Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Automatically put in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

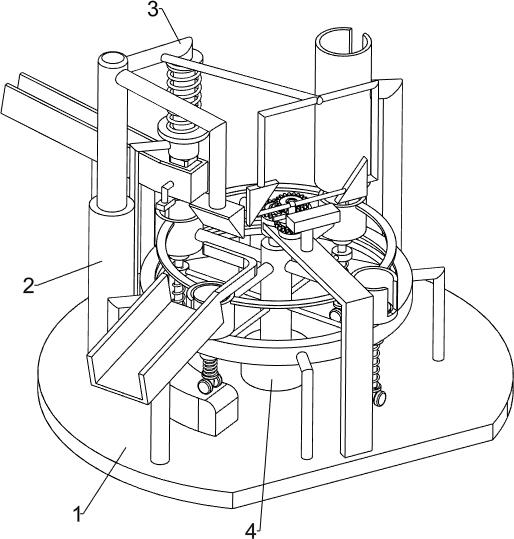

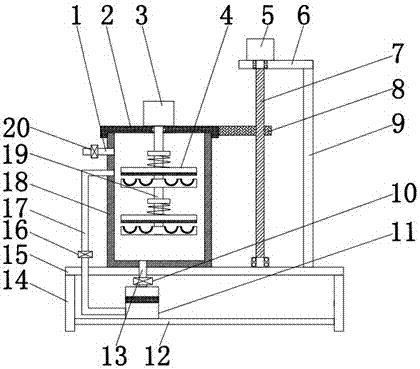

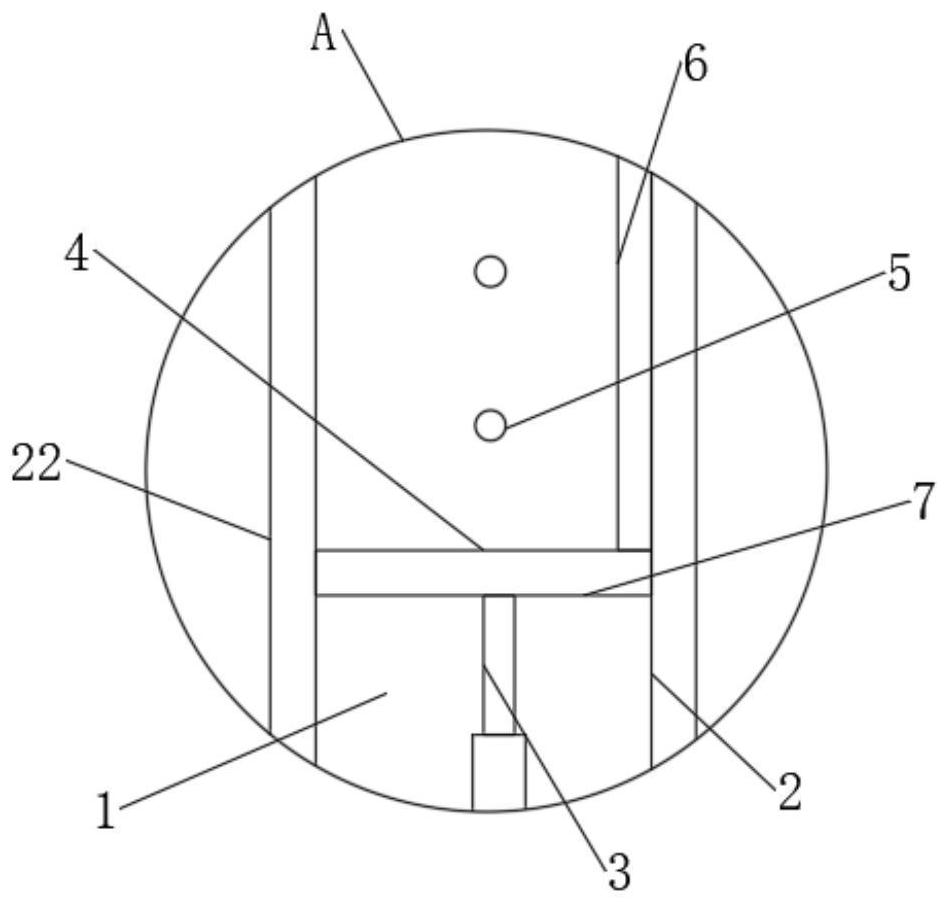

Ball valve pressing type assembling equipment

PendingCN111774844AAutomatic extrusionAutomatically put inMetal working apparatusBall valveManufacturing engineering

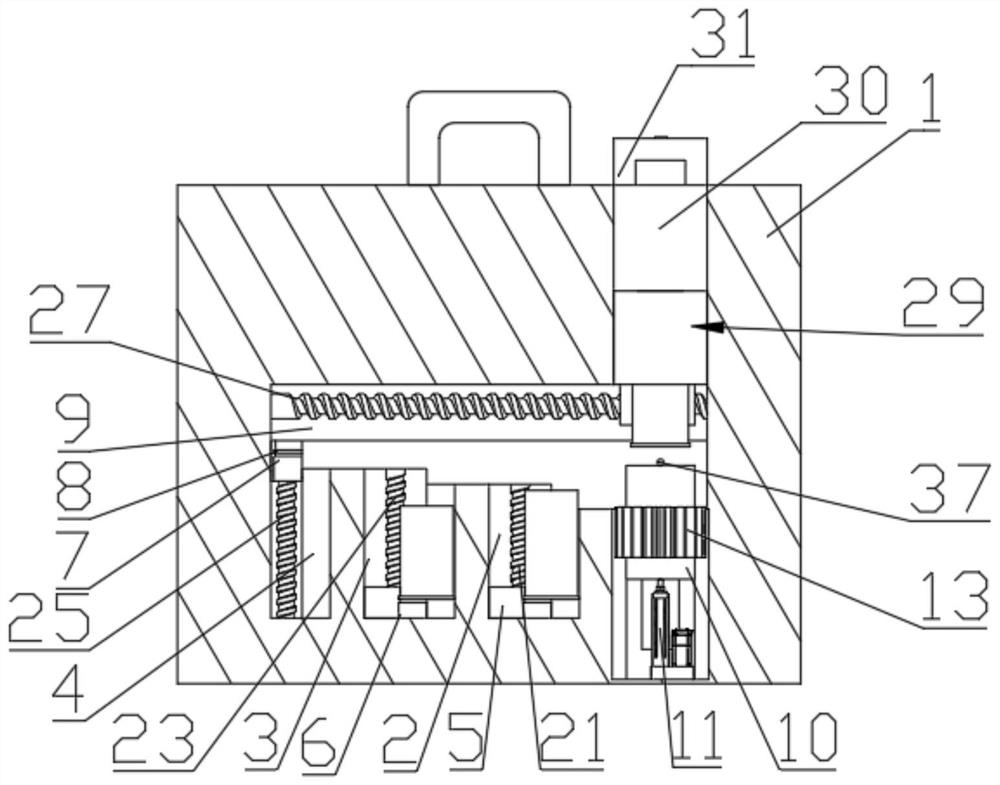

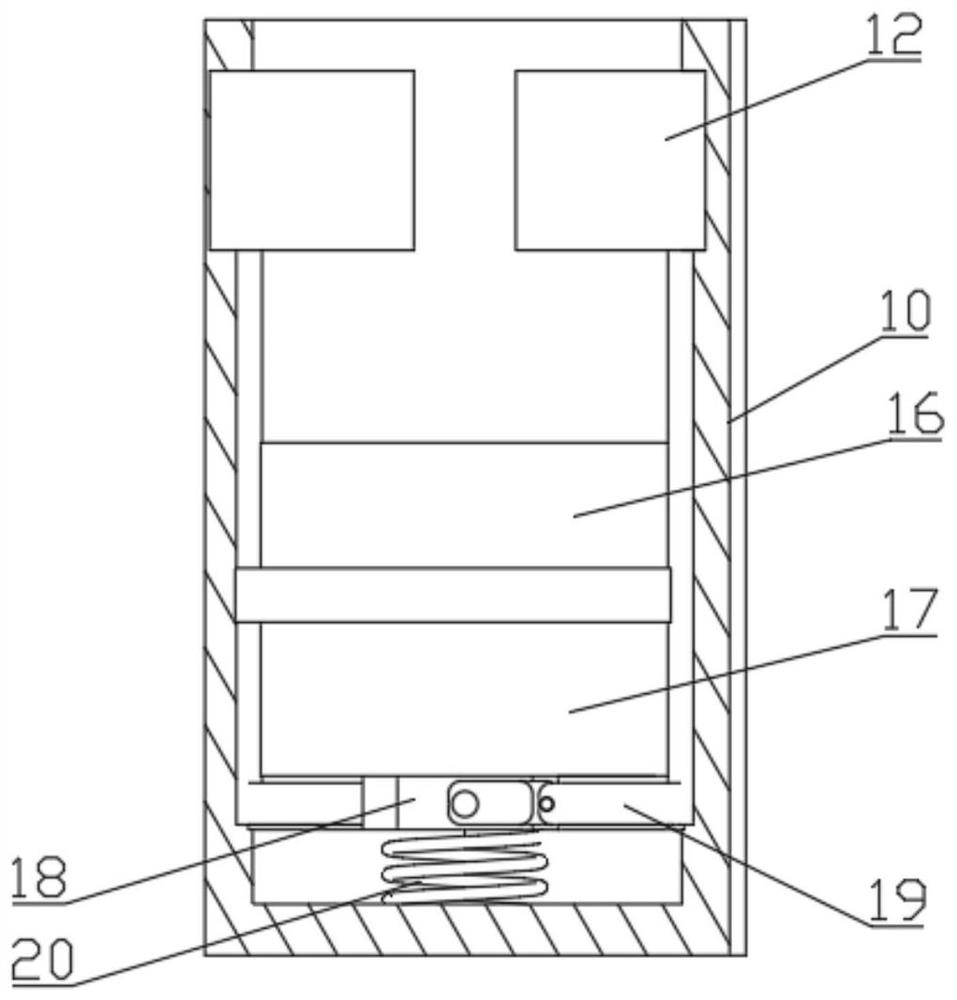

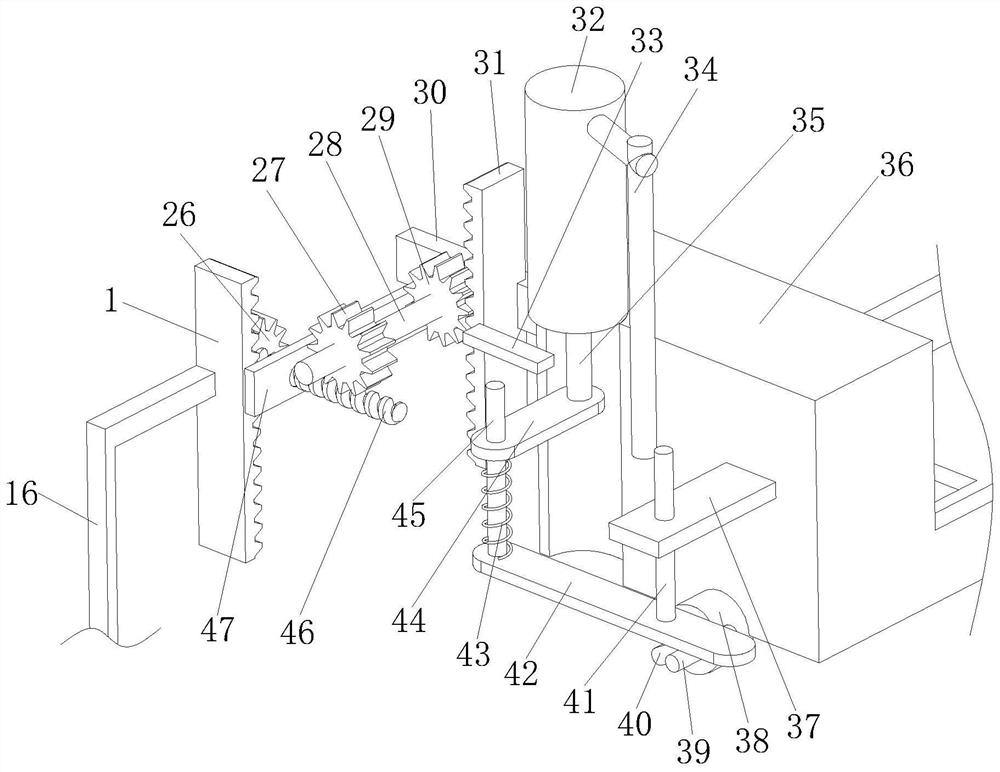

The invention relates to assembling equipment, in particular to ball valve pressing type assembling equipment. The aim is to provide ball valve pressing type assembling equipment capable of automatically placing a valve body inside, pressing a ball into the valve body and automatically extruding a ball valve. The ball valve pressing type assembling equipment comprises a base, an electric push rod,a pressing mechanism and a rotating mechanism. The electric push rod is arranged at the top of the base. The side, close to the electric push rod, of the top of the base is connected with the pressing mechanism, and the pressing mechanism is connected with the electric push rod. The rotating mechanism is mounted in the middle of the top of the base and is connected with the pressing mechanism. Bymeans of the ball valve pressing type assembling equipment, the valve body can be automatically placed into a containing frame, the ball can be automatically pressed into the valve body, the assembled ball valve can be automatically extruded out of the containing frame, and therefore the workloads of people can be relieved, and the ball valve assembling efficiency can be improved.

Owner:刘军强

Automobile comb-moving type honeycomb

The invention relates to an automobile comb-moving type honeycomb, and belongs to the technical field of honeybee culture. The automobile comb-moving type honeycomb comprises a comb transfer manipulator, a honeycomb and a bracket, wherein the comb transfer manipulator comprises a gear, a rack, a horizontal movement motor, a support fork, a bearing support, a support fork motor, a bracket of the support fork motor, a slide block, a horizontal guide rail and a manipulator base; the honeycomb comprises a honeycomb door, a super, a buckle plate of the honeycomb door, a fixed pulley of the honeycomb door, a bracket of a comb-moving motor, a comb-moving chain wheel group, a steel wire rope of the honeycomb door, an upper cover of the super, a motor bracket of the honeycomb door, a motor of the honeycomb door, a comb-moving chain, a comb-moving driven chain wheel, a queen bee separating plate, a guide rail of the honeycomb door, a main box, the comb-moving motor, a shaft of the fixed pulley of the honeycomb door, and a winch of the steel wire rope; the bracket comprises adjusting anchor bolts, a manipulator bracket, a back bracket, a honeycomb bracket, and a front bracket. The automobile comb-moving type honeycomb has the advantages that the automatic putting of the empty comb and the automatic fetching of the comb with full honey are realized, the labor cost is saved, and the production efficiency is improved.

Owner:KUNMING UNIV OF SCI & TECH

Fruit cleaning device having fixing function

PendingCN107348872AAvoid pollutionPrevent fallingClimate change adaptationKitchen equipmentWater filterWater resources

The invention discloses a fruit cleaning device having a fixing function. The fruit cleaning device comprises a box cover, a box body, a second motor, a placement groove, a filter layer and a booster pump, wherein the box body is sealed by arranging the box cover, the phenomenon that when fruits are cleaned, water in the box body is splashed out to pollute the environment is avoided, the arranged placement groove is used for fruits to be cleaned to be placed, reverse rotation of the second motor is utilized to drive a screw to rotate anticlockwise, accordingly upward movement of a connecting rod on the screw is achieved, and thus the box cover is driven to move up. Accordingly, an operator conveniently takes out cleaned fruits from the box body, dirt water entering a filter box through a water outlet pipe is filtered by arranging the filter layer, the booster pump is utilized to make the water filtered in the filter box enter the box body through a water guiding pipe, water recycling is achieved, water resources are saved, the cost of cleaning fruits is reduced, and thus the practicability of the device is improved.

