Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

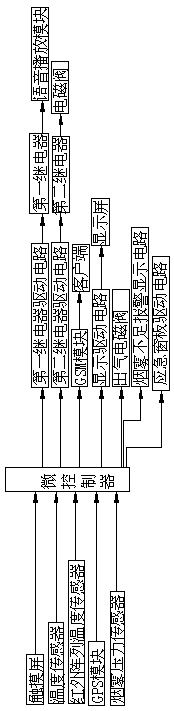

246results about How to "Avoid fatal accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent and quick fault diagnosis instrument for bearing and diagnosis method thereof

InactiveCN107167318AHigh degree of intelligenceUnleash your work potentialMachine bearings testingTime domainData acquisition

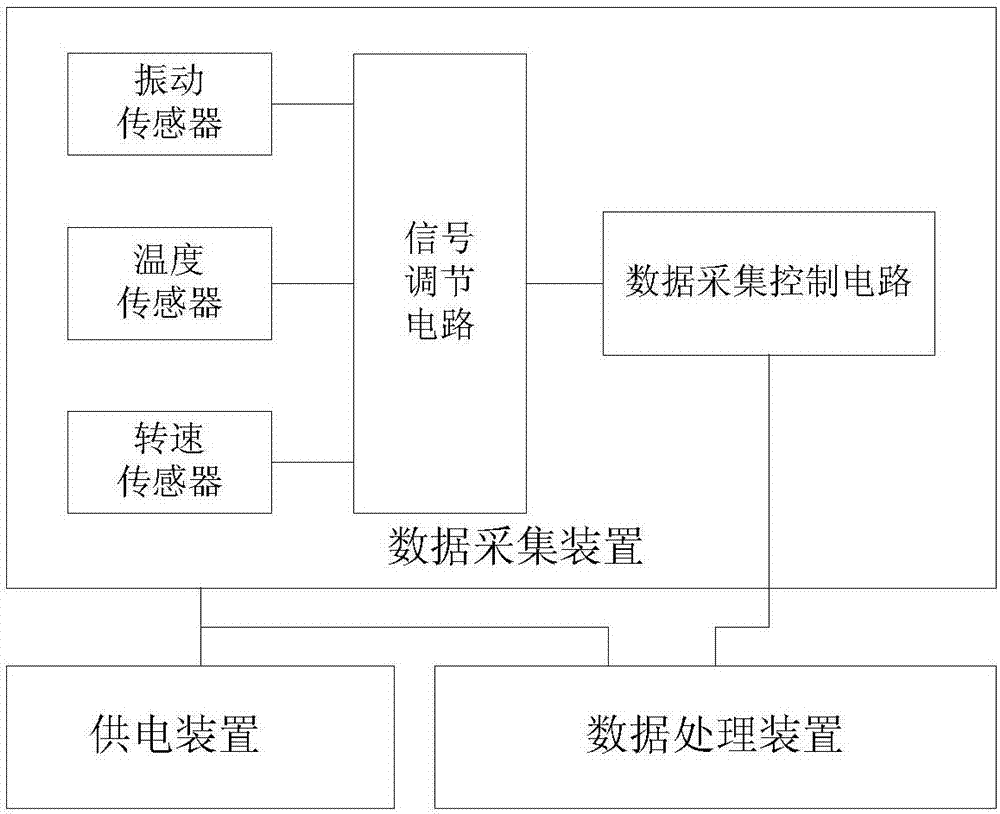

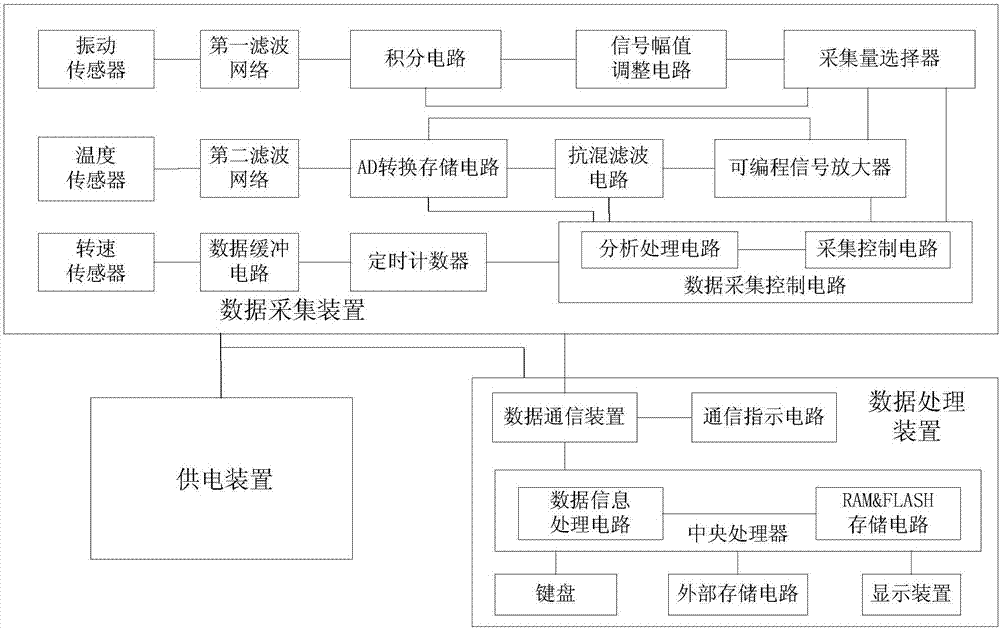

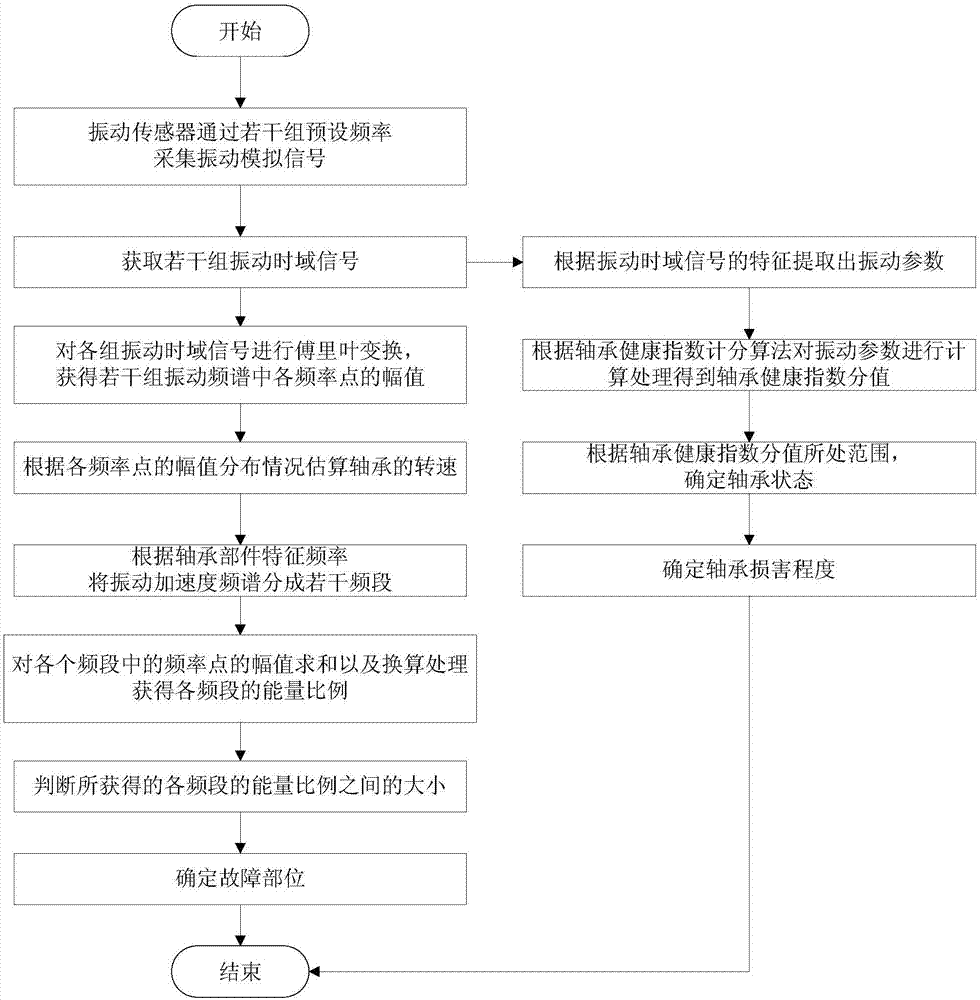

The invention relates to an intelligent and quick fault diagnosis instrument for a bearing and a diagnosis method thereof. The fault diagnosis instrument comprises a data acquisition device and a data processing device which are connected with each other. The data acquisition device comprises a vibration sensor. The data acquisition device acquires a vibration analog signal of a processed bearing based on the vibration sensor. The data processing device acquires the vibration analog signal through a plurality of preset frequencies and obtains a plurality of sets of vibration time domain signals, and then the data processing device performs a series of processing analysis on each vibration time domain signal for finally determining a fault part. The intelligent and quick fault diagnosis instrument and the diagnosis method thereof can generate a clear fault description which comprises a bearing fault development period, a bearing damage part and bearing damage degree. The intelligent and quick fault diagnosis instrument and the diagnosis method further have advantages of high intelligence degree, and low dependence for a professional skill and experience of an operator.

Owner:北京时代龙城科技有限责任公司

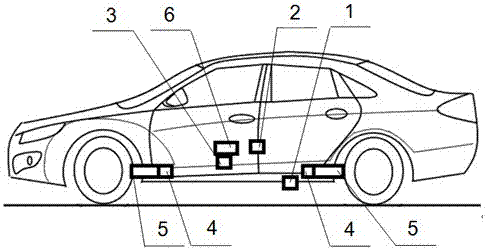

Safety protection device for preventing from mistakenly stepping on accelerator of car

ActiveCN103640479ANo change in driving habitsEasy driving habitsAcoustic signal devicesAutomatic initiationsTraffic accidentControl circuit

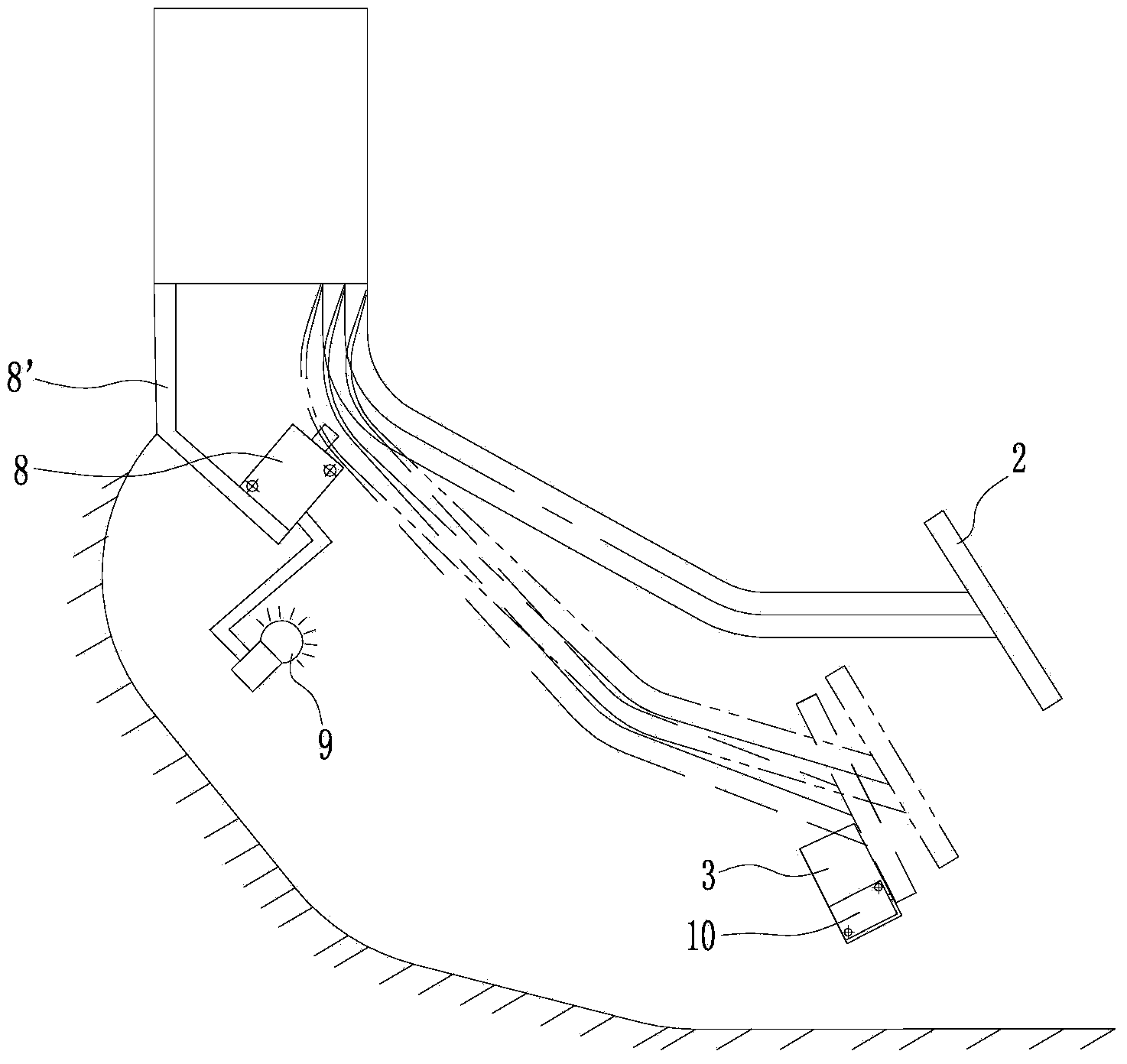

The invention discloses a safety protection device for preventing from mistakenly stepping on an accelerator of a car. According to the safety protection device, an accelerator limit early-warning switch (8) and an engine stalling switch (10) are arranged in a rotating range of an accelerator pedal (2); the accelerator limit early-warning switch (8) is connected with an accelerator limit warning lamp or a voice prompter (9) by a lead wire; the engine stalling switch (10) is mounted on a brake linkage plate (7) and is connected with an engine stalling relay (11) by a lead wire; the engine stalling relay (11) is connected into a control circuit of an engine in series. According to the safety protection device for preventing from mistakenly stepping on the accelerator of the car, a caution and reminding effect is realized when a pre-set speed is exceeded under the precondition of not influencing the normal manipulation of the car, and then a driver can lower the car speed in time; when the driver violently steps on the accelerator pedal by mistake, the safety protection device can timely control the engine to be stalled and emergently brake for stopping the car, so that major traffic accidents or casualty accidents are effectively avoided.

