Automatic calibration device and method for seeding quantity and fertilizing quantity of seeder

A technology for automatic calibration and seeding rate, which is applied to fertilization devices, planter parts, and interval-type quantitative seeding machinery, etc. It can solve the problems of low efficiency, complicated operation, large errors, etc. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

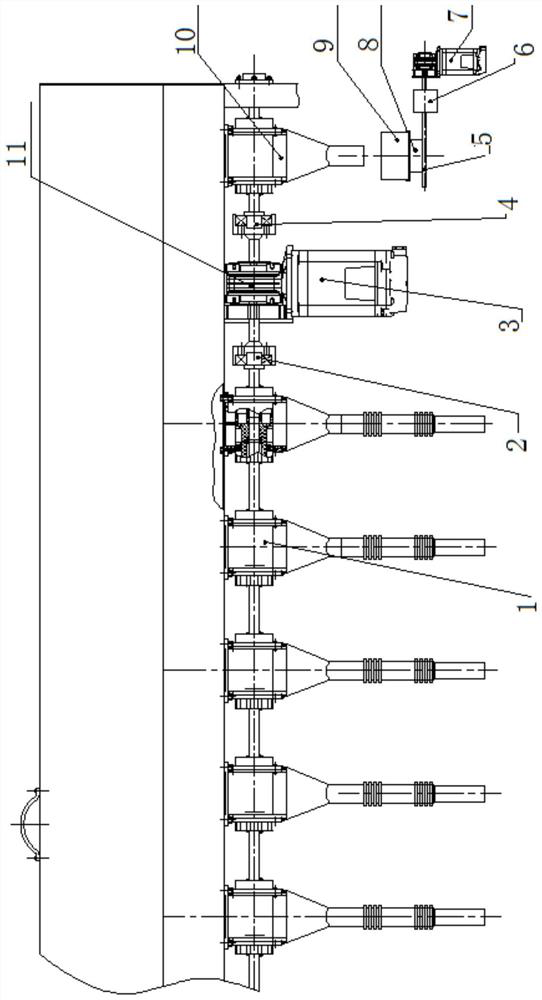

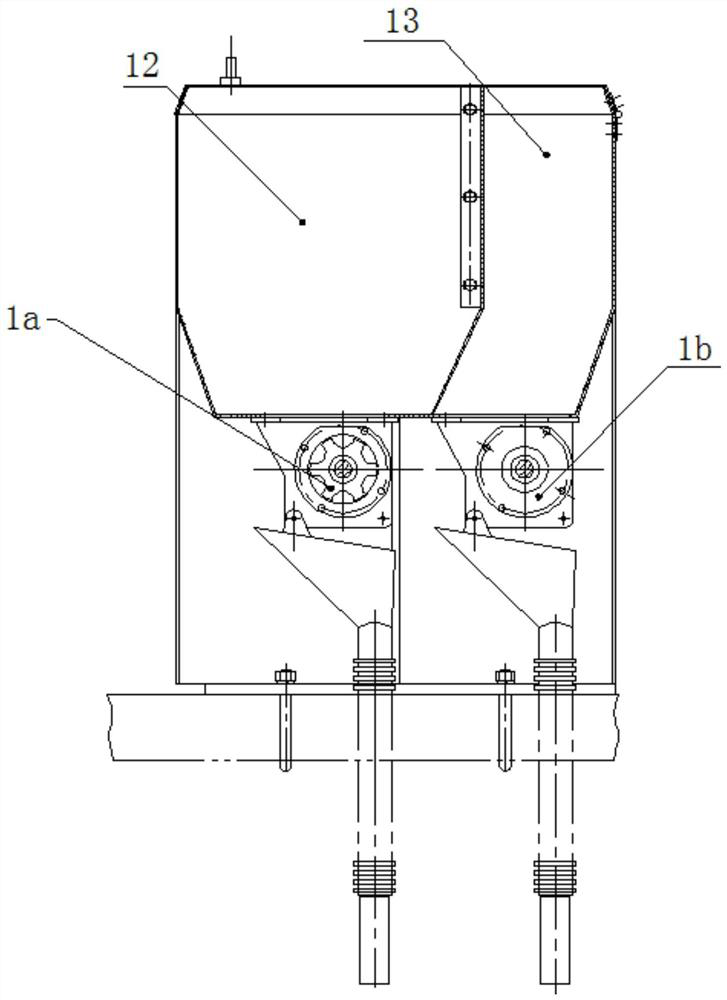

[0022] see Figure 1-Figure 2 , The seeding and fertilizing system on the fertilizing and seeding machine has a seed, 12, a fertilizer box 13, a seeding part 1b, a fertilizer part 1a, a drive motor 3, a drive gearbox 11 and other components.

[0023] Such as figure 1 As shown, the calibration device is also equipped with: the first transmission one-way bearing 2, the second transmission one-way bearing 4, the inoculation fertilizer receiving box 9, the load cell 8, the unloading shaft 5, the unloading gearbox 6, the unloading Material motor 7 and so on. figure 1 Among them, several groups of seeding and fertilizing components on the left side of the drive motor 3 are working row seeding and fertilizing components 1, which are working components for normal sowing and fertilization during work. A group of seed row and fertilizer components on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com