Cambered surface clamping device

A clamping and cambered technology, applied in the workpiece clamping device, positioning device, clamping and other directions, can solve the problem of difficult positioning of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

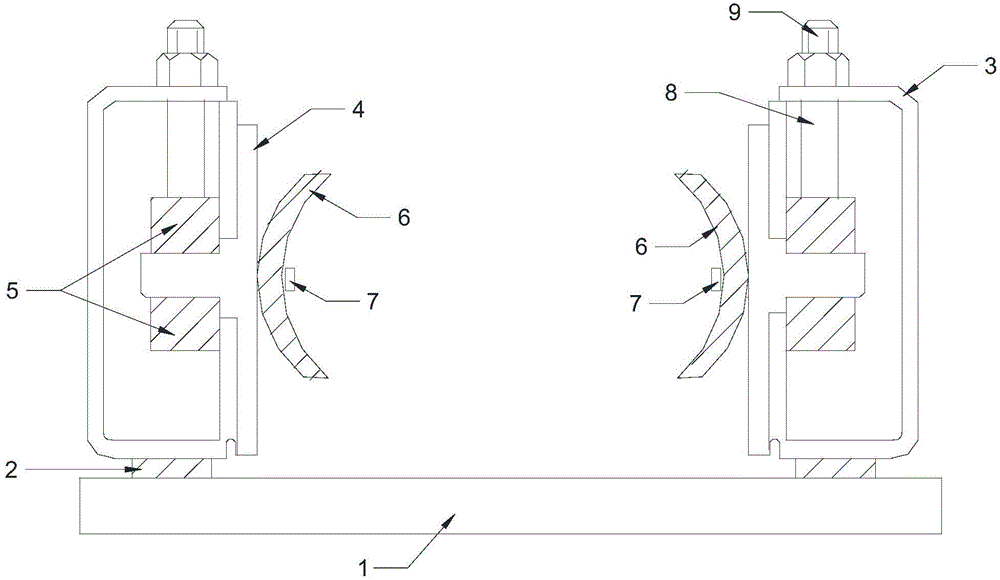

[0012] The arc surface clamping device includes a horizontal work table 1, and plane bearings 2 are symmetrically arranged at both ends of the horizontal work table 1, and also includes a rectangular frame 3 connected to the plane bearing 2. Through the plane bearings, the rectangular frame can realize horizontal Rotation in the vertical plane of the face on which the work table is located;

[0013] The rectangular frame is provided with a through hole on the side wall perpendicular to the horizontal work table, and the opening direction of the through hole is parallel to the plane where the horizontal work table is located;

[0014] Also comprise clamping part, described clamping part comprises T-shaped movable plate 4, the vertical end of described T-shaped movable plate 4, namely is connected in the end that is connected at the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com