Owner:浙江凯欣食品有限公司

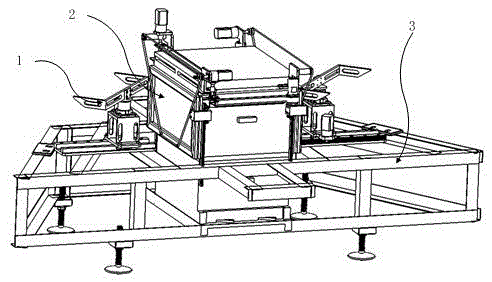

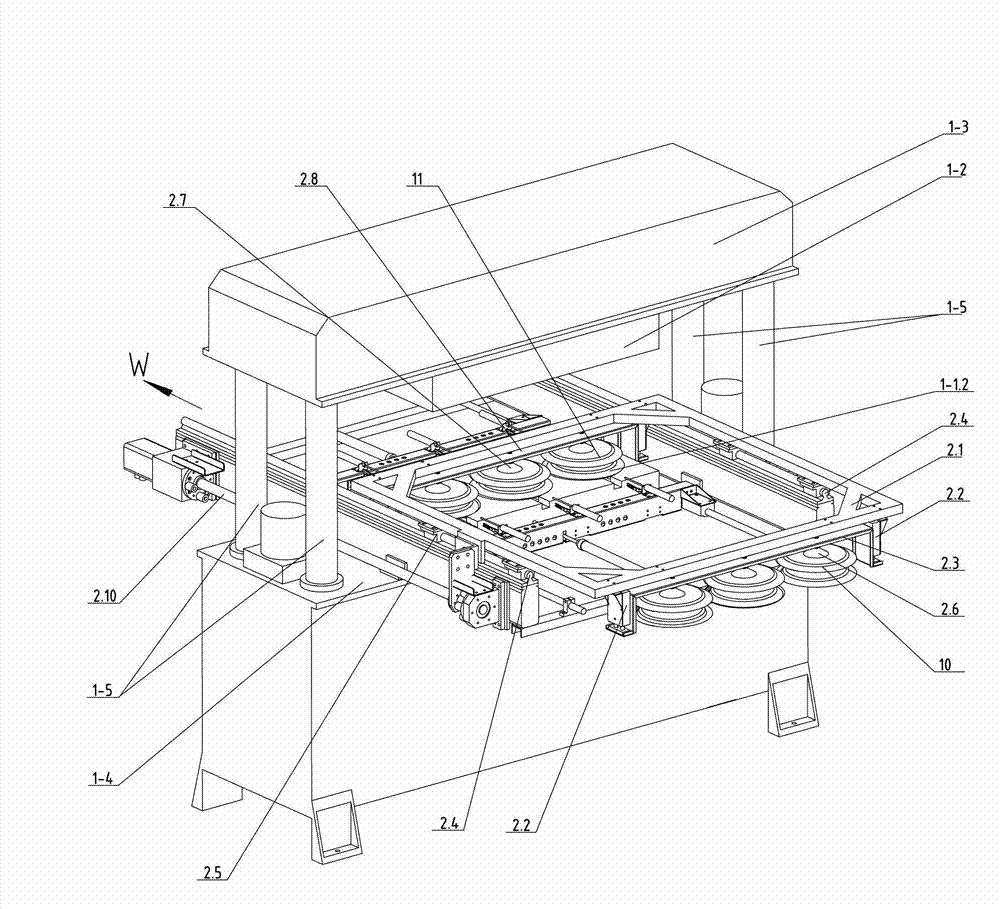

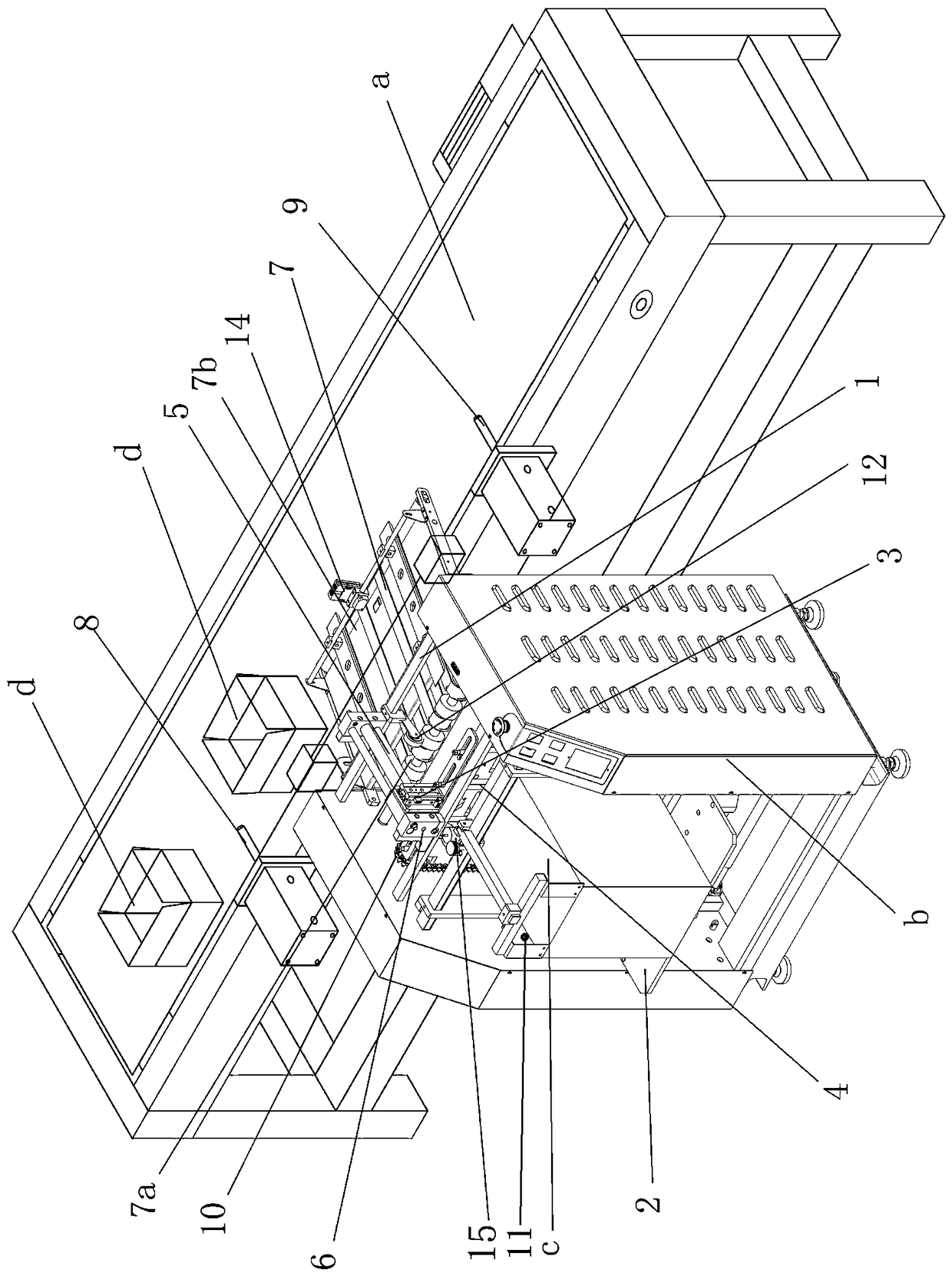

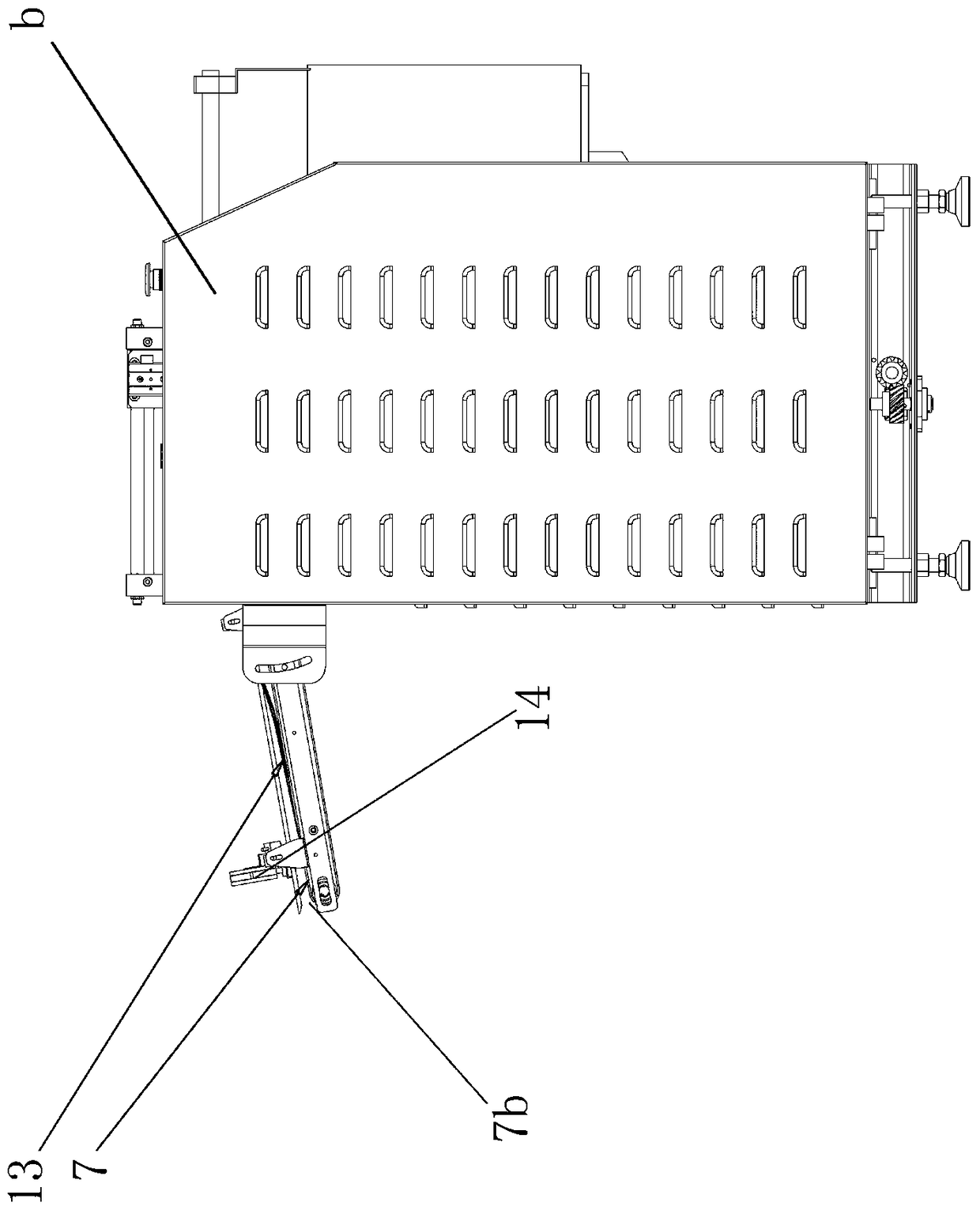

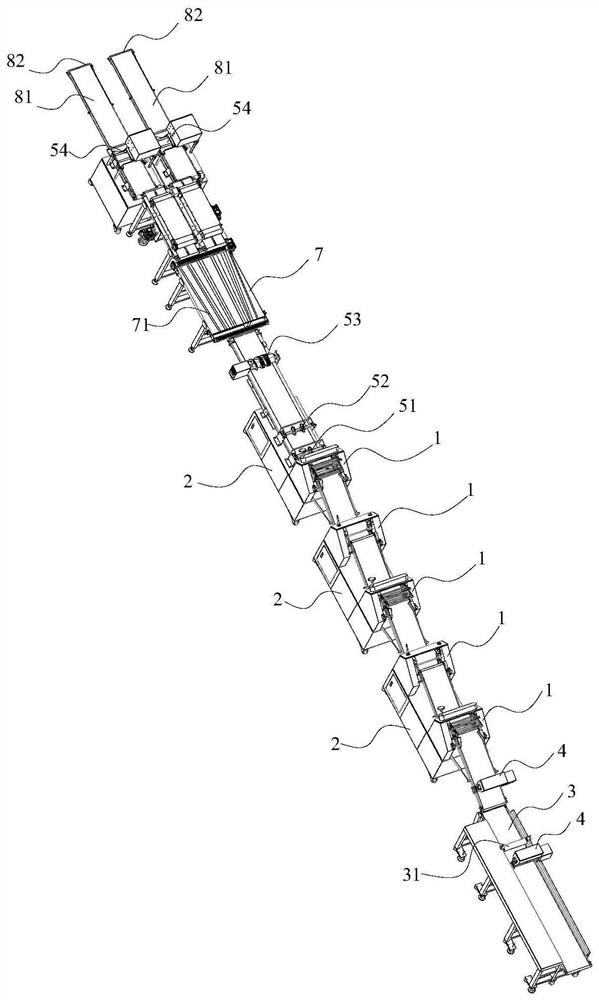

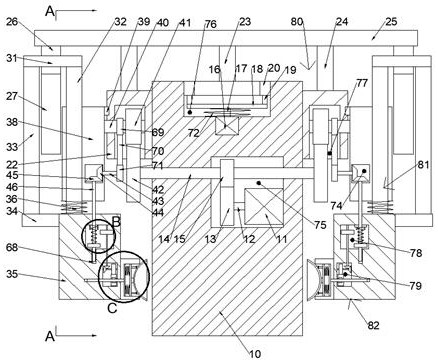

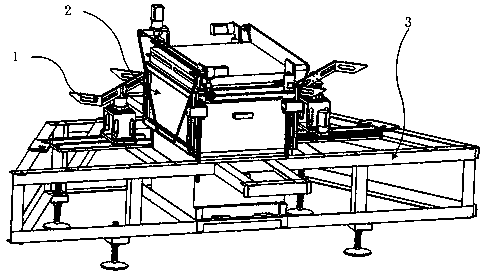

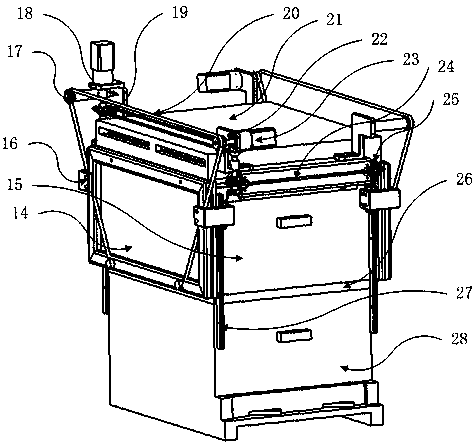

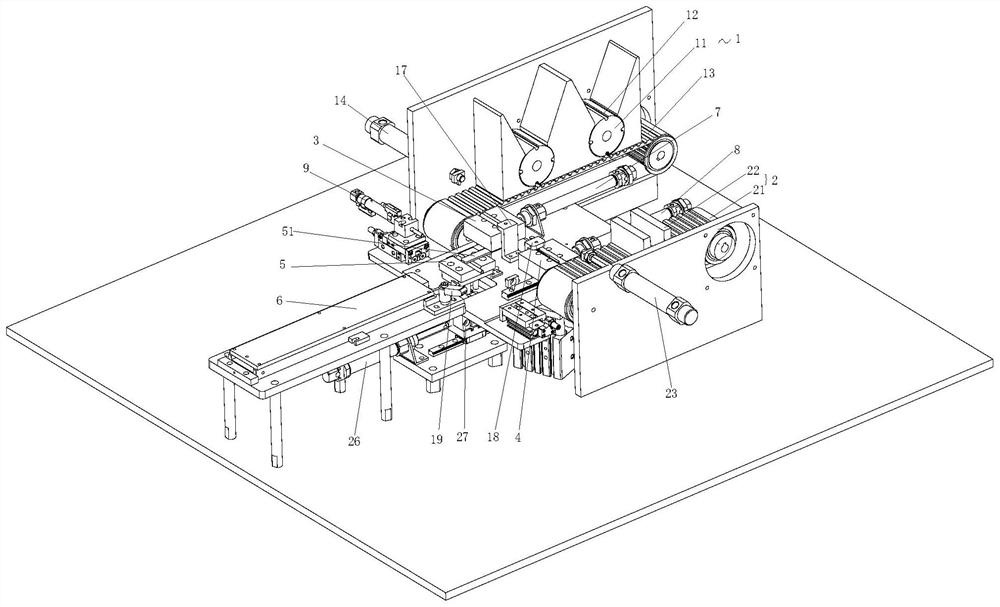

Automatic edge cutting method for plant fiber molding product and automatic edge cutting machine

ActiveCN103042639AAccurate cutting edge positioningHigh speedMetal working apparatusFiberEngineering

