Measuring head calibration method of thread combined function dimensional measurement instrument

A thread synthesis and measuring instrument technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to accurately evaluate the actual screwing quality of the thread, and the inability to determine the actual axis of the thread, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

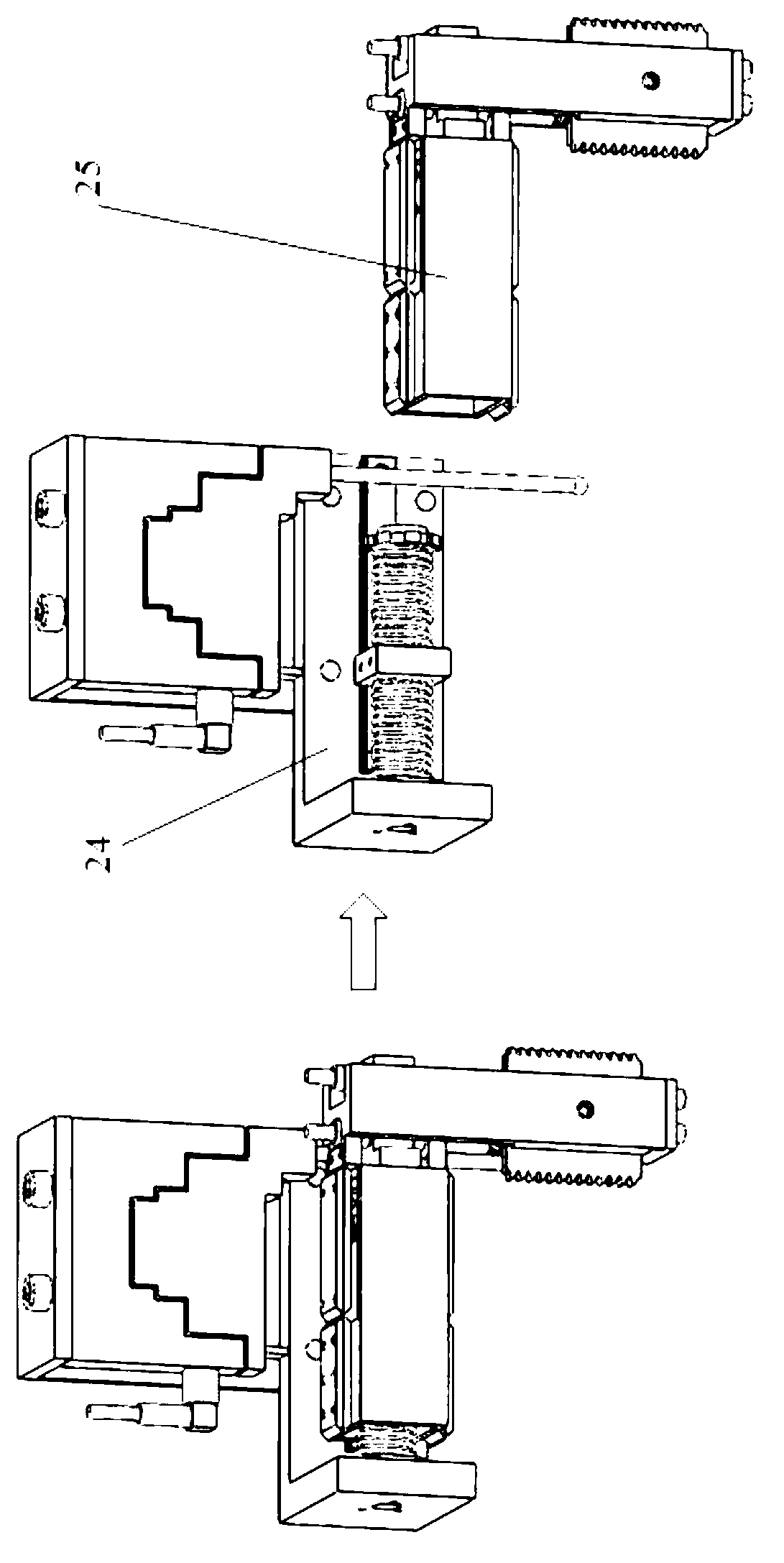

[0045] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0046] Please refer to the accompanying drawings, a method for calibrating the measuring head of a thread comprehensive action dimension measuring instrument, using a standard cylinder 208 to calibrate the reference zero value of the thread comprehensive action dimension measuring instrument probe.

