Fabricated building supporting seat

A support seat and prefabricated technology, which is applied in the directions of architecture, building structure, and on-site preparation of building components, can solve the problems of inability to adjust the length, width and height synchronously, single function of the support seat, and small scope of application. Enhanced usability and flexibility, easy transfer, enhanced clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

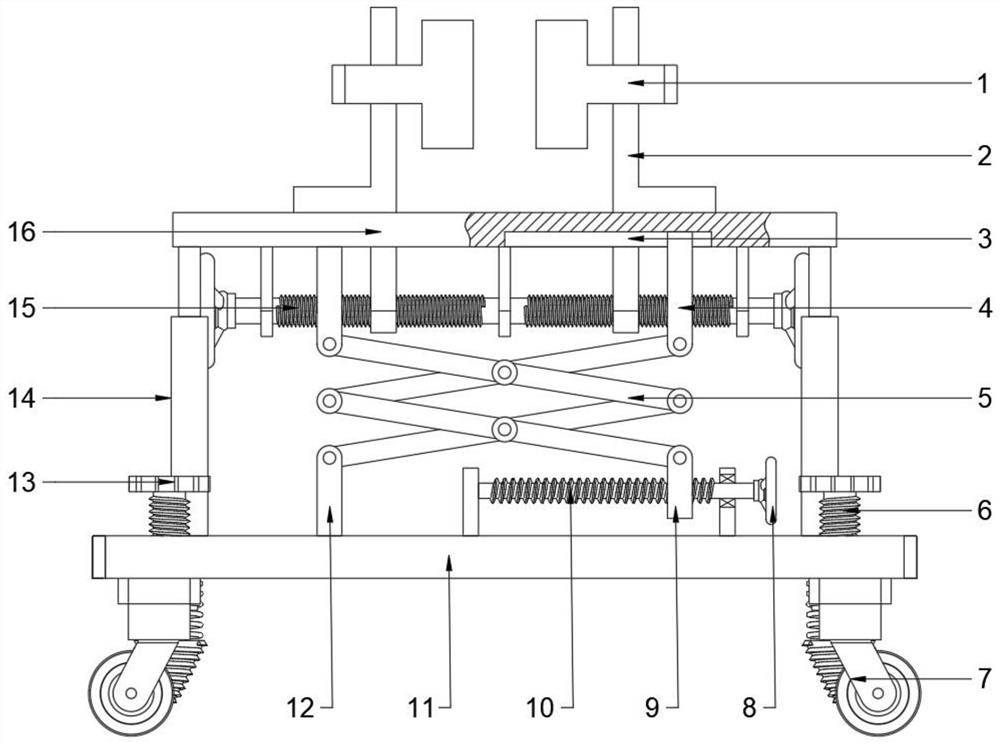

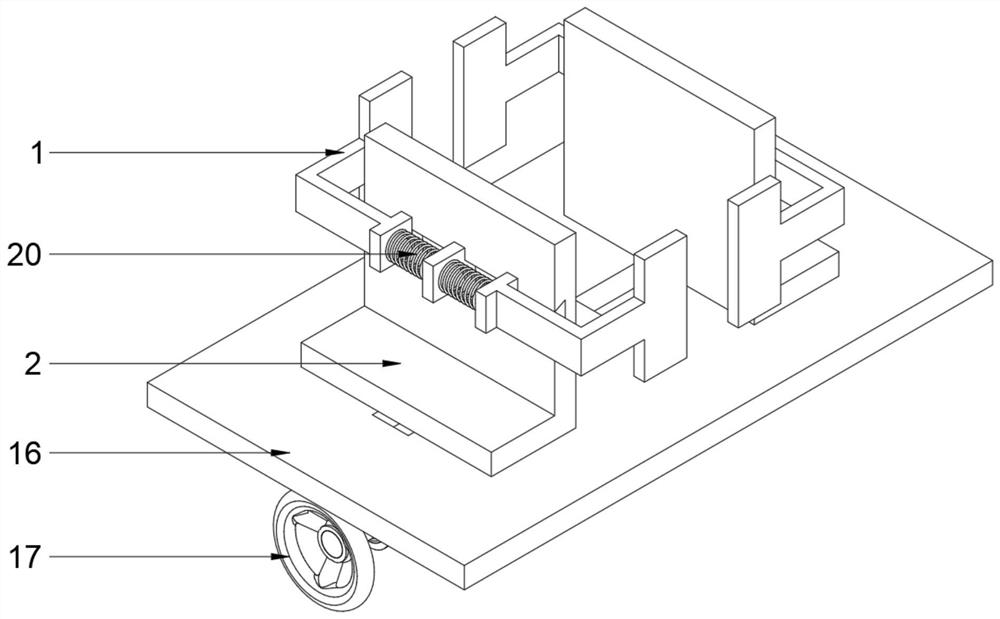

[0026] see Figure 1-5 , In the embodiment of the present invention, a prefabricated building support base includes a support base 11 and a workbench 16 arranged on the support base 11 , and the workbench 16 is installed on the support base 11 through a lifting assembly arranged at the bottom of the workbench 11 , a clamping assembly is also provided above the workbench 16, and the clamping assembly is used to fix the building and facilitate assembly; the clamping assembly includes a clamping plate 2 and a clamping screw 15, and the number of the clamping plate 2 is two groups and its The bottom is fixedly provided with an adjusting block 21. The two sets of splints 2 form a sliding fit with the two sets of rectangular holes 22 opened on the worktable 16 