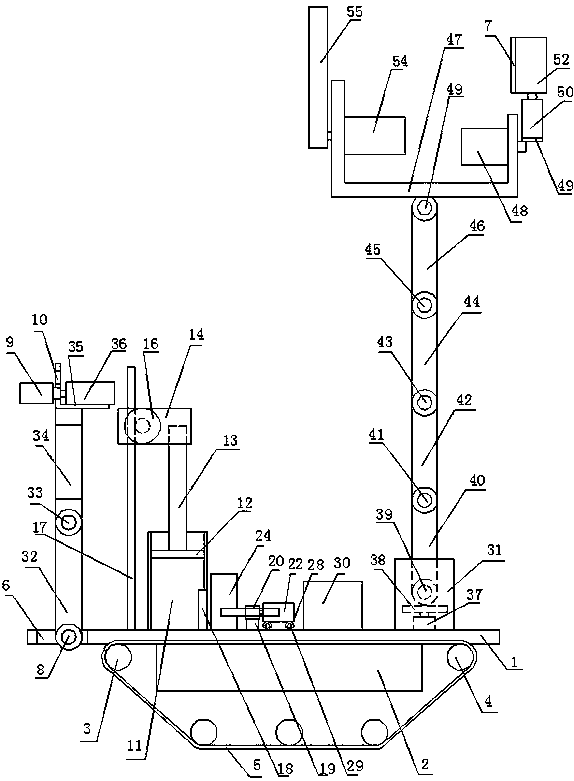

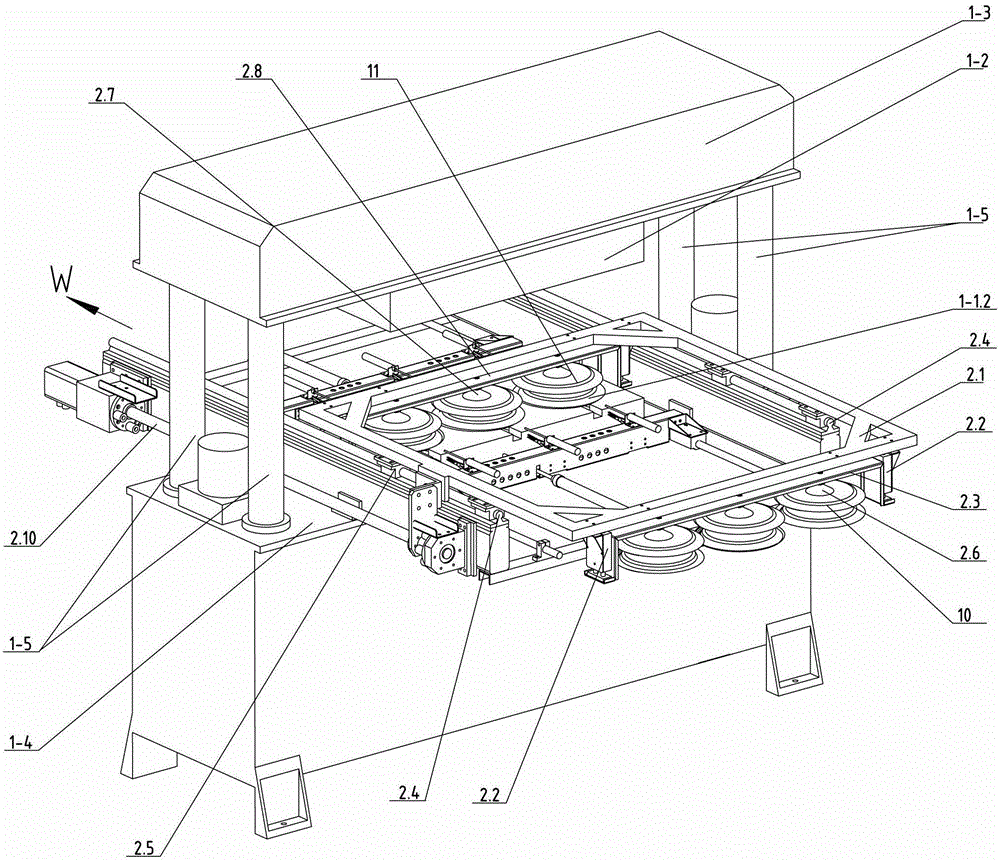

The invention relates to an automatic edge cutting method for a plant fiber molding product and an automatic edge cutting machine. The purposes are that the method has the characteristic of automatic and accurate location, and the automatic cutting machine has the characteristic of stable work. The technical scheme includes that the automatic edge cutting method for the plant fiber molding product proceeds as follows: 1), sucking the product with edges to be cut; 2), driving away waste edges from an edge cutting position; 3), positioning the product to be cut and a product with cut edges respectively; 4), cutting out deckle edges; 5), enabling a front row and a rear row of sucking disk sets to reach the corresponding positions respectively; and 6), sucking the product with edges to be cut and the product with cut edges; repeating from the step 2) to the step 6), and proceeding the circulation over and over again. The automatic edge cutting machine for the plant fiber molding product comprises an edge cutting and die assembly mechanism, wherein the edge cutting and die assembly mechanism comprises an upper edge cutting mold, a lower edge cutting mold, an upper installation plate, a lower installation plate and a power mechanism. The automatic edge cutting machine for the plant fiber molding product is characterized in that a product transferring mechanism and a waste edge moving out mechanism are also arranged on the automatic edge cutting machine.

Owner:EURASIA EP MACHINERY +1

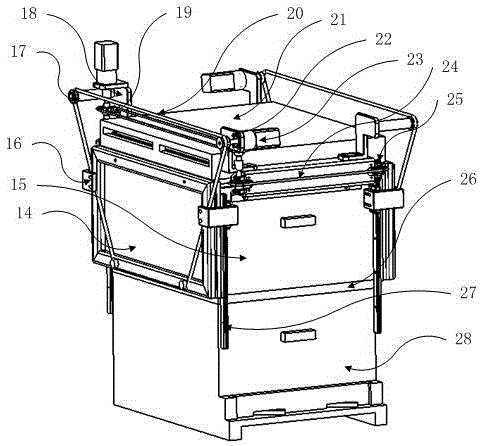

Textile fabric desizing device for textiles

InactiveCN108532172AAutomatically put inEasy to installTextile treatment carriersLiquid/gas/vapor fabric treatmentEngineeringMechanical engineering

The invention discloses a textile fabric desizing device for textiles. The device comprises four vertically arranged support columns, horizontally arranged fixing plates are fixedly mounted among thetop ends of the four support columns, horizontally arranged first mounting plates are rotatably mounted on the middles of the bottom ends of the fixing plates, second mounting plates are welded on both sides of the bottom ends of the first mounting plates, a third mounting plate horizontally disposed is fixedly mounted between the bottom ends of the two second mounting plates, first rotating motors are fixedly mounted on the top ends of the third mounting plates, output shafts of the first rotating motors are fixedly provided with reciprocating screw rods, the top ends of the reciprocating screw rods are rotatably connected to the bottom ends of the first mounting plates, the outer threads of the reciprocating screw rods are provided with horizontally disposed lifting plates, and a vertically formed sliding opening is formed in one of the second mounting plates. The device has the advantages of ingenious structure and convenient use, and can automatically conduct alkali washing and cleaning on cloth, and the installation and disassembling of the cloth are very convenient.

Owner:长兴明远布艺科技有限公司

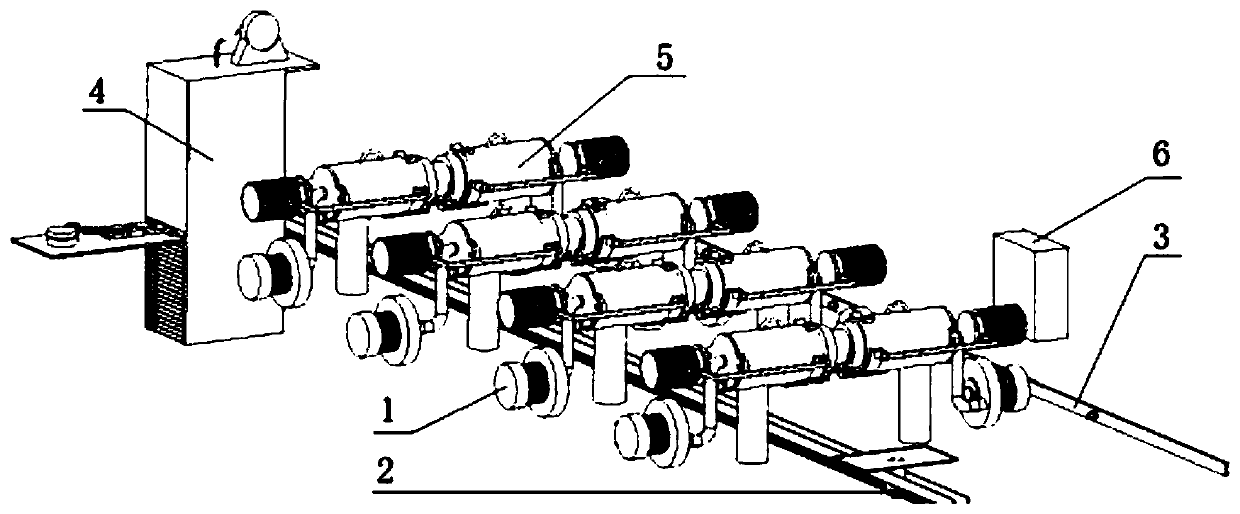

Hard alloy blade multi-procedure integrated automatic production line under robot scheduling

ActiveCN111975640AGood effectExtended service lifeProgramme-controlled manipulatorBlast gunsProduction lineKnife blades

The invention discloses a hard alloy blade multi-procedure integrated automatic production line under robot scheduling. According to the technical scheme, the production line comprises a ground rail robot, wherein a cutter passivation device and a blade cleaning drying device are arranged on one side of the ground rail robot, a blade coating transfer table, a blade coating device, a blade boxing transfer table, a blade tool dismounting device and a blade boxing device are sequentially arranged on the other side of the ground rail robot, and the blade tool dismounting device is arranged on oneside of the blade boxing transfer table; the production line further comprises a squirrel-cage tool for bearing a blade, the squirrel-cage tool provided with the blade can operate between the tool passivation device, the blade cleaning drying device, the blade coating transfer table, and the blade boxing transfer table; and the processed blade is delivered to the blade boxing device through the blade tool dismounting device. According to the production line, the four main functions of blade passivation, blade cleaning and drying, blade coating and blade boxing are integrated; and a carrier ofthe blade in the production line is the squirrel-cage tool, so that the structure of the production line can be simplified.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Pushing device facilitating placing law books into bookshelf

The invention discloses a pushing device facilitating placing law books into a bookshelf. The pushing device facilitating placing the law books into the bookshelf comprises a base, a connecting rod, an air pump, an exhaust tube, an exhaust valve, a piston, a supporting column, a supporting plate, a fixing plate, a threaded rod, a first gear, a motor, a second gear, a sliding clamping plate, a fixing shaft, a drum, a bookmark, a sliding rod, a pushing plate, a chute, an electric push rod and a baffle. The pushing device facilitating placing the law books into the bookshelf is simple in structure and novel in design, a worker conveniently place the law books at the high position of the bookshelf, the placement efficiency of the worker who places the law books is improved, the circumstance that the law books are placed with the assistance of an external device is avoided, the worker uses the pushing device conveniently, the length of the device is adjusted automatically, and books are favorably places on bookshelves with different heights, meanwhile, it can be ensured that the law books are clamped stably, the law books are automatically placed in the bookshelf, stability of the law books in a placing process is ensured, and the practicability value is high.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

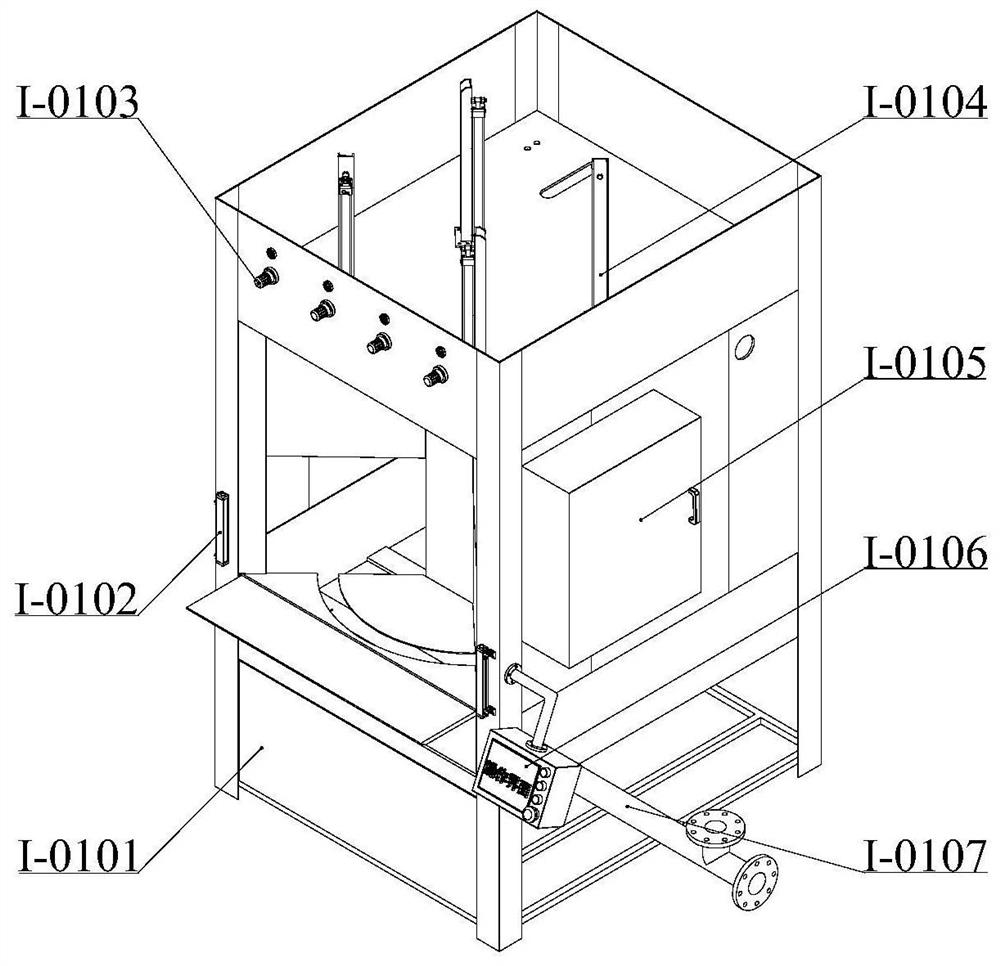

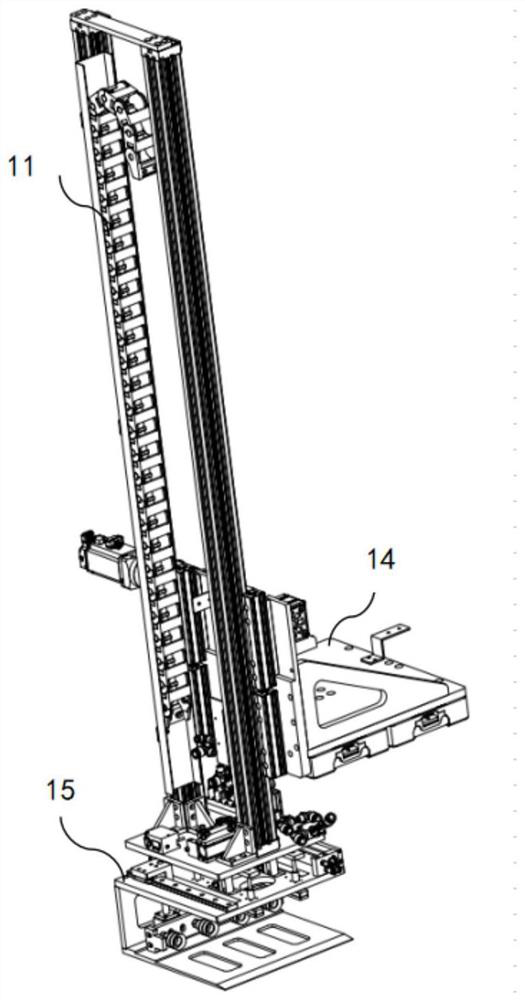

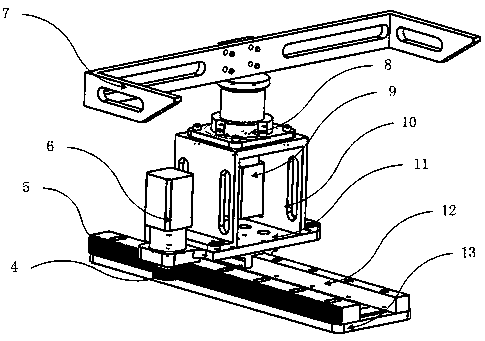

Integral loading and carrying equipment

InactiveCN108675220AAutomatically put inRealize a high degree of automationLifting devicesLoad-engaging elementsCantileverMechanical engineering

Owner:SUZHOU XIAOYAN AUTOMATION EQUIP

Mechanism capable of automatically feeding paper into paper box

PendingCN108082612ATransfer synchronizationIncrease transmission speedPackagingArticle feedersCartonPaperboard

A mechanism capable of automatically feeding paper into a paper box is characterized by comprising a paper box conveying mechanism and a paper board conveying mechanism, wherein the paper board conveying mechanism is arranged beside the paper box conveying mechanism and comprises a rack, a paper board storage bin, a sucker, a front-back power movement mechanism and a power conveying belt or a power conveying roller group; the paper board storage bin is arranged on the outer side of the rack; the sucker is arranged on the paperboard storage bin and is driven by an up-down power movement mechanism; the front-back power movement mechanism is arranged on the rack and drives the up-down power movement mechanism to move along the guide track on the rack in the front-back direction; the power conveying belt or the power conveying roller group is arranged on the rack; and a front paper box stopping mechanism and a rear paper box stopping mechanism are separately arranged on the front and the rear of the paper box conveying mechanism. Compared with the prior art, the mechanism has the advantages that the efficiency is high, the labor is saved, and waterproof paper or thin and hard paperboard can be automatically placed in the paper boxes.

