Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Avoid Manual Picking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

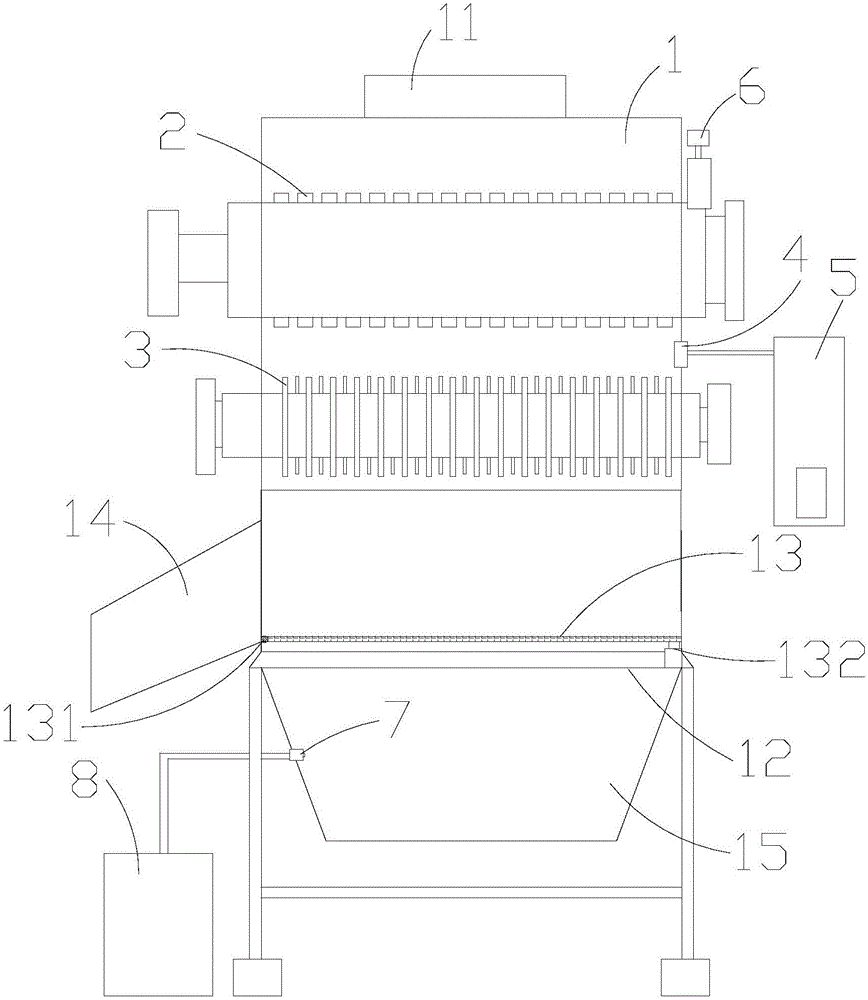

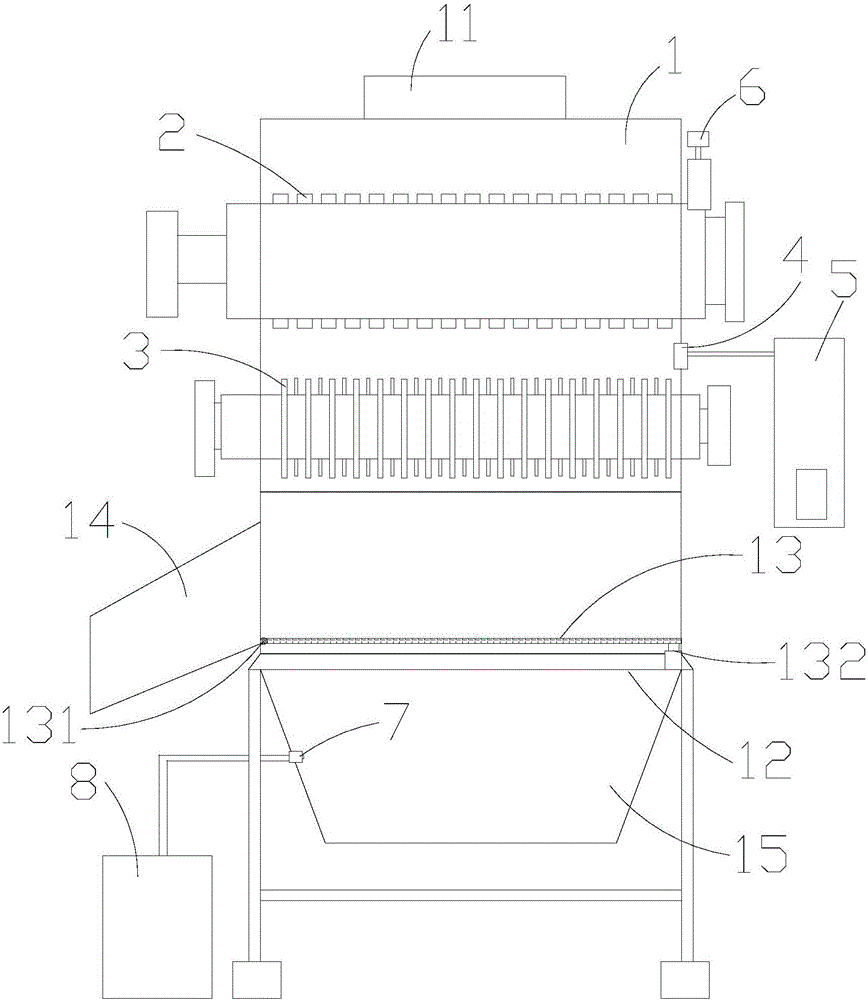

Rust removal device of artware

PendingCN109536978AQuick and effective removalNo manual operationDrying gas arrangementsCleaning using toolsAcid washingEngineering

The invention discloses a rust removal device of an artware. The rust removal device comprises a box body; a first partition board and a second partition board are arranged inside the box body correspondingly, the outer side faces of the first partition board and the second partition board are fixedly connected with the inner side wall of the box body correspondingly, the left side and the right side of the inner bottom wall of the box body are fixedly connected with first driving motors correspondingly, and rotating rods are fixedly connected to the top ends of the output shafts of the two first driving motors correspondingly, and the top ends of the two rotating rods penetrate through and extend to the upper part of the first partition board. According to the device, an acid washing liquid is used for reacting with rusty chips on the artware, so that the rust chips on the artware can fall off conveniently, and cleaning water can be used for washing the rust chips and the acid washingliquid on the artware; and two electromagnetic valves are controlled, so that the washing water is closed when the acid washing liquid is needed, and the acid washing liquid is closed when the washing water is used; and the purposes of economical using the acid washing liquid and the washing water are effectively achieved.

Owner:湖州艺雅斋湖笔有限公司

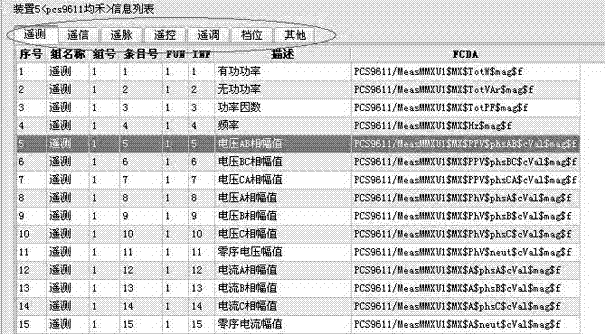

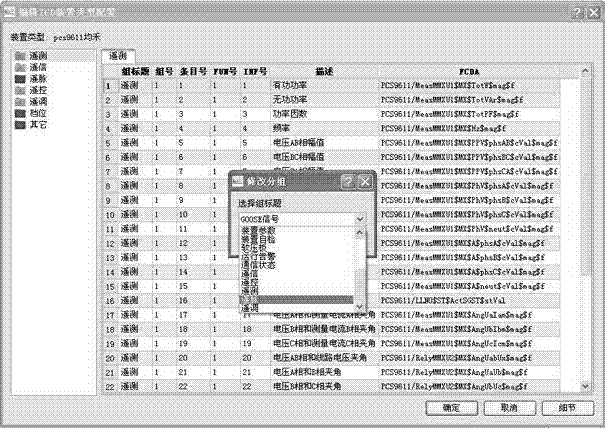

Configuration method for database of communication device in digital substation

InactiveCN102779156AFlexible editingEasy to importSpecial data processing applicationsInterface control documentSoftware engineering

The invention relates to a configuration method for a database of a communication device in a digital substation. The configuration method comprises the following steps: forming an independent middle text, namely, a rule file, according to an IEC61850 standard and a mapping rule for the database of the communication device; automatically generating data of a measuring point according to an engineering requirement and inputting the data of the measuring point into the database of the communication device, for an imported ICD (Interface Control Document) of the device during the configuration process of the communication device; and configuring through configuration software. According to the configuration method, the middle text is supplied to the database of the communication device and the database of the communication device is statically generated according to the corresponding rule in the middle text after the configuration software is imported into the ICD of an IEC61850 device, wherein the rule in the middle text comprises three parts: a basic classifying rule, a prior rule and a shielding rule. According to the configuration method, the database for the measuring point can be flexibly and automatically generated for the imported ICD of the device according to the engineering requirement, so that the process of manually selecting the point by an engineering configuring person is omitted, the possibility of configuration fault is eliminated and the efficiency of engineering configuration is increased.

