Integral loading and carrying equipment

A technology for handling equipment and carrying boxes, which is used in lifting devices, transportation and packaging, load hanging components, etc., can solve problems such as troublesome operation, and achieve the effect of convenient disassembly and assembly and convenient unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

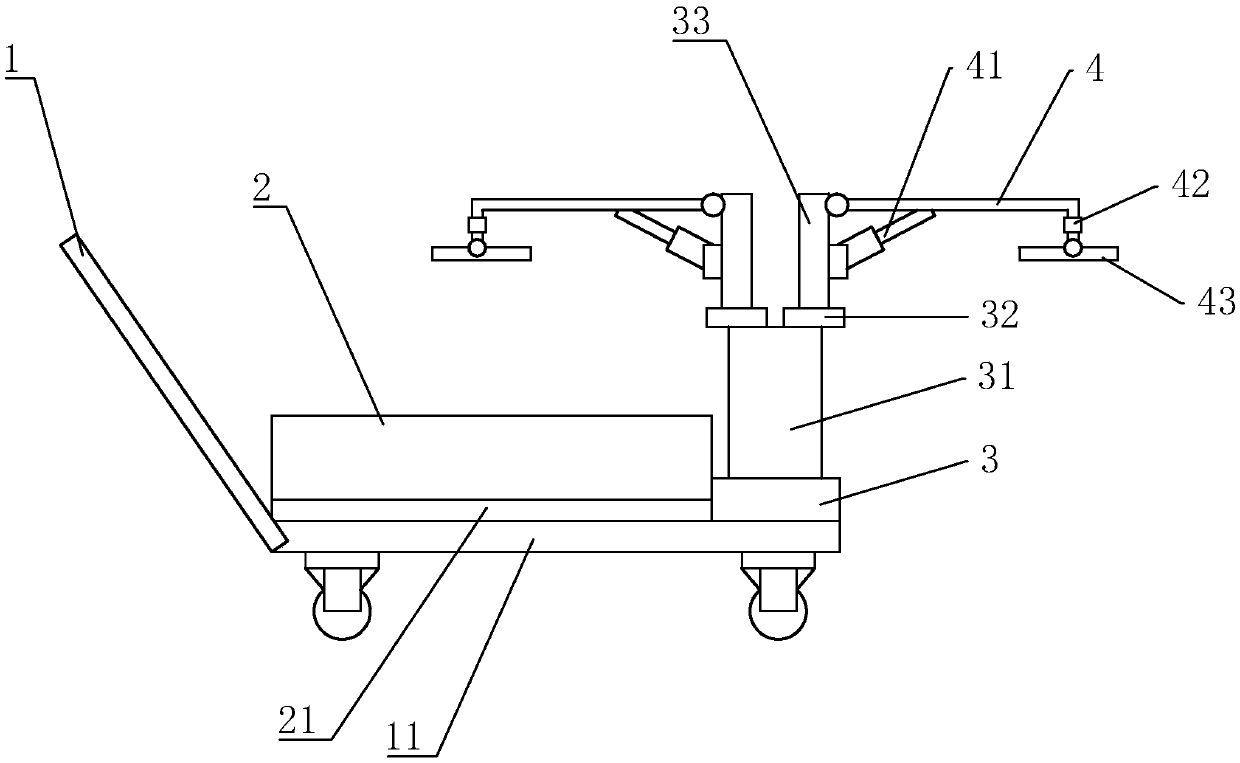

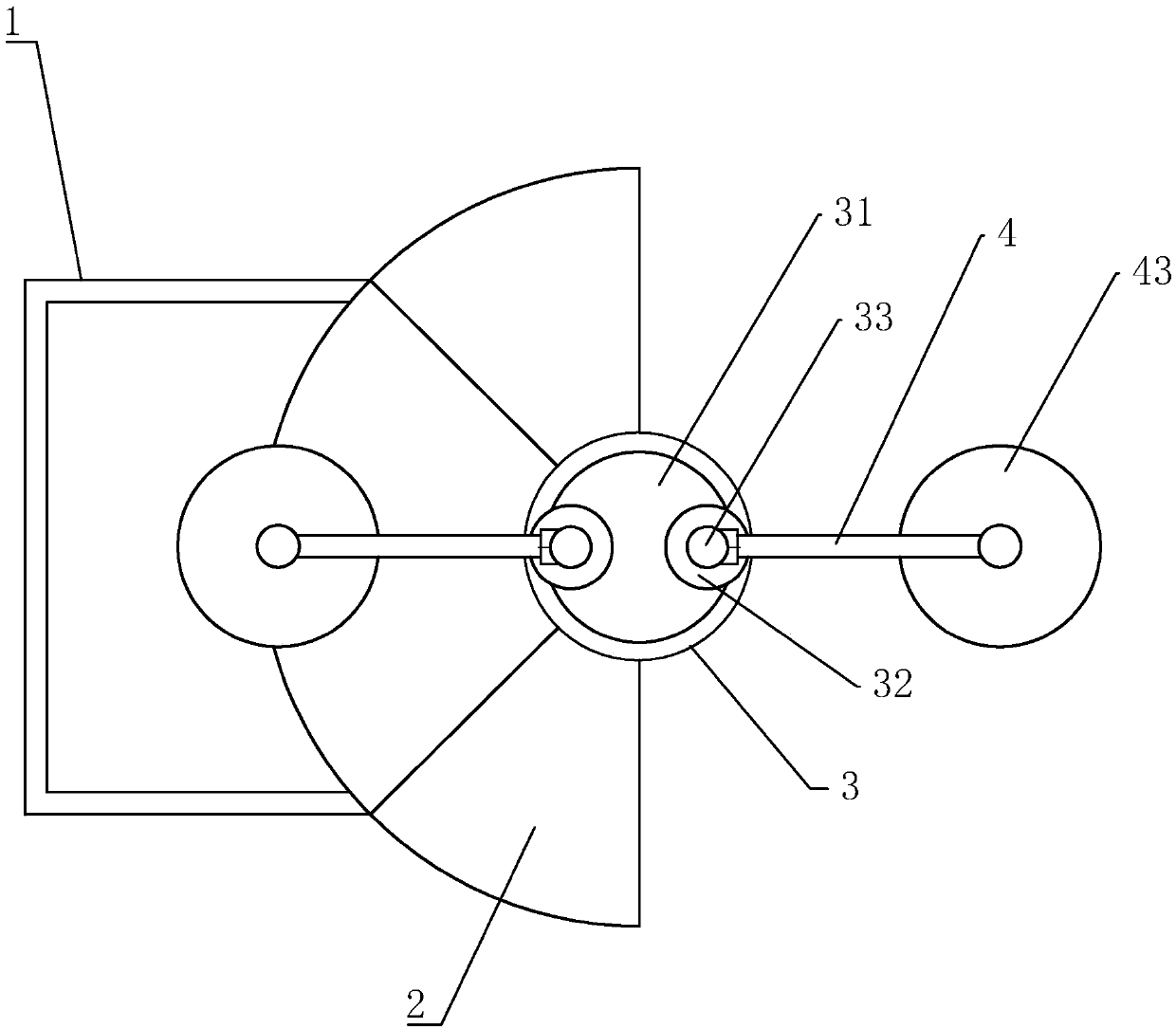

[0022] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0023] An integrated loading and handling equipment, such as figure 1 with 2 As shown, it includes a mobile frame 1, the mobile frame 1 includes a semicircular base 11, a number of bearing boxes 2 are arranged on the base 11, and a rotary table 3 is vertically arranged at the center of the base 11, and the The rotating table 3 is provided with a rotating column 31, and the upper end of the rotating column 31 is hingedly provided with two cantilevers 4, and a lifting device is arranged between the middle part of the cantilever 4 and the rotating column 31, and the end of the cantilever 4 is far away from the rotating column 31 An electric sucker 43 is hingedly arranged; a PLC controller is also included, and the rotary table 3, the lifting device and the electric sucker 43 are all electrically connected to the PLC controller. A tension sensor 42 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com