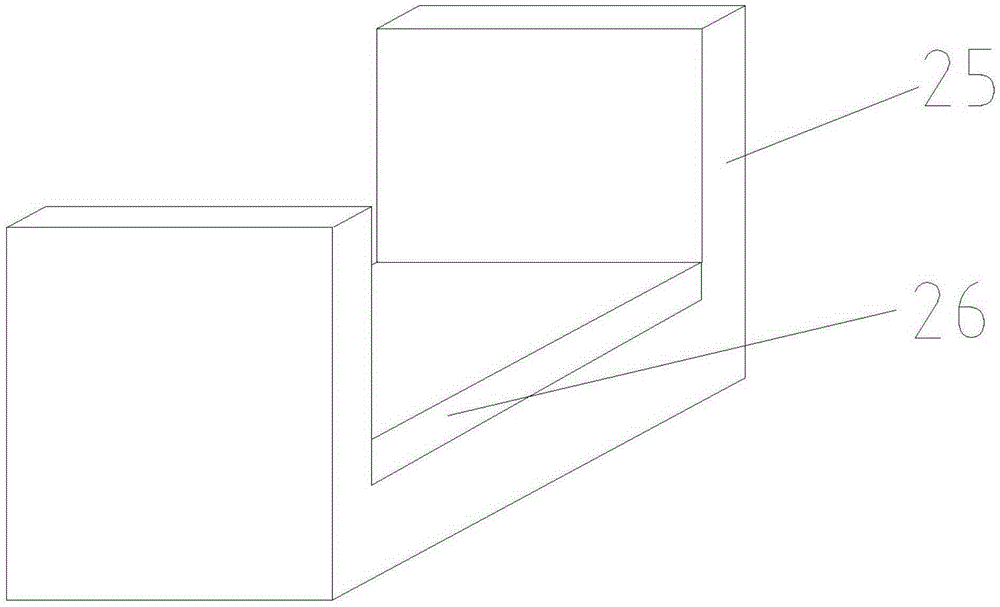

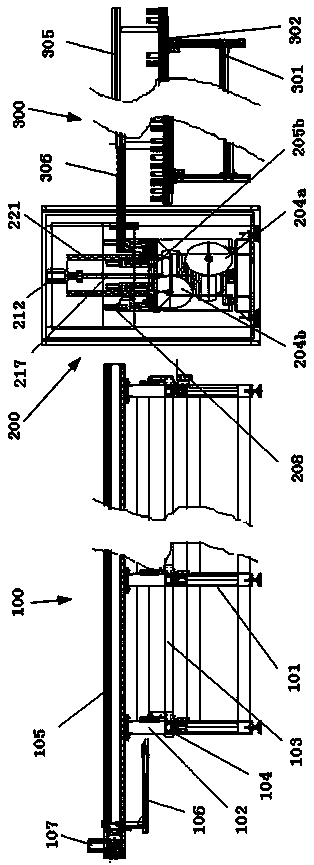

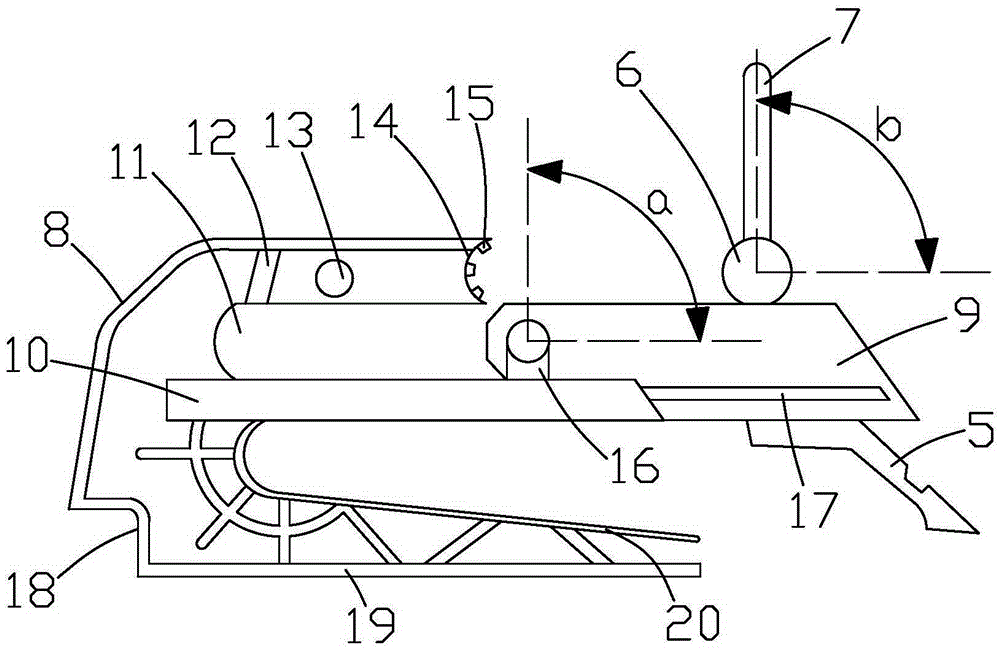

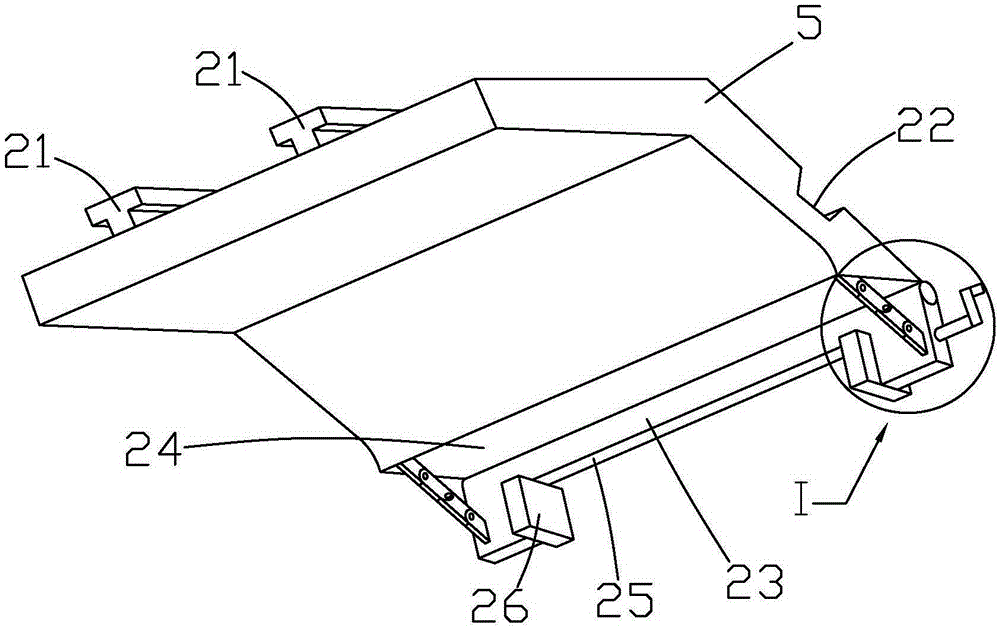

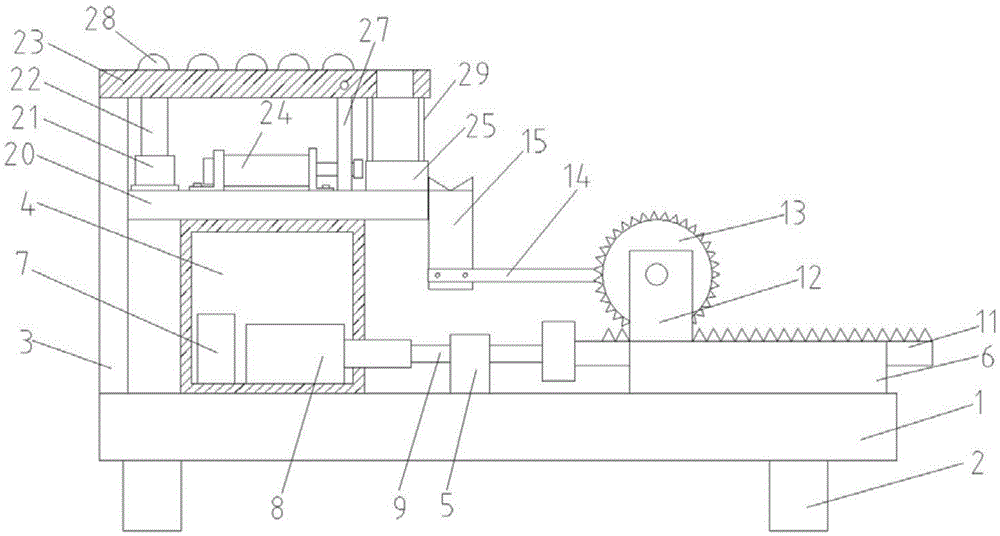

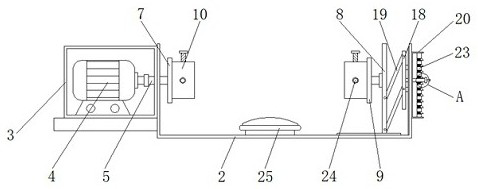

Automatic pipe fitting feeding and grinding device

InactiveCN105538137AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlPipe fittingEngineering

The invention discloses an automatic pipe fitting feeding and grinding device. The feeding and grinding device comprises a feeding device, a supporting device, a grinding device and a measuring device. The supporting device is located at the discharging end of the feeding device, and the grinding device is located above the supporting device; the measuring device is located at the discharging end of the grinding device; through the feeding device, automatic feeding is achieved, a supporting mechanism with the adjusting function is adopted, the structure is simple, operation is convenient, and the adjustable effect is achieved; a lifting device is arranged to enable a whole grinding head mechanism to be capable of vertically moving and moving laterally, use limitation is avoided, and after grinding, the measuring device enables a steel pipe to rotate during clamping through cooperation of a first clamping device and a second clamping device; and multi-angle measuring can be achieved, vibration and shaking of the steel pipe can be reduced, and a bearing plate is arranged, so that the steel pipe is placed more stably and is more accurately measured, error generation is reduced, and the steel pipe measuring effect is better.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

