Method and apparatus for detecting insulating resistance and releasing static electricity

An insulation resistance and static electricity technology, applied in the field of electrostatic discharge devices, can solve the problems of maintenance and inspection workers' workload, many insulation points, hidden dangers, etc., and achieve the effects of reducing labor intensity of workers, sensitive and accurate detection, and high industrial reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

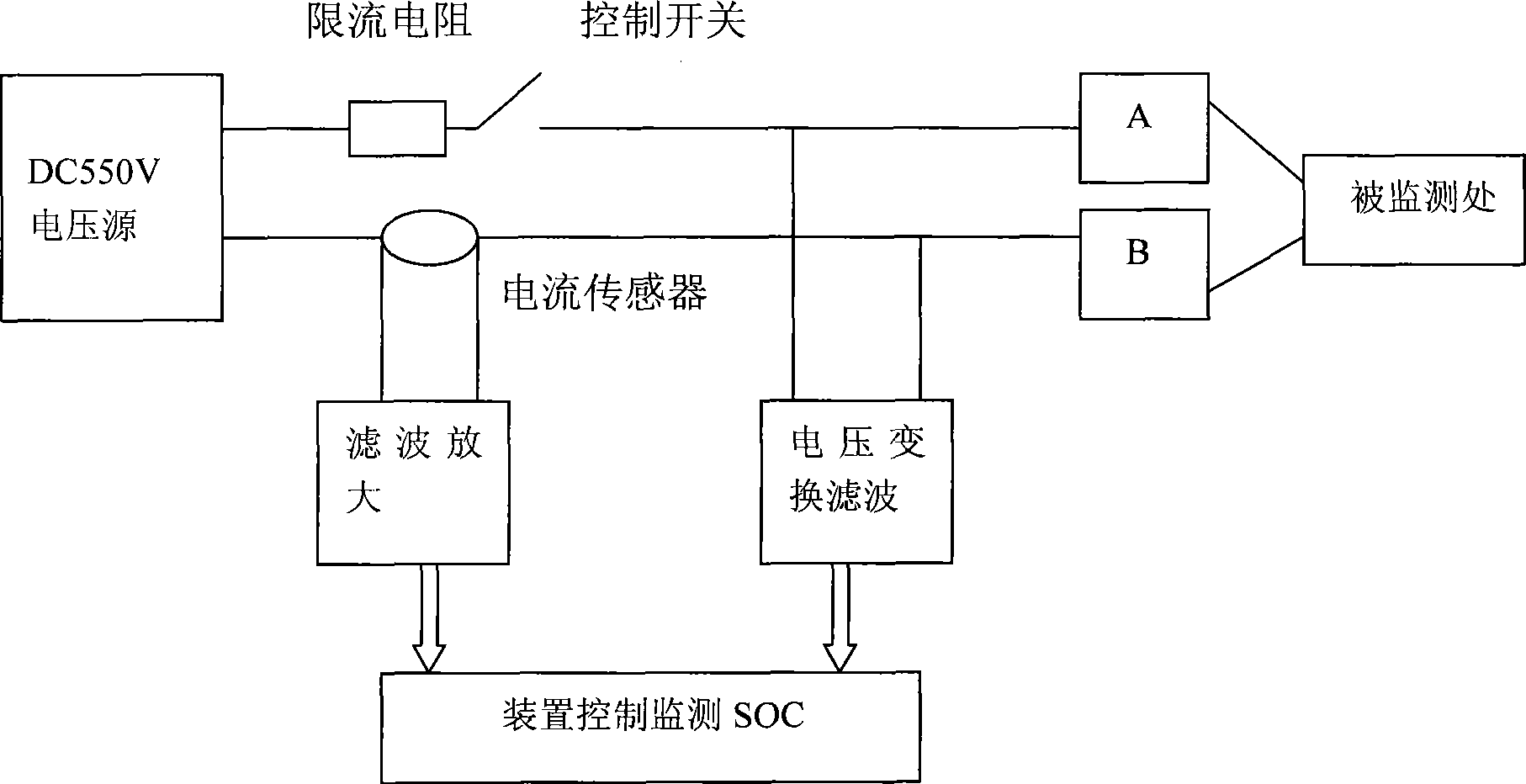

[0014] It can be seen from the accompanying drawings that the present invention is a method for detecting insulation resistance and electrostatic discharge of an aluminum electrolysis multifunctional unit. A DC power supply is installed outside the machine. The DC power supply generates a DC current of a certain voltage, and sends the DC current of a certain voltage to various positions that need to be tested for insulation resistance. The detection device sets up an insulation detection point for each position where insulation resistance detection is required to detect and compare the DC voltage and current changes, and the monitoring device calculates the voltage and current to obtain the insulation resistance of the insulation point and judge the insulation resistance of the insulation point Whether it is normal, and give an early warning or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com