Owner:佛山市广迅科技有限公司

Portable photography auxiliary device

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Heating incubator

The invention relates to a heating and heat-preserving device, in particular to a heating and heat-preserving box. The heating and heat-preserving box comprises a box body and a box door. The box body is internally provided with a heat insulation layer, a heating layer, a first heating and heat-preserving area, a second heating and heat-preserving area and a control system. A detachable partition plate is arranged between the first heating and heat-preserving area and the second heating and heat-preserving area. The control system can control the first heating and heat-preserving area and the second heating and heat-preserving area to achieve independent heating and / or heat preserving, the technical problem that the heat-preserving function of an existing heating and heat-preserving box is single is solved, and the heating and heat-preserving box can be used for carrying out heating and / or heat preserving on milk and meals at the same time.

Owner:许江峰

Sintering recovery device and process for industrial metal scraps

The invention relates to the technical field of sintering and recycling devices for metal scraps, in particular to a sintering and recycling device and process for industrial metal scraps, and provides the following scheme that the sintering and recycling device comprises a base, a first supporting plate and a second supporting plate are fixedly connected to the top face of the base, and a first conveying device is arranged above the first supporting plate; the bottom of the first conveying device is fixedly connected with a first rod, a second groove is formed in the top face of the first supporting plate, the first rod is located in the second groove and slidably connected with the second groove, a third spring is arranged between the bottom end of the first rod and the bottom face of the second groove, and a second conveying device is arranged above the second supporting plate. A third rack is fixedly connected to the bottom of the second conveying device, a first groove is formed in the top face of the second supporting plate, and the first conveying device is matched with the second conveying device. The purpose of preparing a flux mixture with a certain mass according to the mass of the nickel-chromium-iron waste is achieved.

Owner:海宁市现代汽车座套有限公司

Building drilling and pile grouting machine and method

InactiveCN113062309AImprove practicalityImprove work efficiencyDrilling rodsDirectional drillingDrill holeStructural engineering

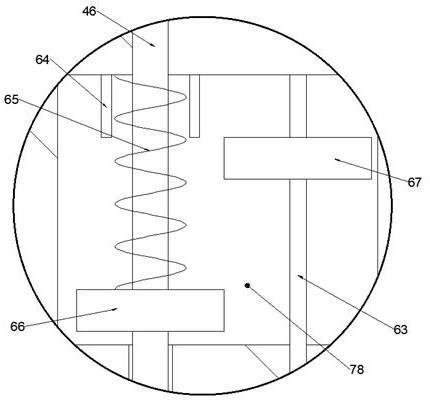

The invention discloses a building drilling and pile grouting machine and method, and particularly relates to the field of construction. The building drilling and pile grouting machine comprises a mounting frame, wherein the mounting frame is mounted on a pile grouting vehicle, a sliding table is slidably arranged on one side of the mounting frame, a top plate is fixedly mounted at the bottom of one side of the sliding table, and a driving box is fixedly embedded in the top of the top plate; a screw rod is rotatably mounted at the bottom of the top plate, a cross-shaped sliding groove is formed in the bottom end of the screw rod, a cross-shaped sliding rod is slidably arranged in the cross-shaped sliding groove, and a spiral drilling plate is fixedly mounted at the bottom end of the cross-shaped sliding rod. According to the building drilling and pile grouting machine, the pile grouting vehicle is started to a to-be-drilled pile grouting site, the screw rod rotates forwards, and a spiral drilling plate rotates and moves downwards, so that the function of drilling holes in the ground by the machine is achieved, the screw rod rotates reversely to drive the spiral drilling plate to move upwards, then a protruding block drives a punching column to move upwards and store energy for the punching column, and therefore, the capability of integrating multiple functions of drilling and tamping a concrete pile can be realized on the same pile grouting machine.

Owner:李明成

Automatic tree planting vehicle

InactiveCN109429978AEasy constructionAutomatically put inPlantingTransmission systemsUltrasonic sensorAgricultural engineering

The invention discloses an automatic tree planting vehicle, and relates to an automatic tree planting vehicle. A through opening I (6) is formed in the front end of a vehicle plate (1), and a mechanical arm I is arranged in the through opening; the front end of the mechanical arm I is connected with a drill head (9); an ultrasonic sensor (10) is arranged above the drill head (9); a group of fertilizer boxes (11) are arranged behind the through opening I (6); a press plate (12) is arranged on each fertilizer box (11); the upper end of each the press plate (12) is connected with a long rod (13);the top ends of a group of the long rods (13) is connected with a fixing frame (14); a gear I (15) is arranged on the fixing frame (14); the gear I (15) is driven by an output shaft of a motor I (16); the gear I (15) meshes with a rack I (17); and the rack (17) is fixed between the fertilizer boxes (11) and the through opening I (6). The automatic tree planting vehicle is easy to be popularized in greening urban areas and green belt construction, planting landscape trees on both sides of roads and greening desert sands, and is a greening device with high quality and inexpensive.

Owner:高越

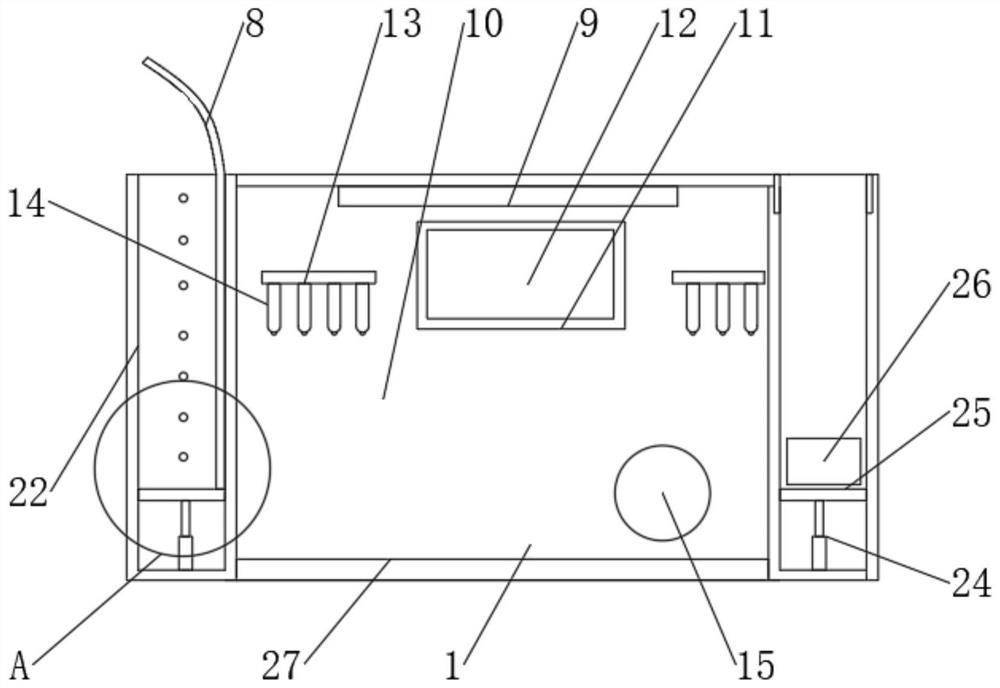

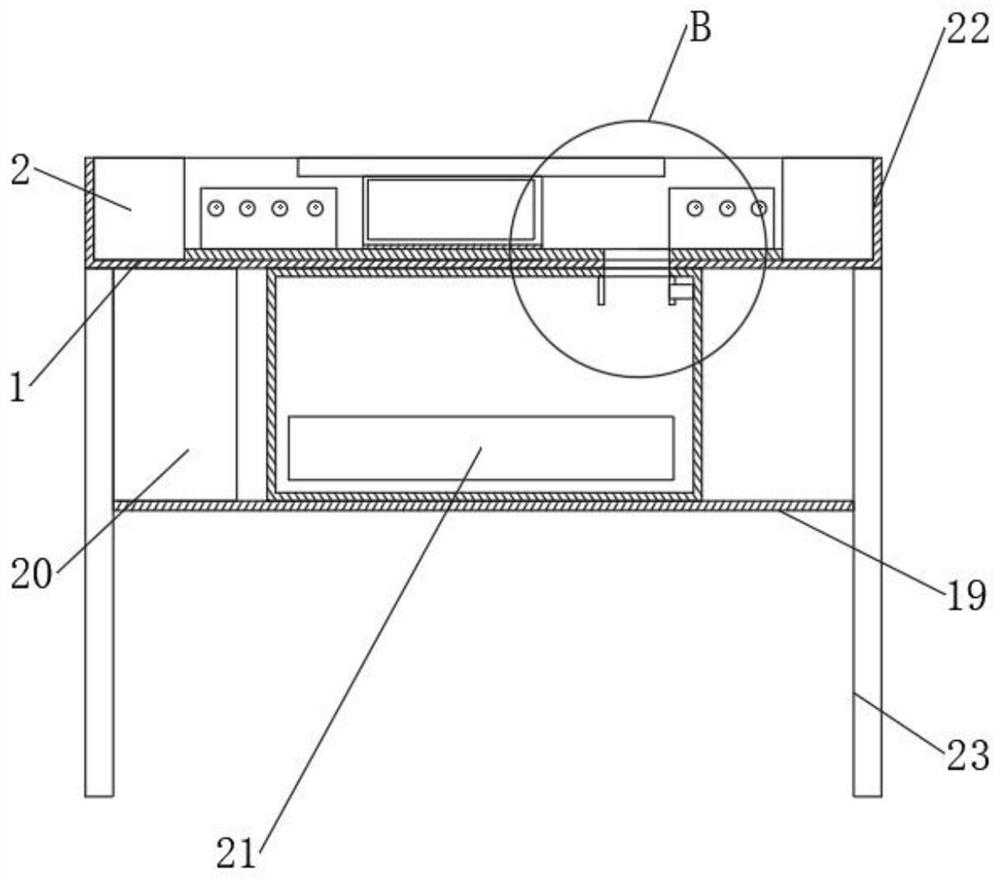

A canteen cooking device

ActiveCN110937174BReduce workloadShorten the timeCoin-freed apparatus detailsSolid materialEngineeringMechanical engineering

The invention relates to a device for making vegetables in a canteen, comprising: a plate receiving mechanism: including a plate receiving platform, and a meal delivery component that carries the meal delivery platform and drives it to move along the direction of meal delivery; it is arranged at the front end of the meal delivery component The plate supply mechanism: used to supply the plate to the plate accepting platform located on the meal out assembly; the vegetable bucket: includes a barrel body with one end open, a vegetable pushing board that is arranged in the barrel and can move along its inner wall, And the bung cover that is blocked at the opening of the barrel body, the side wall of the bottom of the barrel body is provided with an openable and closable vegetable outlet; The barrel frame for placing the vegetable holding barrel and the sealing assembly arranged on the barrel frame and capable of sealing the vegetable outlet. Compared with the prior art, the present invention can effectively solve the problems such as excessive workload of the staff due to the large number of diners in the process of ordering dishes, and long waiting time of the diners during peak times.

Owner:TONGJI UNIV

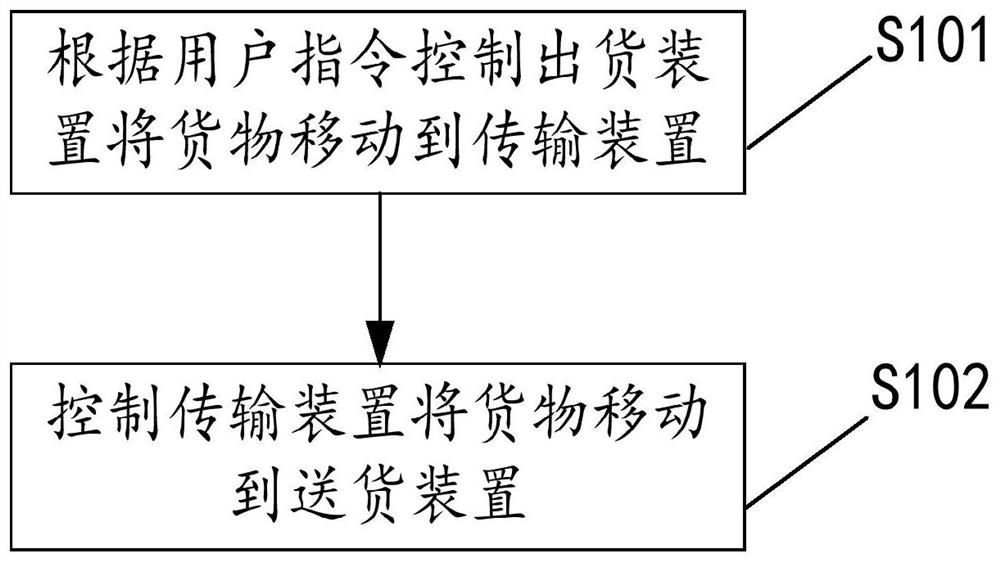

Canteen meal buying device

The invention relates to a canteen meal buying device comprising a dinner plate receiving mechanism, a plate supply mechanism, a food containing bucket and a meal buying mechanism. The dinner plate receiving mechanism comprises a dinner plate receiving platform and a food discharging assembly used for bearing the dinner plate receiving platform and driving the dinner plate receiving platform to move in the food discharging direction; the plate supply mechanism is arranged at the front end of the food discharging assembly and is used for supplying dinner plates to the dinner plate receiving platform on the food discharging assembly; the food containing bucket comprises a bucket body with an opening in one end, a food pushing plate arranged in the bucket body and capable of moving along theinner wall of the bucket body and a bucket cover for sealing the opening of the bucket body, and a food discharging opening capable of being opened and closed is formed in the side wall of the bottomof the bucket body; and the meal buying mechanism is arranged above the food discharging assembly and comprises a bucket bracket located above the food discharging assembly and used for containing thefood containing bucket and a sealing assembly arranged on the bucket bracket and capable of sealing the food discharging opening. Compared with the prior art, the canteen meal buying device can effectively solve the problems that in the meal buying process, the number of persons taking meals is large, the working load of a worker is large, and the waiting time of the person taking the meals is long during peak hours is solved.

Owner:TONGJI UNIV

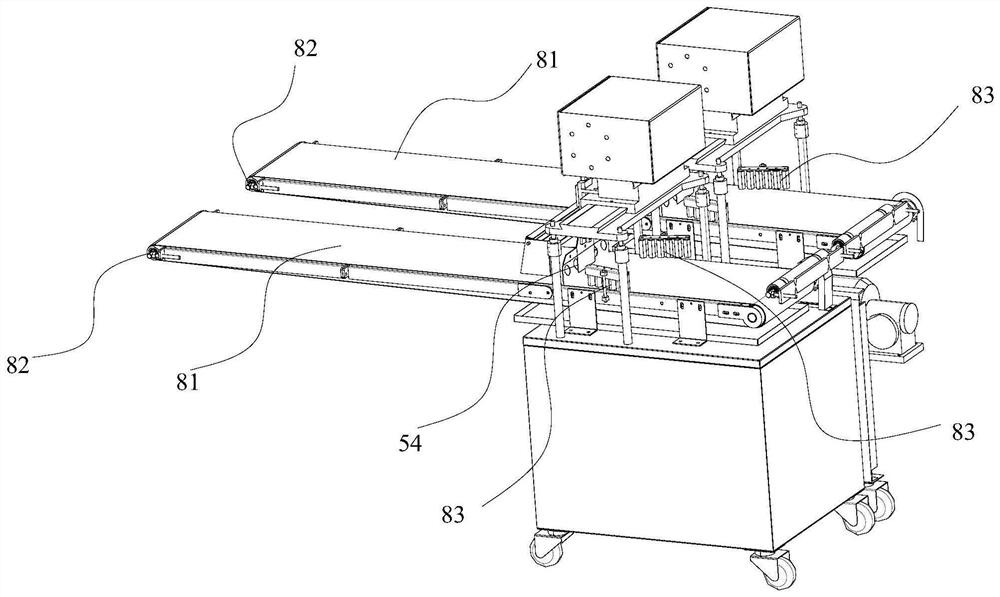

Biscuit production equipment

InactiveCN113729044AAutomatically put inDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusProcess engineeringManufacturing engineering

The invention provides biscuit production equipment, belongs to the technical field of biscuit production, and is characterized in that the biscuit production equipment comprises a noodle press, a cutting device and at least one tray dividing device; the blanking end of the noodle press is connected with the cutting device, and the blanking end of the cutting device is connected with the tray dividing device; and the noodle pressing machine comprises at least two noodle pressing devices, and the blanking end of one noodle pressing device is connected with the feeding end of the other noodle pressing device. The at least two noodle pressing devices are arranged to sequentially press dough, so that the noodle pressing uniformity can be improved, and the production efficiency can be greatly improved by automatically loading wrappers into trays through the tray dividing device.

