Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Calibration operation is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

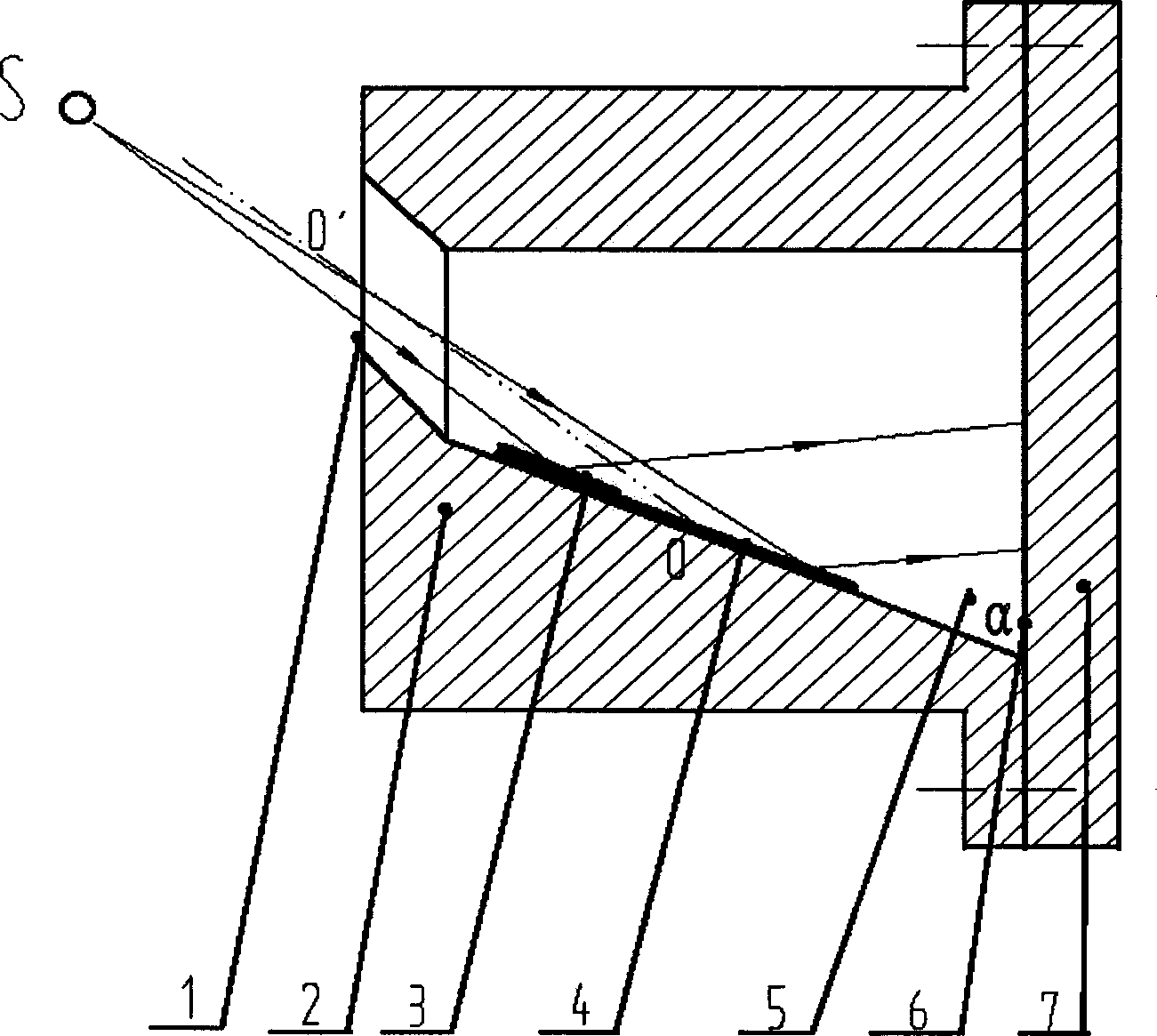

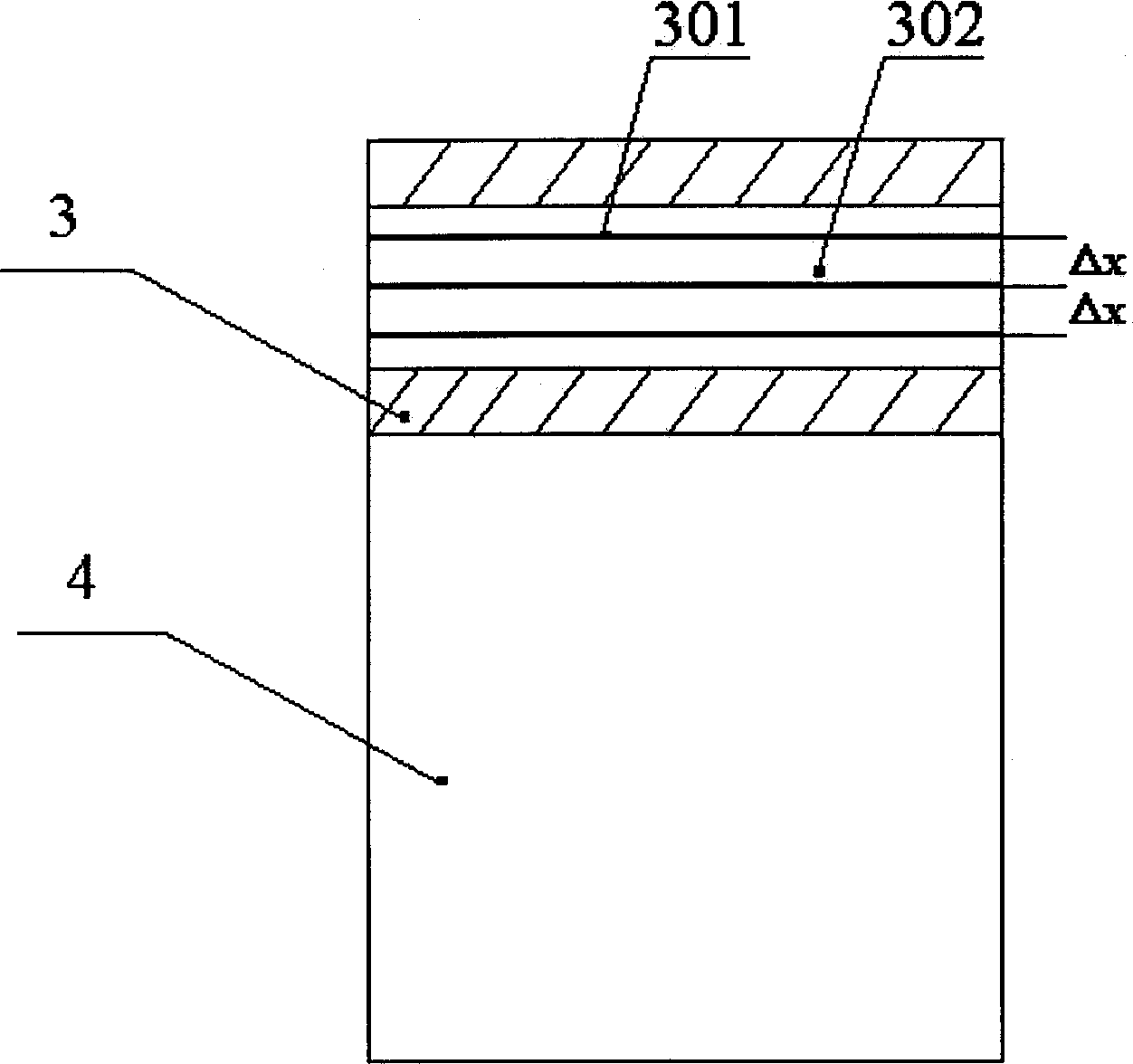

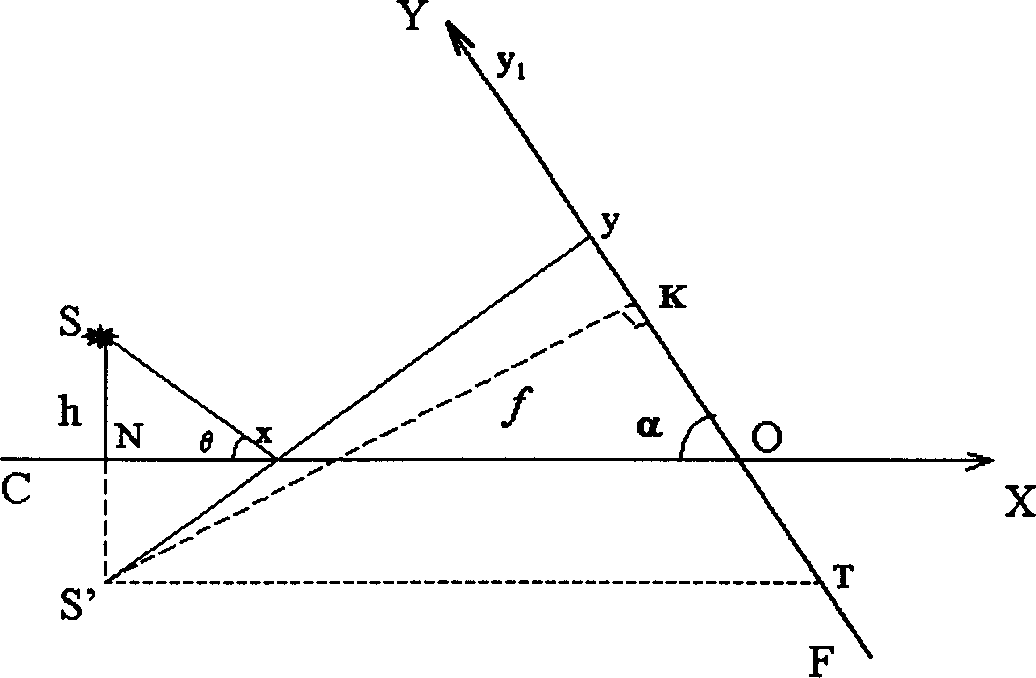

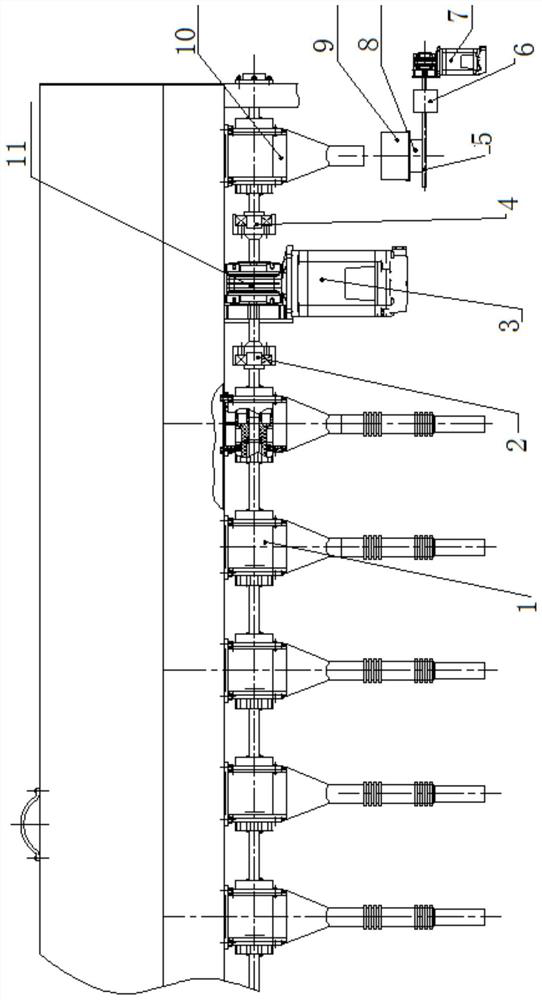

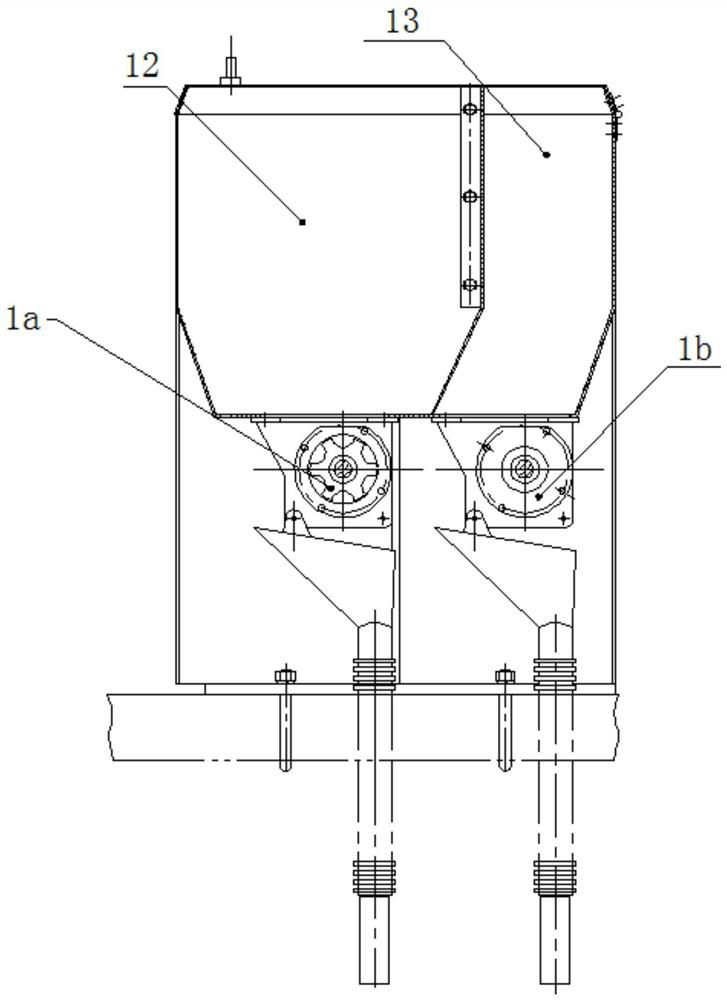

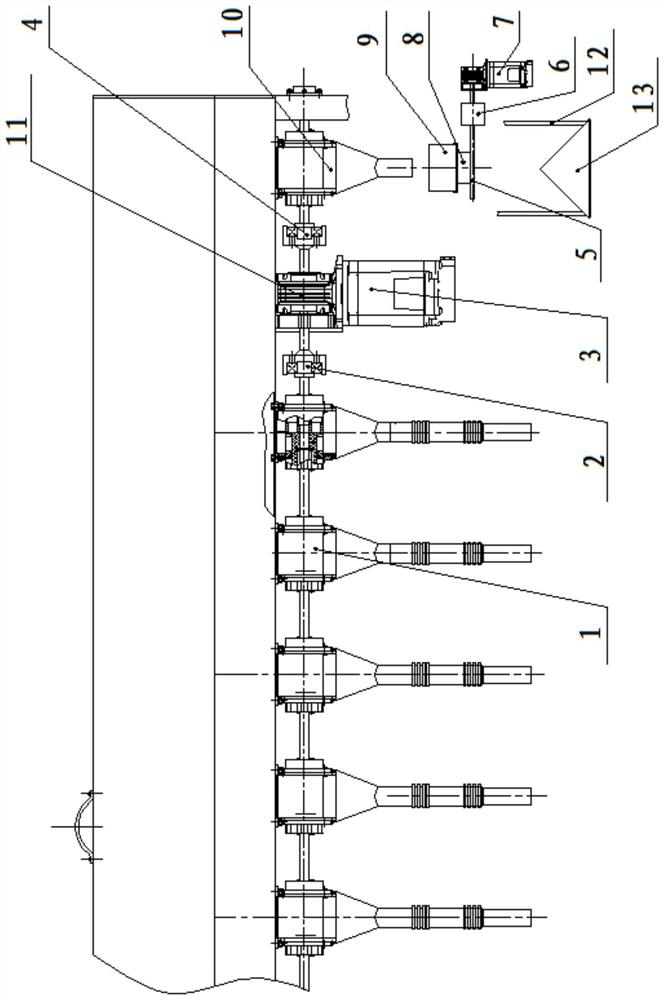

Track geometric irregularity inspection method based on two-dimensional laser displacement sensors

ActiveCN107554553AImprove anti-interference abilityEasy to handleUsing optical meansRailway auxillary equipmentGyroscopeAccelerometer

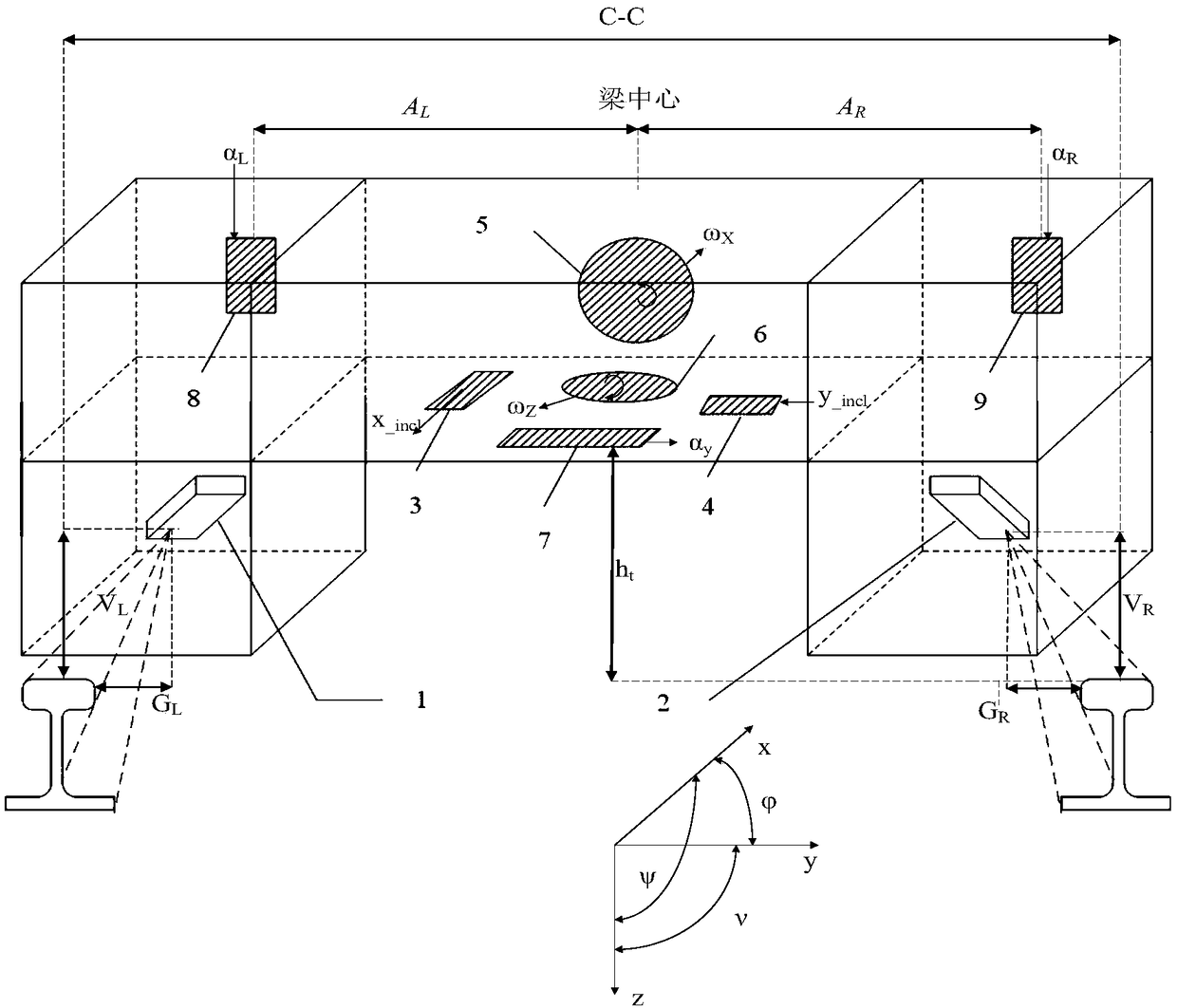

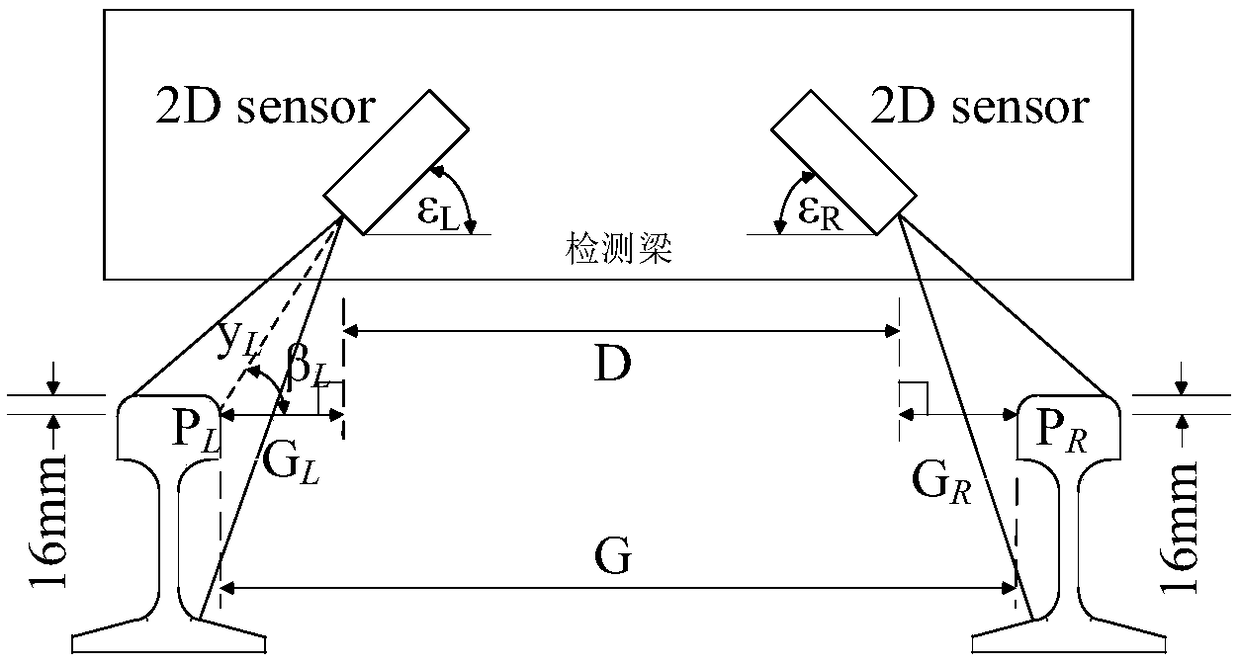

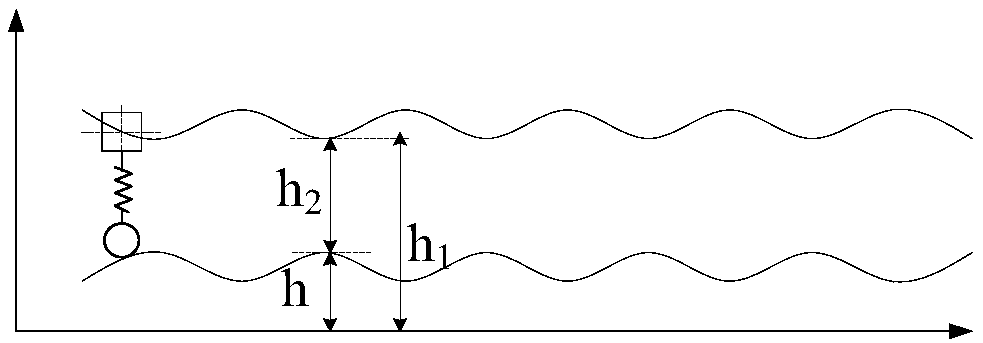

The invention discloses a detection method for track geometric irregularity based on a two-dimensional laser displacement sensor. A left laser sensor, a right laser sensor, a longitudinal inclinometer, a lateral inclination meter, a gyroscope, a lateral accelerometer, and a left vertical acceleration are installed on the detection beam. meter, right vertical accelerometer, the left laser sensor and the right laser sensor are two-dimensional laser sensors; perform the following measurements: track gauge detection, height detection, rail direction detection, horizontal superhigh detection, twist detection, curvature detection, Rail vertical as well as side wear measurements. The present invention adopts a high-speed two-dimensional laser displacement sensor, which has strong anti-interference ability. Based on the two-dimensional sensor, there is no complicated image processing step, and with simple and effective back-end algorithm processing, it has higher detection and calculation speed. It can effectively eliminate the influence of vehicle body vibration on the detection result, the detection result has high repeatability, can compensate the detection result, and has higher detection accuracy.

