A Fertilizer Seeder with Automatic Calibration Function

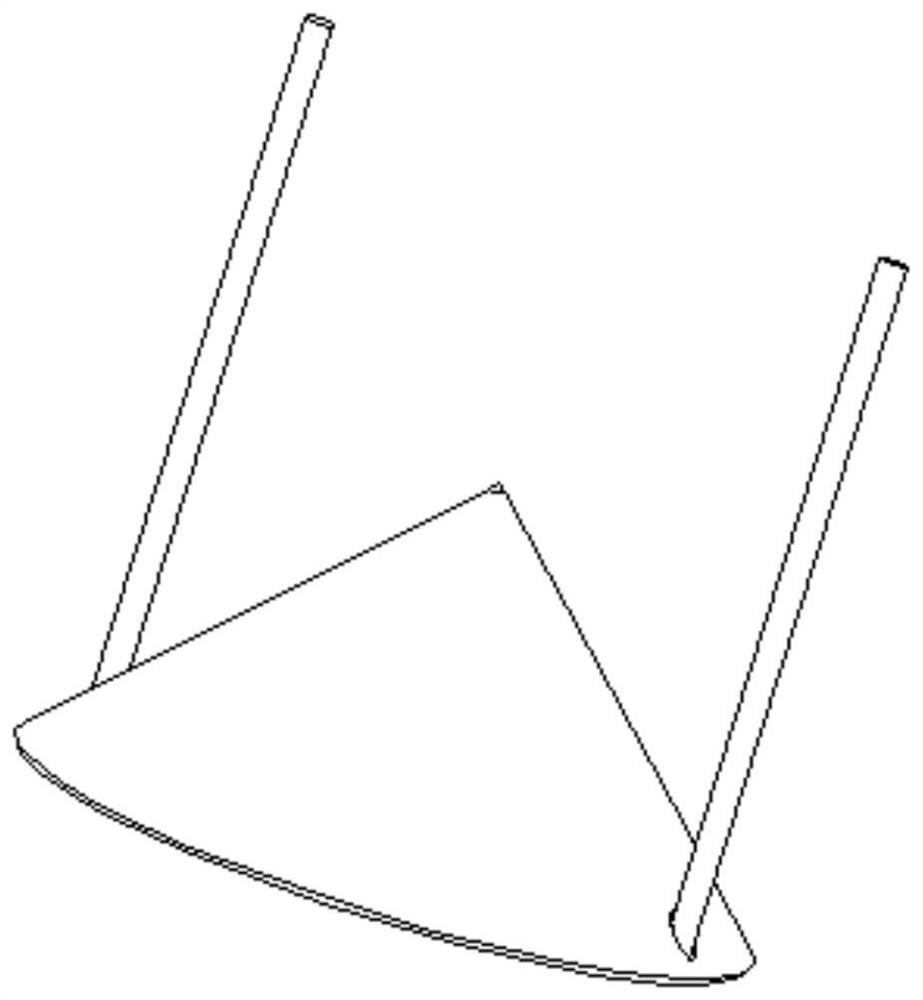

An automatic calibration and seeder technology, applied in agricultural machinery and implements, agriculture, shovels, etc., can solve the problems of low efficiency, complicated operation, time-consuming and laborious, and achieve the effect of increasing equipment cost, simple operation and preventing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

