High-efficiency rubber crusher and recovery method of waste rubber

A rubber breaker and rubber technology, which is applied in the direction of mechanical material recycling, plastic recycling, recycling technology, etc., can solve the problems of rubber sticking to the blade, increasing the working load of the motor, and blocking the rotation of the blade, so as to improve production efficiency , Guarantee the crushing effect and the quality of the broken glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

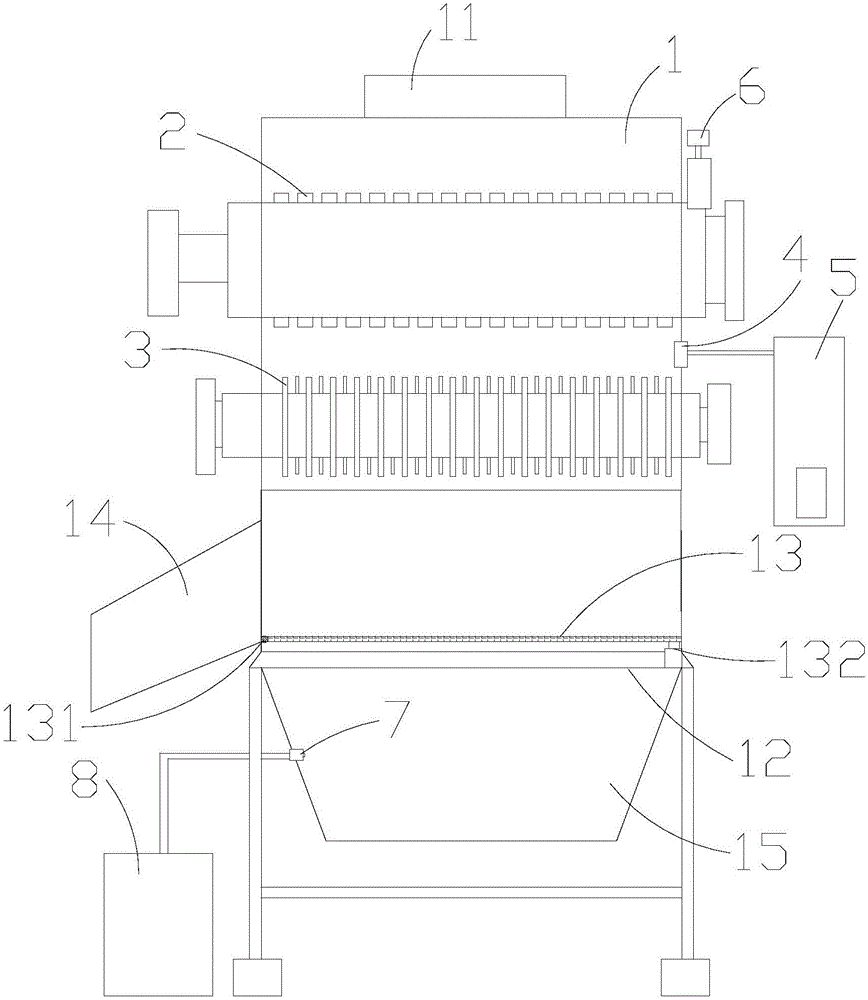

[0021] Such as figure 1 As shown, the present invention provides a high-efficiency rubber breaker, including a breaker chamber 1, a roller assembly 2 installed in the upper part of the breaker chamber 1, a rubber cutting assembly 3 installed in the middle of the breaker chamber 1, a drive The power assembly of the roller assembly 2 and the rubber cutting assembly 3. The roller assembly 2 includes two rollers that cooperate with each other. The rubber cutting assembly 3 includes a moving knife and a fixed knife that cooperate with each other. The glue breaking chamber 1 The top is provided with a feed port 11, the bottom of the gel breaking chamber 1 is provided with a discharge port 12, and the discharge port 12 is equipped with a screen 13, and one end of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com