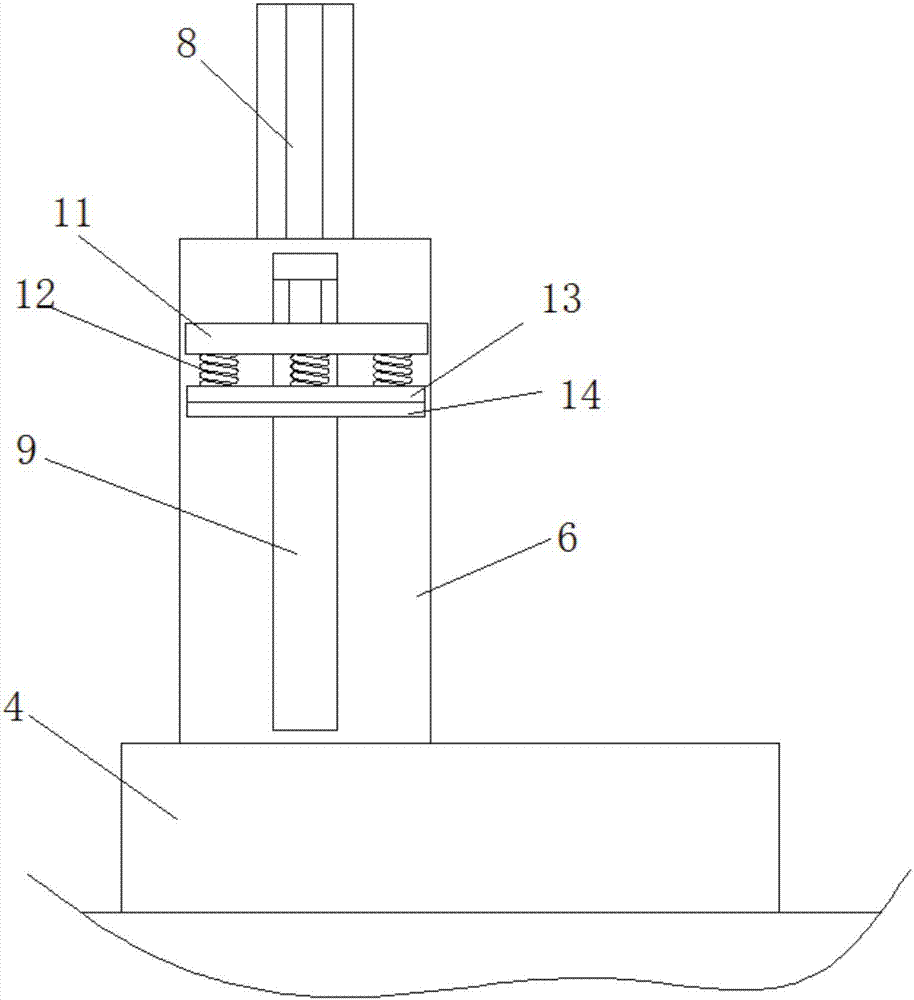

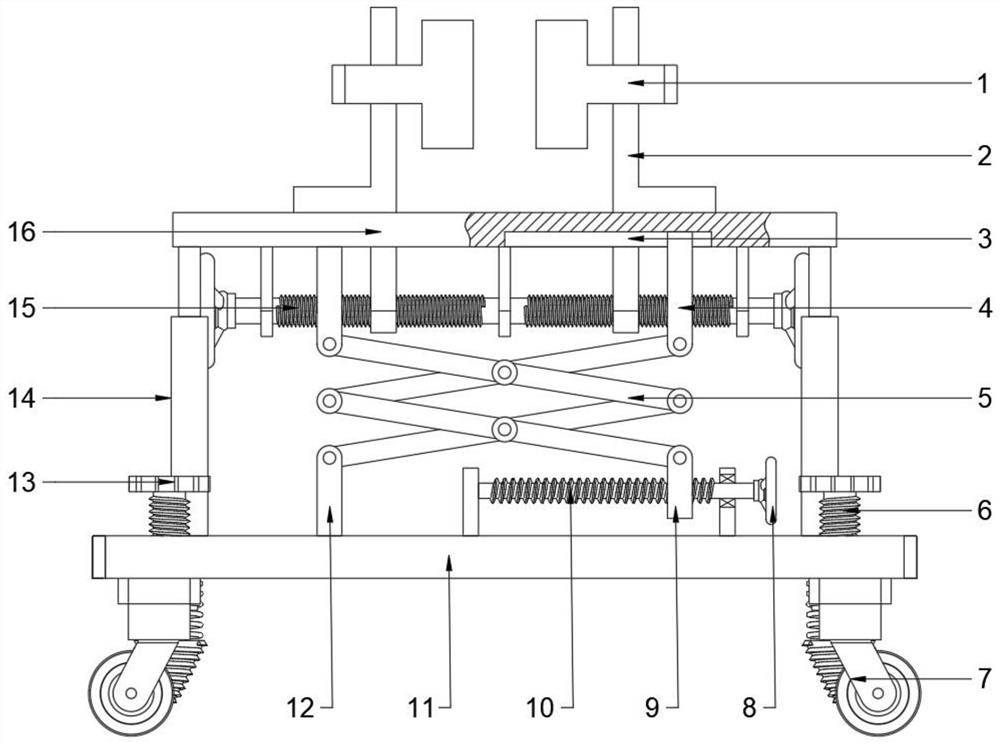

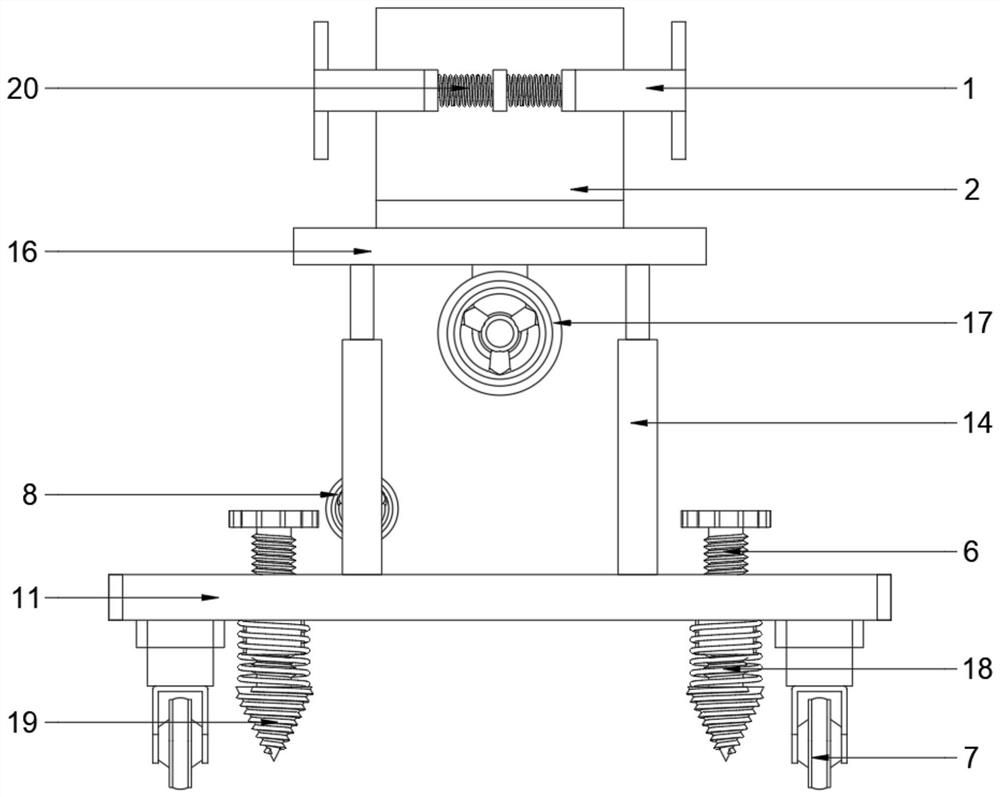

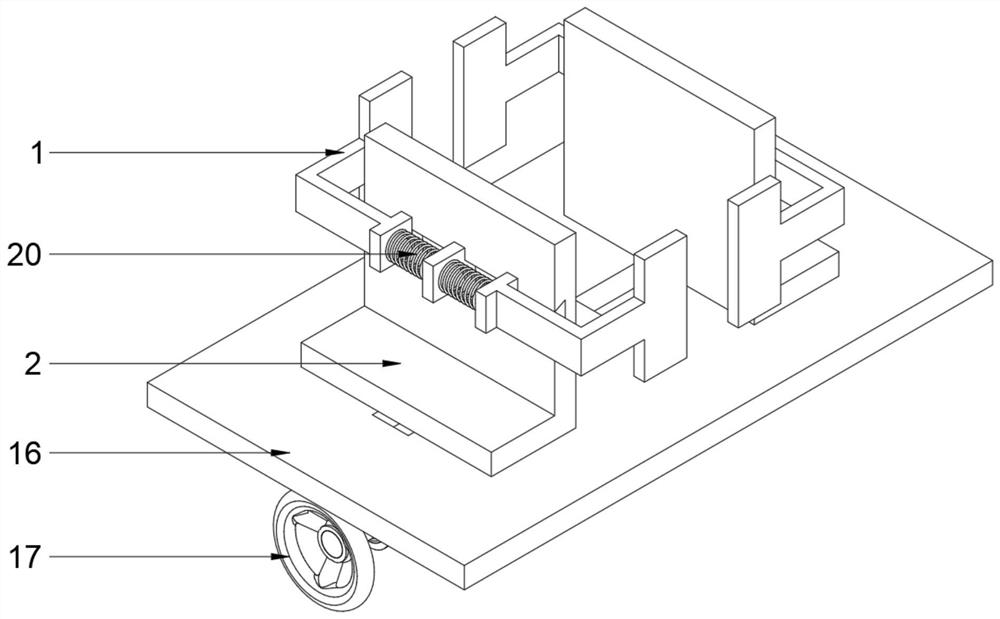

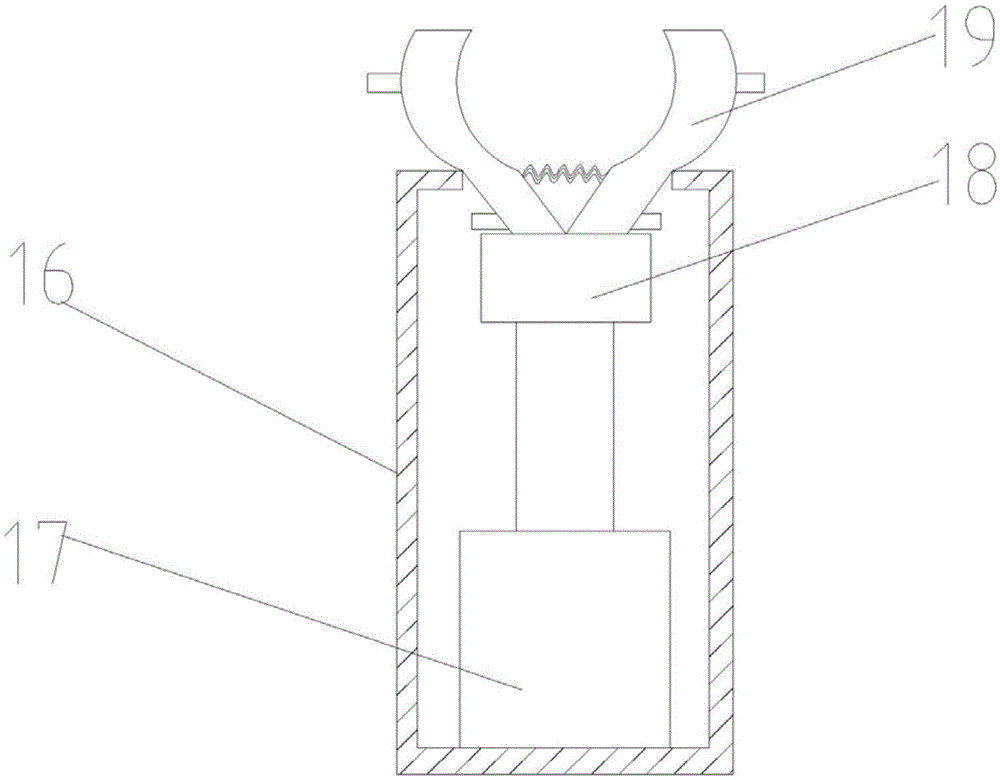

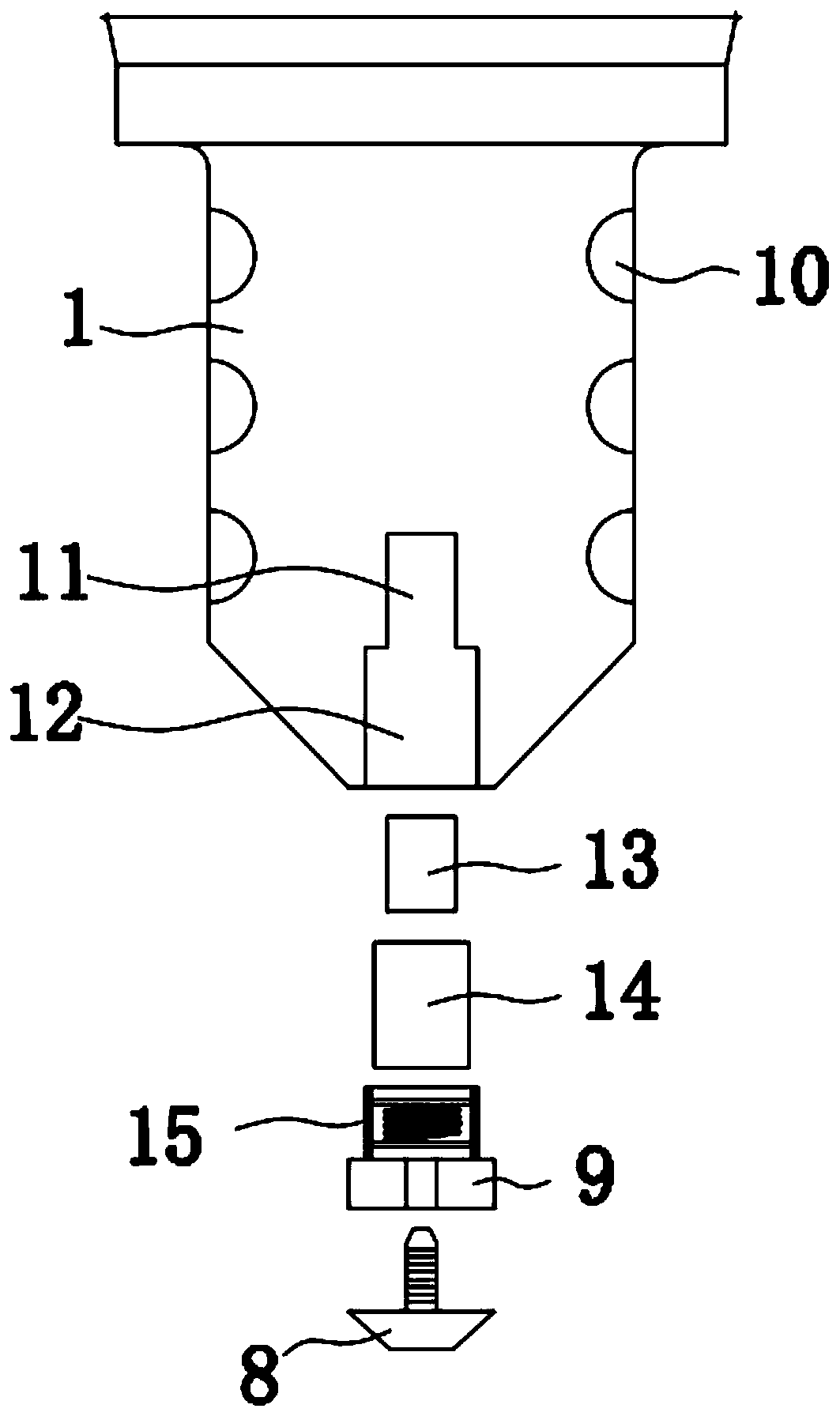

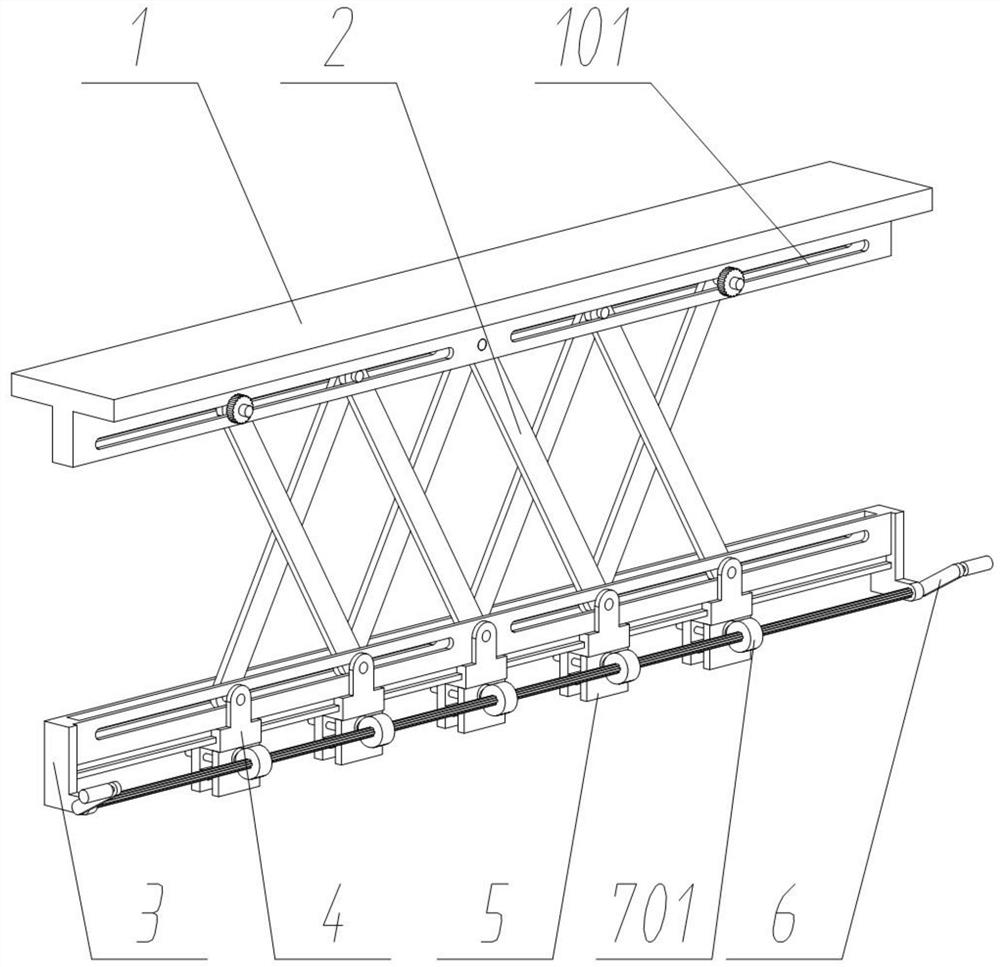

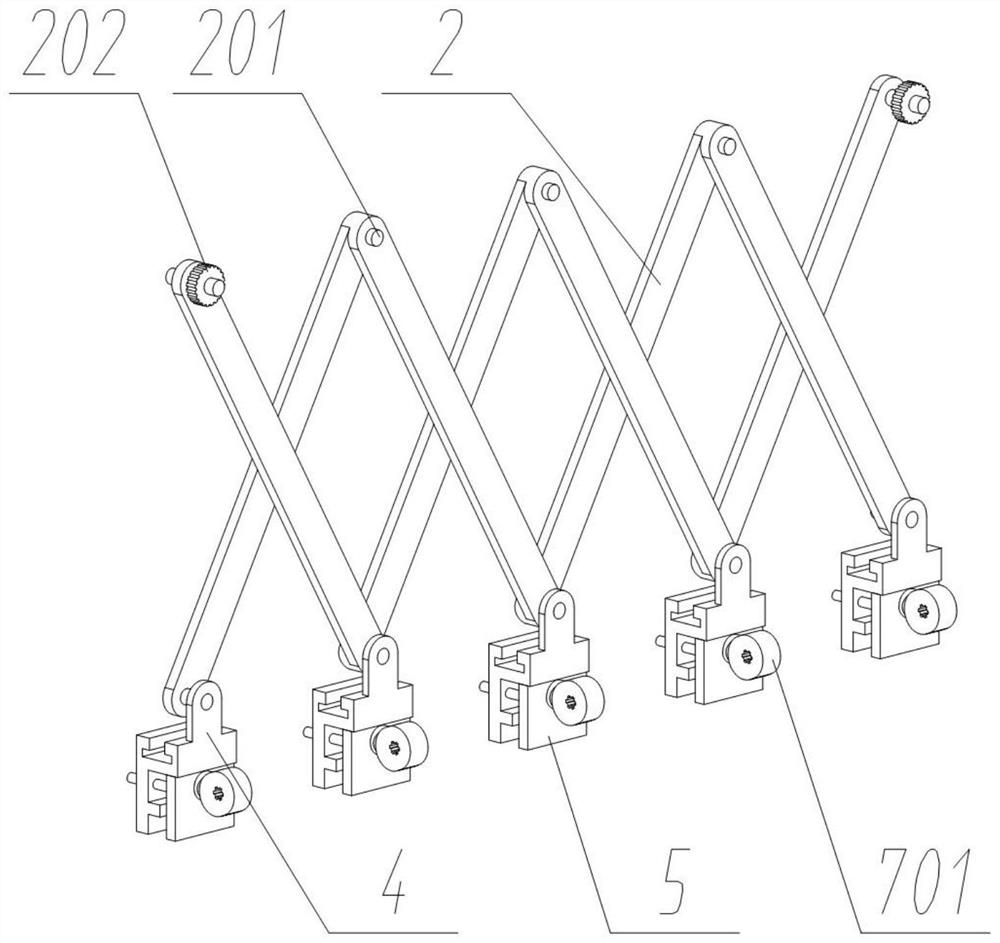

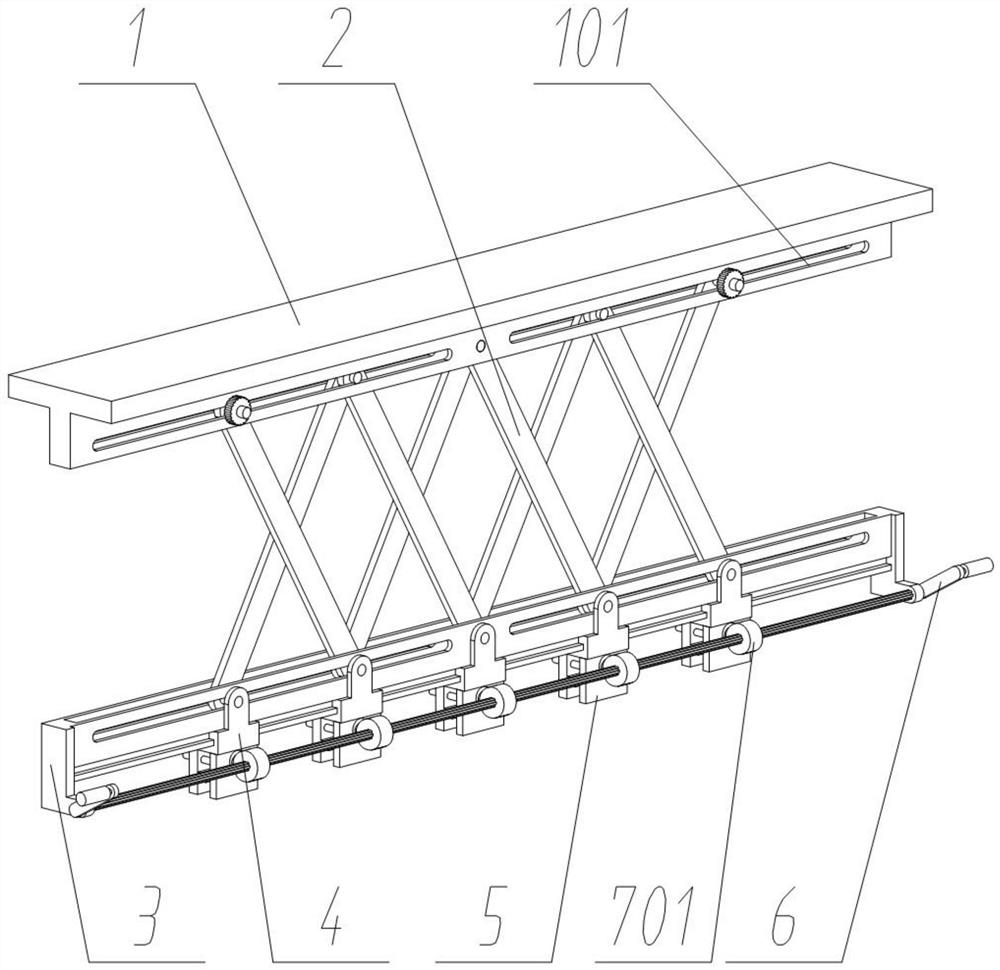

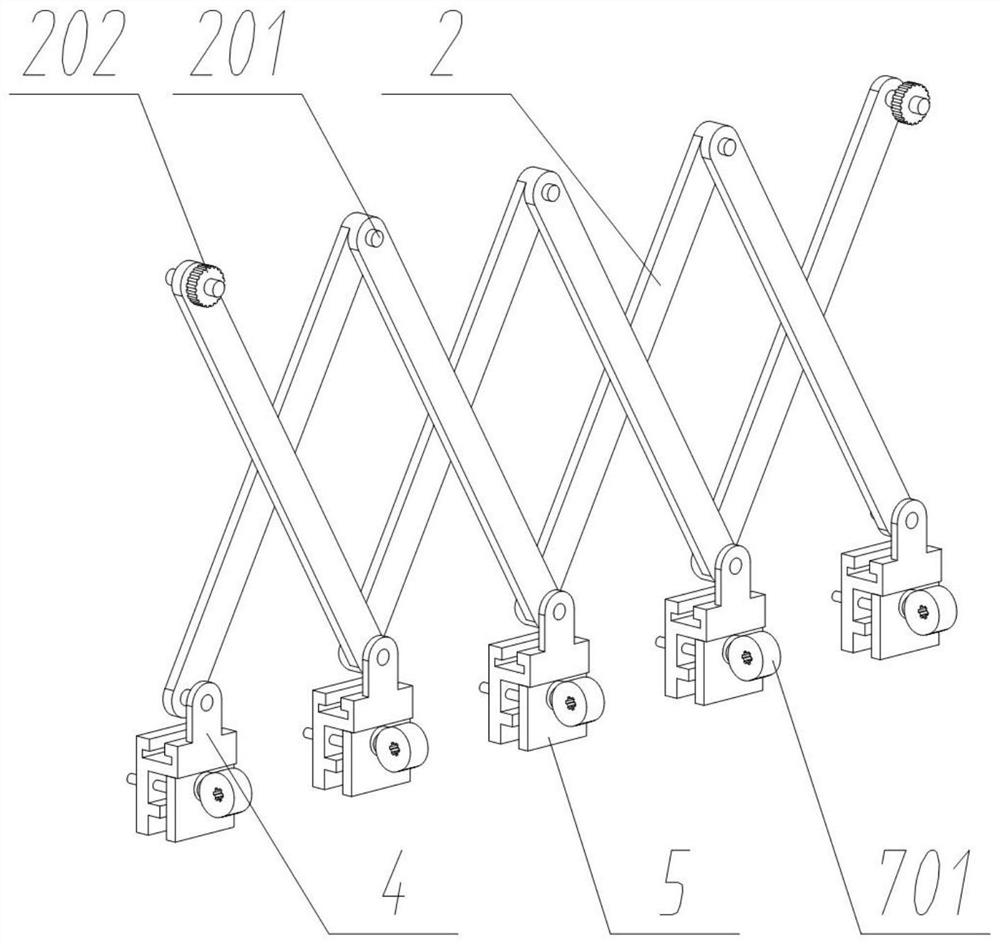

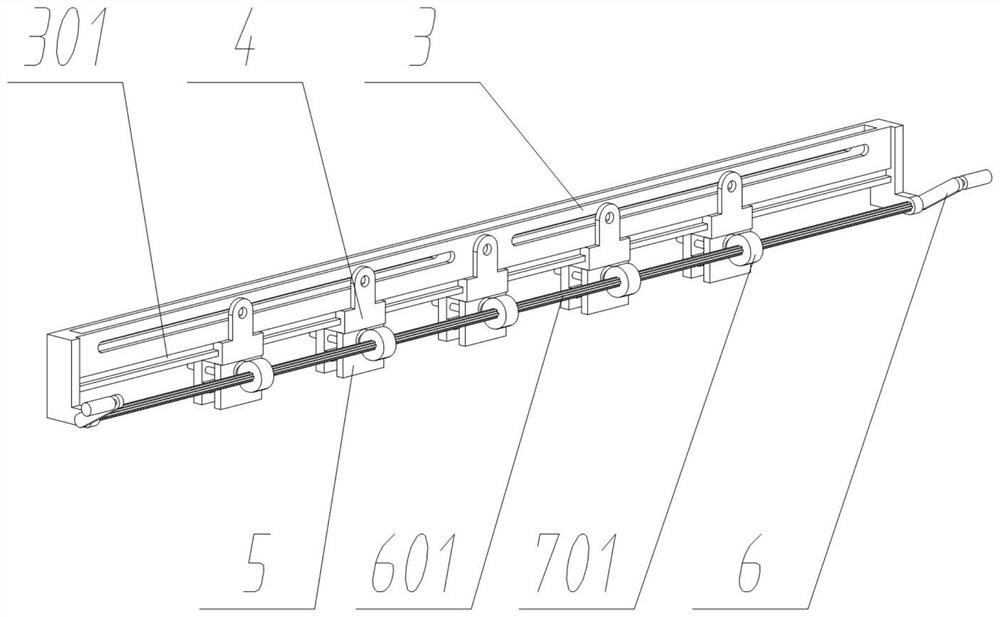

Fabricated building supporting seat

InactiveCN112376946AImprove stabilityClamping meetsVibration suppression adjustmentsShoresArchitectural engineeringScrew thread

The invention discloses a fabricated building supporting seat. The fabricated building supporting seat comprises a supporting base and a workbench arranged on the supporting base, wherein the workbench is arranged on the supporting base through a lifting assembly arranged at the bottom of the workbench, and a clamping assembly is further arranged on the workbench; the clamping assembly comprises clamping plates and clamping screw rods, adjusting blocks are fixedly arranged at the bottoms of the clamping plates and are in threaded connection with the clamping screw rod rotationally arranged atthe bottom of the workbench; and the clamping assembly further comprises side baffle plates and clamping springs, the side baffle plates are arranged on the clamping plates in a sliding mode, and clamping springs are further fixedly arranged between the side baffle plates and the clamping plates. According to the fabricated building supporting seat, the clamping plates and the clamping screw rodsare adopted and matched with the side baffle plates, the clamping springs, a scissors mechanism and a lifting screw rod, clamping of buildings of different sizes is met; limiting telescopic rods is adopted to limit vertical movement, so that left-right shaking is prevented, and the stability of the workbench is enhanced; and fixing screw rods, the damping springs and conical tops are adopted, so that fixing and damping are achieved at the same time, and safety is improved.

