Workpiece clamping mechanism for cutting equipment for cylinder of shock absorber

A technology of cutting equipment and clamping mechanism, which is applied in the direction of metal sawing equipment, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low production efficiency and poor cutting accuracy, and achieve convenient workpiece clamping, high efficiency, The effect of easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

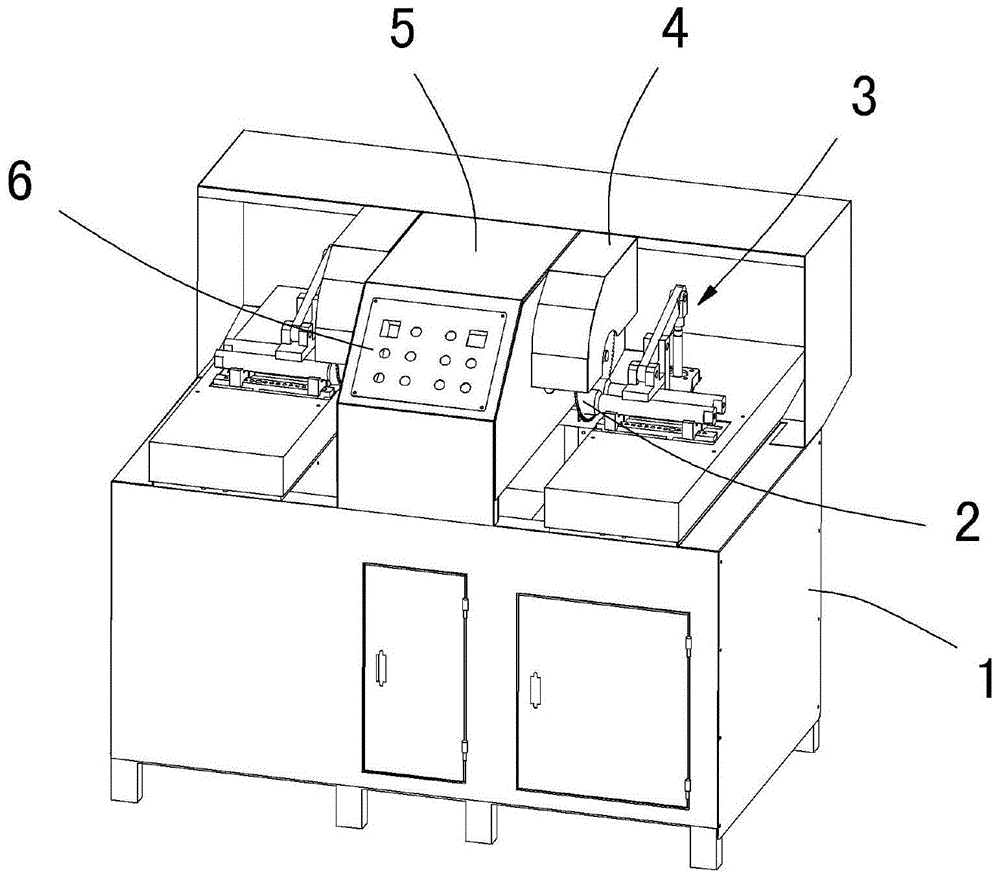

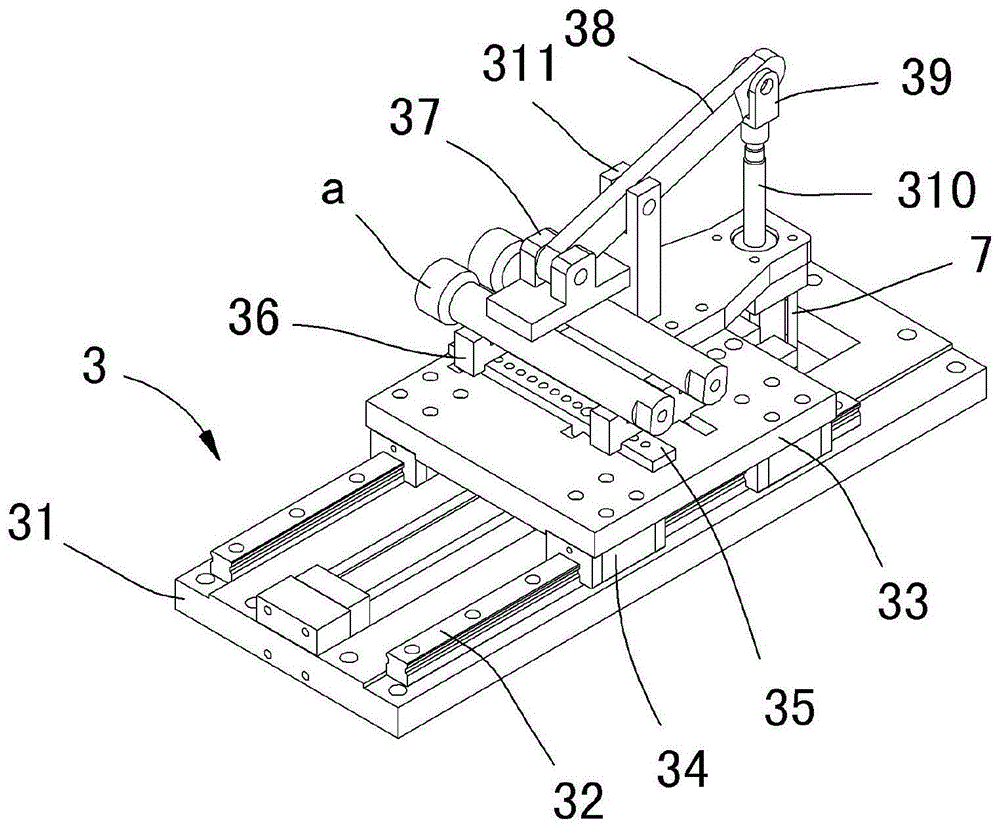

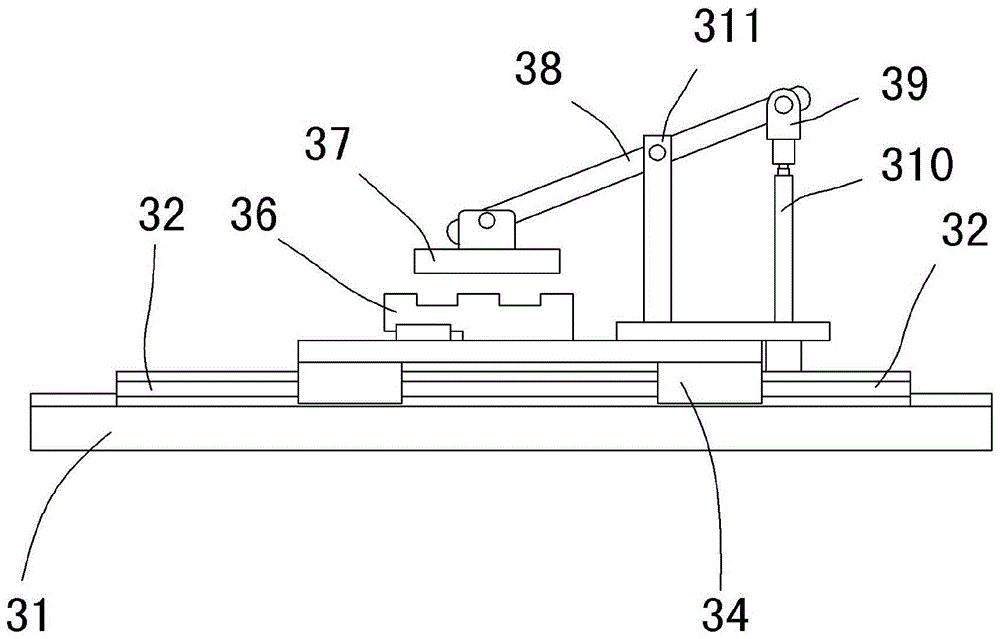

[0025] Example: such as Figures 1 to 9 Shown is an embodiment of the workpiece clamping mechanism used on the cutting equipment of a shock absorber barrel of the present invention, the workpiece clamping mechanism is arranged on the cutting machine, and the cutting machine includes a machine table 1 and a double-axis head motor 5. A cutting saw blade 2 is fixed on each rotating shaft of the double-shaft head motor 5, and two stations are arranged on the position corresponding to the cutting saw blade 2 on the said machine table 1, and each station is provided with a workpiece holder. Tight clamping mechanism 3, described clamping mechanism 3 comprises base plate 31, and described base plate 31 is provided with slide rail 32, and described slide rail 32 is provided with the mobile plate 33 that is driven by hydraulic pressure and moves on slide rail 32, so The moving plate 33 is provided with a workpiece seat 36 for placing workpieces, and the moving plate 33 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com