Owner:铜陵市创威科技股份有限公司

Fast wave eliminating/energy dissipating/cushioning device for mining

The invention belongs to a support facility for mining security and particularly relates to a fast wave eliminating / energy dissipating / cushioning device for mining. The device comprises an upper rigid sleeve (1) and a lower rigid sleeve (2), wherein the bottom of the lower rigid sleeve (2) is fixed with an external bottom cover (6) through threaded connection, the lower rigid sleeve (2) on the external bottom cover (6) is internally provided with a cylindrical compressible energy absorbing material (5), an internal rigid bottom cover (4) is mounted on the energy absorbing material (5), the upper rigid sleeve (1) is arranged on the internal rigid bottom cover (4) through threaded connection, four pin clamps (3) with the same shape are mounted on the lower rigid sleeve (2) in a clamping manner, the internal surface of a circular ring is provided with a trapezoidal boss (3-3), and the trapezoidal boss (3-3) is embedded in a trapezoidal groove (1-1) in the external wall of the upper rigidsleeve (1). Thus, the fast wave eliminating / energy dissipating / cushioning device for mining can avoid damage of mechanical production facilities and casualty accidents of working personnel to the greatest extent.

Owner:LIAONING TECHNICAL UNIVERSITY

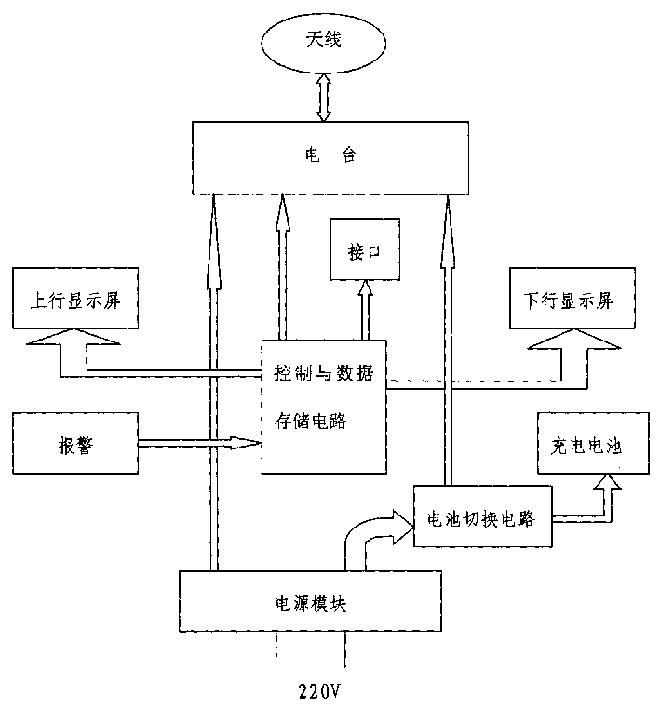

Digital crossing safety early warning device for railway crossing and its method

ActiveCN1491846ALong transmission distanceFastRoad traffic warning meansData transmissionLevel crossing

The present invention discloses a digital railway crossing safety early warning device and method. The early warning device can perform radio communication with train running in railway, and works on comprehensive digital station. The early warning device receives the approach signal the train sends and sends to the train the crossing status information. It has digital work mode and its radio emitting and receiving frequency channel dissimilar to that for train scheduling. Owing to the far transmission distance, fast rate, low error code rate and standard interface, the present invention has no problems of co-channel interference and radio train scheduling signal cross-talk, and can realize the high reliability data transmission between the train and the approached crossing.

Owner:BEIJING CENTURY DONGFANG COMMUNICATION EQUIPMENT CO LTD

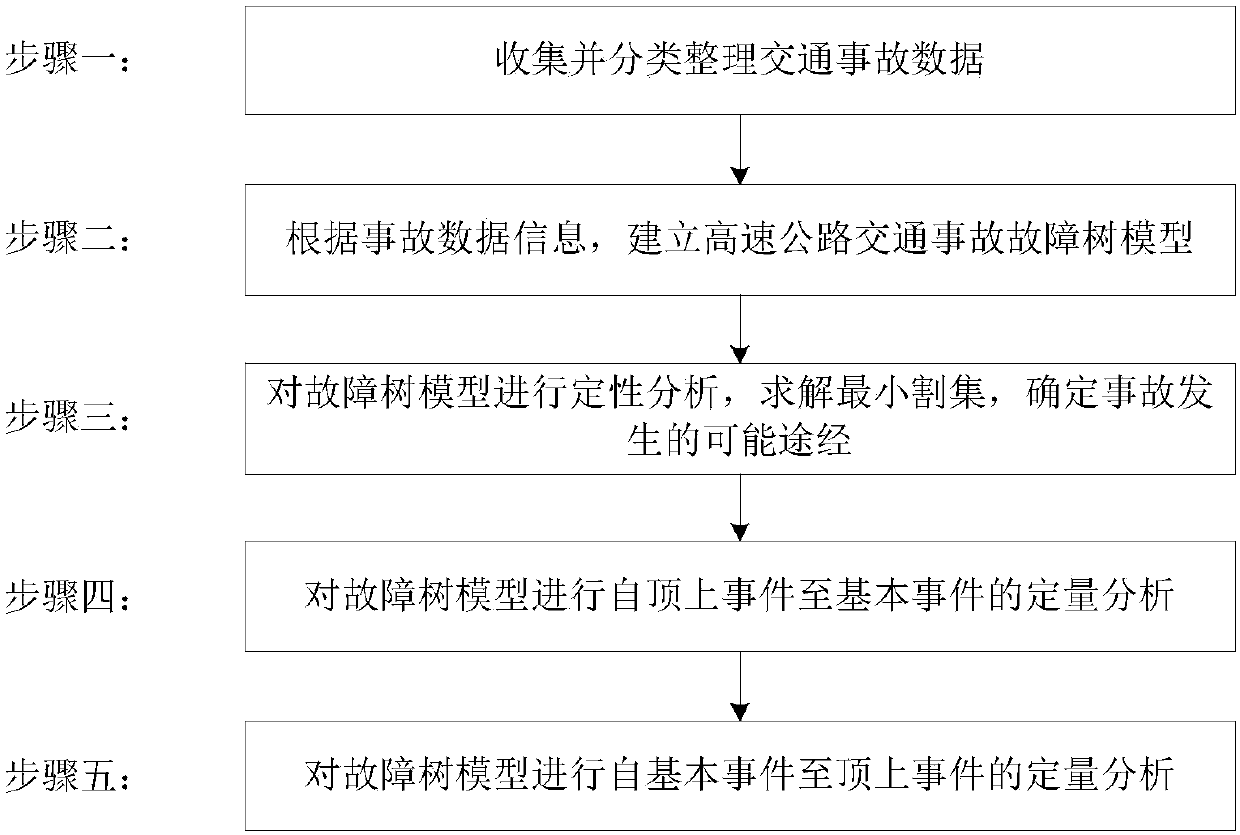

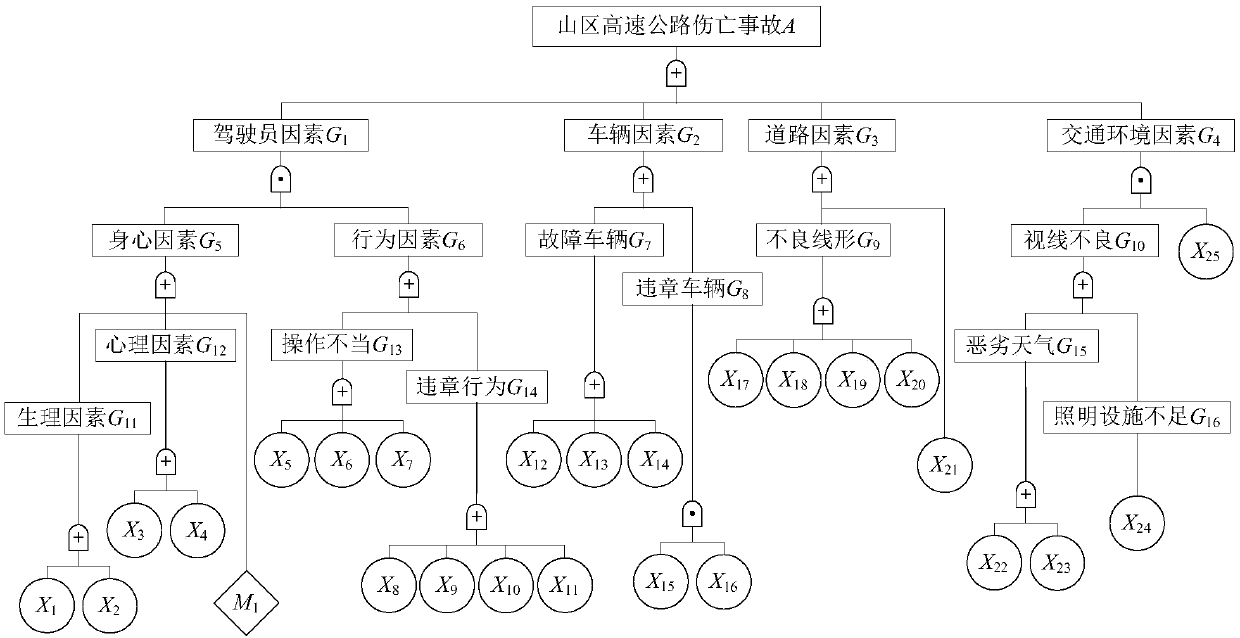

Highway traffic accident reason analysis method based on fault tree model

InactiveCN108550263AImprove the accuracy of cause analysisThe process is simple and easy to understandDetection of traffic movementTraffic accidentSimulation

The invention relates to a highway traffic accident reason analysis method based on a fault tree model and aims at solving the defects that highway traffic accident reason analysis is mostly limited by the qualitative analysis of accident causes, and accident influence factor weight size and the like cannot be determined well, and therefore, the accuracy for the highway traffic accident reason analysis is low. The process is as follows: 1, carrying out collection and classified arrangement on traffic accident data; 2, constructing a highway traffic accident fault tree model; 3, determining allaccident chains of the events; 4, acquiring the main reason chain of highway traffic accidents; and 5, acquiring the proportions of four factors including drivers, vehicles, roads and traffic environment in the traffic accidents. The method can be used for the technical field of highway traffic accident reason analysis.

Owner:HARBIN INST OF TECH +1

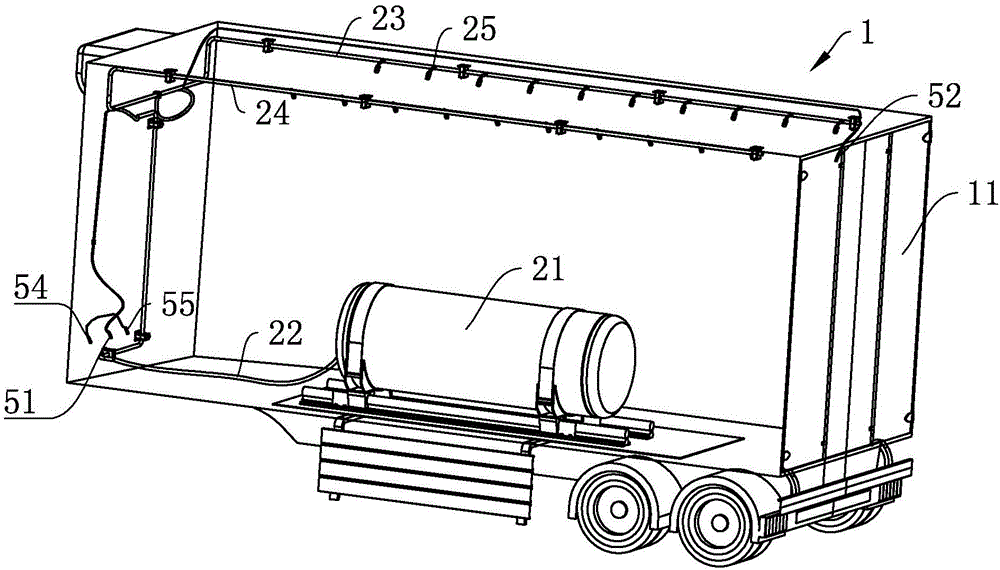

Car-mounted liquid nitrogen spraying and refrigerating system

InactiveCN106183956AAvoid fatal accidentsPrevent frostbiteDomestic cooling apparatusLighting and heating apparatusBody compartmentNitrogen

The invention discloses a car-mounted liquid nitrogen spraying and refrigerating system which comprises a compartment and a liquid nitrogen storage tank. A liquid nitrogen atomizing and spraying mechanism is arranged in the compartment and connected with the liquid nitrogen storage tank through a pipeline, and a human body induction mechanism is further arranged in the compartment and connected to a single-chip microcomputer. The car-mounted liquid nitrogen spraying and refrigerating system has the advantages that a liquid nitrogen atomizing and spraying pipeline connected with the liquid nitrogen storage tank is arranged at the top of the compartment, it is guaranteed that liquid nitrogen is fully atomized and absorbs heat to form nitrogen, and it is avoided that liquid nitrogen drops drop onto a product, and consequently the product is freeze-damaged. The personnel recognition device is arranged in the compartment, it is guaranteed that atomizing and spraying are carried out under the condition that no person exists, and casualty accidents caused by misoperation are effectively eradicated.