Owner:CHANGZHOU LUHANG RAILWAY TRANSPORTATION TECH

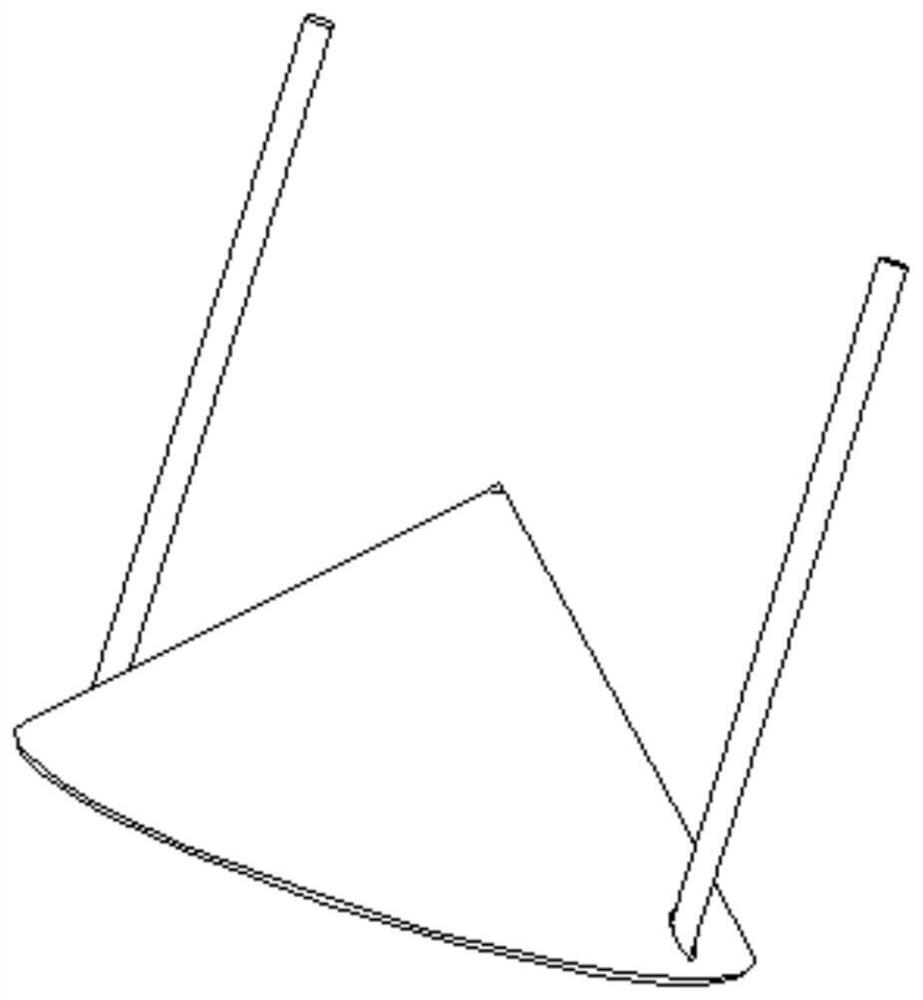

On-board radar calibration equipment and method

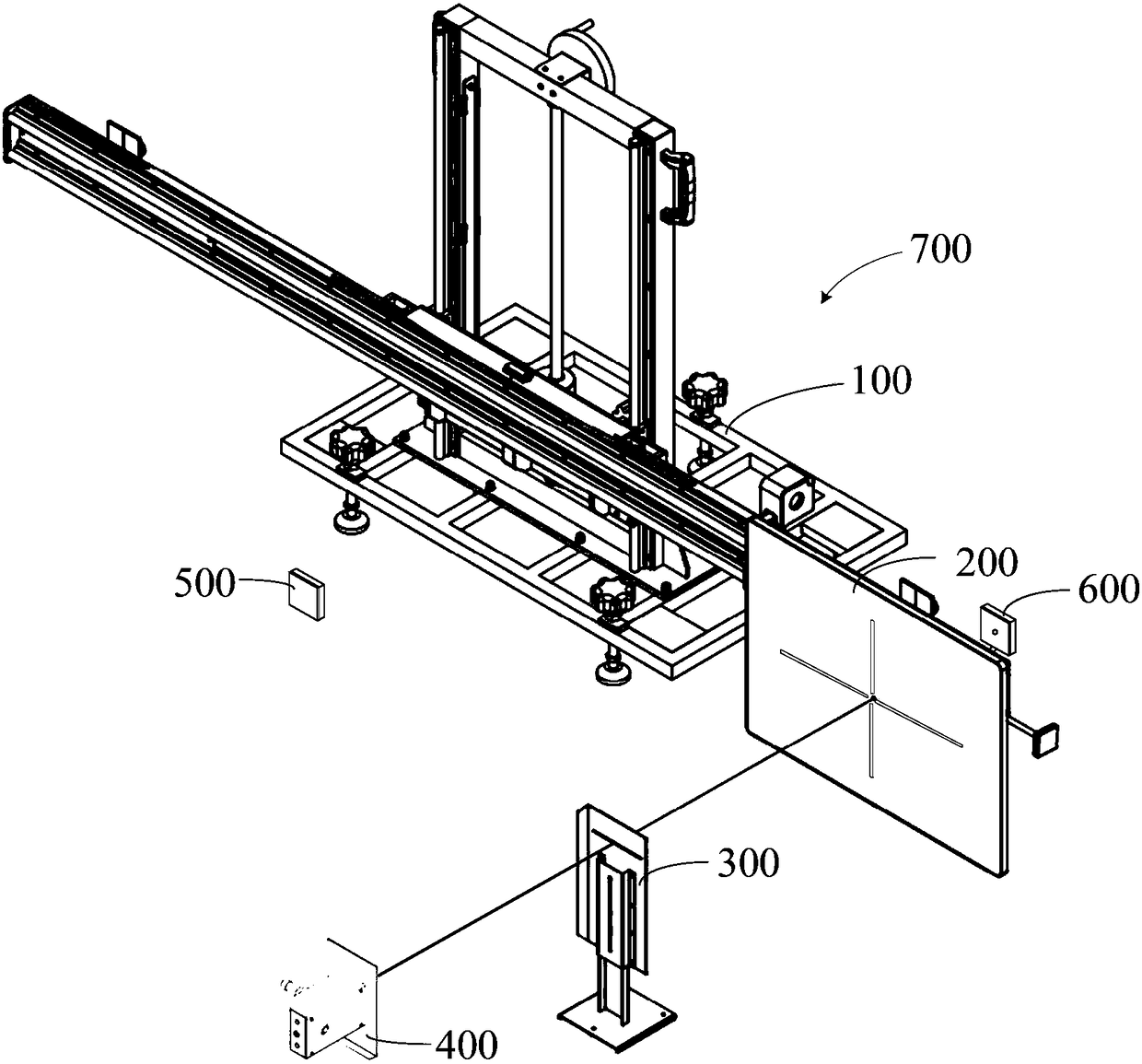

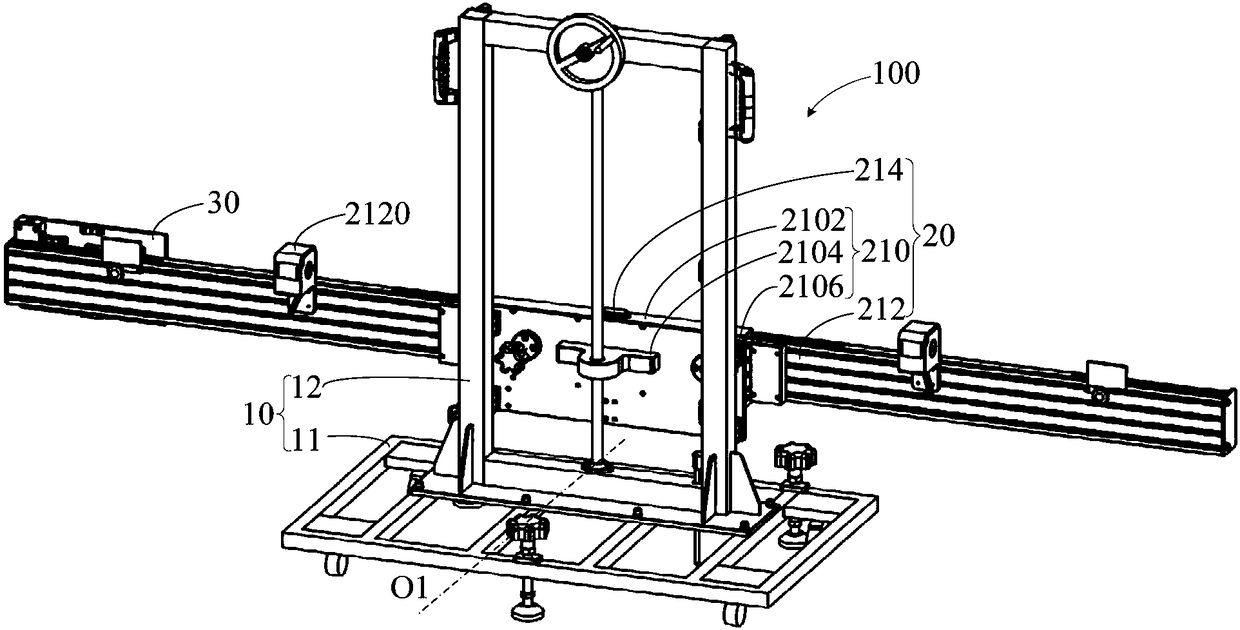

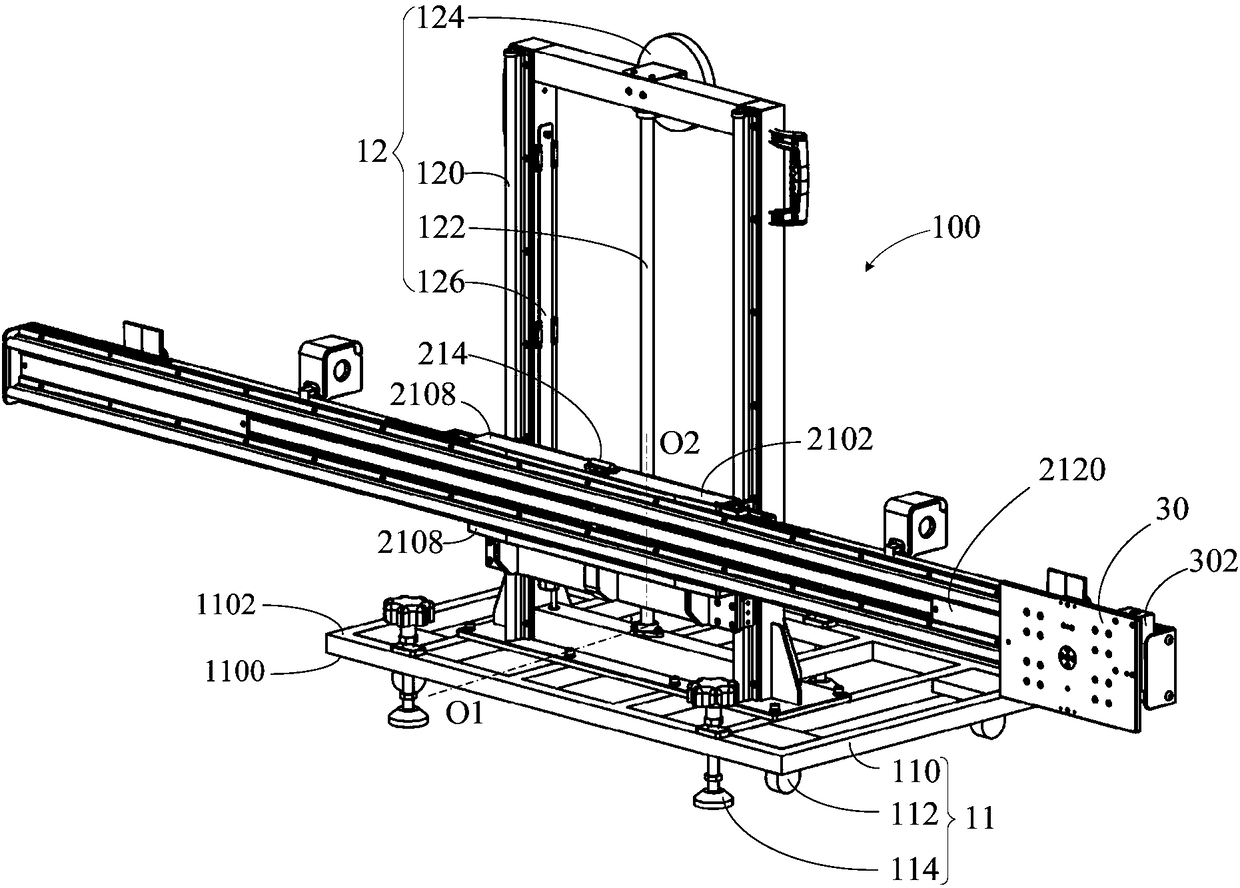

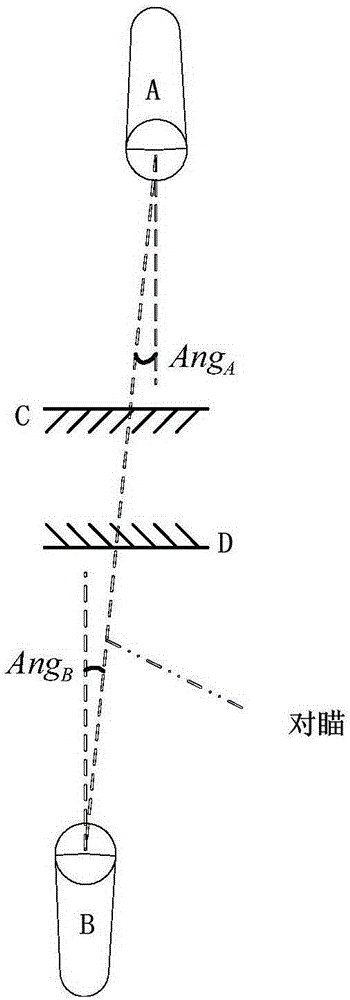

PendingCN108120966AConvenient calibration workReduce in quantityRadio wave reradiation/reflectionOn boardAcoustics

The invention relates to the technical field of automobile maintenance and equipment calibration and discloses on-board radar calibration equipment and a method. The on-board radar calibration equipment comprises a radar calibration plate, a radar calibration laser and a radar calibration reflector. The radar calibration plate comprises a through hole. The radar calibration laser is used for emitting a laser beam to penetrate through the through hole after vertical surface calibration of the radar calibration plate is accomplished. The radar calibration reflector is mounted on a to-be-calibrated on-board radar of an automobile and reflects the laser beam penetrating through the through hole back to the through hole along the original path to achieve the calibration of the on-board radar. According to the equipment, the radar calibration reflector can be mounted on the on-board radar of different automobile types; after a vertical surface of the calibration plate is calibrated, the radar calibration laser emits the laser beam to penetrate through the through hole; the radar calibration reflector reflects the laser beam penetrating through the through hole back to the through hole; the equipment can perform calibration operation on the on-board radar of the different automobile types; and the calibration work of the on-board radar is facilitated.

Owner:AUTEL INTELLIGENT TECHNOLOGY CORP LTD

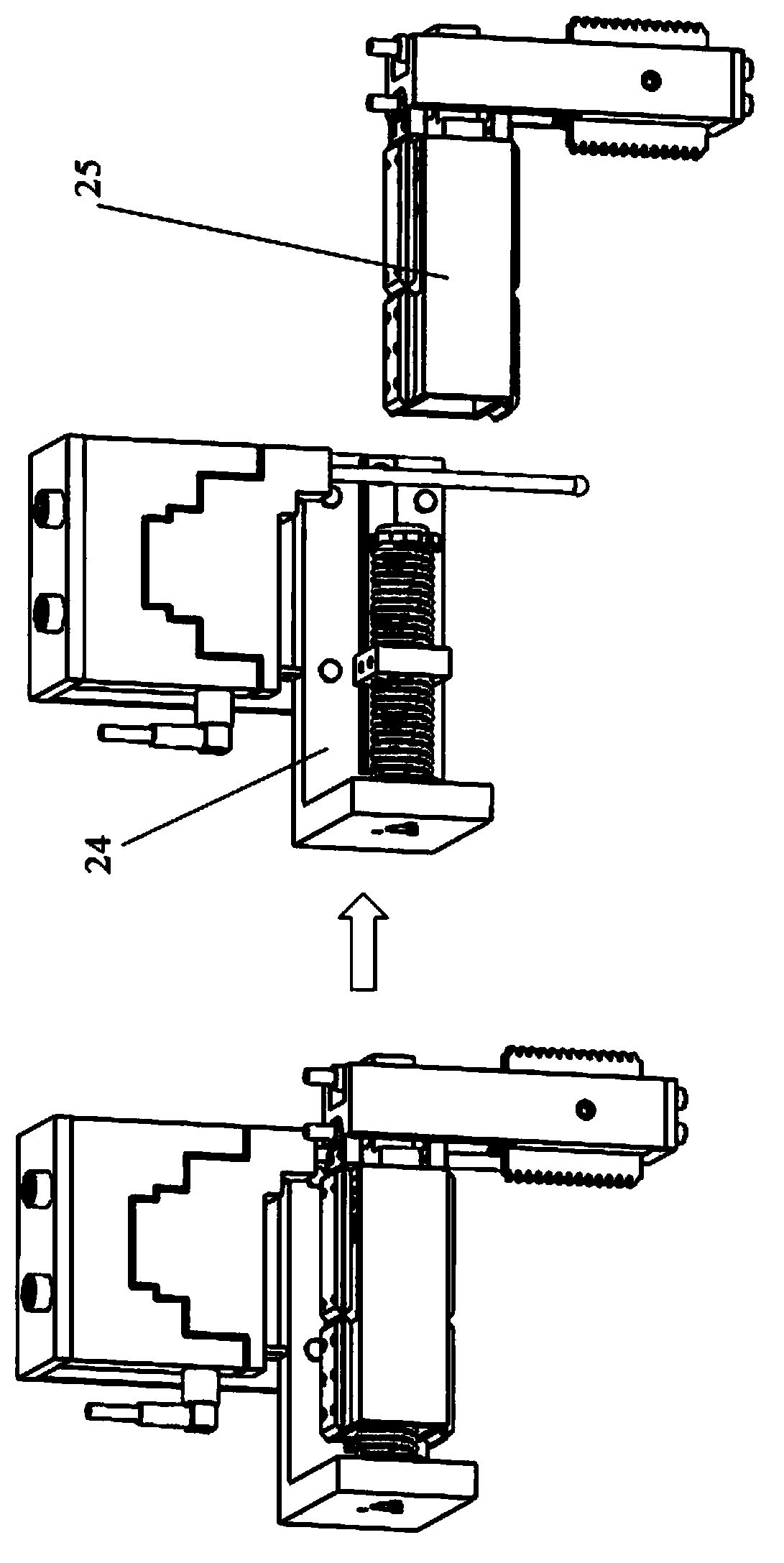

Double-strap-down inertial set orientation deviation calibration device and method of rocket launcher

ActiveCN105222806ALower requirementCalibration operation is simpleMeasurement devicesTheodoliteControl system

The invention provides a double-strap-down inertial set orientation deviation calibration device of a rocket launcher. A double-strap-down inertial set of the rocket launcher comprises two strap-down inertial sets which are installed on one integrated support in parallel so that a complete strap-down inertial set can be formed; the two strap-down inertial sets are movably placed on a horizontal flat plate calibration table; a standard hexahedron and right-angle prisms of the two strap-down inertial sets are arranged at equal height; the standard hexahedron and the strap-down inertial sets are alternately located in the view fields of a first theodolite and a second theodolite as a whole; the first theodolite and the second theodolite are arranged on the two sides of the flat plate calibration table respectively. Meanwhile, a calibration method of the calibration device is provided. The calibration device and the calibration method of the calibration device achieve the purpose that after double-strap-down inertial measurement combination main and salve redundancy is adopted for a control system of the rocket launcher, the orientation deviation of the two strap-down inertial sets is determined. After the main strap-down inertial set is aimed at at the initial orientation in front of the rocket launcher, the orientation of the slave strap-down inertial set is determined through the calibration deviation, the initial alignment and launching process of the rocket launcher provided with the redundant strap-down inertial sets can be simplified, and engineering practicability is high.

Owner:SHANGHAI XINYUE METER FACTORY

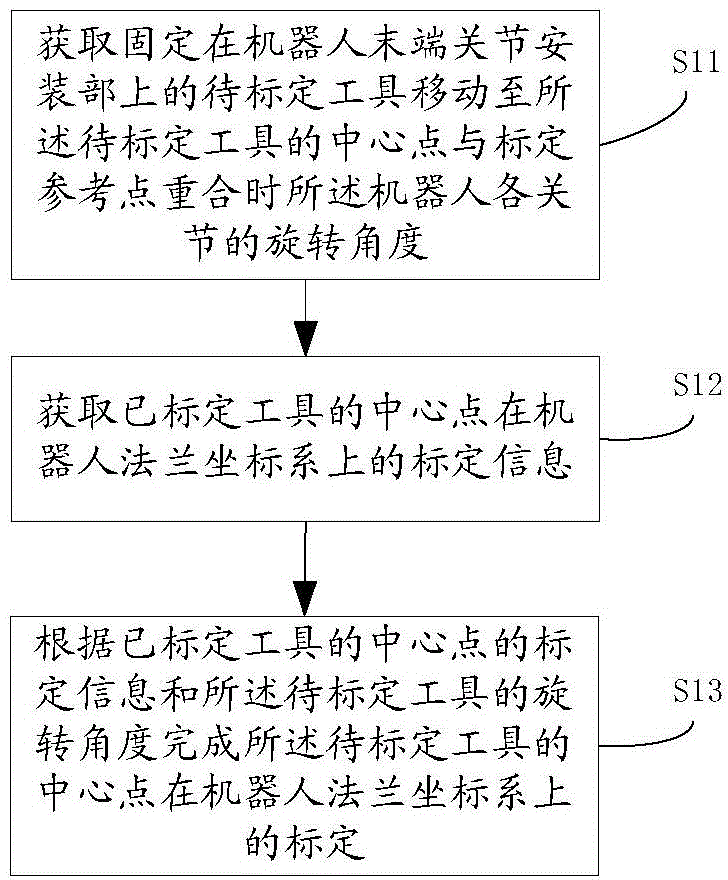

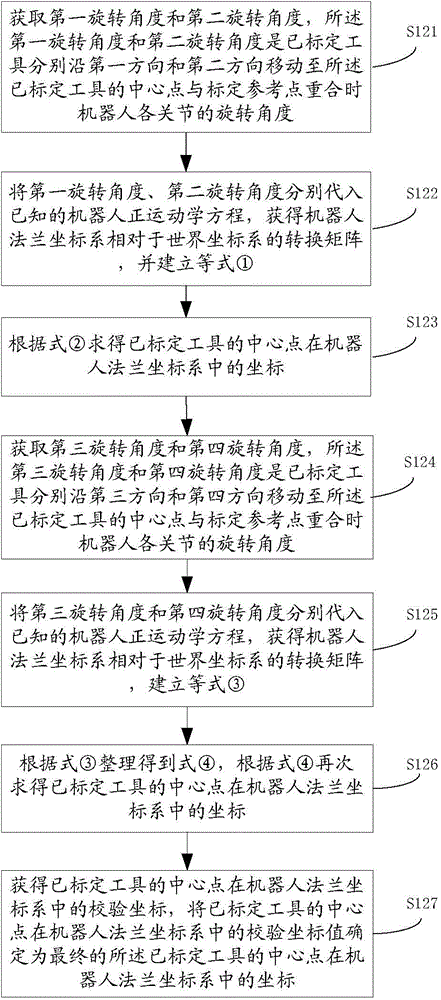

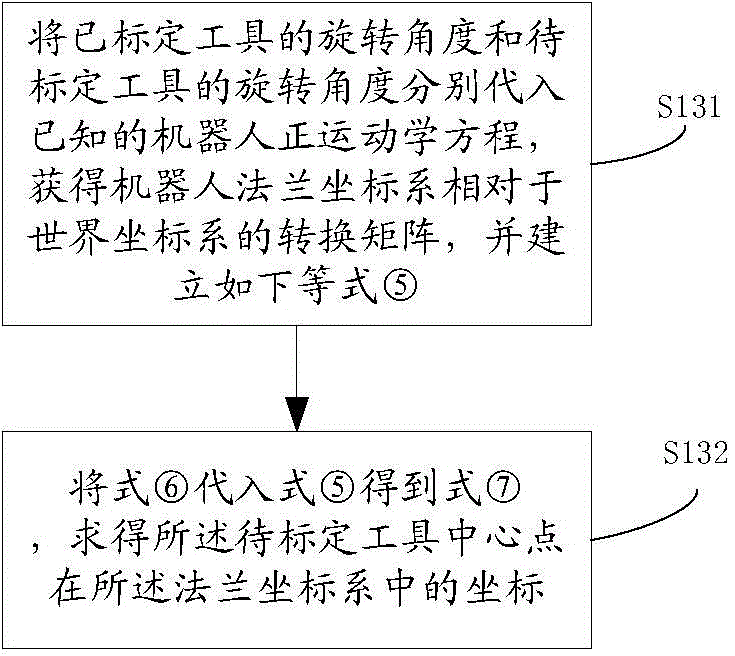

Method and apparatus for calibrating tool on robot flange coordinate system

ActiveCN105588525AImprove calibration efficiencyReduce the number of motion pathsProgramme controlProgramme-controlled manipulatorFlangeControl theory

The invention discloses a method and apparatus for calibrating a tool on a robot flange coordinate system. The method for calibrating the tool in the robot flange coordinate system comprises the following steps: obtaining a rotation angle of each joint when a tool to be calibrated fixed at a robot tail-end joint installation portion moves until the center point of the tool to be calibrated is superposed with a calibration reference point; obtaining calibration information of the center point of an already calibrated tool on the robot flange coordinate system; and according to the calibration information of the center point of the calibrated tool and the rotation angles of the tool to be calibrated, completing calibration of the center point of the tool to be calibrated on the robot flange coordinate system. According to the invention, the needed tool center point movement path quantity can be reduced, the calibration operation is quite simple, and the calibration efficiency of a tool coordinate system is enabled to be quite high.

Owner:BEIJING A&E TECH

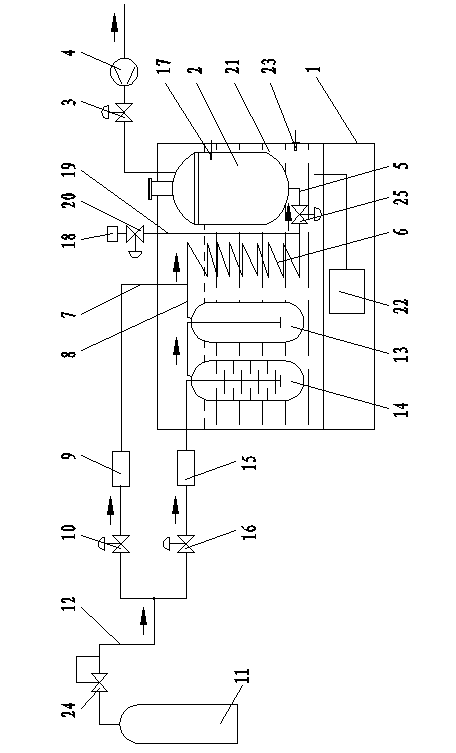

Method and device for calibrating dynamic response characteristic of sonde humidity by double flow method

InactiveCN102998720ACalibration works normally and continuesSimple structureInstrumentsWater bathsControl system

The invention discloses a method and a device for calibrating a dynamic response characteristic of sonde humidity by a double flow method. The method includes that a sonde test chamber with given relative humidity is arranged, a humidity detected value of the sonde is real-timely received and recorded, gases with the given relative humidity are formed by uniformly mixing one way of a known amount of dry nitrogen and another way of a known amount of saturated humidity nitrogen, the nitrogen and the test chamber, both with the given relative humidity, have same environment temperatures which can simulate a lift-off state of the sonde, and the test chamber has a pressure environment which can simulate a high lift-off state of the sonde. The device comprises a control system, a water bath tank, the test chamber, an electrical control adjusting valve, a vacuum pump, a first gas inlet pipeline, a second gas inlet pipeline and the like, and the first gas inlet pipeline and the second gas inlet pipeline are respectively used for providing dry nitrogen and saturated humidity nitrogen which are provided with set amount. The method and the device for calibrating the dynamic response characteristic of the sonde humidity by the double flow method have the advantages that the calibration by the calibration method is accurate, the manufacturing is simple, the calibration efficiency is high, the calibration device is simple in structure, a reliable simulated lift-off environment can be provided for the sonde, and the accurate calibration can be guaranteed.