Owner:无锡嘉鼎机械科技有限公司

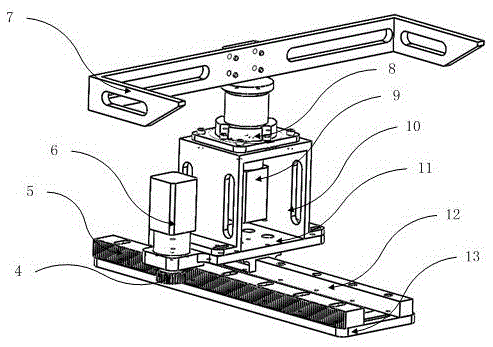

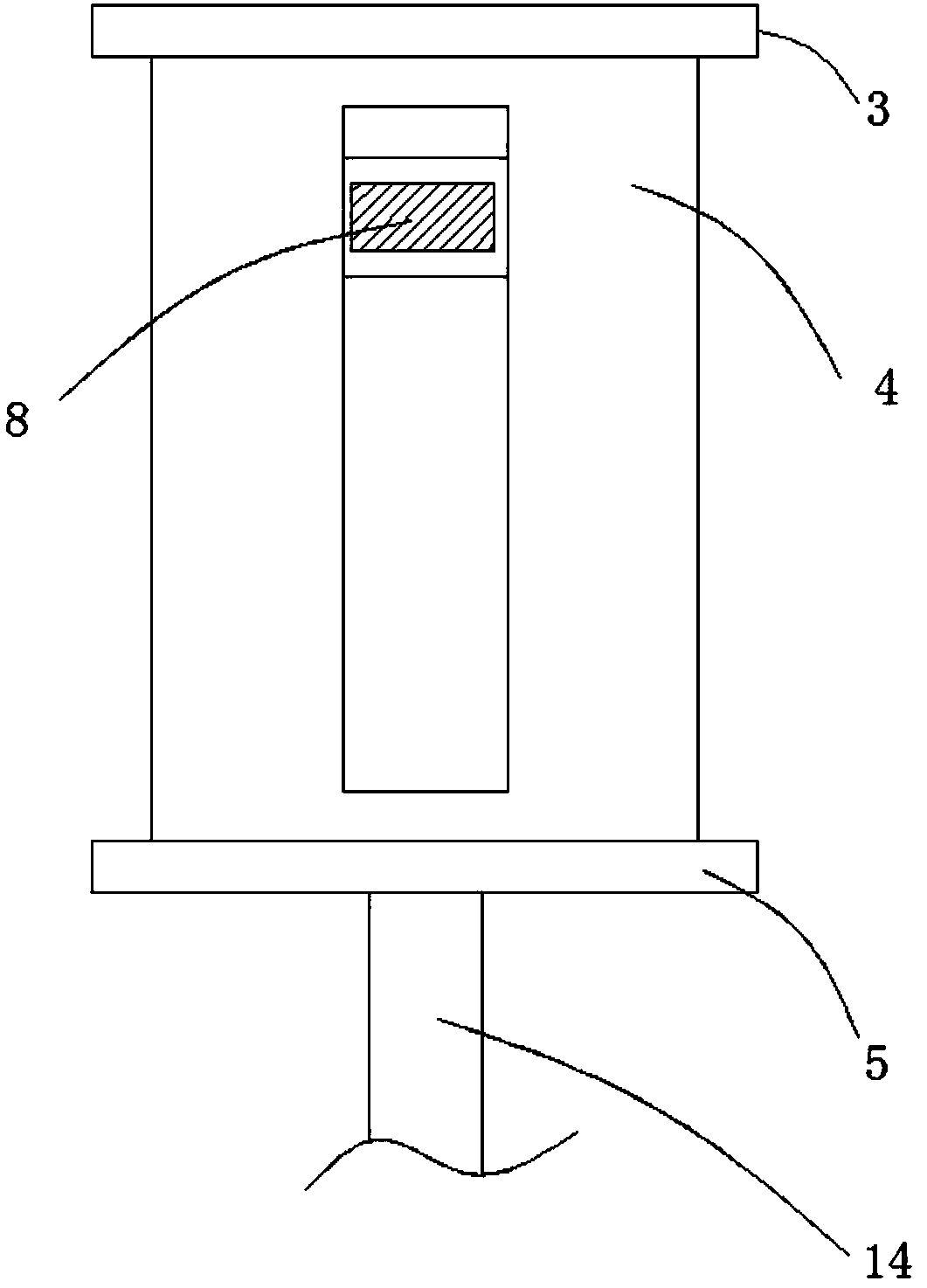

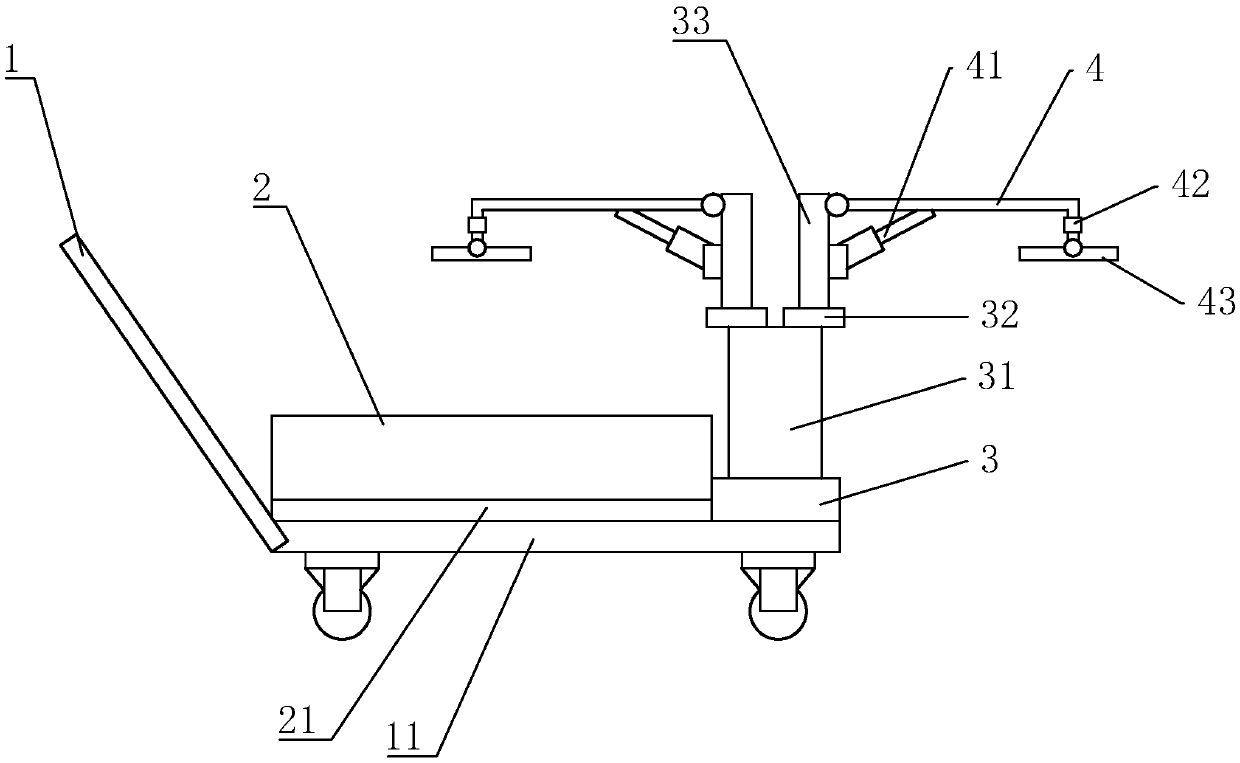

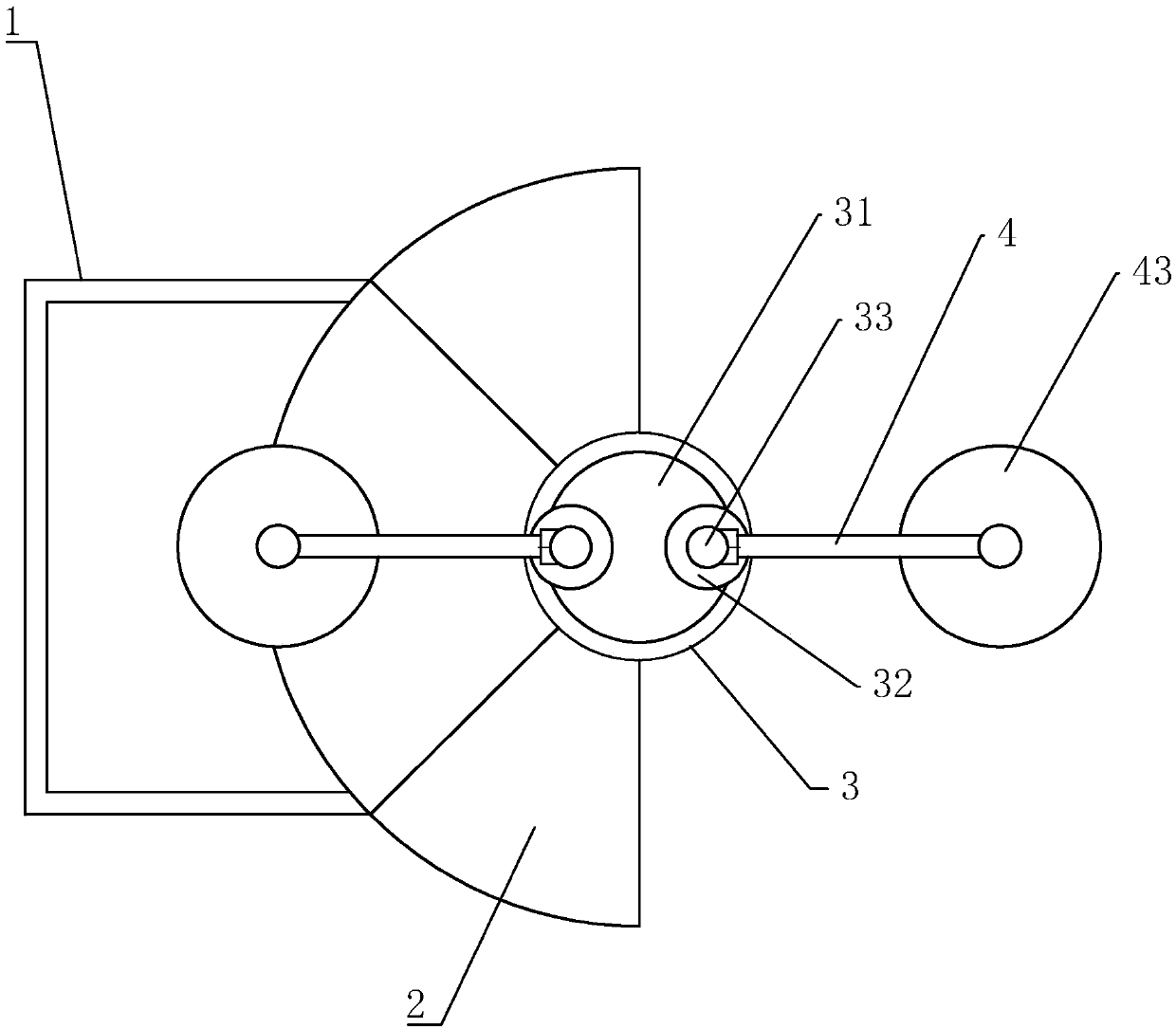

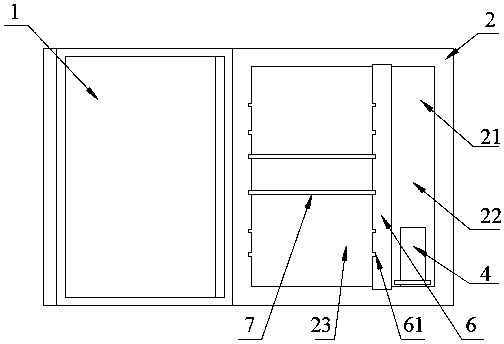

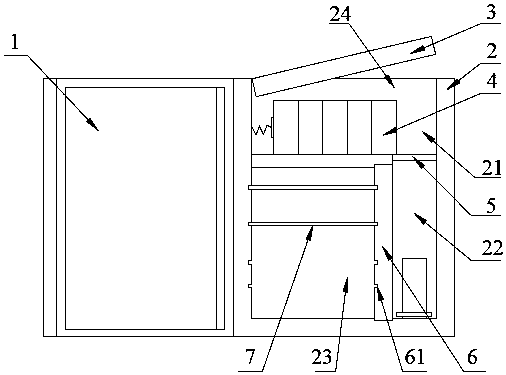

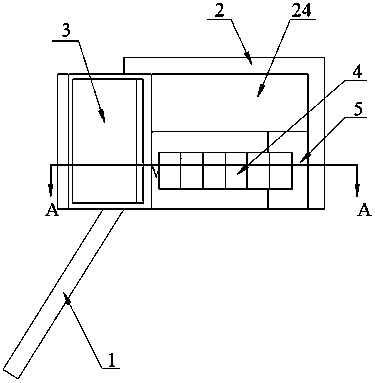

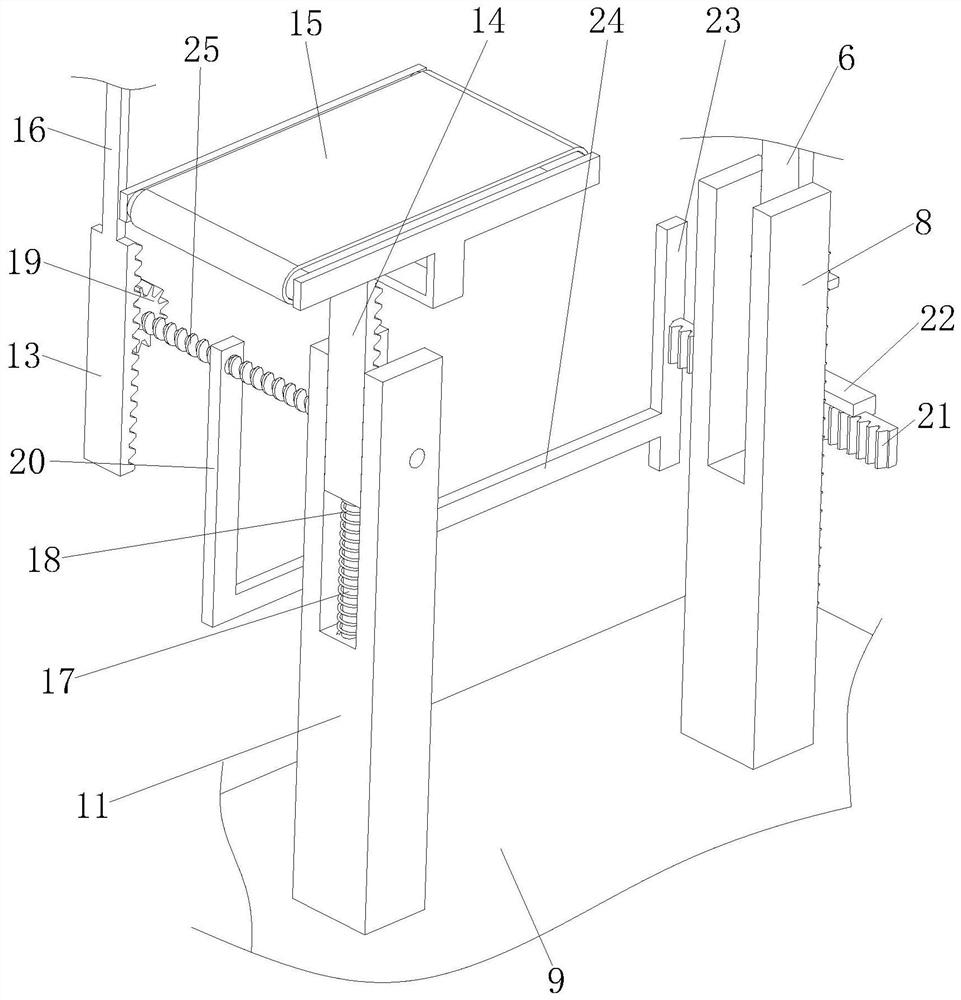

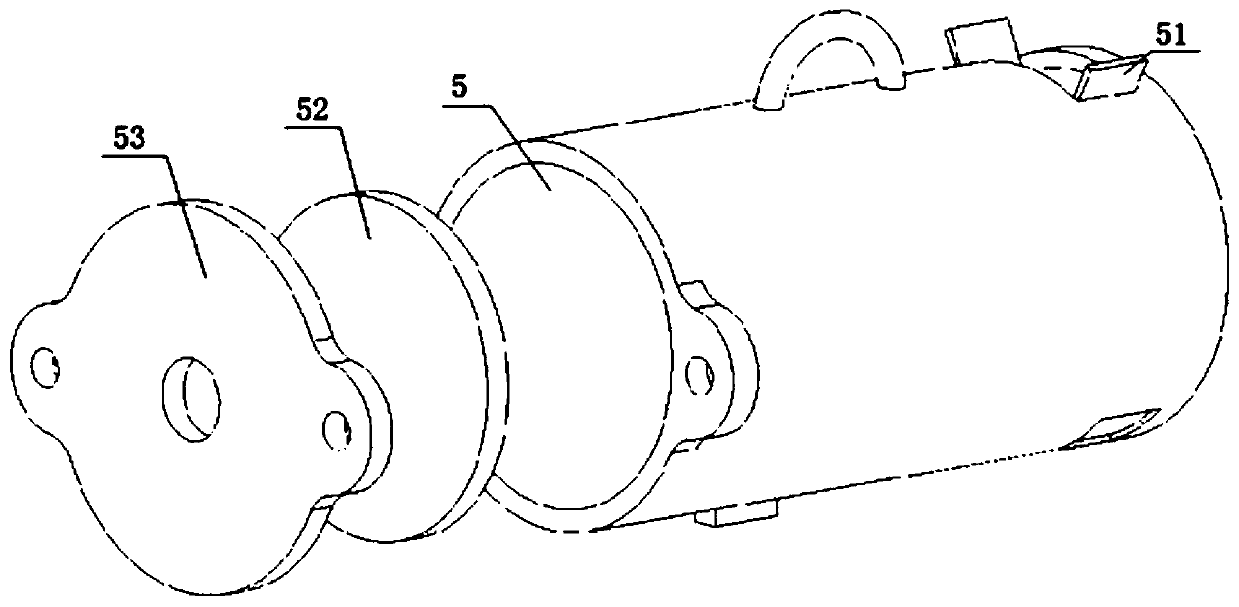

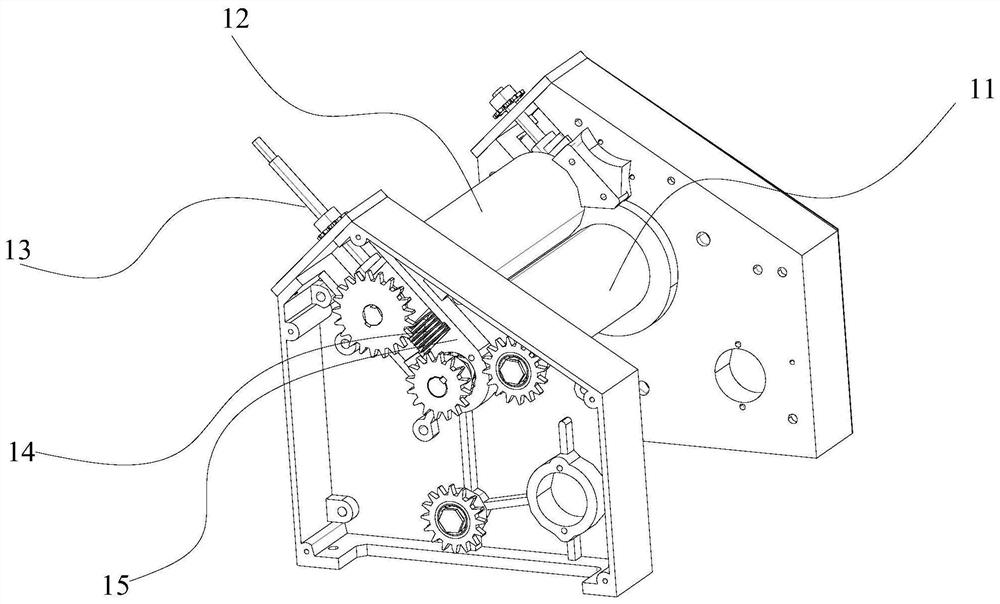

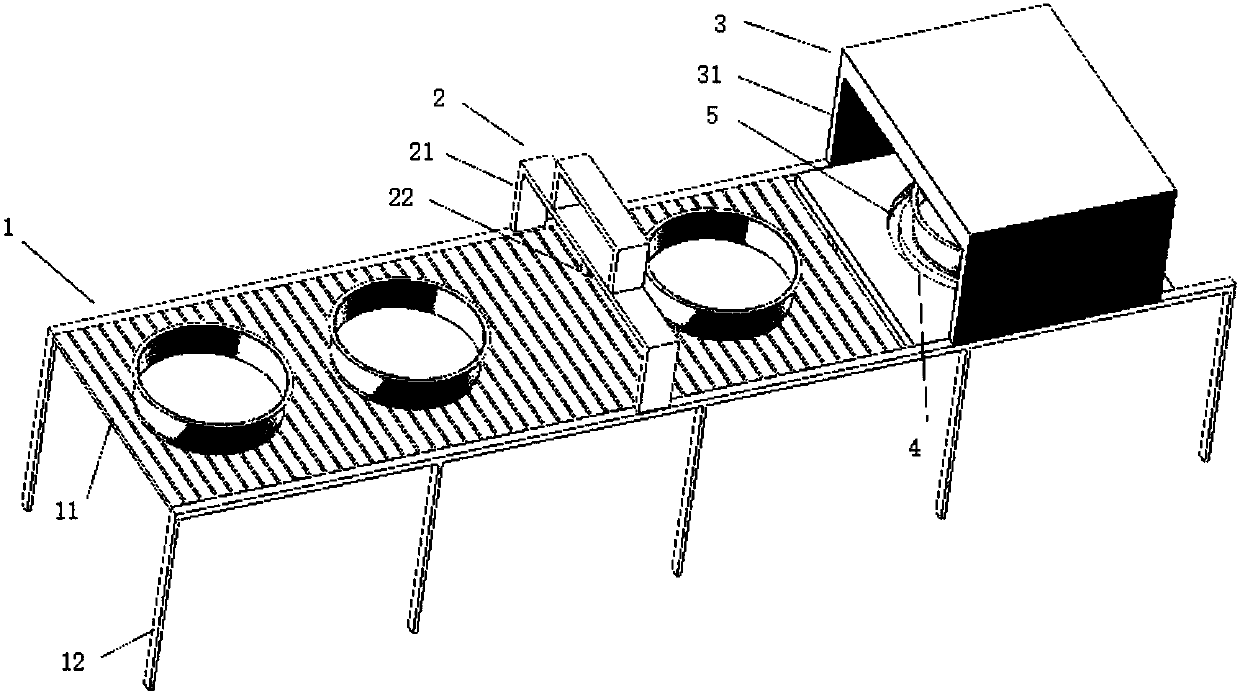

Automatic annealing device

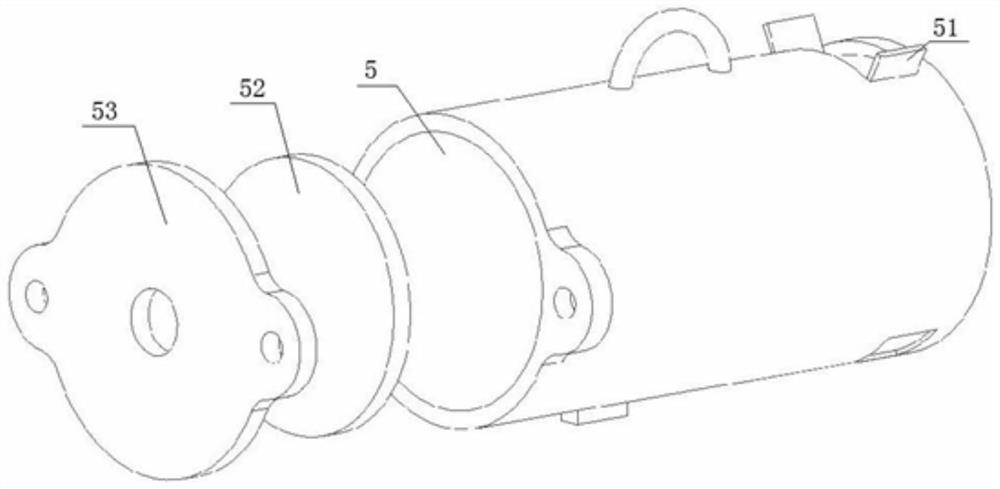

InactiveCN107586924AAutomatically put inIncrease productivityHeat treatment process controlBiomedical engineering

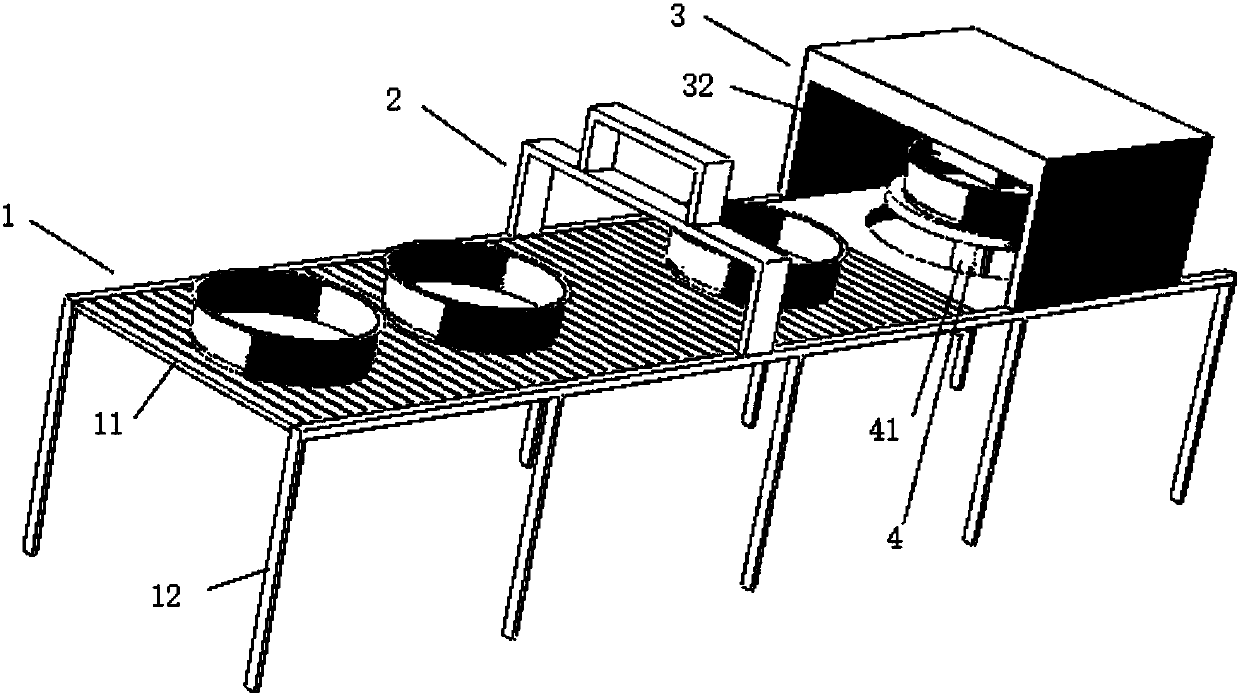

The invention provides an automatic annealing device, which comprises a bracket (1), a detection mechanism (2), an annealing chamber (3) and a telescopic mechanism (4), wherein the detection mechanism(2) and