through the adjusting block 21. Both ends of the clamping screw 15 are rotated and installed on the bottom of the worktable 16 through bearings. And its periphery is also provided with bidirectional threads, the bidirectional ...

Embodiment 2

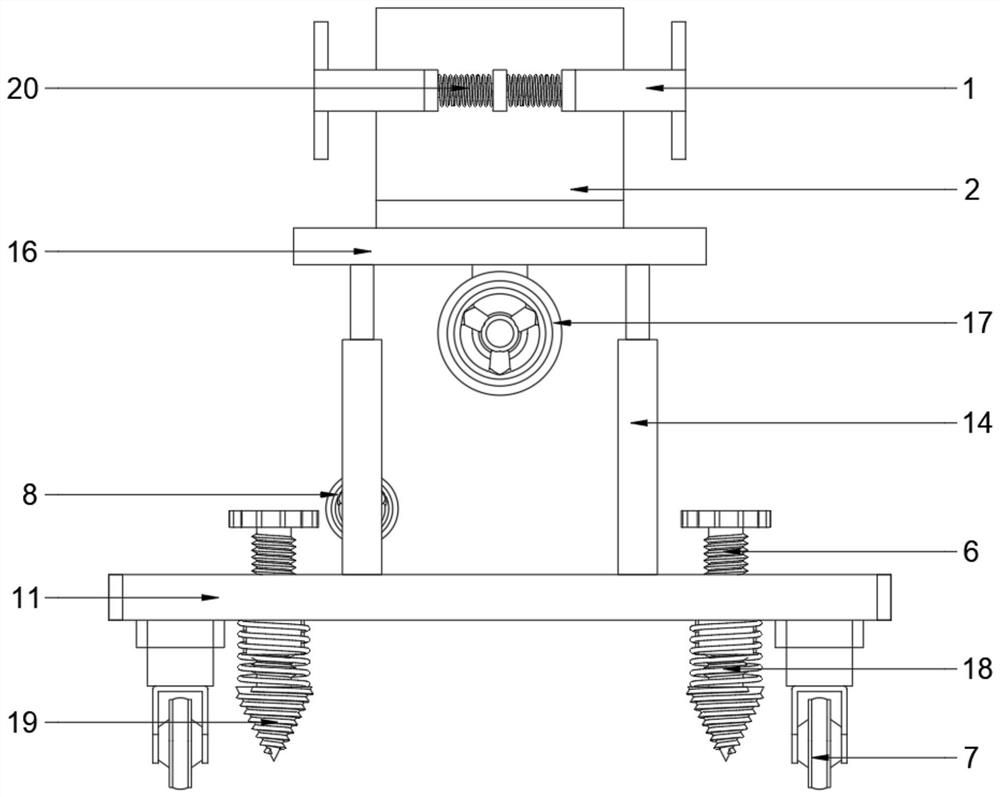

[0033] see figure 2 , 6, in the embodiment of the present invention, a prefabricated building support base, in order to enhance the stability of the device, on the basis of Embodiment 1, the support base 11 is provided with four sets of fixing devices and the fixing devices are located near the roller 7, The fixing device includes a fixing screw 6, a shock-absorbing spring 18 and a conical top 19. The fixing screw 6 is provided with a thread and is threaded with the fixing threaded hole opened on the support base 11. The bottom of the fixing screw 6 is fixed. A conical top 19 is installed and a conical thread is also provided on the periphery of the conical top 19, and a shock-absorbing spring 18 is also sleeved on the periphery of the fixing screw 6, and the two ends of the shock-absorbing spring 18 are respectively in contact with the support base 11 and the conical top 19, In order to slow down the vibration, a fixed handle 13 is also fixedly installed on the top of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com