Engine gear control system and rotary drilling rig

A control system and engine technology, applied in engine control, rotary drilling rig, machine/engine, etc., can solve the problems that the adjustment gear can not meet the real-time demand, the load of the rotary drilling rig becomes larger, etc., to achieve convenient operator operation, The effect of prolonging the service life and simple operation of calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

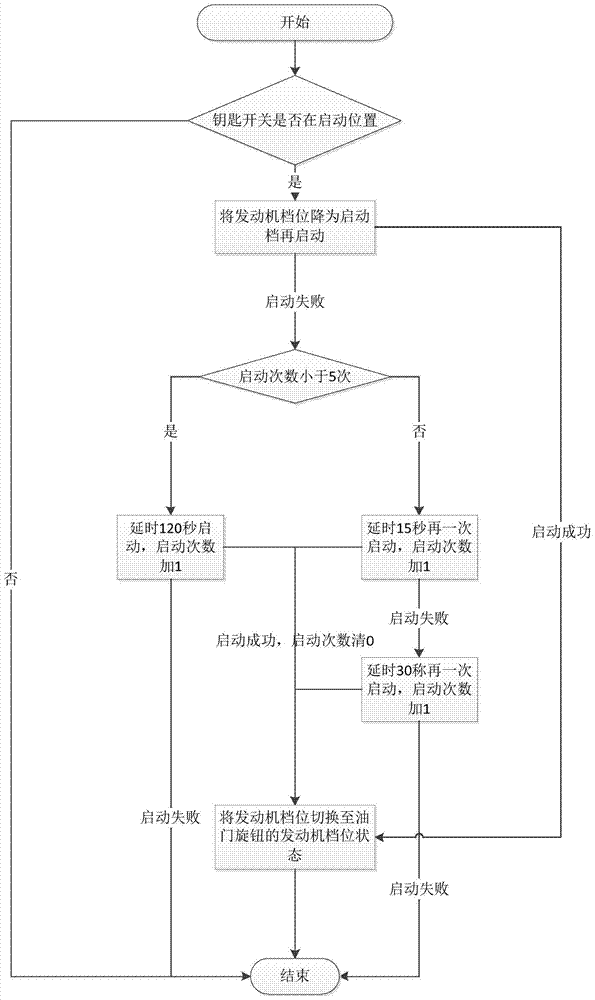

[0025] Such as Figures 1 to 3 As shown, in the preferred engine gear control system of the present invention, the output shaft of the engine is directly connected to the hydraulic pump, and the hydraulic pump provides hydraulic oil power to the hydraulic system of the rotary drilling rig.

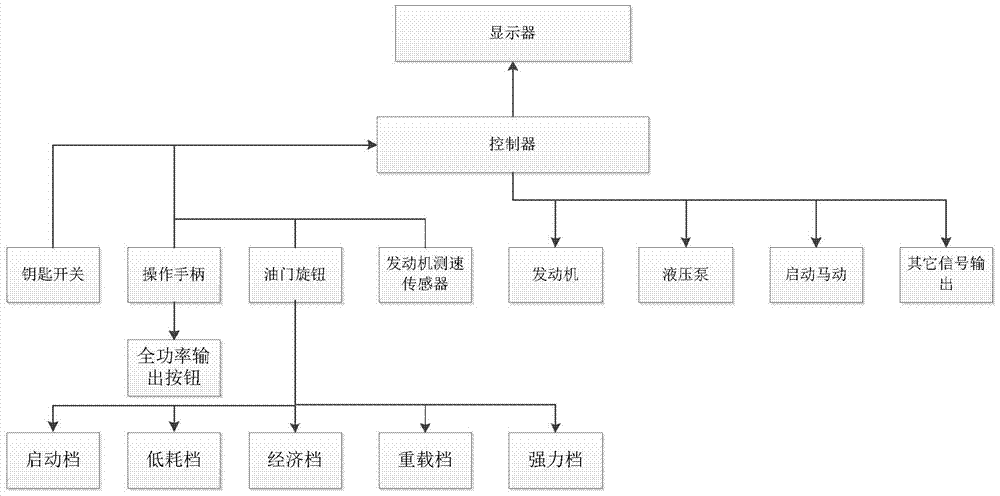

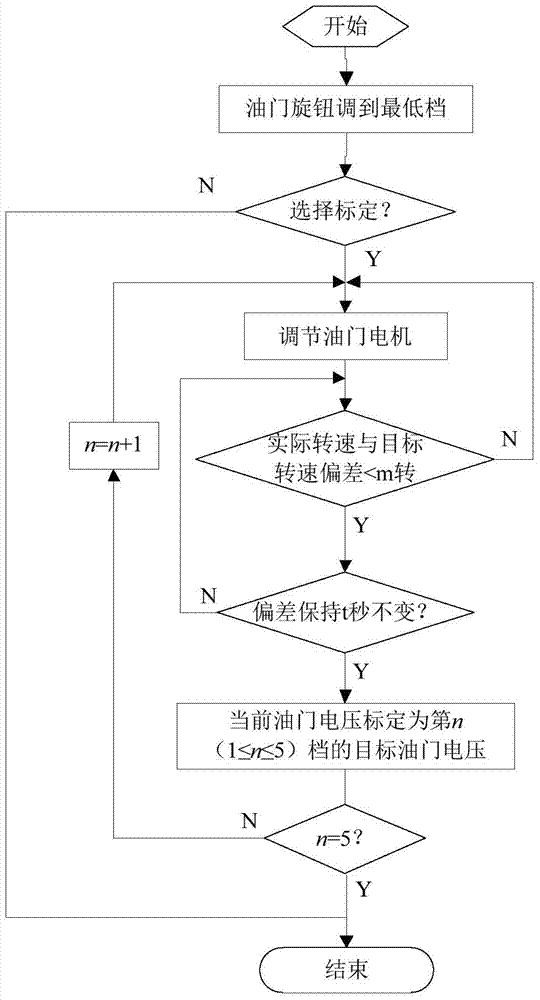

[0026] Such as figure 1 As shown, the engine gear control system includes a display and a controller. The throttle motor adjusts the throttle opening of the engine. The throttle knob, operating handle, engine speed sensor, key switch, and other signal input devices are connected to the input terminal of the controller. There are at least two engine gears on the throttle knob, and each engine gear correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com