Automatic tree planting vehicle

An automatic and vehicle-mounted technology, applied in planting methods, botanical equipment and methods, instruments, etc., can solve the problems of low efficiency of manual operation, achieve the effects of simple structure, reduce environmental pollution, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

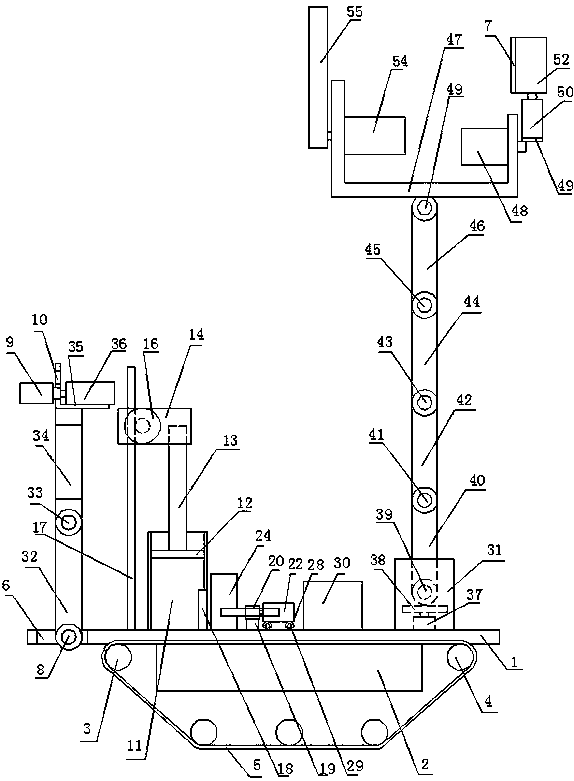

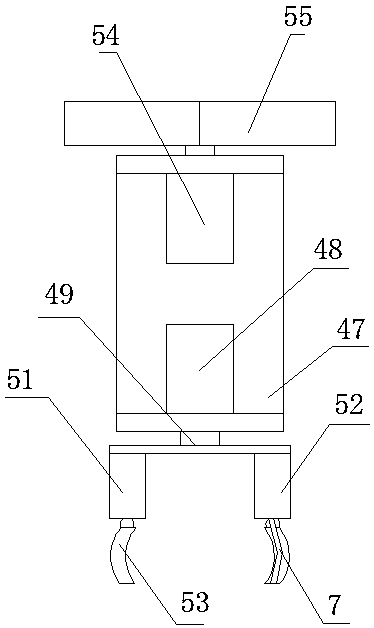

[0045] An automatic tree planting vehicle, which consists of: a car board 1, a control box 2 is arranged on the bottom surface of the car board 1, driving wheels I3 and driving wheels II4 are arranged on both sides of the car board 1, and the driving wheels Ⅰ3 and driving wheel Ⅱ4 are sleeved in the crawler belt 5,

[0046] The front end of the vehicle plate 1 is provided with a port I6 to be loaded into the mechanical arm I, and the front end of the mechanical arm I is connected to a drill bit 9, and an ultrasonic sensor 10 is arranged above the drill bit 9,

[0047] A group of fertilizer boxes 11 are set behind the port I6, and each of the fertilizer boxes 11 is provided with a pressing plate 12, and the upper end of each of the pressing plates 12 is connected to a long rod 13. The top of the long rod 13 is connected to the fixed frame 14, the fixed frame 14 is provided with a gear I15, the gear I15 is driven by the output shaft of the motor I16, the gear I15 meshes with the r...

Embodiment 2

[0054] Embodiment 1 is an automatic tree planting vehicle, the main control unit includes a chip U1, and the No. 1 end of the chip U1 is connected to the No. 24 end of the chip U1, the No. 36 end of the chip U1, the No. 48 end of the chip U1 and the No. 48 end of the chip U1. Connect the working voltage VCC-3.3 after the No. 9 terminal, the No. 23 terminal of the chip U1, the No. 35 terminal of the chip U1, and the No. 47 terminal of the chip U1 are connected to the No. 8 terminal of the chip U1 and grounded.

[0055] The No. 5 end of the chip U1 is connected to the No. 1 end of the interface XT_8M, the No. 6 end of the chip U1 is connected to the No. 3 end of the interface XT_8M, and the No. 2 end of the interface XT_8M is grounded.

[0056] Terminal 30 of the chip U1 is connected to terminal 3 of the chip U2, terminal 31 of the chip U1 is connected to terminal 2 of the chip U2, terminal 1 of the chip U2 is grounded, and the chip U2 The No. 4 end of the chip U2 is connected t...

Embodiment 3

[0081] In the automatic tree-planting vehicle described in Embodiment 1, the No. 4 end of the chip ar1 is connected to the No. 6 end of the chip ar1 and the No. 18 end of the chip ar1 and then connected to the operating voltage VCC-5.0, and the No. 20 end of the chip ar1 is connected in series with a capacitor C110 is then grounded, the No. 4 terminal of the chip ar1 is connected to the No. 5 terminal of the chip ar1 and the No. 21 terminal of the chip ar1 is grounded, and the No. 29 terminal of the chip ar1 is connected to one end of the resistor RR1 and one end of the switch SRST1, The other end of the resistor RR1 is connected to the working voltage VCC-5.0, the other end of the switch SRST1 is grounded, the working voltage VCC-5.0 is connected to the positive pole of the light emitting diode PLED, and the negative pole of the light emitting diode PLED is connected in series with the resistor After RP2 is grounded, the working voltage VCC-5.0 is connected to the anode of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com