Owner:NR ELECTRIC CO LTD +1

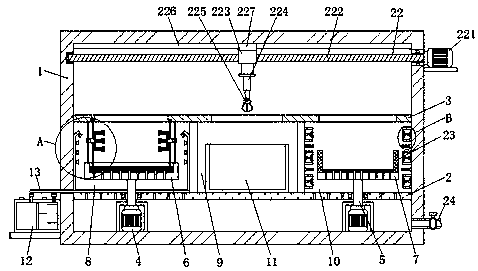

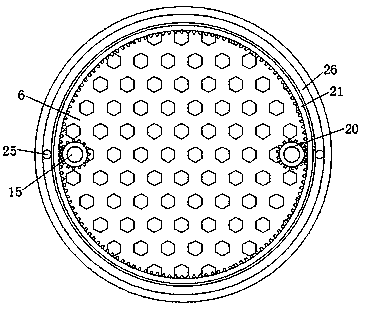

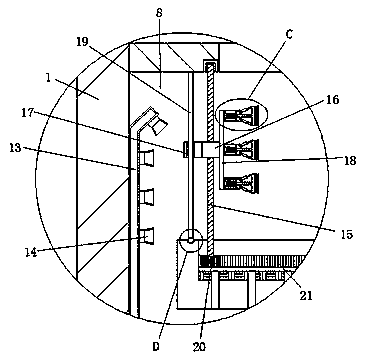

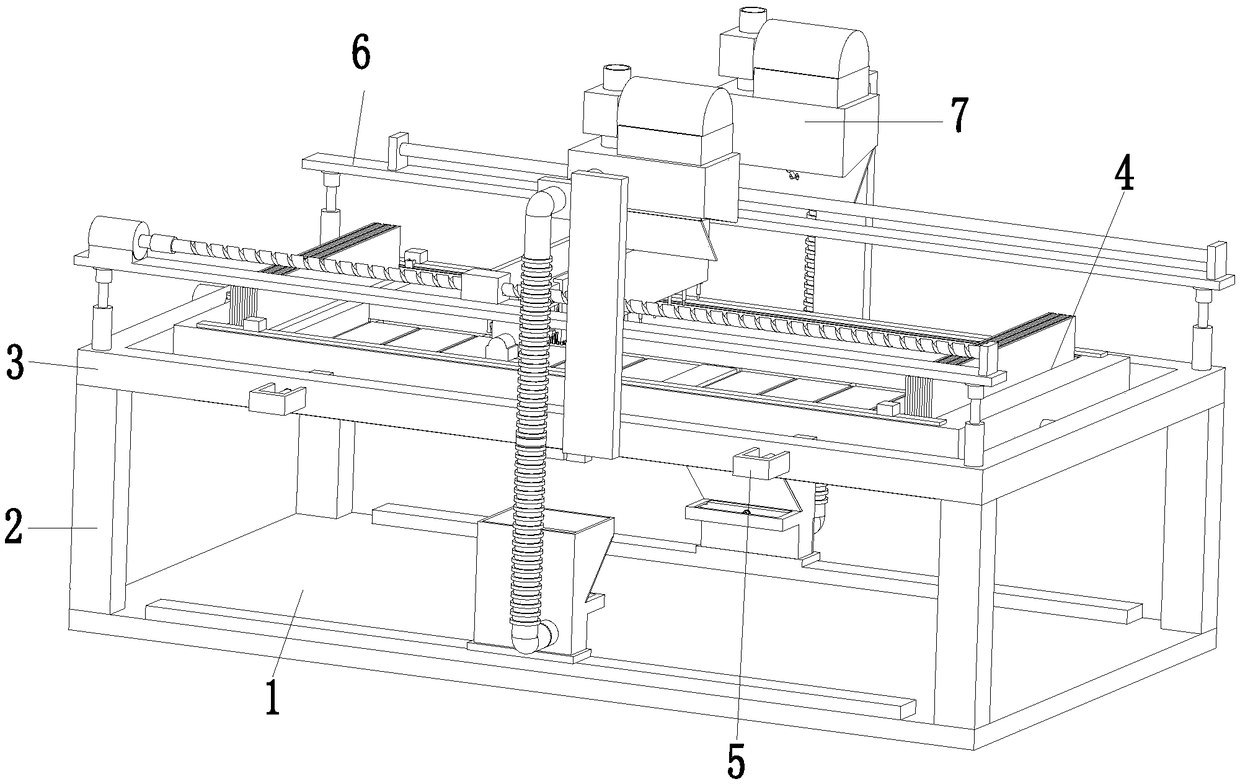

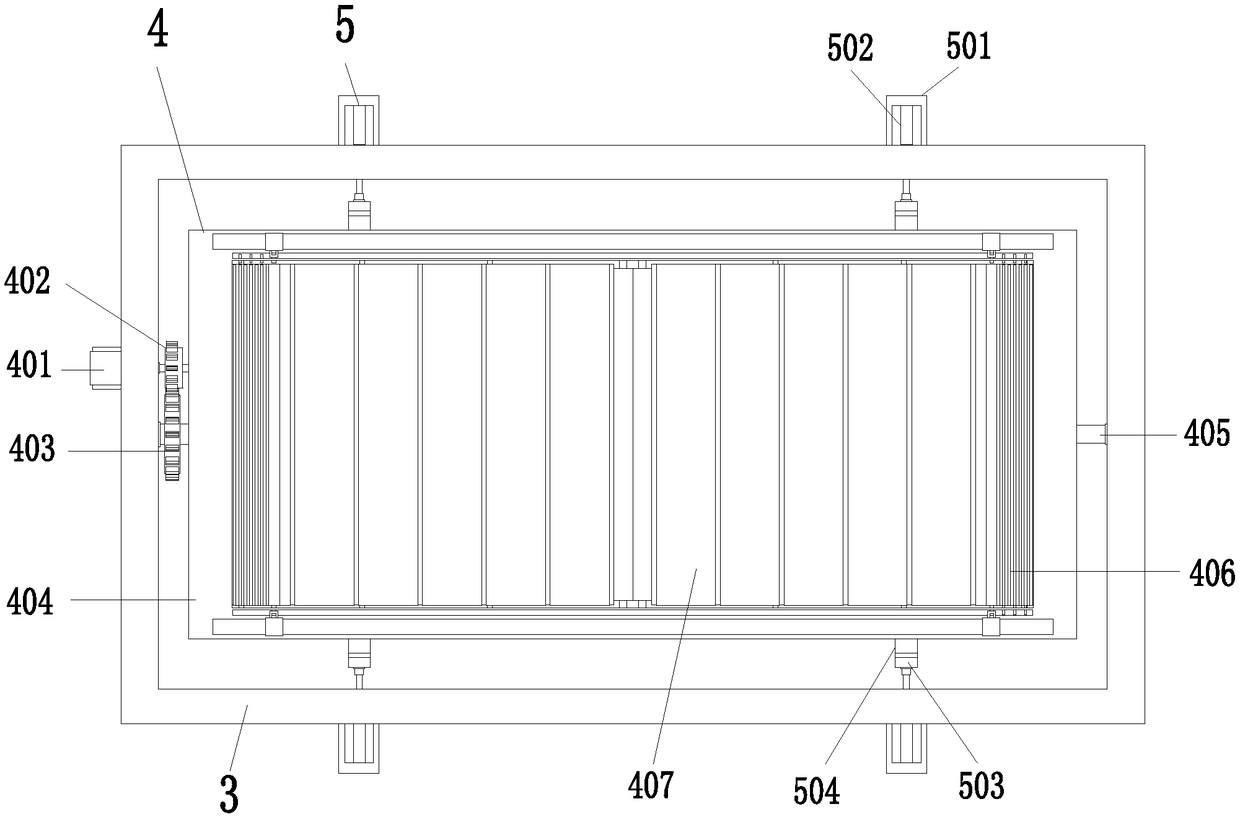

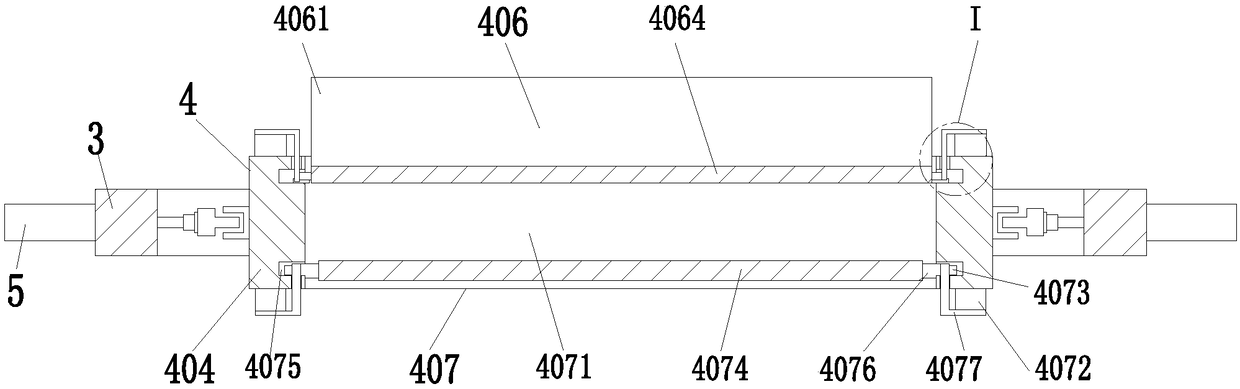

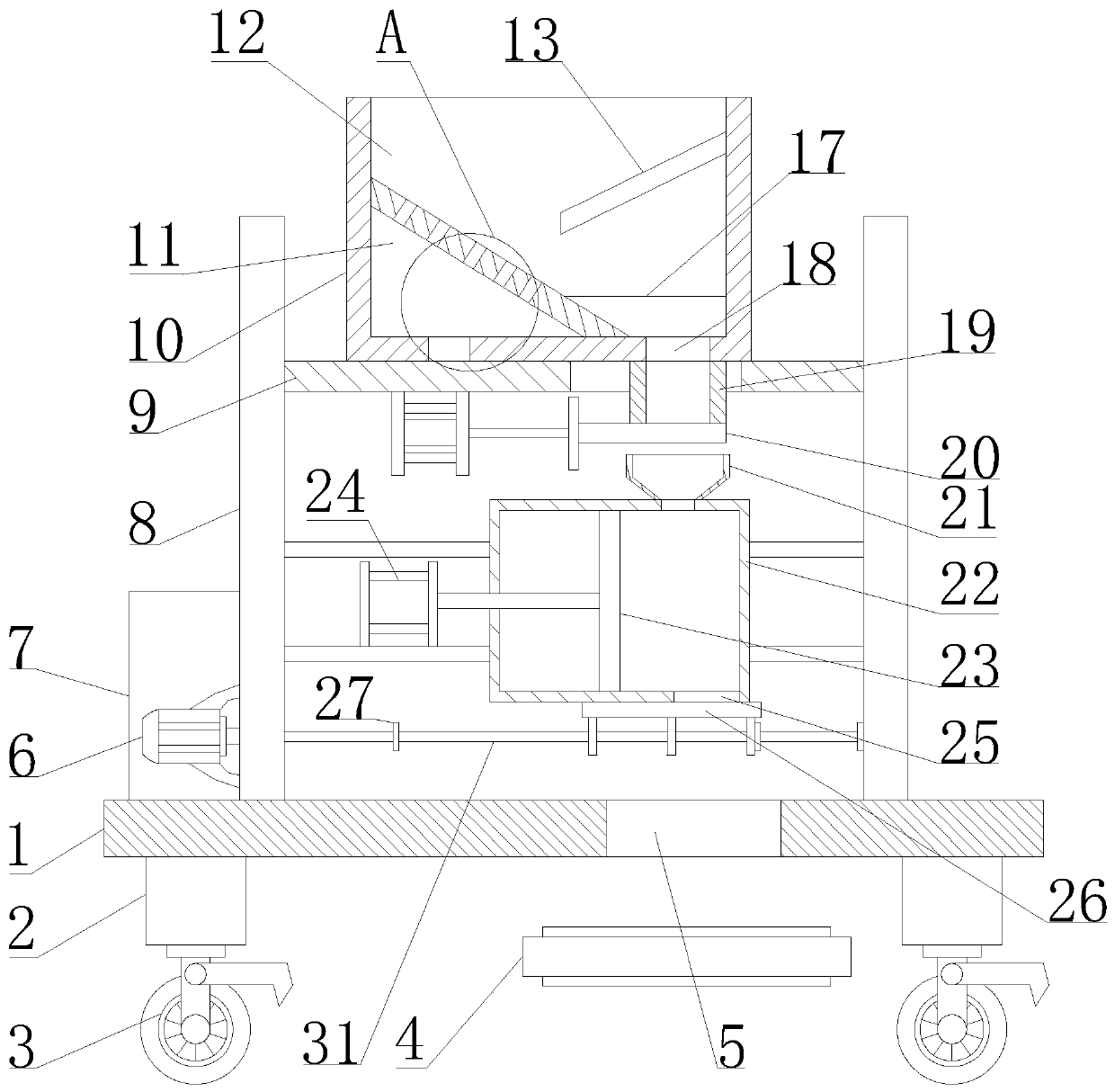

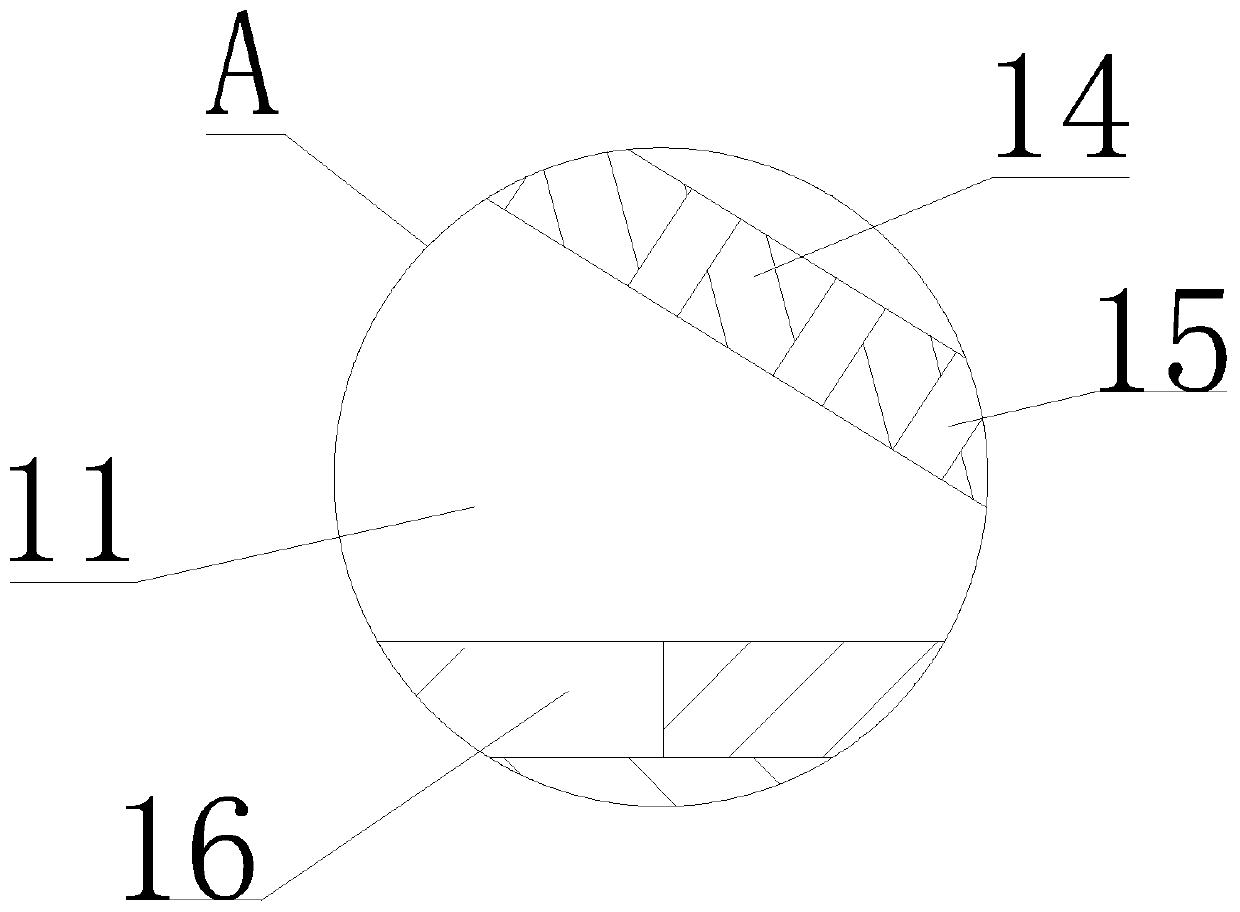

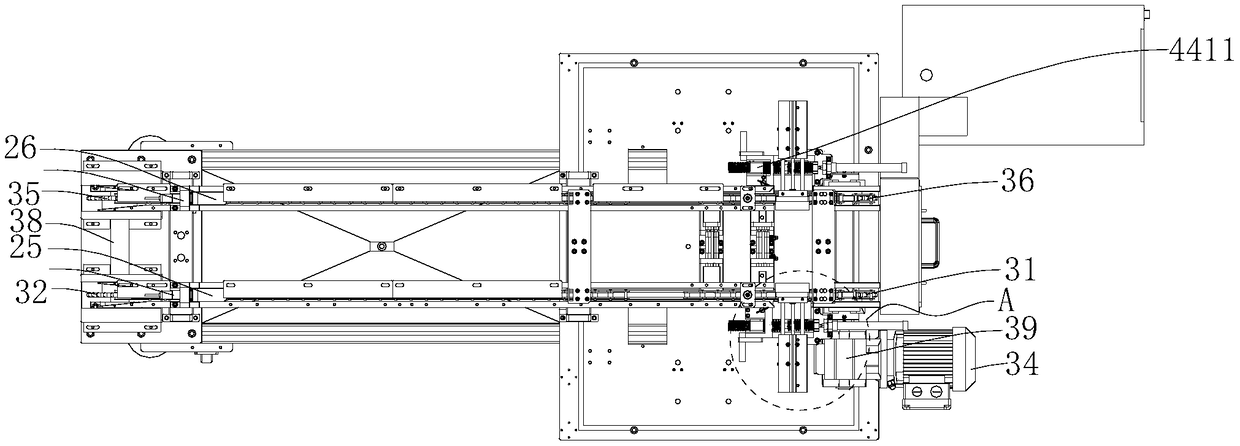

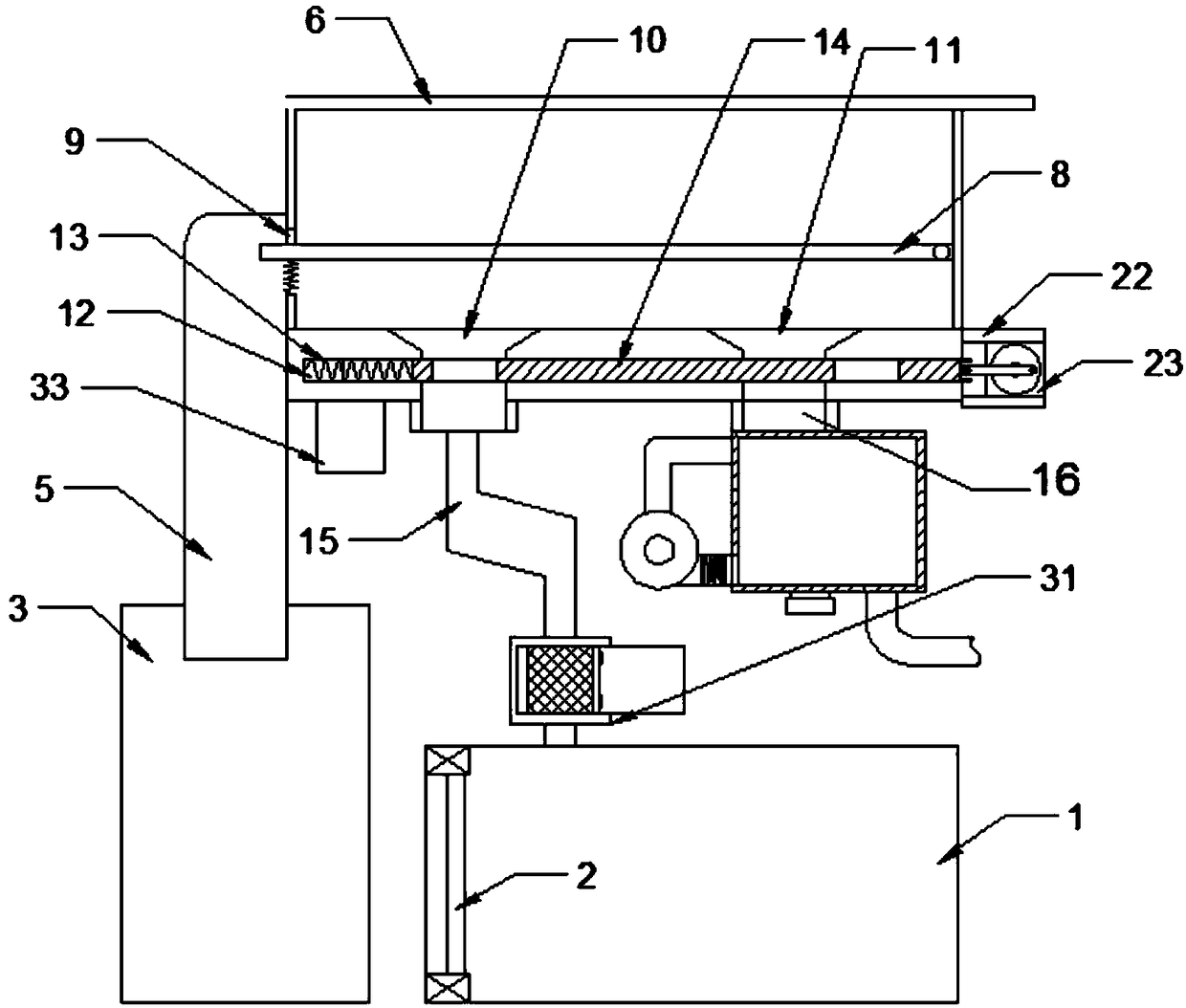

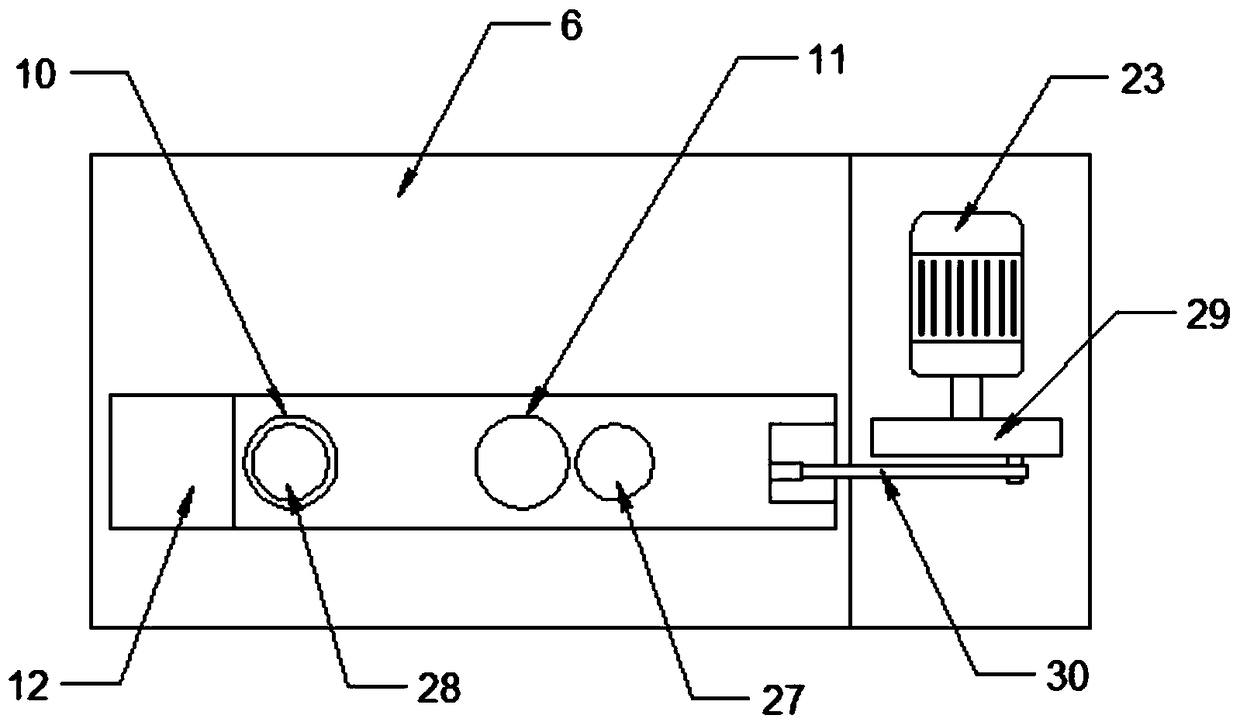

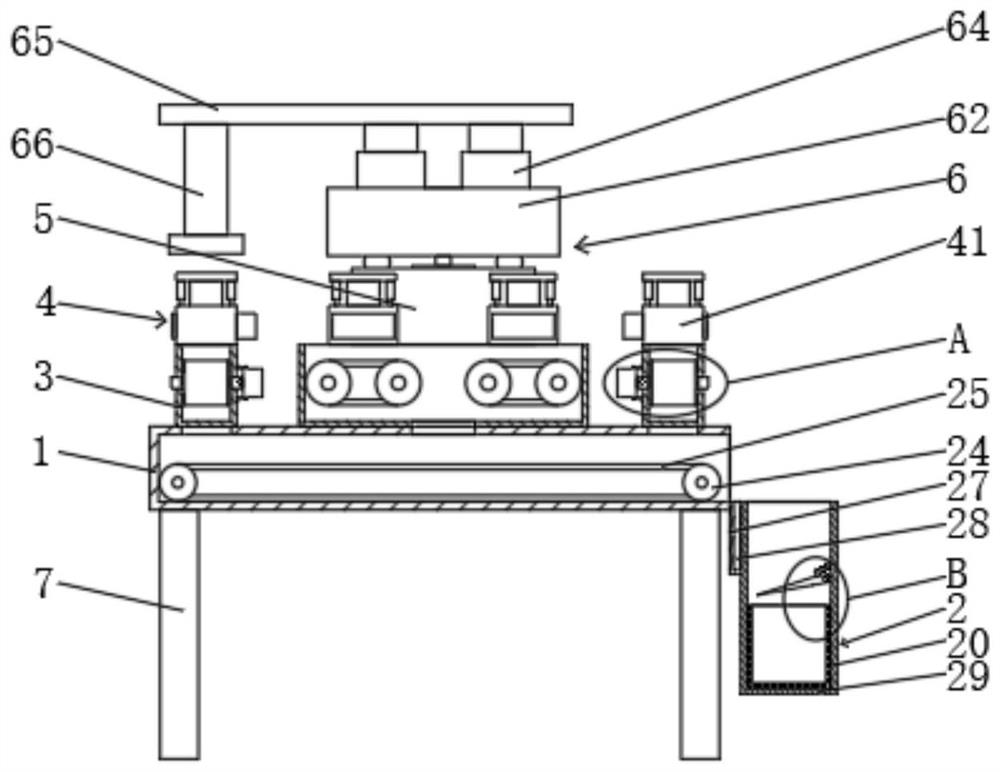

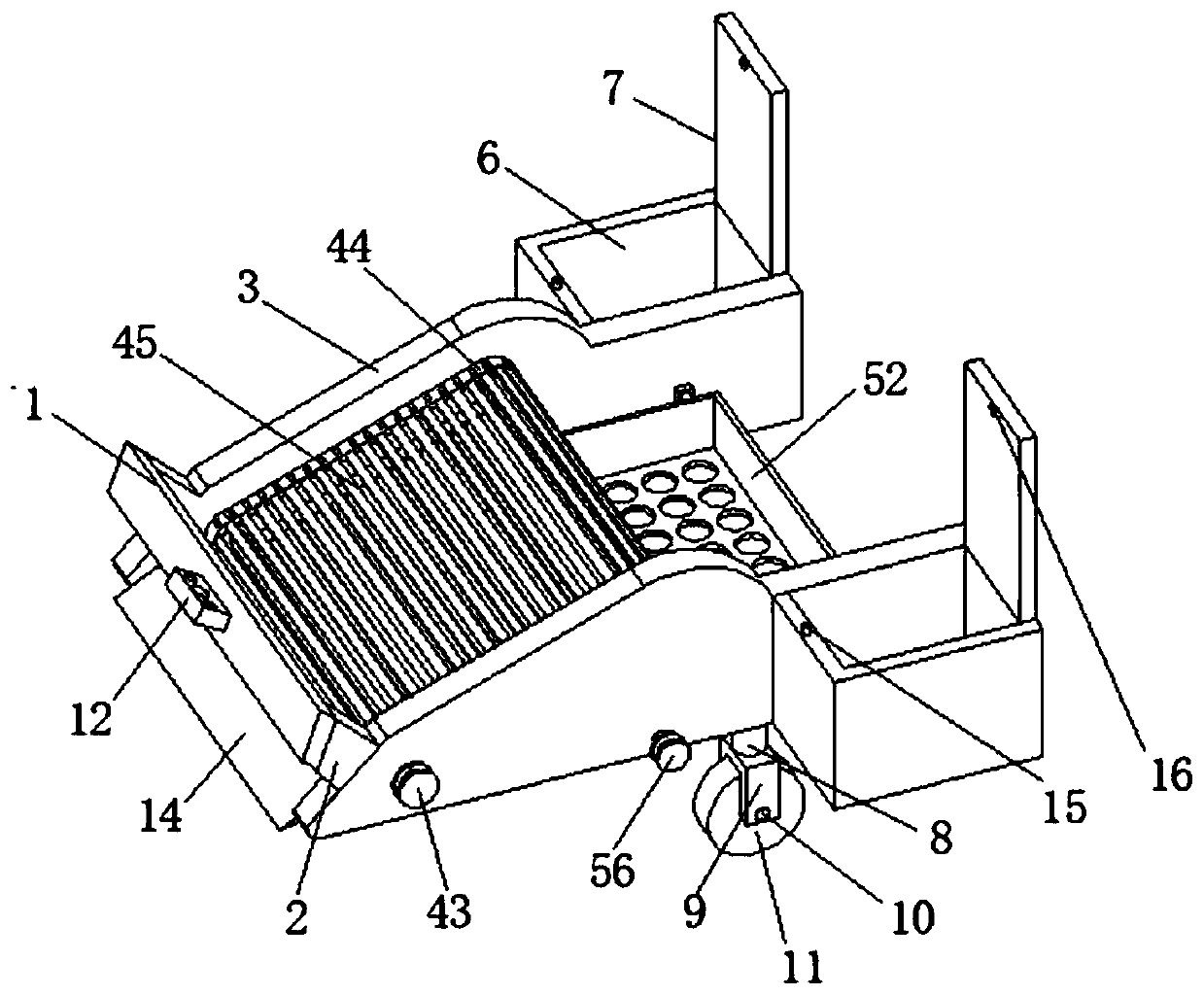

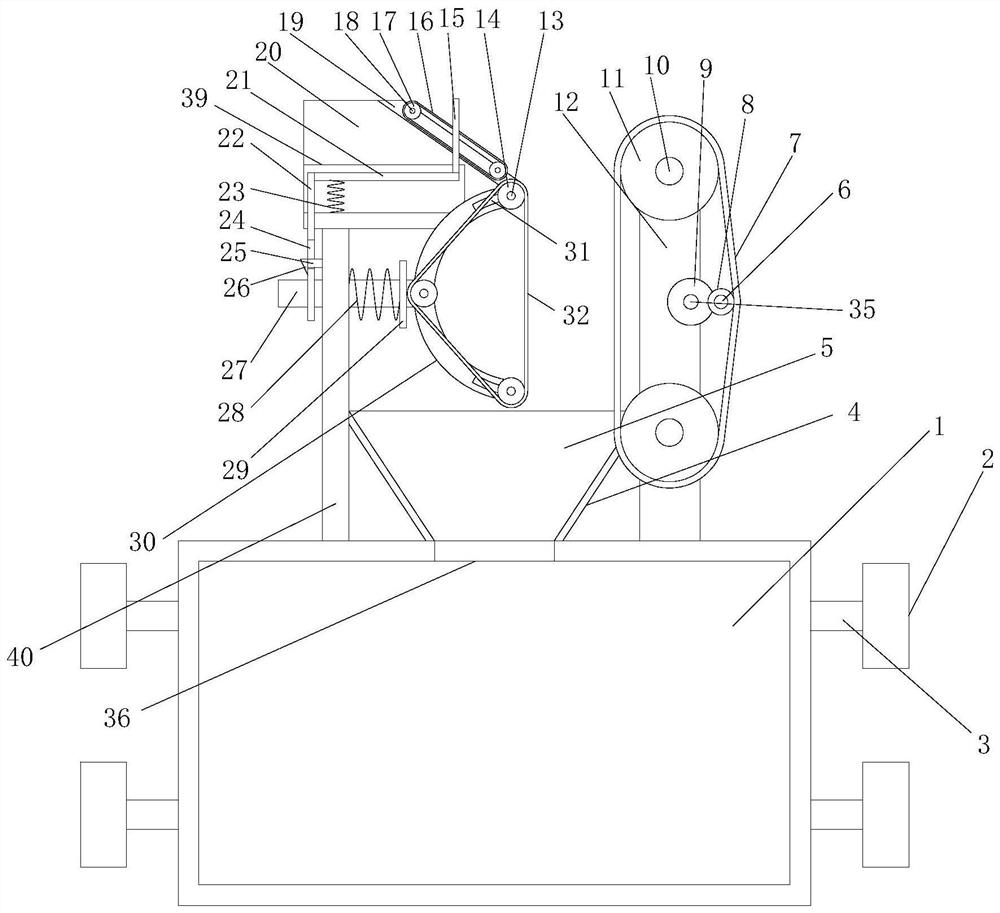

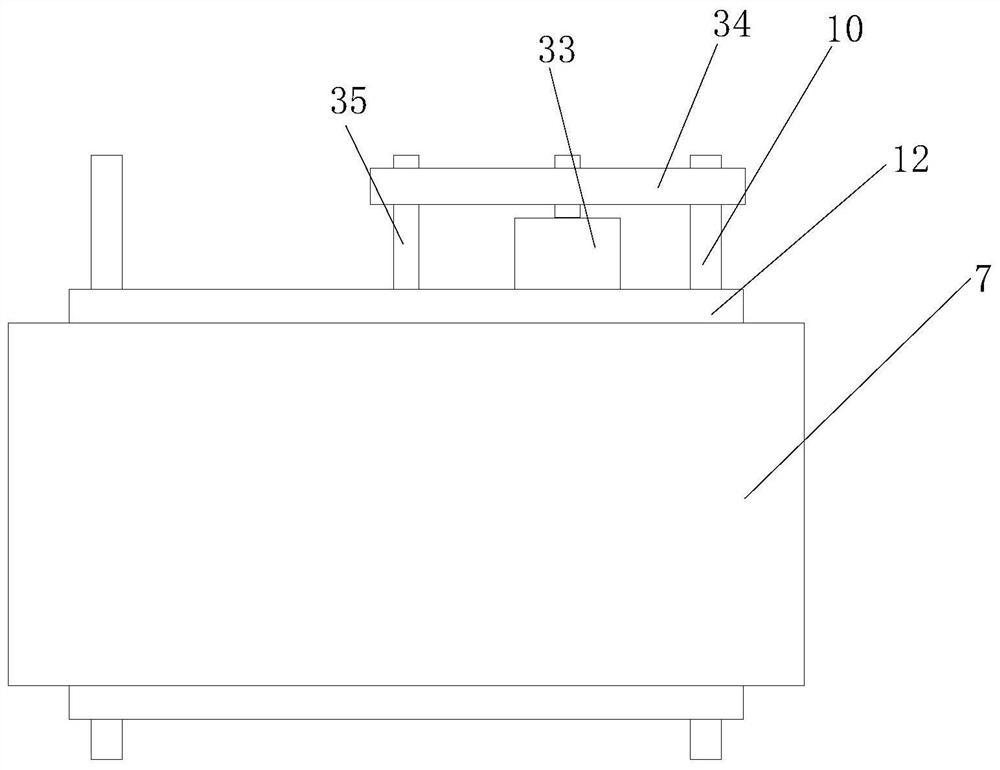

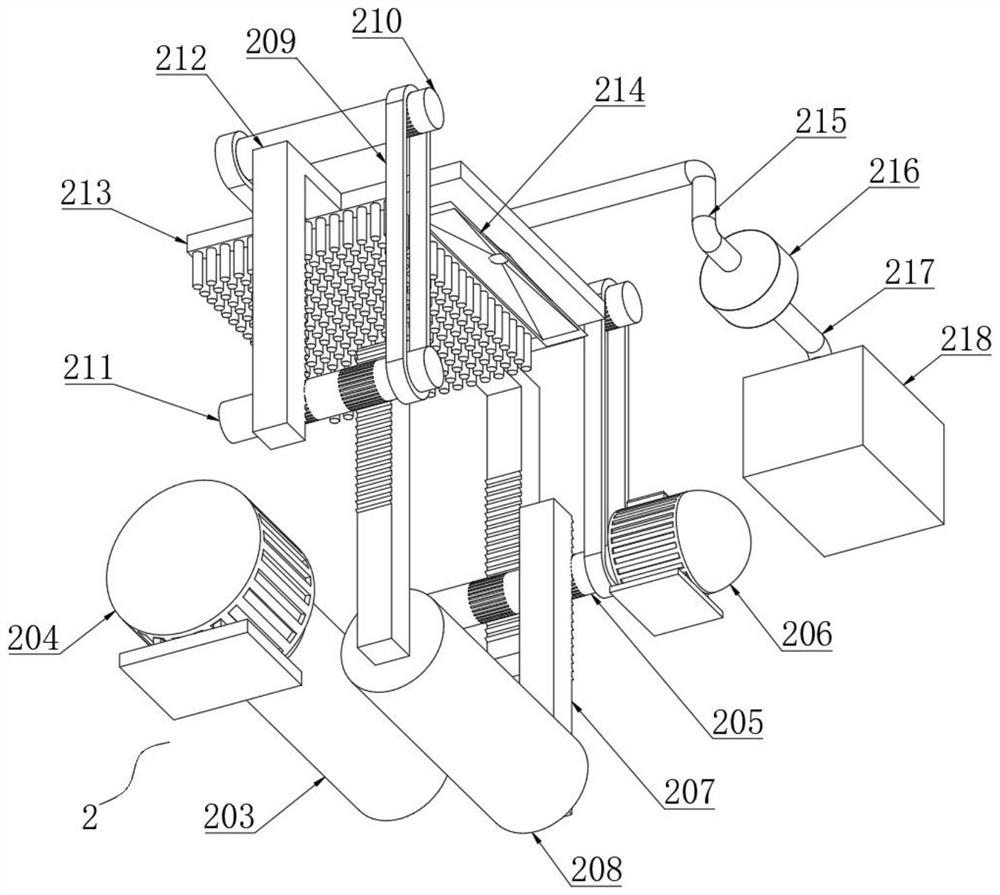

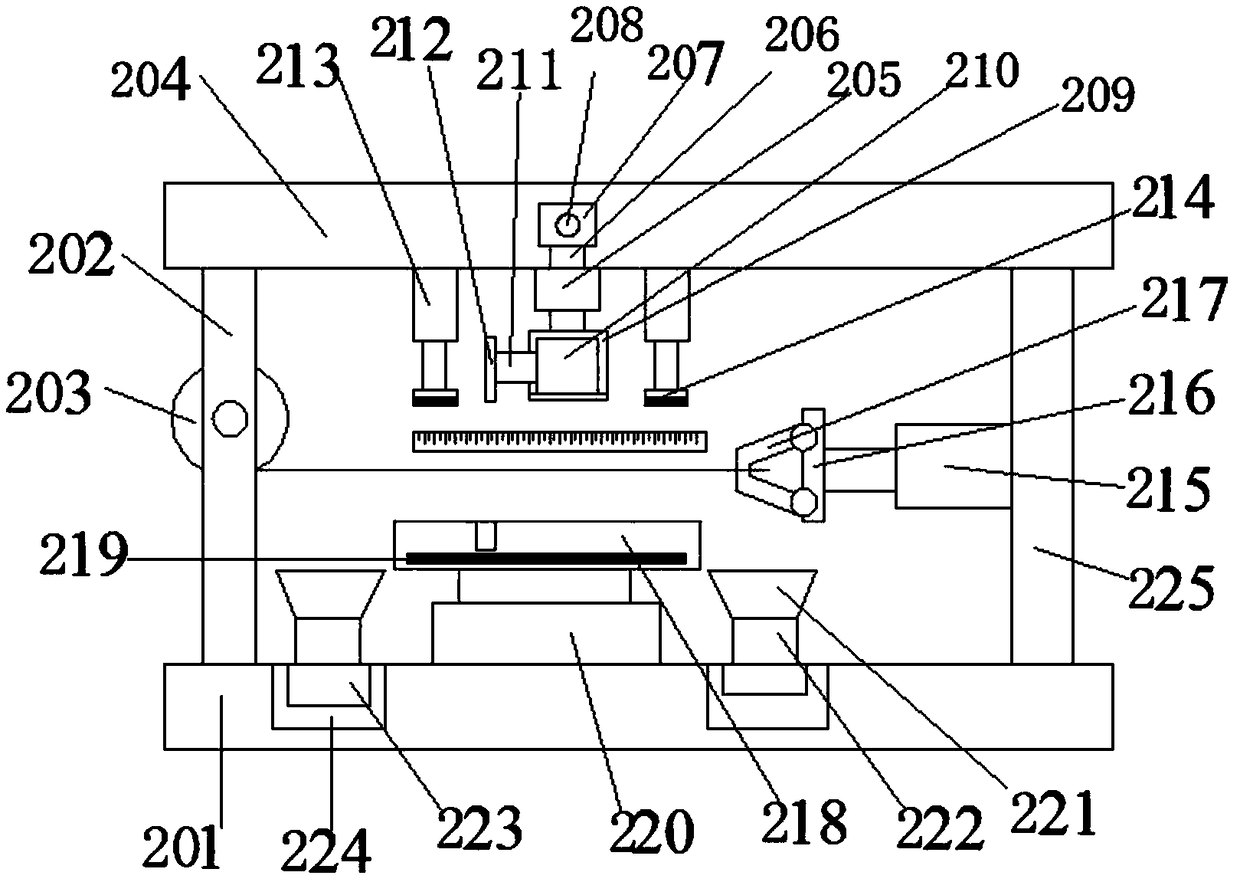

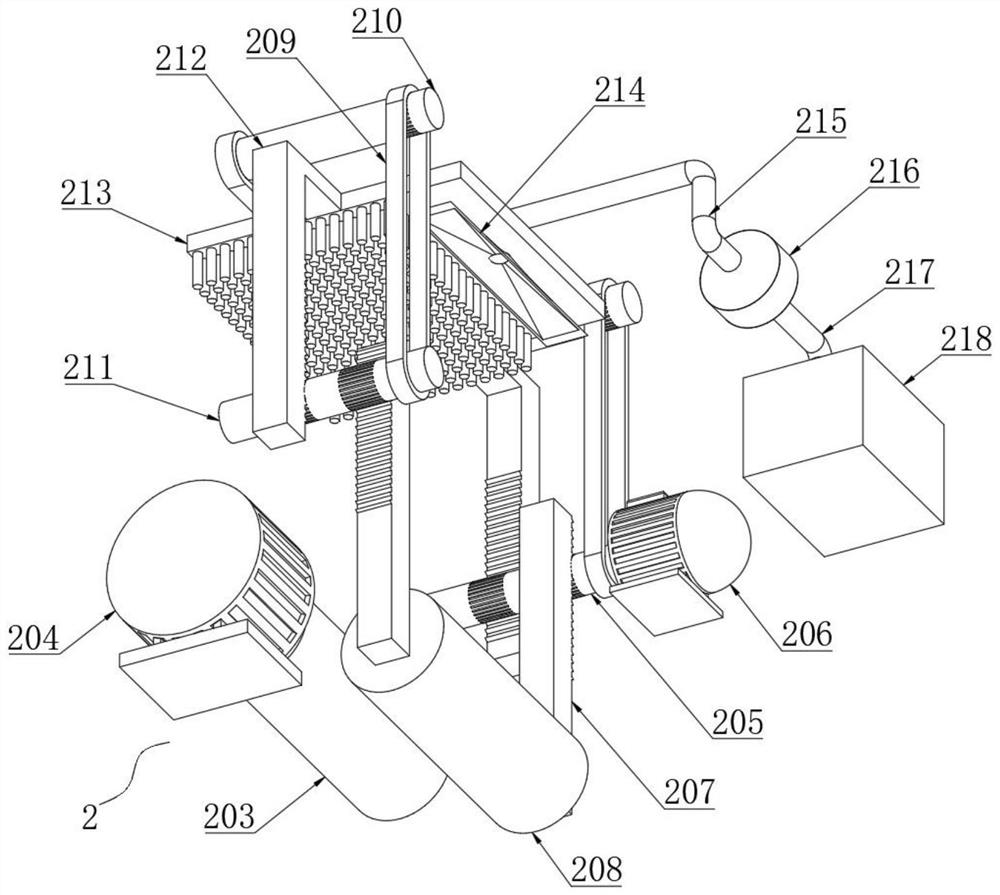

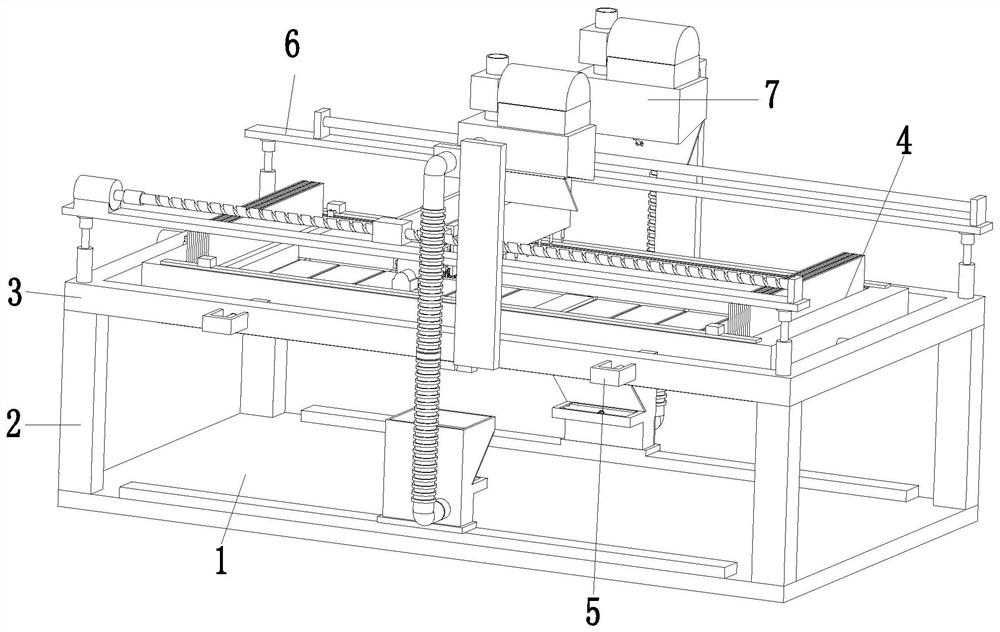

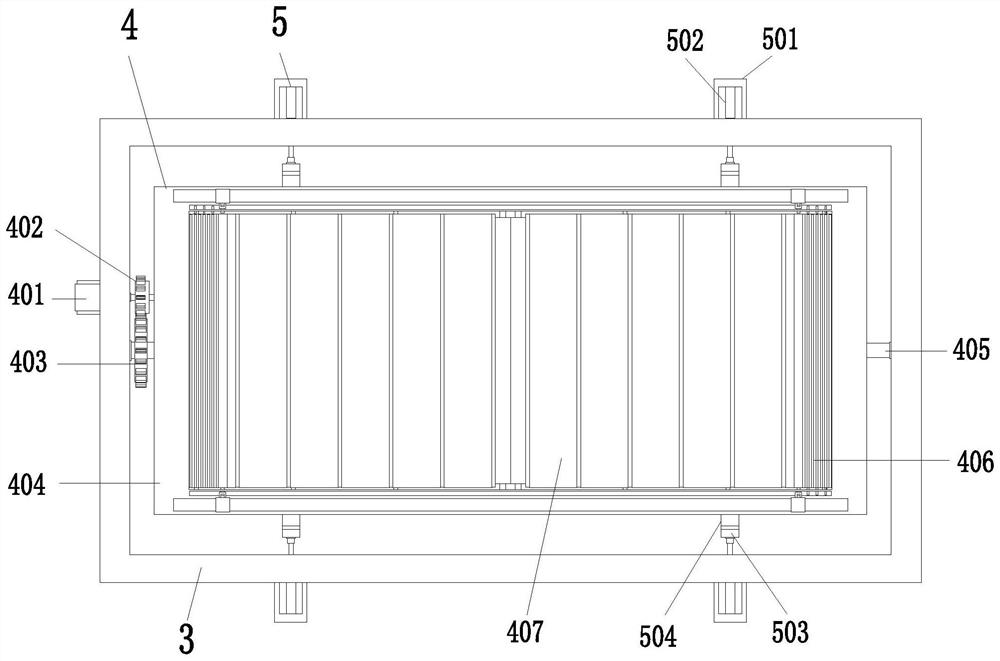

Tea leaf tedding and processing system and tea leaf tedding and processing method thereof