Owner:山东奥扬新能源科技股份有限公司

Method and apparatus for detecting insulating resistance and releasing static electricity

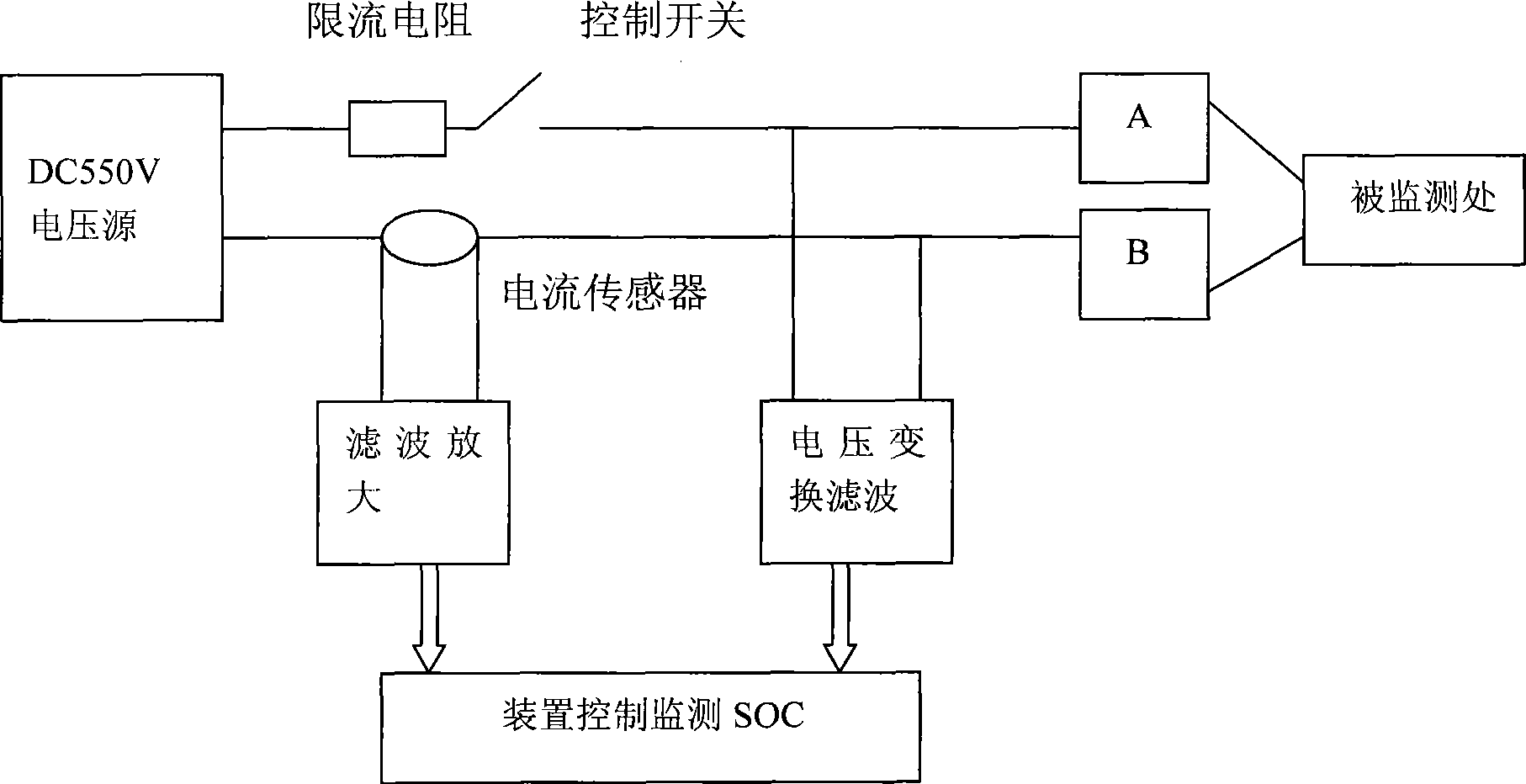

InactiveCN101435837AIncrease productivityReduce labor intensityResistance/reactance/impedenceEmergency protective arrangements for limiting excess voltage/currentElectrical resistance and conductanceDirect current

The invention relates to a method for detecting an insulating resistance and releasing static electricity and a device thereof. An insulating detection point is set in each position of detected equipment which needs the insulating resistance detection; a direct current power supply is arranged outside the detected equipment; direct current with certain voltage is generated through the direct current power supply and is transported to the insulating detection point set in each position of the detected equipment which needs the insulating resistance detection; simultaneously, a voltage and current detection device is arranged in the middle of a direct current loop; the change of the direct current voltage and current of the insulating detection point set in each position of the detected equipment which needs the insulating resistance detection is detected and compared through the detection device; a monitoring device carries out voltage and current calculation to obtain the insulating resistance of the insulating point, judges whether the insulating resistance of the insulating point is normal and forewarns or warns according to the detected insulating resistance; simultaneously, according to the monitoring device, the output static voltage is determined, whether static release is needed is judged, and under the condition of needing static release, the static voltage is released for passing through a resistance network.

Owner:ZHUZHOU TIANQIAO CRANE

Passenger vehicle flooding resistance airbag system

InactiveCN106945623AAvoid fatal accidentsImprove securityPedestrian/occupant safety arrangementAirbag deploymentAutomotive engineering

The invention provides a highly safe passenger car anti-flooding airbag system, which includes a sensor system, a safety airbag control module and an airbag system. The lower water level sensor is used to monitor the warning wading depth that will cause engine damage, and transmit the vehicle wading signal to the airbag control module; the upper water level sensor is used to monitor the dangerous wading depth that will cause the occupant to drown, and send the vehicle wading signal to the airbag control module. The wading signal is transmitted to the airbag control module; the gravity sensor is used to sense the inclination angle signal of the vehicle on the X-axis and the Y-axis, and transmits the inclination angle signal to the airbag control module; the airbag control module Make corresponding judgments on various signals, and send corresponding action signals to the airbag system to control the work of the airbag system, so that the airbag is fully deployed to provide enough buoyancy to float the passenger car on the water surface, avoiding passenger casualties caused by submersion of the passenger car ACCIDENT. Therefore, the security is higher.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

Portable short circuit grounding wire monitoring platform

ActiveCN108598735AUnderstand the work statusUnderstand power informationElectrical testingElectric connection structural associationsComputer moduleElectrical connection

The invention provides a portable short circuit grounding wire monitoring platform. The portable short circuit grounding wire monitoring platform is composed of a monitoring module, a communication forwarding control module and a computer background server; the monitoring module is installed on a grounding rod or a ground clamp; a bare conductor which is hung on the grounding rod or the ground clamp is in contact with an electrode to form an electrical connection loop; the electrical connection loop is connected with the monitoring module on the grounding rod or ground clamp through a lead; anthe monitoring module transmits detected wire hanging state information and electric quantity information of a power supply battery of the monitoring module to the communication forwarding control module through a wireless transparent transmission mode, and the wire hanging state information and the electric quantity information are transmitted to a remote computer background server through a network. According to the portable short circuit grounding wire monitoring platform provided by the invention, the working state of the used ground wire, the electric quantity information of the battery,and the satellite positioning position of the ground wire of the used field of the ground wire can be timely and accurately known. Through an alarm function for a violation operation when the groundwire is removed at the end of work, casualty accidents of accidental electric shocks caused by the violation operation can be timely avoided.

Owner:圣耀(集团)有限公司

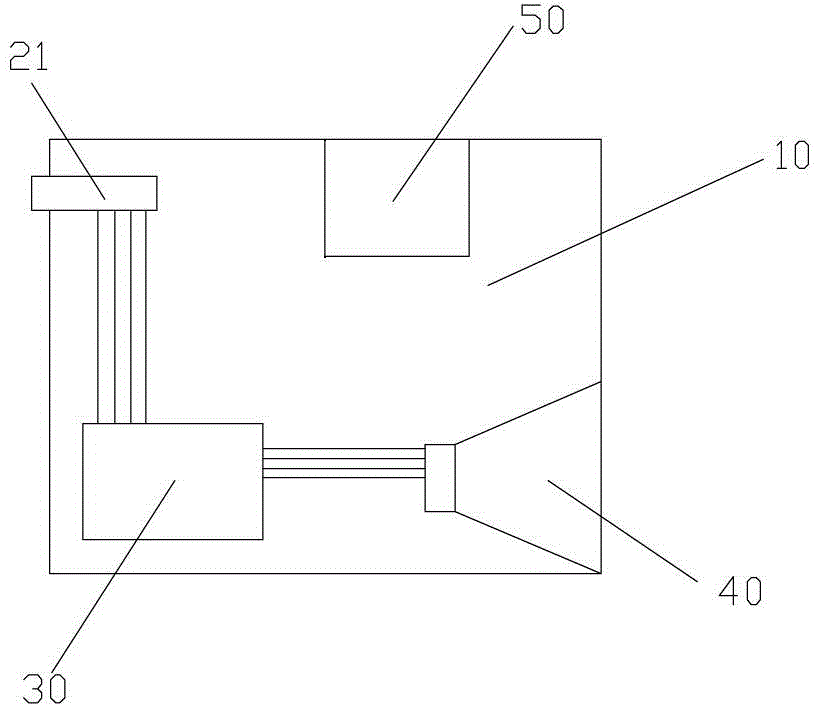

Straying alarm device

The invention provides a straying alarm device which comprises a detection portion, a controller (30) and an alertor (40). The detection portion detects whether people intrude in a protection area and sends signals according to detection results. The controller (30) is connected with the detection portion and receives the signals sent by the detection part. The alertor (40) is connected with the controller (30). The controller (30) controls the alertor (40) to give out alarm according to the signals sent by the detection portion. The straying alarm device can give out an alarm when people stray into the protection area to remind the strayed people of danger, the problem that loss of life and personal injury are prone to being caused when field operation of a transformer substation, a switching station and the like is carried out is solved, and working safety is improved.