Owner:重庆苏试四达试验设备有限公司

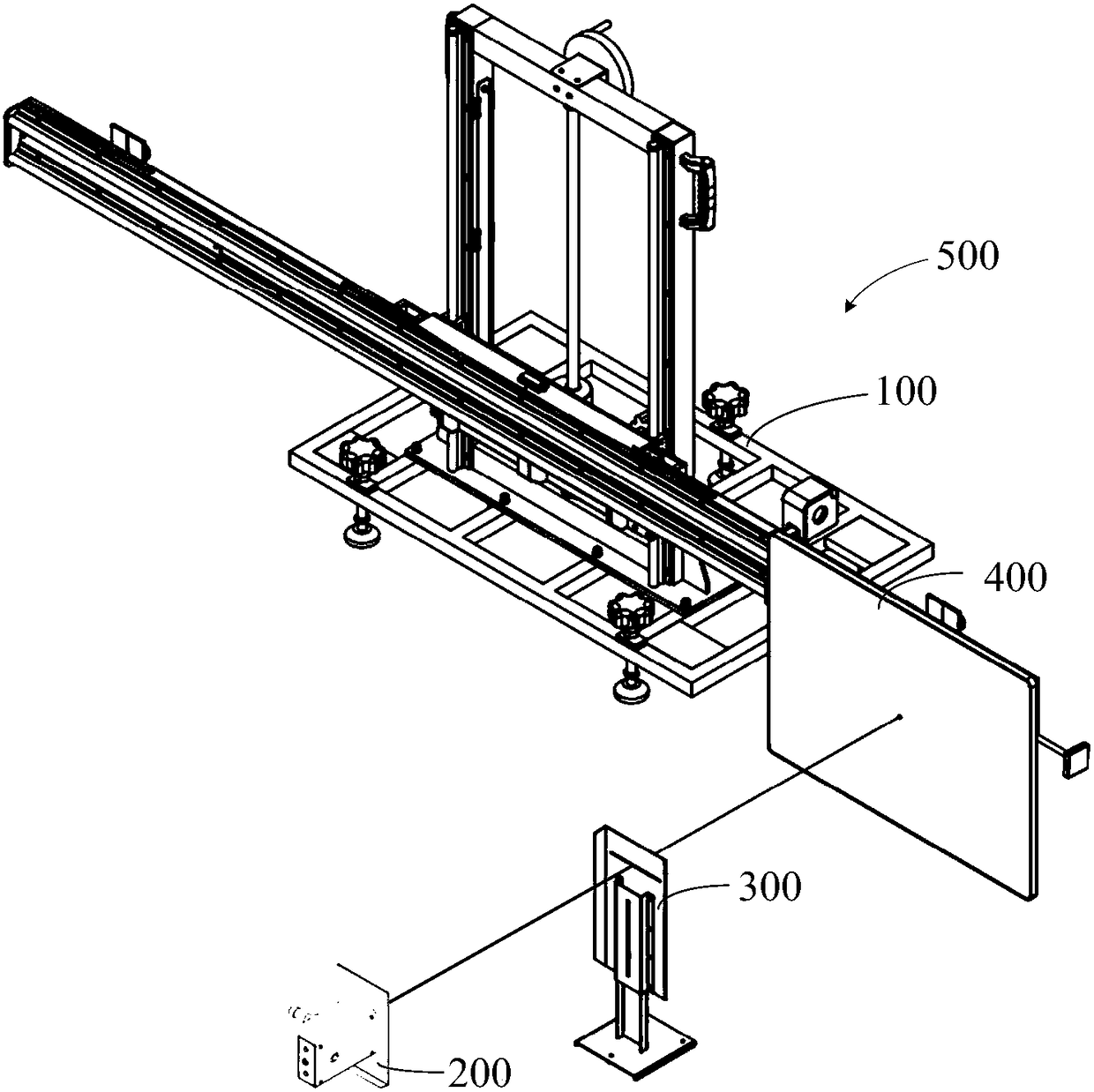

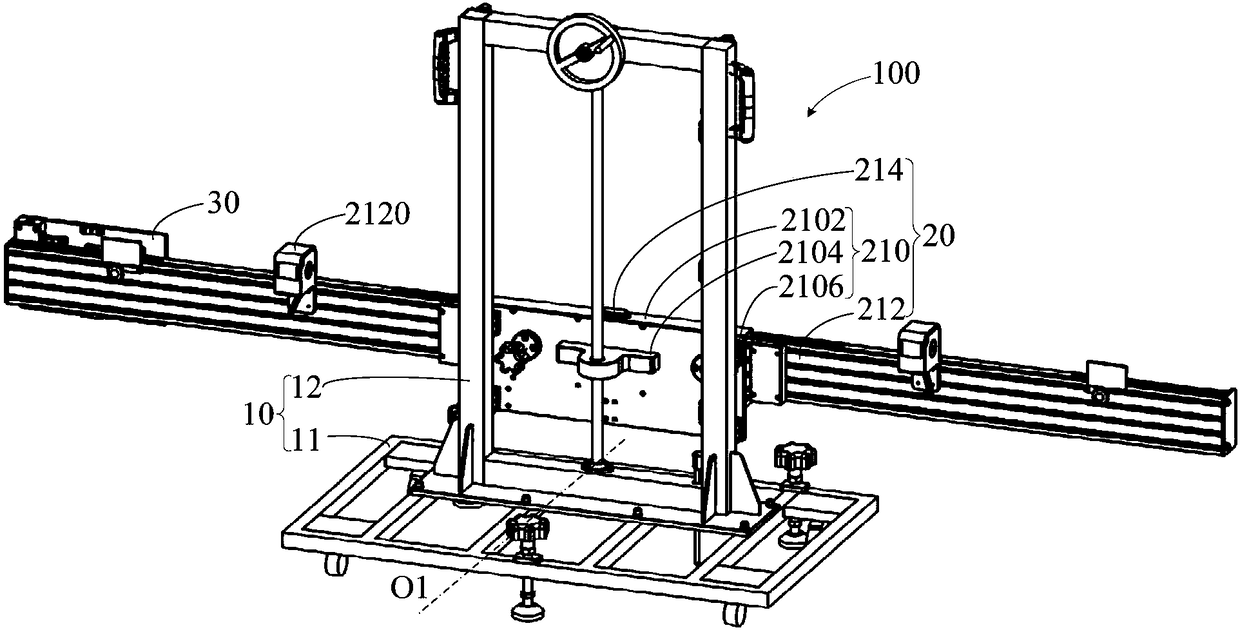

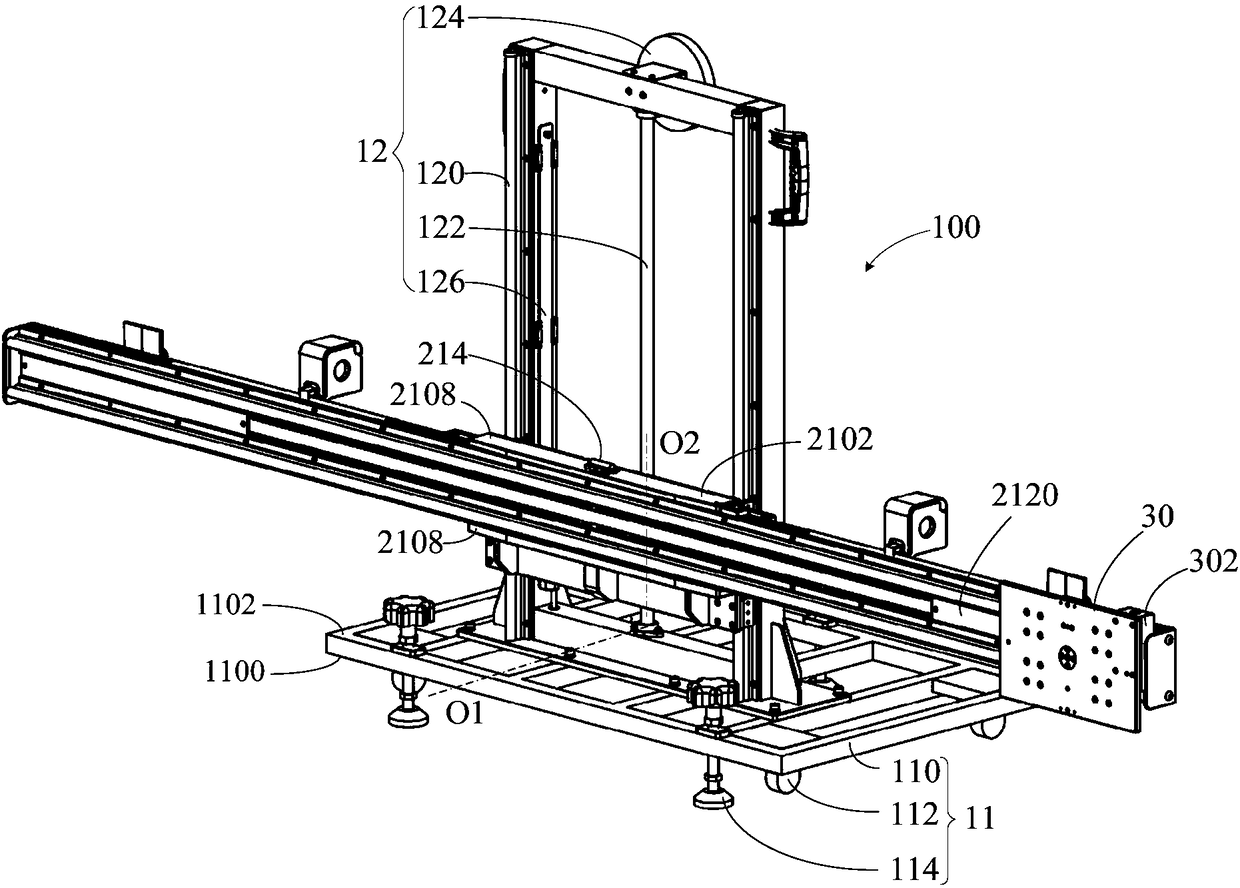

Vehicle-mounted radar calibration device and method

PendingCN108594187AConvenient calibration workReduce in quantityWave based measurement systemsAcousticsRadar calibration

The invention belongs to the automobile maintenance and equipment calibration technical field and discloses a vehicle-mounted radar calibration device and method. The vehicle-mounted radar calibrationdevice comprises a bracket device and a radar calibration component; the radar calibration component is mounted on the bracket device; the radar calibration component includes a substrate; and the radar calibration component is used for reflecting radar waves emitted by the vehicle-mounted radar of a vehicle to be calibrated to the vehicle-mounted radar so as to calibrate the vehicle-mounted radar after the vertical surface of the substrate is calibrated. According to the vehicle-mounted radar calibration device and method of the invention, after the vertical surface of the substrate is calibrated, the radar calibration component is adopted to reflect the radar waves emitted by the vehicle-mounted radar to the vehicle-mounted radar, and therefore, the vehicle-mounted radars of different vehicle models can be calibrated, and therefore, the calibration work of the vehicle-mounted radars can be facilitated.

Owner:AUTEL INTELLIGENT TECHNOLOGY CORP LTD

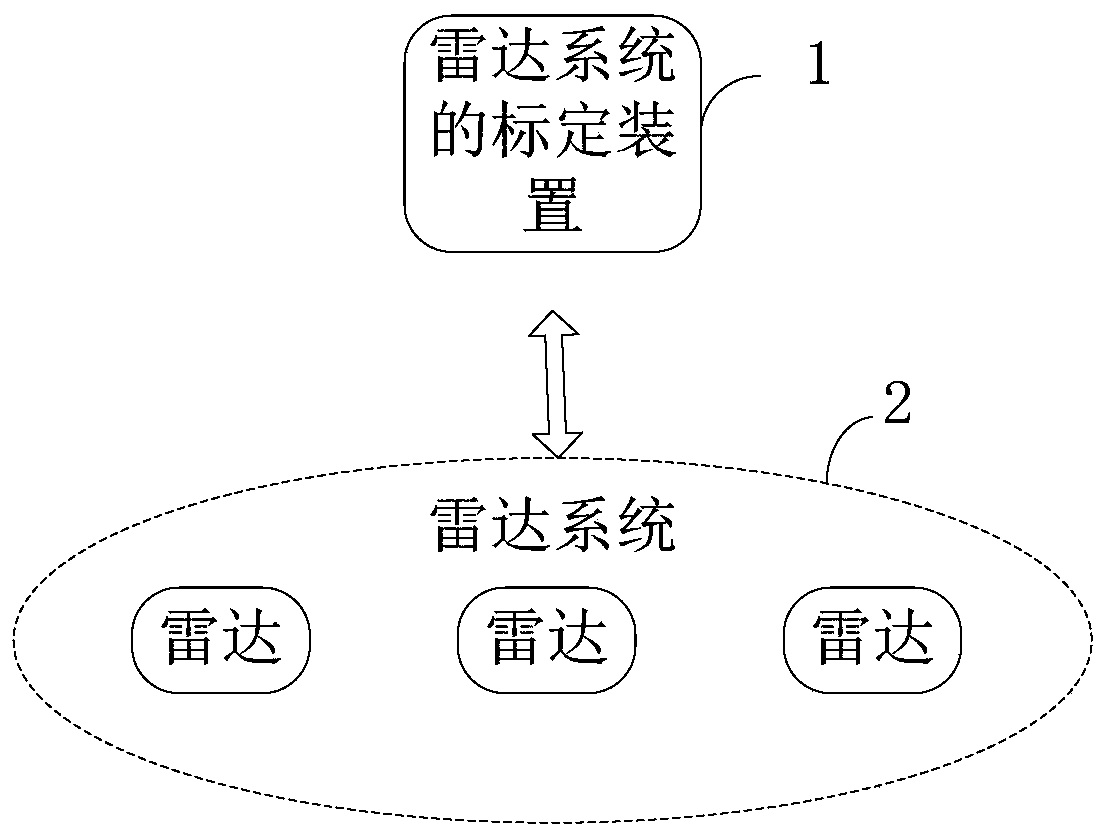

Radar system calibration method and device, electronic equipment and storage medium

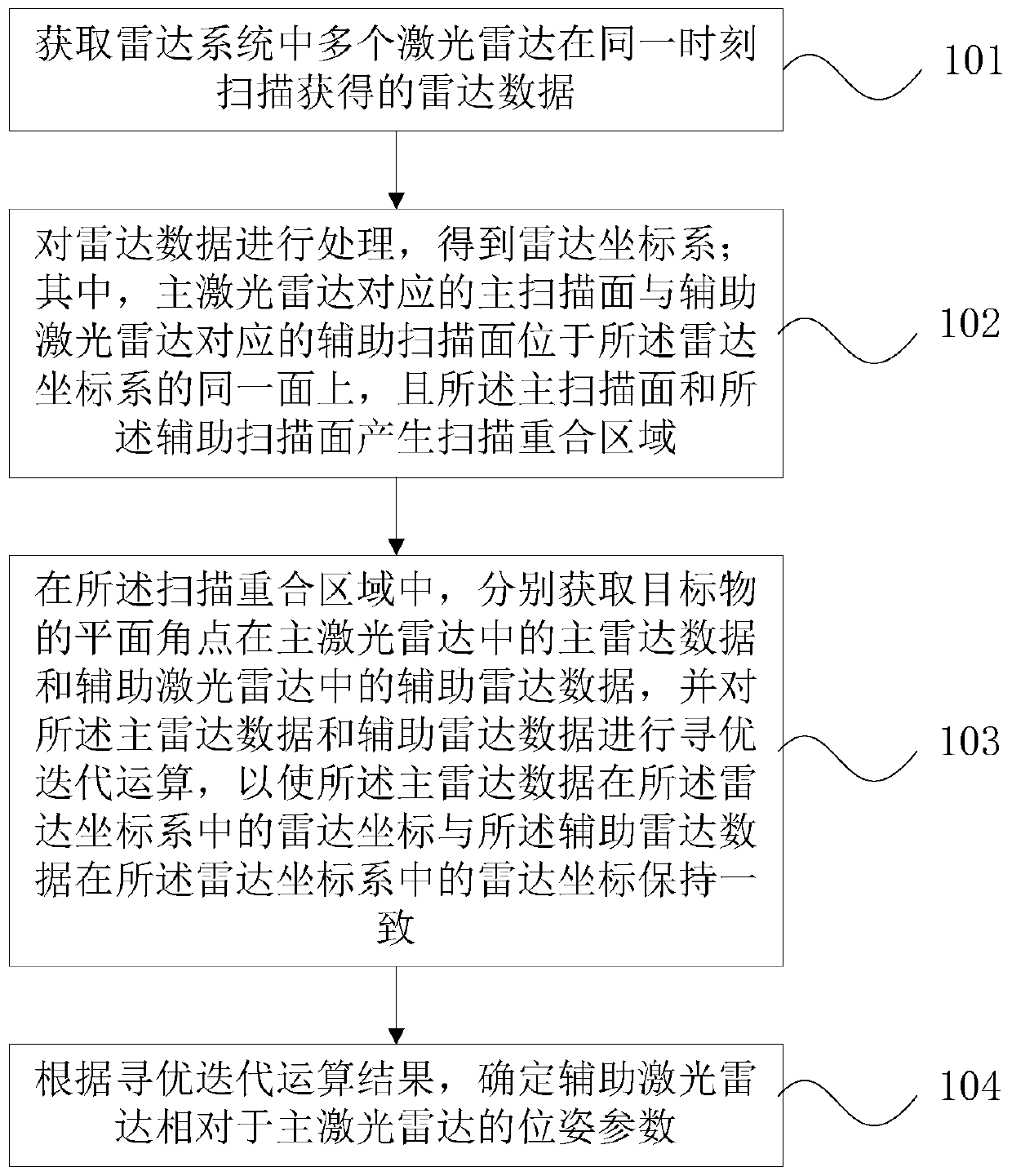

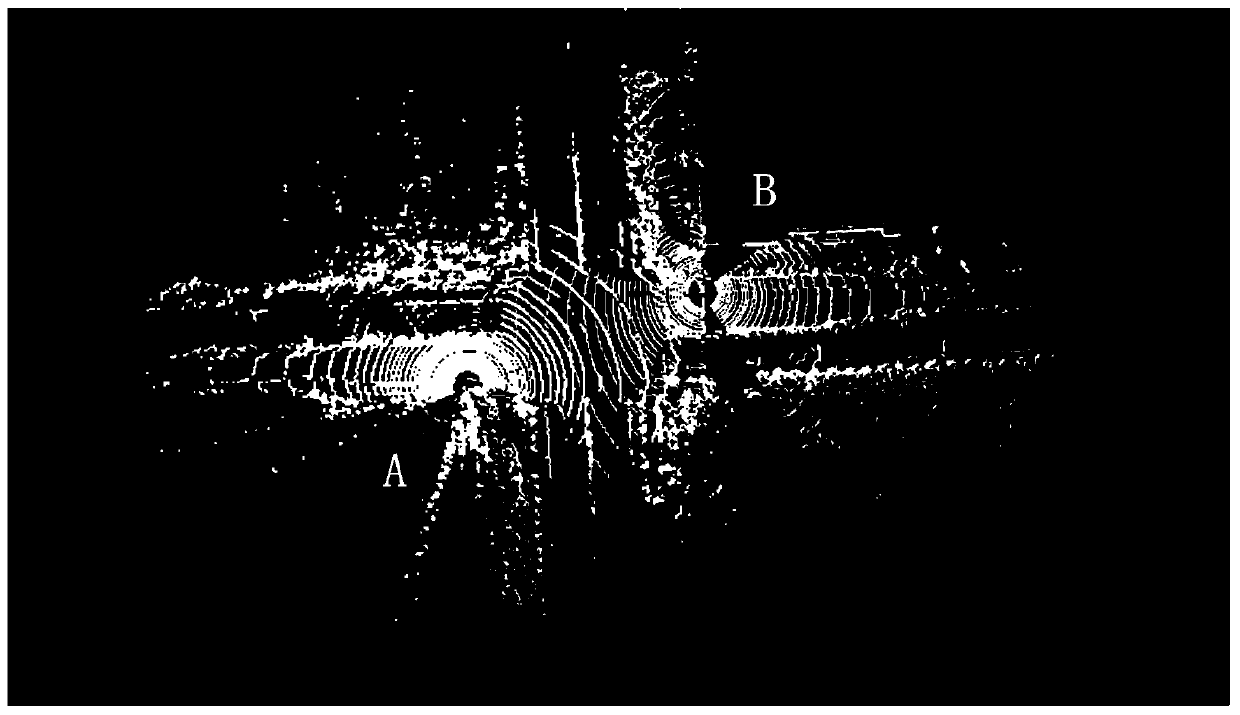

ActiveCN110988849ACalibration operation is simpleImprove applicabilityWave based measurement systemsReal-time computingRadar systems

The embodiment of the invention provides a radar system calibration method and device, electronic equipment and a storage medium. The radar system calibration method comprises the steps of: acquiringradar data obtained by scanning of a plurality of laser radars in a radar system at the same moment; processing the radar data to obtain a radar coordinate system; in a scanning overlapping region formed by scanning surfaces of a main laser radar and an auxiliary laser radar, respectively acquiring main radar data and auxiliary radar data of a plane angle point of a target object, carrying out optimizing iterative operation on the main radar data and the auxiliary radar data to determine the pose parameters of the auxiliary laser radar relative to the main laser radar, thus enabling all laserradars in the radar system to find out radar data of the plane angle point of the target object under a plurality of laser radars directly based on the radar data, also determining the pose parametersof the laser radars based on the radar data, and completing calibration of the laser radars in the radar system. The calibration operation is simple, and the method can be suitable for different scenes and has high applicability.