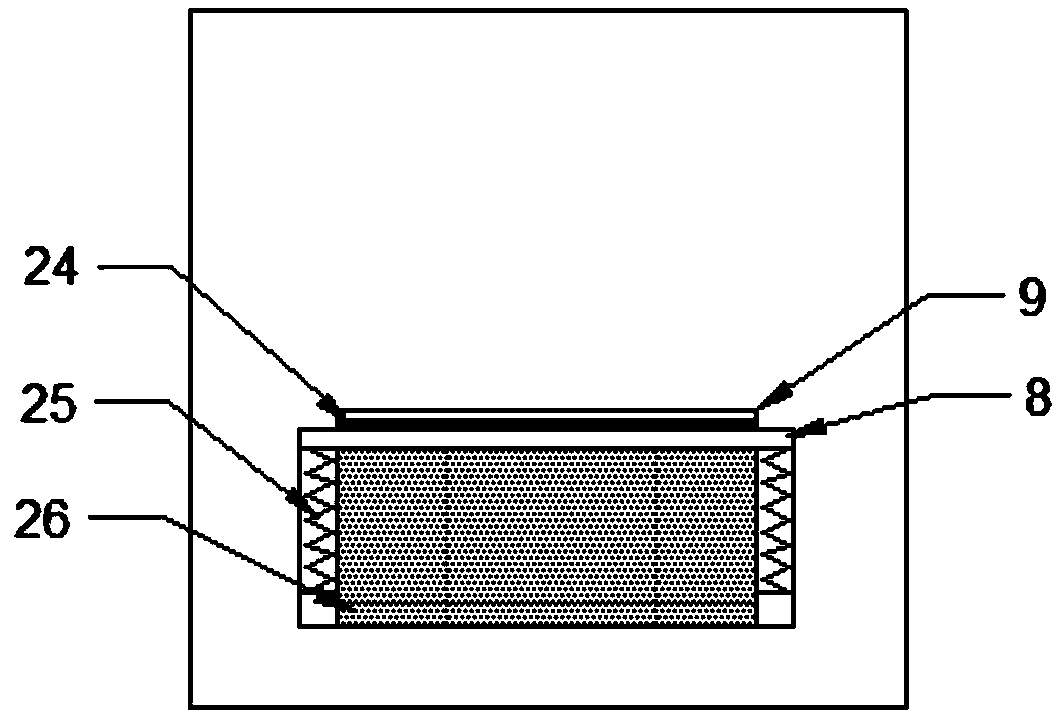

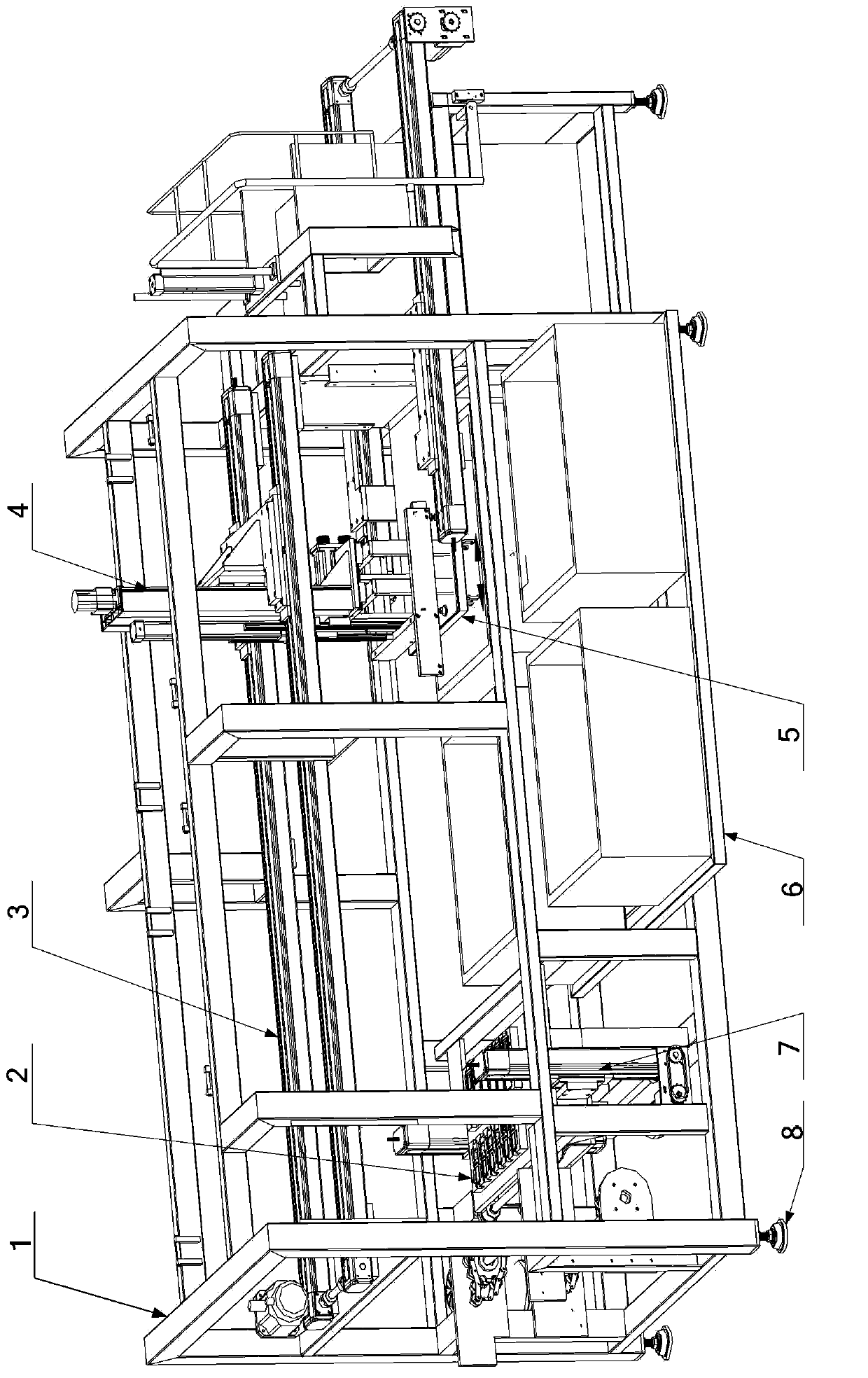

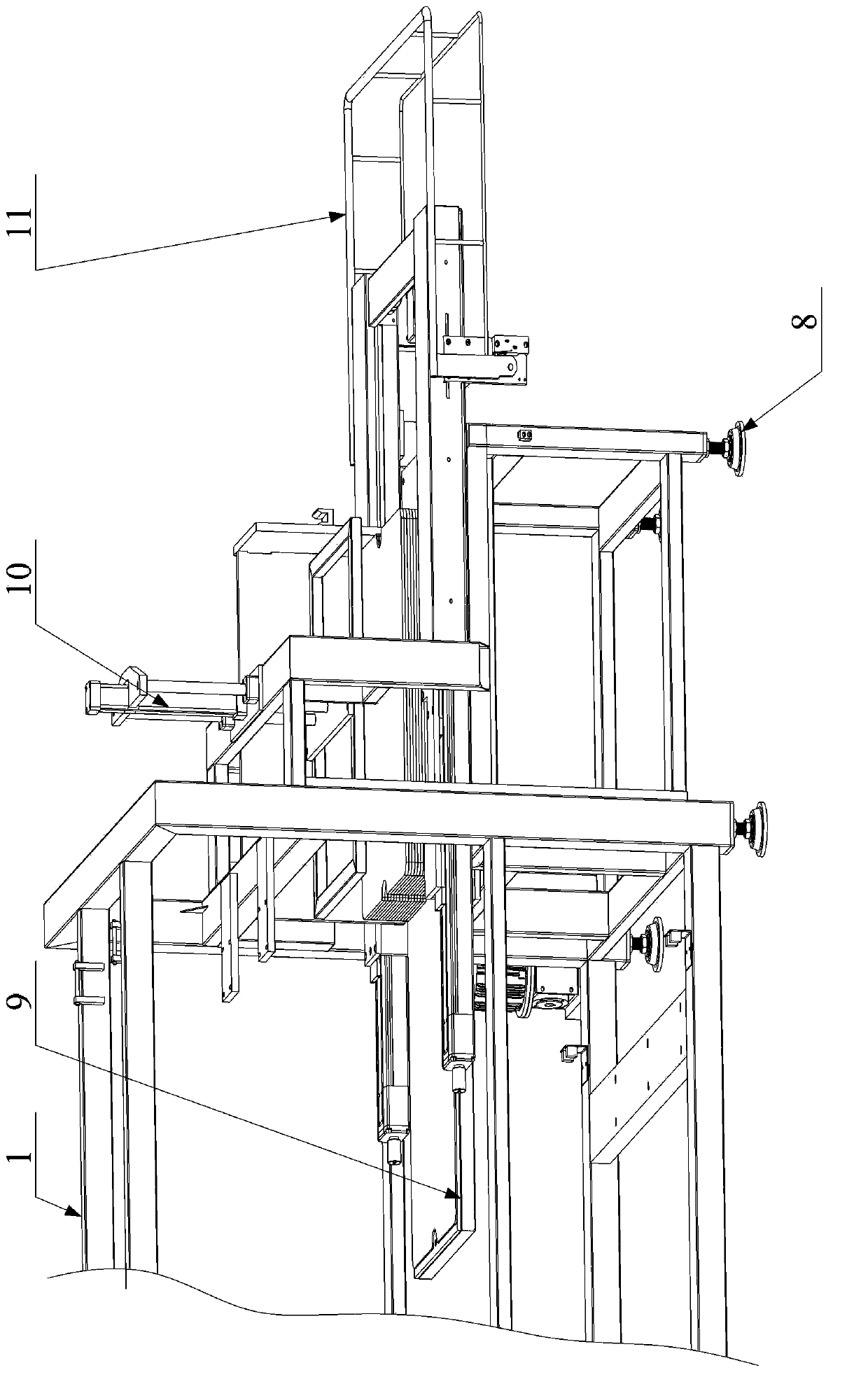

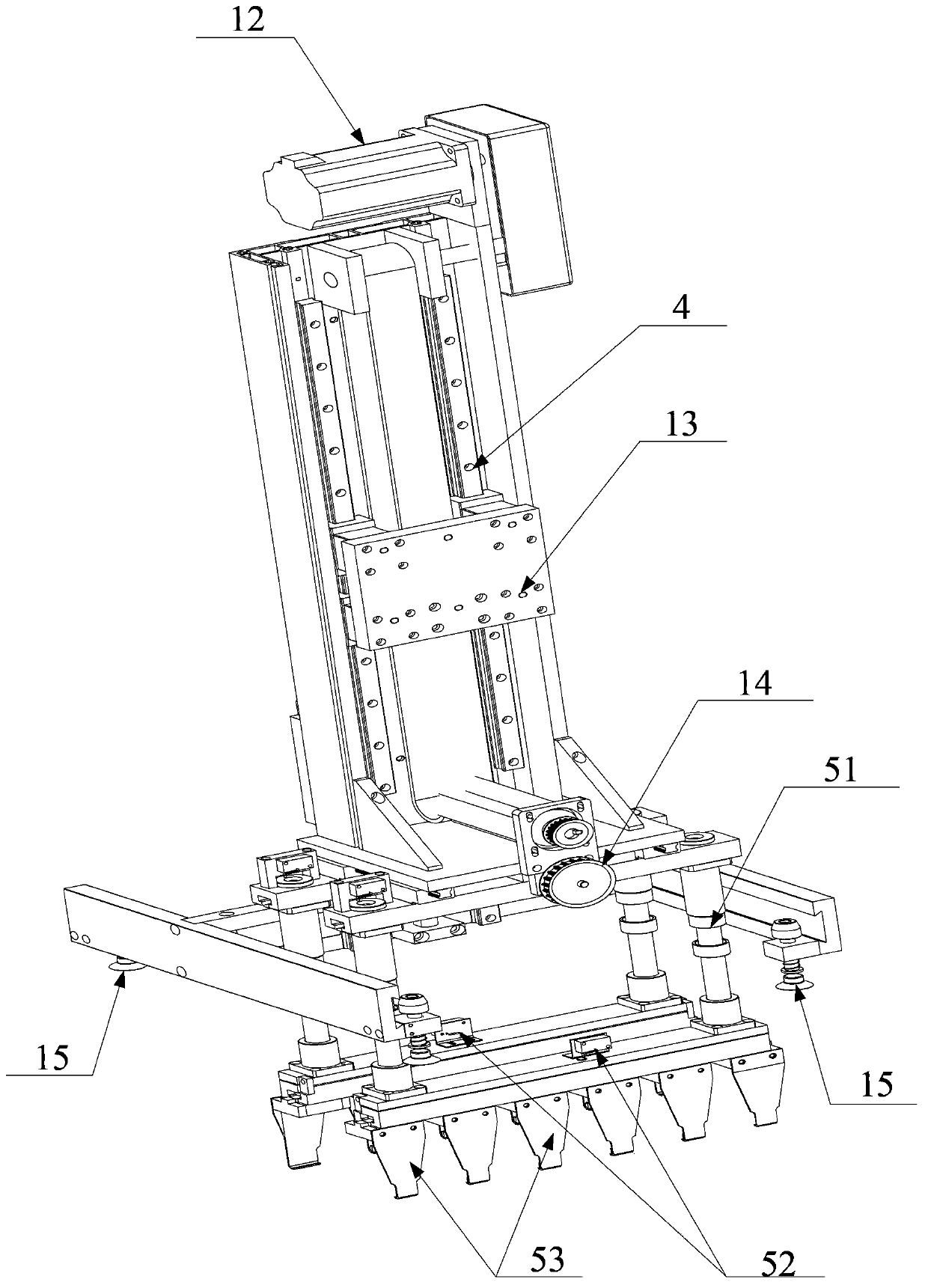

ActiveCN108782829AHigh degree of automationIncrease moisture contentPre-extraction tea treatmentLoss rateFixed frame

The present invention relates to a tea leaf tedding and processing system and a tea leaf tedding and processing method thereof. The tea leaf tedding and processing system comprises a bottom plate, four support columns, a supporting and fixing frame, a turning device, two positioning devices, a tedding device and two recycling devices; the upper end of the bottom plate is provided with the four support columns; the upper ends of the support columns are provided with the supporting and fixing frame; the middle part of the supporting and fixing frame is provided with the turning device; the two positioning devices are symmetrically arranged on the front and rear sides of the fixing and supporting frame; and the upper end of the turning device is provided with the tedding device. The tea leaftedding and processing system solves the following problems during tedding of tea leaves in the prior art: manual operations are usually used; the labor intensity of the manual tedding is high; the efficiency is low; the artificial tedding is uneven in thickness and cannot satisfy the thickness requirement of the tea leaves during the tedding of the tea leaves; besides, the tea leaves on the bottom layer are not easy to be turned over on the upper layer; the tea leaves on the bottom layer cannot be fully air-dried; the water loss rate of the tea leaves is affected; at the same time, the tea leaves are easy to fall during the tedding; the tea leaves cannot be collected automatically; the operation is complicated; the production efficiency is low; the stability is poor; and the tea leaves cannot be turned over automatically.

Owner:湖南壶瓶山茶业有限公司

BOPP (Biaxially-Oriented Polypropylene) slot-free holographic film and preparation method thereof

InactiveCN101927630AAvoid Manual PickingSave materialDecorative surface effectsPattern printingEngineeringPolypropylene

The invention discloses a BOPP (Biaxially-Oriented Polypropylene) slot-free holographic film and a preparation method thereof, belonging to the technical field of anti-counterfeiting printing. The BOPP slot-free holographic film is characterized by being free of slot and prepared by impressing a continuous panel without the slot, wherein the continuous panel comprises a flexible substrate; and an imaged coating is attached to the substrate and carries holographic information. The BOPP holographic film has no slot, can save the materials and prevent manual picking of unqualified products when in later use and is convenient to apply.

Owner:SHANDONG TAIBAO PACKAGING PROD

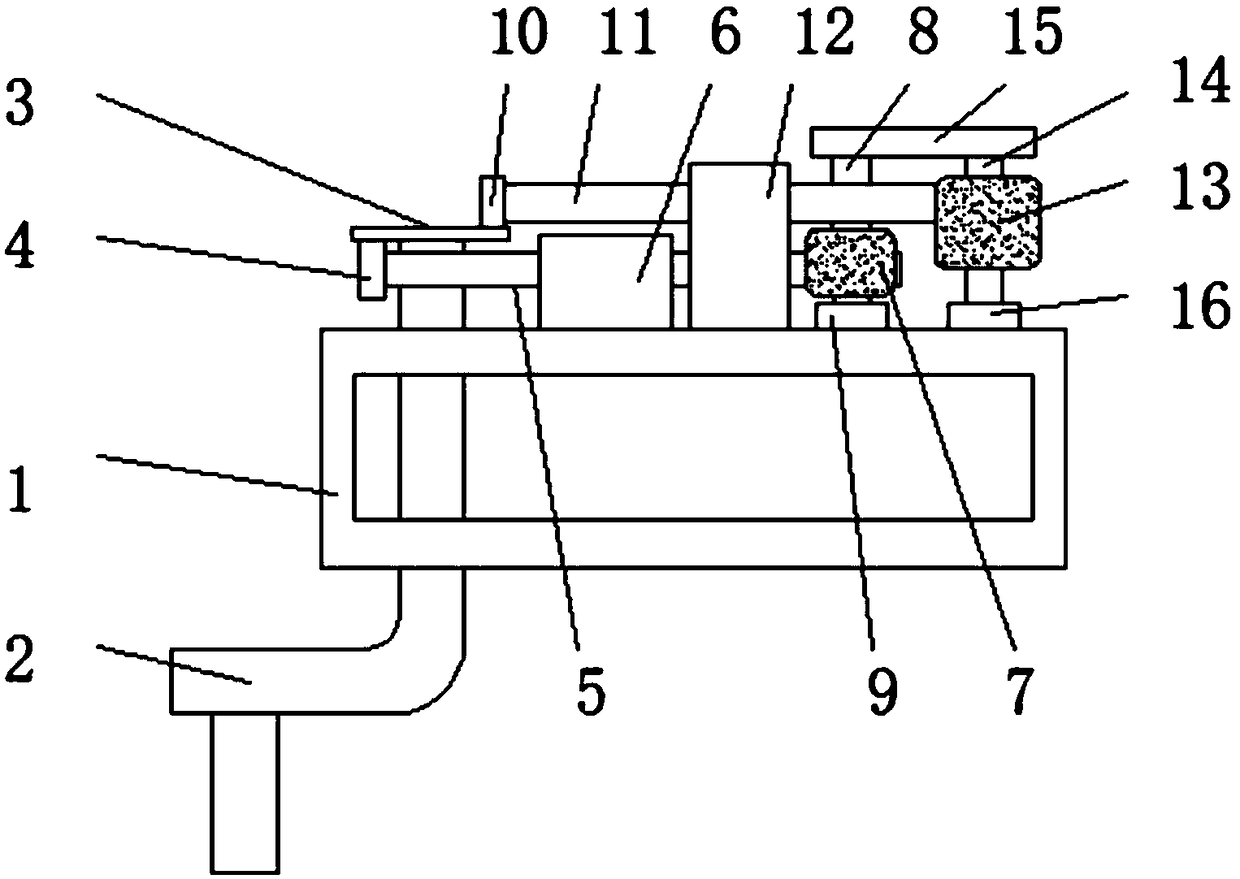

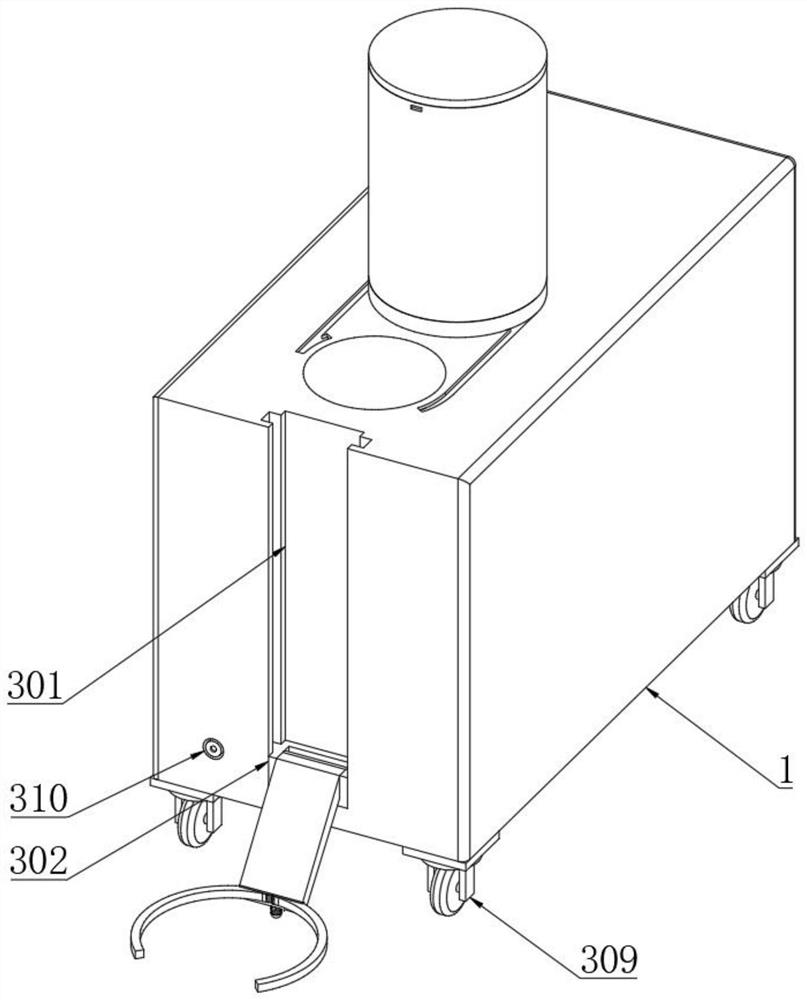

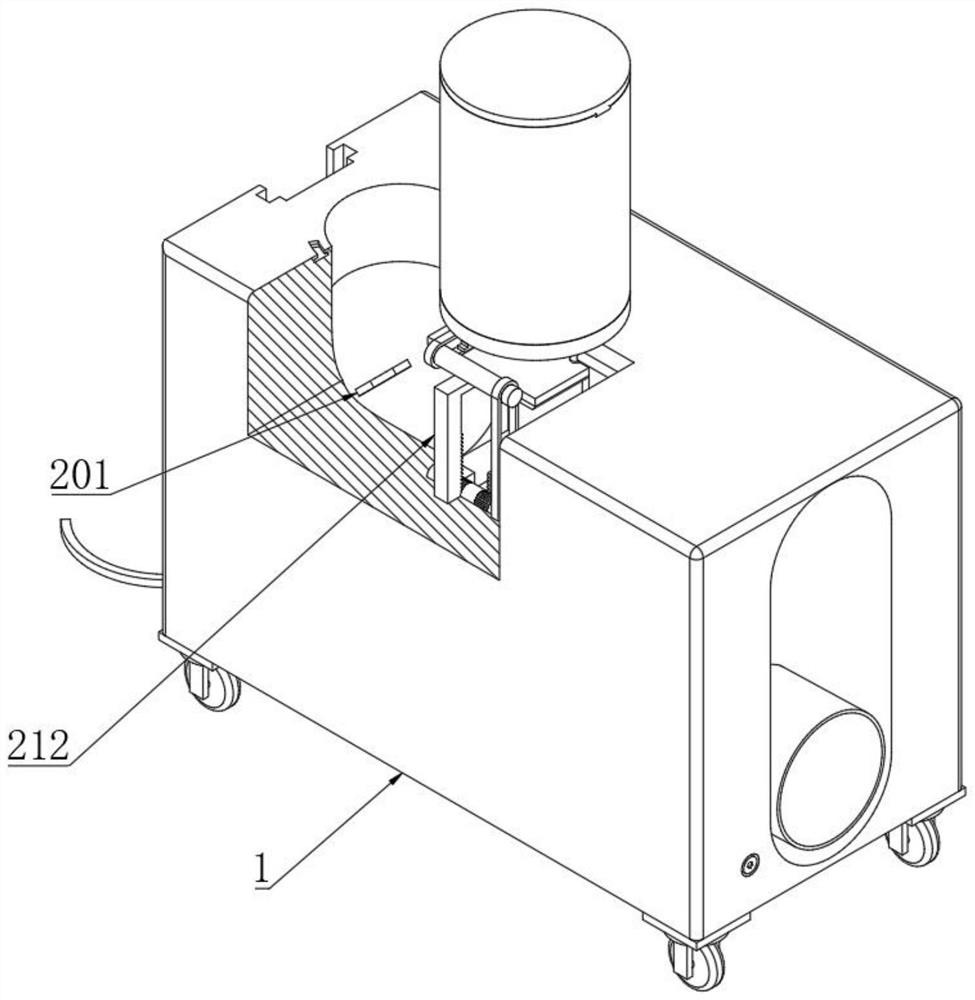

Metal machining debris collecting device

InactiveCN110253441AReduce the space occupied by the collectionAvoid harmGrinding/polishing safety devicesMetal machiningEngineering

The invention belongs to the technical field of metal debris collection, and particularly relates to a metal machining debris collecting device. According to the scheme aiming at solving the problem that existing metal debris is large in occupied space, the metal machining debris collecting device comprises a bottom plate, a liquid collecting box, a mounting frame, a first mounting plate, a sealing assembly, an extrusion box and an anti-falling assembly; the bottom plate is provided with the liquid collecting box and the mounting frame; the first mounting plate on the mounting frame is provided with a material receiving box; a liquid collecting bin and a debris bin are arranged in the material receiving box; the liquid collecting bin communicates with the liquid collecting box; a discharge pipe is arranged in a discharge hole of the debris bin; the sealing assembly is arranged at a pipe opening at the lower end of the discharge pipe; the discharge pipe communicates with the extrusion bin in the extrusion box; an extrusion plate is arranged in the extrusion box in a sliding mode and is connected with a first telescopic device; and the anti-falling assembly is arranged below the extrusion box. The metal machining debris collecting device can effectively separate debris and grinding liquid after metal machining and squeeze the metal debris to reduce space for metal debris collection, and is easy to operate and convenient to use.