Owner:中诚祥建设集团有限公司

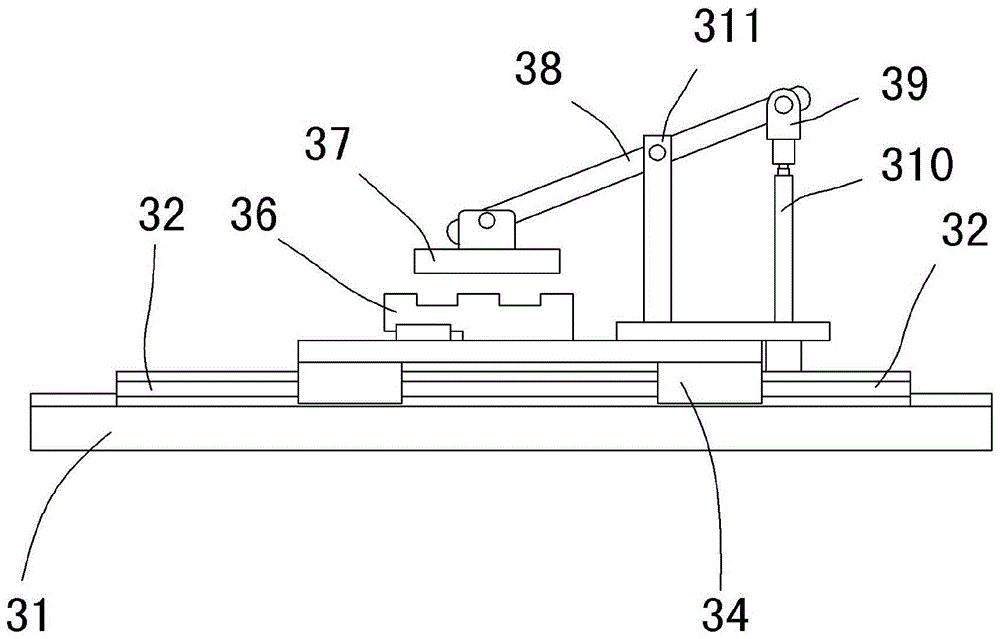

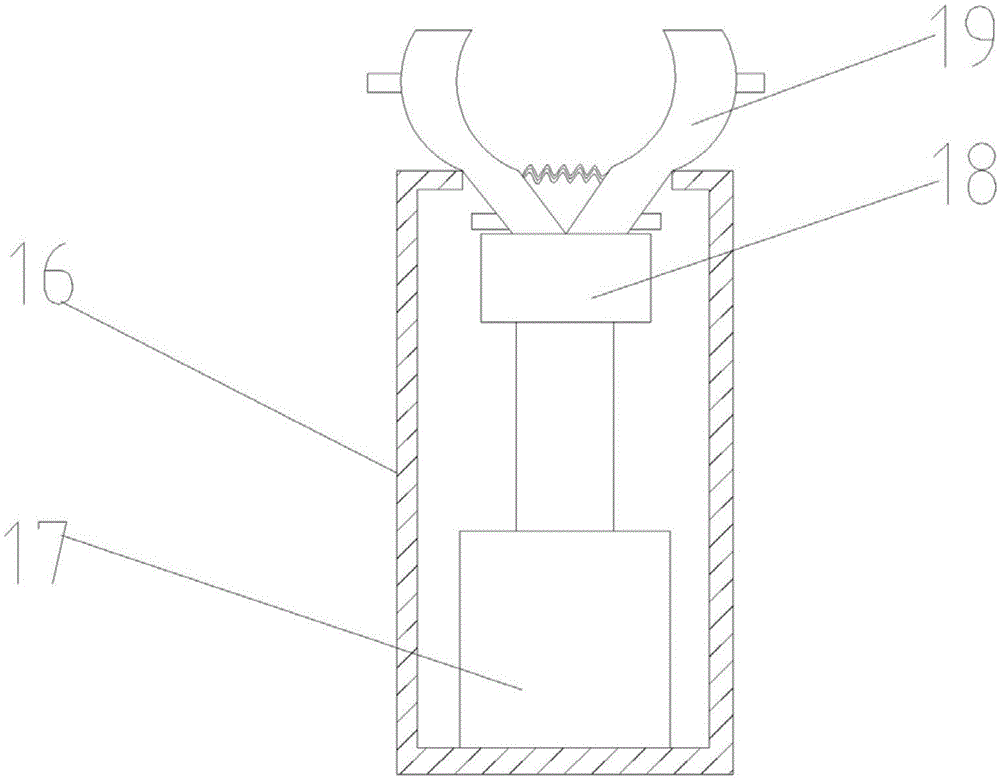

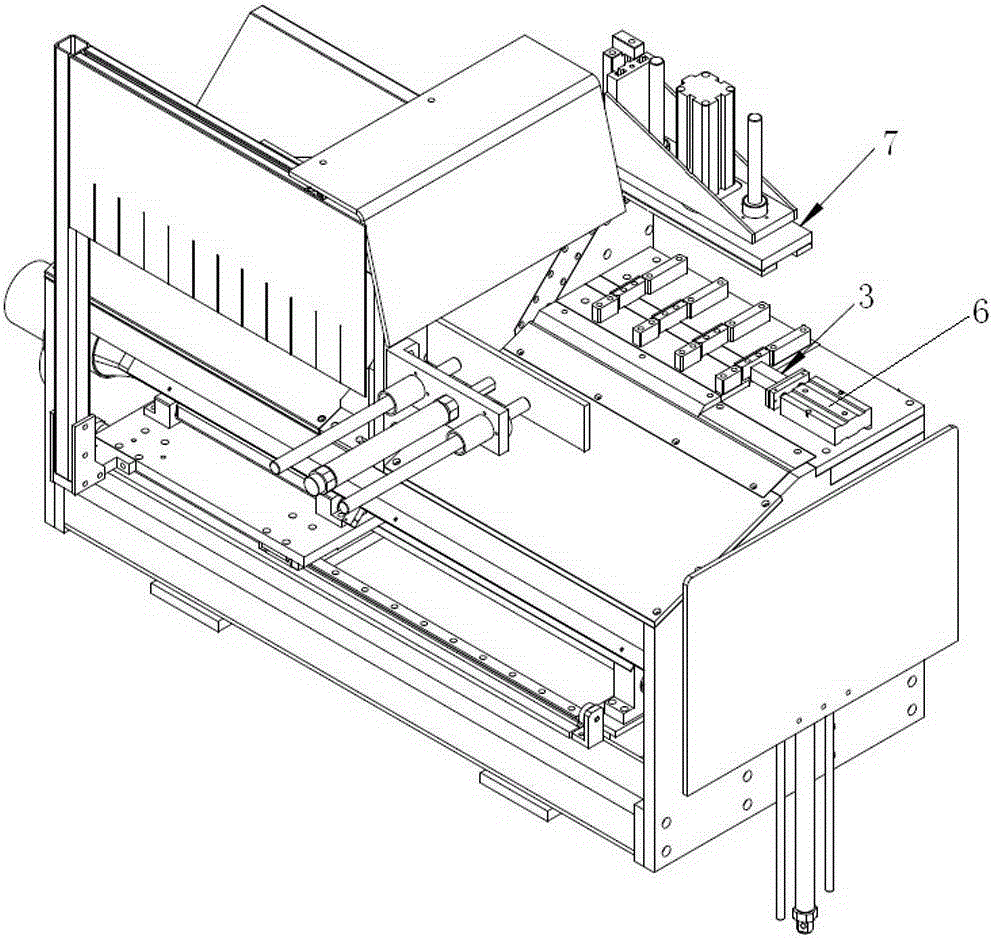

Workpiece clamping mechanism for cutting equipment for cylinder of shock absorber

InactiveCN105312915AImprove clamping efficiencyEasy clampingMetal sawing devicesPositioning apparatusHydraulic cylinderEngineering

The invention discloses a workpiece clamping mechanism for cutting equipment for a cylinder of a shock absorber. The clamping mechanism comprises a bottom plate, wherein slide rails are arranged on the bottom plate, a movable panel hydraulically driven to move on the slide rails is arranged on the slide rails, workpiece seats used for accommodating workpieces are arranged on the movable panel, a pressing linkage mechanism is further arranged on the movable panel and comprises a connecting rod, two ends of the connecting rod are hinged together with a pressing component and an ejection rod respectively, the middle of the connecting rod is hinged to a support rod, the ejection rod is connected with a piston of a hydraulic cylinder, and the pressing component is located above the workpiece seats. The workpiece clamping mechanism has the characteristics of convenience in clamping of the workpieces, and the workpiece seats used for accommodating the workpieces are very convenient to replace.

Owner:NINGBO HAISHU JIADA SHOCK ABSORBER CO LTD

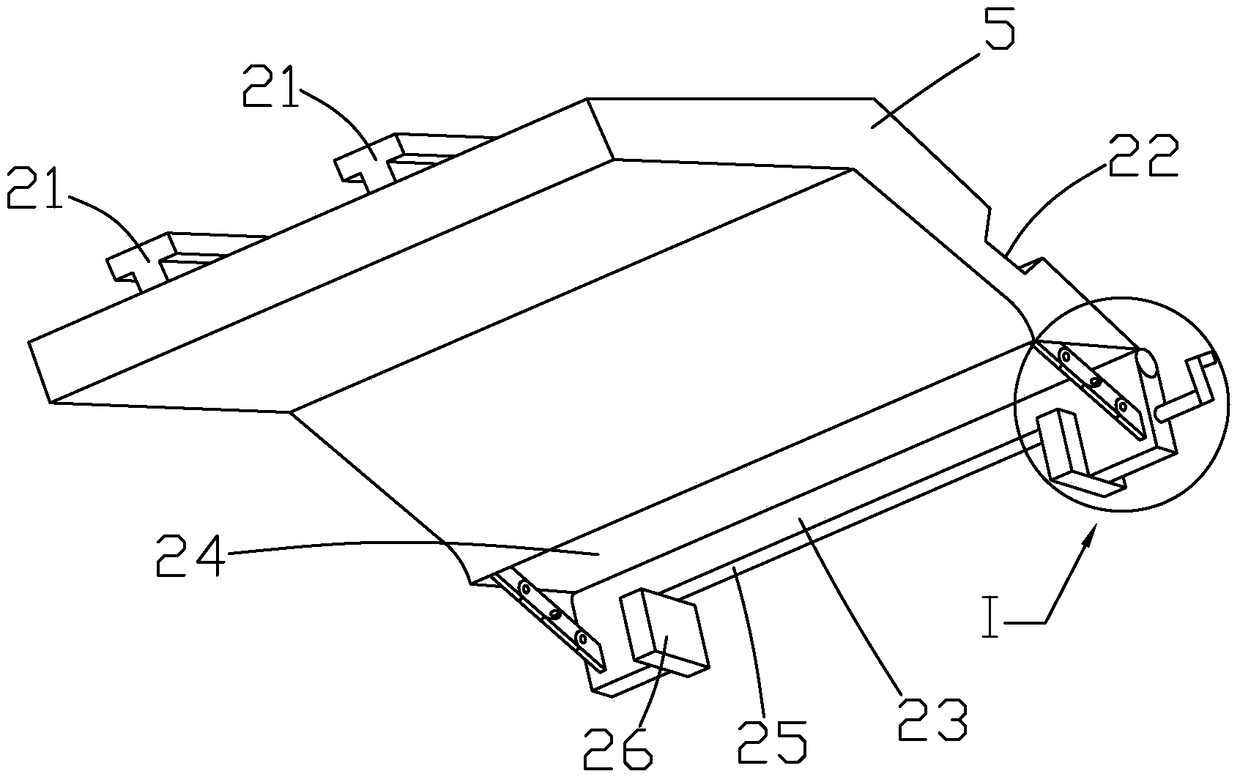

Part carrying device for automobile production

Owner:WUHU RUITAI PRECISION MACHINERY

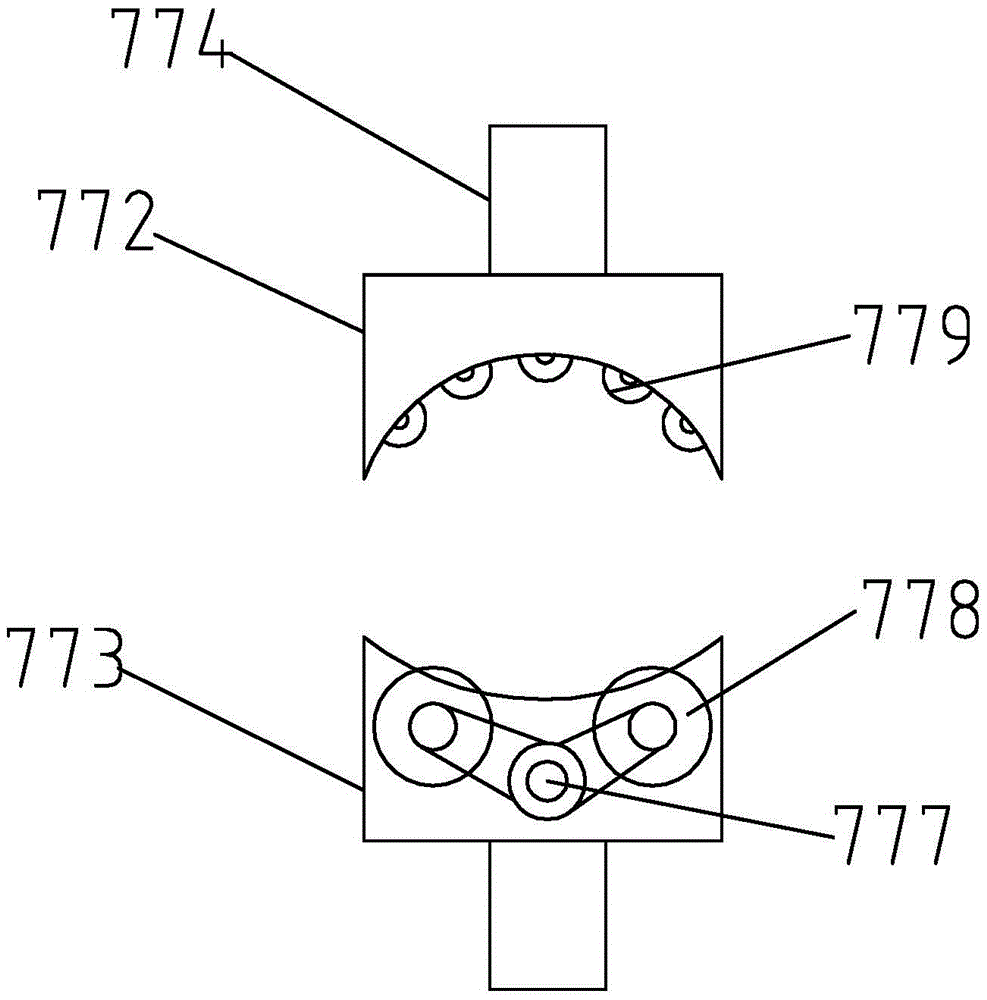

Novel pipe grinding and detecting device

InactiveCN105538138AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlMeasurement deviceMechanical engineering

The invention discloses a novel pipe grinding and detecting device. The novel pipe grinding and detecting device comprises a feeding device, a supporting device, a grinding device and a measuring device. The supporting device is located at the discharging end of the feeding device, and the grinding device is located above the supporting device; the measuring device is located at the discharging end of the grinding device; through the feeding device, automatic feeding is achieved, a supporting mechanism with the adjusting function is adopted, the structure is simple, operation is convenient, and the adjustable effect is achieved; and after grinding, the measuring device enables a steel pipe to rotate during clamping through cooperation of a first clamping device and a second clamping device; and multi-angle measuring can be achieved, vibration and shaking of the steel pipe can be reduced, and a bearing plate is arranged, so that the steel pipe is placed more stably and is more accurately measured, error generation is reduced, and the steel pipe measuring effect is better.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