Owner:苏州万集车联网技术有限公司

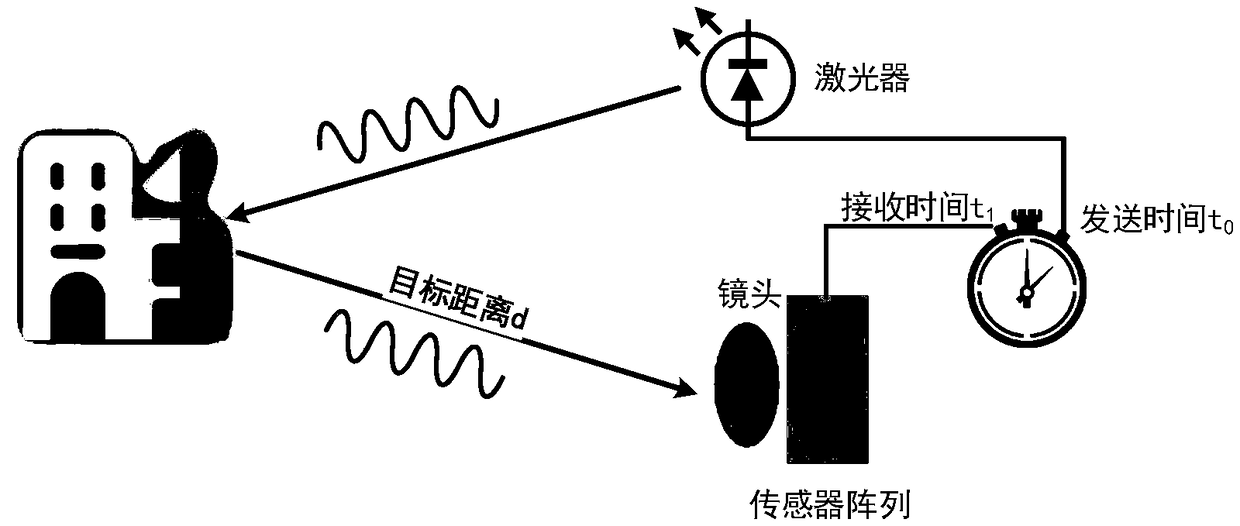

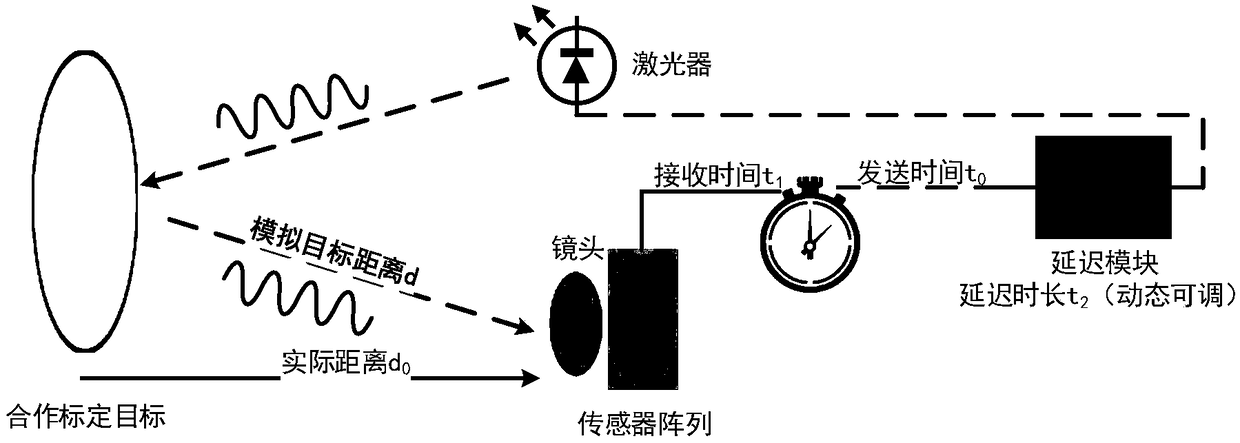

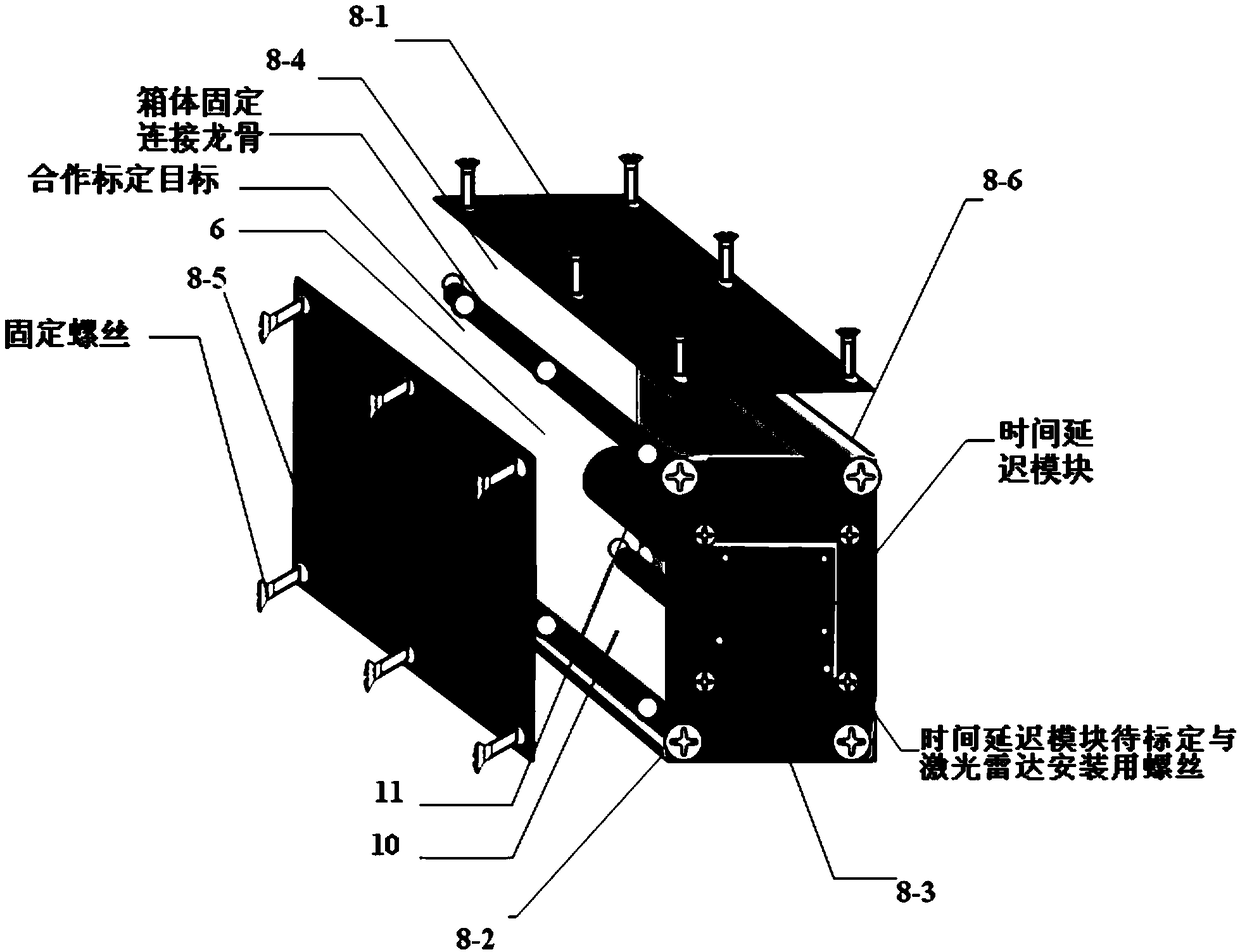

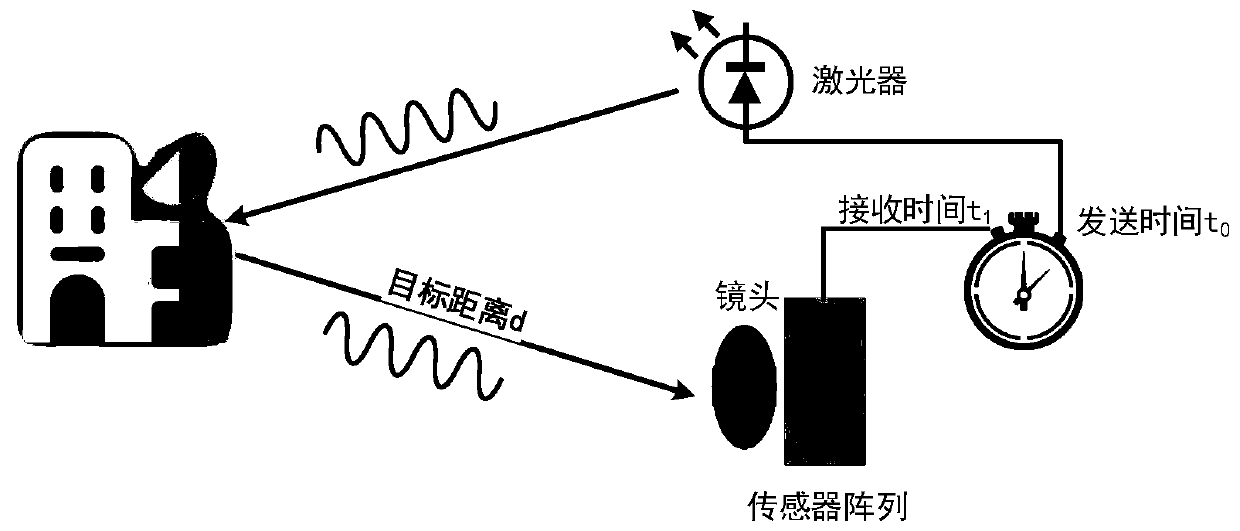

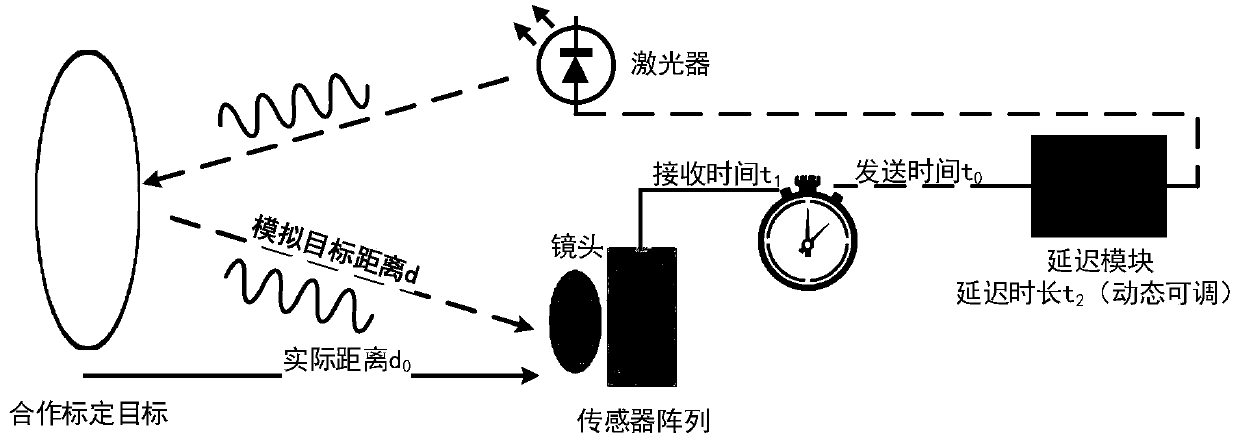

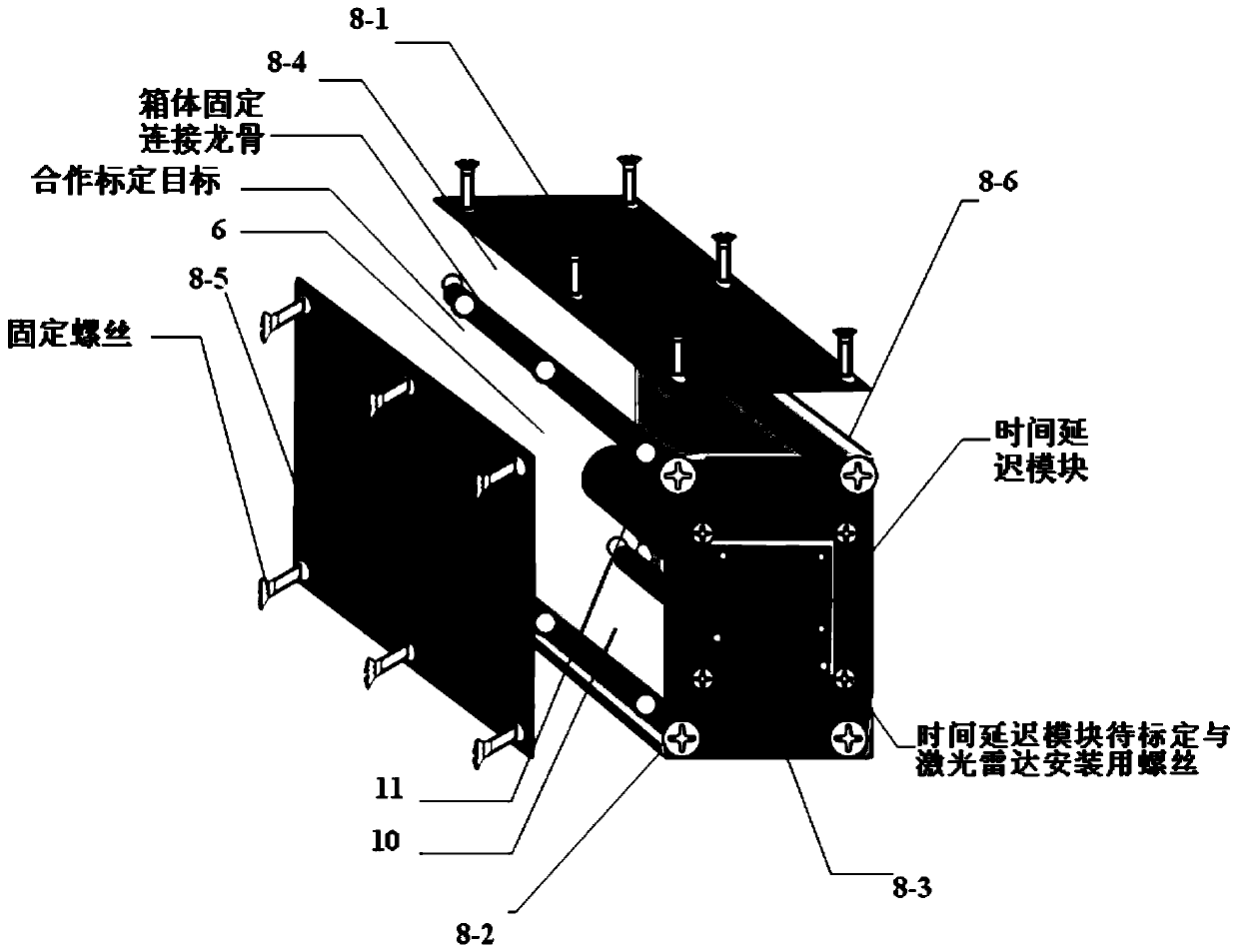

Laser radar calibration device and calibration method based on space-time transformation

ActiveCN109375196AConvenient, quick and accurate calibrationImprove calibration accuracyWave based measurement systemsAll solid stateTime delays

The invention provides a laser radar calibration device based on space-time transformation, which is used for calibration of an all-solid-state three-dimensional planar array laser radar. The laser radar calibration device comprises a to-be-calibrated three-dimensional planar array laser radar installation portion, a cooperative calibration target installation part, an ambient light shielding boxbody, a directional reception active light source conduit and a time delay module, wherein the to-be-calibrated three-dimensional planar array laser radar installation portion, the cooperative calibration target installation part, the ambient light shielding box body, the directional reception active light source conduit and the time delay module are fixed by means of fixing screws and positioningholes, so as to form an integrated three-dimensional planar array laser radar calibration device. The invention further discloses a corresponding calibration method. the simple, convenient and rapidcalibration device and calibration method can perform rapid and precise calibration on the three-dimensional planar array laser radar, is high in calibration precision and wide in calibration distancerange, and does not require a special calibration environment and a special cooperative calibration target.

Owner:BEIJING HUA KEBO BOCHUANG TECH

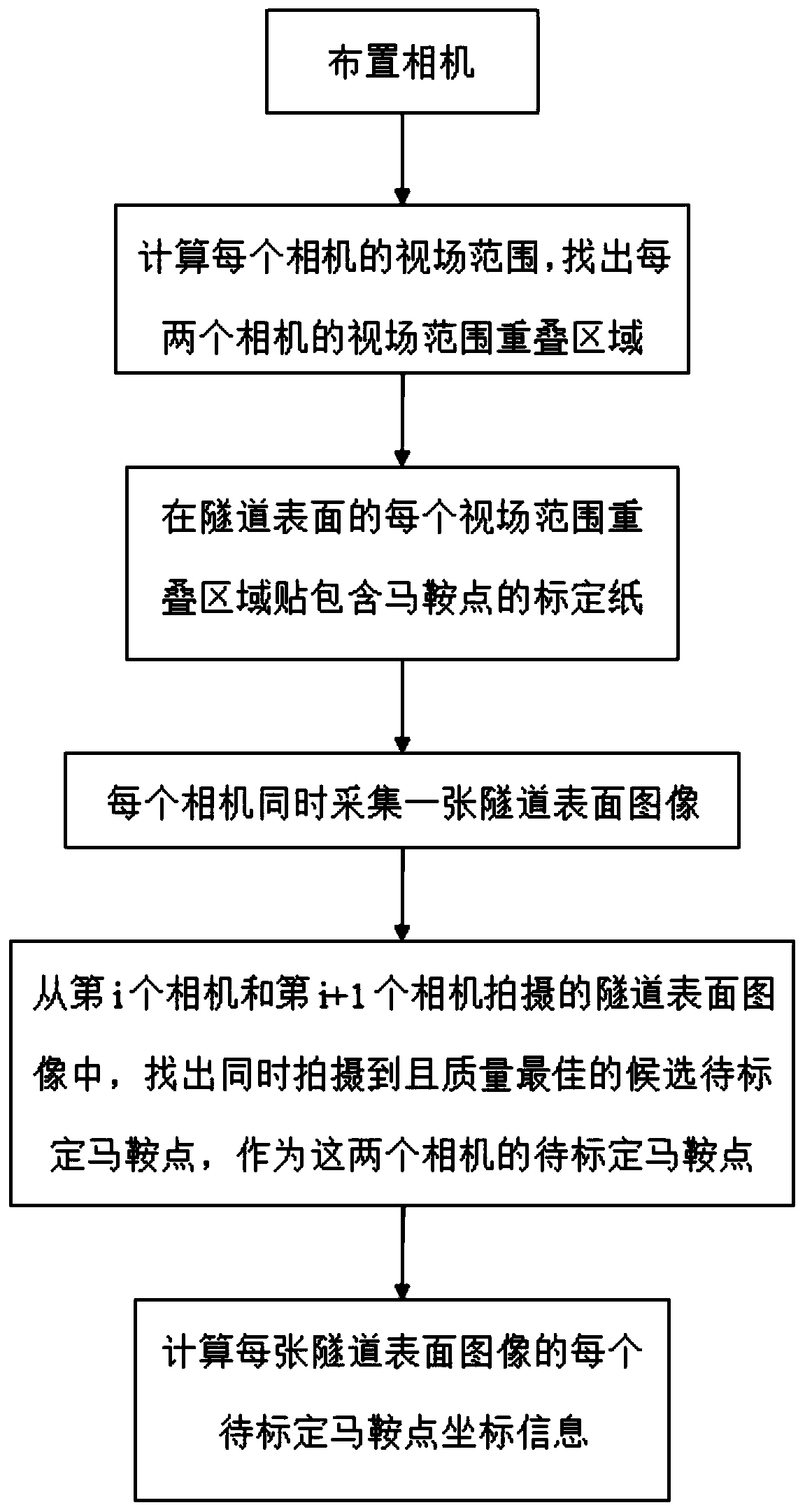

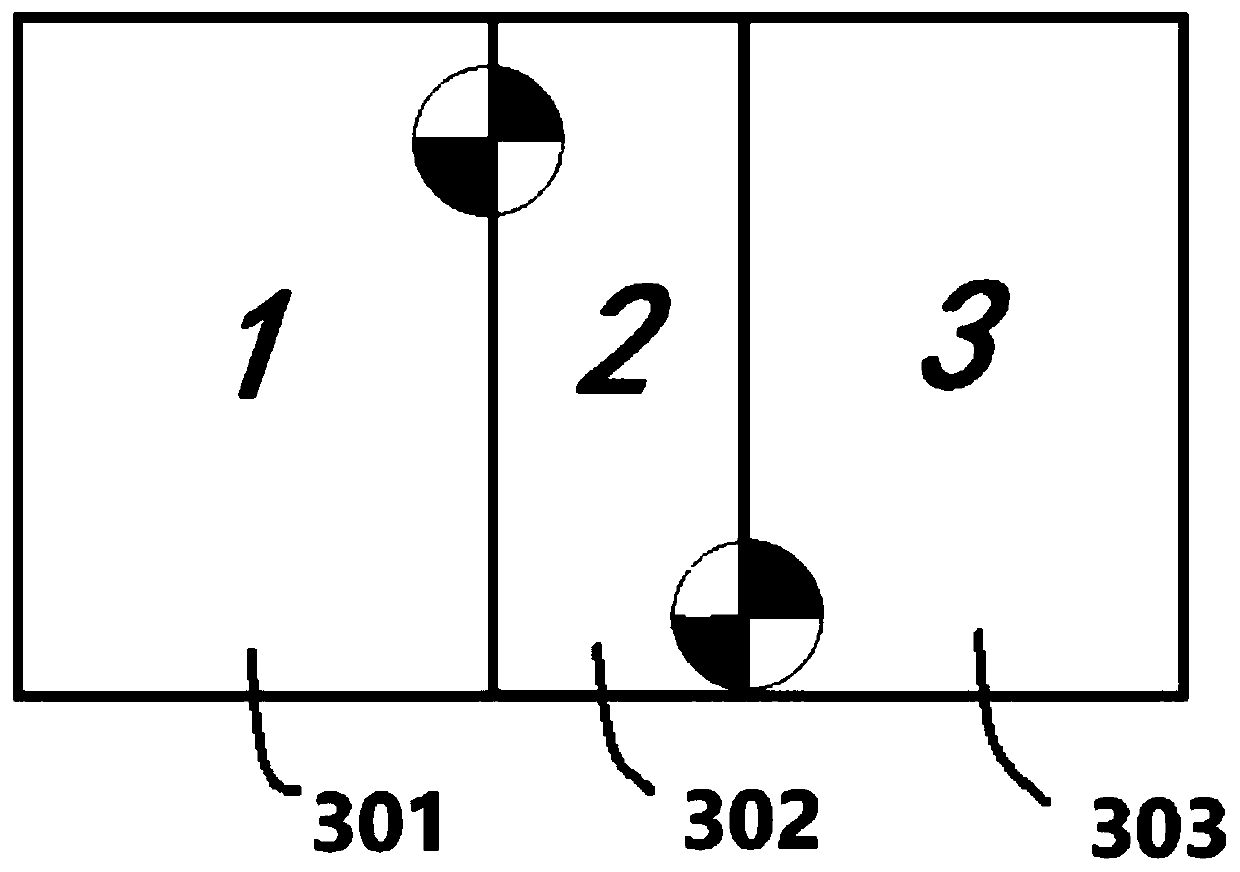

Shield tunnel surface image calibration method, splicing method and splicing system

ActiveCN110033407ACalibration operation is simpleEasy to operateImage analysisGeometric image transformationOptical axisImage calibration

The invention discloses a shield tunnel surface image calibration method, a splicing method and a splicing system, and belongs to the field of tunnel detection. The method is characterized in that itis guaranteed that the optical axis of each camera is perpendicular to the surface of a tunnel, and the field angle of each camera is at least equal to (alphs-sigma(n-1)) / n; the calibration paper is pasted in an overlapped area of each view field range on the surface of the tunnel, so that each overlapped area comprises a plurality of candidate saddle points to be calibrated; each camera collectsa tunnel surface image at the same time; the candidate to-be-calibrated saddle points which are shot at the same time and have the best quality are found out as the to-be-calibrated saddle points of the adjacent cameras; and the coordinate information of each to-be-calibrated saddle point of each tunnel surface image is calcluated. According to the present invention, the saddle point of the view field overlapping area is selected as the calibration point, only one high-quality image needs to be shot, the operation is easy, and the method is suitable for the tunnel environment. The curved planeof the tunnel is unfolded into a plane through the mapping relation between the distorted image and the plane image, the splicing under the same coordinate system is achieved, the cost is lower, thetime is short, and the visual effect is better met.