Owner:STATE GRID CORP OF CHINA +1

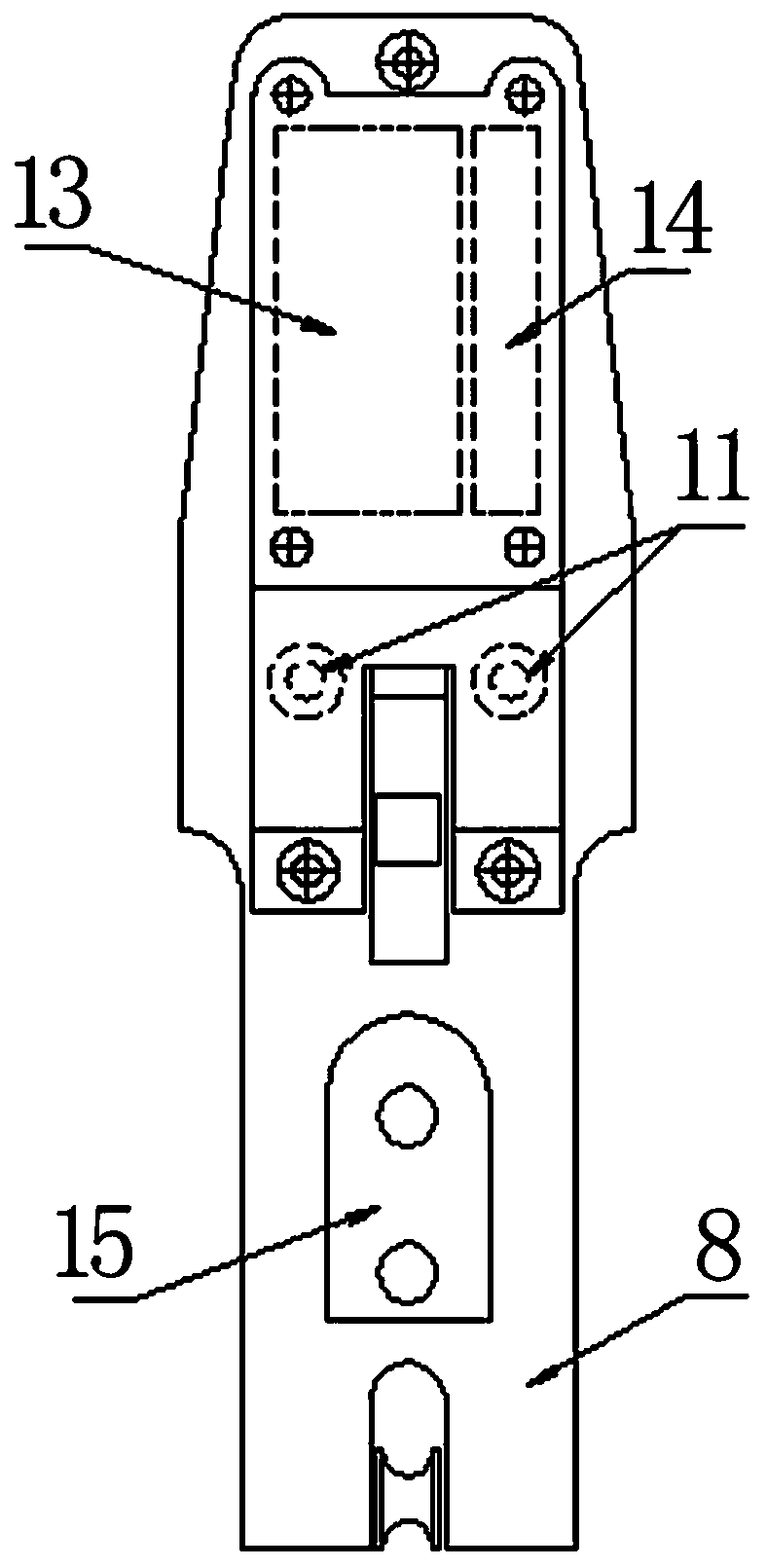

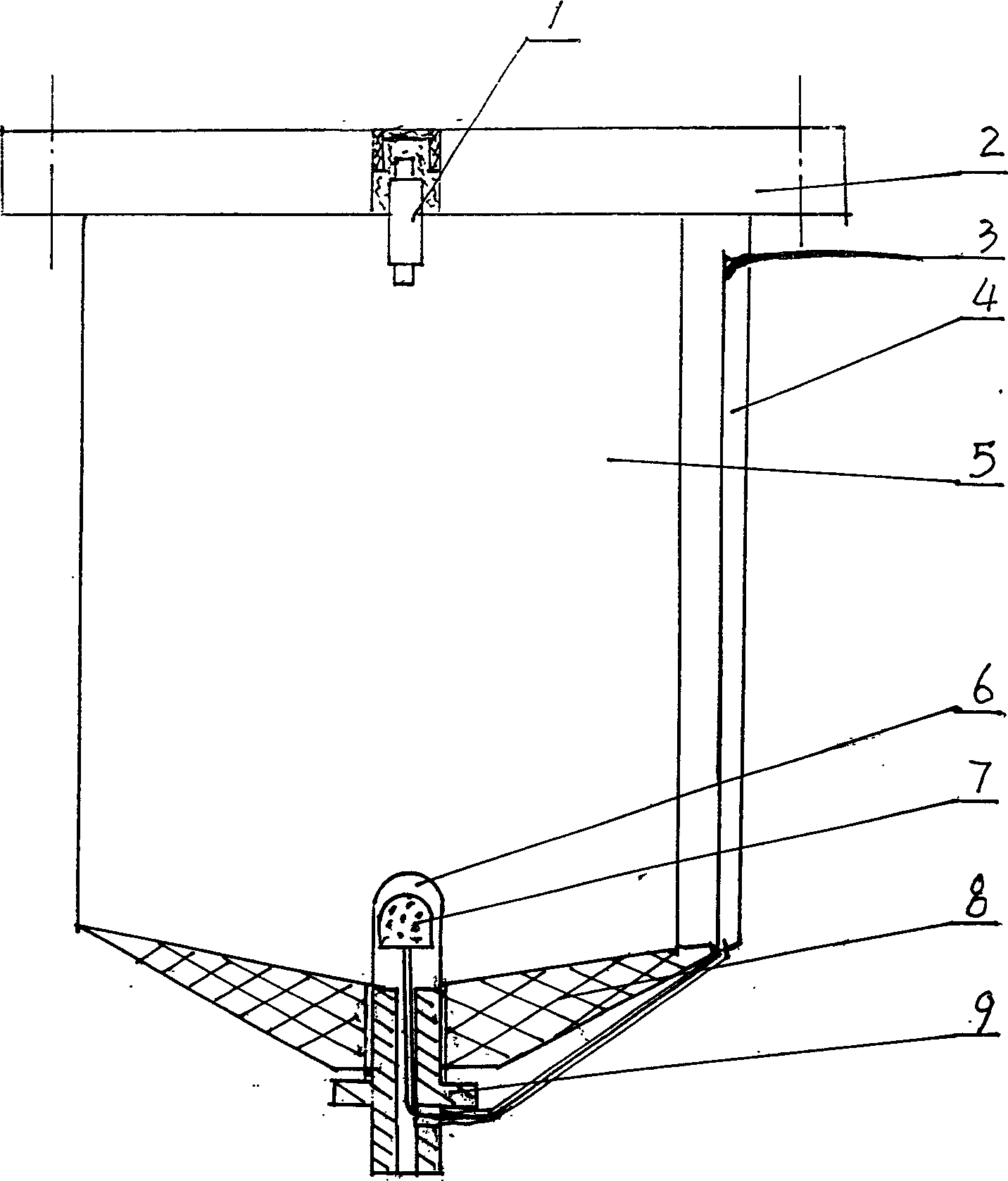

Active type falling protector

InactiveCN103159108AAvoid fatal accidentsPlay an active anti-fall effectElevatorsGear wheelElectric machinery

The invention relates to a safe falling protector of elevators or construction lifters. An active type falling protector is characterized in that an electromagnet coil 9 of the falling protector is connected with a hoisting motor in parallel, when the elevators or the construction lifters are in a static state, a rack 5 of the falling protector drives small gears 4 under the effect of a reset spring 14, the small gears 4 drive eccentric clamping wheels 3 to clamp guide rails 15, and at the moment, the guide rails 15 are tightly clamped by the falling protector. Only after the hoisting motor is power on and started, the electromagnet coil 9 can act and pulls an armature 10, the armature 10 drives a pull bar 7 which pulls the rack 5, the rack 5 drives the two small gears 4 drive the two eccentric clamping wheels 3, the two eccentric clamping wheels 3 are in reversed rotation, so that the clamping wheels 3 are in an opened state, and the elevators or the construction lifters can freely operate up and down. When the elevators or the construction lifters operate in an overloaded mode, people in the elevators or the construction lifters can shut down a power source of a master starting contactor through a button, so that the electromagnet coil 9 of the falling protector is enabled to loss power, the rack 5 enables the eccentric clamping wheels 3 to tightly clamp the guide rails 15 under the effect of the spring 14, and accordingly an active falling protecting effect is achieved, and occurrence of major accidents of casualties is avoided.

Owner:刘姚成

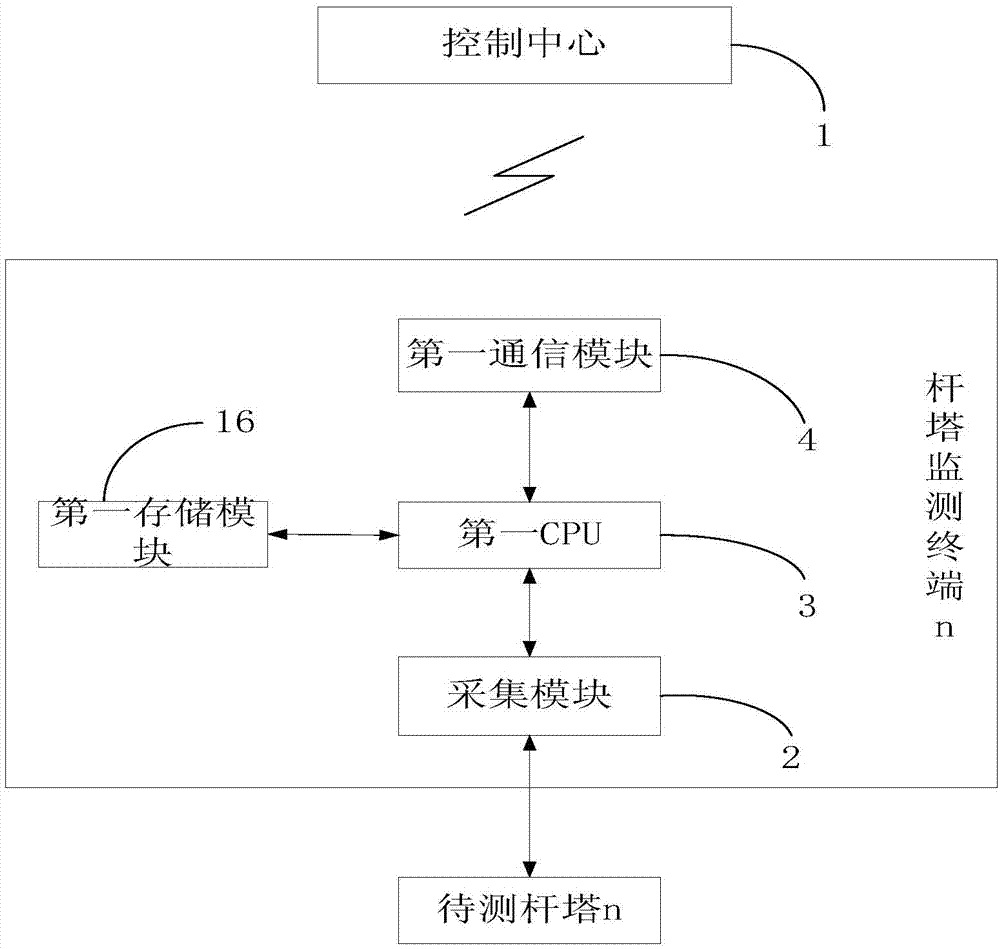

High voltage transmission tower monitoring method and system

ActiveCN104515500APrevent collapse accidentsAvoid fatal accidentsMachines/enginesLevel indicatorsTransmission towerComputer terminal

The invention discloses a high voltage transmission tower monitoring method and system. The system comprises a plurality of tower monitoring terminals and a control center (1) in wireless communication with the tower monitoring terminals. The plurality of tower monitoring terminals are all used for receiving a sampling instruction of the control center (1) and acquiring tower monitoring data which represent a geological condition of a tower foundation section of the tower, and processing the tower monitoring data and then transmitting to the control center (1). The control center (1) is used for sending the sampling instruction to the plurality of tower monitoring terminals at fixed times and receiving a plurality of groups of tower monitoring data acquired by the plurality of tower monitoring terminals, comparing the monitoring parameters of each group of tower monitoring data with corresponding reference parameters in stored reference data one by one, and executing corresponding operations according to comparative results. Due to the adoption of the high voltage transmission tower, the fully automatic online monitoring of the tower can be realized, and the monitoring results are accurate and reliable.

Owner:YUNNAN POWER GRID CO LTD LINCANG POWER SUPPLY BUREAU

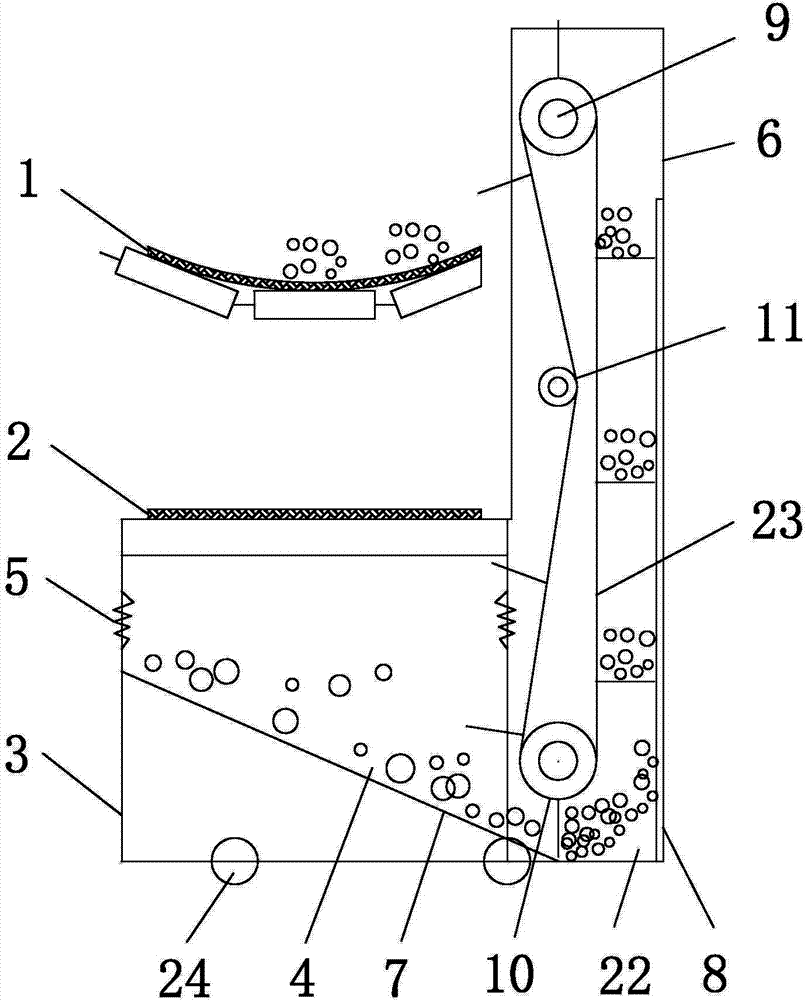

Belt sticky coal removing and recycling machine

The invention discloses a belt sticky coal removing and recycling machine which comprises a base, a rack arranged on one side of the base, and a fallen coal recycling transmission mechanism installed on the rack. The base is located below a lower belt of a belt conveyor, the upper end of the base is opened, the lower end of the base is closed, and a fallen coal bunker and a sticky coal cleaner are arranged in the base. A fallen coal containing cavity communicated with the fallen coal bunker is formed in the rack. The fallen coal recycling transmission mechanism comprises drive chain wheels installed on the rack, driven chain wheels opposite to the drive chain wheels in position, and a drive portion driving the driving chain wheels to rotate. Chains are arranged between the drive chain wheels and the driven chain wheels in a sleeved mode, the drive chain wheels are two in number, the driven chain wheels are two in number, correspondingly, the chains are two in number, and a coal shovel is arranged between the two chains. The belt sticky coal removing and recycling machine can be used for automatically removing sprinkled coal and effectively reducing the phenomena of belt deviation, equipment abrasion, machine tail roller blocking and the like caused by the sprinkled coal, and the maintenance cost of equipment is greatly cut down.

Owner:SHANDONG UNIV OF SCI & TECH

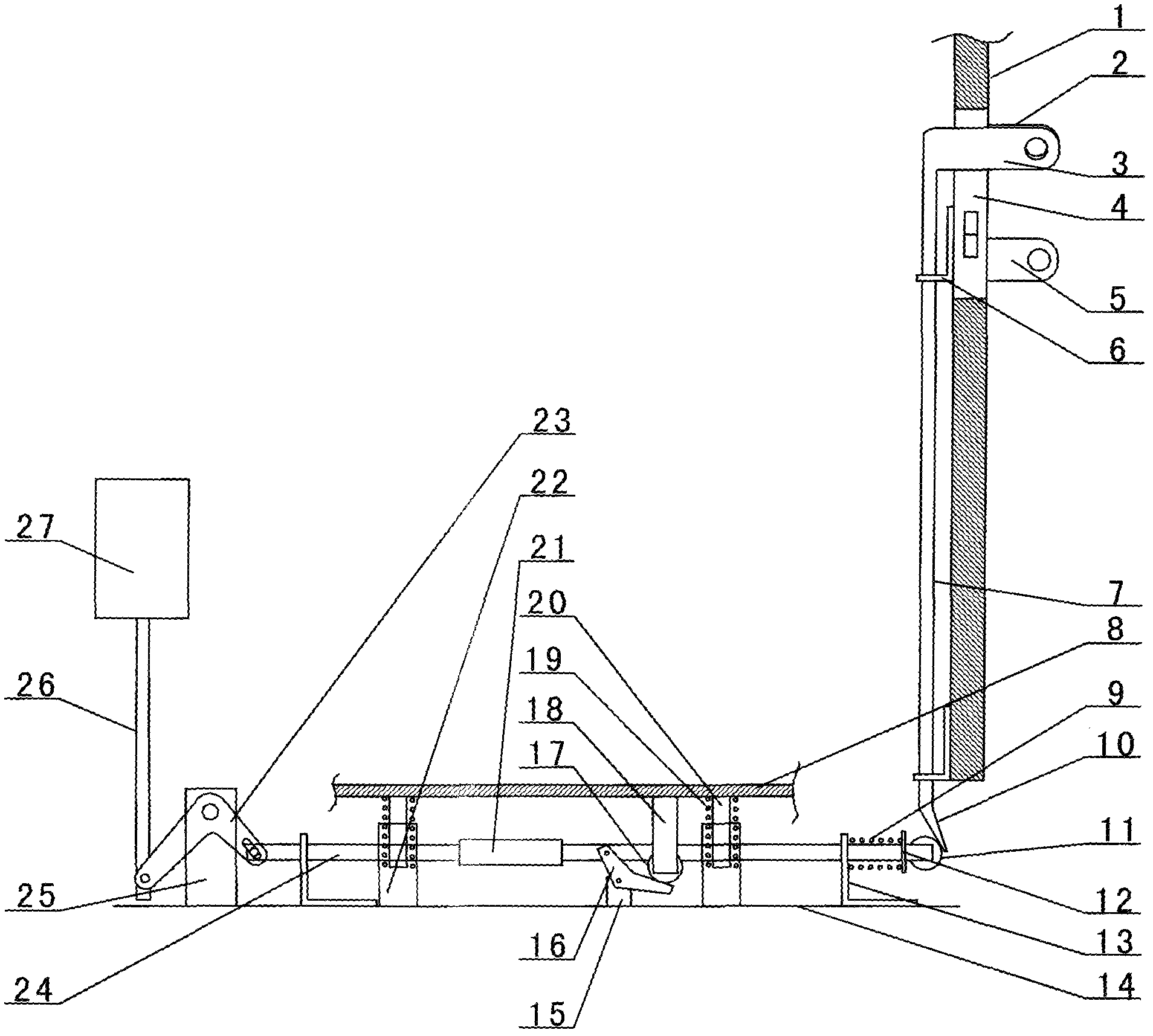

Manual-automatic integrated adjustable chair blocking device of descending flying cart by mine ropeway