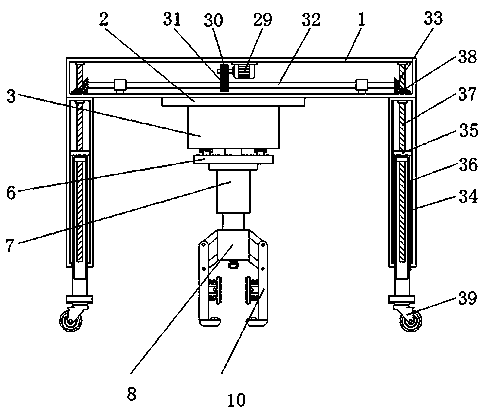

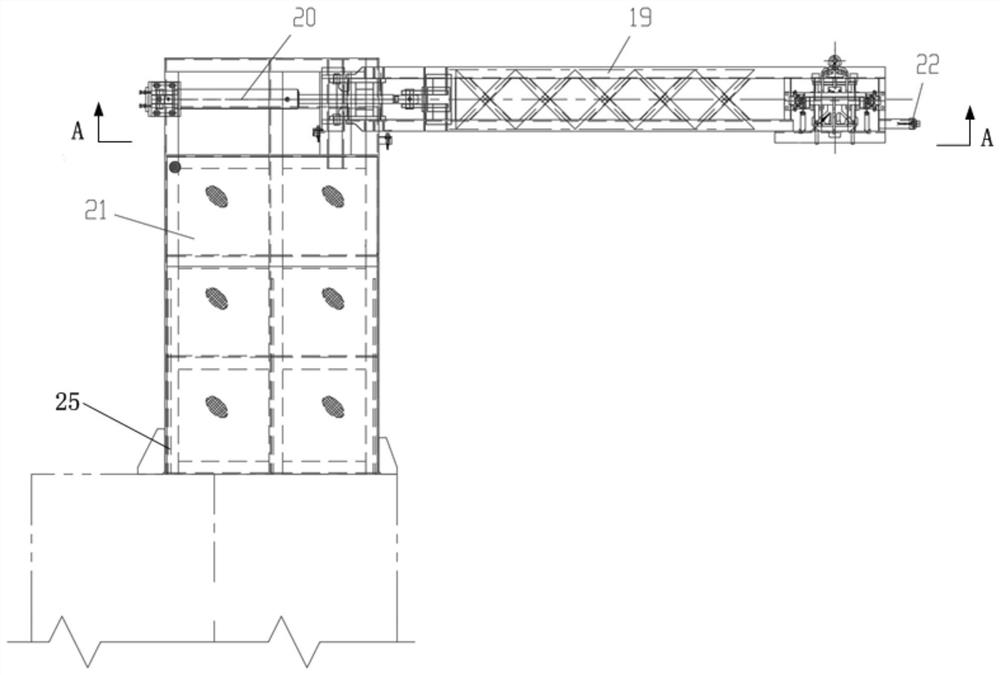

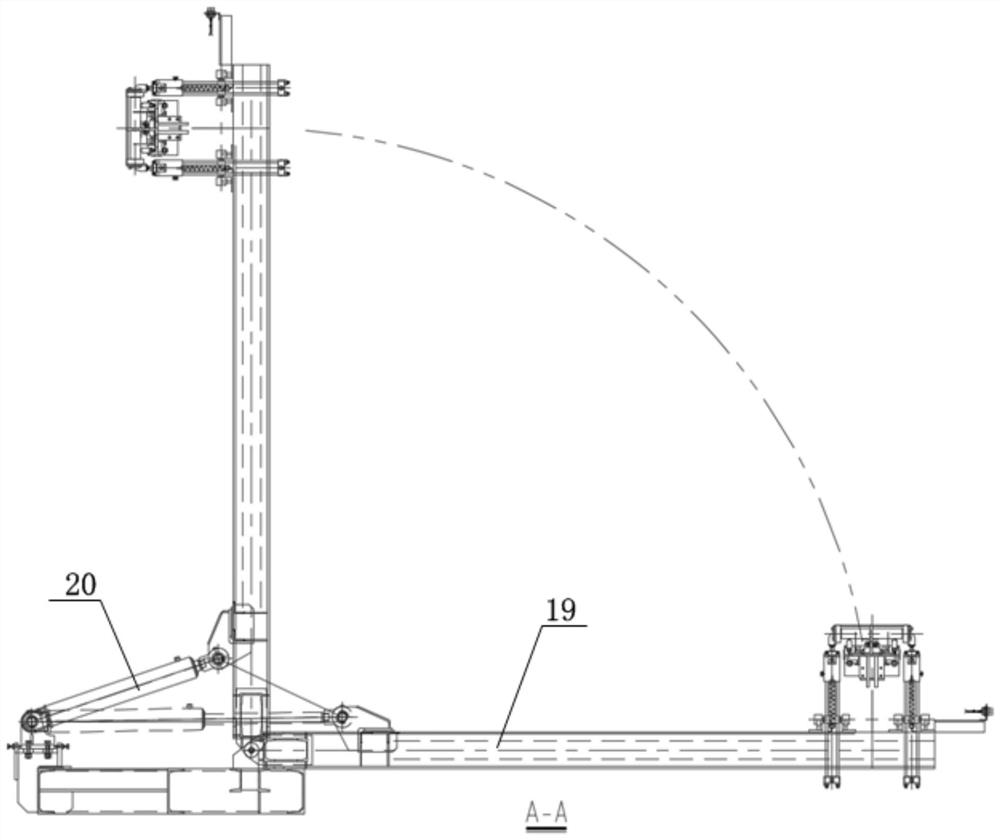

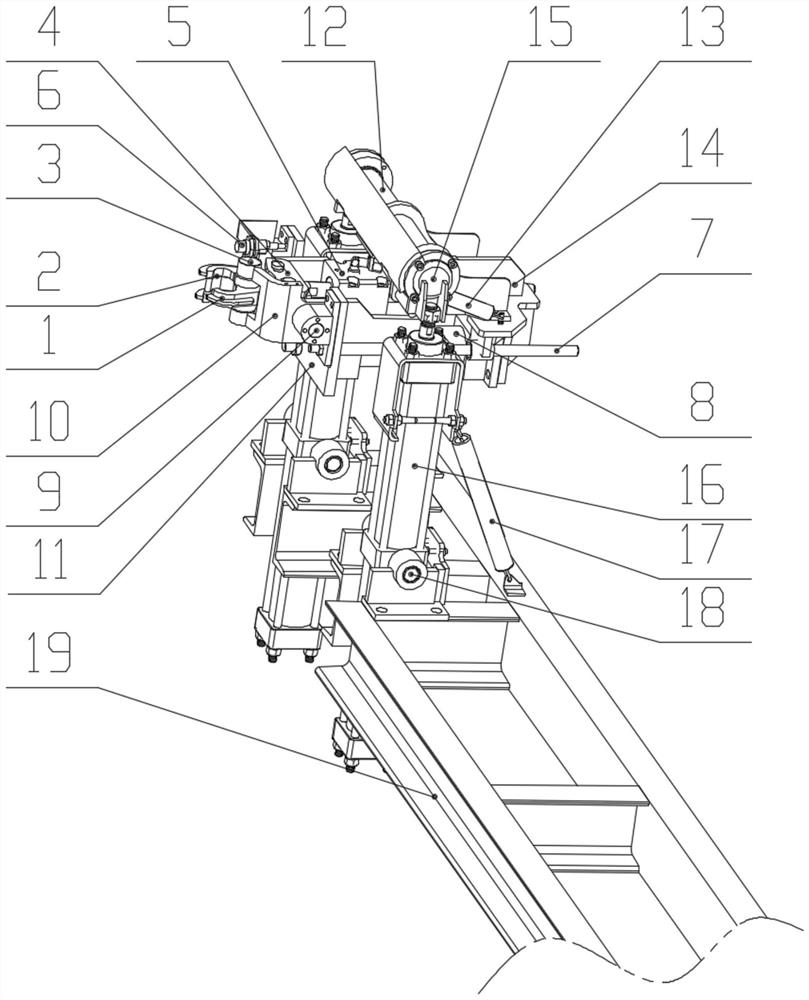

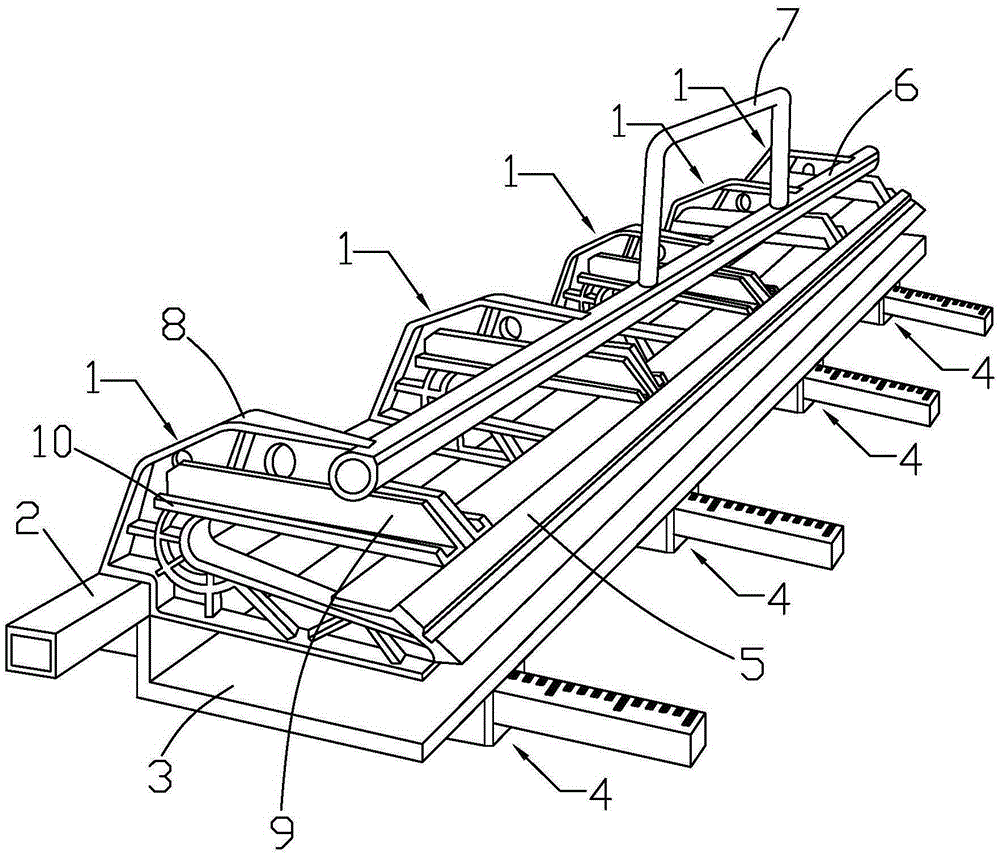

Automatic train unhooking device

PendingCN111703465AAutomatic unhook implementationAchieve clampingRailway coupling accessoriesControl engineeringStructural engineering

The invention relates to the field of railway traffic auxiliary equipment, and provides an automatic train unhooking device which comprises a large-dip-angle clamping mechanism, an unhooking rotatingmechanism, a rotary lifting mechanism and a large arm pitching mechanism. The large-dip-angle clamping mechanism comprises a left clamp, a right clamp, a fixed pin shaft, a clamp connecting base, a clamp oil cylinder, a clamp frame, a clamp push-out oil cylinder and a push-out oil cylinder base. A cylinder body of the clamp push-out oil cylinder is arranged on the push-out oil cylinder base, and apiston rod of the clamp push-out oil cylinder is fixedly connected with the clamp frame. The fixed pin shaft is arranged on the clamp frame; a cylinder body of the clamp oil cylinder is arranged on the clamp frame, and a piston rod of the clamp oil cylinder is fixedly connected with the clamp connecting base. The left clamp and the right clamp are hinged to the clamp connecting base. The left clamp and the right clamp are hinged to the fixed pin shaft and extend out of the clamp frame. The device is high in automation degree, the working intensity of workers is reduced, and the working efficiency is improved.

Owner:大连轩泰重工有限公司

Plastic pipe surface treatment device

InactiveCN105397622AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlMeasurement deviceSteel tube

The invention discloses a plastic pipe surface treatment device which comprises a feeding device, a clamping and locating device, a grinding device and a measuring device. The clamping and locating device is located at the discharging end of the feeding device. The grinding device is located above the clamping and locating device. The measuring device is located at the discharging end of the grinding device. The automatic feeding purpose is achieved through the feeding device; a material carrying mechanism with the adjusting function is adopted, the structure is simple, operation is convenient, and the adjusting effect is achieved; a lifting device is arranged so that a whole grinding head mechanism can move upwards, downwards, leftwards and rightwards, and the use limitation is avoided; after grinding is finished and through the cooperation of a first clamping device and a second clamping device, a steel pipe can be rotated when clamped and can be measured by the measuring device at multiple angles, and vibration and shakes of the steel pipe are reduced; and a carrying board is arranged, so that the steel pipe is placed more stably and measured more accurately, errors are reduced, and the measuring effect of the steel pipe is better.

Owner:CHONGQING XINYONG LIGHTINGS FACTORY

Surface treatment system for plastic tubes

InactiveCN105415173AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlMeasurement deviceEngineering

The invention discloses a surface treatment system for plastic tubes. The surface treatment system for the plastic tubes comprises a loading device, a clamping and locating device, a grinding device and a measurement device, wherein the clamping and locating device is located at the discharge end of the loading device; the grinding device is located above the clamping and locating device; and the measurement device is located at the discharge end of the grinding device. According to the invention, automatic loading is realized through the loading device, and locating is carried out by virtue of the clamping and locating device; the surface treatment system for the plastic tubes is simple in structure and convenient to operate; by arranging a lifting device, a whole grinding head mechanism is capable of moving up and down, and a left-and-right moving element is arranged, so that use limits are avoided; after grinding, through matching between a first clamping device and a second clamping device, steel tubes are capable of rotating while being clamped, the measurement device is capable of carrying out multi-angle measurement, and vibration and shake of the steel tubes are reduced; and by arranging a bearing plate, the steel tubes are more stable in placement and more accurate in measurement, and generation of errors is reduced, so that the measurement effect of the steel tubes is better.

Owner:CHONGQING XINYONG LIGHTINGS FACTORY

Plastic pipe surface super-finishing and polishing device

InactiveCN105382683AImprove securitySecurity threatPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The invention discloses a plastic pipe surface super-finishing and polishing device which comprises a feeding device, a clamping positioning device and a measuring device. The clamping positioning device is located at the discharging end of the feeding device. According to the plastic pipe surface super-finishing and polishing device, automatic feeding is achieved through the feeding device, and the clamping positioning device is used for positioning; by means of the cooperation of a first clamping device and a second clamping device, a steel pipe can rotate while being clamped so that the measuring device can measure the steel pipe in multiple dimensions after grinding is finished; in addition, vibration and shaking of the steel pipe are reduced; a bearing plate is arranged so that the steel pipe can be placed more stably, steel pipe measurement is more accurate, errors are reduced, and the steel pipe measurement effect is better.

Owner:CHONGQING XINYONG LIGHTINGS FACTORY

Pipe grinding equipment

InactiveCN105563310ALabor savingImprove work efficiencyRevolution surface grinding machinesGrinding feed controlArchitectural engineering

The invention discloses pipe grinding equipment. The pipe grinding equipment comprises a loading device, a support device, a grinding device and a measuring device; the support device is positioned at a discharge end of the loading device; the grinding device is positioned above the support device; and the measuring device is positioned at a discharge end of the grinding device. The pipe grinding equipment realizes automatic loading through the loading device, adopts the support mechanism with an adjusting function to achieve the effects of simple structure, convenience for operation and adjusting capacity, and is provided with the lifting device for enabling a whole grinding head mechanism to move up, down, left and right to prevent use limitations; after grinding, the measuring device can rotate steel pipes to perform multi-angle measurement during clamping through matching between a first clamping device and a second clamping device, and the vibration and the shaking of the steel pipes are reduced; and a bearing plate is arranged for enabling the steel pipes to become more stable and the measurement of the steel pipes to become more accurate, so that the generation of errors is reduced, and the measuring effect of the steel pipes is better.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

Plastic pipe surface treatment equipment

InactiveCN105397624AImprove securitySecurity threatPolishing machinesRevolution surface grinding machinesSteel tubeSurface finishing

The invention discloses plastic pipe surface treatment equipment which comprises a feeding device, a clamping and locating device, a grinding device and a measuring device. The clamping and locating device is located at the discharging end of the feeding device. The grinding device is located above the clamping and locating device. The measuring device is located at the discharging end of the grinding device. The automatic feeding purpose is achieved through the feeding device; a material carrying mechanism with the adjusting function is adopted, the structure is simple, operation is convenient, and the adjusting effect is achieved; a lifting device is arranged so that a whole grinding head mechanism can move upwards, downwards, leftwards and rightwards, and the use limitation is avoided; after grinding is finished and through the cooperation of a first clamping device and a second clamping device, a steel pipe can be rotated when clamped and can be measured by the measuring device at multiple angles, and vibration and shakes of the steel pipe are reduced; and a carrying board is arranged, so that the steel pipe is placed more stably and measured more accurately, errors are reduced, and the measuring effect of the steel pipe is better.