Owner:HUAZHONG UNIV OF SCI & TECH

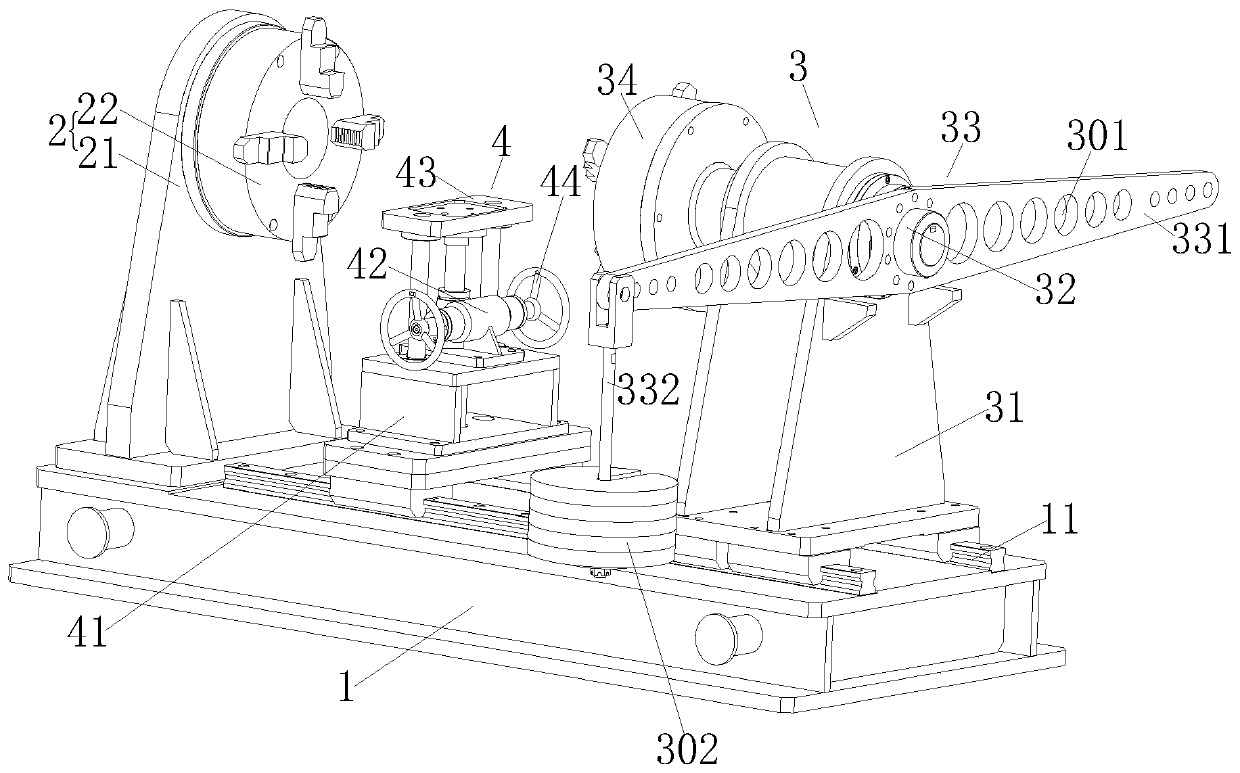

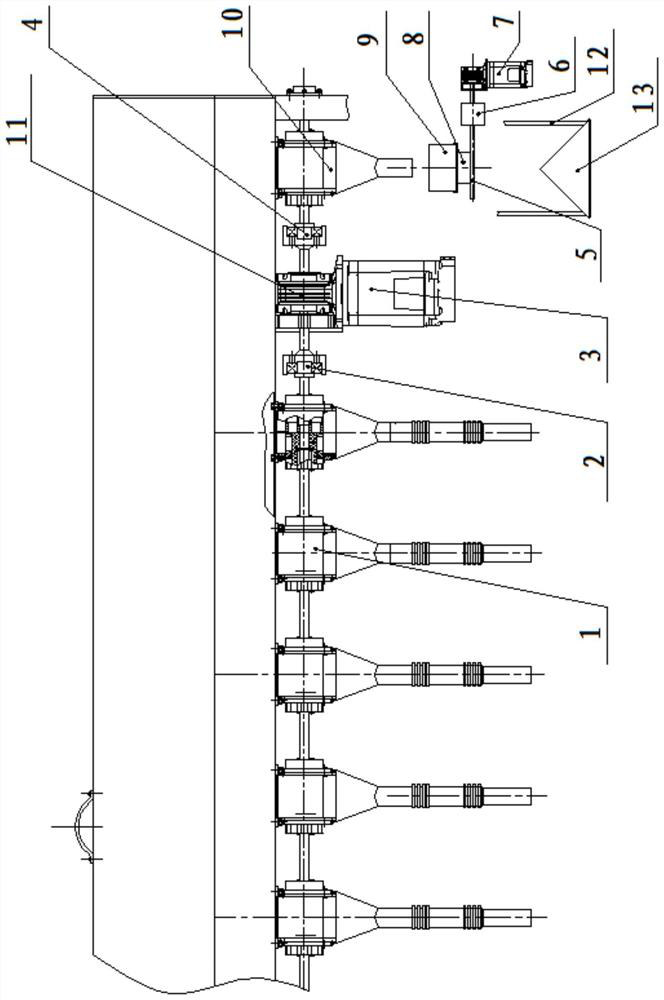

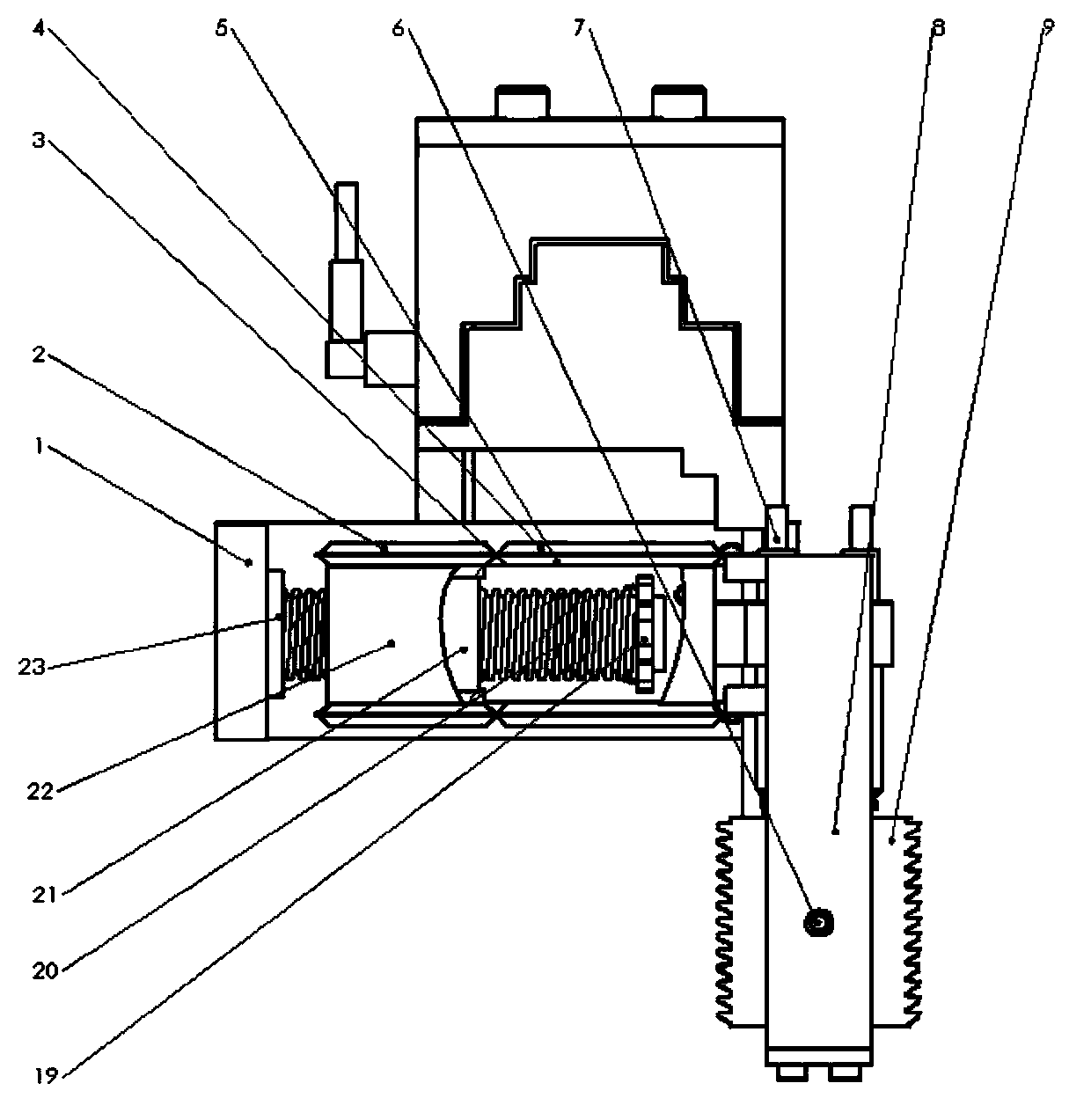

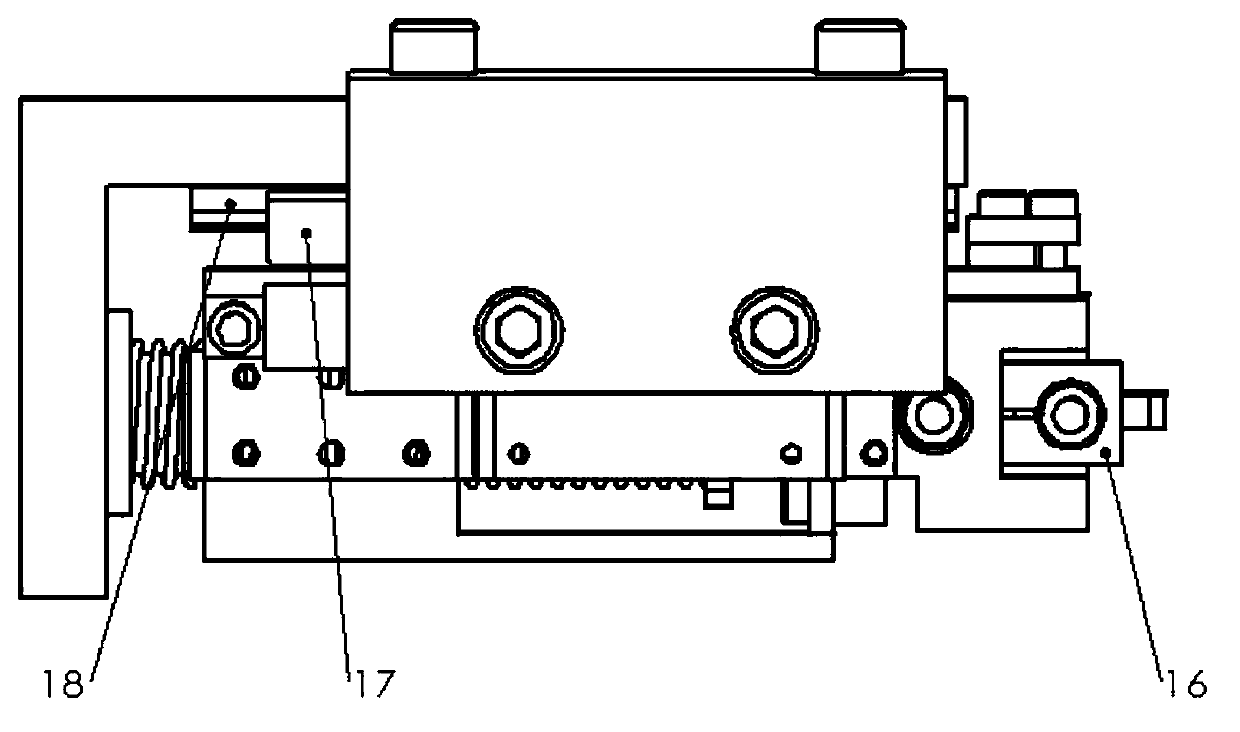

Torque calibration system of rotating speed torque sensor, and calibration method thereof

PendingCN109765001AEasy to adjustAvoid damageForce/torque/work measurement apparatus calibration/testingControl theoryTorque sensor

The invention discloses a torque calibration system of a rotating speed torque sensor, and a calibration method thereof. The torque calibration system comprises bas, and further comprises a guide railfixedly arranged on an upper surface of the base, and a fixing mechanism, a loading mechanism and a lifting mechanism capable of horizontally moving along the guide rail; a to-be-calibrated sensor isfixedly arranged at the top of the lifting mechanism, and one end of the to-be-calibrated sensor is connected with the fixing mechanism, and the other end is connected with the loading mechanism. Thecalibration system of the rotating speed torque sensor is set to include the base, the fixing mechanism arranged on the base, the loading mechanism and the lifting mechanism; the height adjusting ofthe rotating speed torque sensor arranged t the top can be realized through the lifting mechanism; and the fixing mechanism, the loading mechanism and the lifting mechanism can translate along the guide rail on the base, thereby conveniently adjusting the location among the rotating speed torque sensor, the fixing mechanism and the loading mechanism.

Owner:ANHUI HELI CO LTD

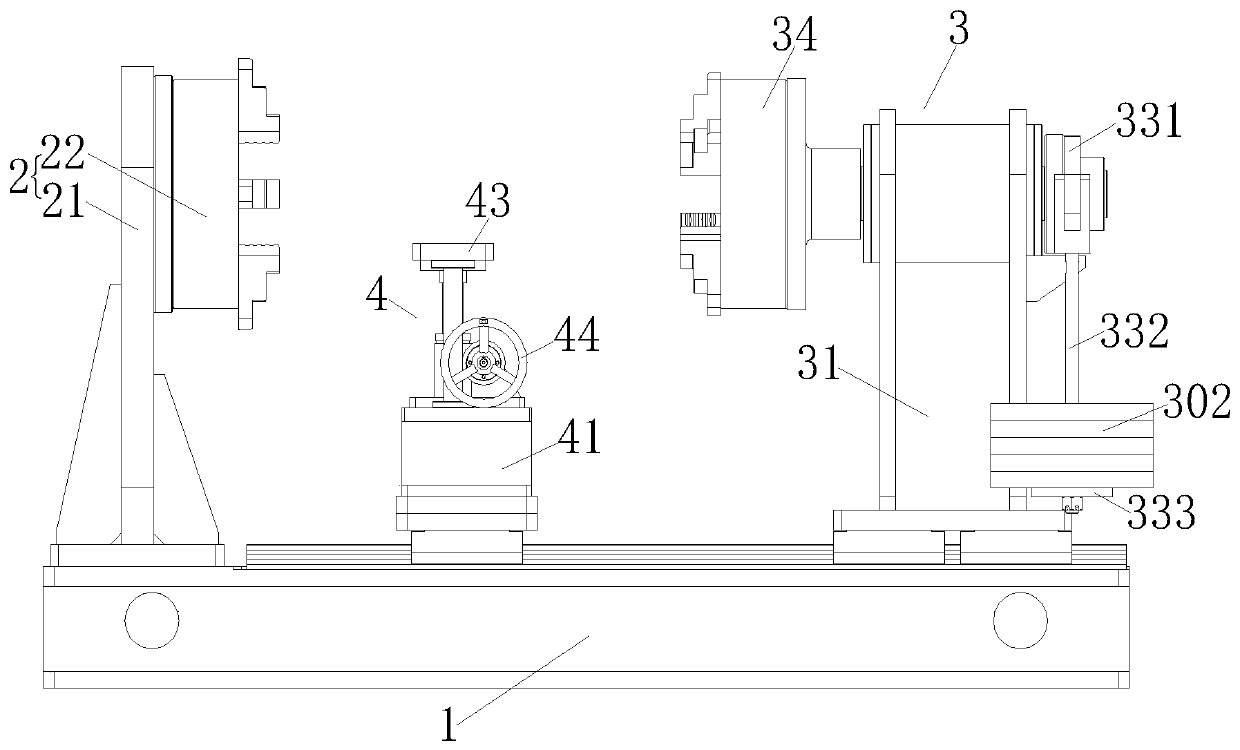

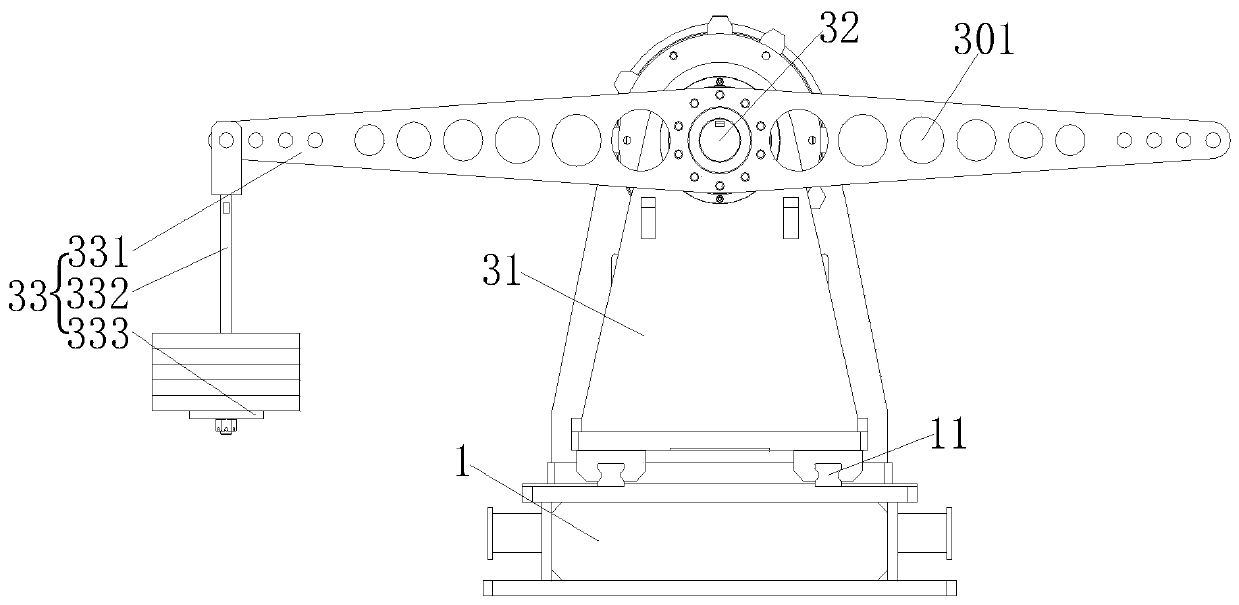

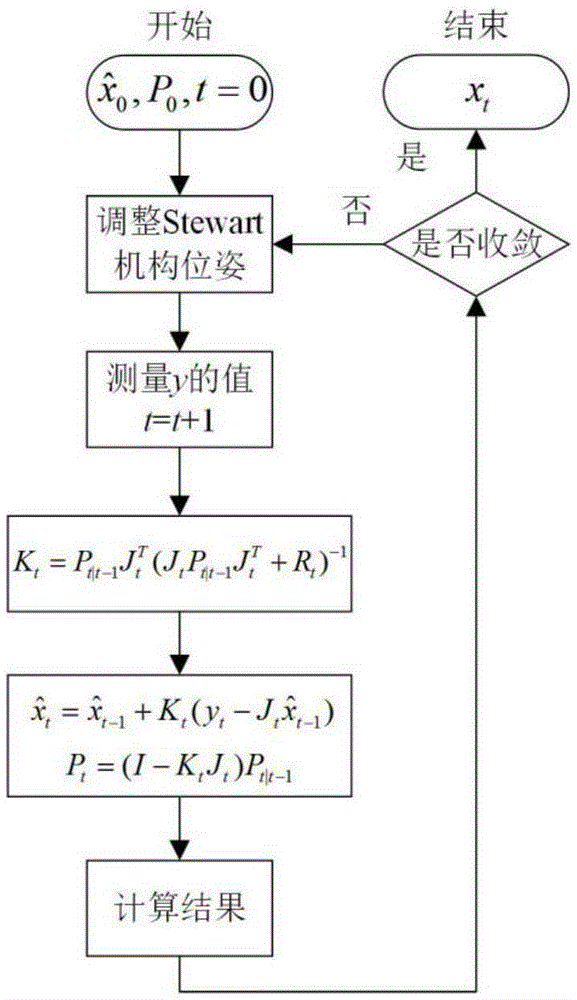

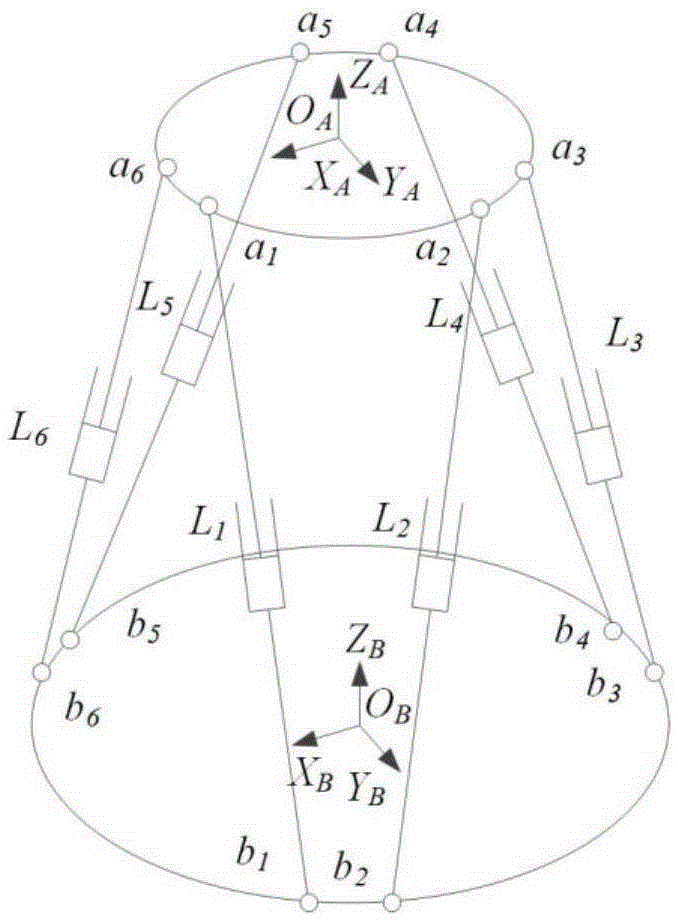

Kalman filtering based online calibrating method of Stewart mechanism

ActiveCN105425582ACalibration operation is simpleLow implementation costAdaptive controlKinematicsRange of motion

The invention relates to a Kalman filtering based online calibrating method of a Stewart mechanism. The calibrating method comprises the steps that 1) a pose measuring device is fixed at one side of the Stewart mechanism, and the working space of the pose measuring device covers the motion range of the Stewart mechanism; 2) the pose of the Stewart mechanism is adjusted so that a moving platform of the Stewart mechanism moves in different directions, the pose measuring device measures the pose of the moving platform of the Stewart mechanism, and measured pose data is compared with theoretical pose data to obtain pose error data; 3) the theoretical pose data and the pose error data are substituted into the Kalman filtering algorithm, and error source data is obtained via iteration; 4) the error source data is substituted into the kinematic positive solution of the Stewart mechanism to correct the kinematic positive solution; and 5) the steps 2) to 4) are implemented cycled till the pose error data is converged. According to the invention, operation is simple, the cost is low, and the calibration efficiency is high.

Owner:苏州铸正机器人有限公司

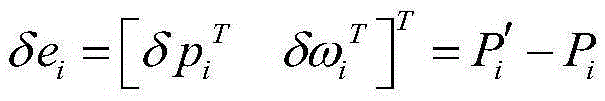

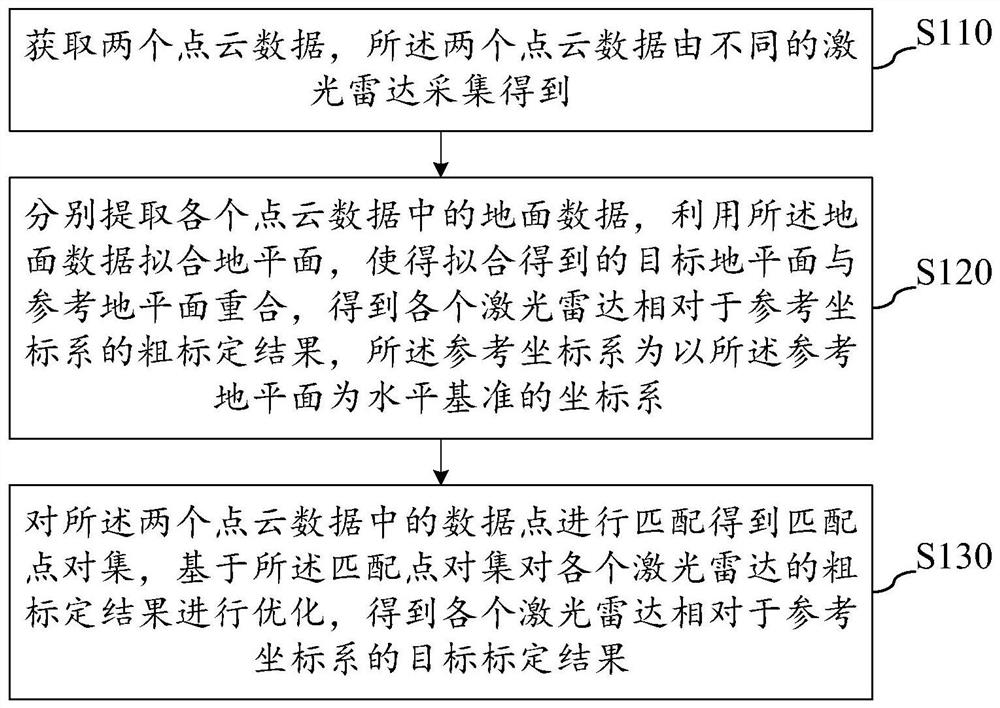

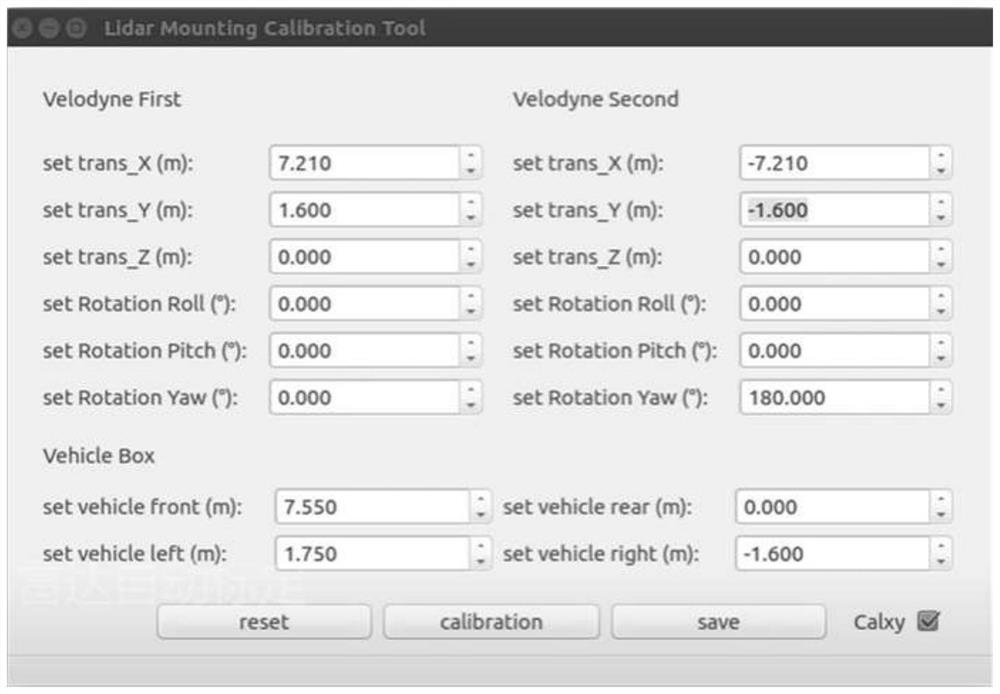

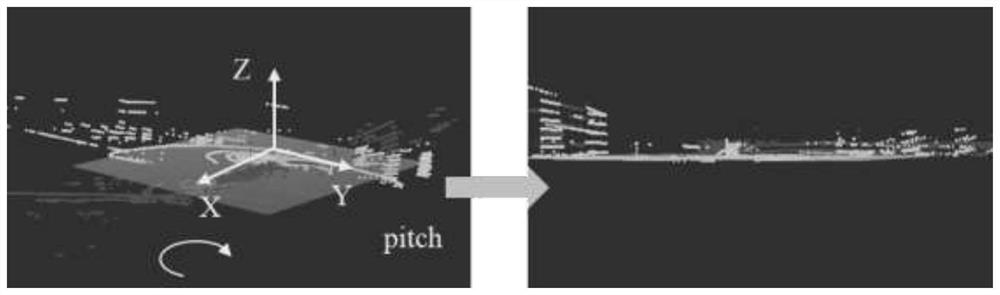

Multi-laser radar external parameter calibration method, device and equipment and storage medium

The invention provides a multi-laser radar external parameter calibration method, device and equipment and a storage medium, and the method comprises the steps of: acquiring two pieces of point cloud data which are collected by different laser radars; extracting ground data from the point cloud data respectively, fitting a ground plane by utilizing the ground data, coinciding a target ground plane obtained through fitting with a reference ground plane to obtain a rough calibration result of the laser radars relative to a reference coordinate system, wherein the reference coordinate system is a coordinate system with the reference ground plane as a horizontal datum; and matching data points in the two pieces of point cloud data to obtain a matching point pair set, and optimizing the rough calibration result of each laser radar based on the matching point pair set to obtain a target calibration result of each laser radar relative to the reference coordinate system. According to the multi-laser radar external parameter calibration method, the calibration operation is simple, and the precision and efficiency of laser radar external parameter calibration can be improved.

Owner:SHANGHAI ZHENHUA HEAVY IND

Measuring head calibration method of thread combined function dimensional measurement instrument

ActiveCN103134453AEasy to processTruly reflect the real results of the measurementsMeasurement devicesNumerical controlSize measurement

The invention discloses a measuring head calibration method of a thread combined function dimensional measurement instrument. According to the measuring head calibration method, a standard cylinder is used for calibrating a reference zero position value of a measuring head of the thread combined function dimensional measurement instrument. The measuring head calibration method includes the following steps of placing and fixing the standard cylinder in the middle of a numerical control rotary table, enabling a full-thread measuring end to be closely attached to the standard cylinder, enabling the numerical control rotary table to rotate for a circle, and obtaining corresponding collection values of two axial micrometers at any rotary angle of the numerical control rotary table, a collecting value of a lateral micrometer, an X-direction coordinate of an X-direction sliding block and a Z-direction coordinate of a Z-direction sliding block; obtaining a corresponding position posture reference zero position value parameter of the full-thread measuring end at the any rotary angle of the numerical control rotary table through data treatment, and conducting measurement based on the corresponding position posture reference zero position value parameter. The measuring head calibration method of the thread combined function dimensional measurement instrument achieves calibration of the thread function dimensional reference zero position value parameter in three dimensions through the simple standard cylinder, and a function parameter of the standard cylinder is directly measured. Therefore, the measuring head calibration method of the thread combined function dimensional measurement instrument fits in with consistency of calibration and a measuring method.