Owner:徐州三美电器科技有限公司

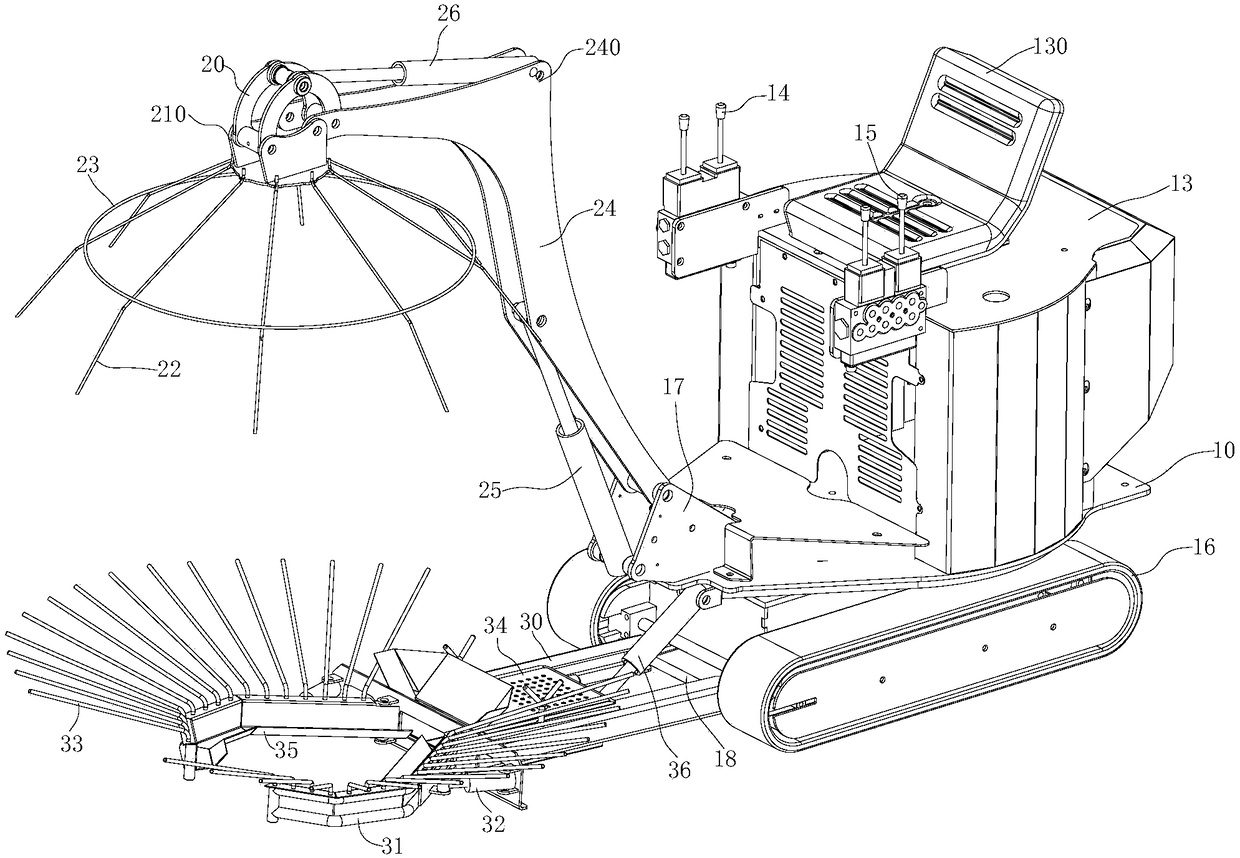

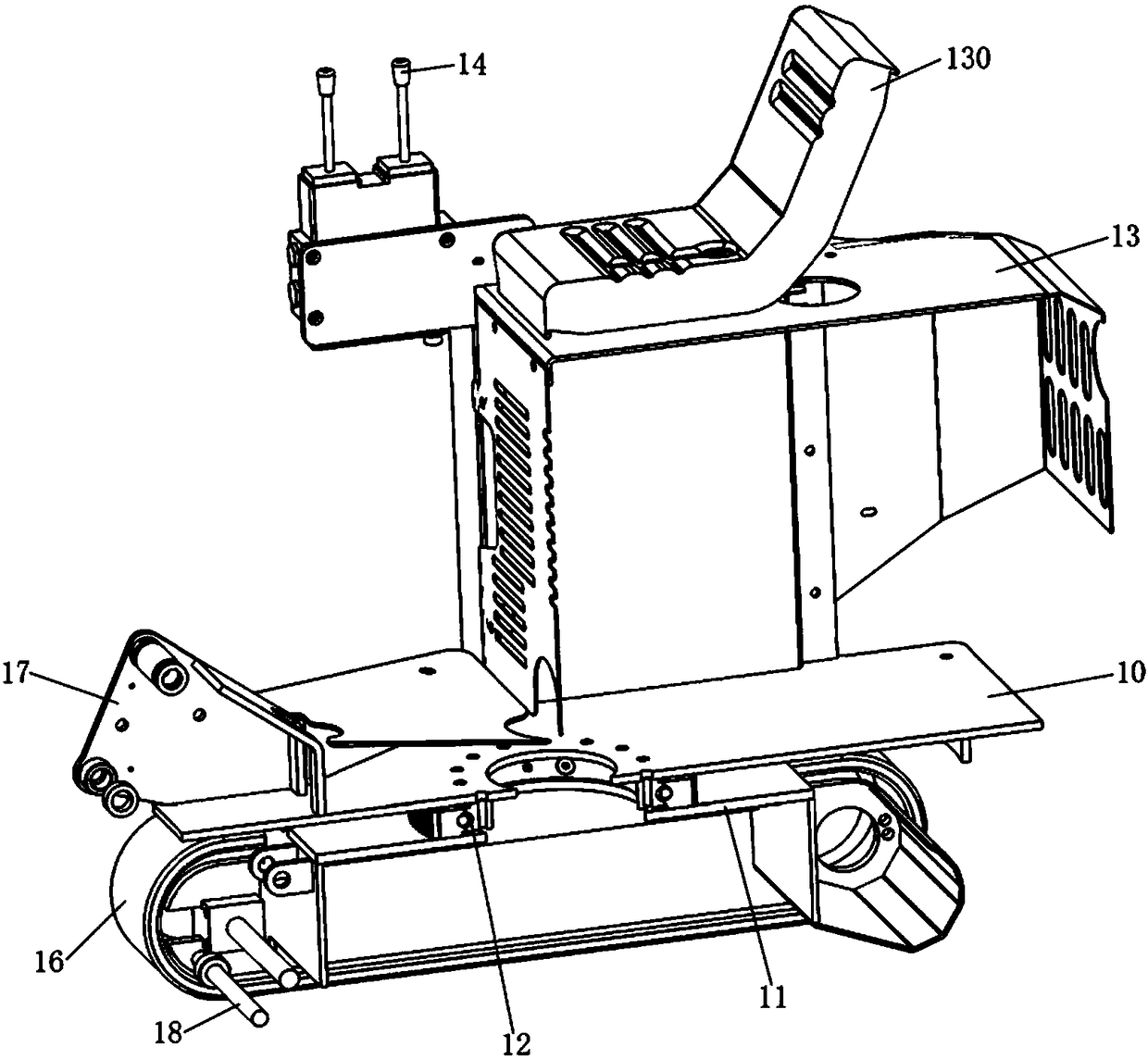

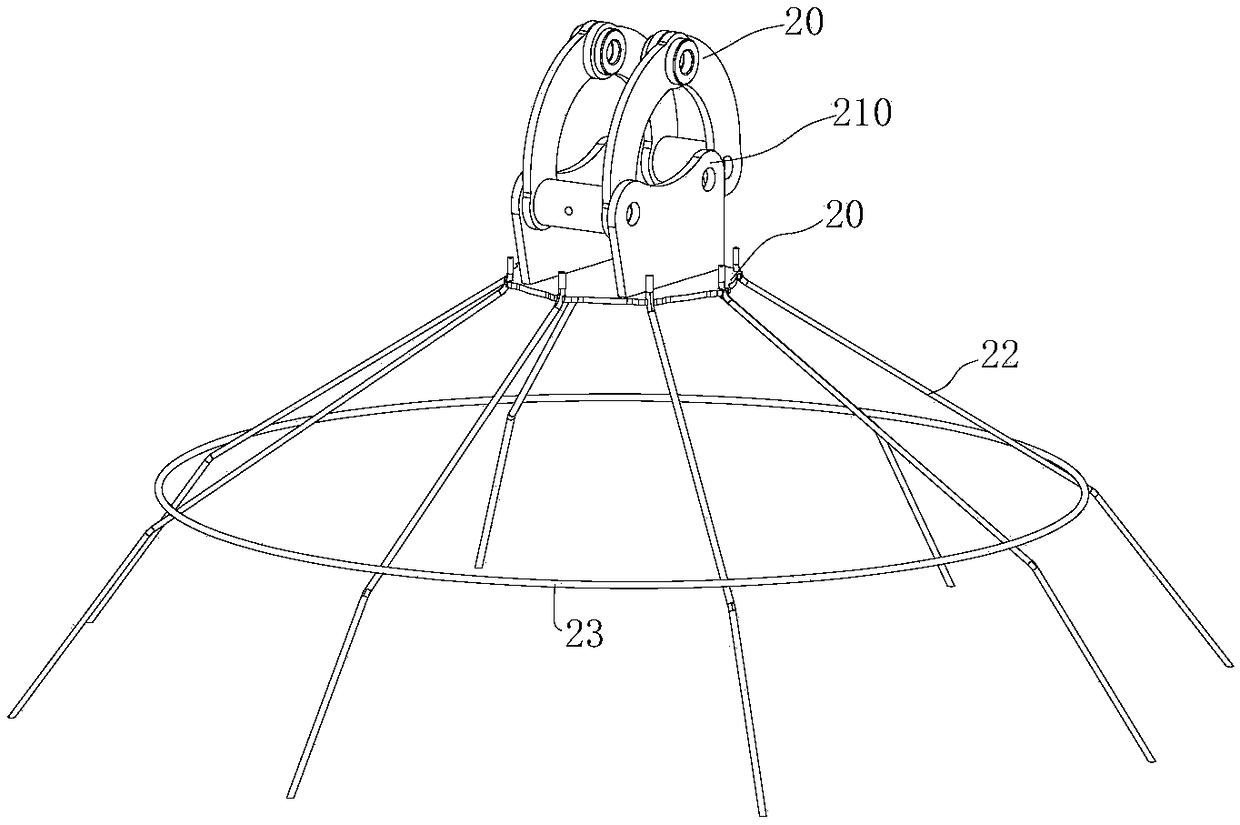

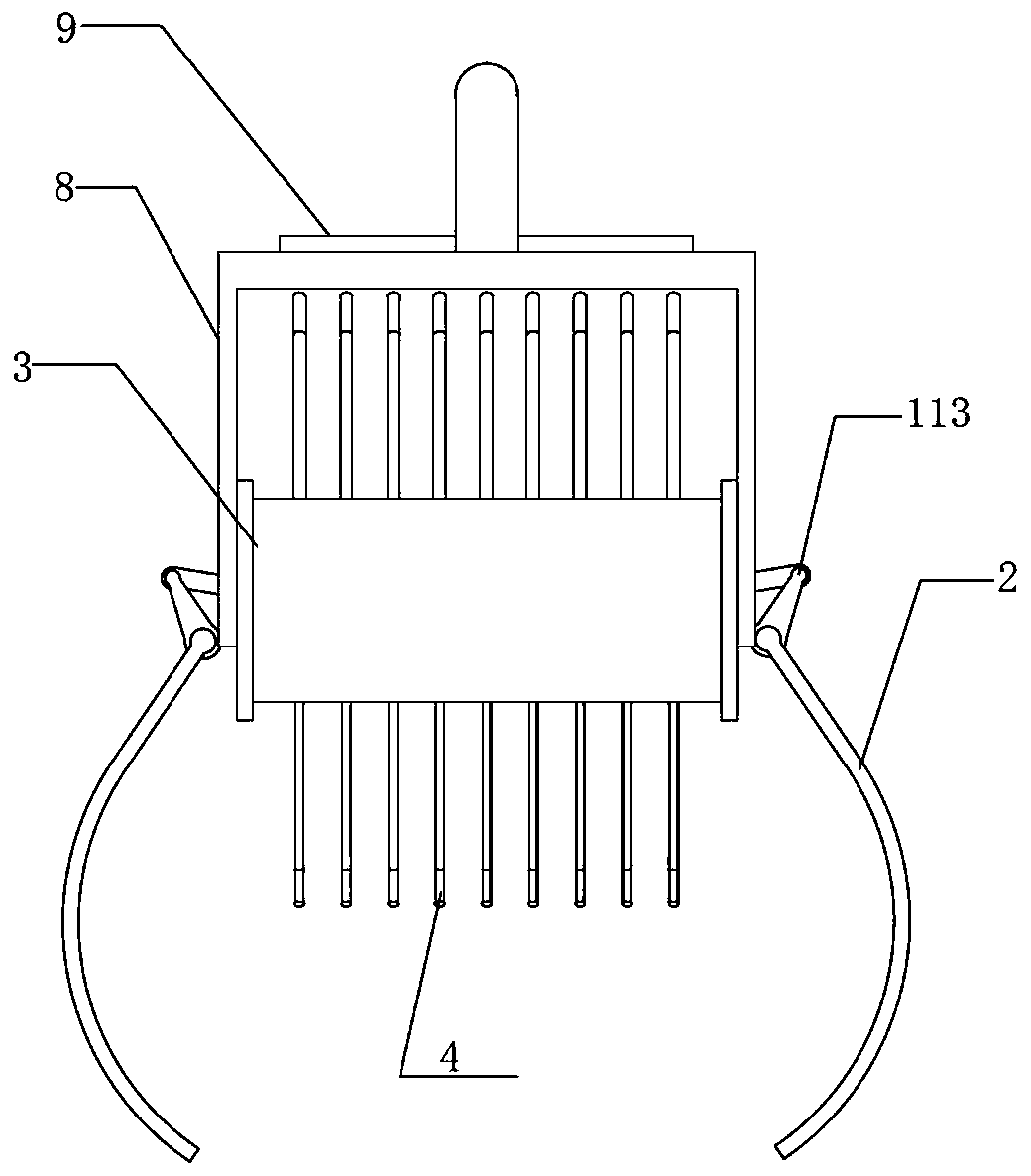

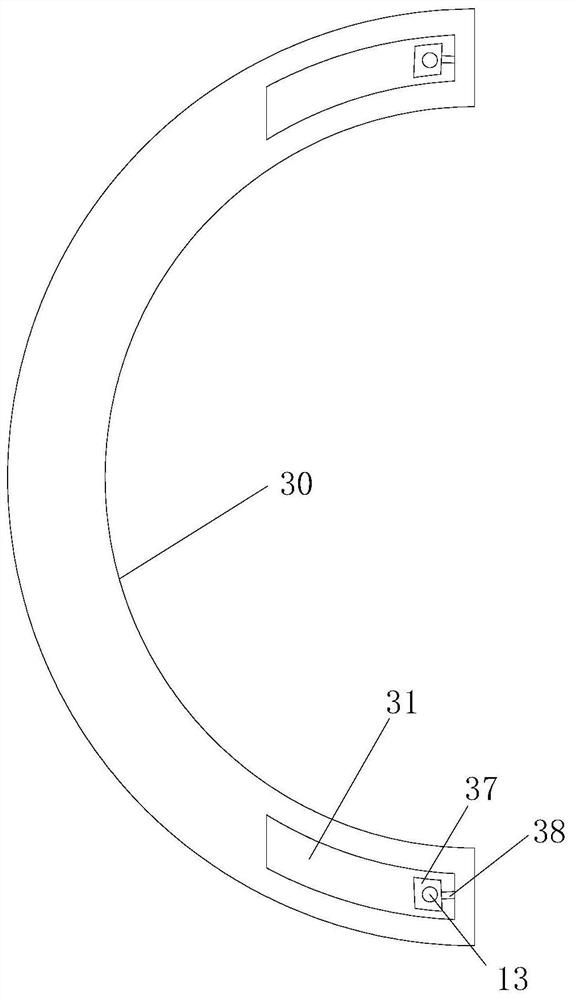

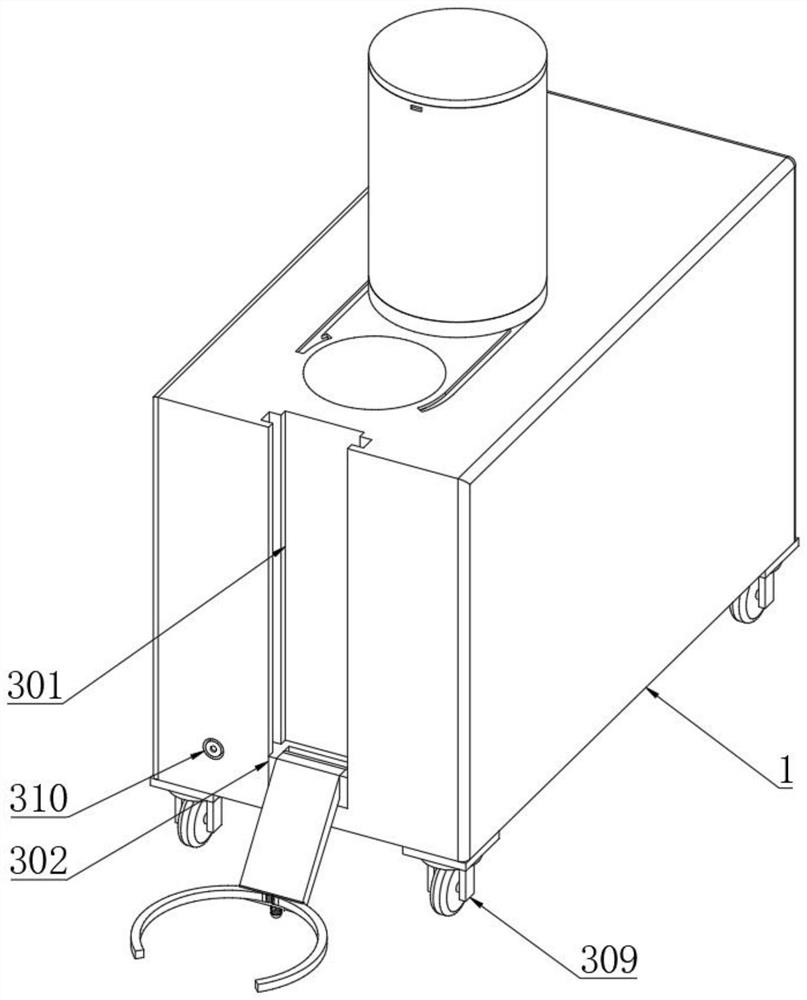

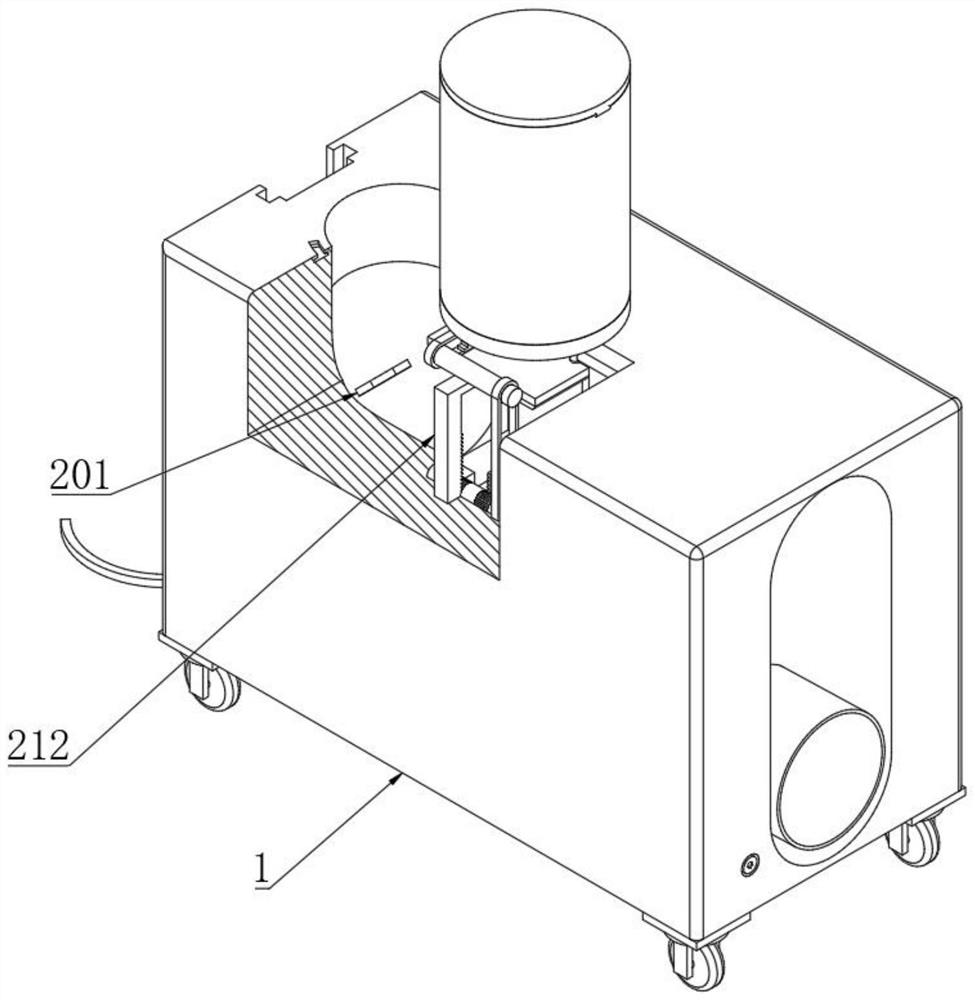

Bush fruit harvester

The invention discloses a bush fruit harvester, comprising: a traveling device; an enclosure mechanism that applies shaking or patting force to bushes, wherein one end of the enclosure mechanism is connected with the traveling device, and the other end of the enclosure mechanism is a free end that encloses the top of the bushes and / or part of the side of the bushes; a fruit collecting mechanism, wherein part of the fruit collecting mechanism is used for surrounding trunks of the bushes and for collecting fruits fallen when the enclosure mechanism shakes or pats the bushes, one end of the fruitcollecting mechanism is connected with the traveling device, and the fruit collecting mechanism is positioned below the enclosure mechanism. The bush fruit harvester can prevent fruits from being damaged during harvesting.

Owner:CHANGZHOU CLOVERAGRI MACHINERY CO LTD

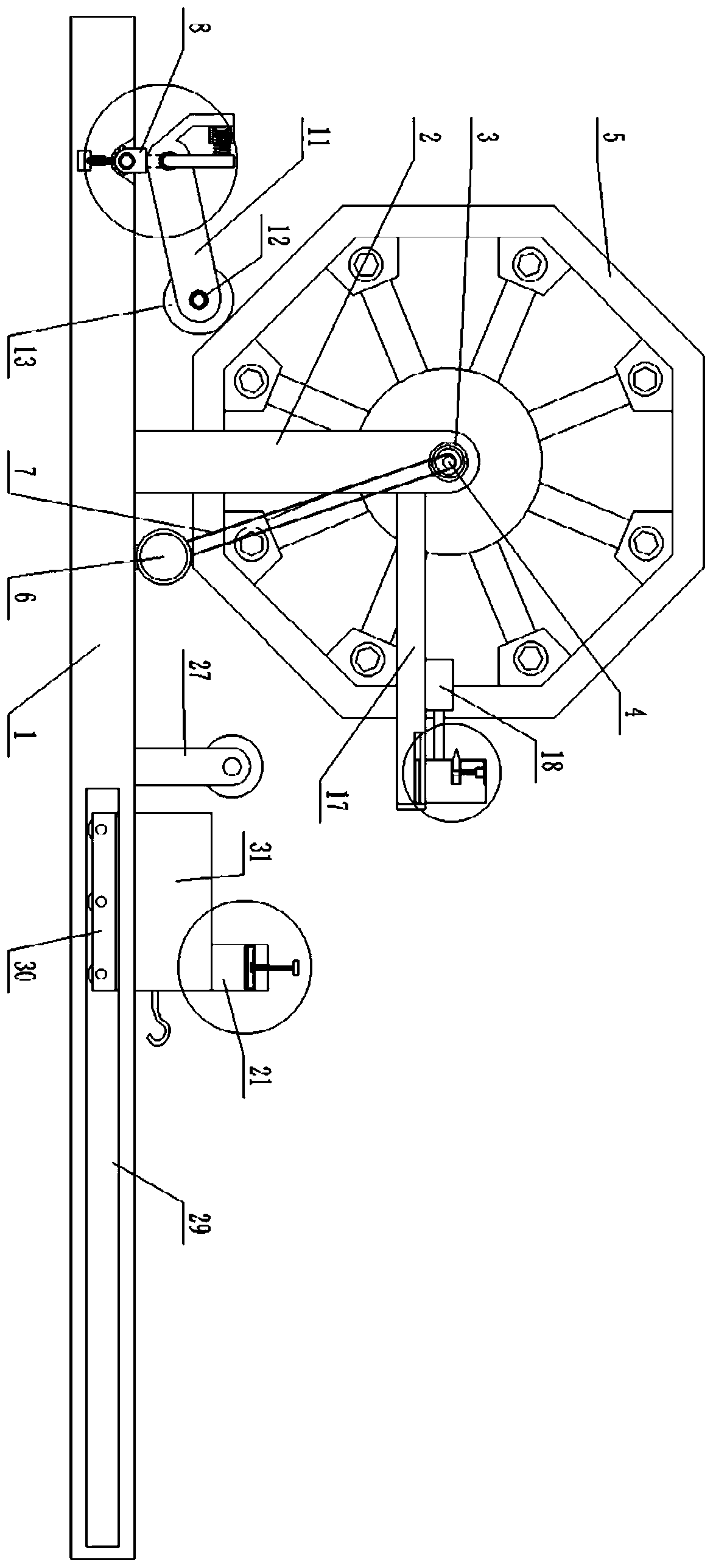

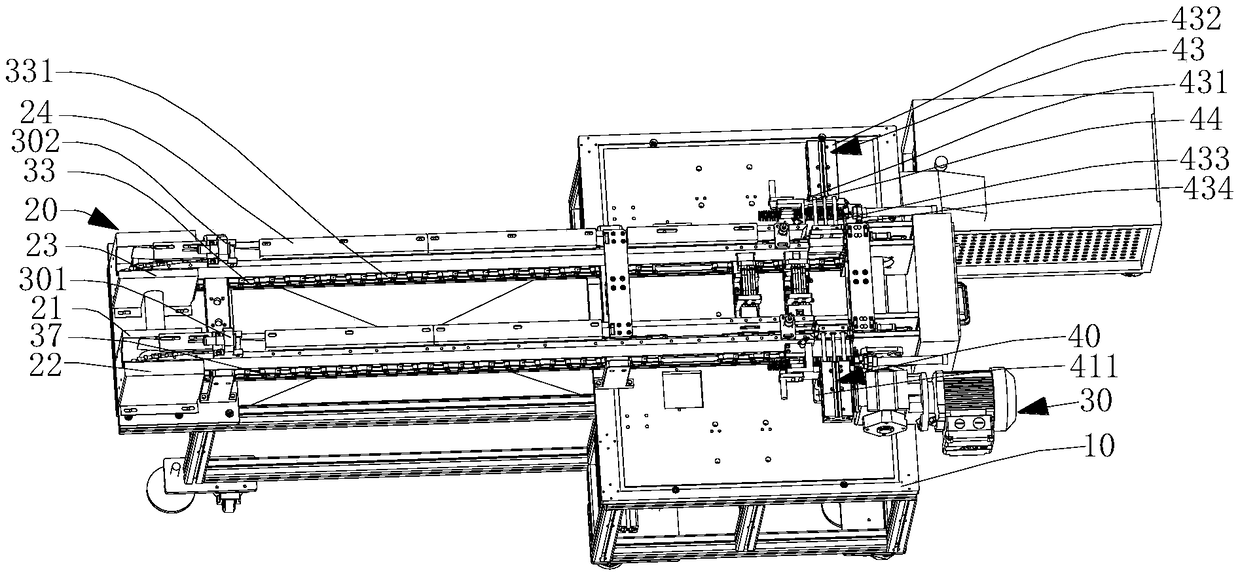

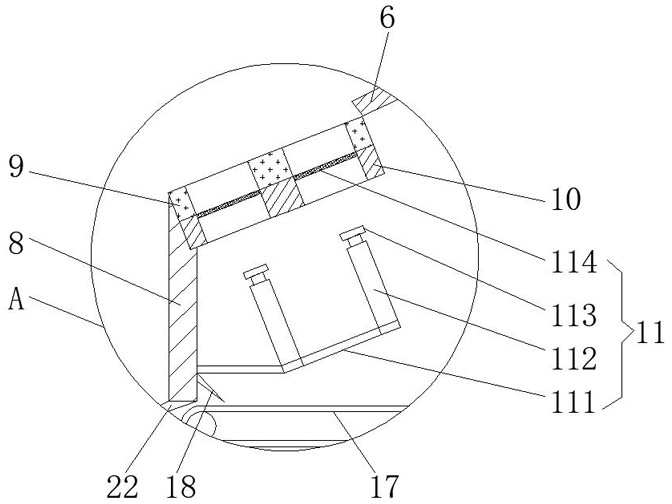

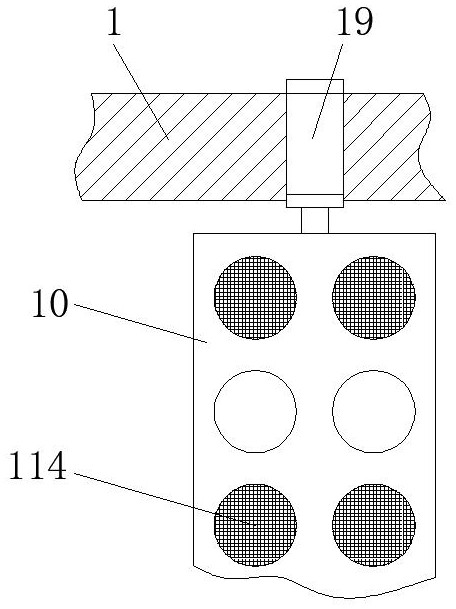

Automatic octagonal system production equipment for paper box production

ActiveCN110524950AEasy to processAvoid Manual PickingBox making operationsPaper-makingMechanical engineeringExpanded access

The invention discloses automatic octagonal system production equipment for paper box production. The equipment comprises a bottom plate, a connecting rod, a bearing A, a shaft rod A, an octagonal frame, a motor and a belt, and the lower end of the connecting rod is connected to the front side and the rear side of the upper surface of the bottom plate correspondingly. The bearing A is fixedly embedded in the upper end of the connecting rod; the shaft rod A is fixedly sleeved in the bearing A; the front side surface and the rear side surface of the octagonal frame are connected with the shaft rod A; the motor is connected to the upper surface of the bottom plate, the output end of the motor and the shaft rod A are sleeved in the belt, a pressing mechanism is arranged on the upper surface ofthe bottom plate, a cutting mechanism is connected to the side surface of the connecting rod, and a conveying mechanism is arranged on the bottom plate. The equipment has the beneficial effects thatthe angle of the rolling wheel is adjusted through the adjusting part of the pressing mechanism, so that the application range is expanded, manual taking is prevented after cutting is facilitated through the cutting mechanism and the conveying mechanism, and unnecessary injuries are effectively avoided.