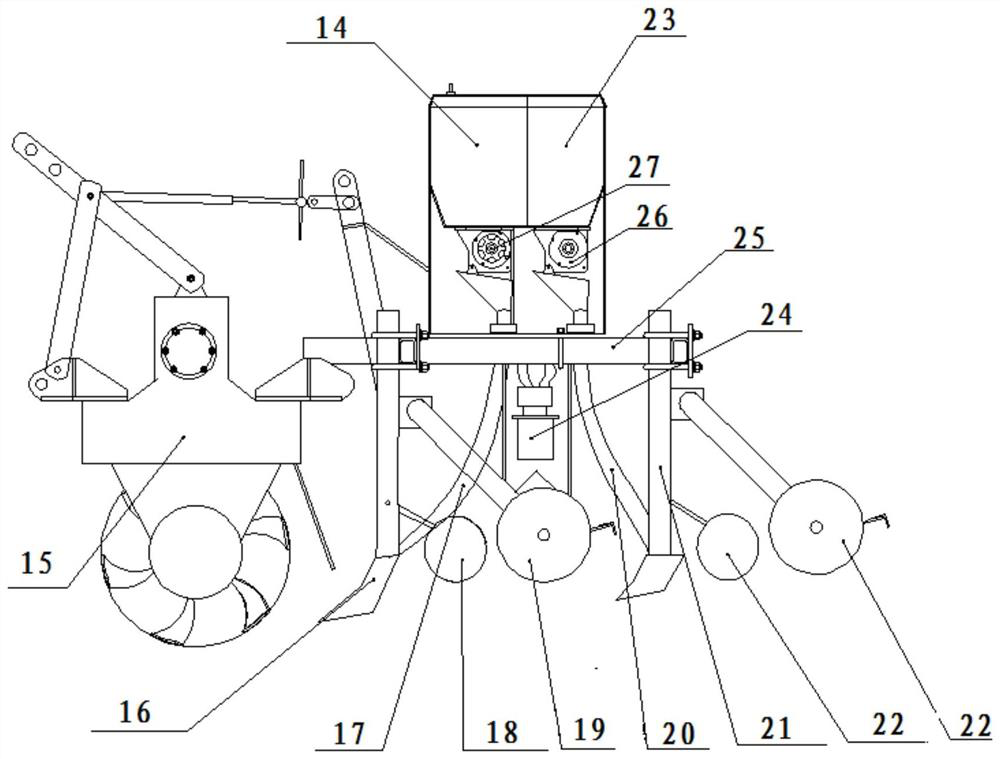

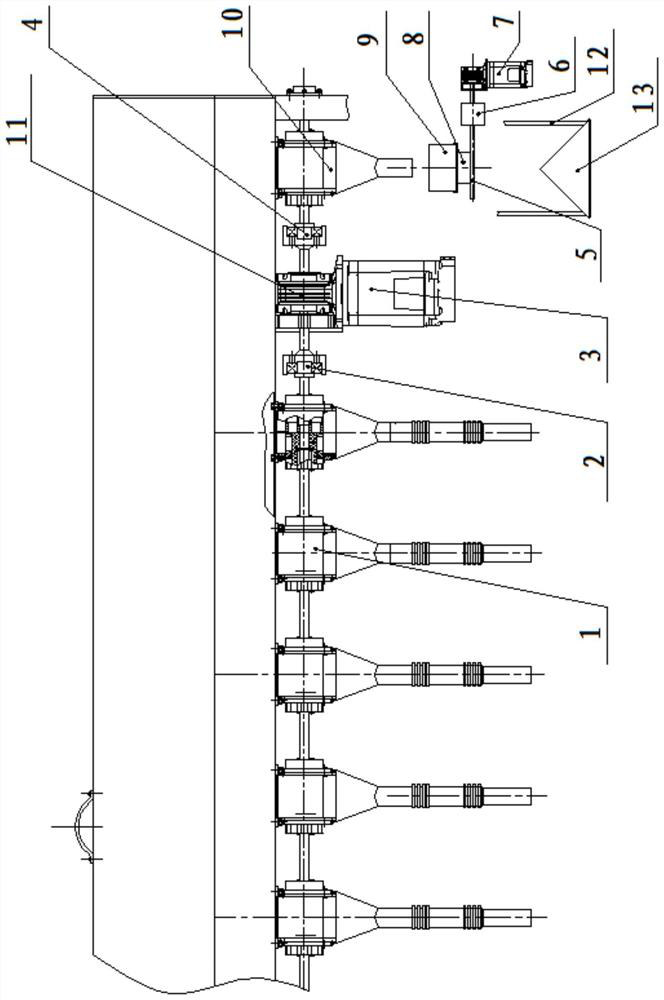

[0031] see Figure 1-5 , a fertilization planter with automatic calibration function. The power component that can rotate in both forward and reverse directions has two-sided power output ends; The second transmission one-way bearing 4 is connected with the seed metering and fertilizer distributing component 10 for calibration; the first transmission one-way bearing 2 and the second transmission one-way bearing 4 have opposite locking directions and opposite free rotation directions; There is an inoculation and fertilizer receiving box 9 under the seed fertilizing component 10, and a load-bearing sensor 8 is arranged at the lower part of the inoculation and fertilizer receiving box 9; the supporting control system is connected with the load-bearing sensor 8 and the power component; The fertilization amount is compared with the value measured by the load-bearing sensor 8, and the control system adjusts the relative working speed of the drive motor according to the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com