ActiveCN102039901ABy not affectingControlled by electromagnet, when the mine ropeway is running normally, it will not affectRope railwaysEngineeringCable transport

The invention discloses a manual-automatic integrated adjustable chair blocking device of a descending flying cart by a mine ropeway, comprising a lifting frame; a fixed shaft is arranged on a movable plate which is arranged on the lifting frame by a U-shaped bolt; the fixed shaft is provided with a shaft sleeve which is fixed by a nut; the lower side of the shaft sleeve is provided with a baffle; the upper side of the shaft sleeve is provided with a shifting block; a traction electromagnet is arranged on the lifting frame; a pull rod of the traction electromagnet is connected with the shifting block; the electromagnet can be controlled by an over-speed safety protection circuit; a manual switch of the over-speed safety protection circuit is controlled by a pull rope; and a speed sensor is arranged at a supporting wheel side. The manual-automatic integrated adjustable chair blocking device has the beneficial effects that since the baffle is controlled by the electromagnet, when the mine ropeway operates normally, the electromagnet pulls up the baffle, so that the passing of a movable rope clip; when the mine ropeway generates power failures in operating process, and in cart flying, a lifting chair in the descending direction slides downwards and fast under the gravity function; and when the speed is detected to overpass the safety value by the speed sensor, the electromagnet pulls the baffle, the baffle moves downwards and is clamped on a steel wire rope, so that the movable rope clip can be prevented from sliding downwards, and the occurrence of casualty accidents of personnel sitting on the lifting chair can be avoided.

Owner:XIANGTAN HENGXIN IND

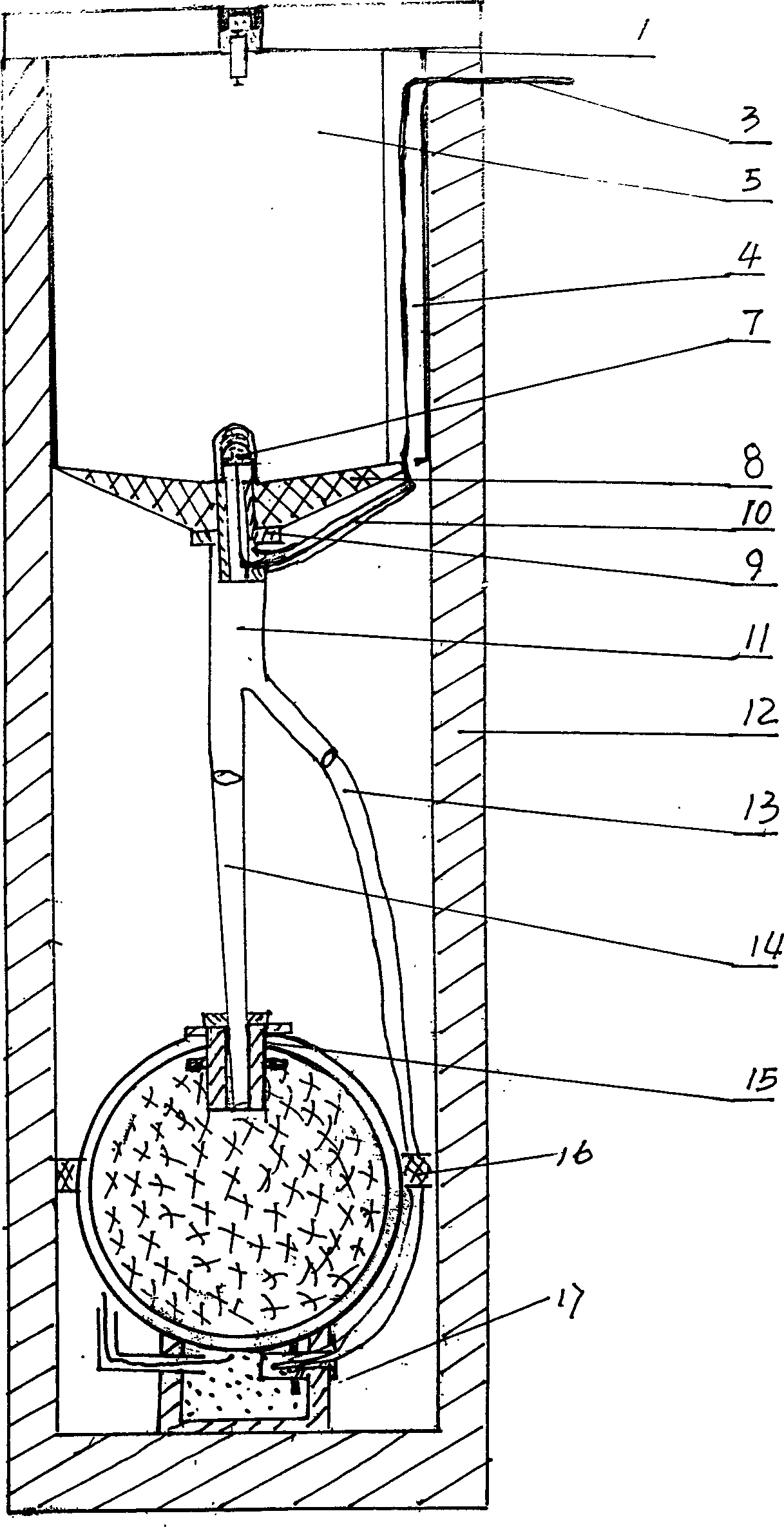

Unattended automatic driving system for gas high-outburst roadway

InactiveCN107575225AAvoid fatal accidentsRealize safe productionMining devicesDisloding machinesIntrinsic safetyControl system

The invention discloses an unattended automatic driving system for a gas high-outburst roadway. The unattended automatic driving system comprises an intelligent mining drill carriage and a remote control system for controlling the intelligent mining drill carriage. The intelligent mining drill carriage comprises a power system and an execution system driven by the power system. The execution system comprises a track-type rotating chassis, a supporting plate, two vertical columns, two fixing plates, corner lifting oil cylinders and a rod-replacing drilling system. The functions of automatic positioning hole-drilling, automatic drill-up, automatic drill connection, automatic drilling, automatic monitoring, intelligent identification and processing, automatic drill detaching and the like canbe achieved; mechanical, intelligent and unattended driving hole-drilling is achieved; casualty accidents caused by outburst of coal and gas in the coal roadway driving process are avoided; and intrinsically-safe production of driving of the gas high-outburst roadway is formed, the current situation of frequent major and extraordinarily-serious gas outburst accidents in the mine driving period inChina is turned around fundamentally, and safety production of gas high-outburst mines is achieved.

Owner:GUIZHOU INST OF TECH

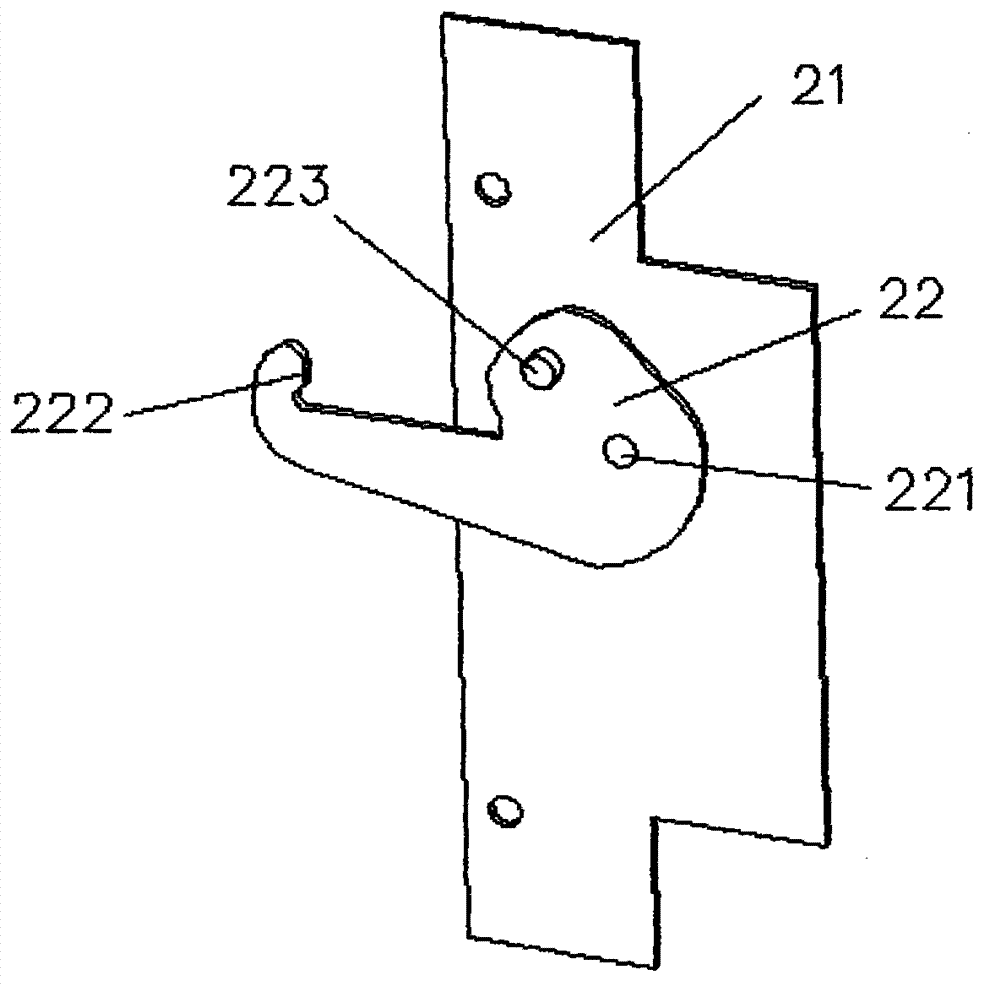

Device and method for blocking human body when elevator landing door is not normally opened

ActiveCN104724586ANormal use is not affectedNo hindranceElevatorsBuilding liftsEngineeringRotating disc

The invention relates to a device and method for blocking a human body when an elevator landing door is not normally opened. The device comprises a blocking start part and a blocking part. The blocking start part is composed of a large rotating disc, a small rotating disc, a pawl tripping mechanism, a rotating disc push rod and a starting part base, wherein the large rotating disc and the small rotating disc are connected with pawls respectively, and pawl tripping opening hooks are arranged below the pawls. The blocking part is composed of a locking hook, a blocking piece and a blocking part base. The method includes the steps that firstly, people can not enter an elevator cage when the elevator cage is not on a certain landing and the landing door of the landing is not normally opened, and therefore the safety protection effect is achieved; when the elevator cage arrives at the certain landing, the normal use of an elevator is not influenced. The casualty accident that people fall off a building from the landing door of the elevator can be prevented, and potential safety hazards can be eliminated; due to the mechanical blocking structure, blocking is visible and reliable.

Owner:梁伟联

Safe self-destruction device for fireworks

A safe self-destruction device of fireworks consists of pressure valve for water injection at top cover , powder train tube , high pressure water cavity , powder column cavity , fireproof cap , powder column , quick burning train , high pressure water and fire extinguishing chemical agent . The quick burning train can ignite powder column to explode powder column cavity for jetting out high pressure water to make fireworks lose their efficiency when there is open fire on transportation or in production.

Owner:赵子刚 +1

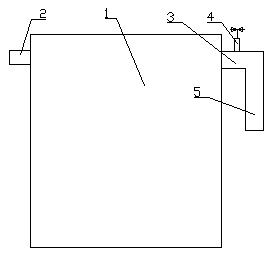

Pre-warning device used when elevator is close to landing door

The invention discloses an elevator near-floor door safety early warning device, which is composed of a door interlock switch (1), a distance sensor (2), a controller (3) and an audible and visual alarm device (4). The quantity of distance sensor (2) is more than one, is installed on the landing door of elevator, controls sound and light alarm device (4) to work by controller (3). The invention is simple in structure and easy to install. When the passenger is too close to the elevator landing door, an alarm can be issued to remind the elevator passenger to keep a certain safe distance from the elevator landing door, which can effectively prevent the accidental opening of the elevator landing door. Casualty accidents caused by elevator slipping.