Owner:重庆英耐尔科技有限公司

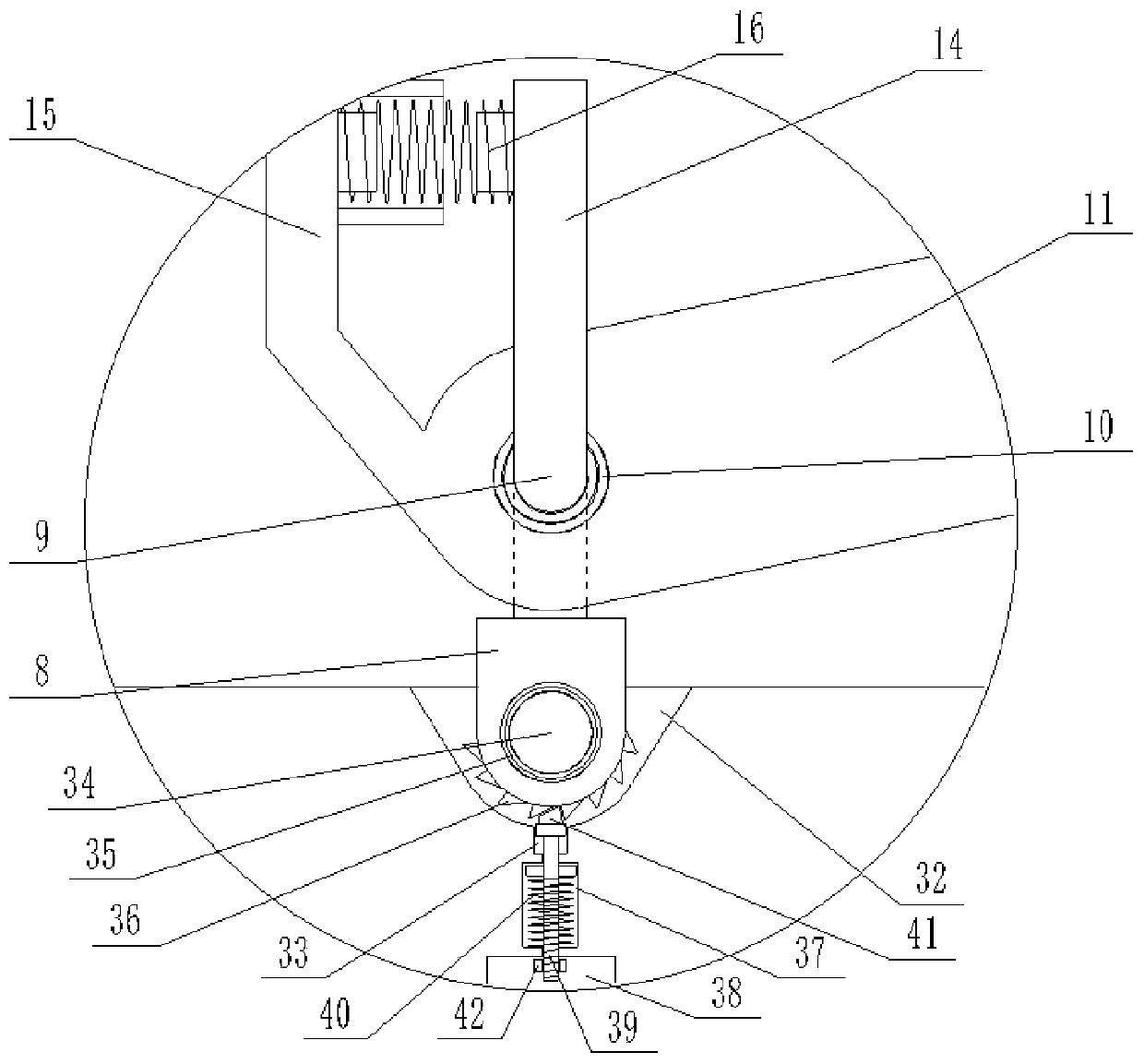

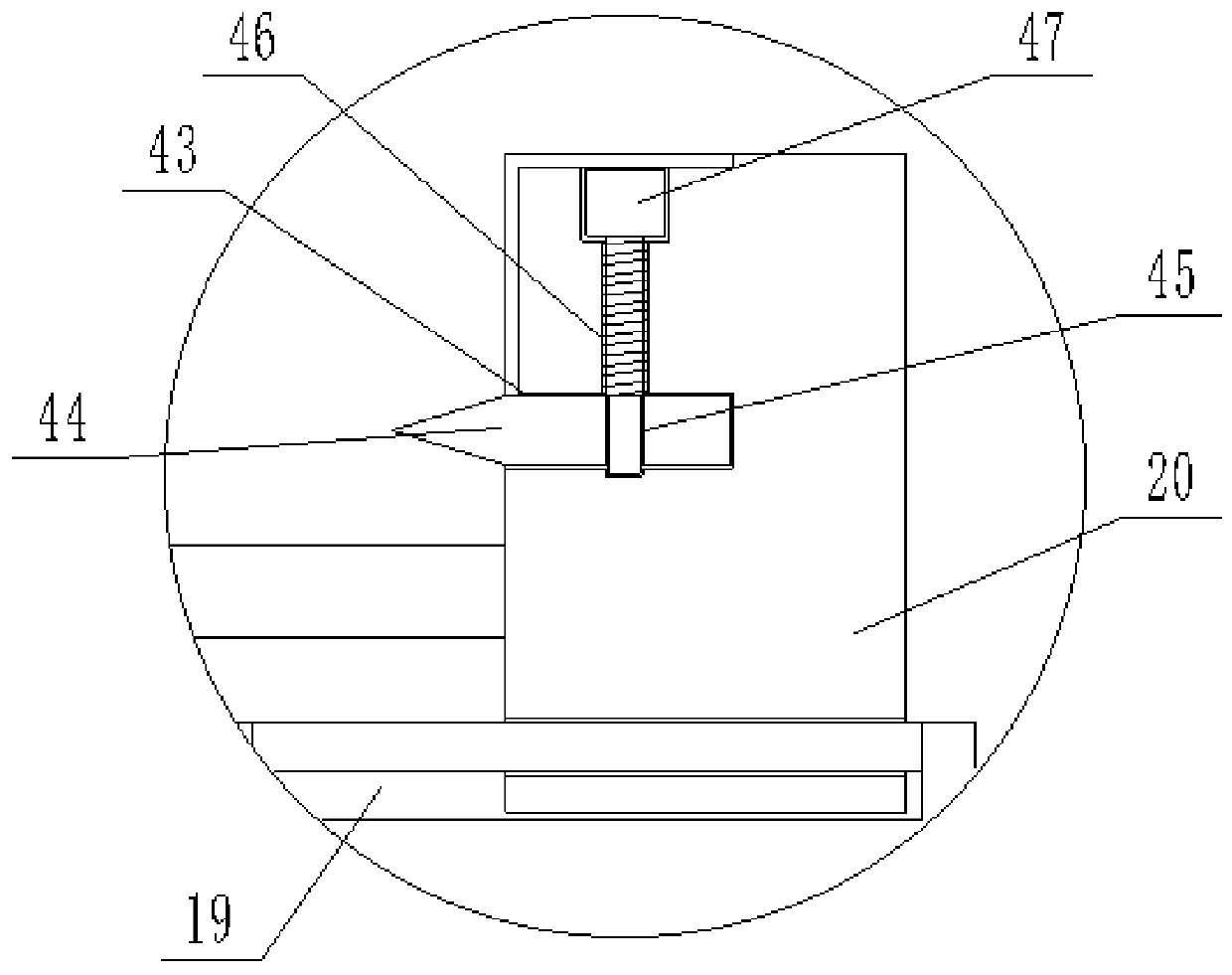

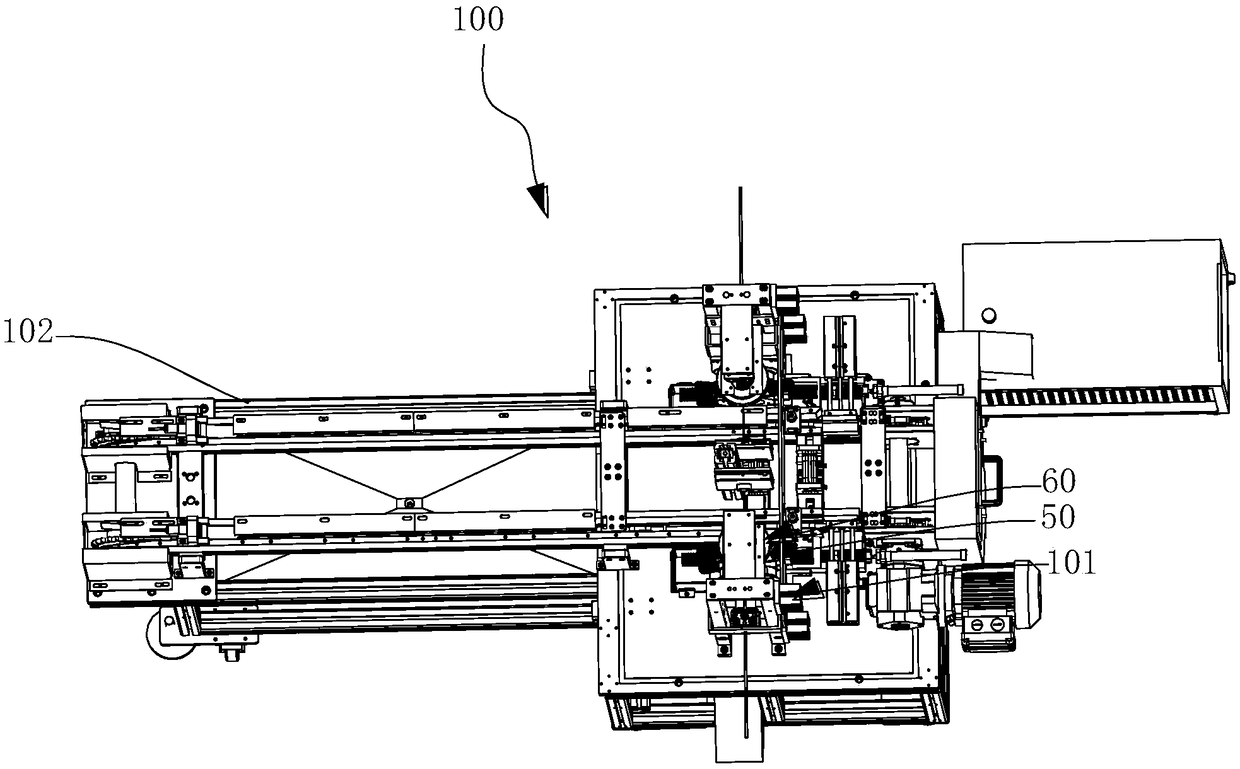

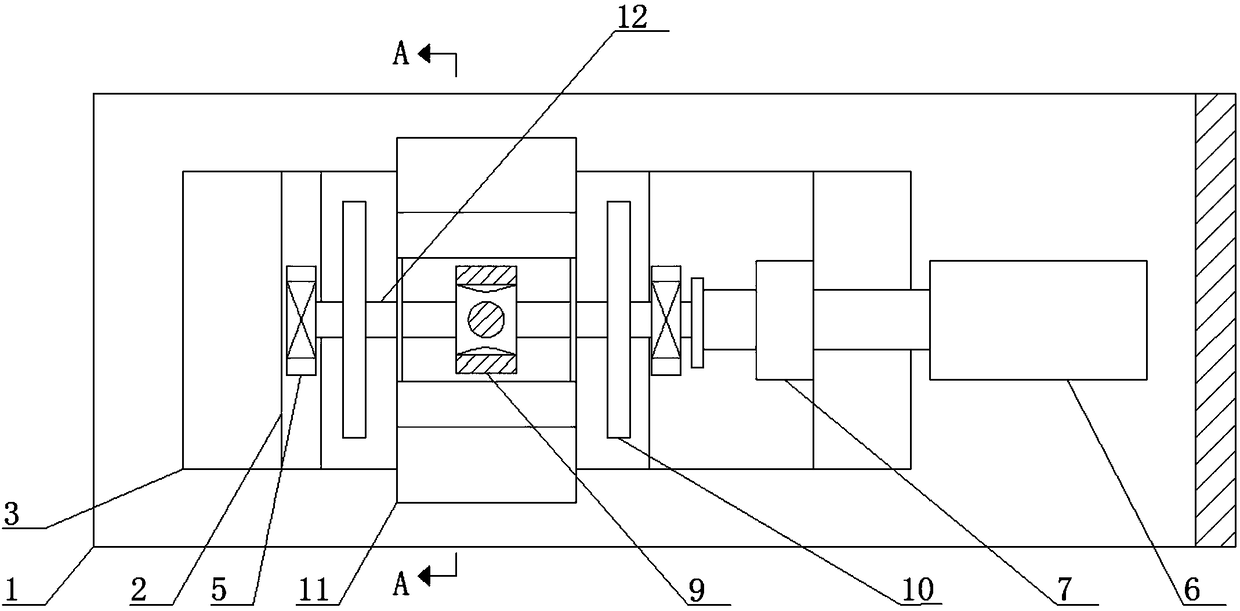

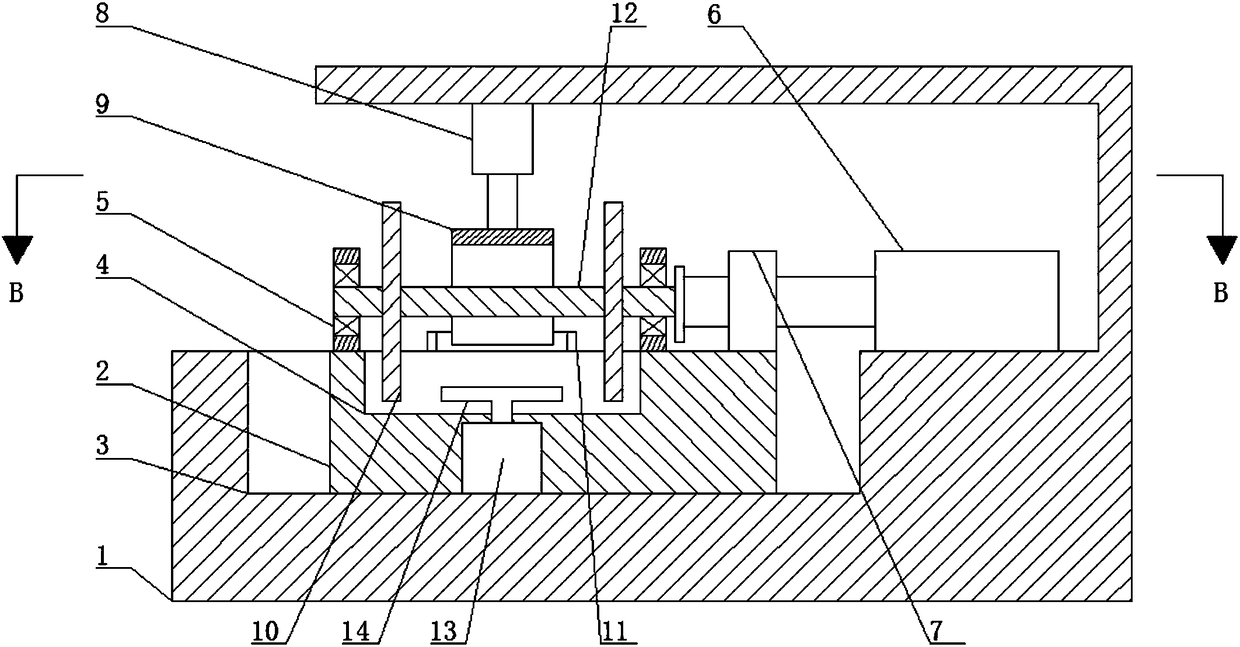

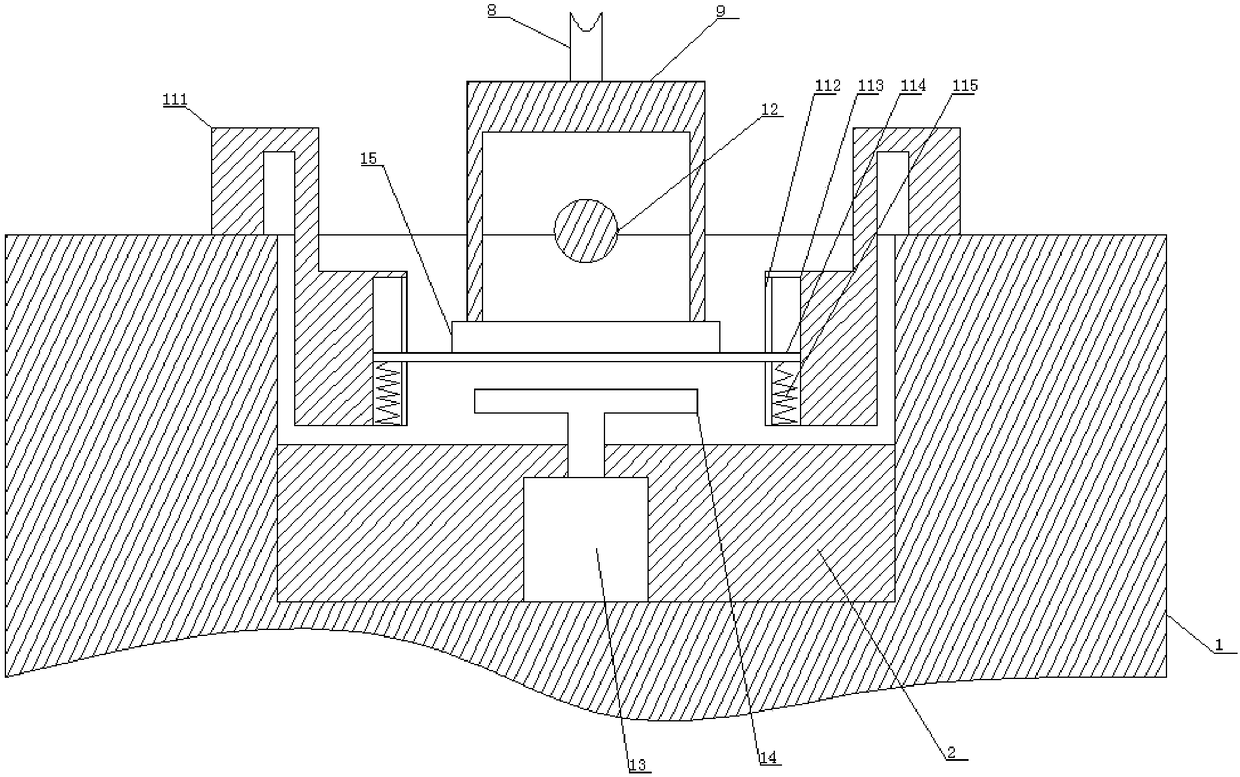

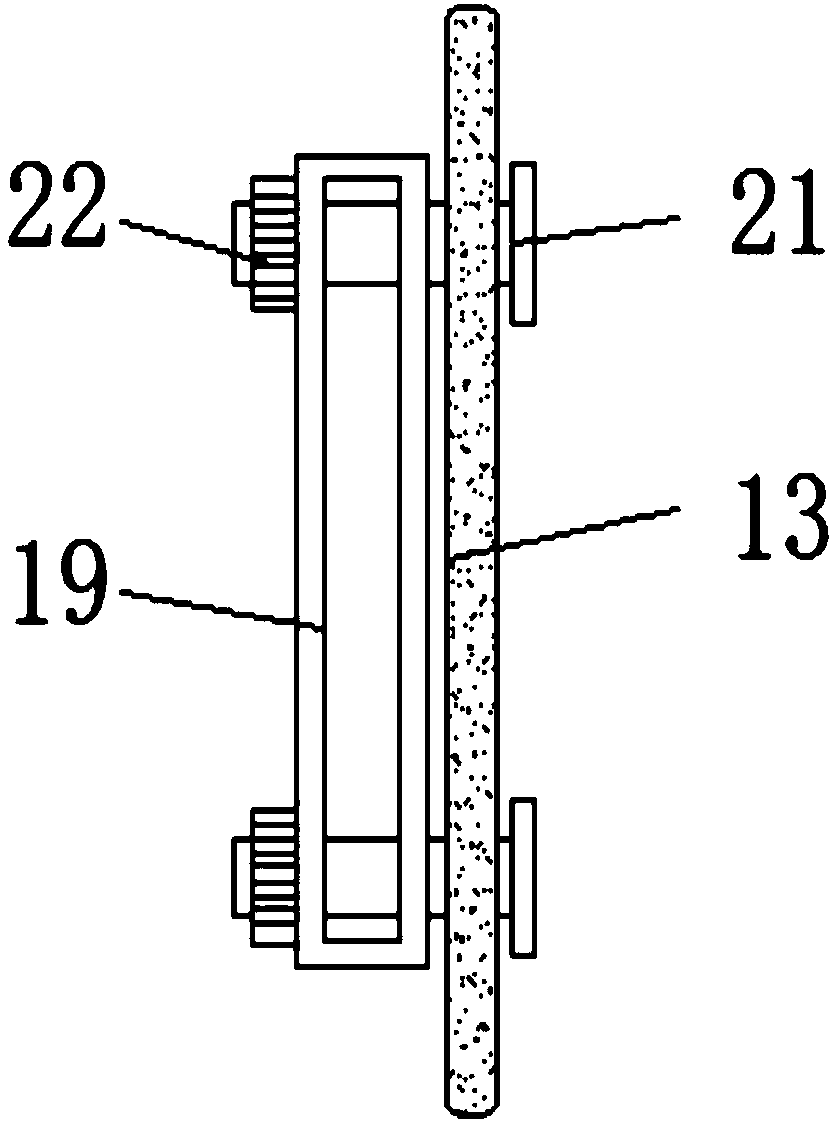

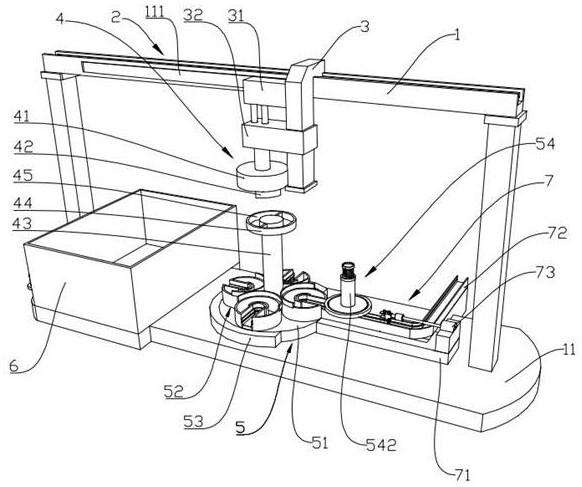

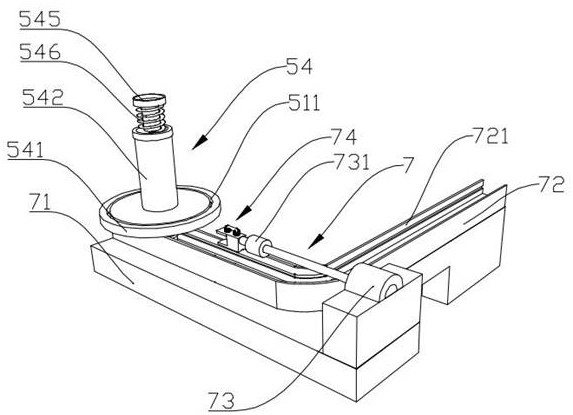

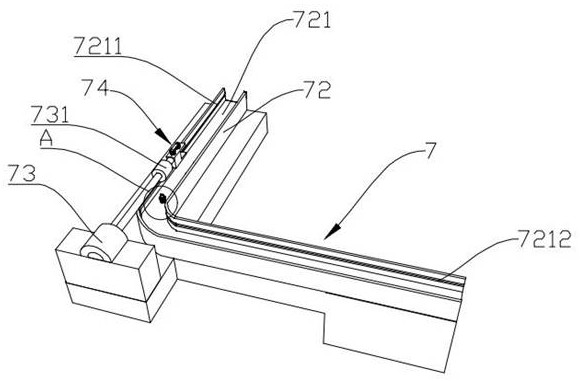

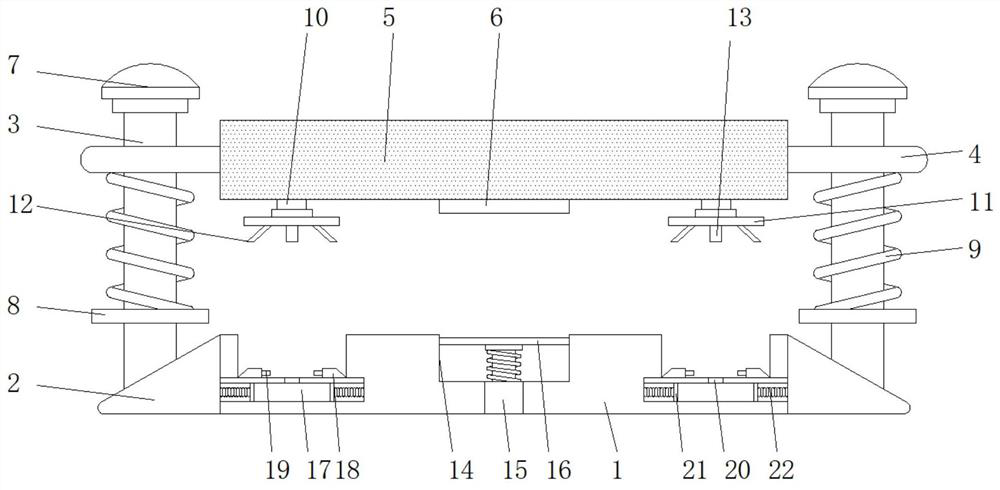

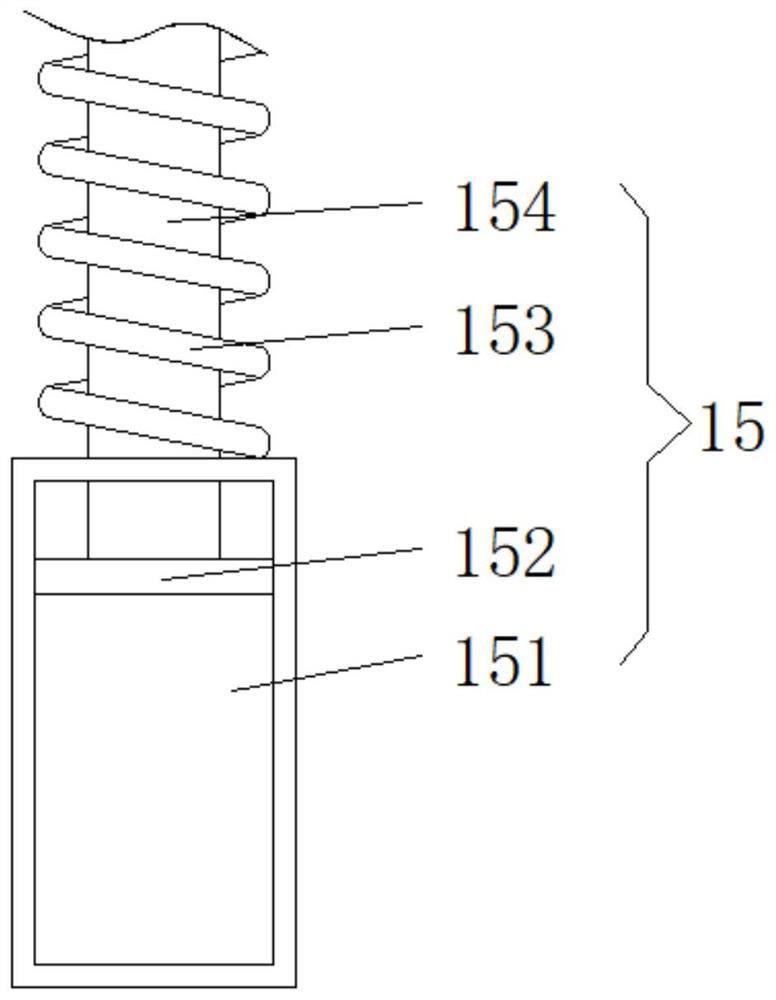

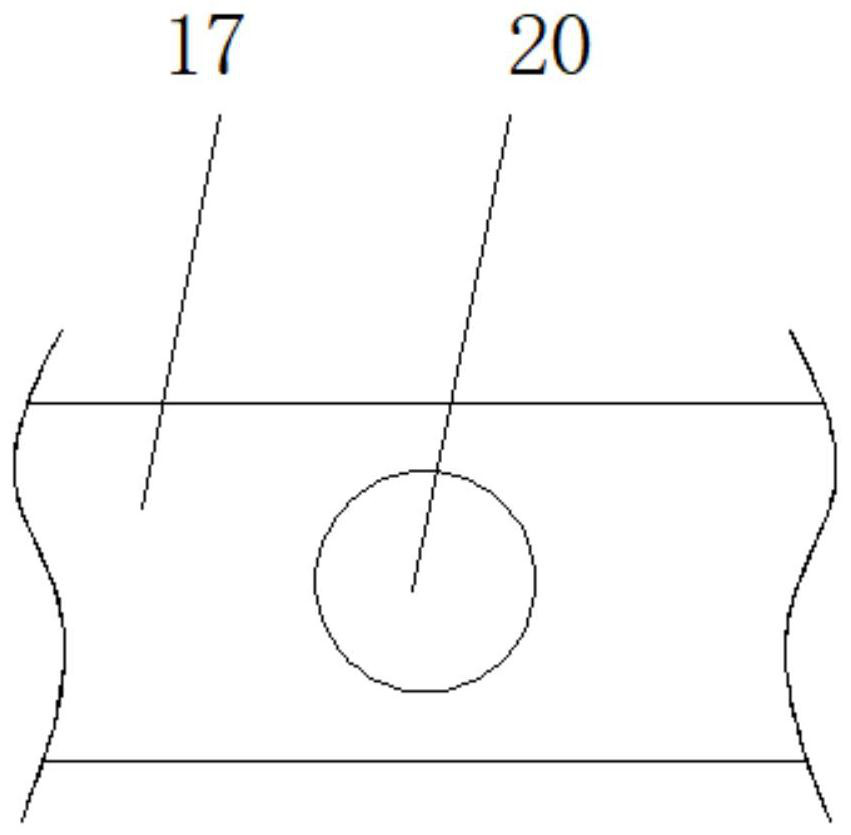

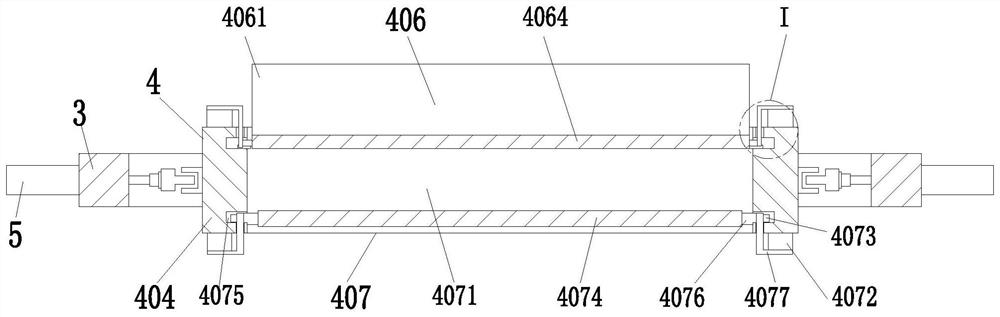

Spring detection apparatus, and spring detection method and device

Owner:慕贝尔汽车部件(太仓)有限公司

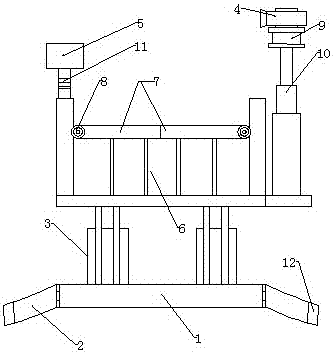

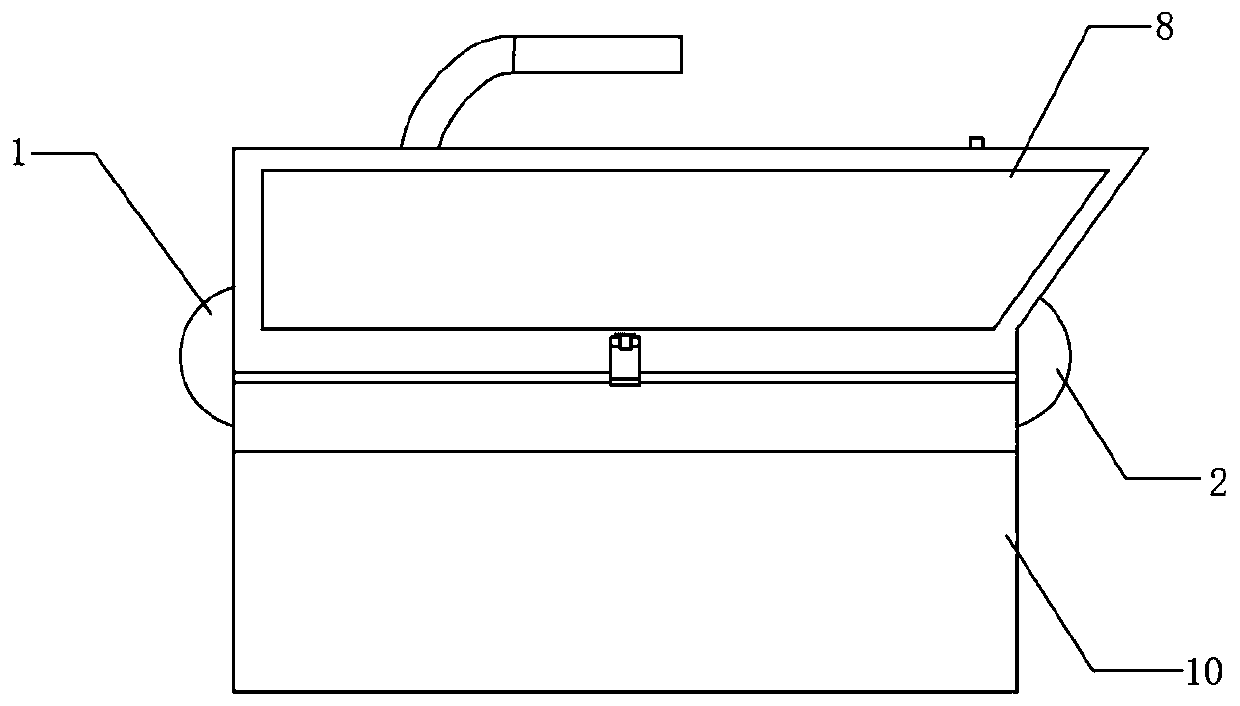

Portable electric power overhauling tool box

InactiveCN107414769AReasonably placedWork lessWork benchesWork tools storageElectric power equipmentPower equipment

The invention discloses a portable electric power overhauling tool box. The portable electric power overhauling tool box comprises a bottom plate, a binding belt fixed to the bottom plate and bound on the waist of an operator, an operation storage table assembly arranged at the upper end of the bottom plate, a first telescopic part connected between the bottom plate and the operation storage table assembly, an infrared video camera arranged on the operation storage table assembly, and a display screen connected to the infrared video camera. The operation storage table assembly with the adjustable height is arranged, tools can be conveniently stored, the effect of an operation table is achieved, the operation storage table assembly is fixed to the waist of the operator through the binding belt, and the dual hands are liberated; the tools can be placed reasonably, a worker can conveniently finish the overhauling work, the infrared video camera and the display screen are matched, a worker can more conveniently observe the state of power equipment, and work efficiency is improved.