Owner:TIANJIN UNIV

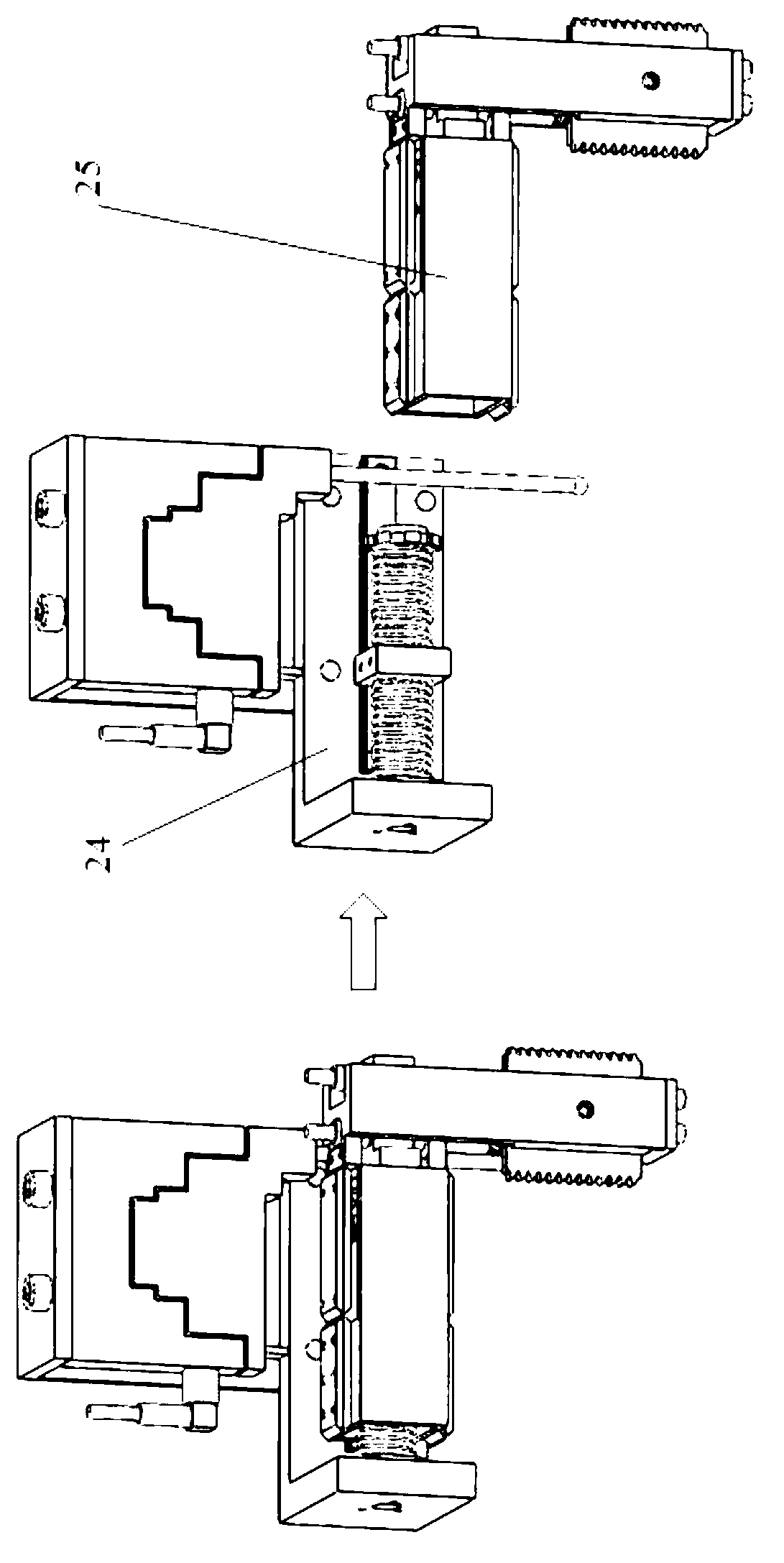

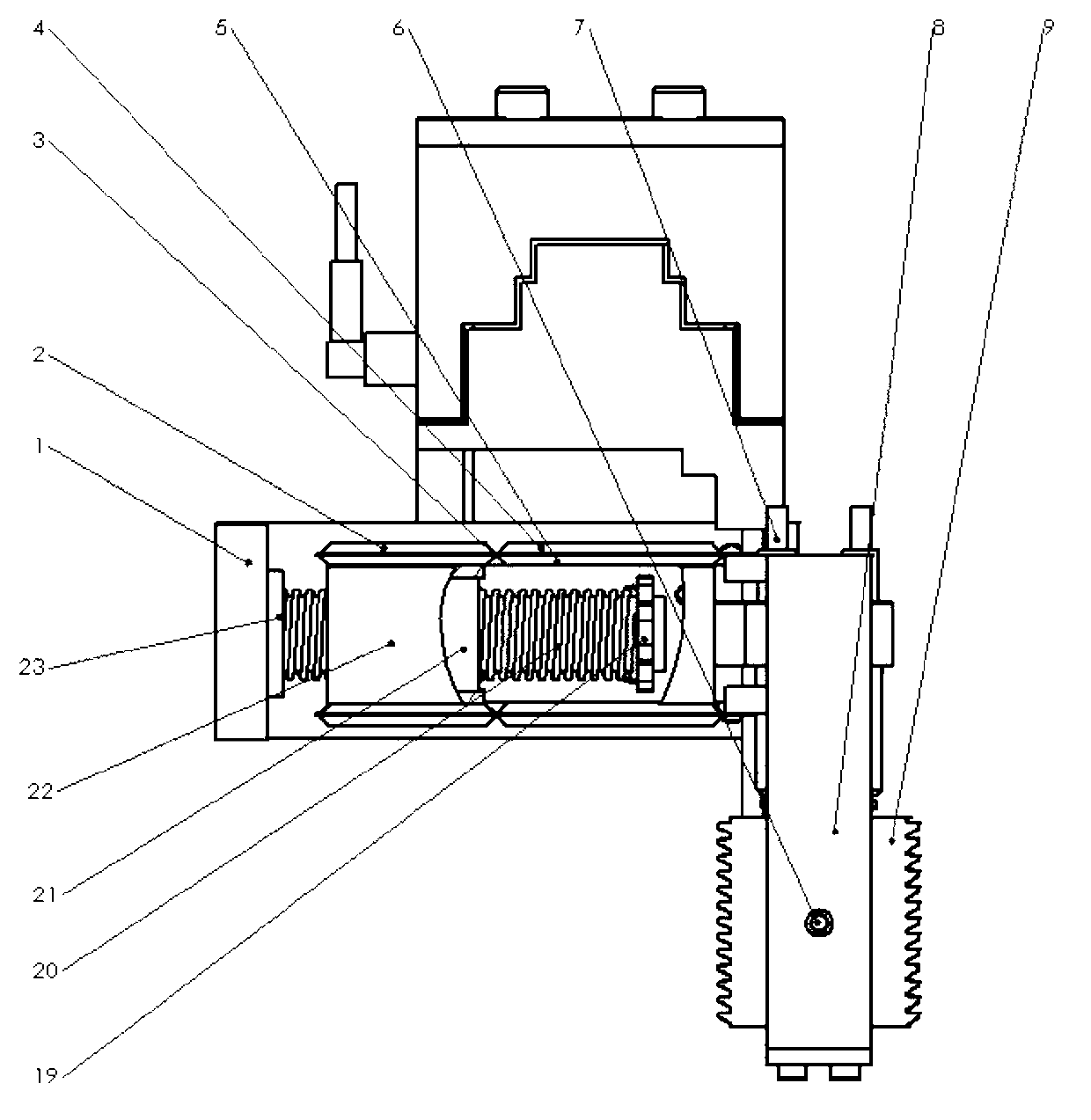

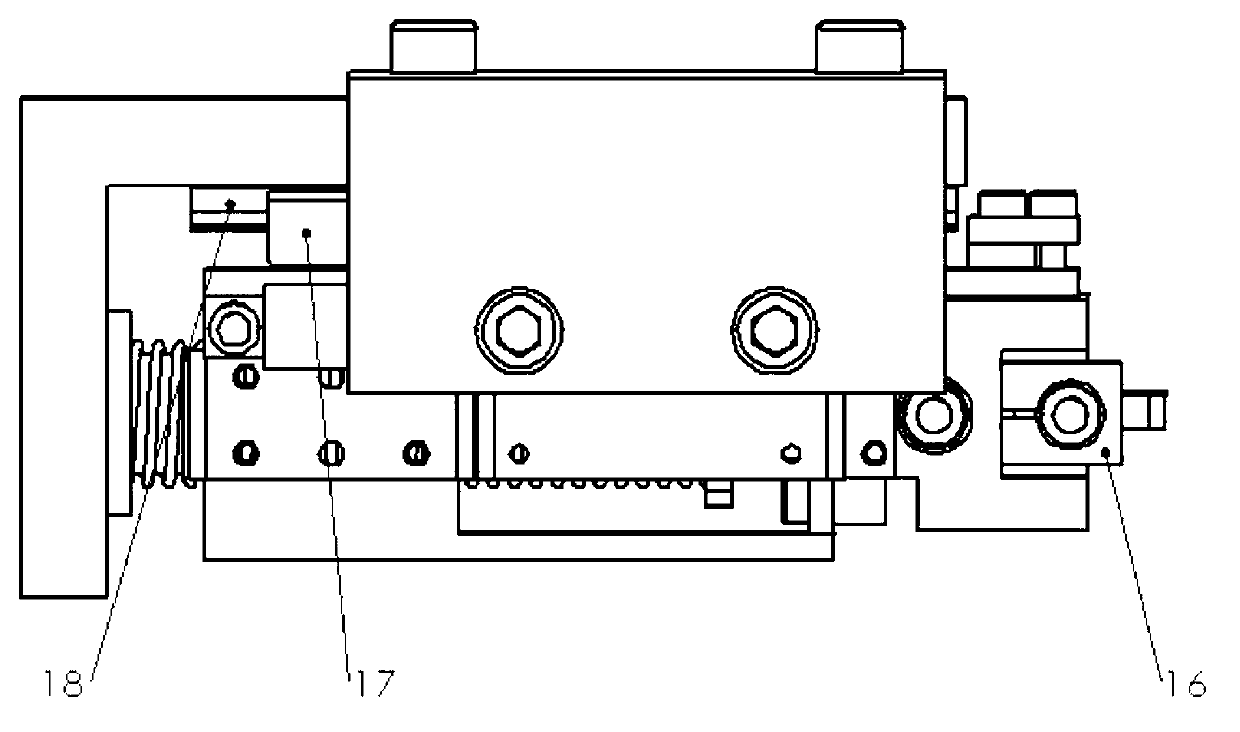

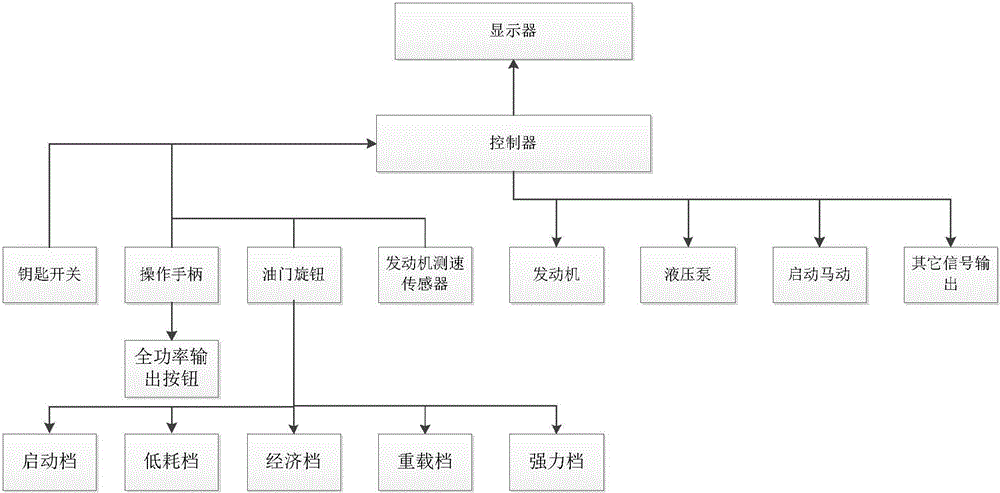

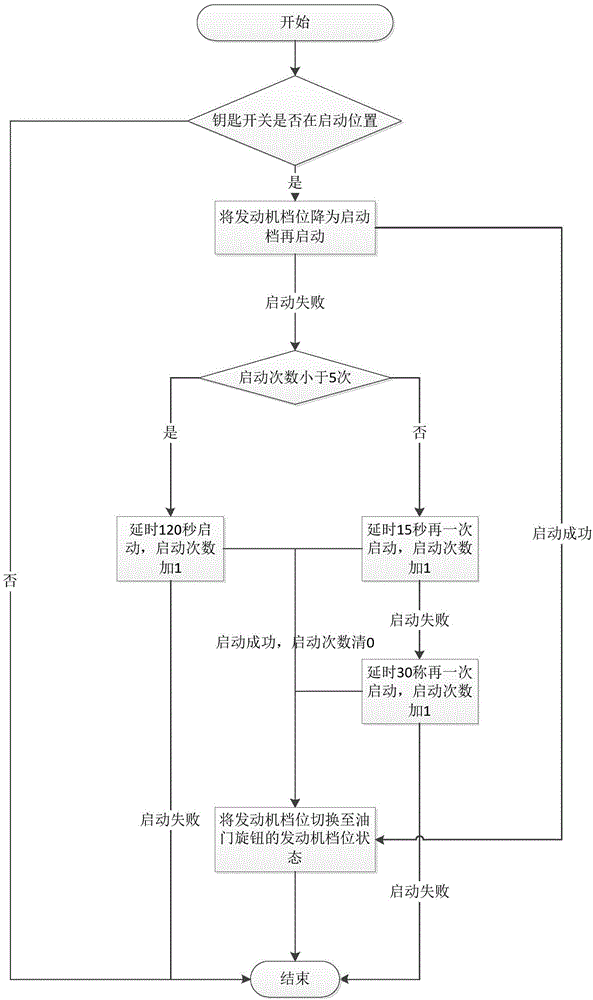

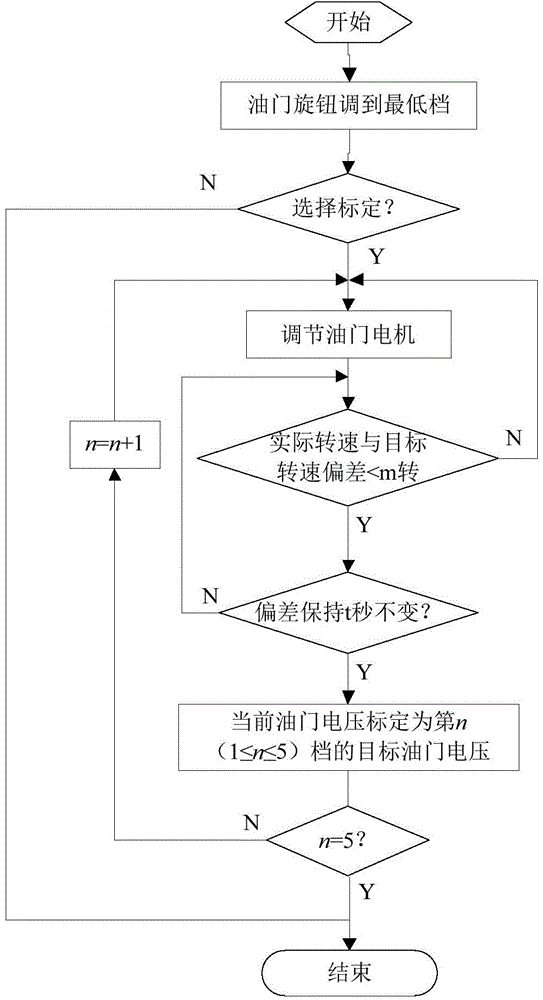

Engine gear control system and rotary drilling rig

ActiveCN104832298ASolve the situation that the load suddenly increases in a short timeSolve problems that cannot meet real-time requirementsConstructionsEngine controllersControl systemComputer module

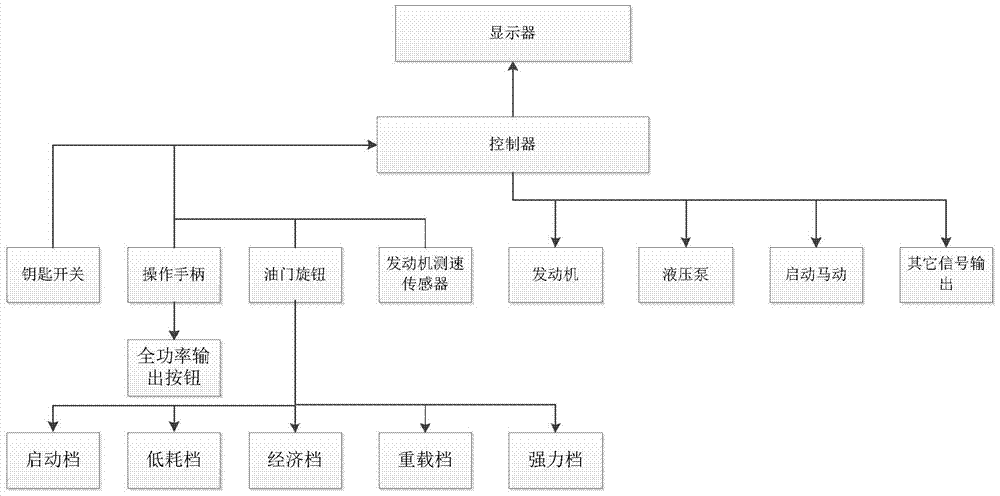

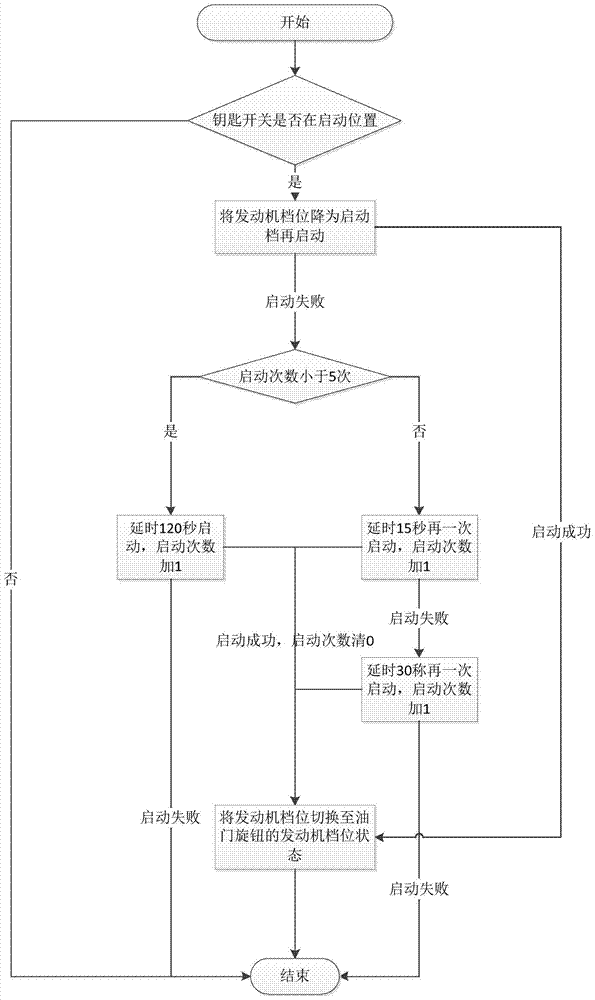

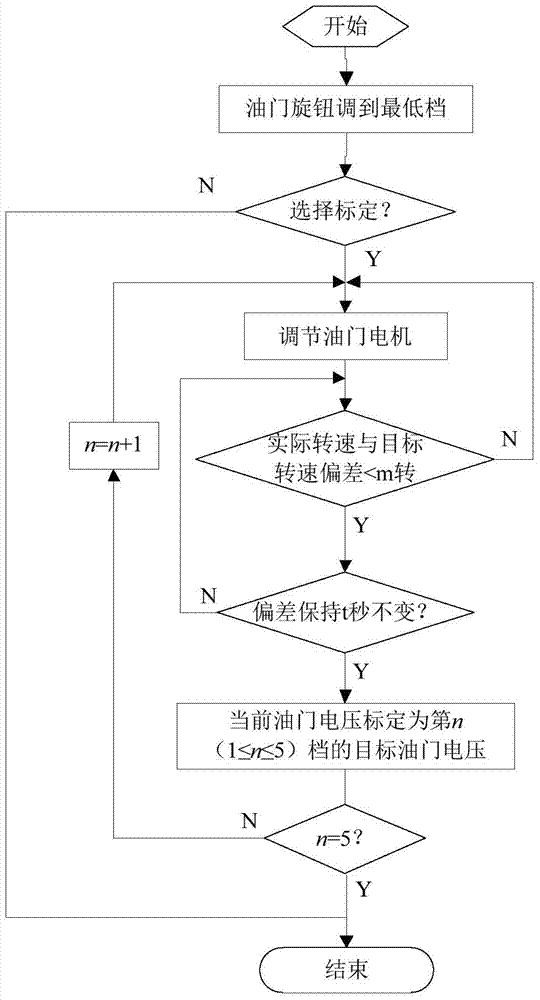

The invention discloses an engine gear control system comprising a controller, a throttle knob, and an operating handle. The throttle knob is provided with at least two engine gears which correspond to different engine speeds and power outputs. The operating handle is provided with a full-power output button used for controlling full-power output of an engine. When the full-power output button is pressed, the controller makes the engine perform output at full power, or the engine performs output at a corresponding engine speed according to the engine gear of the throttle knob. The invention further provides a rotary drilling rig. The engine gear control system can quickly adapt to sudden load increase of the rotary drilling rig in a short time and other bad working conditions, the service life of engines is prolonged, and the efficiency of construction is improved. An engine starting protection module can effectively prevent a machinist from starting an engine improperly. A calibration module achieves a one-button calibration function, makes calibration operation simple, and is convenient for machinist to operate.

Owner:BEIJING SANY HEAVY MASCH CO LTD

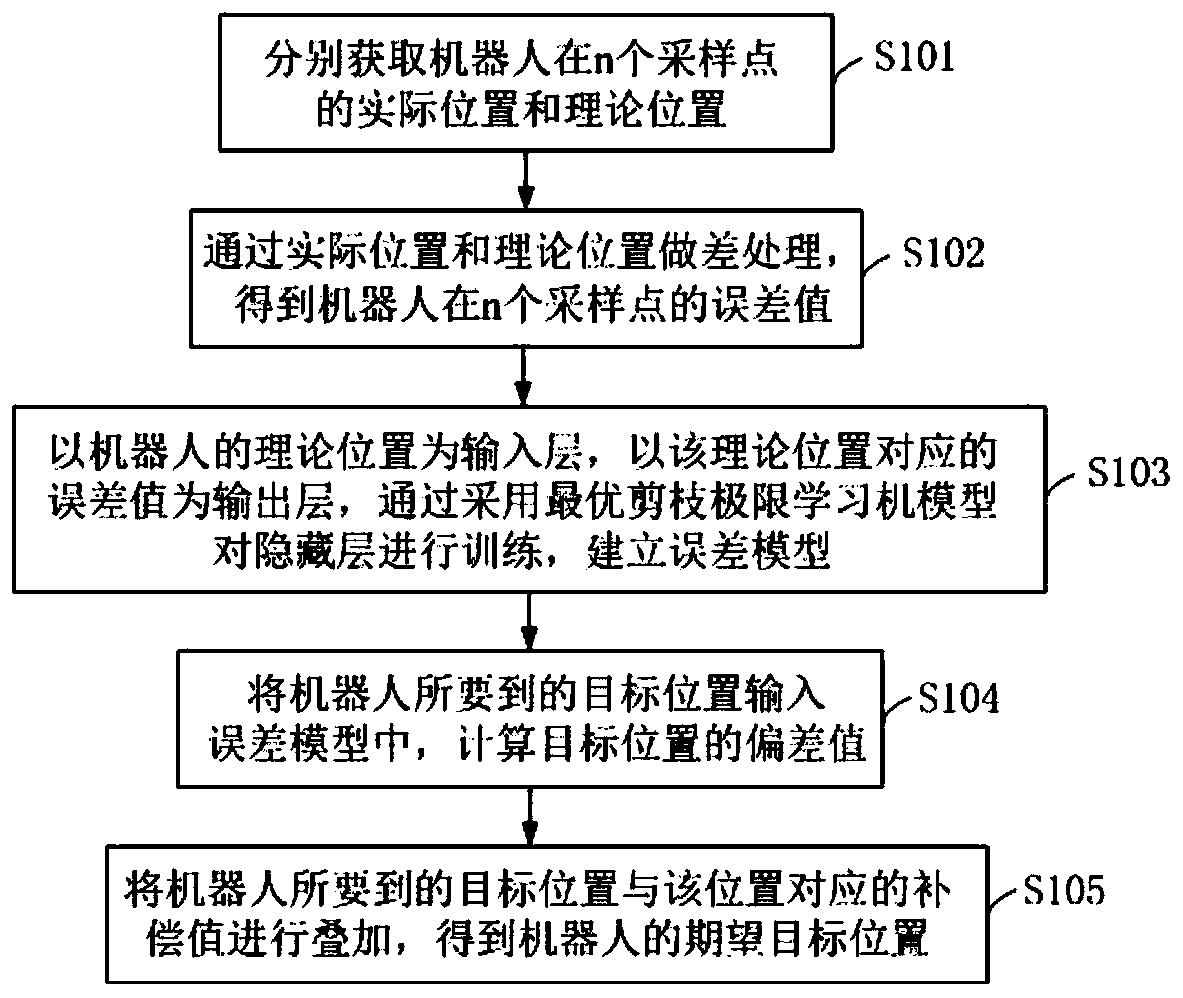

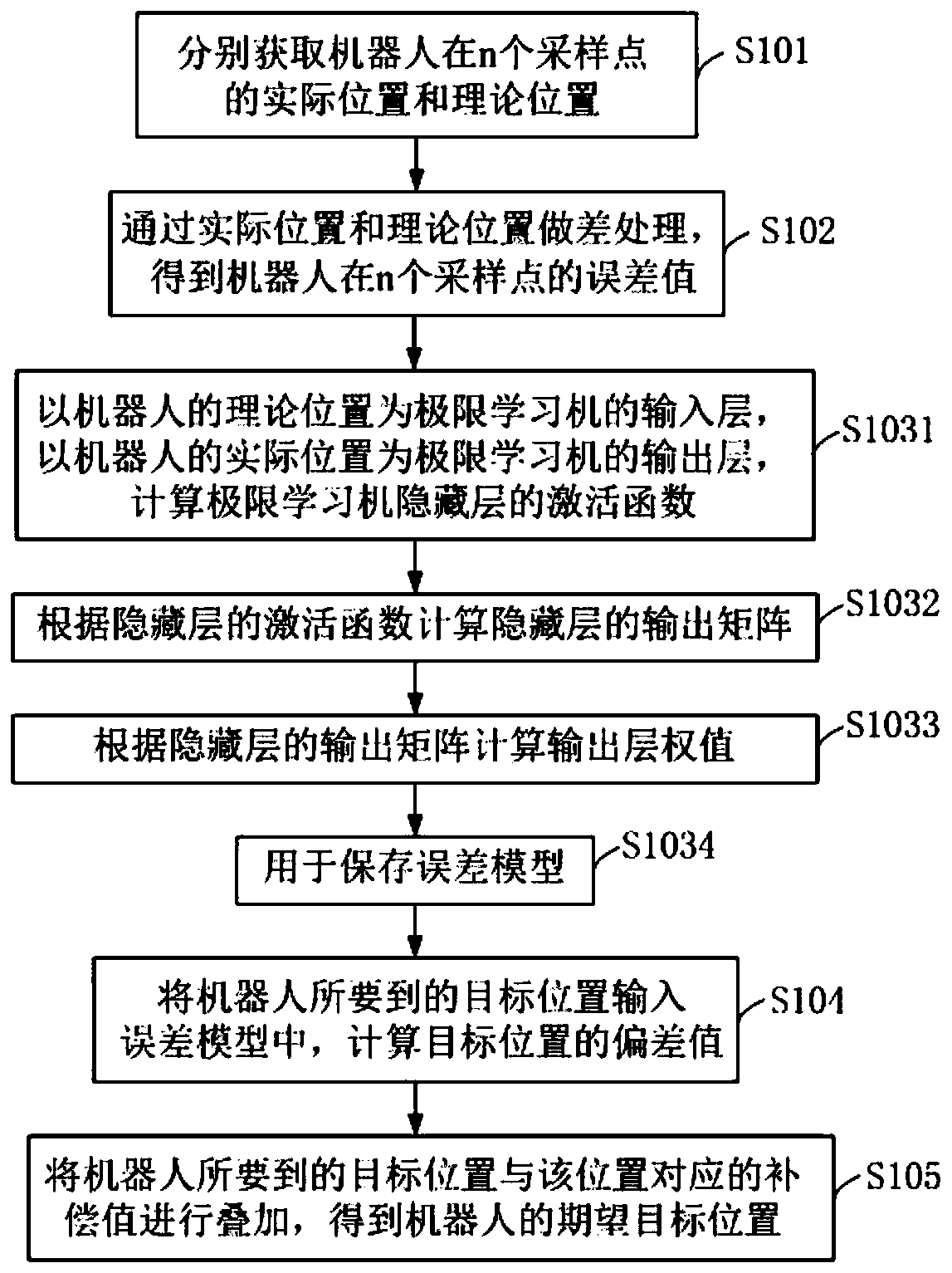

Industrial robot positioning precision calibration method, device and system

InactiveCN110967042AImprove absolute accuracyReduce the degree of developmentMeasurement devicesLearning machineHidden layer