the annealing chamber (3) are arranged on the bracket (1), and the detection mechanism is arranged at the inlet side of the annealing chamber (3); the telescopic mechanism (4) is arranged atthe lower part of the bracket (1) and can extend out of the annealing chamber (3) through a first opening (5) in the bracket (1), and the bracket (1) comprises a conveying mechanism (11) and a plurality of support legs (12); the detection mechanism (2) comprises a detection rack (21) and a detector (22), and the annealing chamber (3) comprises an annealing house (31) and a heating device (32); thetelescopic mechanism (4) comprises a telescopic rod (41) and a telescopic power device.

Owner:江门市凯骏机电有限公司

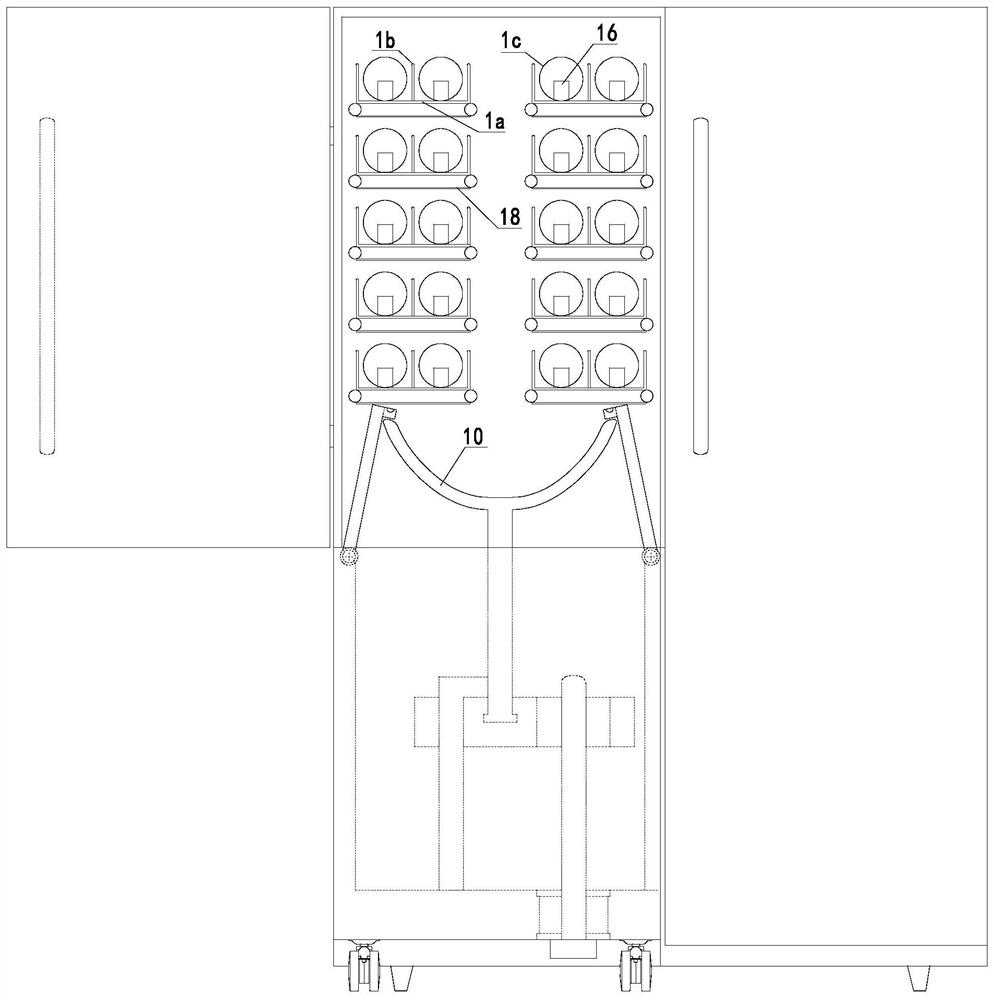

Food automatic heating supply machine

ActiveCN106348030BAutomatically put inHigh selectivityCoin-freed apparatus detailsDe-stacking articlesMicrowave ovenEngineering