Owner:SUZHOU POWER SUPPLY COMPANY OF STATE GRID ANHUI PROVINCE ELECTRIC POWER +1

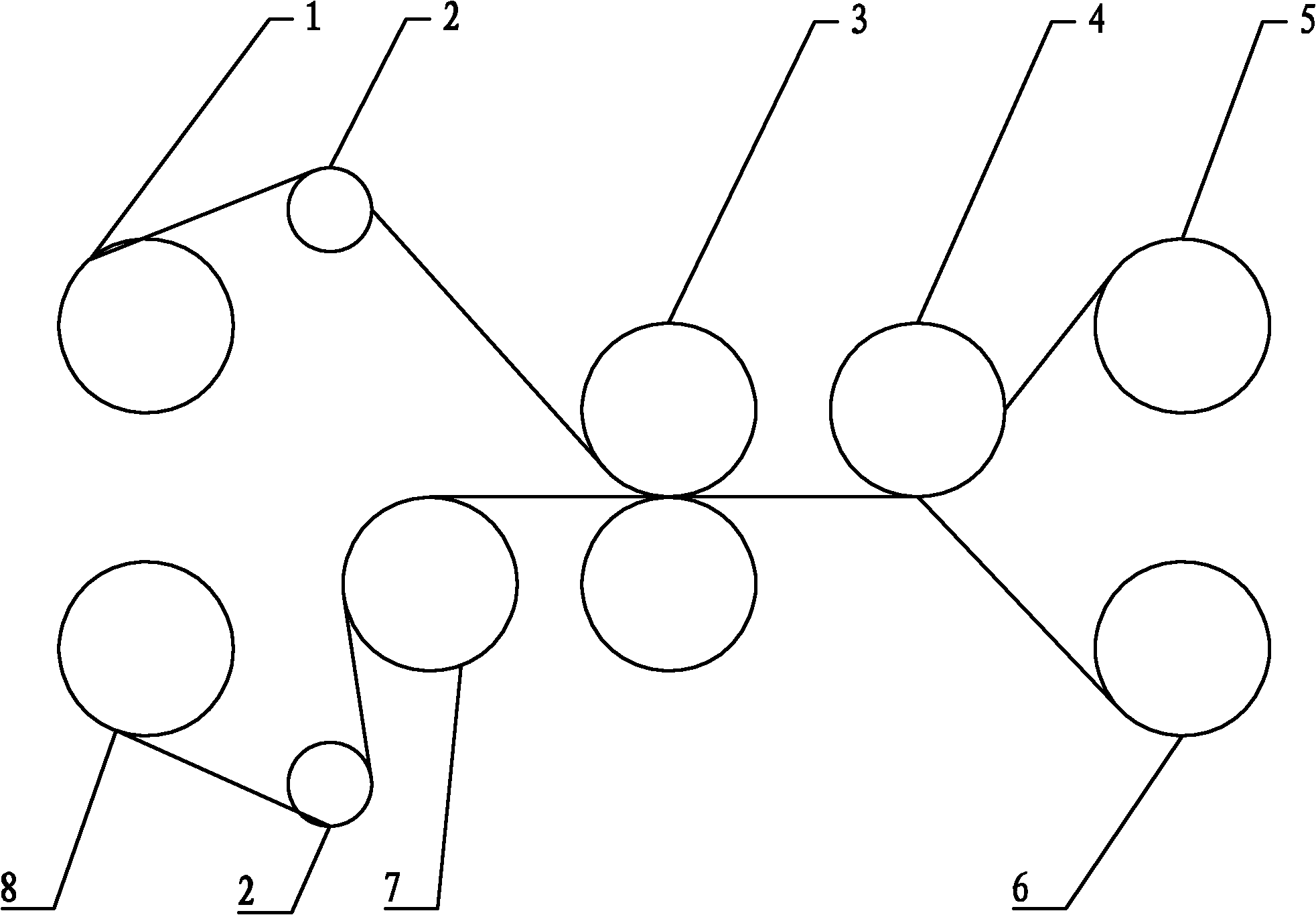

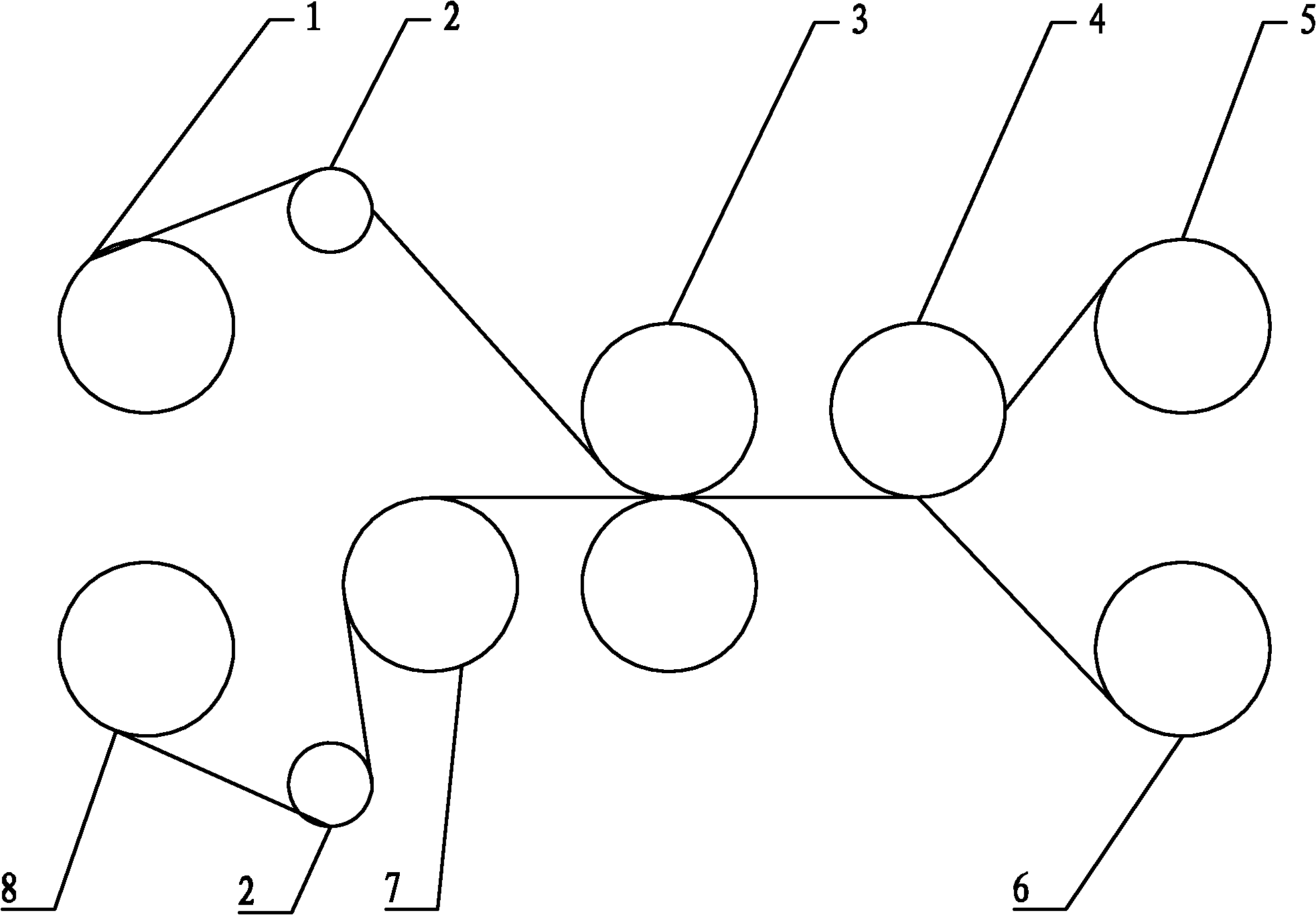

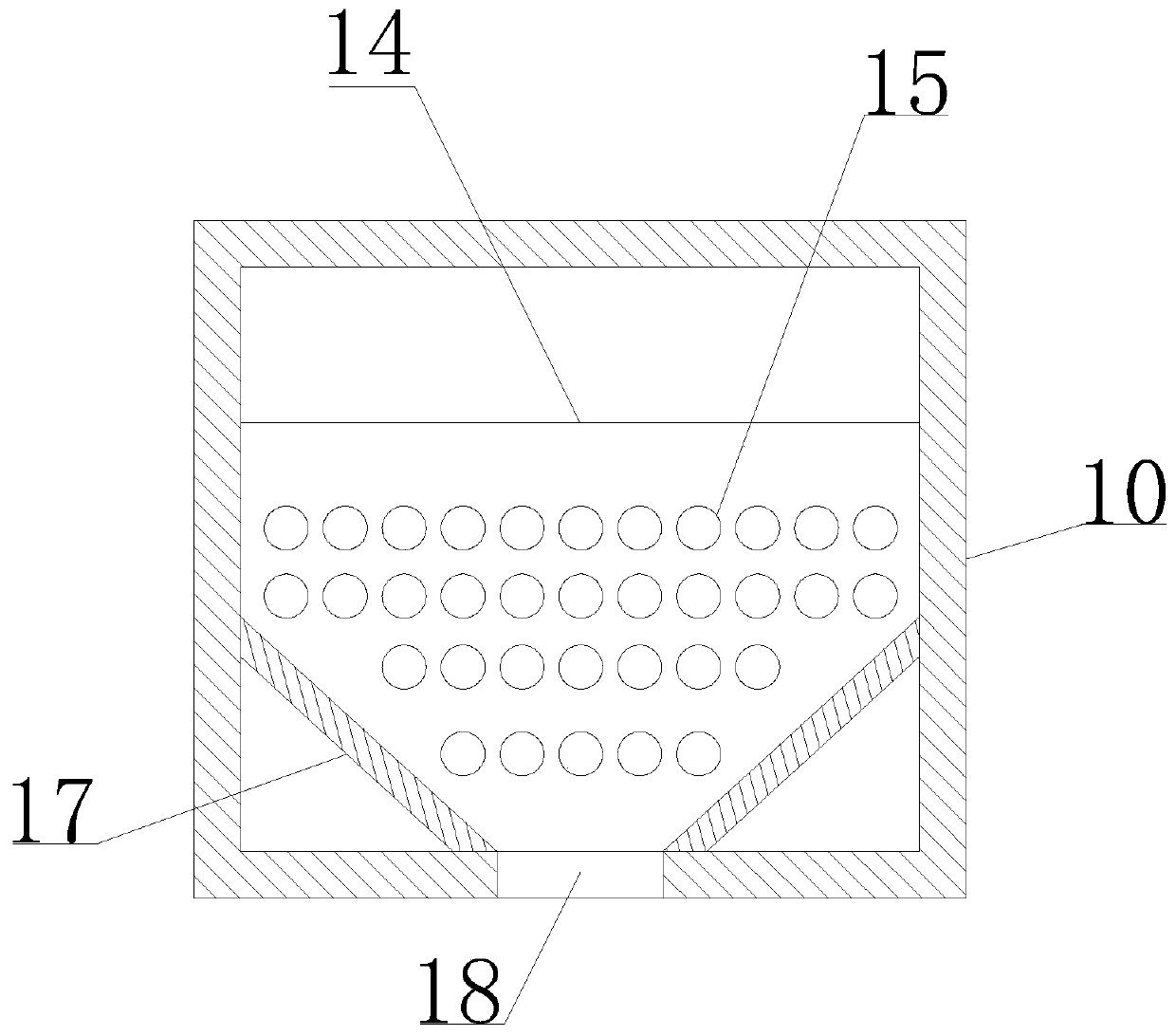

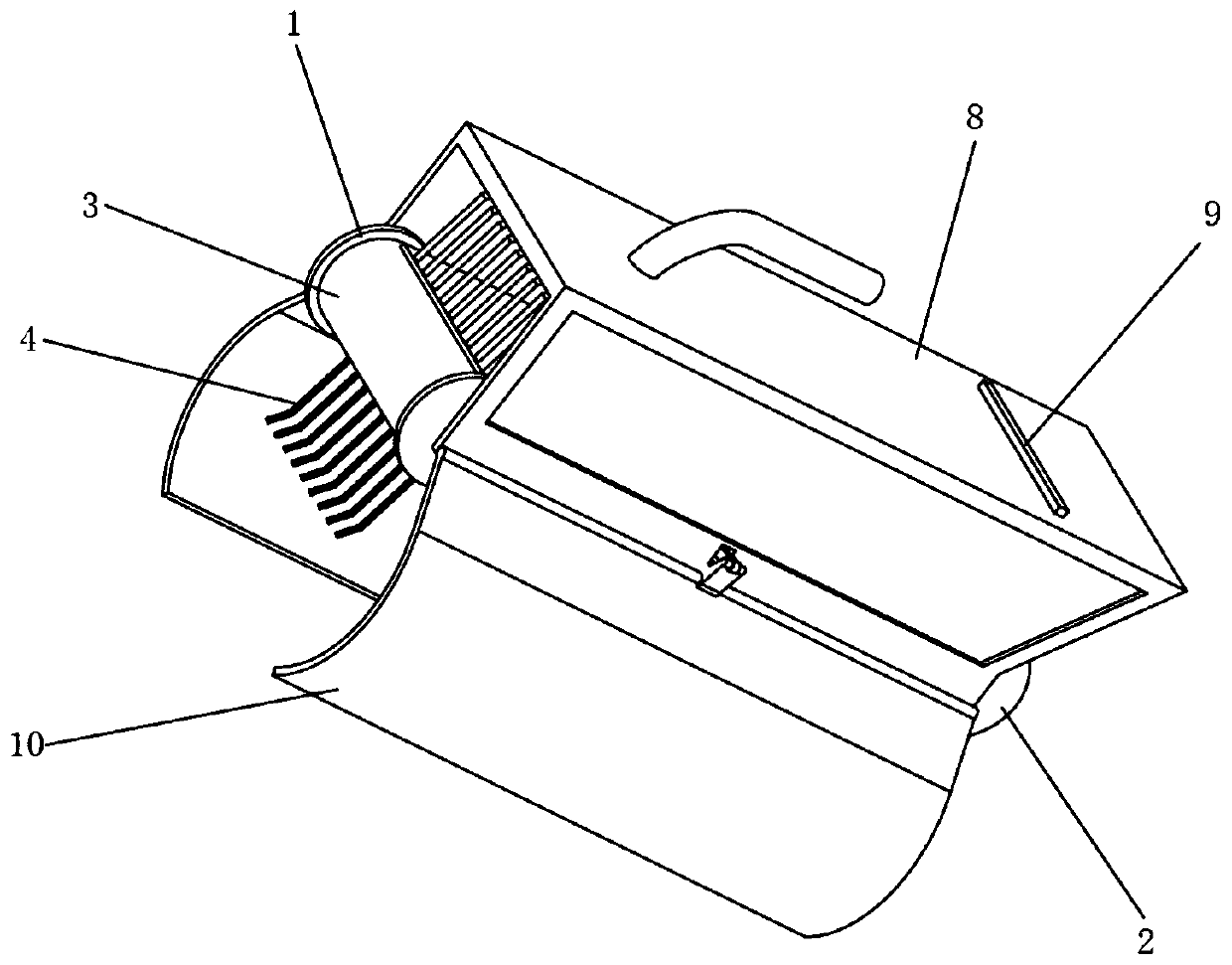

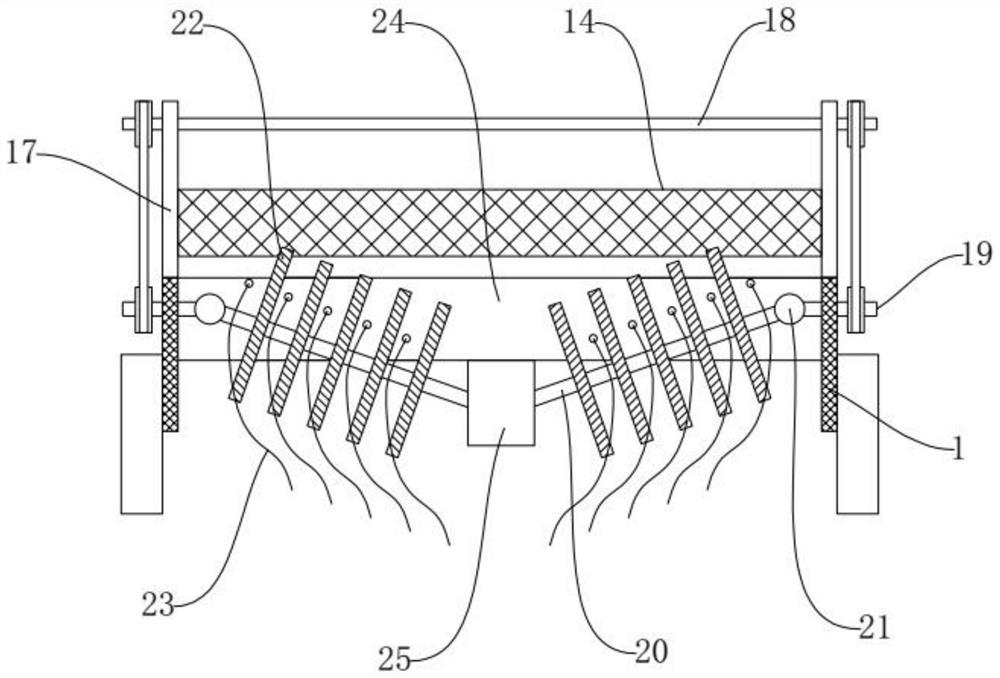

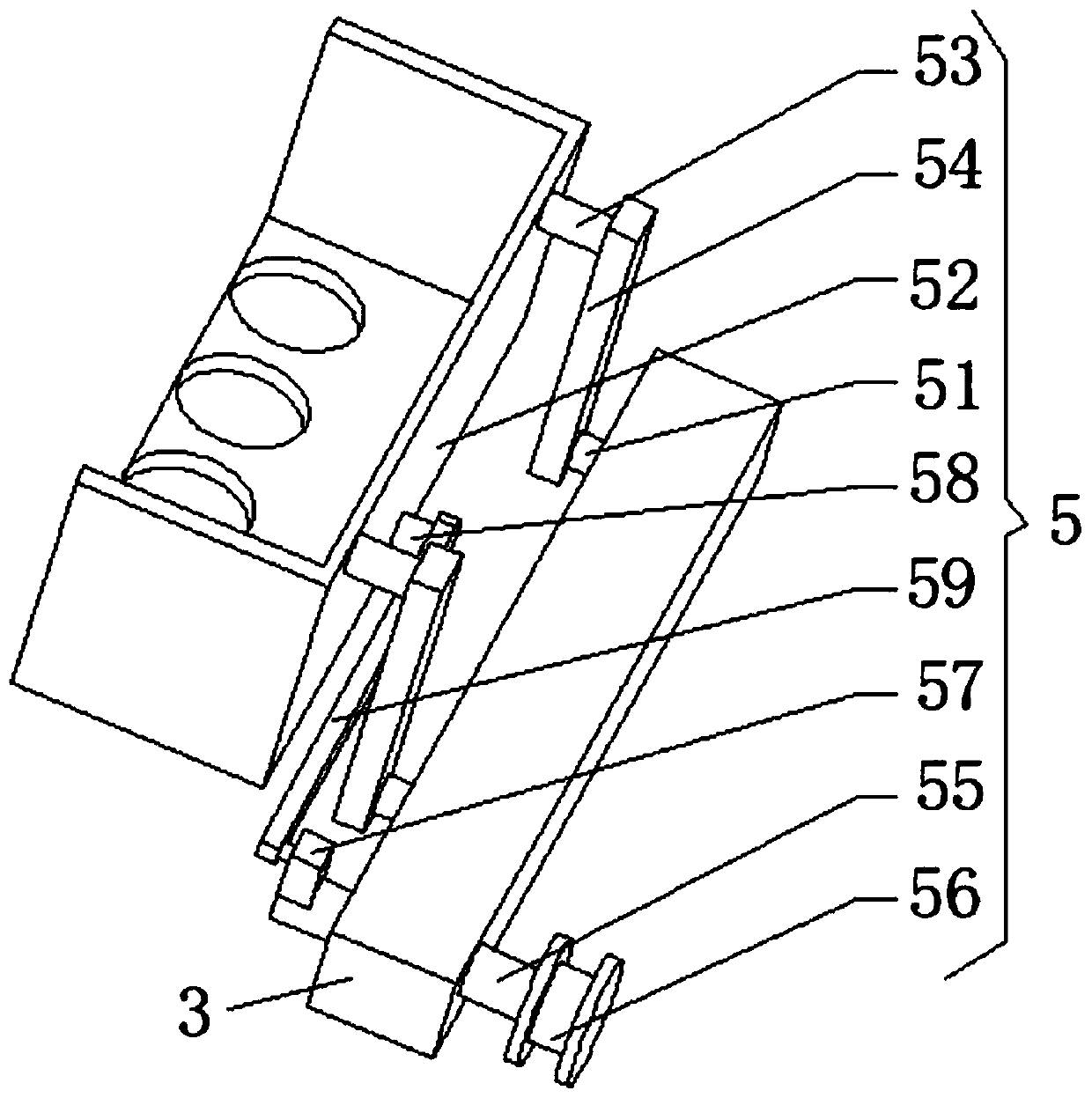

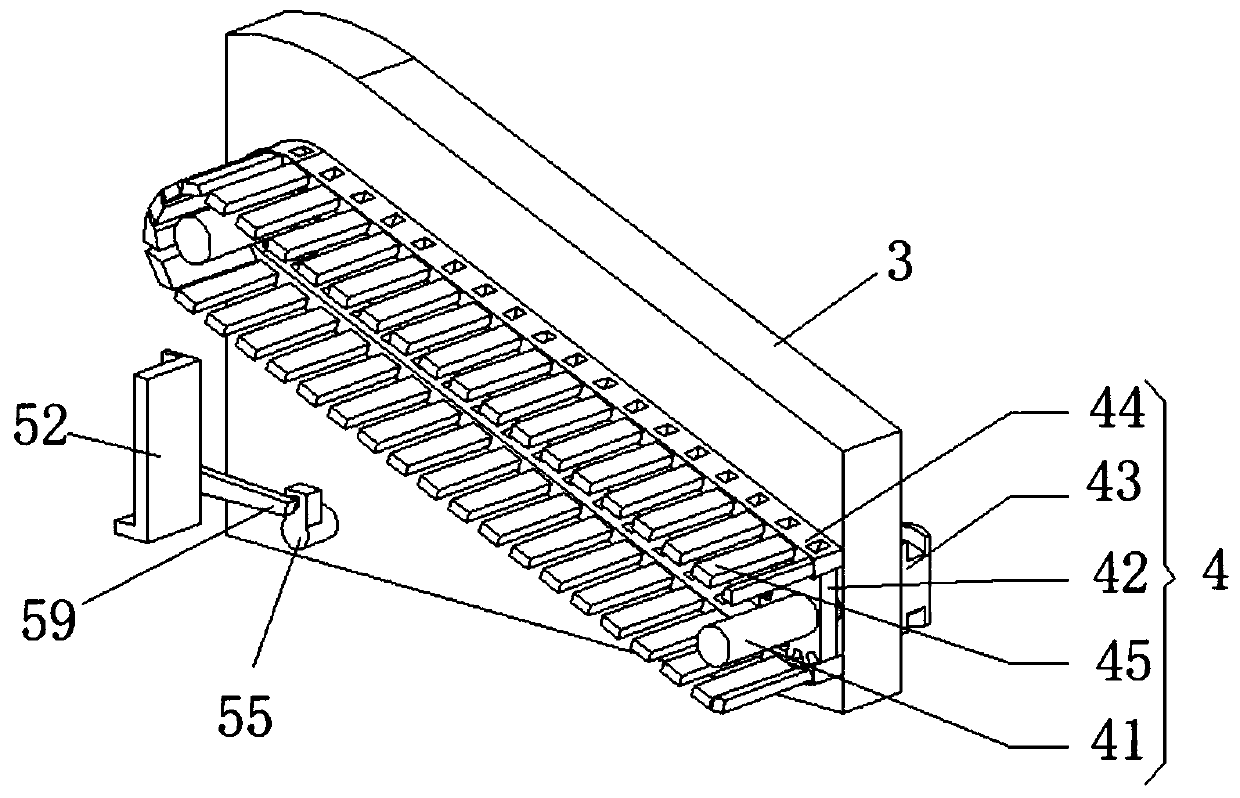

Camellia seed picking device

ActiveCN110896729AReduce labor intensityAvoid scatterPicking devicesAgricultural engineeringStructural engineering

The invention discloses a camellia seed picking device. The camellia seed picking device comprises a driving belt, picking teeth, a power device, a collecting box and a side fence, wherein the drivingbelt is an annular synchronous belt winding around a front roller and a rear roller; the picking teeth equidistantly arranged on the driving belt through a connecting seat; the power device is arranged in a frame body and located between the front roller and the rear roller; the collecting box is arranged on the frame body and surrounds the upper part of the driving belt; the side fence is rotatably arranged on the frame body through a rotating shaft, and surrounds the lower part of the driving belt in an openable manner. The reciprocating driving belt is provided, and the picking teeth are arranged on the driving belt, as the gaps between the picking teeth are smaller than the radius of camellia seeds, when the picking teeth are inserted into camellia trees, the camellia seeds can fall off along with movement of the driving belt, mechanized picking is realized, manual picking by workers is avoided, and the labor intensity of picking is greatly reduced; and at the same time, by arrangement of the side fence, scattering of the camellia seeds during the picking process can be avoided, and the picking quality is improved.