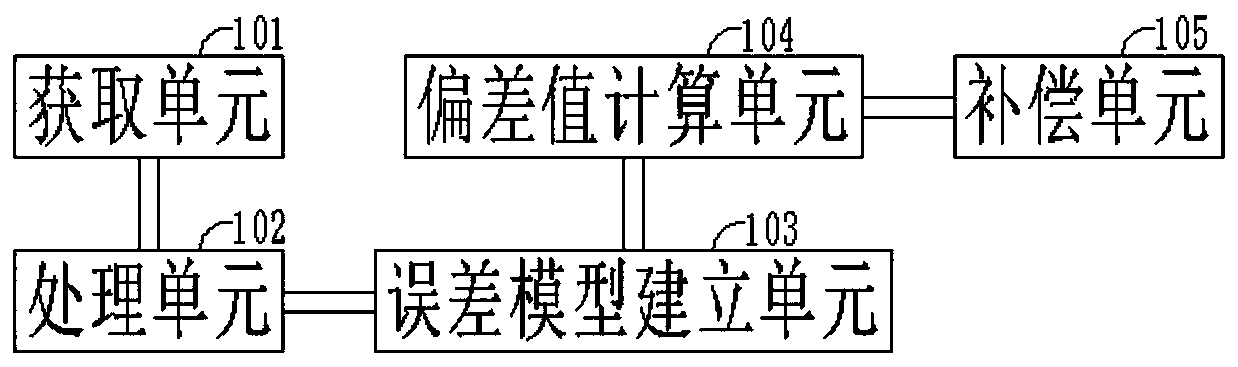

The invention discloses an industrial robot positioning precision calibration method, device and system, and the method comprises the steps: S101, respectively obtaining the actual positions and theoretical positions of a robot at n sampling points; S102, performing difference processing on the actual position and the theoretical position to obtain error values of the robot at n sampling points; S103, taking the theoretical position of the robot as an input layer, taking an error value corresponding to the theoretical position as an output layer, training a hidden layer by adopting an optimalpruning extreme learning machine model, and establishing an error model; S104, inputting a target position to be reached by the robot into the error model, and calculating a deviation value of the target position; S105, superposing the target position to be reached by the robot with the compensation value corresponding to the position to obtain an expected target position of the robot. Motion parameters of the industrial robot control system do not need to be modified, the development degree of the industrial robot control system is reduced, and the use cost of enterprises is reduced.

Owner:XY HUST ADVANCED MFG ENG RES INST +2

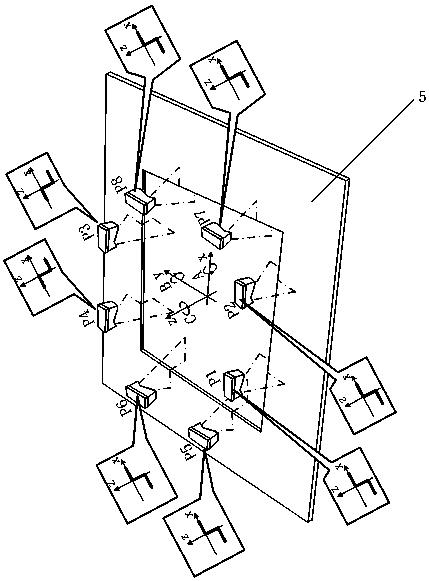

Three-dimensional calibration scene of automobile panoramic system and calibration method using scene

InactiveCN108665501AImprove reliabilityAvoid Calibration FailuresImage analysisComputer graphics (images)Computer vision

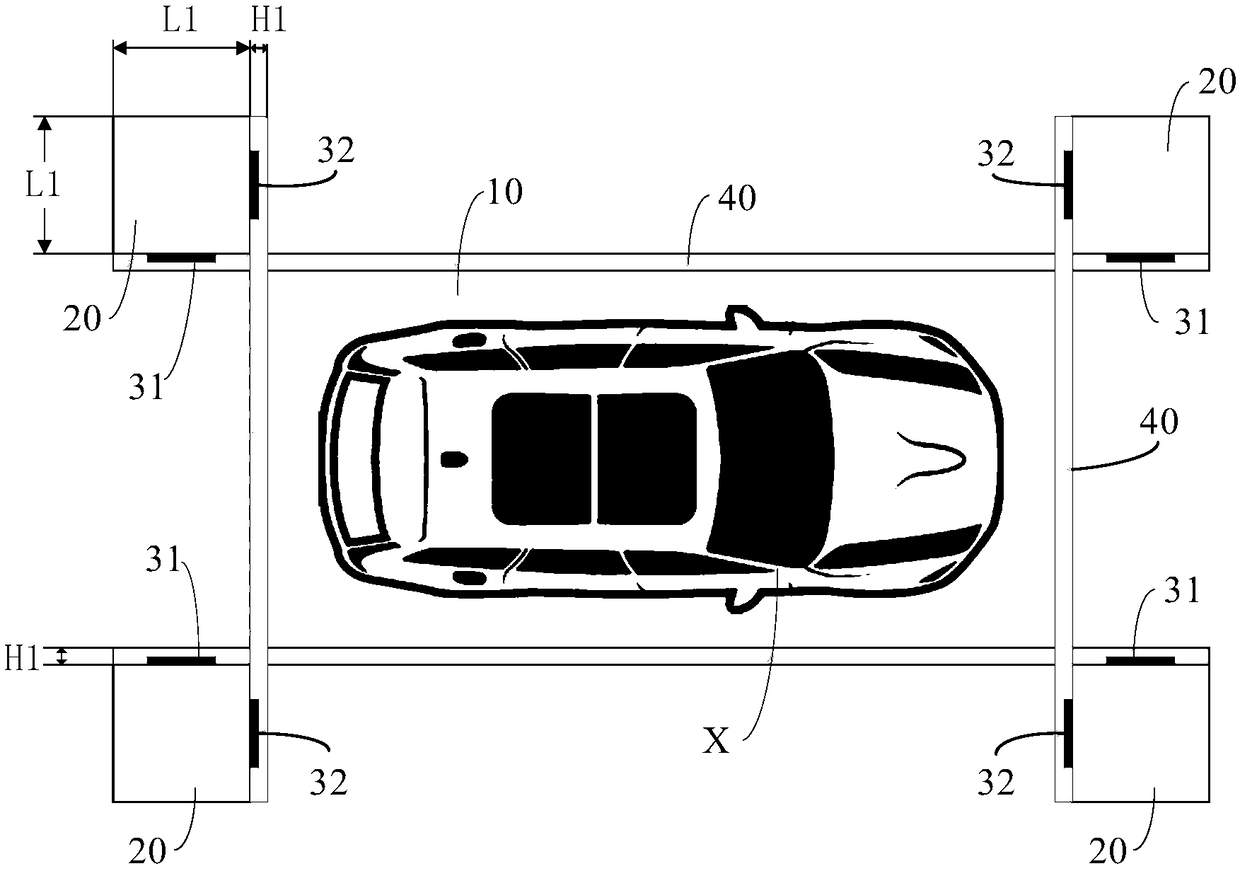

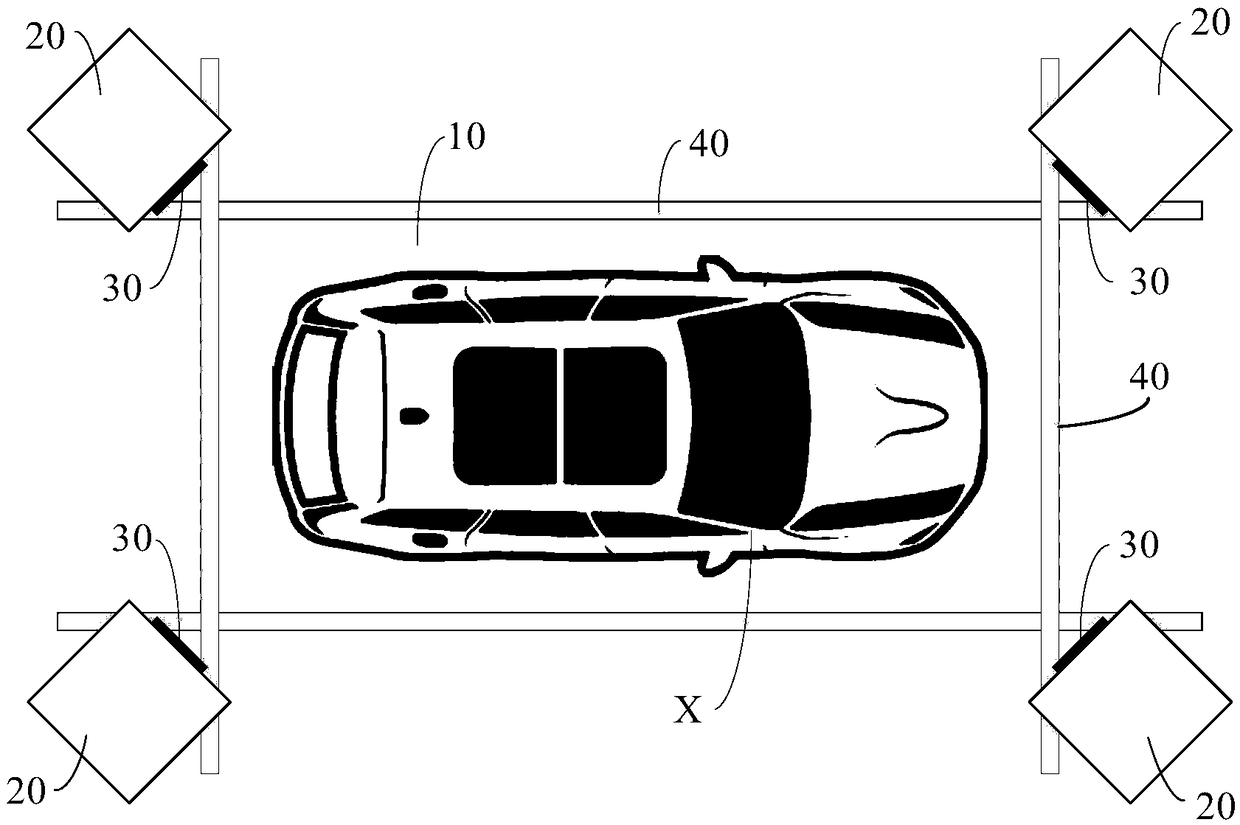

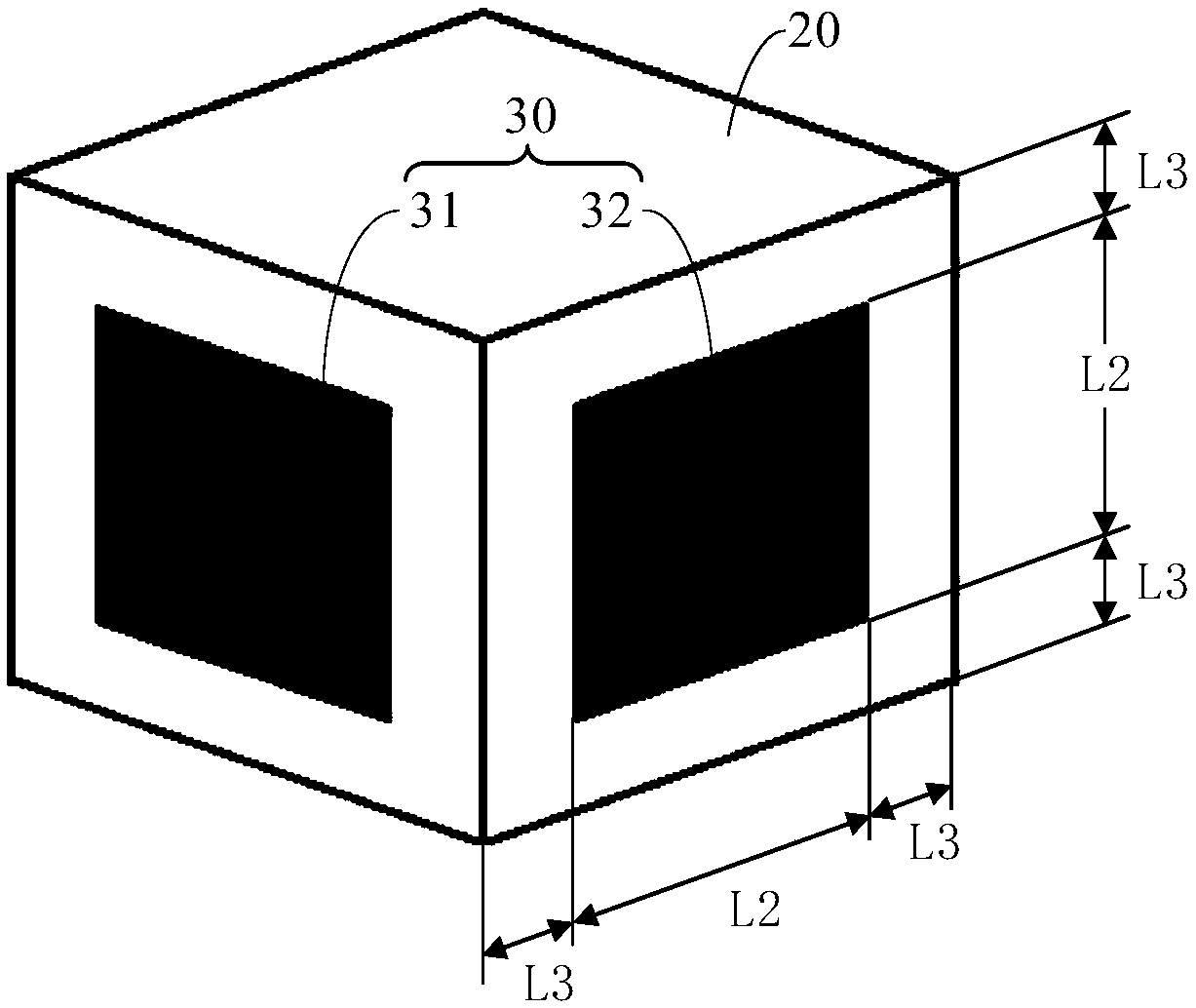

A three-dimensional calibration scene of an automobile panoramic system comprises a central area used for parking a to-be-calibrated vehicle, the central area is a rectangular area, and the outer sides of the four corner points of the central area are symmetrically provided with calibration units respectively; each calibration unit is provided with a calibration surface, and the calibration surfaces are located in a plumb bob surface and arranged facing the vehicle. The calibration surfaces are far away from the running path of the vehicle, so that the calibration scene is high in reliability.The calibration surfaces located in the plumb bob surface effectively avoid calibration failures caused when light is reflected on the ground and makes characteristic points disappear, and the calibration success rate is greatly increased. The calibration operation using the calibration scene is simple, the computer detection precision is high, the success rate is high, and calibration can be completed without manual operation.

Owner:HEFEI SOFTEC AUTO ELECTRONICS

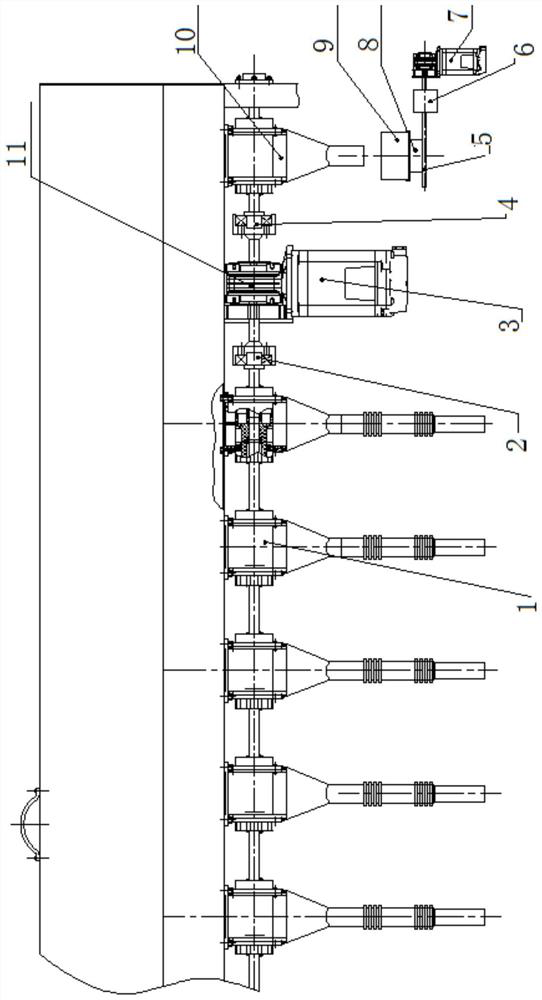

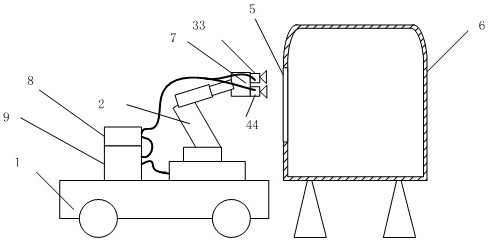

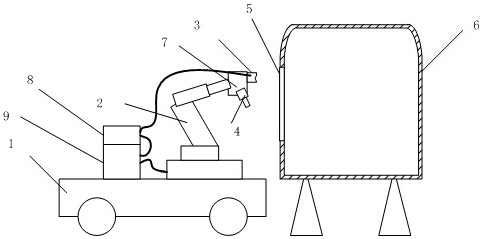

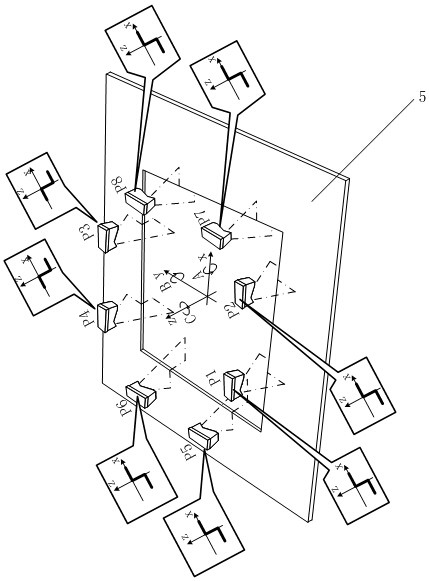

2D (two-dimensional) laser positioning method of door and window on train body of train

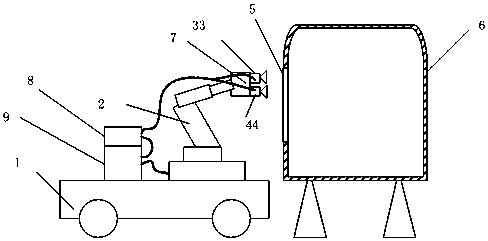

ActiveCN110625614AImprove robustnessEasy CalibrationProgramme-controlled manipulatorVisual observationEngineering

A 2D (two-dimensional) laser positioning method of a door and a window on a train body of a train includes a process of performing calibration measurement on the train body of the train, wherein the process includes the steps of: first, manually moving an AGV (automatic guided vehicle) to a working station, positioning the AGV through visual observation, and setting the center position of a door and window frame as the manipulator base coordinate origin; indicating a manipulator to operate, and saving a trajectory of the manipulator as a work trajectory; indicating the manipulator to perform the calibration measurement; performing the calibration measurement on trisection positions of each edge of the frame, indicating the manipulator to carry a 2D sensor for scanning the 2D outline of theframe and record data, then calculating out six freedom degree coordinate value of the frame, and using the coordinate value as calibration position value; keeping a calibration measurement path of the manipulator as a path of following measurement work; and then moving the AGV to all stations to perform operation, calculating coordinate deviation between the current frame coordinate and the calibration position value, invoking the work trajectory of the manipulator, compensating the coordinate deviation, and obtaining a new work trajectory. The 2D laser positioning method of the door and thewindow on the train body of the train improves robustness and usability of a system, and is easy in calibration.

Owner:SHANGHAI RO INTELLIGENT SYST

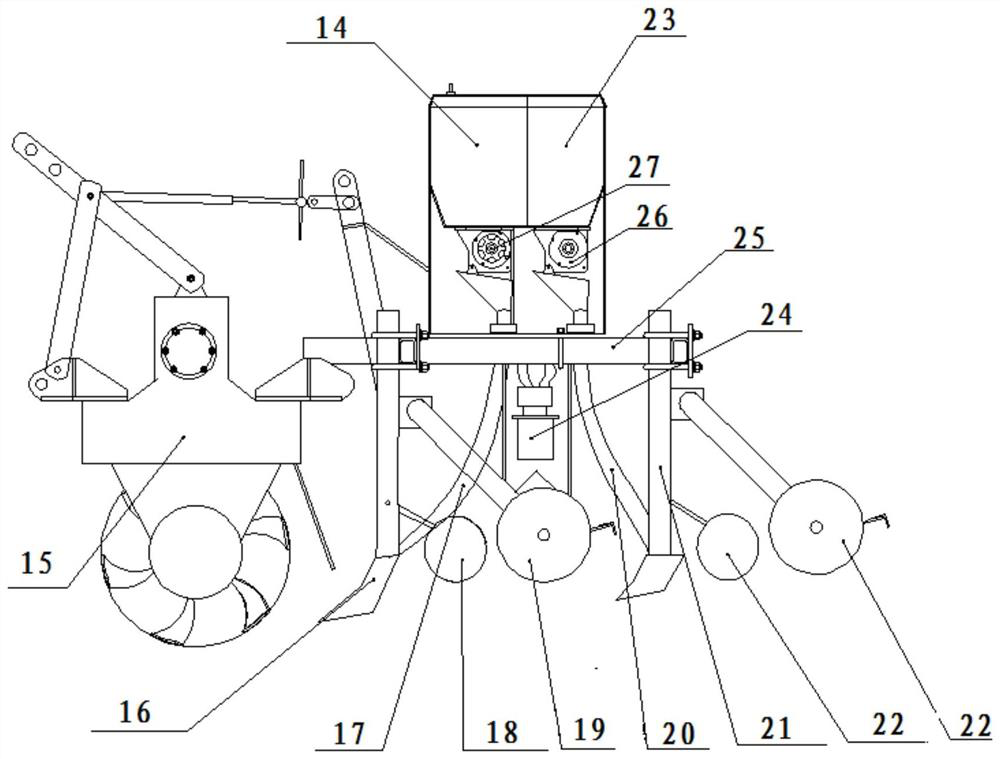

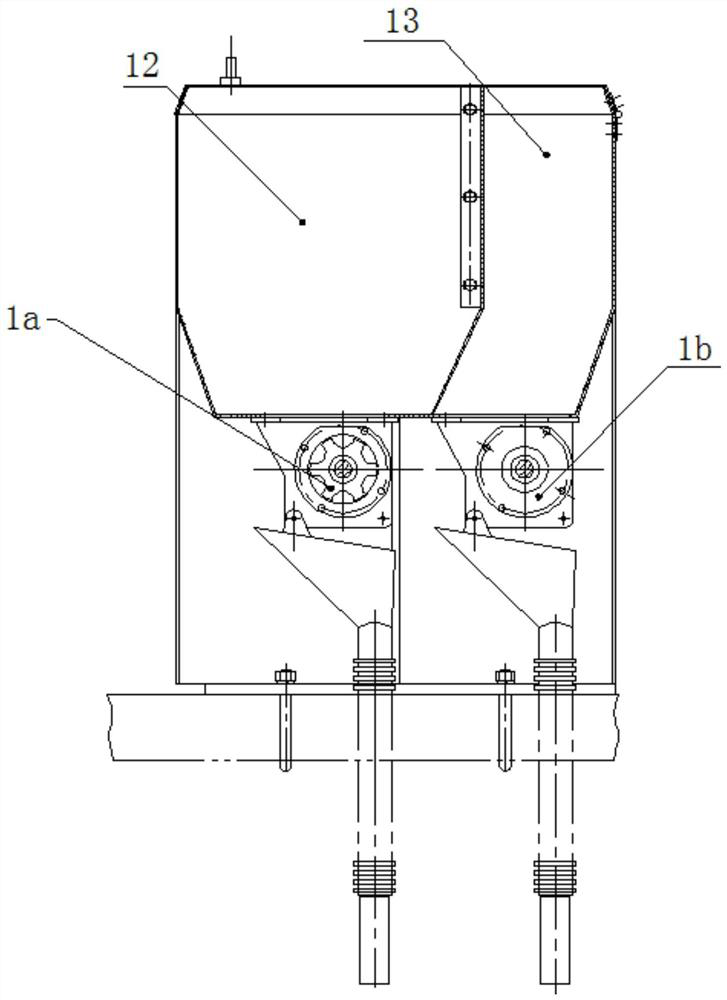

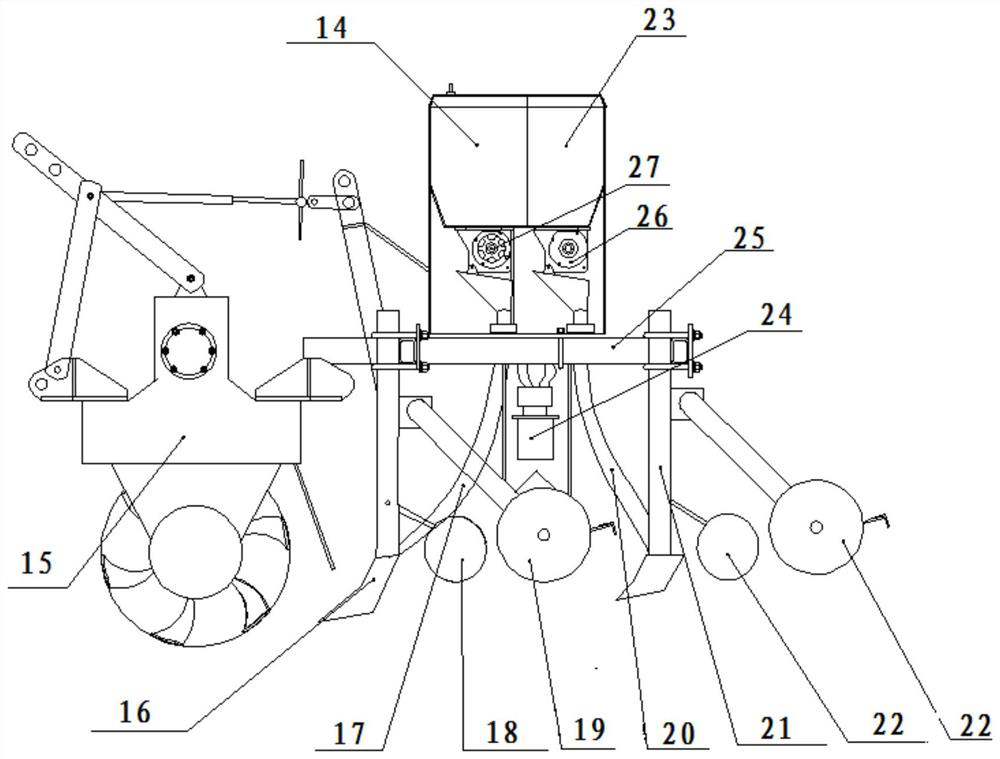

A Fertilizer Seeder with Automatic Calibration Function

The invention relates to a fertilizing and seeding machine with automatic calibration function. The power part which can rotate positively and negatively has double-sided power output ends; The second transmission one-way bearing is connected with the seeding and fertilizer components for calibration; the locking direction of the first transmission one-way bearing and the second transmission one-way bearing are opposite, and the free rotation direction is opposite; the comparator will target the amount of sowing or fertilization Compared with the measured value of the load-bearing sensor, the control system adjusts the relative working speed of the drive motor according to the corresponding ratio, so that the amount of seed discharge and fertilization can reach the target value; the inoculation fertilizer box and the load-bearing sensor are supported by the discharge shaft as a whole The unloading shaft is driven and rotated by the unloading power part, which drives the inoculation and fertilizer box to turn over, and pours out the seeds or fertilizer inside, so that the next calibration can be carried out normally; there is a reversible cone device under the weighing acquisition module.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Track geometric irregularity detection method based on two-dimensional laser displacement sensor

