Automatic safe rubber crusher

A rubber breaker and rubber technology, which is applied in the direction of mechanical material recovery, filter screen, grille, etc., can solve the problems of affecting rubber cutting, increasing the working load of the motor, and uneven force on sundries, so as to reduce labor intensity and ensure The effect of safe operation and improved gel breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

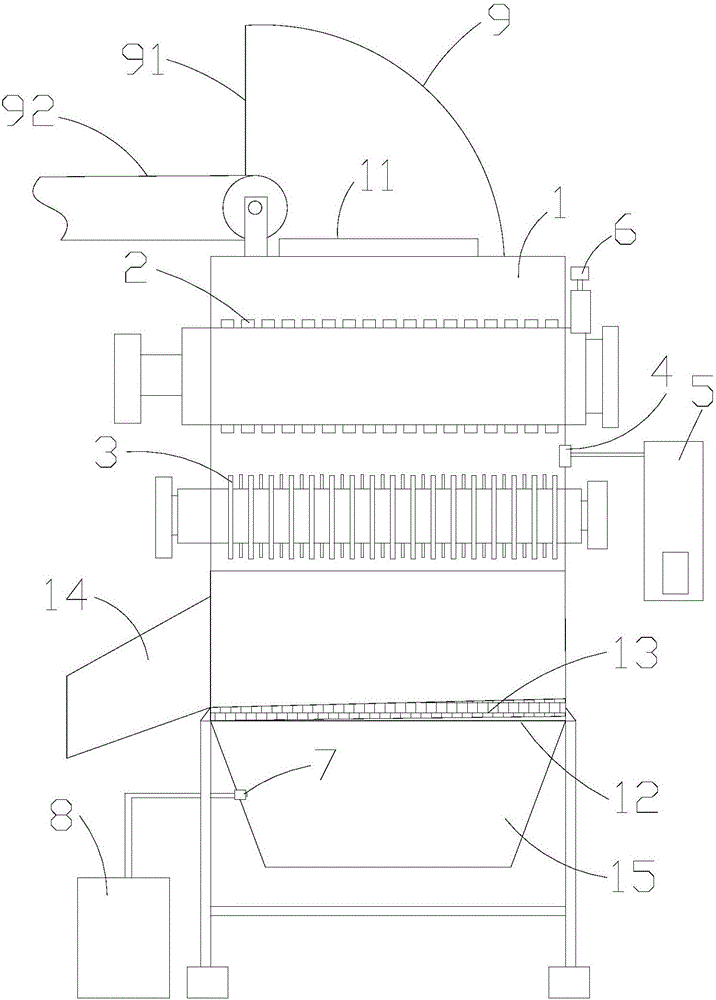

[0018] Such as figure 1 As shown, the present invention provides an automatic safety rubber breaker, including a breaker chamber 1, a roller assembly 2 installed in the upper part of the breaker chamber 1, a rubber cutting assembly 3 installed in the middle of the breaker chamber 1, The power assembly for driving the roller assembly 2 and the rubber cutting assembly 3. The roller assembly 2 includes two rollers that cooperate with each other. The rubber cutting assembly 3 includes a moving knife and a fixed knife that cooperate with each other. The glue breaking chamber 1 is provided with a feeding port 11 on the top, and a discharge port 12 is provided at the bottom of the gel breaking chamber 1, and a screen 13 is installed on the discharge port 12, and a bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com