Owner:CHONGQING XINYONG LIGHTINGS FACTORY

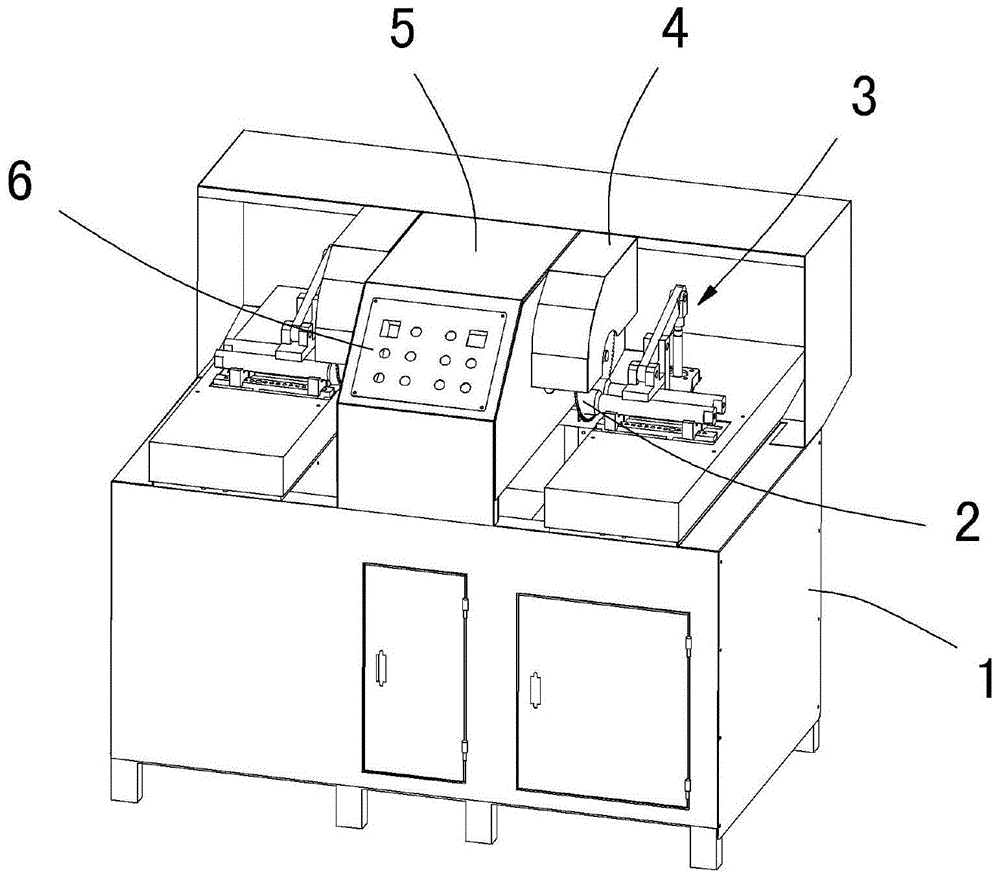

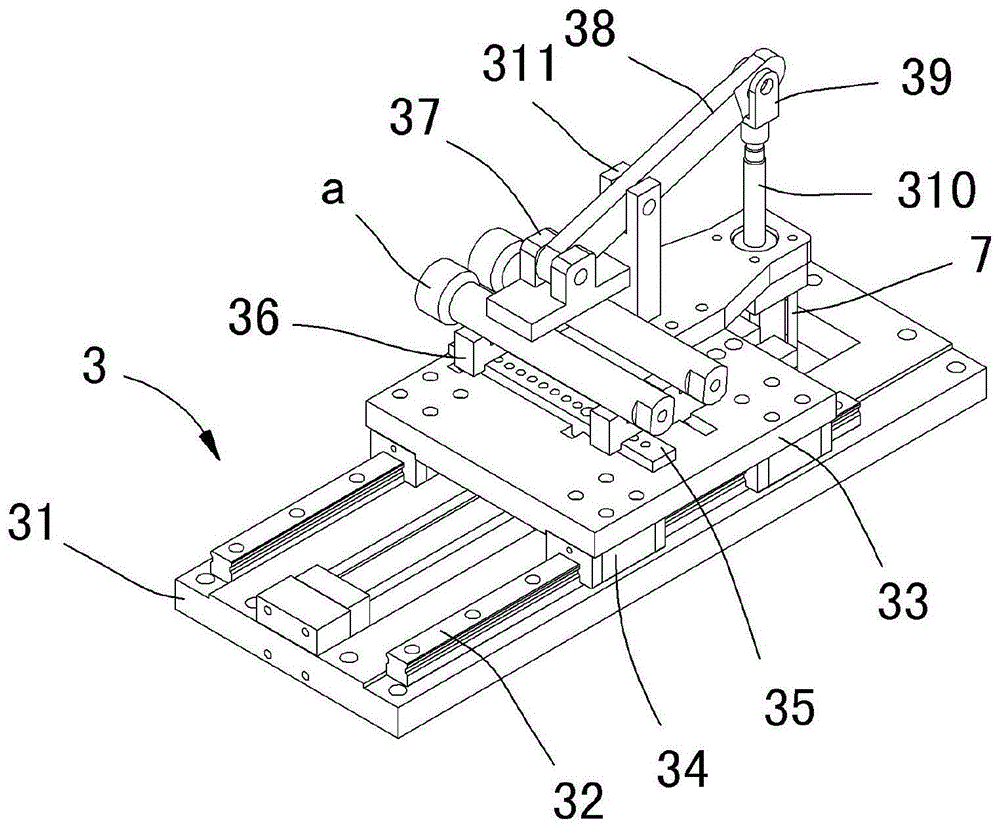

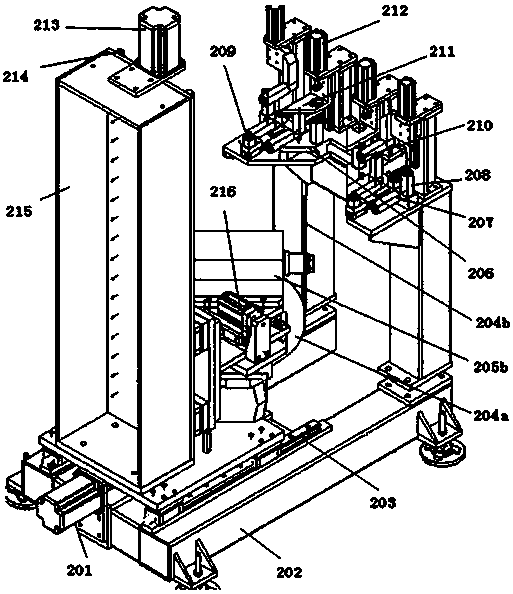

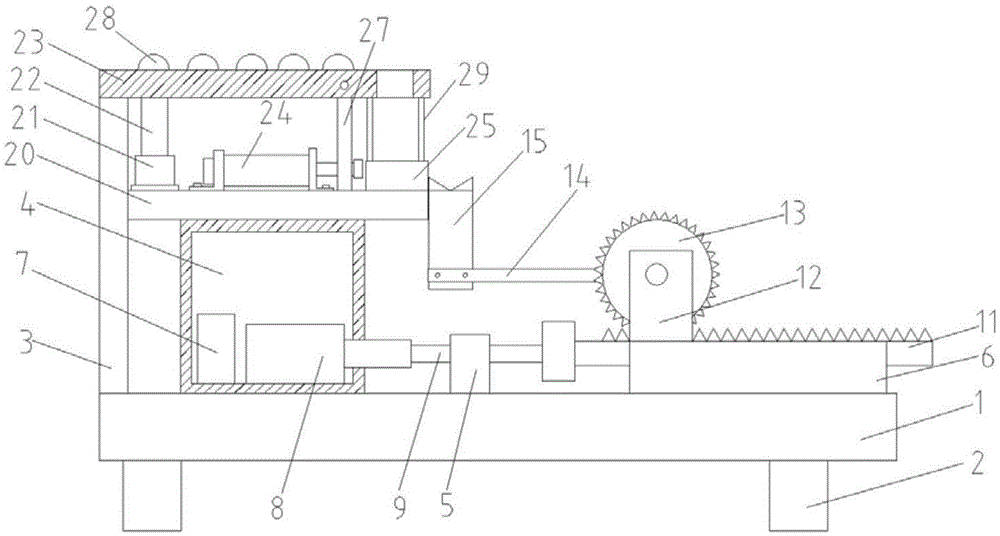

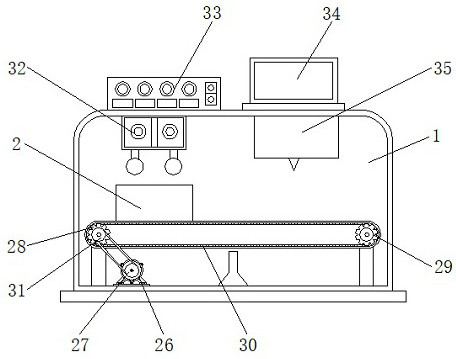

An automatic production line for sawing aluminum alloy profiles

InactiveCN105397183BThe setting position is accurateClamping meetsMetal sawing devicesFeeding apparatusProduction lineEngineering

An automatic production line for sawing aluminum alloy profiles, which belongs to the field of profile processing equipment. The production line includes a cutting device, a feeding device and a discharging device are respectively arranged at the front and rear positions of the cutting device, a cutting table is provided in the cutting device, and a cutting table is provided on the cutting table. The pressing plate and the positioning mechanism, the cutting table is provided with a figure-eight gap in the horizontal plane, the cutting head is arranged under the cutting table, and two cutting saw blades with different angles are arranged opposite to each other in the vertical direction of the cutting head, and the cutting head is connected There are multi-directional driving devices. The production line is equipped with a PLC controller. When cutting, the pressing plate on the cutting device presses the profile, and the cutting saw moves from bottom to top to cut the profile. By using this production line, the processing speed can be improved and the Machining accuracy, saving human resource costs, and improving the economic benefits of profile processing manufacturers.

Owner:刘坤

Measurement tool for aluminum strip bender

ActiveCN105403118AAccurate measurementReliable measurementMechanical measuring arrangementsMeasurement deviceAluminum can

The invention discloses a measurement tool for an aluminum strip bender. The measurement tool comprises brake devices, an object carrying plate, a clamping device and measurement devices, wherein the end portions of the brake devices and the object carrying plate are connected with a slide rail, each brake device comprises a fixation support frame, each fixation support frame is successively provided with a limiting clamping groove, a second cantilever, an over beam and a base plate from top to bottom, each second cantilever is symmetrically distributed at the two sides of each fixation support frame, each limiting clamping groove is internally provided with a first cantilever, the two sides of each first cantilever are each provided with a limiting protruding strip, each limiting protruding strip is movably connected with each second cantilever, each first cantilever is rotationally connected with the corresponding limiting protruding strips through a fixation rod, the bottom of the front end of each first cantilever is provided with the clamping device, and the measurement devices are fixedly connected with the bottom of the object carrying plate. The structure is simple, the practicality is high, an aluminum strip can be clamped and positioned, the aluminum can also be loaded and carried, the labor intensity is reduced, the operation is simple and convenient, the safety is high, and the steps for measuring the aluminum strip are simplified.

Owner:嵊州博远铝业有限公司

Freely-adjustable novel pipe grinding system

InactiveCN105643436ALabor savingImprove work efficiencyRevolution surface grinding machinesGrinding feed controlSteel tubeMeasurement device

The invention discloses a freely-adjustable novel pipe grinding system comprising a feeding device, a supporting device, a grinding device and a measuring device, wherein the supporting device is located at the discharging end of the feeding device; the grinding device is located above the supporting device; and the measuring device is located at the discharging end of the grinding device. Automatic feeding is realized through the feeding device; due to the adoption of a supporting mechanism with an adjusting function, the freely-adjustable novel pipe grinding system is simple in structure and convenient to operate, and an adjustable effect is achieved; through the match of a first clamping device and a second clamping device of the measuring device used after grinding, a steel pipe can rotate when being clamped, multi-angle measurement can be realized, and the vibration and shake of the steel pipe are reduced; and due to the arrangement of a bearing plate, the steel pipe is more stable and is more accurately measured, errors are reduced, and the steel pipe measuring effect is better.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

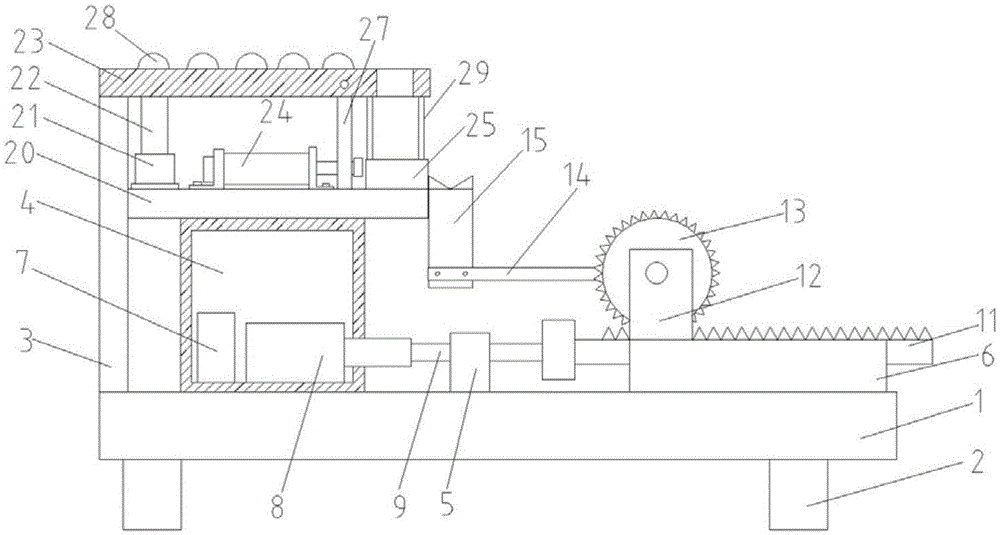

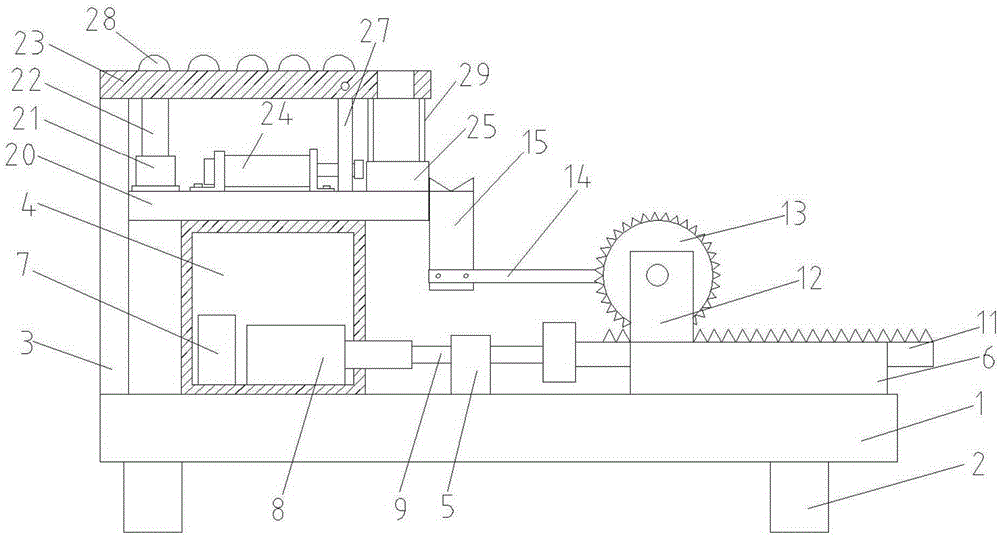

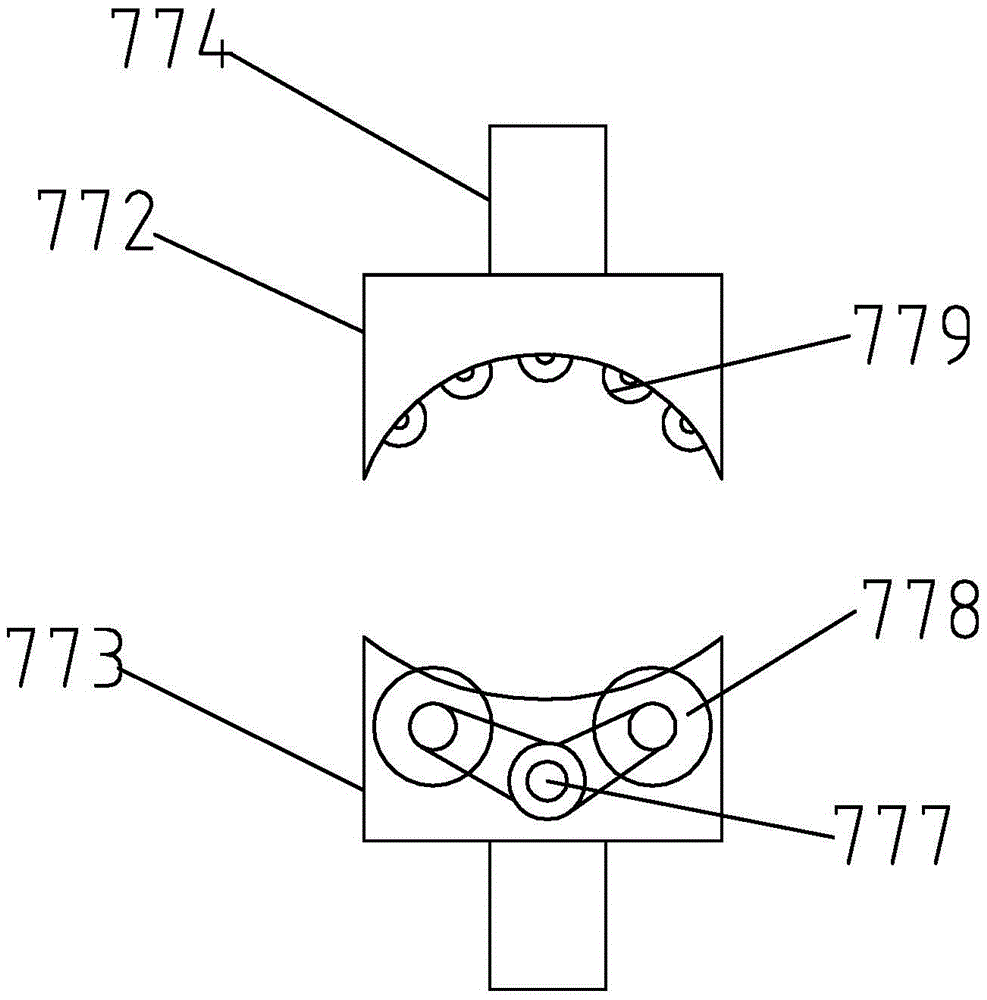

Grinding and clamping tool suitable for center-hole-shaped parts of various specifications and thicknesses

PendingCN112223116AClamping meetsReduce manufacturing costGrinding work supportsGear wheelEngineering

The invention relates to a grinding and clamping tool suitable for center-hole-shaped parts of various specifications and thicknesses. The grinding and clamping tool comprises a fixing frame plate, agrinding centering bearing shaft seat arranged on the fixing frame plate, a distance adjusting mechanism arranged on the central axis of the grinding centering bearing shaft seat, and an opening and closing clamping mechanism arranged on the distance adjusting mechanism and in sliding fit with the grinding centering bearing shaft seat. According to the grinding and clamping tool, through the arrangement of the fixing frame plate, the grinding centering bearing shaft seat, an adjusting worm, an adjusting sleeve seat, a clamping rod, a clamping gear and a rack, on the basis that the clamping rodand the fixing frame plate are used for clamping the center-hole-shaped parts, the distance between the clamping rod and the fixing frame plate can be automatically adjusted, so that clamping of thevarious center-hole-shaped parts with the different thicknesses can be met; and compared with the prior art, the grinding and clamping tool is low in manufacturing cost, easy to use and easy to operate, and the grinding efficiency is effectively improved.

