Side-clamping and self-locking device for parts and use method thereof

A technology of self-locking device and parts, which is applied to workpiece clamping device, feeding device, positioning device, etc., can solve the problem that it takes a long time to rotate the handle several times, which does not meet the requirements of mass production, and the retraction and advance distance of the extrusion head is long. Over-extrusion or insufficient extrusion, etc., to achieve the effect of small occupied space, simple structure and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

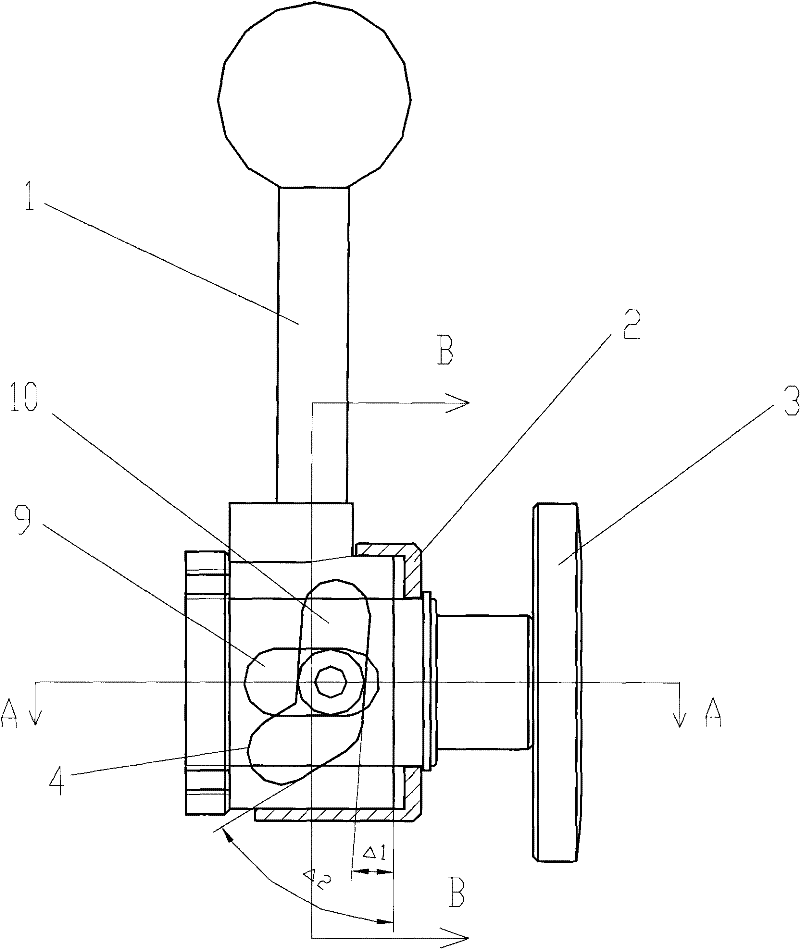

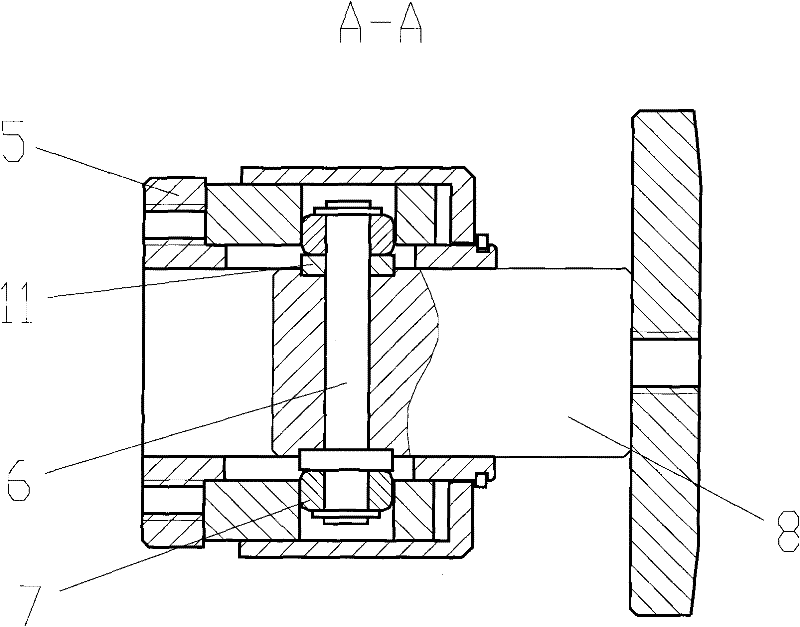

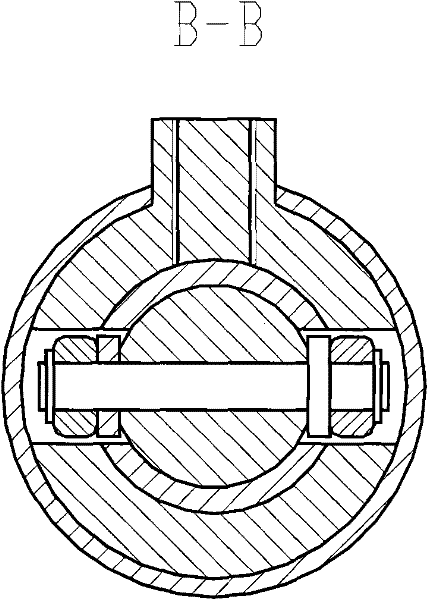

[0030] figure 1 The structure shown is a schematic diagram of the side clamping self-locking device for this kind of parts. figure 2 for figure 1 A schematic cross-sectional view of the A-A direction of the structure shown, image 3 for figure 1 Schematic cross-sectional view of the B-B direction of the structure shown. Depend on Figure 1-3 Combining the shown structures, it can be seen that the side clamping self-locking device for this kind of parts includes a positioning flange 5 fixed on the positioning fixture of the part to be processed, and the shaft end of the positioning flange 5 is provided with a step shaft 6 and a roller washer 11 The long groove 9 with clearance fit, the stepped shaft 6 and the roller washer 11 can slide or roll freely in the long groove 9, and a roller 7 is installed at both ends of the stepped shaft 6; the spiral grooved cylinder 4 is set on the positioning flange 5, and the spiral groove cylinder 4 is provided with two connected spiral c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com