Owner:叶庆杰

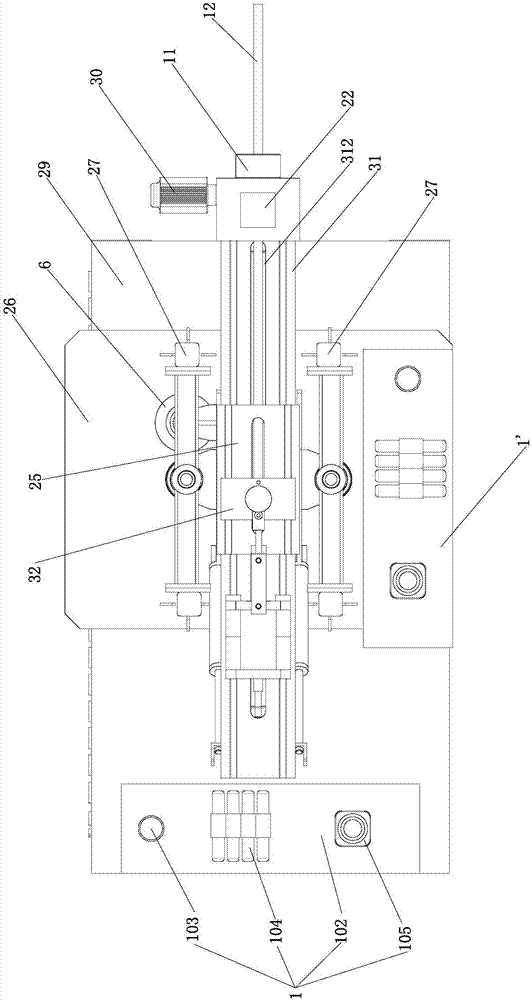

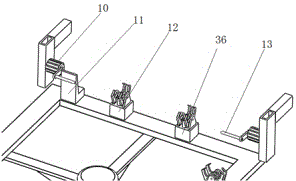

Special pagoda spring assembling machine of sliding plate clamp plate and assembling method of assembling machine

ActiveCN103552032AImprove assembly efficiencyAvoid fatal accidentsMetal working apparatusMetal-working hand toolsEngineeringSlide plate

The invention discloses a special pagoda spring assembling machine of a sliding plate clamp plate and an assembling method of the assembling machine. The assembling machine comprises a base plate, positioning blocks, fixing seats, pushing blocks, sliders, air cylinders, springs and a mandrel. The assembling machine is suitable for being used to assemble pagoda springs into workpieces. Each sealed air cylinder and air guide pipes are fixed beside the corresponding fixing seat to allow the air cylinder to be in a sealed environment. A user slightly steps on a switch to control an air valve to inflate the air cylinders so as to allow pressure in the air cylinders to be increased, the pushing blocks and the sliders are driven to move forwards, and the pagoda springs can be assembled. The special pagoda spring assembling machine is simple in assembling method, low in technological level requirements of workers, high in production efficiency, simple in machining, low in cost, and applicable to pagoda spring assembling.

Owner:ZHEJIANG LONGSHENG AUTO PARTS TECH CO LTD

Environmental protective cover for ship thruster

The invention discloses an effect for preventing coiling of a thruster. An environmental protective cover for a ship thruster comprises a ship body and a thruster; a coiling-prevention protective cover is arranged at the periphery of the thrust on the ship body; a plurality of through holes are formed on the protective cover which is fixed on the ship body; by using the coiling-prevention protective cover, sundries such as fishing nets can be prevented from being coiled on a propeller at the outer end of the thruster and the thruster can be protected; moreover, injuries and deaths of people and animals in water during working of the ship thrust as well as dangerous accidents due to fail of the ship thrust coiled by similar finishing nets during working can be prevented.

Owner:李欣坡

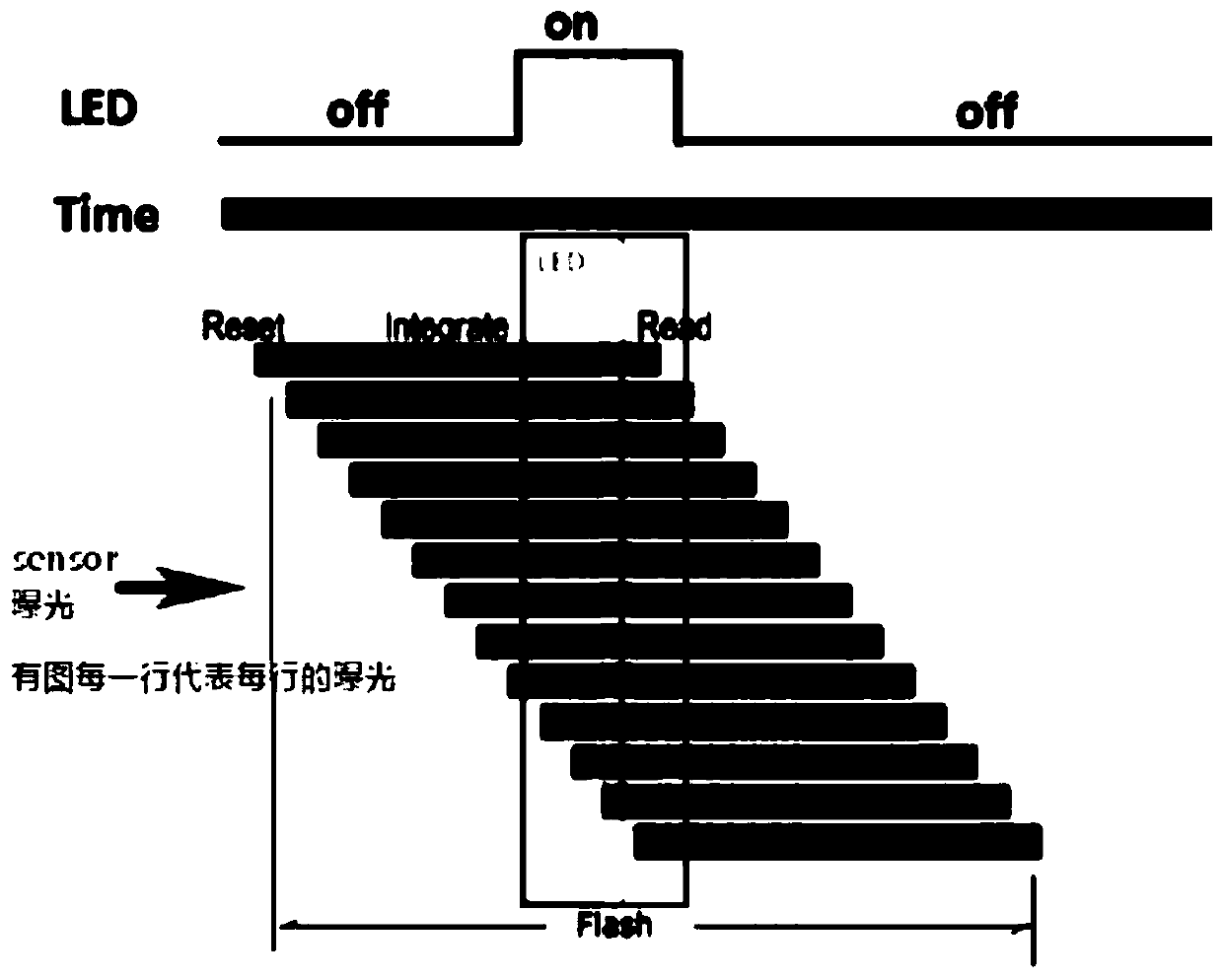

Dark environment driving state monitoring method

ActiveCN111601046AImprove driving safetyAvoid fatal accidentsTelevision system detailsColor television detailsDriver/operatorEngineering

The invention relates to a dark environment driving state monitoring method, which is applied to a camera assembly provided with a light supplementing lamp, and the camera assembly further comprises alens, an image sensor and an image signal processor. The dark environment driving state monitoring method comprises the following steps of: initializing the camera assembly; collecting video data ofa current driving state of a driver in real time through using the camera assembly, and acquiring current environment brightness in real time; and adjusting the light supplementing lamp to perform auxiliary shooting according to the current environment brightness. The dark environment driving state monitoring method has the advantages that the driving state of a driver is collected at night, in atunnel and in other dark environments by arranging the light supplementing lamp, the driving safety of the driver is further improved, and casualty accidents caused by fatigue driving or distraction and the like of the driver are avoided.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

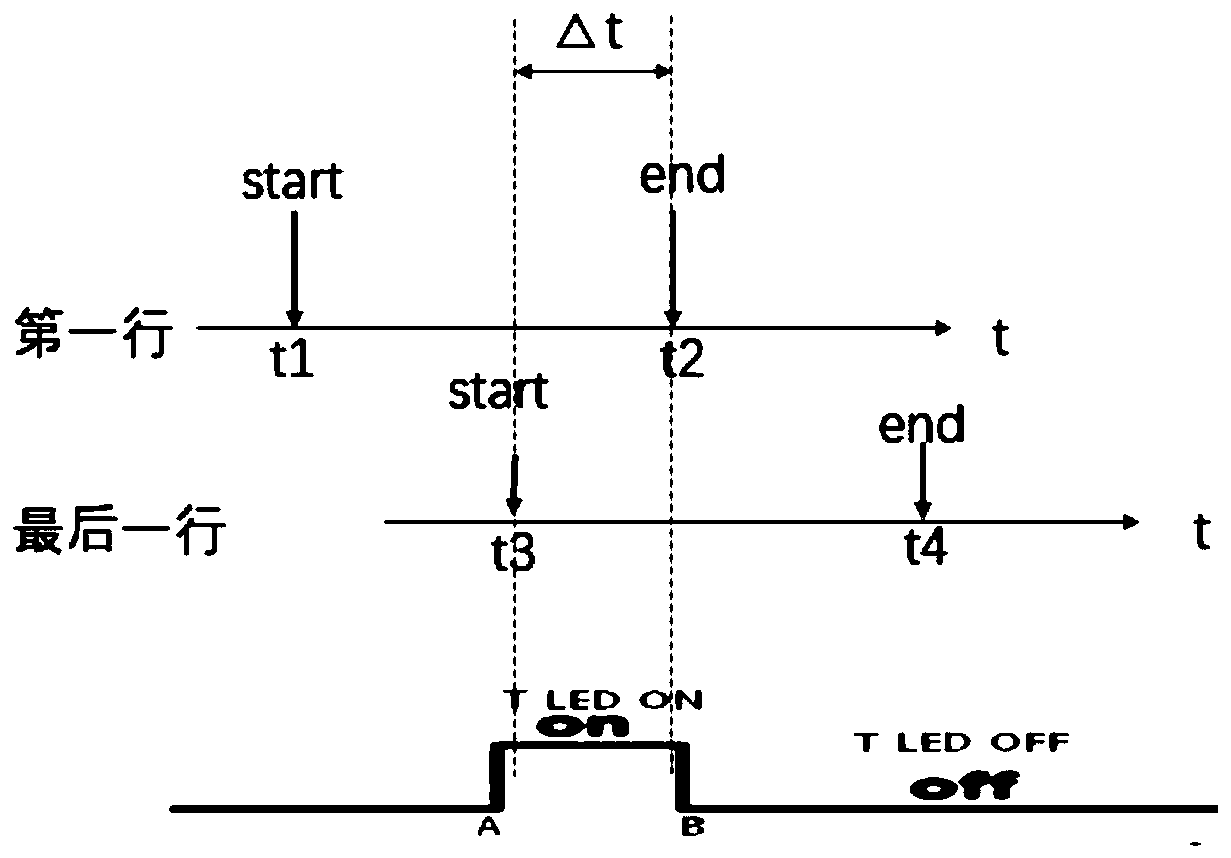

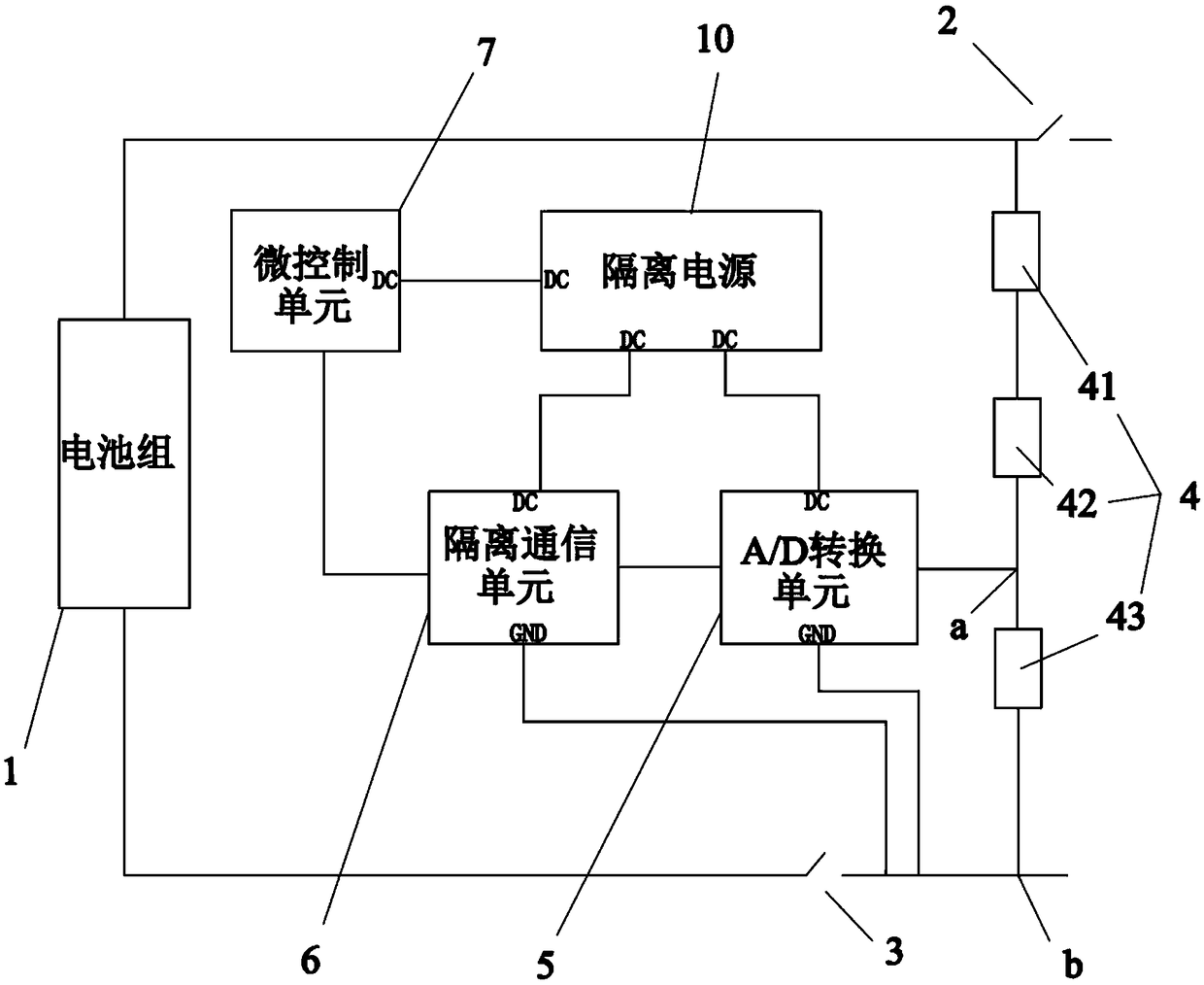

High-voltage negative electrode relay adhesion detection circuit and detection method thereof