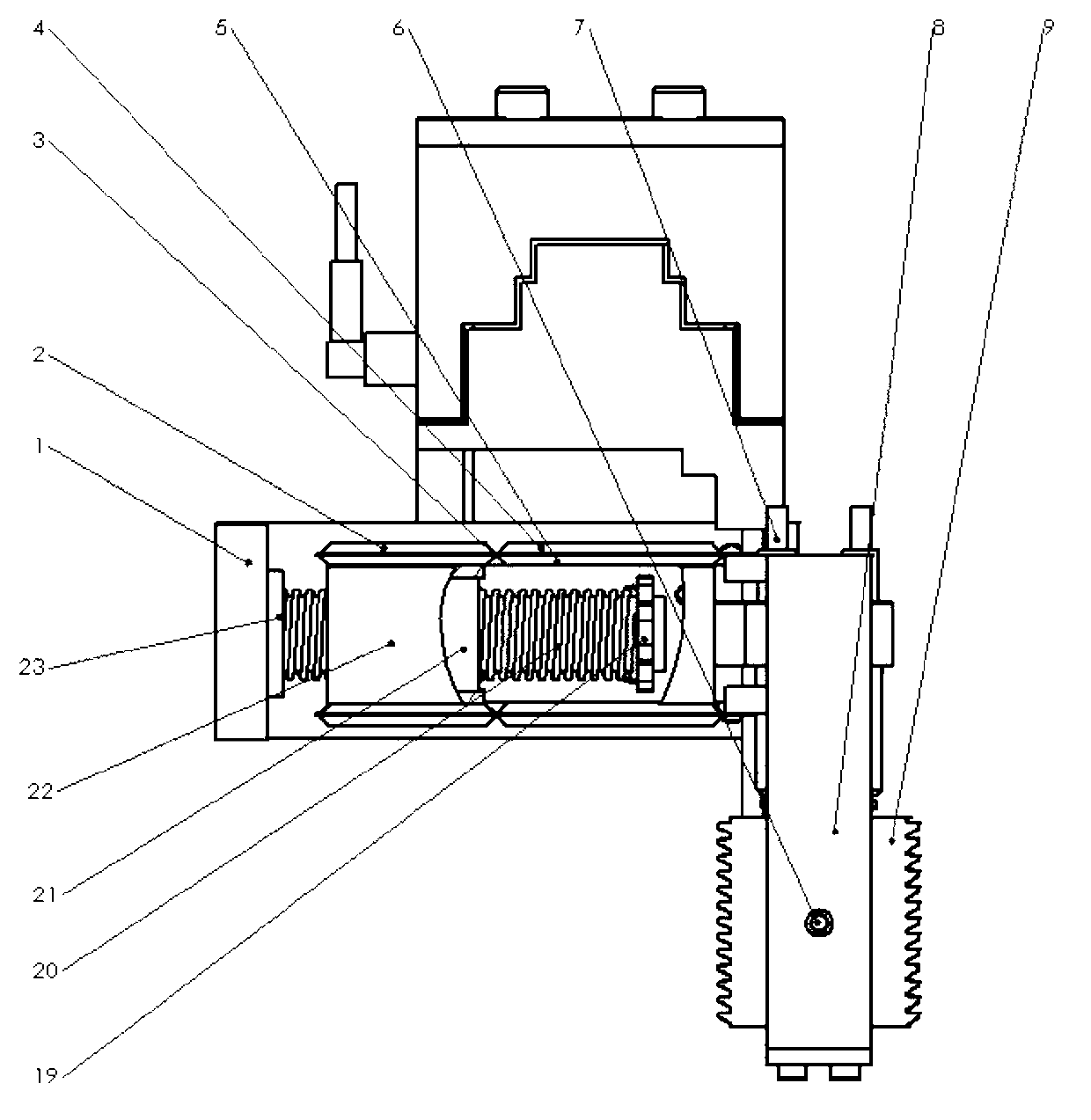

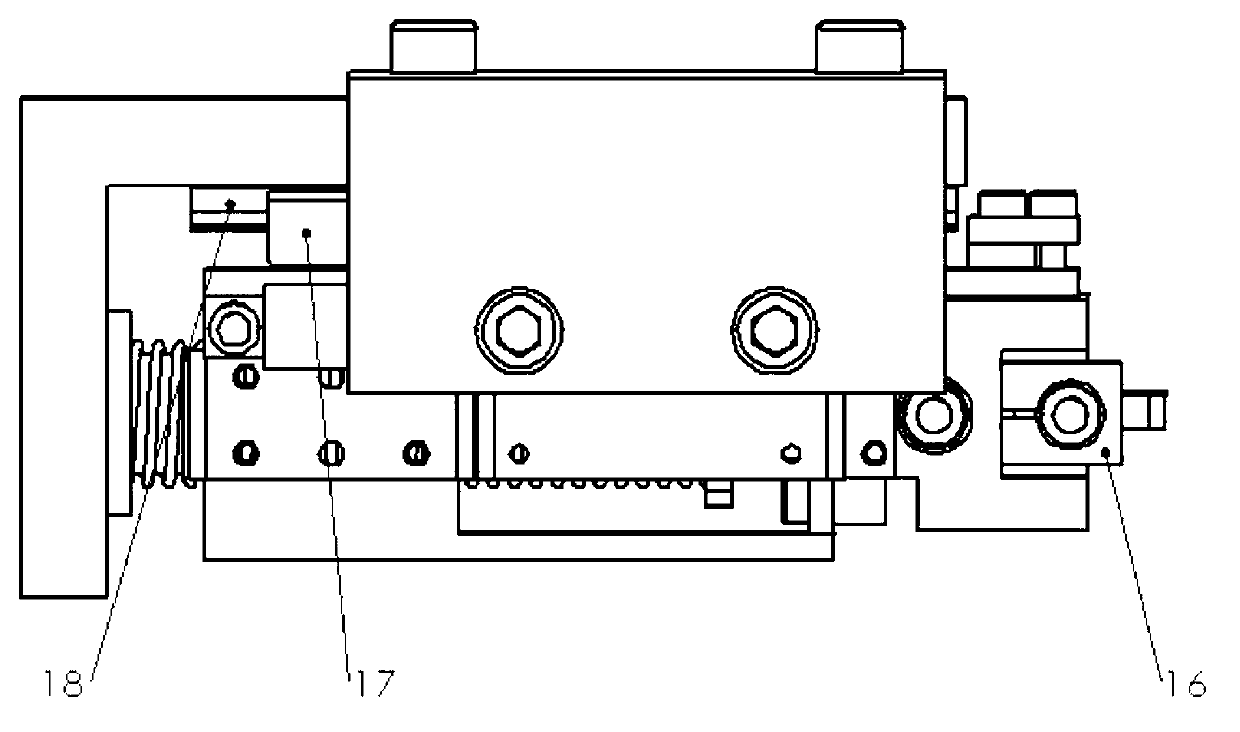

[0047] like Figure 9 As shown, the thread comprehensive function size measuring instrument includes a base 201 , a numerical control turntable 202 , a z-guiding rail 203 , a z-directing slider 204 , an x-guiding rail 205 , an x-directing slider 206 and a probe mechanism 207 .

[0048] The z-direction rail 203 is vertically fixed on the base 201, on which a z-direction slider 204 is installed, on which the z-direction slider 204 is fixed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com