Owner:ANHUI YUMIN ECOLOGICAL AGRI

Multistage screening equipment for cherries

The invention discloses multistage screening equipment for cherries. The multistage screening equipment comprises a screening groove and a filtering plate, a discharging opening is formed in the innerwall of the screening groove, a first discharging port and a second discharging port are formed in the bottom of the screening groove, the bottom of the first discharging port and the bottom of the second discharging port are connected with a first collection pipeline and a second collection pipeline respectively, and a power assembly is arranged at the lower end of the screening groove. According to the multistage screening equipment, the problems that in the process of harvesting the cherries, workers manually screen the cherries through screens so that only the relatively few cherries canbe screened at a time through the method, the surfaces of the cherries cannot be damaged in the screening process, however, the efficiency is low, moreover, if secondary screening needs to be carriedout, the work also needs to be performed repeatedly, so that the collection time of the cherries is prolonged, and the workload of the workers is increased are solved.

Owner:王燕

Collecting device of remote controller

Owner:GREE ELECTRIC APPLIANCES INC

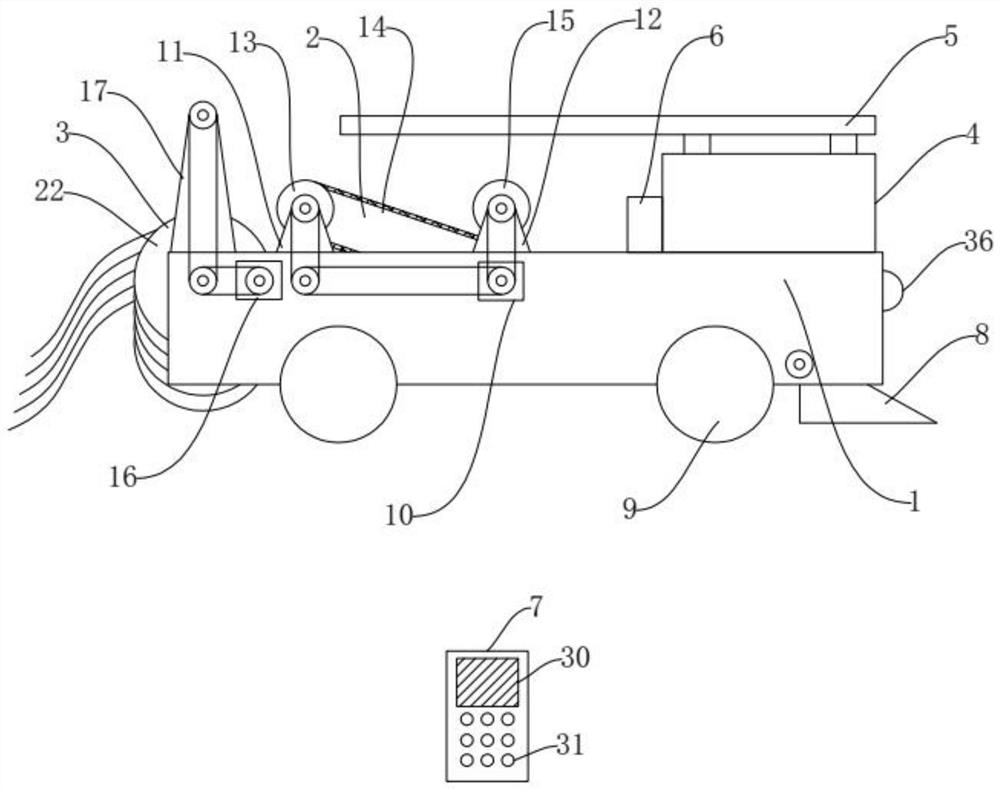

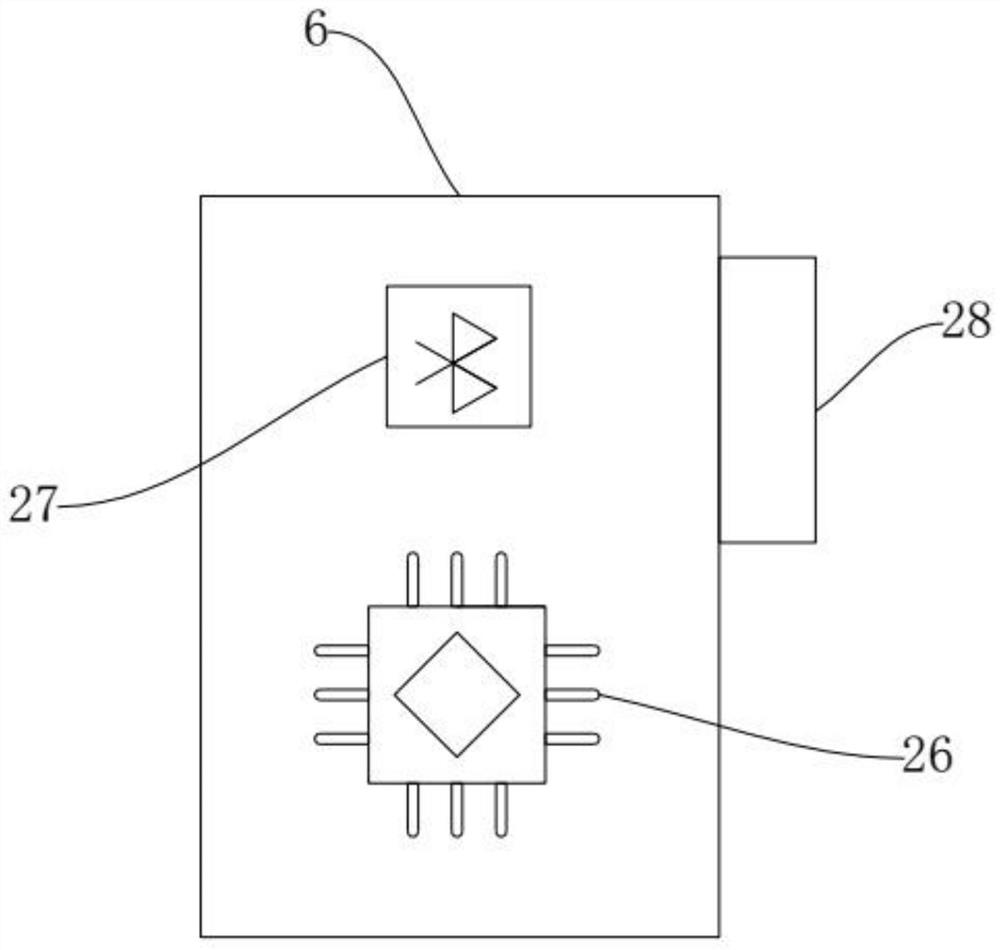

Novel peanut excavator

A novel peanut excavator is disclosed. The peanut excavator comprises a machine shell, a conveying and soil shaking mechanism, a V-shaped discharging mechanism, a storage battery, a solar cell panel, a control box, a remote control panel, an excavating head and a driving mechanism, wherein the V-shaped discharging mechanism and the excavating head are arranged at the rear end and the front end of the machine shell respectively; the conveying and soil shaking mechanism penetrates through the lower wall of the machine shell and is arranged in the machine shell; the V-shaped discharging mechanism and the excavating head are connected to the two ends of the conveying and soil shaking mechanism respectively, the storage battery and the control box are fixedly connected to the upper wall of the machine shell, the solar cell panel is fixedly connected to the upper portion of the storage battery, the driving mechanism is arranged in the machine shell, and the remote control panel is arranged on the outer side of the machine shell. The invention belongs to the technical field of agricultural harvesting machinery, and particularly provides a novel peanut excavator which works in a remote control mode, saves energy, is environmentally friendly, free of pollution and low in noise, has the functions of excavating peanuts, conveying peanut vines, vibrating and shaking soil and stacking the peanut vines, saves time and labor, and is high in practicability, easy to operate and low in cost.

Owner:赵文印

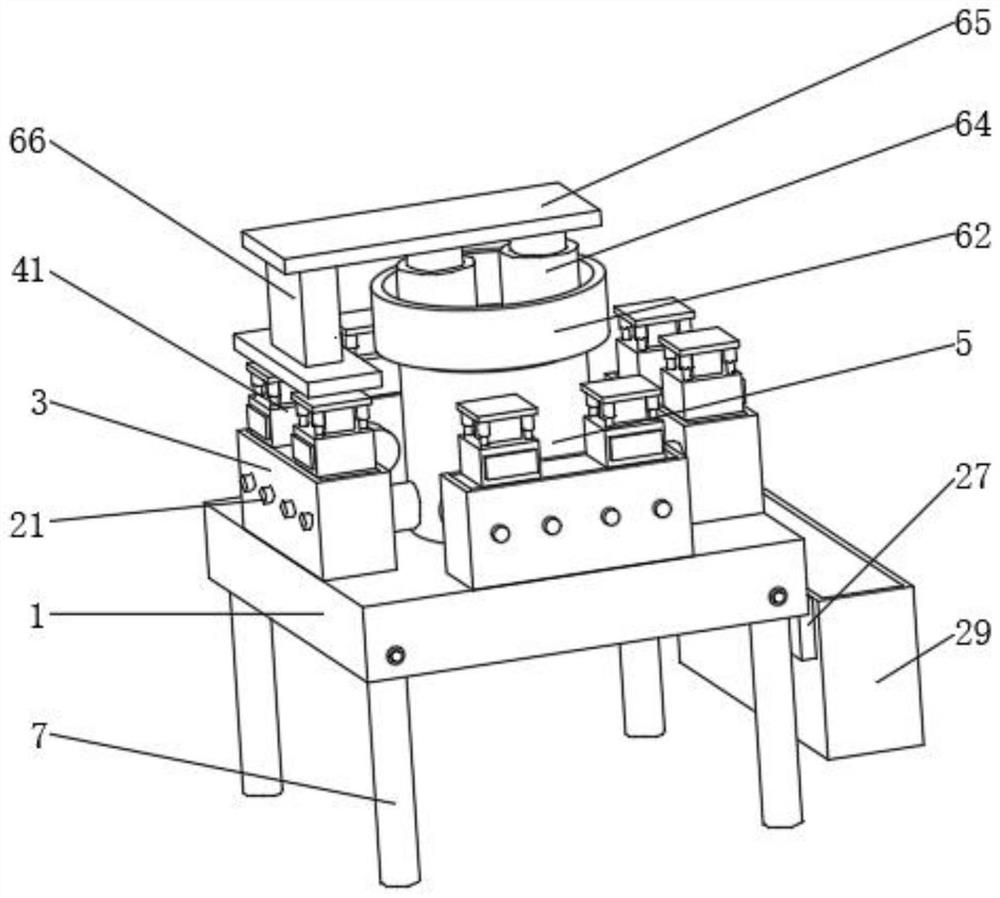

Rotary multi-station blanking device for computer mainboard manufacturing

ActiveCN114378899ANo accidental injuryEasy to collectMetal working apparatusMechanical engineeringEngineering

The invention discloses a rotary multi-station blanking device for computer mainboard manufacturing, which comprises an operation table, a material receiving mechanism, four supporting boxes, a blanking mechanism, a rotating seat, a rotating mechanism and supporting legs, the material receiving mechanism is arranged on the operation table, the supporting boxes are fixedly connected to the operation table, and the rotating seat is fixedly connected with the supporting boxes. The four supporting boxes are evenly distributed on the operation table, a blanking mechanism is arranged on the supporting boxes, a rotating seat is fixedly connected to the operation table, a rotating mechanism is arranged on the rotating seat, and four evenly-distributed supporting legs are fixedly connected to the lower end of the operation table. The invention relates to a rotary multi-station blanking device for manufacturing computer mainboards. The rotary multi-station blanking device has the characteristics that the mainboards are convenient to replace, and the blanked mainboards are convenient to collect.

Owner:田华

Steel ingot grinding device

InactiveCN108161684AAvoid Manual PickingImprove securityGrinding machinesGrinding work supportsElectric machineryIngot

The invention discloses a steel ingot grinding device, and relates to the field of steel ingot equipment. The steel ingot grinding device comprises a machine seat and a supporting seat, and the upperend of the machine seat is provided with a guide rail of the supporting seat and a first air cylinder is fixedly connected to the right end of the machine seat; a bottom grinding wheel is connected toan output shaft of a motor in a key mode, and the motor is fixedly connected to an output end of the first air cylinder; bearing devices and grinding wheels are sequentially and symmetrically connected to a rotating rod, and a grinding bracket fixedly connected with the machine seat is arranged between the symmetrical grinding wheels; and a pressing plate is fixedly connected to an output end ofa second air cylinder. According to the steel ingot grinding device, a steel ingot is placed on support rods at both sides, the steel ingot is pressed down by the pressing plate which is driven by thesecond air cylinder, and both ends of the steel ingot are ground by the grinding wheels in the process of the first air cylinder moving back and forth; and when the steel ingot is pressed down to thebottom grinding wheel, one side of the steel ingot is ground, and then the other side of the steel ingot is ground repeatedly by directly facing the bottom grinding wheel, so that direct operation ofthe steel ingot on the grinding wheels through manual taking is avoided, and the safety is high.

Owner:马鞍山市鑫龙特钢有限公司

Peach picking device

InactiveCN108307799AImprove stabilityAvoid compromising stabilityPicking devicesEngineeringRotary stage

The invention relates to the technical field of agricultural equipment, and discloses a peach picking device. The peach picking device comprises a support frame, wherein a handle is movably arranged on a side surface of the support frame in a sleeving manner; one end of the handle penetrates through the support frame and extends to the outside of the support frame; and one end of the handle is fixedly connected with a rotating table which is positioned above the support frame. By cooperation of the handle and the rotating table of the peach picking device, a connecting shaft and a transmissionrod move oppositely; by cooperation of a positioning block and a limiting block, a connecting rod and an extending rod always move in the positioning block and the limiting block when moving, and thecircumstances that when moving, the connecting rod and the extending rod deviate from the original positions, thus, cutting of a blade and a cutting knife fails, and the stability of the product is affected are avoided; and by cooperation of a connecting block, a fixing rod and a limiting rod, the circumstances that when moving, a cross rod and a supporting rod move back and forth on the supportframe, and the stability of cutting is affected are avoided.

Owner:浙江开创智库科技有限公司

Frame of potato harvester

The invention discloses a frame of a potato harvester. The frame of the potato harvester comprises a mounting plate and a screening unit. Two corresponding supporting plates are mounted on the lower side face of the mounting plate, and a fixed plate is fixed to the lower side face of each supporting plate. The screening unit comprises two first connecting shafts, a storage box, four second connecting shafts, steel plates, a second rotating shaft, a second belt wheel, a mounting block, a third connecting shaft and a connecting plate, wherein two corresponding first connecting shafts are rotatably connected to the side faces of the fixed plates and are connected to the second connecting shafts through the steel plates, the storage box is positioned between the two fixed plates, the four corresponding second connecting shafts are mounted on the front and back side faces of the storage box, and end face bearings of the first connecting shafts and the second connecting shafts are connectedto the side faces of the steel plates. The frame of the potato harvester can collect potatoes while the potatoes are dug out and separated from one another, so that manual picking is avoided and working efficiency is greatly improved.

Owner:DANYANG RONGJIA PRECISION MACHINERY

Agricultural pineapple picking device

InactiveCN112616429AAvoid manual pickingEconomic lossPicking devicesAgricultural engineeringEngineering

The invention relates to the technical field of agriculture, and discloses an agricultural pineapple picking device. Two fixing plates are fixedly mounted at the upper side of a supporting box, two supporting rods are arranged between the two fixing plates, the upper ends and the lower ends of the two supporting rods movably penetrate through the two fixing plates respectively, and the two supporting rods are fixedly sleeved with rotating rollers; the two rotating rollers are movably sleeved with a movable belt, and a rotating motor is started, so that the supporting rod below can be driven to rotate through a transmission belt, the rotating roller below can be driven to rotate, the movable belt is driven to rotate and move,and the device is moved forwards and upwards; and when a friction belt and the movable belt move to the two sides of a pineapple, through supporting of the friction belt, the pineapple can be driven to rotate through the movable belt, and the pineapple can be twisted off from the roots, so that manual pineapple picking can be avoided, meanwhile, the working efficiency is improved, manual pineapple picking injuries can be avoided, the pineapple can be quickly picked, and economic losses of planters are prevented from being affected by rotting.

Owner:田泽林

High-efficiency rubber crusher and recovery method of waste rubber

InactiveCN106541517AAvoid Melting StickyGuaranteed crushing effectPlastic recyclingMechanical material recoveryRecovery methodWaste rubber

The invention discloses a high-efficiency rubber crusher and a recovery method of waste rubber. The high-efficiency rubber crusher comprises a rubber crushing chamber, a roller assembly arranged on the inner upper portion of the rubber crushing chamber, a rubber cutting assembly arranged in the middle of the rubber crushing chamber and a power assembly used for driving the roller assembly and the rubber cutting assembly. A feeding inlet is formed in the top of the rubber crushing chamber, and a discharging outlet is formed in the bottom of the rubber crushing chamber. The discharging outlet is provided with a screen net. One end of the screen net is rotatably connected with the side wall of the rubber crushing chamber through a hinge, and the bottom of the other end of the screen net is movably mounted on the side wall of the rubber crushing chamber through a lifting rod. An unqualified-rubber outlet is formed in the side, close to the hinge, of the rubber crushing chamber on the screen net. A discharging channel communicates with the space below the screen net. An air vent is formed in the side wall of the rubber crushing wall and communicates with an air condenser. The high-efficiency rubber crusher has the beneficial effects that the structure is simple, the temperature of a rubber crusher blade is reduced effectively, sticking of rubber is avoided, the rubber crushing effect is guaranteed, meanwhile, unqualified rubber blocks can be separated and transferred rapidly, the rubber crushing efficiency is improved, the recovery method of the rubber is simple, and operation is convenient.

Owner:四川邑诚科技有限公司

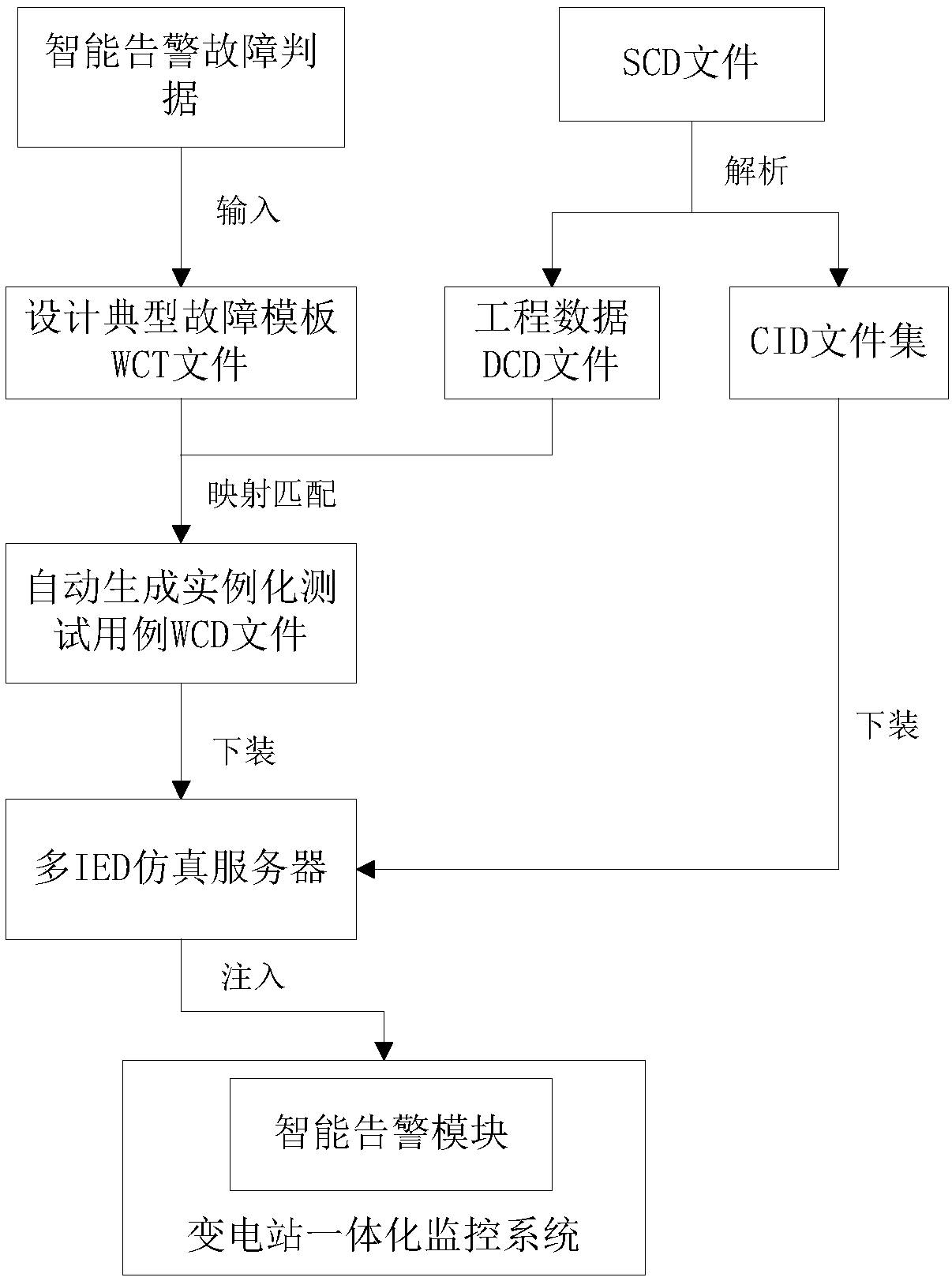

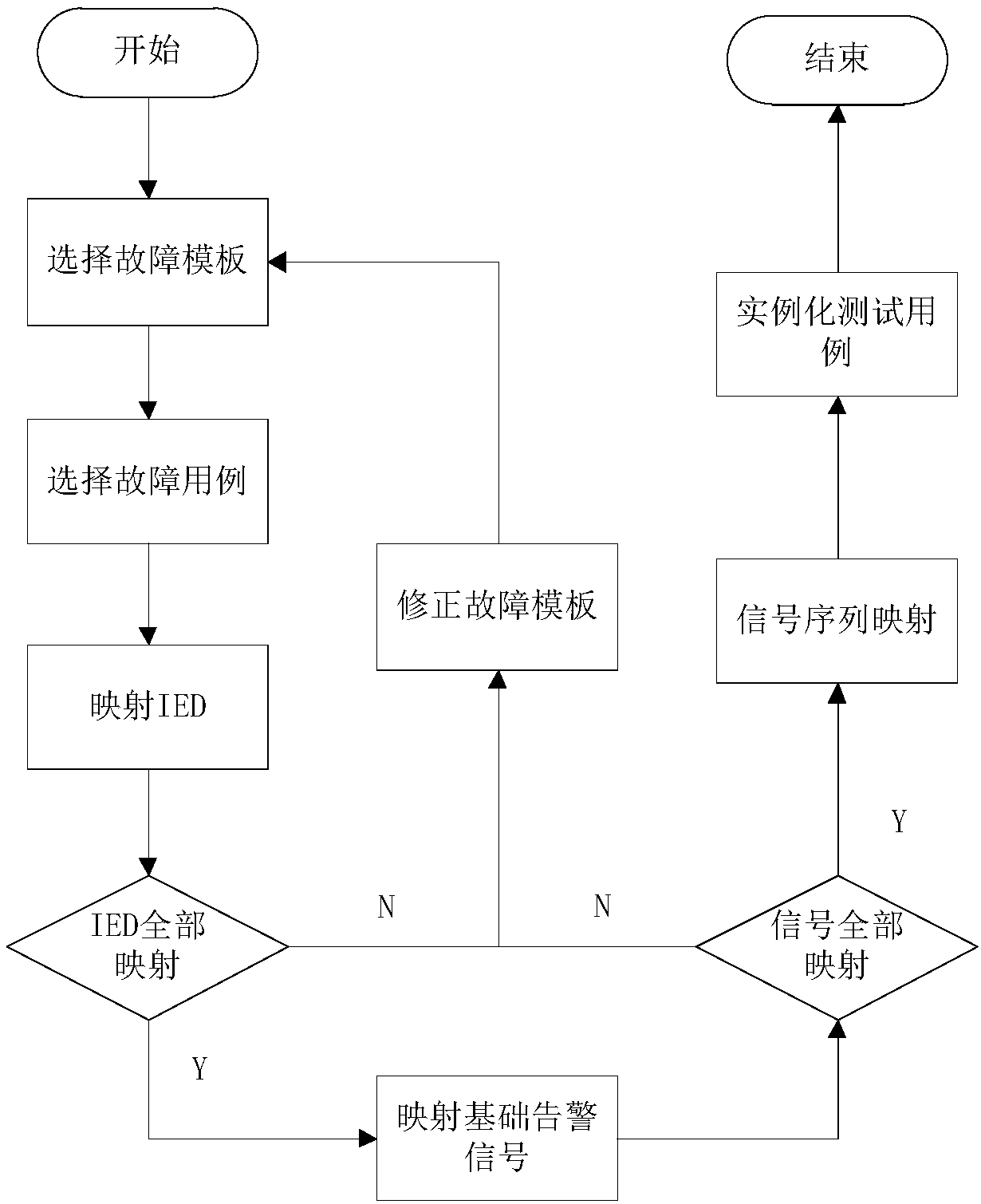

Intelligent substation alarm test data pre-set method and system

ActiveCN108490282AImplement automated testingAvoid Manual PickingElectrical testingSmart substationData file

The invention relates to an intelligent substation alarm test data pre-set method and system. The method includes the following steps that: a fault case is selected from a pre-designed fault templatefile on the basis of test requirements; and mapping matching is performed on the fault case and a pre-generated engineering data file, so that an instantiated test case file can be generated; and theinstantiated test case file is injected into a monitoring system through an IED emulation server. According to the intelligent substation alarm test data pre-set method and system of the invention, anautomatic generation and injection method is adopted, so that complicated manual point picking and configuration processes can be avoided; test personnel with no IEC61850 basis knowledge can also operate the system; the automatic test of an intelligent alarm reasoning function can be truly realized; and the popularization of intelligent alarm standardized tests can be facilitated.

Owner:CHINA ELECTRIC POWER RES INST +1

Automatic and efficient rubber crusher

InactiveCN106378885AKeep abreast of the operationEasy to increase or decrease feedPlastic recyclingMechanical material recoveryEngineeringCrusher

The invention relates to the technical field of rubber processing equipment, and discloses an automatic and efficient rubber crusher. The automatic and efficient rubber crusher comprises a rubber crushing chamber, a roller assembly installed at the upper portion of the interior of the rubber crushing chamber, a rubber cutting assembly installed at the middle portion of the interior of the rubber crushing chamber and a power assembly for driving the roller assembly and the rubber cutting assembly; a feeding opening is formed in the top of the rubber crushing chamber, a discharging opening is formed in the bottom of the rubber crushing chamber and is provided with a screen, one end of the screen is rotationally connected with the side wall of the rubber crushing chamber through a hinge, the bottom of the other end of the screen is movably installed on the side wall of the rubber crushing chamber through a lifting rod, and the position, located above the screen and located on the side close to the hinge, of the rubber crushing chamber is provided with an unqualified rubber outlet; and air holes are formed in the side wall of the rubber crushing chamber, and the roller assembly and the rubber cutting assembly are each provided with an automatic detecting device. The automatic and efficient rubber crusher is simple in structure, the temperature of a blade of the rubber crusher is effectively reduced, adhering of rubber is avoided, and the crushing effect of the rubber is guaranteed; and meanwhile, unqualified block rubber can be rapidly separated and transferred, the rubber crushing efficiency is improved, and the automation degree is high.