PendingCN109188266AImprove applicabilityImprove communication efficiencyPropulsion by batteries/cellsElectric vehicle charging technologyElectricityCommunication unit

The invention discloses a high-voltage negative relay adhesion detection circuit and a detection method thereof, which comprises a battery pack, a positive relay and a negative relay connected to thetotal positive pole and the total negative pole of the battery pack, and further comprises a voltage division circuit connected with the total positive pole and the output end of the negative relay, an A / D conversion unit electrically connected with the voltage division circuit, an isolation communication unit electrically connected with the A / D conversion unit, and a micro control unit electrically connected with the isolation communication unit, the voltage division circuit comprises a first resistor unit and a second resistor unit connected in series, one end of the first resistor unit is connected to the total positive pole, a voltage acquisition point is arranged between the first resistor unit and the second resistor unit, the voltage acquisition point is electrically connected withthe input end of the A / D conversion unit, a sampling reference ground is arranged between the output end of the second resistor unit and the negative relay. The high-voltage negative relay adhesion detection circuit can find whether the negative relay is connected or not, and improve the reliability of the circuit, in addition, the invention further discloses a detection method of the high-voltagenegative relay adhesion detection circuit.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

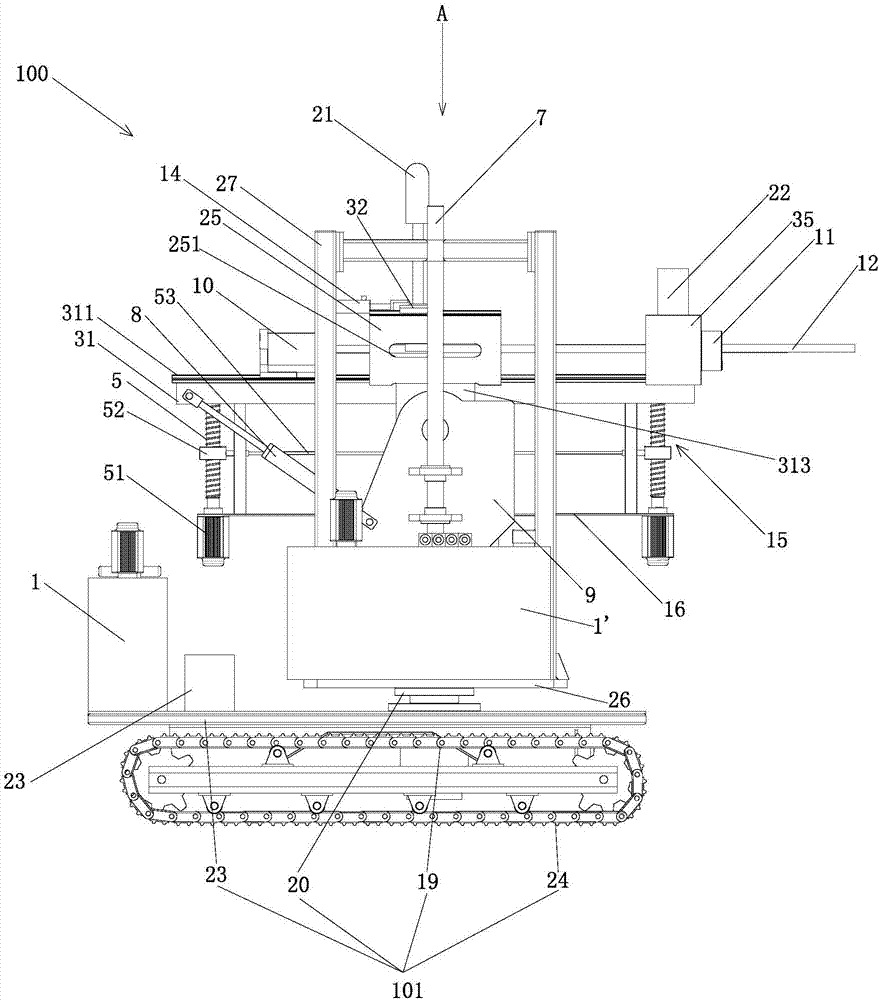

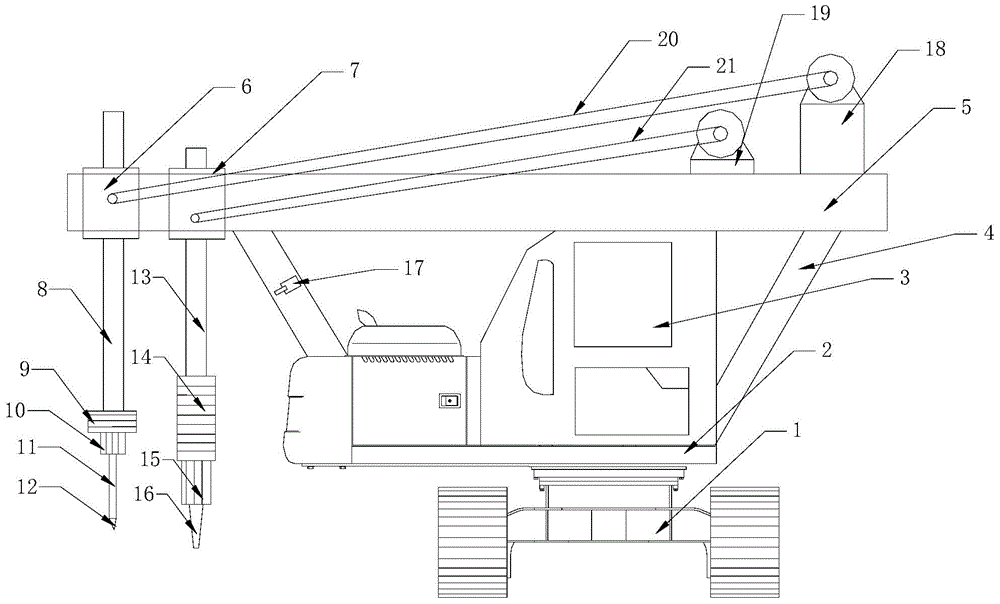

Crawler-type mountain drilling machine

InactiveCN104453897AImprove work efficiencyAvoid fatal accidentsDisloding machinesDrilling machines and methodsHydraulic motorHydraulic cylinder

The invention provides a crawler-type mountain drilling machine which comprises a crawler-type traveling chassis, wherein a rotating seat is rotationally arranged on the crawler-type traveling chassis; a cab is arranged on the rotating seat; a platform sliding rail is arranged on the rotating seat by virtue of a support frame; a drilling tool sliding seat and a shale planer sliding seat are arranged on the platform sliding rail in a sliding mode; a drilling tool is arranged on the drilling tool sliding seat; a shale planer is arranged on the shale planer sliding seat; the drilling tool comprises a drilling tool connecting rod; the drilling tool connecting rod is connected with a hydraulic motor; the hydraulic motor is connected with an impactor; the impactor is connected with a drill stem; the drill stem is connected with a drill bit; the shale planer comprises a shale planer connecting rod; the shale planer connecting rod is connected with a hydraulic cylinder; the hydraulic cylinder is connected with a cylinder protection wall pipe; the cylinder protection wall pipe is connected with an expansion tool; and the hydraulic motor and the hydraulic cylinder are connected with a reversing cylinder together. According to the crawler-type mountain drilling machine, the drilling tool and the shale planer alternatively operate and do not interfere with each other, the working efficiency is improved, the time and labor are saved, and casualty accidents caused by blasting by using explosives are avoided.

Owner:潍坊连海潜孔凿岩机械有限公司

Method for preventing and monitoring danger caused by leaving infant in vehicle

PendingCN110576819AIncrease the chance of being rescuedAvoid fatal accidentsPedestrian/occupant safety arrangementSignalling/lighting devicesSocial benefitsIn vehicle

The invention discloses a method for preventing and monitoring a danger caused by leaving an infant in a vehicle. In the process that a millimeter wave radar sensor in a vehicle interior physical signmonitoring system scans a vehicle interior environment, if no activity of a life body is found, it shows that no person is in the vehicle, and the vehicle interior physical sign monitoring system does not need to monitor the life body. At the moment, a vehicle interior system is controlled to enter a sleep mode so that unnecessary energy consumption can be reduced. According to a control method of a system for preventing the infant in the vehicle from being trapped to die, the dangerous index of the infant can be judged according to a vehicle interior environment change situation; different rescue methods are adopted according to the dangerous index so that the rescue probability of the infant is further increased; and therefore, casualty accidents of the infants caused by leaving the infants in the vehicles can be effectively avoided, and obvious economic and social benefits are realized.

Owner:XICHANG COLLEGE

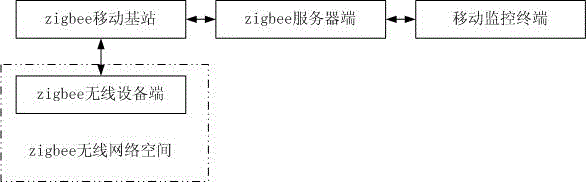

Wireless electronic fence system for industrial fields

InactiveCN105578418AAvoid fatal accidentsNetwork topologiesLocation information based serviceComputer terminalAlarm signal

The invention discloses a wireless electronic fence system for industrial fields. The wireless electronic fence system comprises a plurality of zigbee mobile base stations, a zigbee wireless device terminal arranged on a constructor, a zigbee server terminal and a mobile monitoring terminal; the zigbee wireless device terminal comprises multiple types of wireless device terminals, and different types of wireless device terminals are provided with authority of different access areas; when the zigbee wireless device terminal moves to an unauthorized area edge, the zigbee wireless device terminal automatically generates audible and visual alarm and sends an alarm signal to the mobile monitoring terminal through the zigbee server terminal, or after receiving a position signal sent by the zigbee server terminal, the mobile monitoring terminal sends remote reminding alarm to the zigbee wireless device terminal and sends a channel closure signal of an access channel at the area edge. According to the wireless electronic fence system disclosed by the invention, the zigbee wireless device terminal is worn on the constructor, thus allowing the constructor to remotely manage the construction. The constructor is avoided entering a dangerous area to cause casualties.

Owner:CHENGDU BILSUM SCI & TECH DEVCO

School bus alarm system and method for young children left behind

PendingCN108248507ASimple system structureEasy to installPower-operated mechanismSignalling/lighting devicesSchool busGsm module

Disclosed are a school bus alarm system and method for young children left behind. The system comprises a client and a vehicle-mounted alarm device, the vehicle-mounted alarm device comprises a microcontroller, a temperature sensor, an infrared array temperature sensor, a GPS module, a first relay driving circuit, a second relay driving circuit, an electromagnetic valve, a voice broadcasting module, a GSM module and a touch screen; the method comprises the steps that (1), whether or not the temperature in the bus is higher than 28 DEG C is determined; (2), whether or not there is a person inthe bus is determined; (3), vehicle position information is obtained; (4), whether or not the temperature in the bus is higher than 30 DEG C is determined; (5), alarm information is transmitted to theclient; (6), whether or not the temperature in the bus is high than 35 DEG C is determined; (7), the door of the bus is opened, voice information is broadcast to urge the person in the bus to get outof the bus, and prompting information of opening the door of the bus is transmitted to the client. By means of the system and the method, dangers triggered by leaving young children behind in a school bus can be effectively avoided to ensure the safety of the young children, and the system and the method have better social benefits.

Owner:HUANGHUAI UNIV

Novel scaffold putting-up robot

InactiveCN104612400AQuick and automatic buildEfficient and automatic constructionBuilding material handlingComputer moduleEngineering

The invention discloses a novel scaffold putting-up robot which comprises a storage and separation module, a transfer module and a putting-up module. The storage and separation module is formed by a single-tube separation mechanism and an adjusting alignment mechanism, and therefore cross rods can be stored and output quantitatively in a directional mode. The transfer module can transfer the output cross rods to the putting-up module. The putting-up module can finish putting up a scaffold. The robot mainly aims at the direct inserting type scaffold, is capable of finishing putting up the scaffold fast, improves the scaffold putting-up efficiency, saves labor force, and is capable of meeting the technical requirement of engineering construction.

