Black fungus bag prefabricating and hoisting device

A hoisting device and technology of black fungus, applied in gardening, botany equipment and methods, plant cultivation, etc., can solve problems such as slow speed, and achieve the effect of increasing work efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

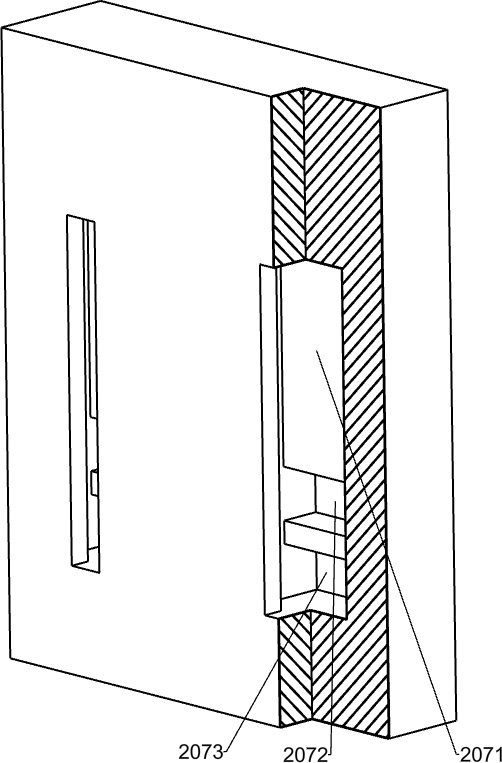

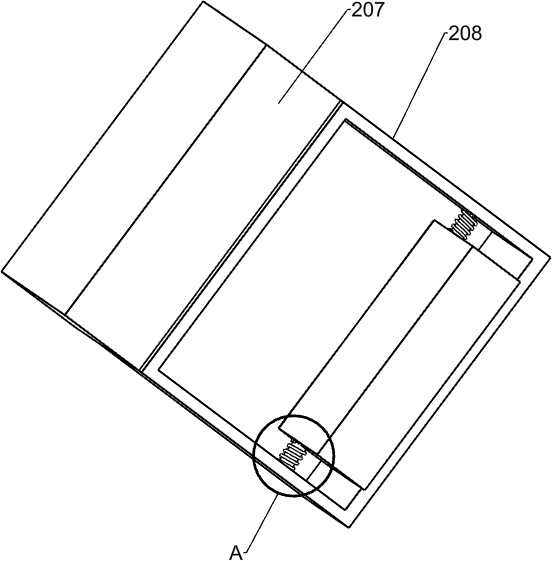

[0033] A kind of black fungus bag prefabricated hoisting device, such as Figure 1-2 As shown, it includes a first support 1, a workbench 2, a first support leg 3, a roller 204, a transmission device, a rope jacking device and a material receiving device. The right side of the first support 1 is fixedly connected with a workbench 2. The concave surface of a bracket 1 is connected with a second winding shaft 104 and a third winding shaft 105, a U-shaped groove 103 is opened on the upper left side of the first bracket 1, and a support base 102 is fixedly connected to the left side of the first bracket 1, and the top of the support base 102 is Connected with the first winding shaft 101, the first winding shaft 101, the second winding shaft 104 and the third winding shaft 105 are used to install the reel, the reel is used to roll the rope, the reel is wound with a fixed rope, and the workbench 2 The bottom is fixed with the first supporting leg 3 for support, and the upper left si...

Embodiment 2

[0036] On the basis of Example 1, such as image 3 As shown, the transmission device includes a first idler roller 401 and a second idler roller 403 that are rotatably connected to both sides of the inner wall of the first groove 201 of the workbench 2, and the conveyor belt 4 is rotatably connected to the first idler roller 401 and the second idler roller 403. Above, a plurality of stoppers 402 are evenly spaced on the conveyor belt 4 , and the stoppers 402 are used to divide the triangular partition 213 .

[0037] Whenever the first triangular partition 213 is pushed to the right, the lower part of the triangular partition 213 contacts the stopper 402 on the conveyor belt 4, driving the conveyor belt 4 to rotate, and the movement of the triangular partition 213 will drive the uniformly spaced and fixed stoppers on the conveyor belt 4. The block 402 will push the remaining triangular partitions 213 to move forward to realize the function of transmitting the triangular partiti...

Embodiment 3

[0043] On the basis of Example 12, such as figure 1 As shown, it also includes a conveyor 5, a conveyor belt 501, a second baffle 502, and a feeding shell 503. The conveyor 5 is rollingly connected with a conveyor belt 501, and the conveyor belt 501 is evenly equipped with a second baffle 502. There are also two large baffles on both sides of the belt 501 to prevent the bacteria bags from slipping off from both sides of the conveyor belt. The feeding shell 503 is connected to the right side of the top of the workbench 2, and the feeding shell 503 can guide the bacteria bags to roll into the workbench , and can prevent the bacteria bag from rolling down from the back of the workbench.

[0044] After opening the conveyor 5, the bacteria bag is placed in the gap in the second baffle plate 502 evenly installed on the conveyor belt 501. When the bacteria bag was forwarded to the place where the conveyor belt 501 was close to the feeding shell 503, the bacteria bag would move from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com