Equipment for automatically sorting and loading spiced corned eggs in containers

An automatic sorting and marinated egg technology, which is applied in the directions of automatic packaging control, packaging, packaging protection, etc., to achieve the effects of improving production efficiency, high-efficiency automation, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

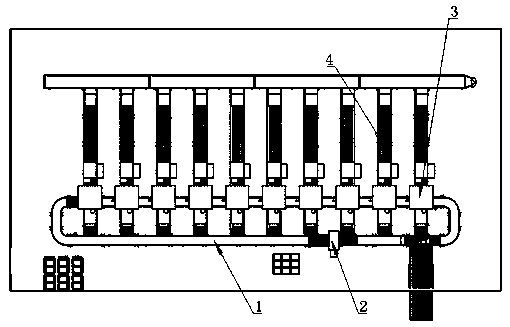

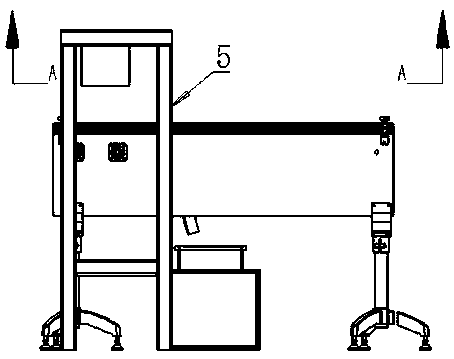

[0021] Such as Figure 1 to Figure 6 As shown, an automatic sorting and palletizing equipment for marinated eggs, which adopts automatic sorting and palletizing as a whole, can effectively solve the problem of manually completing the sorting and palletizing operations of marinated eggs in the prior art. The sorting speed is fast, the loading effect is better, the processing efficiency of the whole process is higher, it can replace the existing manual operation method, and the labor cost can be effectively saved in the whole process, and the quality of the product can be effectively improved, so that the overall Processing and production costs are also lower. It includes an annular conveying line 1, and an unqualified product detection and rejecting mechanism 2 is provided on one side of the annular conveying line 1 above the conveying line, which can be used to effectively sort out unqualified marinated egg products to ensure Overall product quality at the time of packaging. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com