Owner:四川邑诚科技有限公司

Rotary electric vehicle hub cooling manipulator

ActiveCN114770564AAvoid cumbersomenessAvoid hidden dangersElectric machinesManipulatorCircular discStructural engineering

The invention discloses a rotary electric vehicle hub cooling manipulator, and relates to the technical field of electric vehicle hub production, the rotary electric vehicle hub cooling manipulator comprises a fixing frame, the top of the fixing frame is connected with a walking frame through a driving mechanism, the walking frame is fixedly provided with a lifting cylinder, and the end, away from the fixing frame, of the walking frame is slidably sleeved with a sliding seat; the sliding seat is fixedly connected with a piston rod of the lifting air cylinder, a cooling placement frame is attracted to the sliding seat through a lifting electromagnet, the cooling placement frame comprises a placement disc seat, a plurality of hub placement bins are evenly distributed on the placement disc seat in the circumferential direction, and a bottom plate is arranged at the bottom of the fixing frame; a cooling water tank, an arc-shaped limiting groove and a feeding and discharging device are sequentially arranged on the bottom plate, and the containing disc base is located in an arc-shaped opening of the arc-shaped limiting groove. The hub cooling device has the advantages that the hub can be automatically grabbed for cooling work, manual clamping and taking work is replaced, and safety and working efficiency are improved.

Owner:JIANGSU JUN SUPER ELECTRIC CAR ACCESSORIES MFG

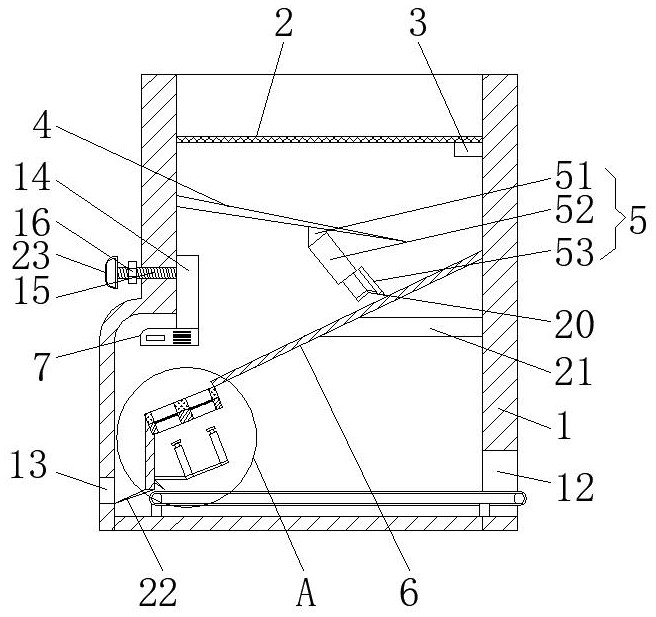

Screening device with visual detection function

InactiveCN112108406ASolve the problem of not having visual detection functionVisual inspection hasSievingScreeningEngineeringStructural engineering

The invention discloses a screening device with a visual detection function. The screening device comprises a screening box, wherein a screening plate is fixedly connected to the top of the inner wallof the screening box, a vibration motor is fixedly connected to the right side of the bottom of the screening plate, a material guide plate located at the bottom of the screening plate is fixedly connected to the top of the left side of the inner wall of the screening box, a material separation mechanism is fixedly connected to the bottom of the guide plate, a blanking plate is fixedly connectedto the right side of the inner wall of the screening box, and a visual detection camera is movably mounted at the bottom of the left side of the inner wall of the screening box. Through cooperative use of the screening box, the screening plate, the vibration motor, the material guide plate, the material separation mechanism, the blanking plate, the visual detection camera, a mounting plate, a detection plate, a discharging plate, a pneumatic screening mechanism, a qualified product discharging port and an inferior-quality product discharging port, the problems that an existing screening devicedoes not have the visual detection function, the manual type screening efficiency is low, the error rate is high, the screening efficiency is reduced and the product quality is influenced are solved,and the advantage of visual detection is achieved.

Owner:孙国花

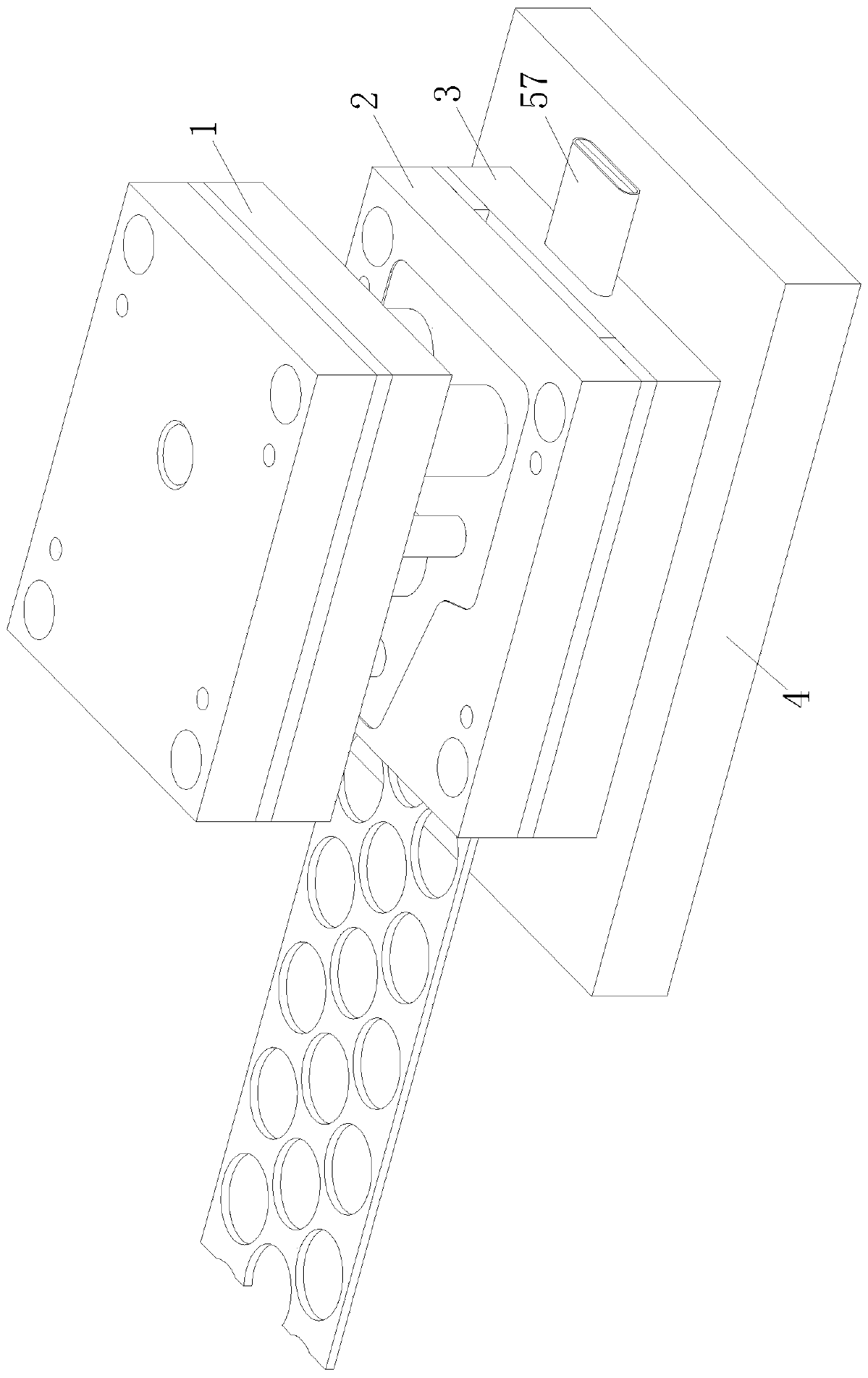

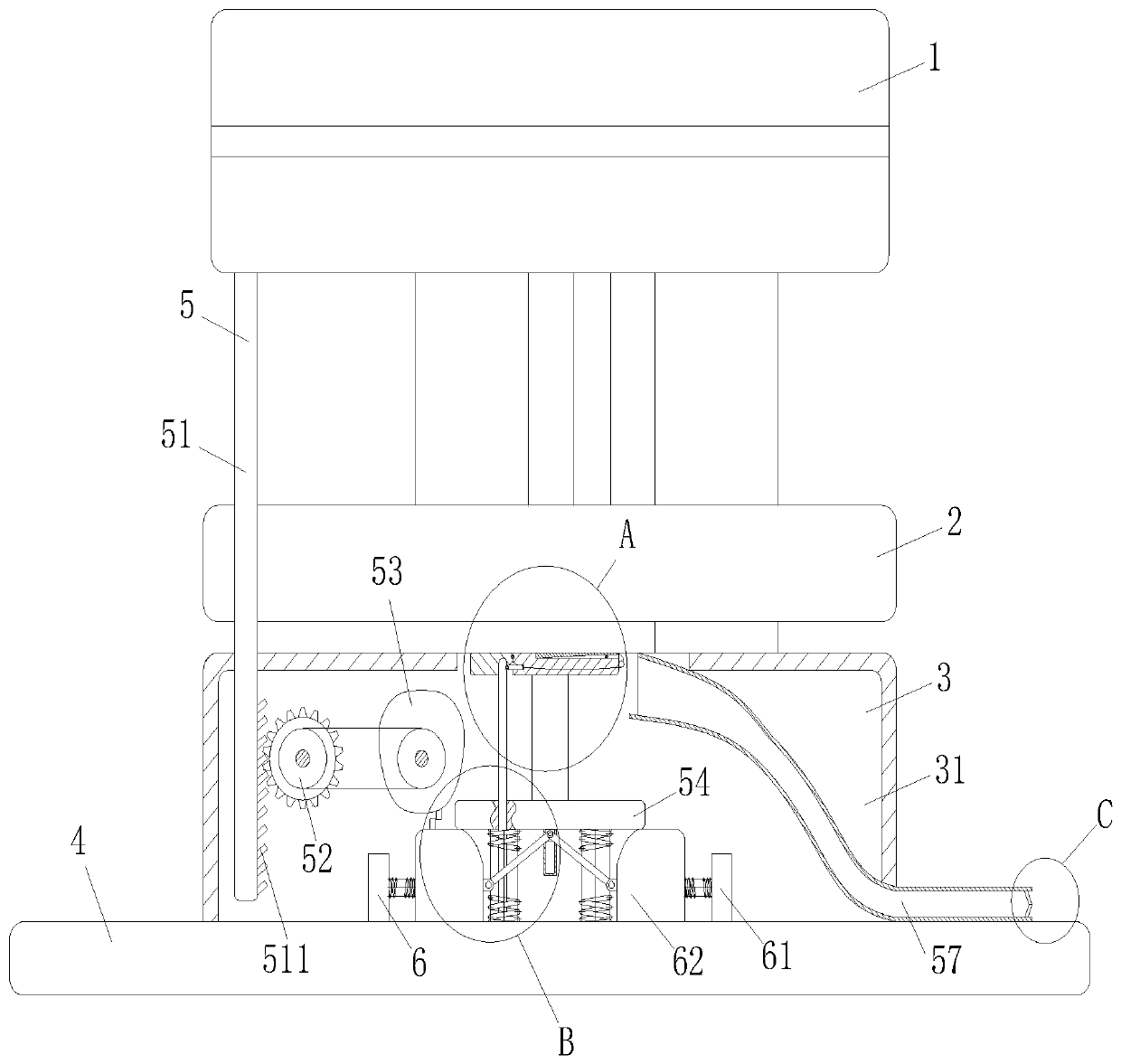

Punching process of sheet metal part

ActiveCN111014424AReduce labor costsImprove work efficiencyPerforating toolsMetal-working feeding devicesStamping processCam

The invention belongs to the technical field of die manufacturing, and particularly relates to a punching process of a sheet metal part. A die adopted by the punching process comprises an upper die plate, a stamping plate, a bottom plate and a base, a cavity is formed in the bottom plate, and a conveying unit is arranged in the cavity. The conveying unit comprises a push rod, a gear, a cam, a first plate, a second plate, an ejector rod and a discharging pipe; one end of the ejector rod is fixed to the bottom side of the cavity, and the other end of the ejector rod penetrates through the firstplate to make contact with the bottom end of an auxiliary plate; and the discharging pipe is installed in the cavity, one end of the discharging pipe is close to the side wall, opposite to the auxiliary plate, of a main plate, and the other end of the discharging pipe extends out of the bottom plate. Through cooperation of the push rod, the gear, the cam, the first plate, the second plate, the ejector rod and the discharging pipe, after the part is stamped, discharged materials can slide out along the discharging pipe, automatic taking of the discharged materials is completed, manual taking isavoided, the labor cost in the stamping process is saved, the working efficiency is improved, and great convenience is brought to workers.

Owner:TONGLING ZHAOLIN IND & TRADE CO LTD

A safe basketball self-training device based on basketball training

ActiveCN112451935BScientific and reasonable structureEasy to useBall sportsVentilation tubePhysical medicine and rehabilitation

The invention discloses a safe basketball self-training device based on basketball training, which includes a fixed base, and a cleaning mechanism is installed inside the fixed base, and the cleaning mechanism includes a block, an electric telescopic rod, a driving roller, a rotating motor, Driving shaft, linkage motor, connecting rod, driven roller, transmission belt, linkage shaft, driven shaft, L-shaped rod, cleaning brush, dust cover, ventilation pipe, blower fan, air outlet pipe and collection box, the present invention is cleaned by cleaning The mechanism is convenient for the athletes to clean the collected basketballs, and it is also convenient for the athletes to limit the position of the basketballs during cleaning, so as to avoid the phenomenon of the position movement of the basketballs during cleaning. At the same time, it is also convenient for the athletes to collect and process the cleaned impurities , thereby reducing the difficulty of cleaning the impurities, thereby avoiding the discomfort caused by the impurities attached to the surface of the basketball to the athletes holding the basketball, and optimizing the cleaning process of the basketball self-training device.

Owner:JILIN NORMAL UNIV

A chip-based processing and production equipment

The invention relates to the technical field of chip processing, and discloses machining and production equipment for chips. The machining and production equipment comprises a lower mold. Supporting blocks are fixedly connected to the two sides of the lower mold. The top of each supporting block is fixedly connected with a supporting rod. The outer surfaces of the supporting rods are movably provided with a supporting plate in a sleeved manner. An upper mold is fixedly connected to the side face of the supporting plate. The bottom of the upper mold is fixedly connected with a packing block. Limiting springs located on the outer surfaces of the supporting rods are fixedly connected to the bottom of the supporting plate. Through the action of the supporting blocks, the contact area of the lower mold and the supporting rods is increased, the supporting rods are prevented from falling off from the lower mold during use, and meanwhile the precision of contact between the lower mold and theupper mold is increased; through the action of the supporting plate, movement of the upper mold is facilitated; through the function of the packing block, processing and production of the chips are facilitated; and through the action of locating pins, the situation that the upper mold moves upwards all the time, and the supporting plate is driven to move out of the range of the supporting rods isavoided.

Owner:深圳市天昕朗科技有限公司

Complete sets of equipment for garment processing

ActiveCN106367938BEasy to storeKeep drySevering textilesWork-collecting devicesPulp and paper industryDrying Agents

The invention discloses complete equipment for tailoring. The complete equipment comprises a fabric storage cabinet, a fabric cutting machine, a sewing machine, a button sewing machine and an ironing machine, wherein the fabric storage cabinet comprises a cabinet body; the cabinet body is divided into left and right fabric accommodating cavities by virtue of a drying agent separator which is arranged at the center of the cabinet body, and the length of each fabric accommodating cavity is equal to the diameter of the fabric; the top end of the cabinet body is connected with a cover plate through a rotary hinge; a base is arranged at the bottom end of the cabinet body; and bottom ends of left and right side walls of the cabinet body are respectively connected with an upward lifting door through the rotary hinge. The fabric storage cabinet can be used for greatly reducing the time for searching fabrics, the dryness of the environment in the cabinet body is effectively maintained, and long-term fabric storage is facilitated.

Owner:MEISHENG CULTURE INNOVATION HLDG

Safety basketball self-training device based on basketball training

ActiveCN112451935AScientific and reasonable structureEasy to useBall sportsVentilation tubePhysical medicine and rehabilitation

The invention discloses a safety basketball self-training device based on basketball training, which comprises a fixed base, a cleaning mechanism is arranged in the fixed base, the cleaning mechanismcomprises a check block, an electric telescopic rod, a driving roller, a rotating motor, a driving shaft, a linkage motor, a connecting rod, a driven roller, a transmission belt, a linkage shaft, a driven shaft, an L-shaped rod, a cleaning brush, a dust suction hood, a ventilation pipe, a draught fan, an air outlet pipe and a collecting box. The basketball cleaning device is simple in structure and convenient for athletes to limit the position of a basketball during cleaning, so that the basketball is prevented from moving during cleaning, meanwhile, the athletes can conveniently collect and treat cleaned impurities, the cleaning difficulty of the impurities is reduced, and the cleaning efficiency is improved. Therefore, the influence of impurities attached to the surface of the basketballon discomfort caused when athletes hold the basketball with hands is avoided, and the cleaning process of the basketball self-training device is optimized.

Owner:JILIN NORMAL UNIV

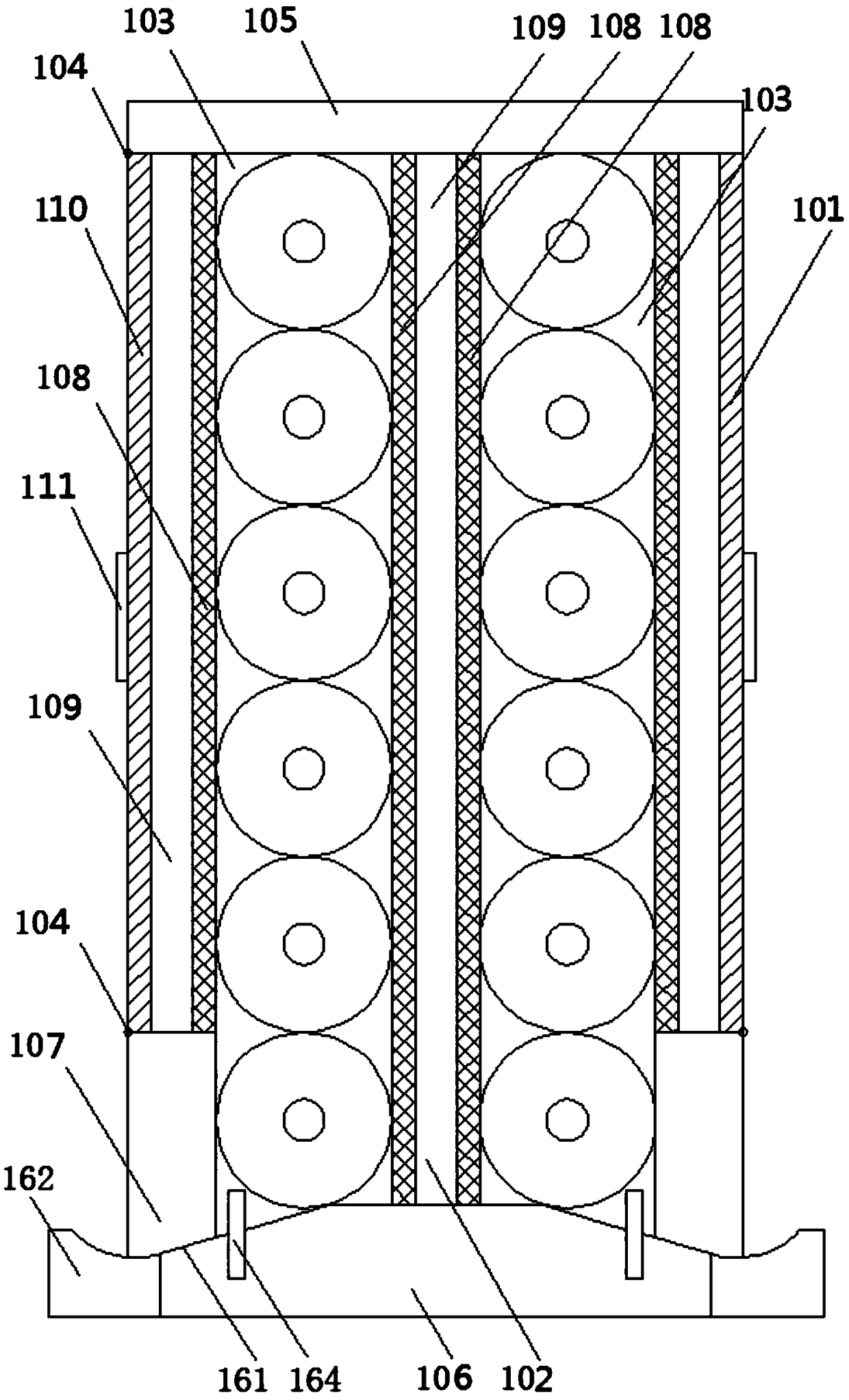

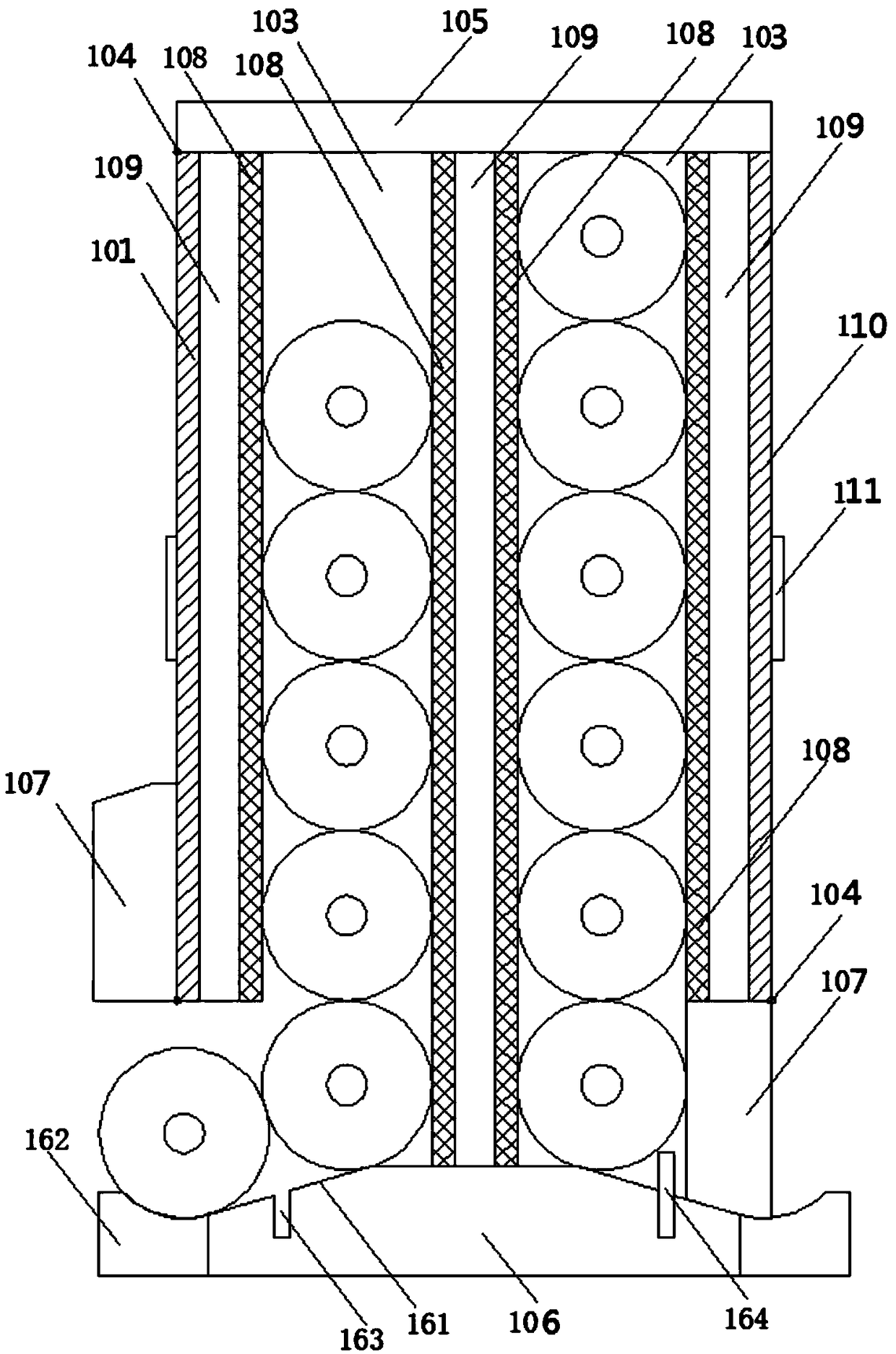

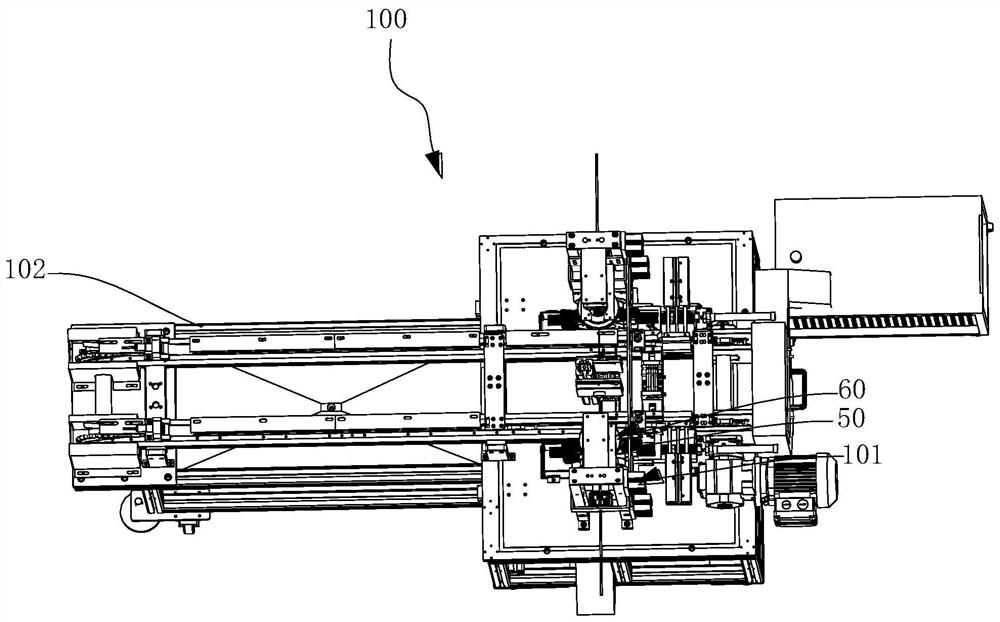

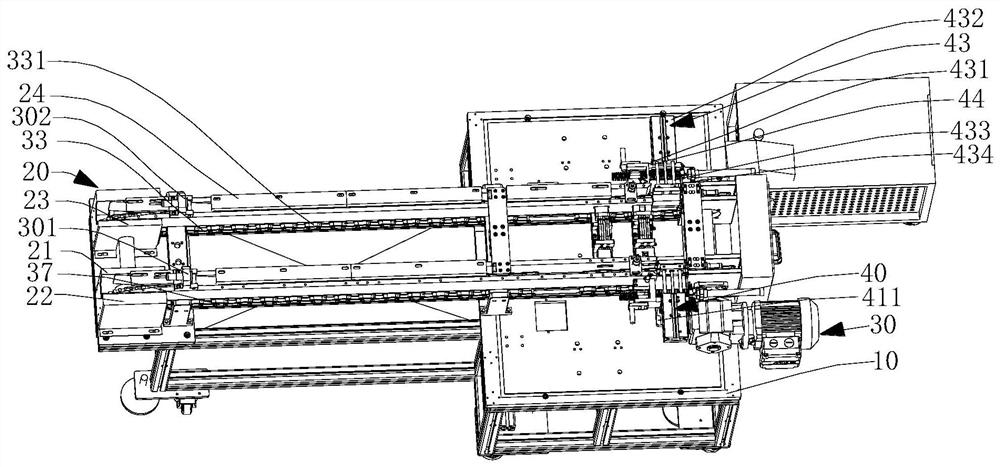

Spring detection equipment, spring detection method and device

ActiveCN108846836BAvoid manual pickingEasy to operateImage enhancementImage analysisMechanical engineeringPhysics

Owner:慕贝尔汽车部件(太仓)有限公司

A kind of tea spread green processing system and tea spread green processing method

ActiveCN108782829BHigh degree of automationIncrease moisture contentPre-extraction tea treatmentProcess engineeringTea leaf

The invention relates to a green tea stand processing system and a tea stand green processing method thereof, comprising a base plate, a support column, a support fixing frame, a turning device, a positioning device, a green spread device and a recovery device, and a support column is installed on the top of the base plate , the upper end of the supporting column is equipped with a supporting fixed frame, the middle part of the supporting fixed frame is equipped with a turning device, the front and rear sides of the supporting fixed frame are symmetrically equipped with positioning devices, and the upper end of the turning device is equipped with a spreading device. The present invention solves the problem that the existing tea leaves are usually manually operated, the labor intensity is high, the efficiency is low, the thickness of the manual spreading is uneven, and the thickness requirements of the tea cannot be met, and the tea leaves at the bottom are not easy to turn over To the upper layer, the tea leaves at the bottom layer cannot be fully dried, which affects the water loss rate of the tea leaves. At the same time, the tea leaves are prone to fall when they are spread green, and cannot be collected automatically. The operation is complicated, the production efficiency is low, the stability is poor, and the tea leaves cannot be turned over automatically. Wait for the problem.

Owner:湖南壶瓶山茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com