ActiveCN107554553BImprove anti-interference abilityEasy to handleUsing optical meansRailway auxillary equipmentAnti jammingAccelerometer

The invention discloses a track geometric irregularity inspection method based on a two-dimensional laser displacement sensors. The track geometric irregularity inspection method comprises the steps of mounting a left laser sensor and a right laser sensor which are two-dimensional laser sensors, a longitudinal inclinometer, a transverse inclinometer, gyroscopes, a transverse accelerometer, a leftvertical accelerometer and a right vertical accelerometer at an inspection beam, and carrying out a gauge inspection, a height inspection, a track alignment inspection, a level superelevation inspection, a warping inspection, a curvature inspection and a track verticality and lateral wear measurement. The invention adopts the high-speed two-dimensional laser displacement sensors which have high anti-jamming capability. Based on the two-dimensional laser sensors, without a complex image processing step and by virtue of simple and effective back-end algorithm processing, the track geometric irregularity inspection method has higher inspection and calculation speed and can effectively eliminate the influence of vehicle body vibration on inspection results. The inspection results have high repeatability and can be compensated, so that the inspection precision is higher.

Owner:CHANGZHOU LUHANG RAILWAY TRANSPORTATION TECH

Machine vision calibration system based on LabVIEW platform

InactiveCN103279953AShort development cycleEasy and fast image acquisitionImage analysisCamera lensMachine vision

The invention discloses a machine vision calibration system based on a LabVIEW platform. The system comprises an image acquiring module and a distortion correcting module, wherein the image acquiring module is used for acquiring an image of a calibration plate; the distortion correcting module is used for correcting distortion of the image of the calibration plate caused by a camera lens by using a radial distortion model and a coordinate conversion algorithm. The invention also discloses a machine vision calibration method based on the LabVIEW platform. The distortion caused by the camera lens is corrected by using the radial distortion model and the coordinate conversion algorithm according to image information of the calibration plate. The development period of the whole system is short, the image is simply, conveniently and quickly acquired, the calibration operation is simple, and the calibration precision is relatively high.

Owner:SUZHOU RISING AUTO PARTS

Automatic calibration device and method for seeding quantity and fertilizing quantity of seeder

ActiveCN112673769AHigh precisionMinor changes to equipmentFertiliser distributersSeed depositing seeder partsFertilizerDrive motor

The invention relates to an automatic calibration device for the seeding quantity and the fertilizing quantity of a seeder. A power part capable of rotating forwards and reversely is provided with two-side power output ends, one side is connected with an operation row seed-metering and fertilizer-discharging part through a first transmission one-way bearing, and the other side is connected with a calibration seed-metering and fertilizer-discharging part through a second transmission one-way bearing; the locking directions and the free rotation directions of the first transmission one-way bearing and the second transmission one-way bearing are opposite; a seed-receiving and fertilizer-receiving box is arranged below the calibration seed-metering and fertilizer-discharging part, and a load-bearing sensor is arranged on the lower portion of the seed-receiving and fertilizer-receiving box; a matched control system is connected with the load-bearing sensor and the power part; and a comparator is used for comparing the target seeding quantity or fertilizing quantity with a value measured by the load-bearing sensor, and the control system adjusts the relative working rotating speed of a driving motor according to a corresponding proportion, so that the seed-metering quantity and the fertilizing quantity reach target values. The automatic calibration device can be used on the seeder driven by a motor to meter seeds and discharge fertilizers, is matched with a calibration control system, and can realize on-line automatic rapid calibration.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

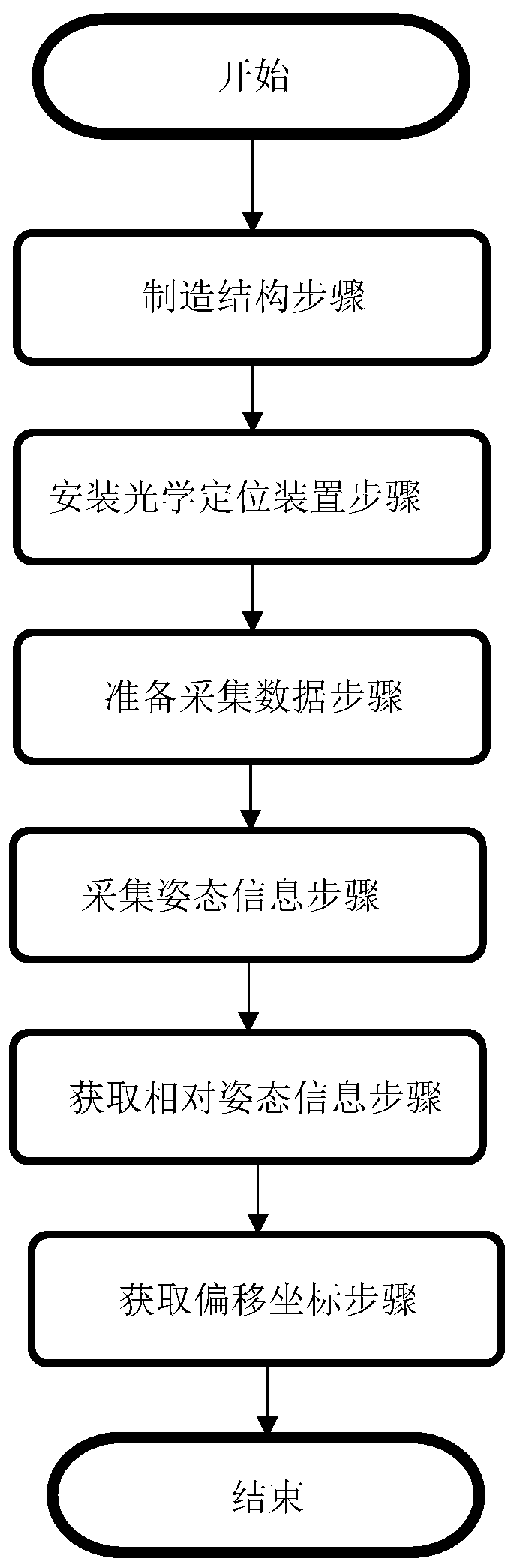

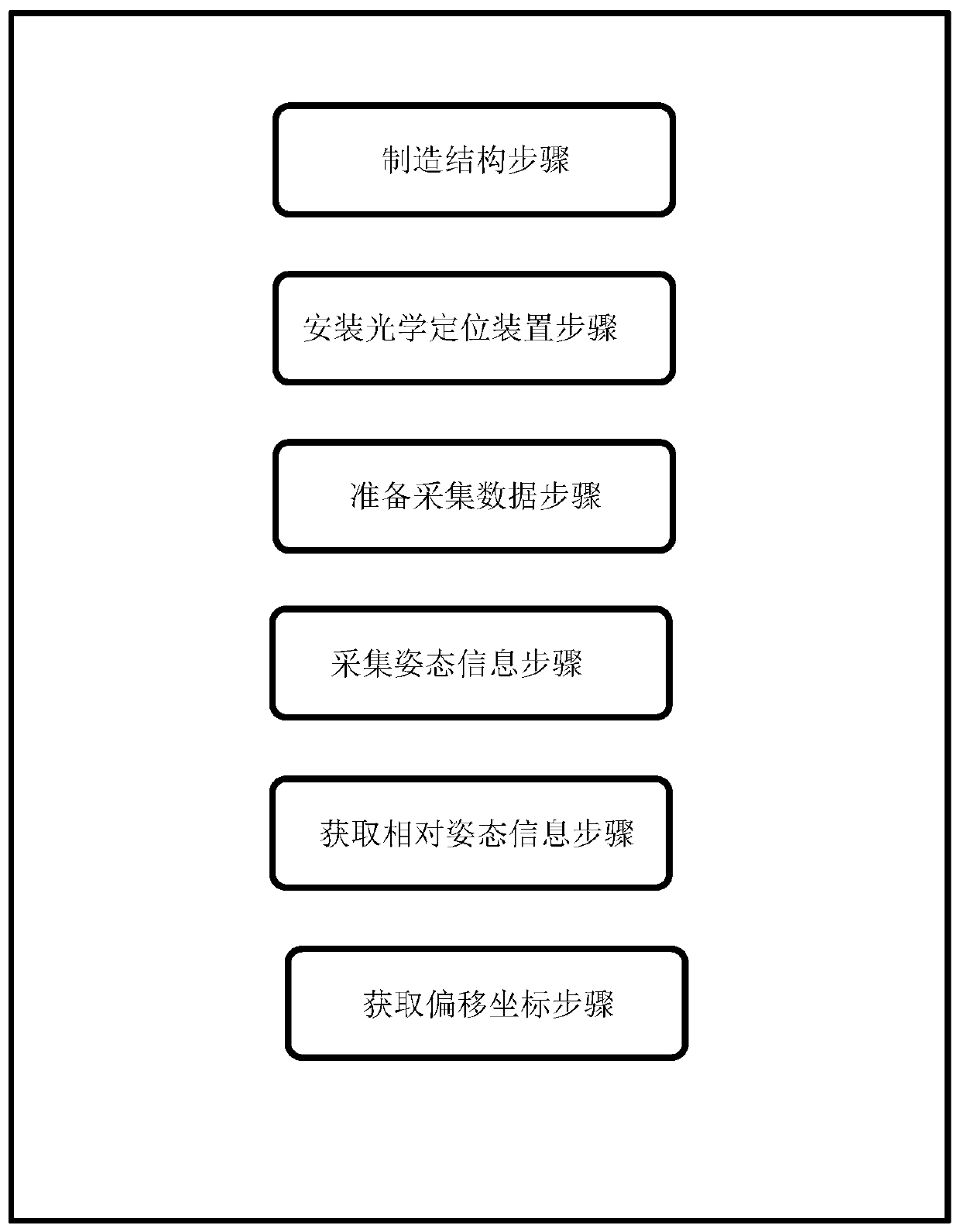

Dynamic tool tip position calibration method and system based on optical locator, medium and equipment

InactiveCN111043959ACalibration operation is simpleReasonable designUsing optical meansComputer visionEngineering

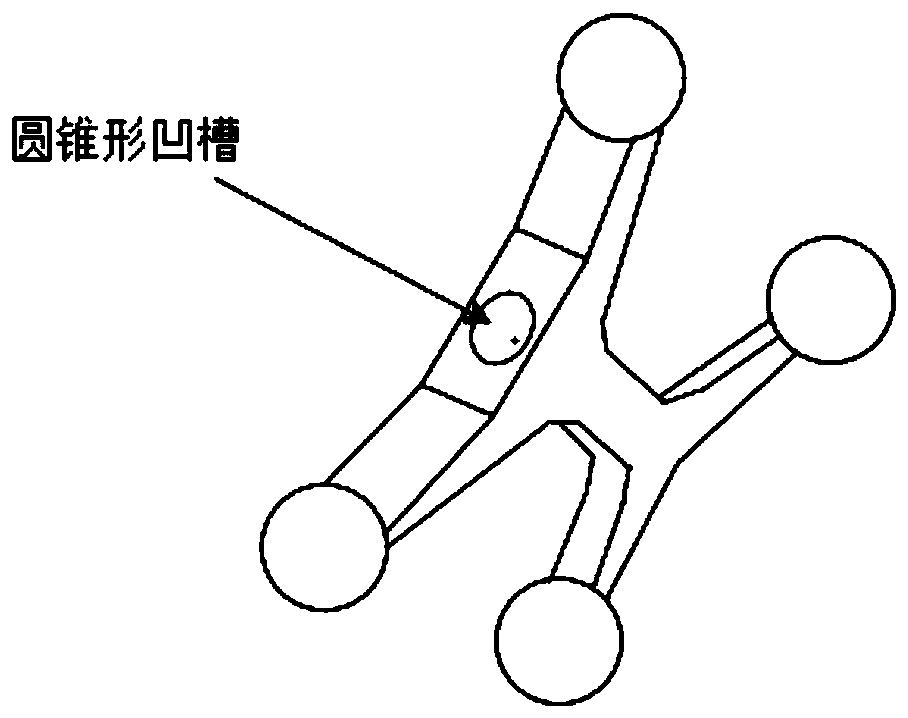

The invention provides a dynamic tool tip position calibration method and system based on an optical locator, a medium and equipment. The method comprises the steps of constructing a structure; mounting an optical positioning device by forming a conical groove in a specific surface position of a reference block, and mounting the optical locater in a specific position; preparing for data collectionby tightly jacking the tool tip against the groove of the reference positioning block, and preparing to acquire data; acquiring attitude information by rotating a tool around the tool tip , and acquiring the attitude information of the tool and the attitude information of the reference positioning block through the optical locator; and acquiring relative attitude information by transmitting the acquired information to a conversion algorithm, transmitting the attitude information of the tool relative to the reference positioning block into a spherical fitting algorithm, and obtaining the offset coordinates of the tool tip phase under a tool coordinate system. According to the invention, the purpose of obtaining accurate tool tip offset data can be achieved, and meanwhile calibration operation becomes more convenient.

Owner:上海嘉奥信息科技发展有限公司

Engine gear control system and rotary drilling rig

ActiveCN104832298BSolve the situation that the load suddenly increases in a short timeSolve problems that cannot meet real-time requirementsConstructionsEngine controllersControl systemComputer module

The invention discloses an engine gear position control system, comprising a controller, an accelerator knob, and an operating handle. The accelerator knob is provided with at least two engine gear positions, and each engine gear position corresponds to a different engine speed and power output. There is a full power output button for controlling the full power output of the engine; when the full power output button is pressed, the controller controls the full power output of the engine, otherwise, the corresponding engine speed output of the engine is controlled according to the engine gear of the throttle knob. The invention also provides a rotary drilling machine. The invention can quickly apply to harsh working conditions such as sudden increase in the load of the rotary drilling rig in a short time, prolongs the service life of the engine, and improves the construction efficiency; the engine start protection module can effectively prevent the machine operator from starting the engine in an irregular manner; the calibration module realizes one key The calibration function makes the calibration operation simple and convenient for the machine operator.

Owner:BEIJING SANY HEAVY MASCH CO LTD

Planar crystal spectrometer capable of calibrating wave length of spectral line directly

InactiveCN1350165ACalibration operation is simpleAccurate self-calibrationEmission spectroscopyOptical measurementsParallel plateCrystal spectrometer

The plane crystal spectrometer capable of directly calibrating spectral line wavelength includes reflector using plate crystal as parallel plate which is placed on the oblique plane of long trapezoidal internal cavity in the base body, and on the surface of parallel plate reflector an auxiliary light diaphragm containing n (n is greater than or equal to 3) equidistant parallel lines formed from metal wire is placed. When the light beam sent by tested light source is projected on the parallel plate reflector, a reference zone coverong the auxiliary light diaphragm and a measuring zone non-covering auxiliary light diaphram are formed, and the parallel lines on the auxiliary light diaphragm in the reference zone are formed into shaded image on the receiving surface of receiver, it utilizes the measurement of distance between the formed shade images, and can define the absolute wavelength of any spectral line in the spectral film on the receiving surface. As compared with existent technique it features high calibrating accuracy and extensive application.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

A laser radar calibration device and calibration method based on space-time transformation

ActiveCN109375196BConvenient, quick and accurate calibrationImprove calibration accuracyWave based measurement systemsAll solid stateTime delays

Owner:BEIJING HUA KEBO BOCHUANG TECH

Device and method for automatic calibration of seeding rate and fertilization rate of seeder

ActiveCN112673769BCalibration operation is simpleHigh precisionFertiliser distributersSeed depositing seeder partsSeederControl system

The invention relates to an automatic calibrating device for seeding rate and fertilizing rate of a planter. A power component that can rotate in both forward and reverse directions has two-sided power output ends; One side is connected with the seed metering and fertilizing part for calibration through the second transmission one-way bearing; the locking direction of the first transmission one-way bearing and the second transmission one-way bearing are opposite to the direction of free rotation; There is an inoculation and fertilizer receiving box under the fertilizer part, and a load-bearing sensor is arranged at the lower part of the inoculation and fertilizer receiving box; the supporting control system is connected with the load-bearing sensor and the power part; the comparator measures the target seeding amount or fertilization amount with the load-bearing sensor The control system adjusts the relative working speed of the drive motor according to the corresponding ratio, so that the amount of seeding and the amount of fertilization reach the target value. It can be used on the planter driven by the motor for seeding and fertilizing, and in cooperation with the calibration control system, it can realize online automatic and rapid calibration.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Combined seed and fertilizer drill with automatic calibration function

ActiveCN112655297ACalibration operation is simpleNo need for recalibration verificationSpadesPloughsSeederAgricultural science

The invention relates to a combined seed and fertilizer drill with an automatic calibration function. A power component capable of rotating positively and negatively is provided with double-side power output ends; one side is connected with an operation row seed-metering and fertilizer-discharging part through a first transmission one-way bearing, and the other side is connected with a calibration seed-metering and fertilizer-discharging part through a second transmission one-way bearing; the locking directions of the first transmission one-way bearing and the second transmission one-way bearing are opposite, and the free rotation directions are opposite; a comparator compares the target seeding quantity or fertilizing quantity with a value measured by a load-bearing sensor, and a control system adjusts the relative working speed of a driving motor according to a corresponding proportion, so that the seeding quantity and the fertilizing quantity reach target values; a seed and fertilizer receiving box and the load-bearing sensor are integrally supported by a discharging shaft, and the discharging shaft is driven by a discharging power part to rotate to drive the seed and fertilizer receiving box to turn over, so that seeds or fertilizers in the seed and fertilizer receiving box are poured out and emptied, and normal calibration of next time is facilitated; and a turnover conical disc device is arranged below a weighing and collecting module.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

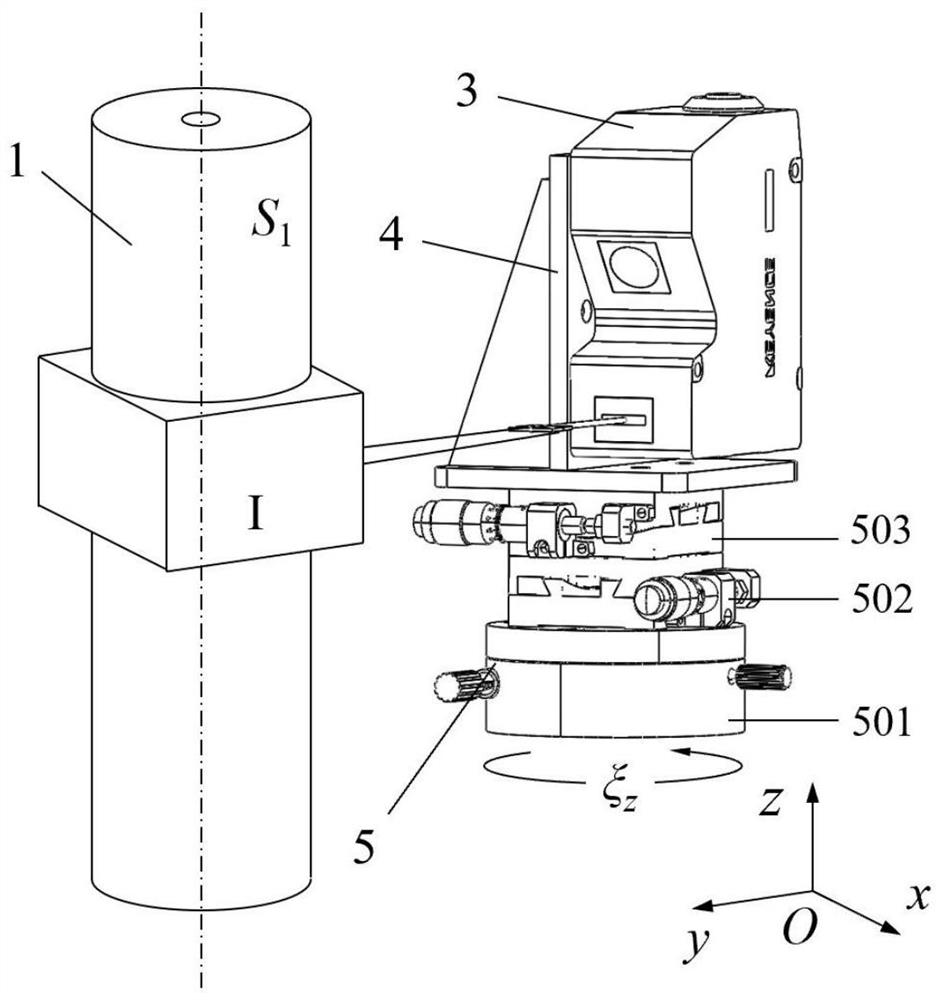

Line laser sensor space pose calibration piece and calibration method

ActiveCN113358025ASimple structureCalibration operation is simpleUsing optical meansLaser sensorMachining

The invention discloses a line laser sensor space pose calibration piece and a calibration method, which combine the advantages of gear measurement center contact measurement and a simple geometric feature calibration piece, and realize accurate calibration of a line laser sensor through simple and easy calibration operation. On the basis of a standard mandrel, a cuboid metal block is arranged in the middle of the axis, and the centers of the upper end face and the lower end face of the standard mandrel are each provided with a conical hole for fixing. The coaxiality and cylindricity of an upper shaft section S1 and a lower shaft section S2 of a standard core shaft part of the calibration piece are required to be 1 [mu]m. The perpendicularity of the plane I and the plane II is 1 [mu]m, and the parallelism of the plane I and the plane II and the axis of the standard mandrel is 1 [mu]m. The calibration piece is simple in structure, the existing manufacturing process can meet the machining requirement of high-precision geometrical characteristics, the calibration piece is combined with the advantage of gear measurement center contact type measurement, calibration operation is simple and easy to implement, and accurate calibration of the line laser sensor can be achieved.

Owner:BEIJING UNIV OF TECH

Measuring head calibration method of thread combined function dimensional measurement instrument

ActiveCN103134453BEasy to processTruly reflect the real results of the measurementsMeasurement devicesNumerical controlSize measurement

Owner:TIANJIN UNIV

A 2D laser positioning method for train body doors and windows

ActiveCN110625614BImprove robustnessEasy CalibrationProgramme-controlled manipulatorSimulationComputer vision

A 2D laser positioning method for doors and windows of a train body, including a process of calibrating and measuring the body of the train; first, the AGV car is manually moved to the working position, and the positioning is performed visually, and the center of the door and window frame is set as the base coordinate of the manipulator The origin; the manipulator is taught to operate, and the trajectory of the manipulator is saved as the working track; the manipulator is taught to perform calibration measurement, and the calibration measurement is at the 3 equal parts of each side of the frame, and the manipulator with the 2D sensor scans the 2D of the frame. outline and record the data, and then calculate the 6-degree-of-freedom coordinate value of the frame as the calibration position value; save the calibration measurement path of the manipulator as the path of subsequent measurement work; then move the AGV to each station for operation, and calculate the current frame The coordinate deviation between the body coordinate and the calibrated position value is called, and the working trajectory of the manipulator is called, and the coordinate deviation is compensated to obtain a new working trajectory. The invention improves the robustness and usability of the system, and is easy to calibrate.

Owner:SHANGHAI RO INTELLIGENT SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com