Owner:胡镔

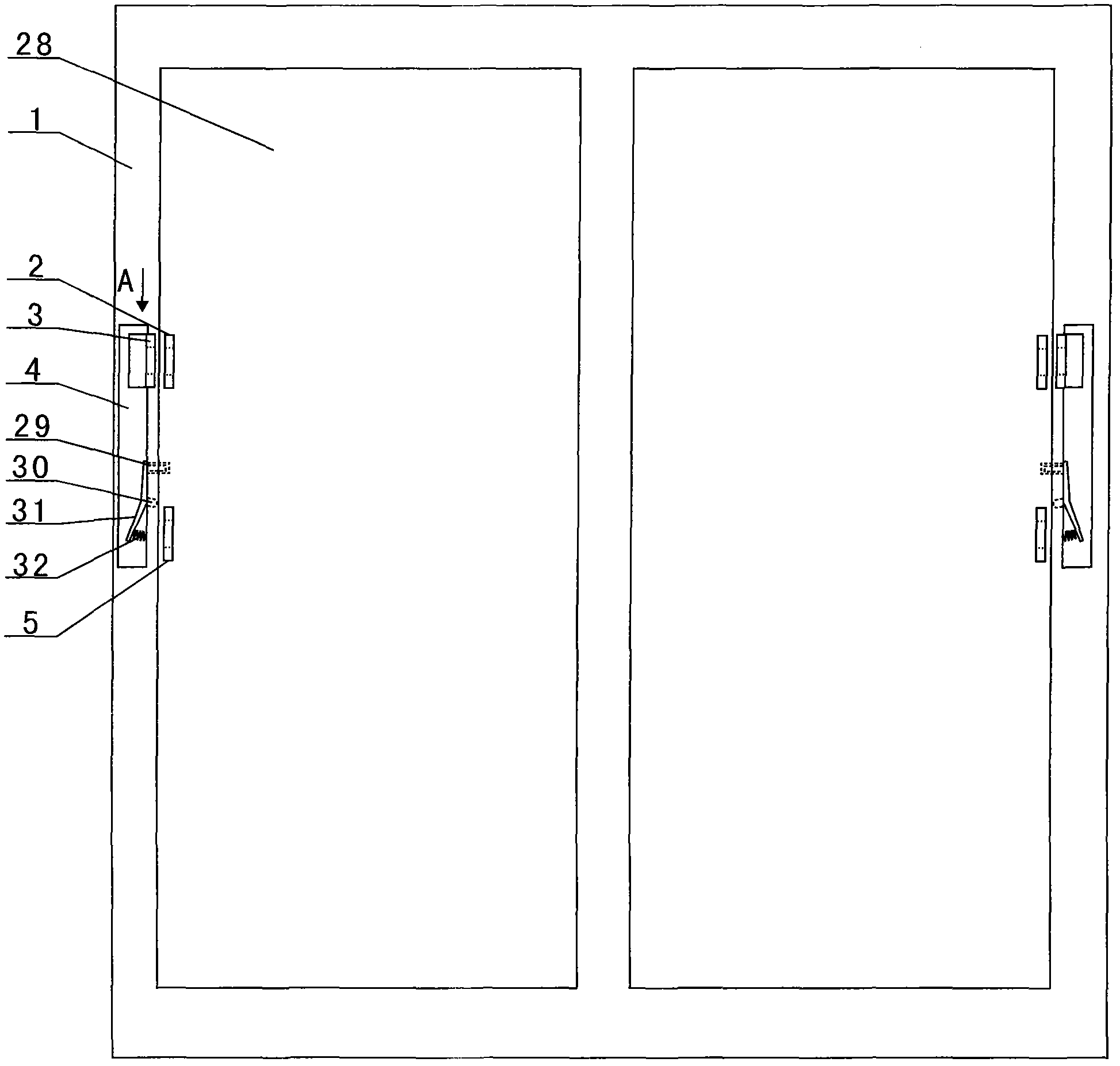

Back door interlock of high voltage switchgear

InactiveCN102290709AAvoid fatal accidentsSubstation/switching arrangement casingsElectric switchesEngineeringBack door

A rear door interlocking of a high-voltage switchgear, which relates to an interlocking device, which not only realizes the prevention of mis-opening of live high-voltage switchgears, but also prevents the high-voltage switchgear from being locked by mistake At the same time, the weight of the human body makes the bottom plate sink, and the pressure column drives the fan-shaped plate, horizontal connecting rod and circuit breaker to make the high-voltage switchgear unable to be energized, realizing the double insurance to prevent casualties.

Owner:国网河南栾川县供电公司

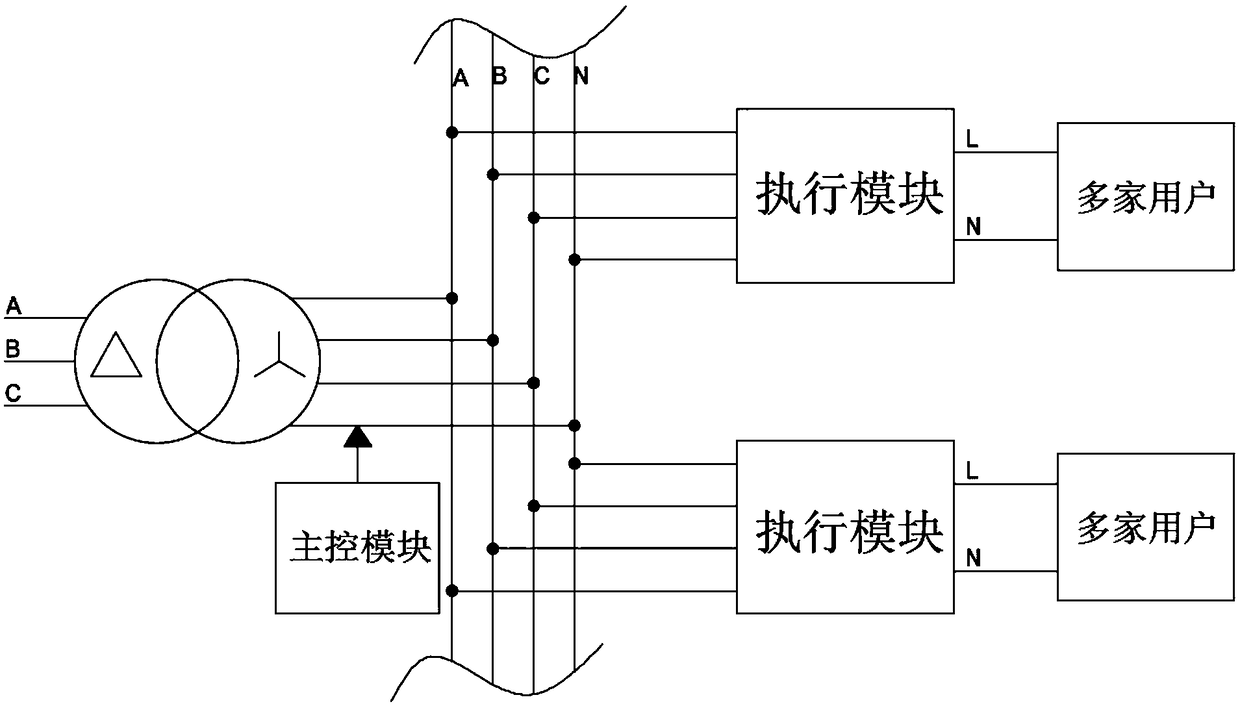

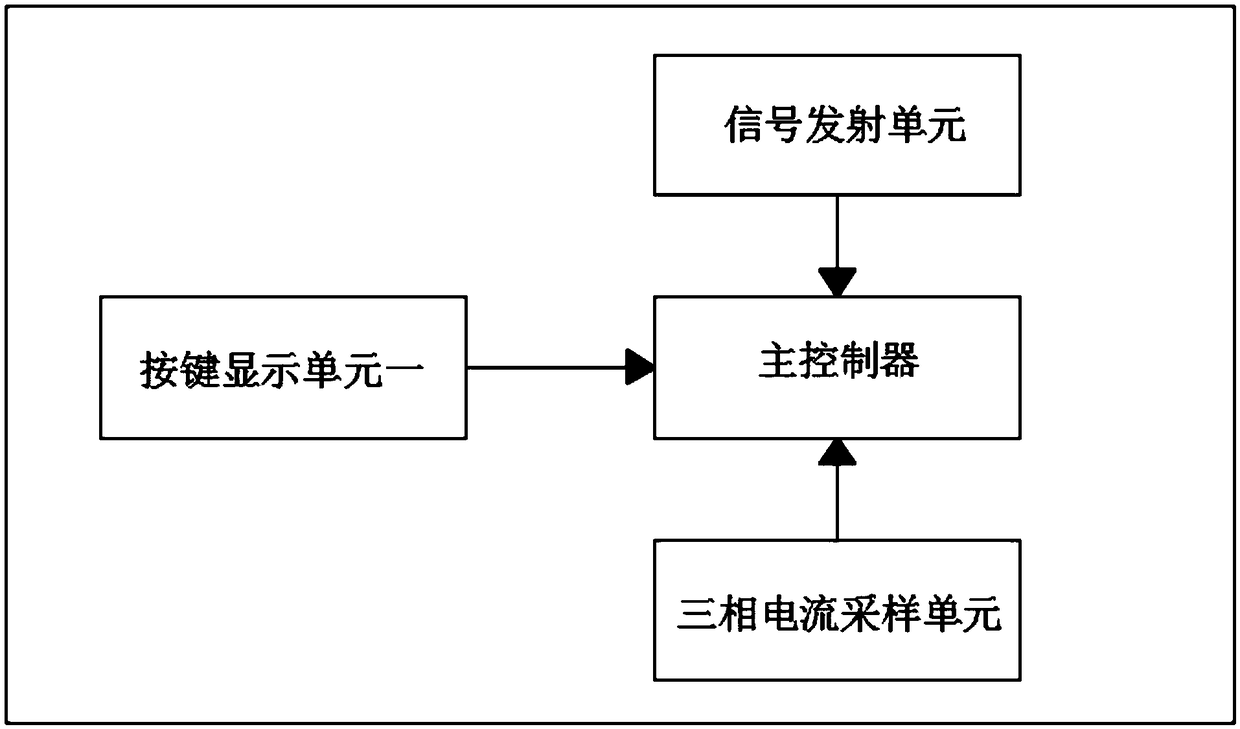

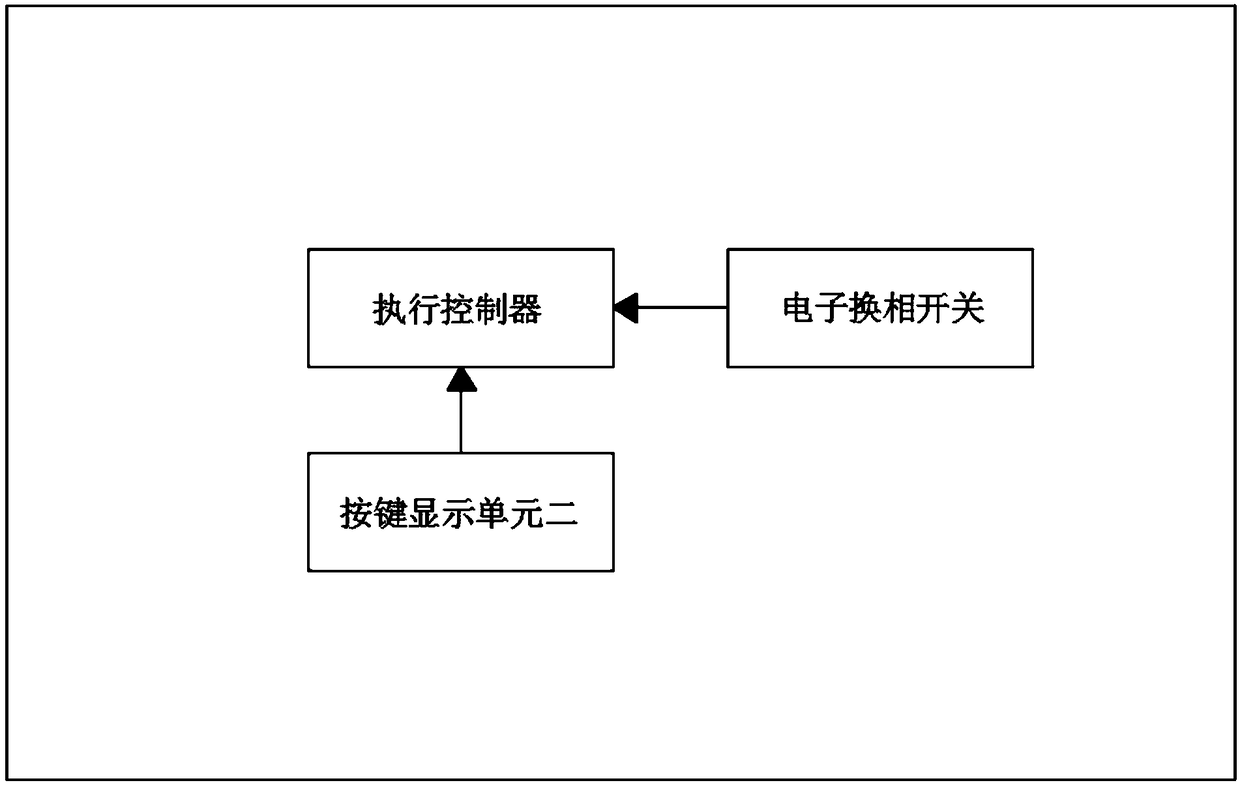

Multifunctional automatic phase changing system for medium/low voltage line and phase changing method thereof

ActiveCN108649592AReduce line lossGuarantee power qualityPolyphase network asymmetry elimination/reductionFault location by conductor typesPower qualityDistribution transformer

The invention discloses a multifunctional automatic phase changing system for a medium / low voltage line and a phase changing method thereof. The phase changing system comprises a master control moduleand multiple execution modules; each execution module corresponds to multiple users that are connected in parallel; the master control module comprises a master controller and a three-phase current sampling unit; each execution unit includes an electronic phase changing switch; and the electronic phase changing switch selects, according to a switching command, one phase corresponding to the switching command from three power supply phases of a transformer to supply a power to the multiple users corresponding to the execution modules. According to the multifunctional automatic phase changing system for the medium / low voltage line and the phase changing method thereof, the master control module and the execution modules are provided, lines in a power distribution area are divided, and the multiple execution modules are controlled via the master control module arranged at a power distribution transformer end to switch three phases of each line, so that three-phase power loads of all switched lines tend to balance; and thus, the unbalancedness of the three phases is improved, the line loss of the power distribution area is reduced, the power quality of the users is guaranteed, and thepurposes of saving the energy and reducing an electricity price are implemented.

Owner:ANHUI ZENITH ELECTRICITY & ELECTRONICS

Big data-based geological disaster rock mass collapse intelligent monitoring and early warning system

The invention discloses a big data-based geological disaster rock mass collapse intelligent monitoring and early warning system. The system comprises a region division module, a detection point distribution module, a pressure detection module, a pressure parameter processing module, a pressure analysis module, an image acquisition module, an image processing module, a crack area detection module,a crack area analysis module, an analysis server, an early warning reminding module, a display terminal and a storage database. According to the system, a to-be-detected rock mass region is divided; an average value of pressure at a central point of each sub-region in each acquisition time period is detected; whether rock mass of each sub-region is in a safe stage or not is analyzed; image acquisition is performed on the surface of the rock mass of each sub-region in a dangerous stage; crack areas in rock mass surface images of the sub-regions are measured; a proportion of the crack areas in the rock mass of each sub-region is calculated; whether the rock mass of each sub-region has a collapse risk or not is judged by comparing; and early warning reminding is performed, so that the life and property safety of surrounding residents is guaranteed.

Owner:深圳中神电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com