Plasma electrode hafnium filament brazing device and brazing method

A plasma electrode and electrode technology, applied in welding equipment, metal processing equipment, electric heating devices, etc., can solve the problems of inability to achieve the strength of use, softening, etc., to avoid temperature rise and softening, improve service life, and fix firmly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

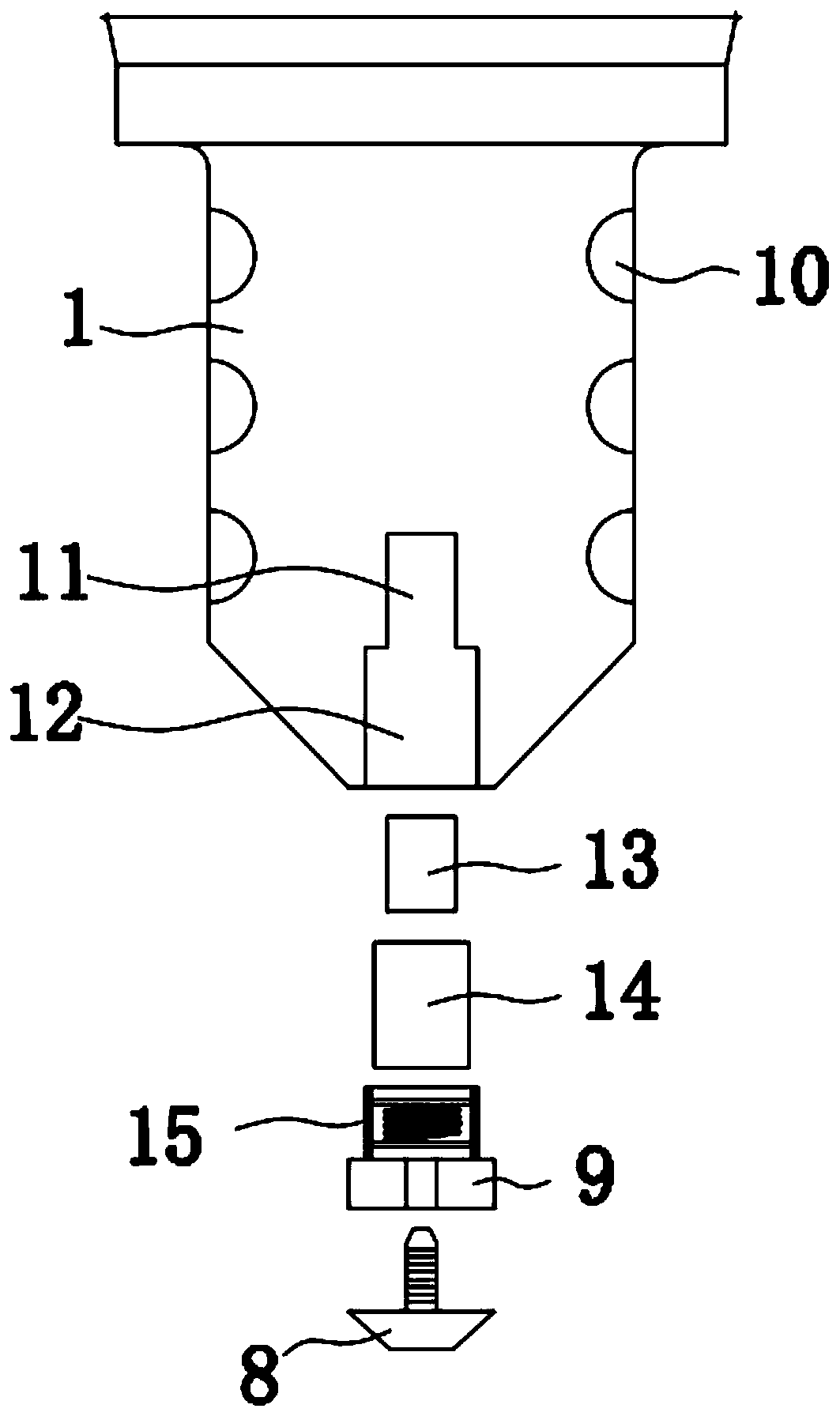

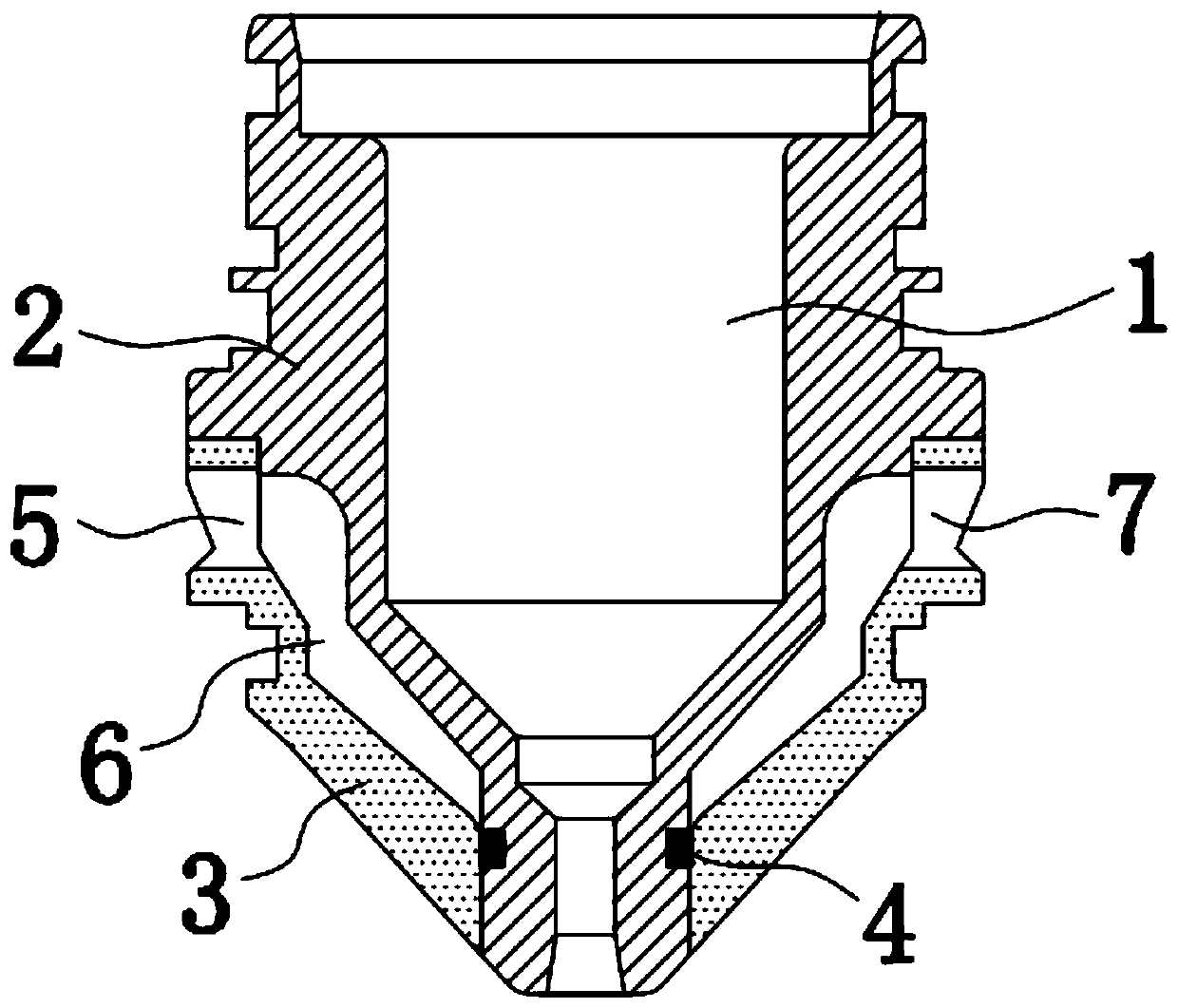

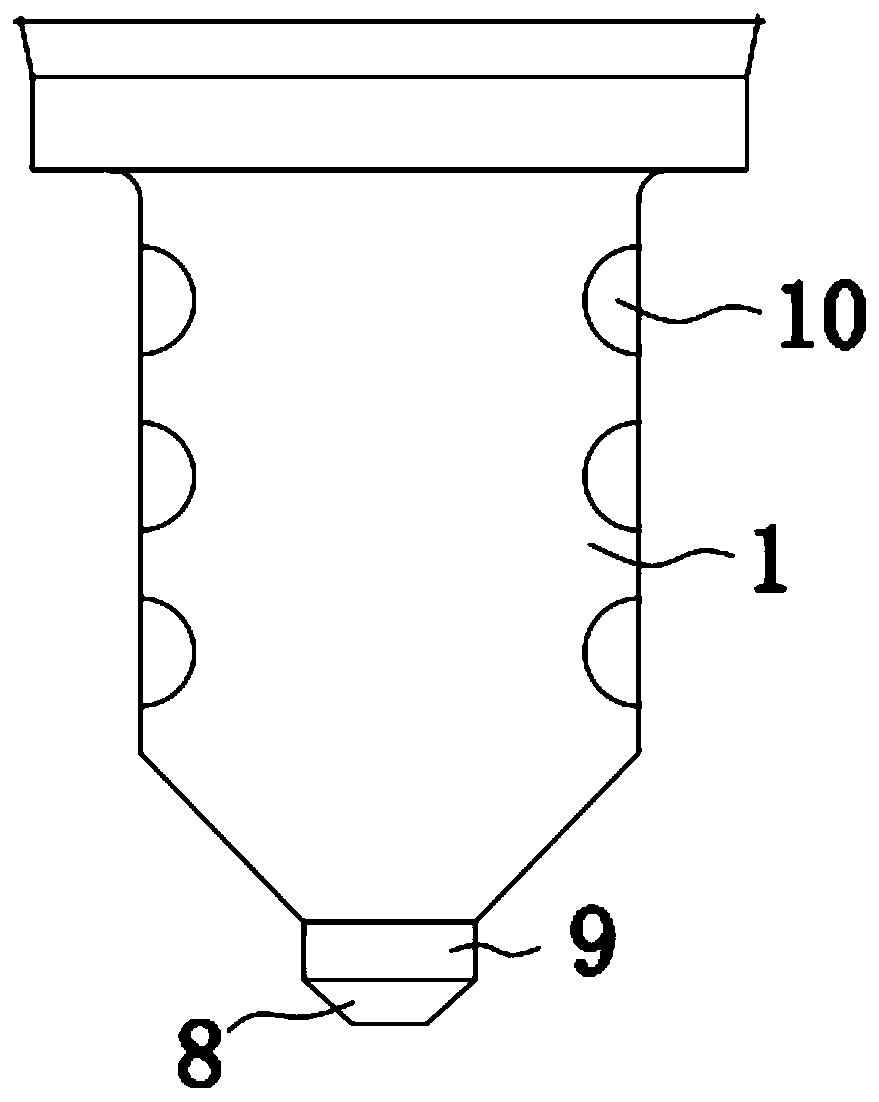

[0024] The present invention provides such Figure 1-4 A kind of plasma electrode hafnium wire brazing equipment, including an electrode body 1 and a fixing part, the electrode body 1 is installed in a fixing sleeve 2, and the lower end of the fixing sleeve 2 is sleeved with a cooling cover 3, and the cooling cover 3 A cooling water circulation cavity 6 is formed between the fixed sleeve 2, and a cooling water injection port 5 and a cooling water discharge port 7 communicating with the cooling water circulation cavity 6 are also provided on both sides of the upper part of the cooling cover 3. The lower end of the electrode body 1 is inside There is a first opening 11 for placing a solder wire 13, and a second opening 12 communicating with the first opening 11 is provided inside the lower end of the electrode body 1, and a second opening 12 is provided in the second opening 12. Hafnium wire 14, the fixture includes a sealing disc 9 and an externally threaded cylinder 15 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com