Owner:杭州海灵智电科技有限公司

Automatic pipe fitting feeding and grinding system

InactiveCN105643435AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlPipe fittingEngineering

The invention discloses an automatic pipe fitting feeding and grinding system comprising a feeding device, a supporting device, a grinding device and a measuring device, wherein the supporting device is located at the discharging end of the feeding device; the grinding device is located above the supporting device; and the measuring device is located at the discharging end of the grinding device. Automatic feeding is realized through the feeding device; due to the adoption of a supporting mechanism with an adjusting function, the automatic pipe fitting feeding and grinding system is simple in structure and convenient to operate, and an adjustable effect is achieved; due to the arrangement of a lifting device, the whole grinding head mechanism not only can vertically move, but also can horizontally move, and service restrictions are avoided; through the match of a first clamping device and a second clamping device of the measuring device used after grinding, a steel pipe can rotate when being clamped, multi-angle measurement can be realized, and the vibration and shake of the steel pipe are reduced; and due to the arrangement of a bearing plate, the steel pipe is more stable and is more accurately measured, errors are reduced, and the steel pipe measuring effect is better.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

A fixture for machining process based on shaft chamfering

ActiveCN109015051BIncrease diversityEasy to useLarge fixed membersPositioning apparatusEngineeringSlide plate

The invention discloses a clamp for the shaft-type chamfering process, and relates to the technical field of shaft-type clamps. The clamp comprises a workbench; the top of the workbench is rotatably connected with a circular plate; the top of the circular plate is fixedly connected with a sleeve; sliding plates are slidably connected to the positions, on the two sides of the sleeve, of the top ofthe workbench correspondingly; one sides of the sliding plates are fixedly connected with hydraulic telescopic rods; and one ends of the hydraulic telescopic rods are fixedly connected with arc-shapedblocks. According to the clamp for the shaft-type chamfering process, shaft-type parts can be clamped well, the clamping effect is very good, the situation that the shaft-type parts move during chamfering, and consequently the chamfering quality and effect are affected is avoided, and clamping plates can be mounted and dismounted so as to be convenient to maintain; and the clamping plates with different sizes and types are convenient to mount to clamp the shaft-type parts with different sizes and types, and the comprehensiveness and usability of the shaft-type clamps are improved.

Owner:GUANGZHOU ROVMA AUTO PARTS

Plasma electrode hafnium filament brazing device and brazing method

ActiveCN110280865AExtended service lifeEasy to fixHeating appliancesMetal working apparatusEngineeringWater circulation

The present invention discloses a plasma electrode hafnium filament brazing device, comprising an electrode body and a fixing member, wherein the electrode body is installed in a fixing sleeve, a cooling cover is sleeved at one lower end of the fixing sleeve, and a cooling water circulation chamber is formed therebetween; a second open pore is provided with a hafnium filament; an external threaded cylinder is screwed to the second open pore, and the lower end of the hafnium filament is inserted into the external threaded cylinder; the clamping structure comprises an upper sliding plate and a sliding plate slidably connected in the external threaded cylinder, and a spring connects the upper sliding plate with the sliding plate. The hafnium filament disclosed by the present invention has firm fastening, preventing the electrode body from softening due to increasing temperature, so that meet with the expected use strength; the height of the clamping structure in the external threaded cylinder can be adjusted by rotating a bolt to meet the different lengths of the hafnium filament; cooling water continuously flows in the cooling water circulation chamber to cool the electrode body, thereby improving the service life of the electrode body.

Owner:南京卡德威焊切器材有限公司

A measuring tool for aluminum bar bending machine

ActiveCN105403118BAccurate measurementReliable measurementMechanical measuring arrangementsMeasurement deviceAluminum can

The invention discloses a measurement tool for an aluminum strip bender. The measurement tool comprises brake devices, an object carrying plate, a clamping device and measurement devices, wherein the end portions of the brake devices and the object carrying plate are connected with a slide rail, each brake device comprises a fixation support frame, each fixation support frame is successively provided with a limiting clamping groove, a second cantilever, an over beam and a base plate from top to bottom, each second cantilever is symmetrically distributed at the two sides of each fixation support frame, each limiting clamping groove is internally provided with a first cantilever, the two sides of each first cantilever are each provided with a limiting protruding strip, each limiting protruding strip is movably connected with each second cantilever, each first cantilever is rotationally connected with the corresponding limiting protruding strips through a fixation rod, the bottom of the front end of each first cantilever is provided with the clamping device, and the measurement devices are fixedly connected with the bottom of the object carrying plate. The structure is simple, the practicality is high, an aluminum strip can be clamped and positioned, the aluminum can also be loaded and carried, the labor intensity is reduced, the operation is simple and convenient, the safety is high, and the steps for measuring the aluminum strip are simplified.

Owner:嵊州博远铝业有限公司

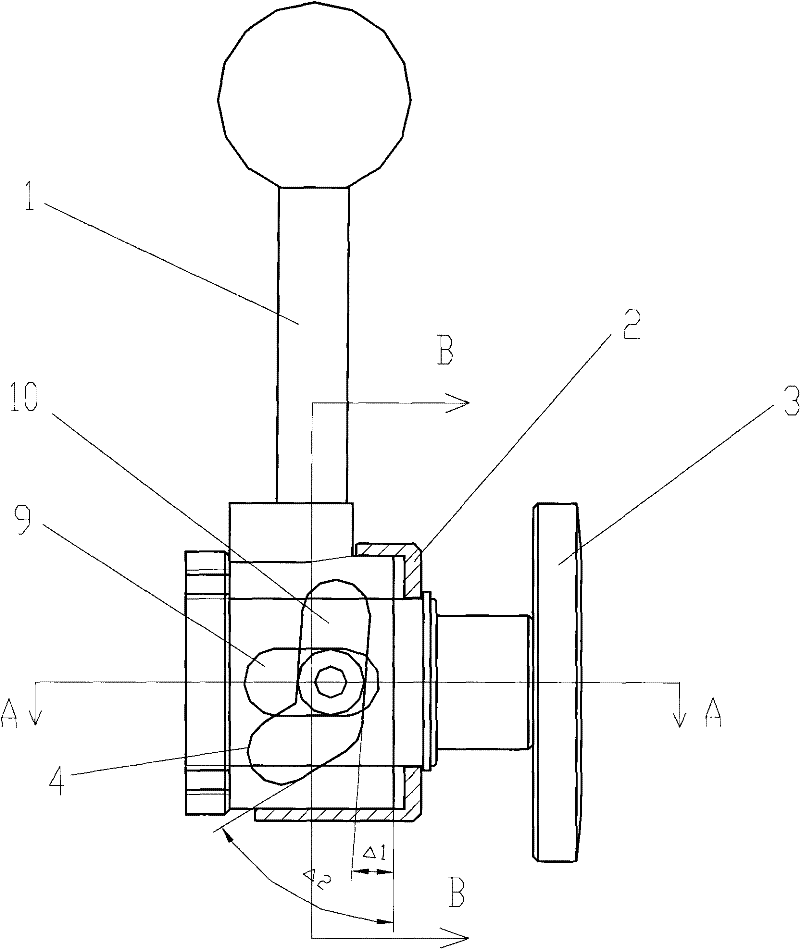

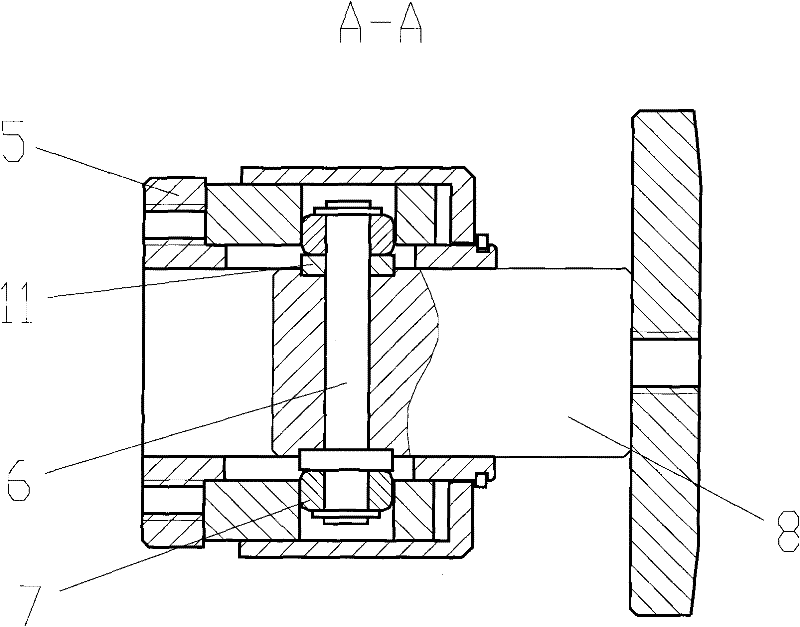

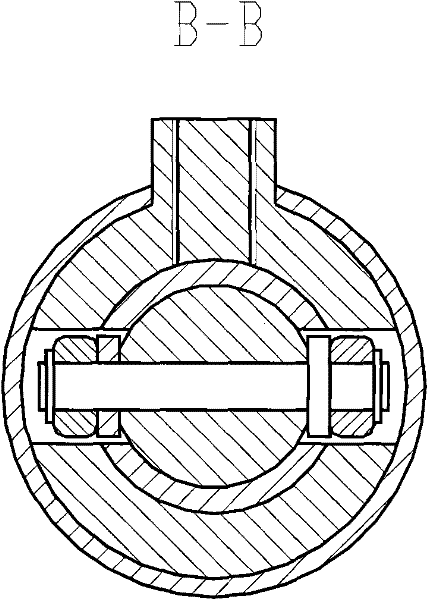

Side-clamping and self-locking device for parts and use method thereof

ActiveCN101973005BClamping meetsIncrease productivityMetal-working feeding devicesWork holdersEngineeringSelf locking

The invention discloses a side-clamping and self-locking device for parts and a use method thereof. The self-locking device comprises a positioning flange (5) fixed on a part to be processed, a shaft end part of the positioning flange (5) is provided with an elongated slot (9) in clearance fit with a step shaft (6) and a roller gasket (11), and the step shaft (6) and the roller gasket (11) can feely slide in the elongated slot (9); a spiral groove drum (4) is sleeved on the shaft end of the positioning flange (5) and provided with two sections of spiral chutes (10) which are connected and have different spiral angles; and the step shaft (6) passes through the elongated slot (9), the spiral chute (10) and the front end of a telescopic shaft (8) and is fixed, and the end part of the telescopic shaft (8) is provided with a clamping disk (3). The device can meet the requirements on rapidly clamping the parts and guarantee the self-locking on the parts after the clamping, and a clamping and self-locking point can be automatically adjusted in a certain range, therefore, the requirement on massive production is favorably satisfied.

Owner:江苏环宇钢构重工有限公司

Tube grinding system

InactiveCN105563311AImprove securitySecurity threatRevolution surface grinding machinesGrinding feed controlEngineeringMechanical engineering

The invention discloses a tube grinding system. The tube grinding system comprises a feeding device, a supporting device, a grinding device and a measuring device, wherein the supporting device is positioned at a discharging end of the feeding device; the grinding device is positioned above the supporting device; and the measuring device is positioned at a discharging end of the grinding device. Automatic feeding is realized through the feeding device, the supporting mechanism with an adjusting function is adopted, and is simple in structure and convenient to operate, an adjustable effect is achieved, through a lifting device, a whole grinding head mechanism can move in the up-down direction and the left-right direction, service restriction is avoided, after a steel tube is ground, a first clamping device is matched with a second clamping device, the steel tube can rotate when clamped, and then can be measured by the measuring device at various angles, vibrating and shaking of the steel tube are reduced, by a bearing plate, the steel tube can be placed stably and is measured accurately, errors are reduced, and the measurement effect of the steel tube is good.

Owner:RONGCHANG YONGXIN STEEL STRUCTURE PROCESSING FACTORY

A special preventive test device for lightning arresters

ActiveCN108957043BNo looseningImprove stabilityMeasurement instrument housingElectric machineTest frame

The invention discloses a special preventive test device for lightning arresters. The device comprises a test frame and a U-shaped block; a motor box is fixedly connected to one side of the U-shaped block; the bottom of the inner wall of the motor box is fixedly connected with a first motor; the output shaft of the first motor is fixedly connected with a rotating shaft; and one end of the rotatingshaft sequentially penetrates the motor box and the U-shaped block and extends into the U-shaped block. The invention belongs to the lightning arrester detection equipment technical field. The special preventive test device for the lightning arresters of the invention can clamp lightning arresters of different lengths; a second arc-shaped clamping block can be driven to move through the rotationof a threaded rod, so that the lightning arresters can be fixed, and therefore, operation is simple; and in a detection process, the lightning arresters will not loosen, and therefore, the stability of the lightning arresters during detection can be greatly improved, the clamping of different types of lightning arresters can be satisfied, and the practicality of the preventive test device for thelightning arresters can be greatly improved.

Owner:WUHU KAIXIN ARRESTER

Circuit board electroplating method

ActiveCN112638050AClamping meetsImprove clamping effectPrinted circuit manufactureMechanical engineeringMaterials science

The invention discloses a circuit board electroplating method which is completed on the basis of circuit board electroplating equipment so as to realize electroplating of a circuit board. The circuit board electroplating equipment comprises an upper mounting base, four pairs of adjusting connecting rods are arranged at the bottom of the upper mounting base; and the bottoms of the four pairs of adjusting connecting rods are jointly connected with a group of lower mounting bases. The method is good in adjusting capacity, higher in adaptability and better in circuit board clamping effect, meanwhile, the synchronous pressing of the five sets of driving clamping blocks can be achieved by rotating a clamping operation piece, the operation is reduced, and the working efficiency is improved.