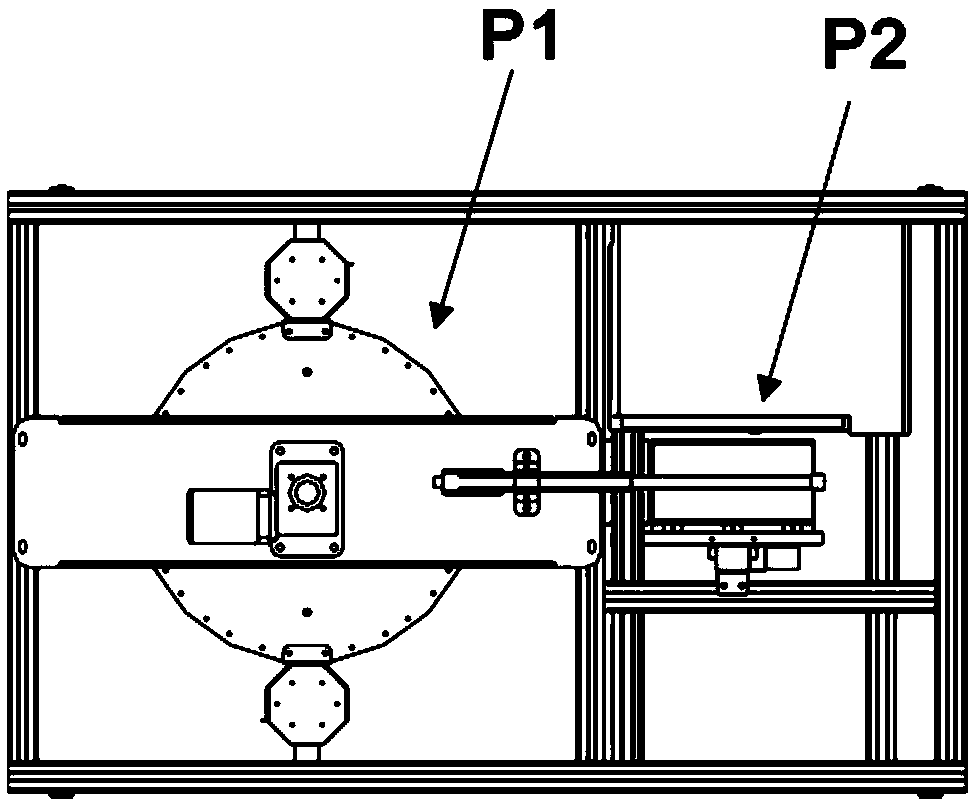

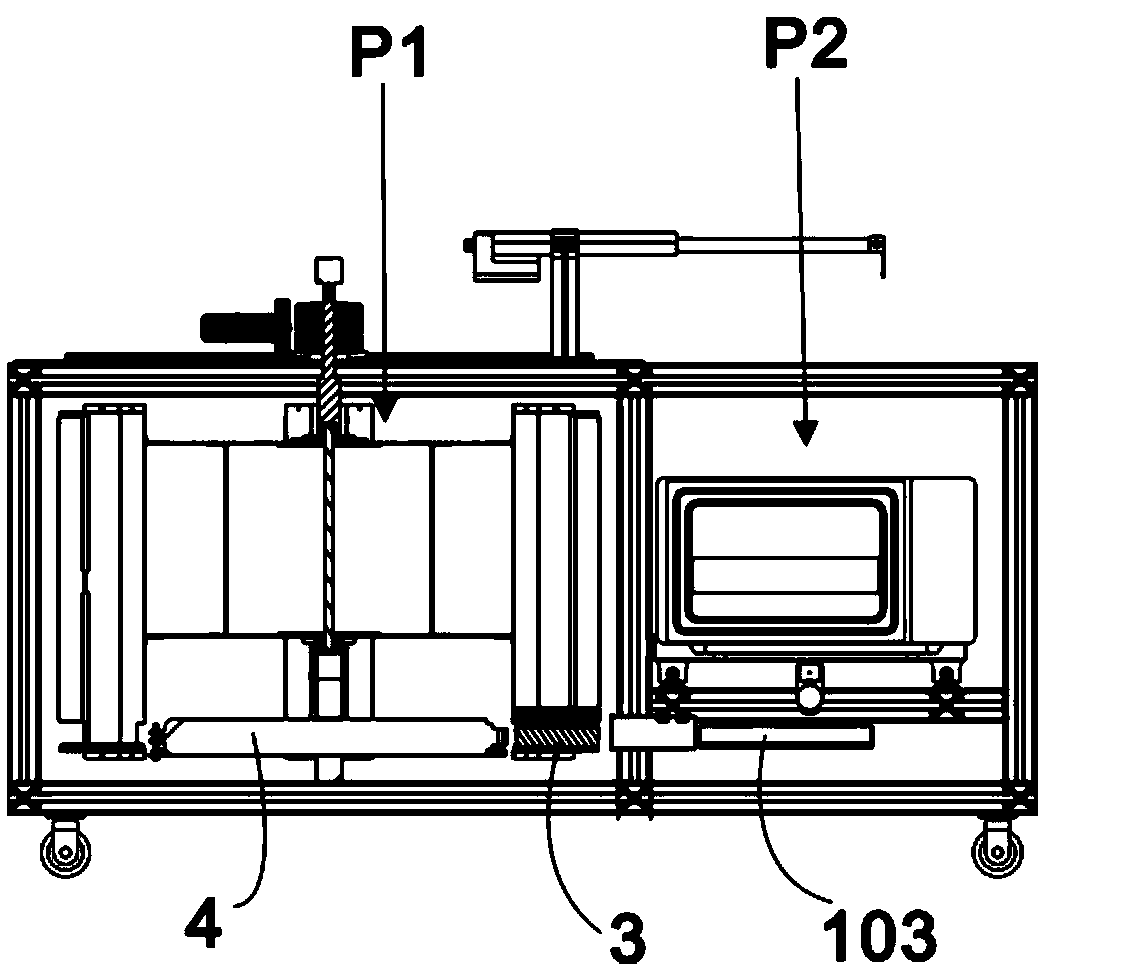

The invention discloses an automatic food heating and supplying machine. The automatic food heating and supplying machine comprises an automatic food conveying device and an automatic food heating device, wherein charging barrels of the automatic food conveying device rotate along with rotation of a rotating body, and multiple foods are stored in the charging barrels and conveyed to a specific position through rotation of the rotating body; for the automatic food heating device, the selected food from the automatic food conveying device is conveyed vertically by a lifting device, a microwave oven is pushed to the specific position through a driving device, the food is fed into the microwave oven, and the microwave oven is closed through cooperation of a first small door and a second small door; then the heated food is output by the lifting device. The automatic food heating and supplying machine realizes various functions such as food storage, selection, automatic heating and the like and solves the problems about sales space and manpower of traditional shops.

Owner:福建省小白心里软食品有限公司

Automatic edge cutting method for plant fiber molding product and automatic edge cutting machine

ActiveCN103042639BAccurate cutting edge positioningHigh speedMetal working apparatusFiberEngineering

The invention relates to an automatic edge cutting method for a plant fiber molding product and an automatic edge cutting machine. The purposes are that the method has the characteristic of automatic and accurate location, and the automatic cutting machine has the characteristic of stable work. The technical scheme includes that the automatic edge cutting method for the plant fiber molding product proceeds as follows: 1), sucking the product with edges to be cut; 2), driving away waste edges from an edge cutting position; 3), positioning the product to be cut and a product with cut edges respectively; 4), cutting out deckle edges; 5), enabling a front row and a rear row of sucking disk sets to reach the corresponding positions respectively; and 6), sucking the product with edges to be cut and the product with cut edges; repeating from the step 2) to the step 6), and proceeding the circulation over and over again. The automatic edge cutting machine for the plant fiber molding product comprises an edge cutting and die assembly mechanism, wherein the edge cutting and die assembly mechanism comprises an upper edge cutting mold, a lower edge cutting mold, an upper installation plate, a lower installation plate and a power mechanism. The automatic edge cutting machine for the plant fiber molding product is characterized in that a product transferring mechanism and a waste edge moving out mechanism are also arranged on the automatic edge cutting machine.

Owner:EURASIA EP MACHINERY +1

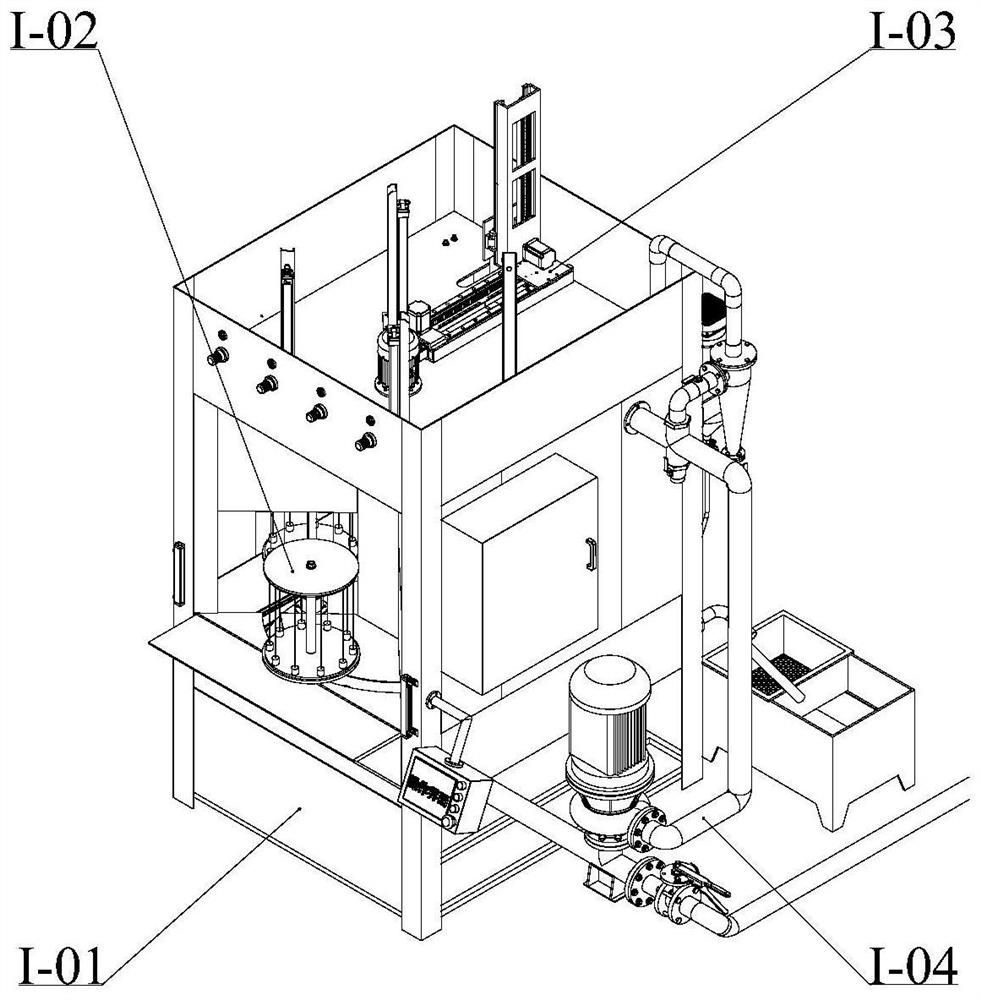

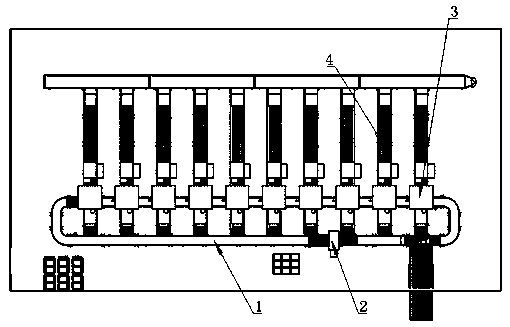

Equipment for automatically sorting and loading spiced corned eggs in containers

InactiveCN110667914ARun fastIncrease productivityPackaging automatic controlIndividual articlesProcess engineeringManual handling

The invention relates to the technical field of sorting and loading food in containers, in particular to equipment for automatically sorting and loading spiced corned eggs in containers. According tothe technical scheme adopted by the invention, the equipment comprises a circular conveying line, wherein a non-conforming product detection and rejection mechanism is arranged above one side conveying line of the circular conveying line; a spiced corned egg input connecting device is arranged on the circular conveying line and is located at the right side of the circular conveying line; a group of mechanisms for automatically sorting and loading acceptable products in the containers are arranged in the conveying direction of the circular conveying line and are located at the rear side of thenon-conforming product detection and rejection mechanism; and the rear sides of the mechanisms for automatically sorting and loading the acceptable products in the containers are connected to stretchpackaging equipment. The equipment for automatically sorting and loading the spiced corned eggs in the containers has the advantages that the equipment has relatively high processing efficiency in theentire process, can replace an existing manual operation mode, can effectively save labor cost in the entire process, can effectively improve the product quality, and enables the overall processing and production cost to be relatively low.

Owner:华粹智能装备有限公司

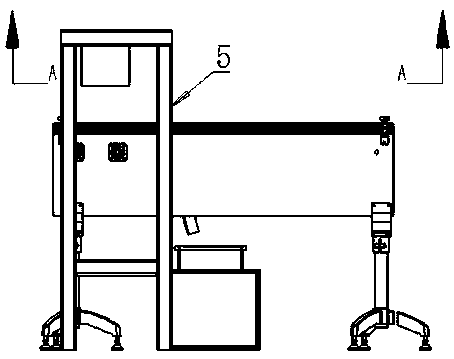

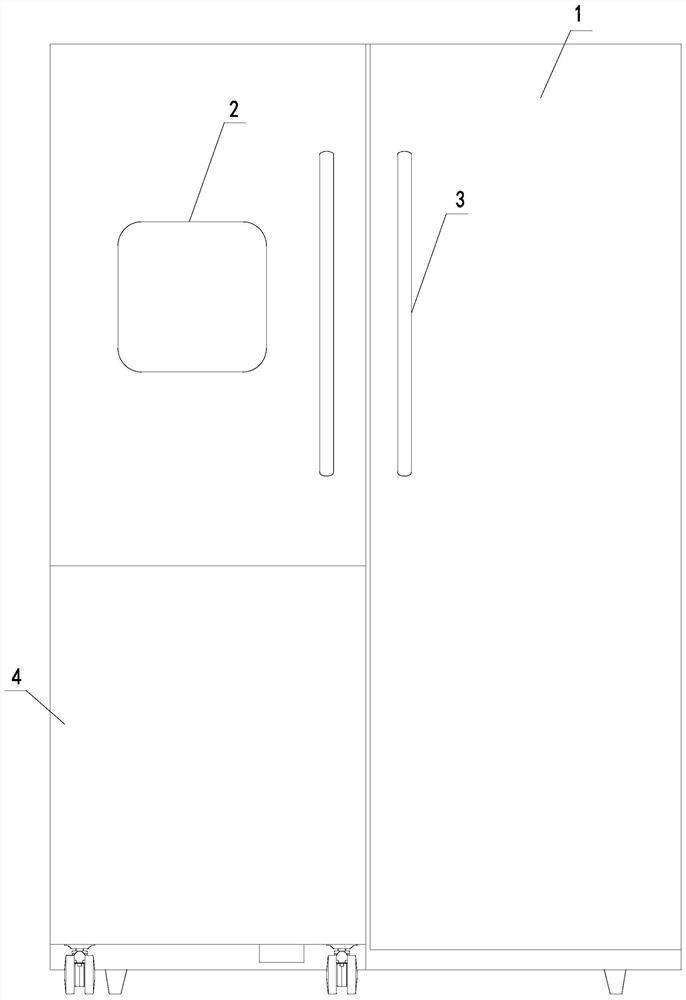

Goods configuration method and device and goods delivery device

PendingCN113126663AAutomatically put inImprove experienceLighting and heating apparatusDomestic refrigeratorsIndustrial engineeringOperations management

Owner:QINGDAO HAIGAO DESIGN MFG CO LTD +1

Shoe box storing and taking equipment

PendingCN114030705ARealize automatic removalAutomatically put inPackagingStorage devicesMechanical engineeringEngineering

The invention discloses shoe box storing and taking equipment which comprises a storing and taking fixing frame, a shoe box grabbing assembly and a driving mechanism, at least one shoe box storage space is arranged in the storing and taking fixing frame, the shoe box grabbing assembly is used for fixing empty shoe boxes or packaged full shoe boxes in the conveying process, and the driving mechanism is used for driving the shoebox grabbing assembly to move in the three-dimensional space. When an empty shoe box needs to be taken out, the shoe box grabbing assembly is conveyed to the position where the empty shoe box is placed through linkage of three shoe box storing and taking-out linear modules, the shoe box grabbing assembly takes out the empty shoe box and conveys the empty shoe box to the designated position for a next station to use, and similarly, when a packaged full shoe box need to be stored, the shoe box is stored and taken out through linkage of the three shoe box storing and taking-out linear modules, the shoe box grabbing assembly is conveyed to the position of the packaged full shoe box, the shoe box grabbing assembly collects the packaged full shoe box and conveys the packaged full shoe box into the shoe box storage space. According to the invention, automatic taking-out of the empty shoe box and automatic putting-in of the packaged full shoe box are achieved.

Owner:丽荣鞋业(深圳)有限公司

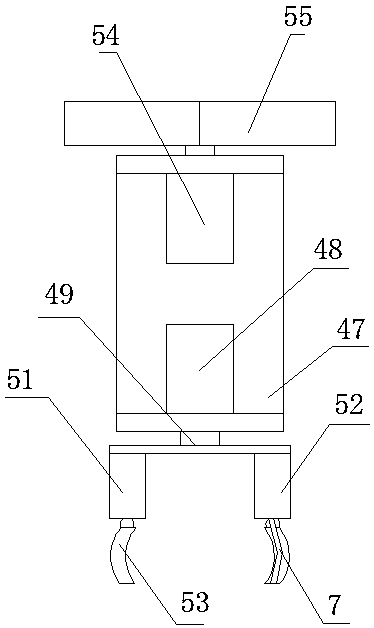

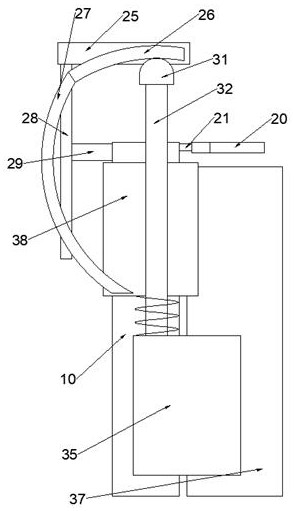

Manipulator for assisting water dispenser in placing bucket

The invention discloses a manipulator for assisting a water dispenser in placing a bucket. The manipulator comprises a machine body and a water dispenser base, the machine body is placed on the rear side of the water dispenser base, a power cavity is formed in the machine body, a pressure cavity is formed in the upper side of the machine body, side edge blocks are fixedly arranged on the left sidewall and the right side wall of the machine body correspondingly, a rotating cavity is formed in each side edge block, and a first supporting rod is fixedly arranged on the upper side face of the machine body; second supporting rods are fixedly arranged on the upper side faces of the two side edge blocks correspondingly, a top plate is fixedly arranged on the upper sides of the first supporting rods and the second supporting rods, a connecting plate is fixedly arranged on the rear side face of the machine body, a vertical supporting plate is fixedly arranged on the rear sides of the connecting plate and the top plate, rotating devices rising in a rotating mode are arranged on the side edge blocks, and a rotating block is provided with a moving device which moves and extends in rotation. Aclamping device for clamping the bucket is arranged in the rotating block. According to the water dispenser, the water bucket can be automatically placed into the water dispenser, the water bucket iscarried to the position above the water dispenser through rotation, the water bucket is installed, manual labor-consuming carrying is not needed, and people in an office cannot use water to the factthat the bucket cannot be carried.

Owner:江西博用环保材料有限公司

A kind of honeycomb that moves spleen automatically

Owner:KUNMING UNIV OF SCI & TECH

Black fungus bag prefabricating and hoisting device

PendingCN114145184AHigh speedPrevent rollingCultivating equipmentsMushroom cultivationGreenhouseControl engineering

The invention relates to a prefabricated hoisting device, in particular to a prefabricated hoisting device for black fungus bags. According to the auricularia auricula fungus bag prefabricating and hoisting device, firstly, seven fungus bags can be rapidly placed between the fixing ropes, and then the fixed fungus bags are hung on a greenhouse top beam through the clamping mechanism. According to the technical scheme, the black fungus bag prefabricating and hoisting device comprises a first support, a workbench, first supporting legs, a conveying device and the like, the workbench is fixedly connected to the right side of the first support, the first supporting legs are fixedly connected to the bottom of the workbench, and the conveying device is rotationally connected with the workbench. According to the invention, seven fungus bags can be fixed among the three fixing ropes in advance, and the fixed fungus bags can be hung on the top beam of the greenhouse only by using one hoisting mechanism; the conveying device can automatically push the triangular partition plate forwards; the telescopic air cylinder replaces an existing manual material pushing process, and the fungus bag pushing speed is greatly increased.

Owner:刘肖温

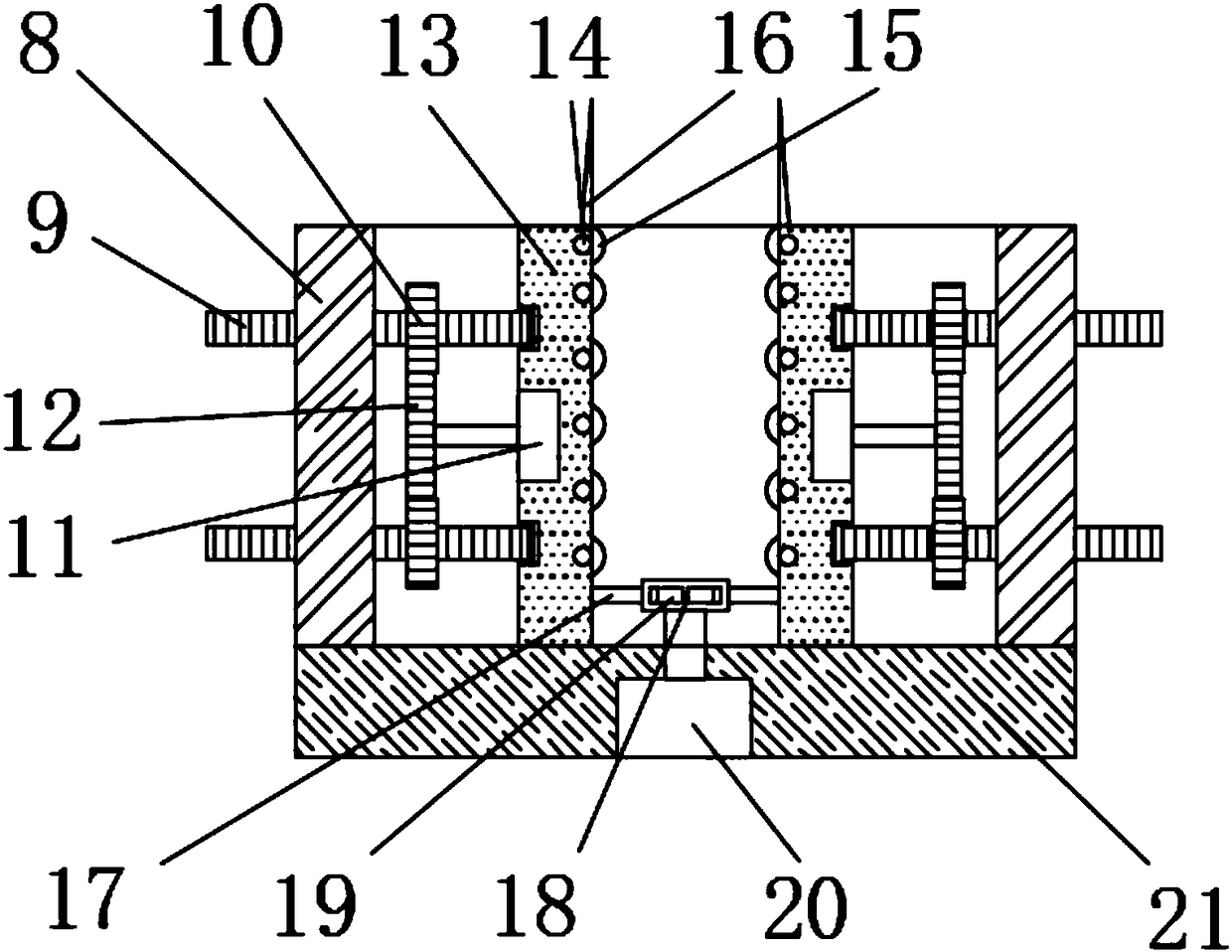

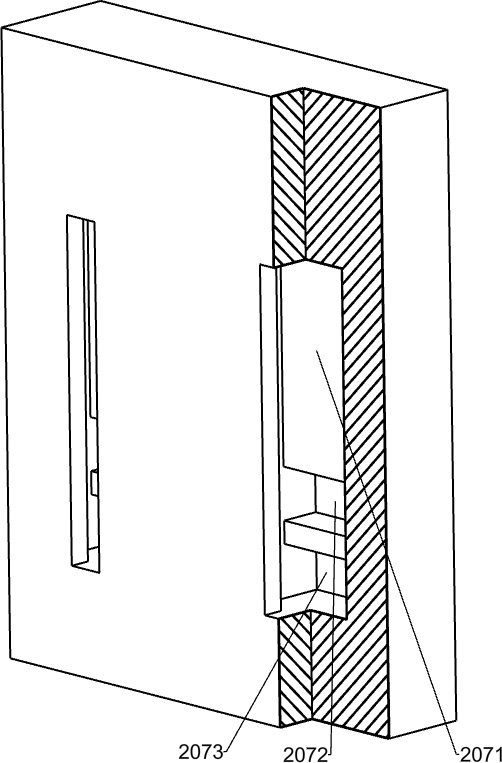

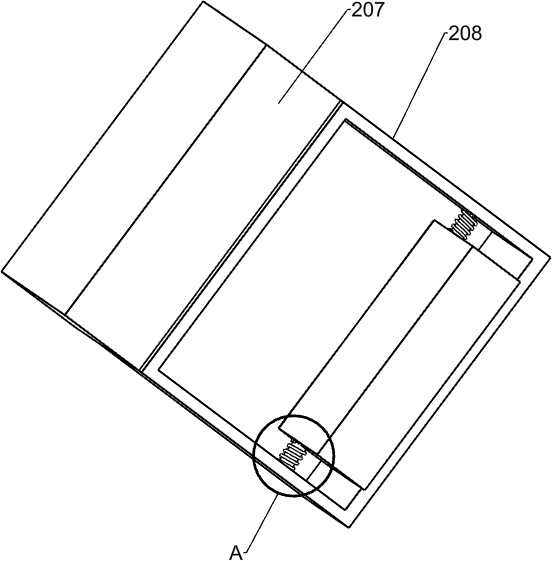

Mold for membrane insert molding

The invention relates to a mold for membrane insert molding. The mold includes mold cores and a mold frame; the mold cores include a movable mold core and a fixed mold core, and a first movable mold insert and a second movable mold insert are inserted into a fame of the movable mold core through a guide positioning structure; a fixed mold insert is inserted into a frame of the fixed mold core through the guide positioning structure, and membranes are embedded into the end surface of the fixed mold insert; the mold frame includes a fixed mold platen, a first movable mold platen, and a second movable mold platen, the fixed mold core is loaded into a frame of the fixed mold platen and is locked by screws, and guide pillars and pull rods are installed on the fixed mold platen; and the movablemold core is loaded into the first movable mold platen, the second movable mold platen is provided with ejector pins, four corners of the second movable mold platen are provided with movable mold guide columns, the first movable mold platen is arranged on the guide columns in a sleeving mode, a shutter is mounted on the first movable mold platen, and pull plates are installed at the diagonal position of two sides of the first movable mold platen and the second movable mold platen. The membranes with the thickness of 0.2mm can be automatically embedded for molding production, and automatic placement, automatic positioning, automatic adsorption, and automatic ejection and demoulding are realized.

Owner:苏州川鹏塑料有限公司

Intelligent electronic product detection equipment

PendingCN114812668AAutomatically put inImprove detection efficiencyMeasurement apparatus componentsOptical detectionEngineeringAssembly line

The invention provides intelligent electronic product detection equipment. The intelligent electronic product detection equipment comprises a bottom horizontal supporting plate, supporting legs are fixedly connected to the lower surface of the bottom horizontal supporting plate, a supporting plate is fixedly connected to the side surfaces of the supporting legs, a waste box is fixedly connected to the upper surface of the supporting plate, and a fixing piece is fixedly connected to the top inner wall of the waste box. A first counter is arranged on the right side of the fixing piece, a side box plate is fixedly connected to the upper surface of the bottom horizontal supporting plate, a feeding box is fixedly connected to the left inner wall of the side box plate, and a pushing device is arranged on the rear inner wall of the feeding box. By designing the pushing device and the infrared sensor, the device is placed beside an assembly line in the overhauling process, electronic products are automatically put in and pushed out, the detection efficiency is improved, by designing the two counters, the yield can be automatically calculated in the using process of the device, and the using convenience of the device is improved.

Owner:深圳市凯博检测认证有限公司

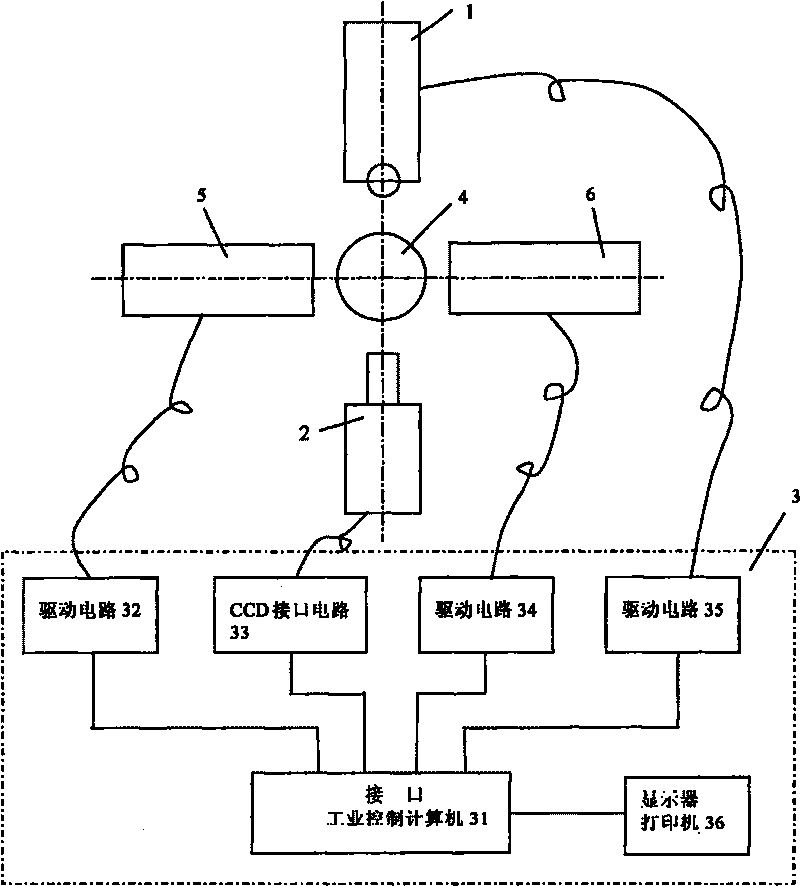

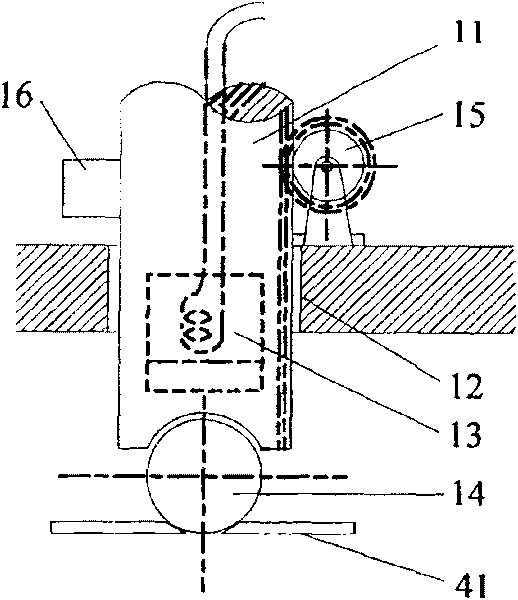

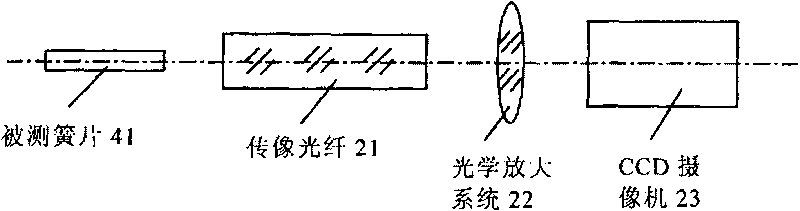

Automatic detector for spring leaves used for geophone

InactiveCN1702478BReduce labor intensityIncrease productivitySeismic signal receiversGeophoneAutomatic control

An automatic monitor of spring blade at least comprises spring blade testing work table for placing the spring blade; electromagnetic weight reinforcing mechanism for loading the load moment onto thespring blade; CCD displacement measurement unit for forward and outward the spring blade; drive and control system for driving and controlling the reinforcing of electromagnetic weight, feeding and blanking structure of spring blade, in addition controlling automatically the signals ejected from CCD displacement measurement unit and displaying the measuring results.

Owner:BEIHANG UNIV

Automatic needle assembling device and needle assembling method

PendingCN112676794AAutomatically put inImprove assembly accuracyMetal working apparatusBiomedical engineeringGeneral surgery

Owner:SUZHOU MEISHANZI GARMENTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com