Owner:徐州里程碑智能科技有限公司

A kind of circuit board electroplating method

ActiveCN112638050BAchieve compactionClamping meetsPrinted circuit manufactureEngineeringMechanical engineering

The invention discloses a circuit board electroplating method. The circuit board electroplating method is completed based on circuit board electroplating equipment, and further realizes circuit board electroplating; the circuit board electroplating equipment includes an upper mounting seat; the upper mounting seat Four pairs of adjusting connecting rods are arranged at the bottom of the bottom; the bottoms of the four pairs of adjusting connecting rods are jointly connected with a group of lower mounting seats. The invention has good adjustment ability and stronger adaptability, and the clamping effect of the circuit board is better. At the same time, the synchronous pressing of five groups of active clamping blocks can be realized by rotating the clamping operation part, which reduces the operation and improves the work efficiency.

Owner:徐州里程碑智能科技有限公司

Circuit board electroplating equipment

PendingCN112831823AAchieve compactionClamping meetsElectrolysis componentsControl theoryMechanical engineering

The invention discloses circuit board electroplating equipment, relates to the technical field of circuit board processing, and solves the problems that circuit boards need to be fixed on the electroplating equipment when existing circuit board electroplating equipment is used, the circuit boards of the existing electroplating equipment need to be fixed through clamps, the positions of the existing clamps are generally fixed, when the sizes of circuit boards are different, the distance between the clamps is difficult to adjust, so that fixation is poor, meanwhile, when the circuit boards are fixed, the clamps need to be operated as much as possible one by one, operation is troublesome, and the production efficiency. Four pairs of adjusting connecting rods are arranged at the bottom of an upper mounting seat; and the bottoms of the four pairs of adjusting connecting rods are jointly connected with a group of lower mounting seats. The circuit board electroplating equipment has good adjusting capacity and higher adaptability, the clamping effect of a circuit board is better, meanwhile, synchronous pressing of five sets of active clamping blocks can be achieved by rotating clamping operation pieces, operation is reduced, and working efficiency is improved.

Owner:沛县卓凡科技服务中心

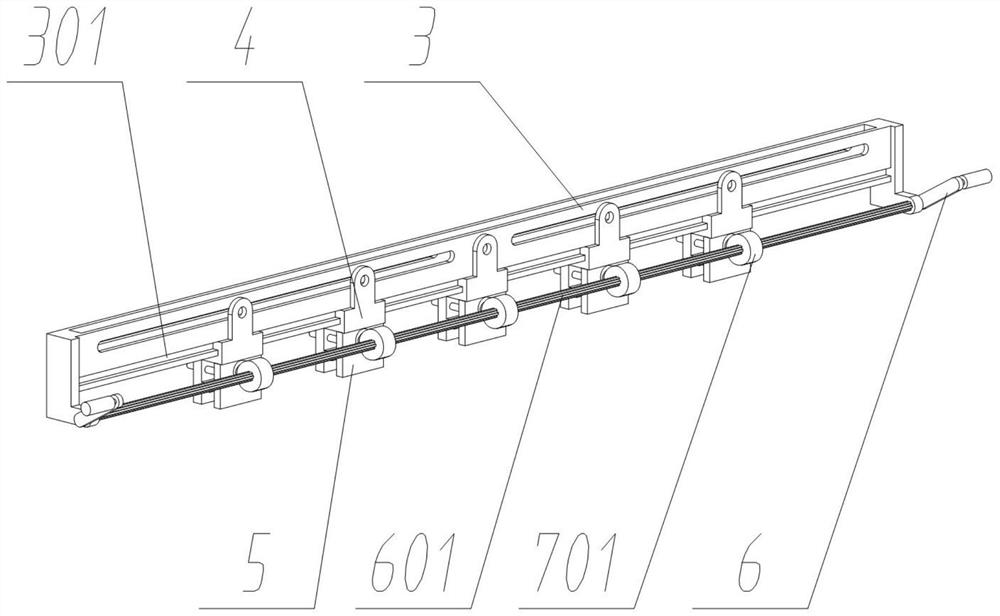

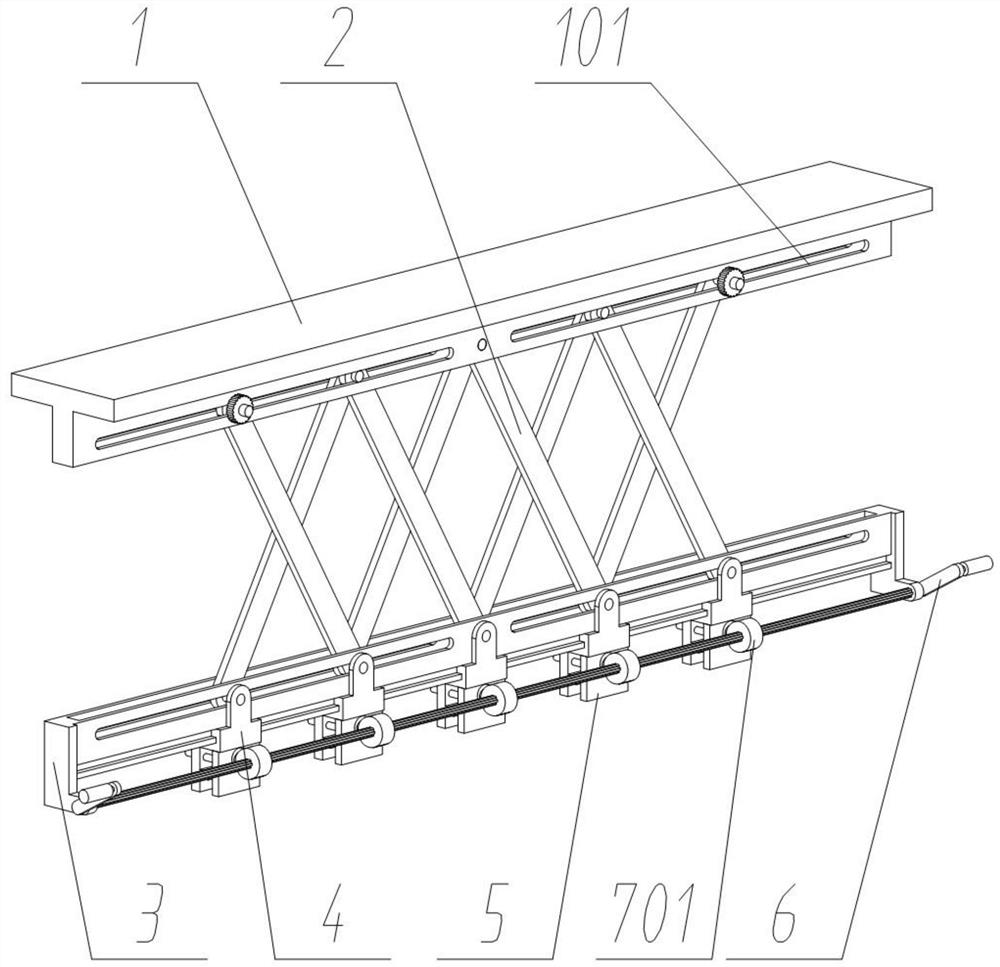

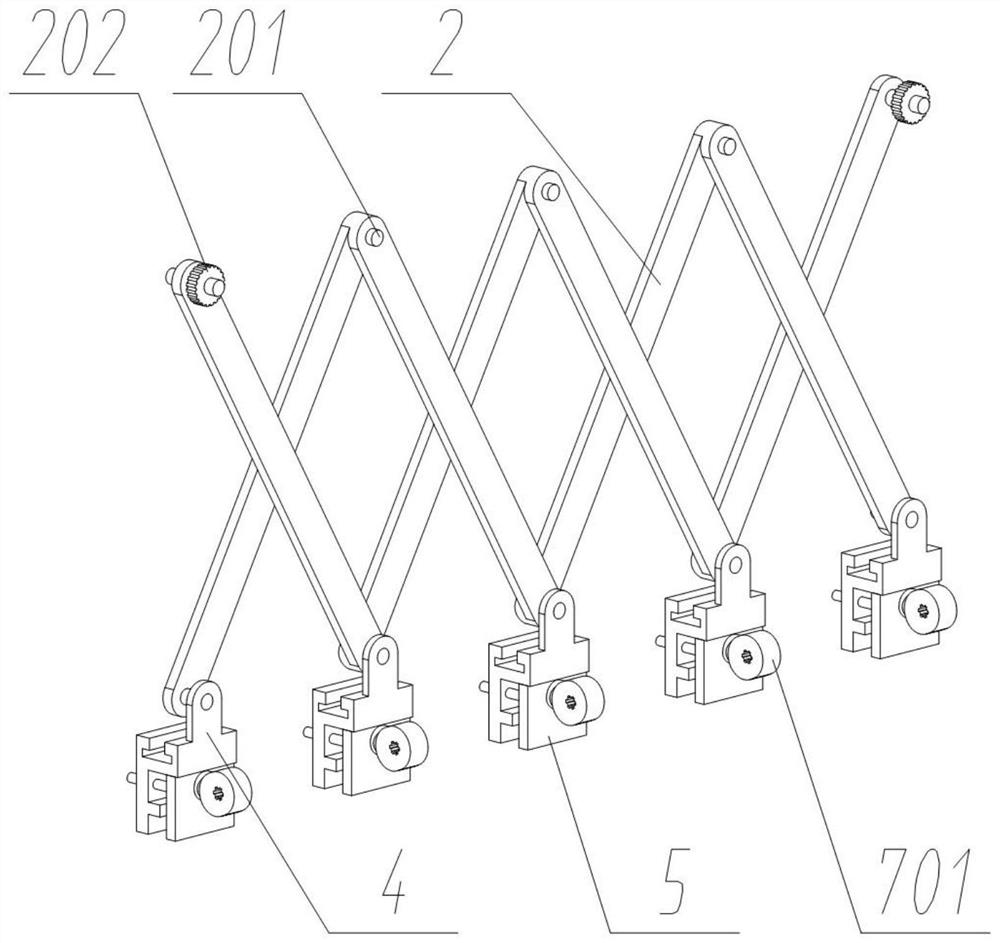

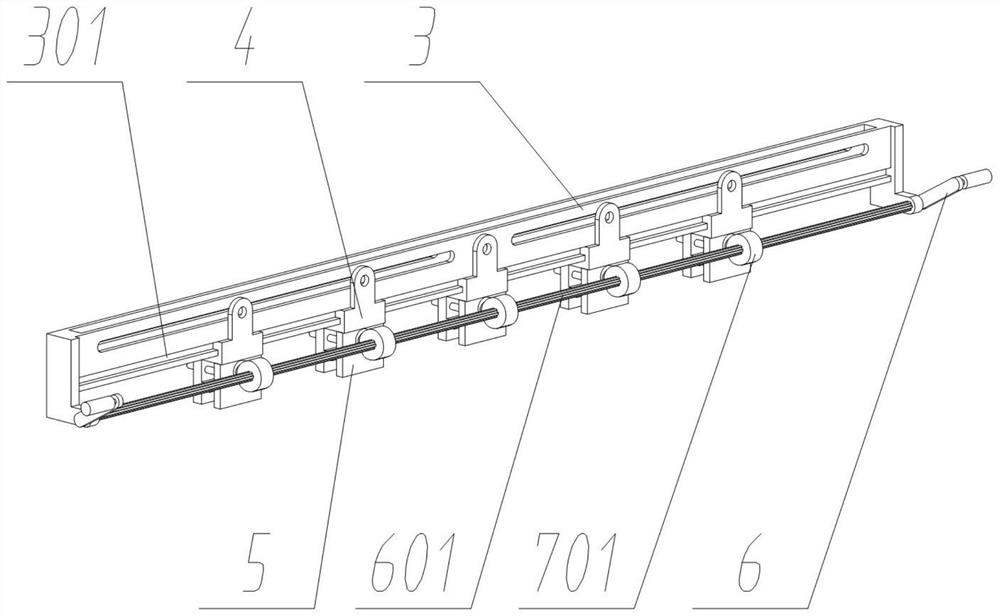

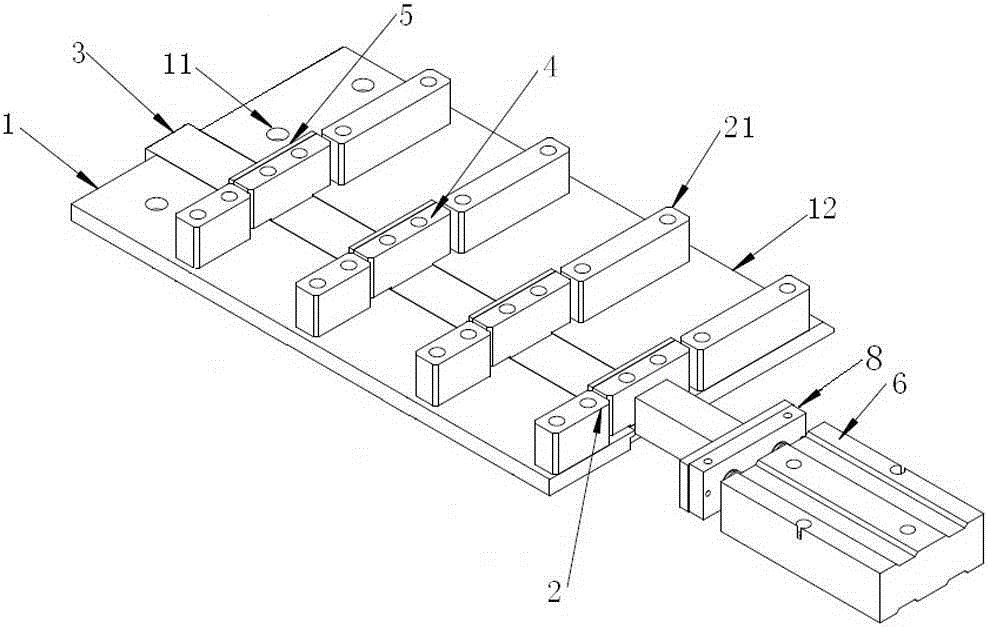

Linkage clamping multi-profile mechanism

ActiveCN103722420BClamping meetsGuaranteed positioning accuracyWork clamping meansPositioning apparatusEngineeringUltimate tensile strength

The invention discloses a multi-profile linkage clamping mechanism. The multi-profile linkage clamping mechanism comprises a lower bottom plate A, a lower bottom plate B, locating blocks A, locating blocks B, a sliding block, clamping blocks, ribs, a flat double-shaft air cylinder and a connecting piece, wherein the bottom plate A and the bottom plate B are arranged on the two sides of the sliding block, the sliding block, the lower bottom plate A and the lower bottom plate B form a sliding pair, the sliding block is connected with the flat double-shaft air cylinder through the connecting piece, the clamping blocks are arranged on the upper portion of the sliding block, the ribs are arranged on the clamping blocks, and the locating blocks A and the locating blocks B are arranged on the two sides of the sliding block respectively and serve as profile locating references. According to the multi-profile linkage clamping mechanism, the effect that each profile has a reference plane when clamping is carried out is achieved by using the clamping mechanism, locating accuracy is ensured, multiple profiles are fed at one time and located and clamped simultaneously, feeding time and discharging time are saved, labor intensity is lowered, labor efficiency is improved, the requirements for clamping profiles of different types and sizes can be met, and equipment cost can be reduced effectively.

Owner:TAICANG WEGOMA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com