Biscuit production equipment

A production equipment and biscuit technology, which is applied in dough forming and cutting equipment, food science, dough sheeting machine/rolling machine/rolling pin, etc. It can solve the problem of uneven pressing surface, automatic plate loading and insufficient biscuits Uniformity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

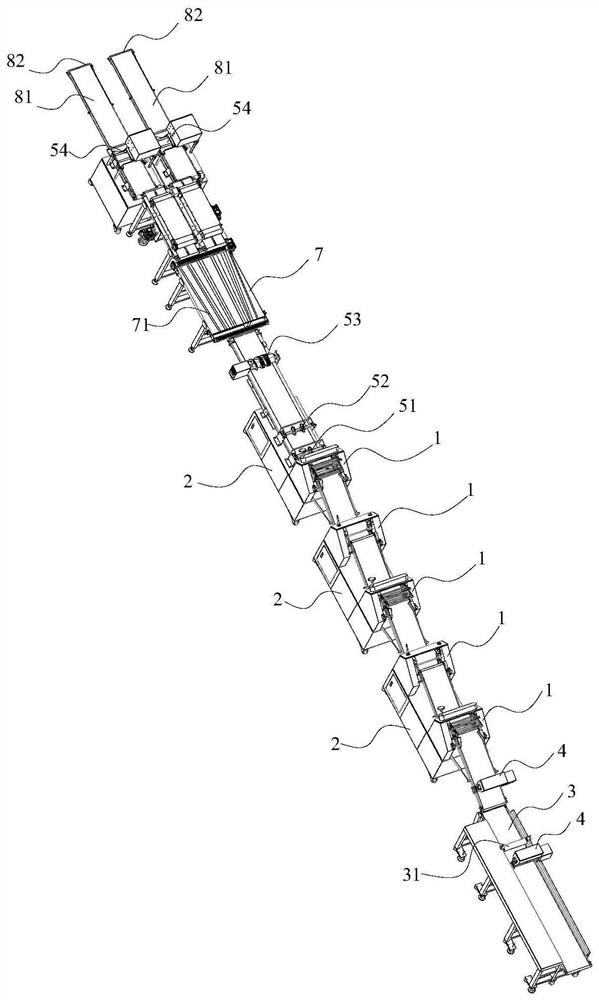

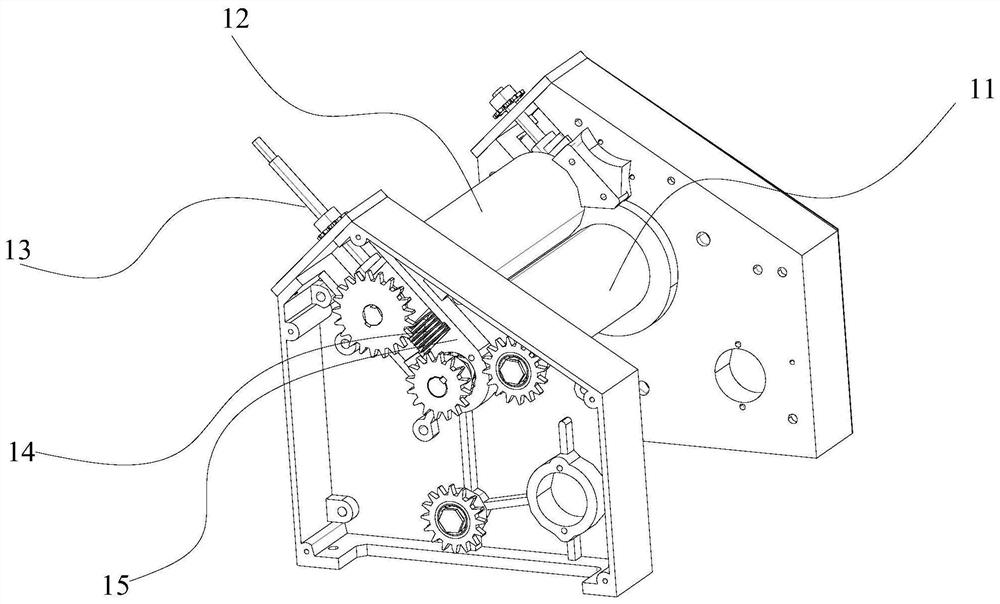

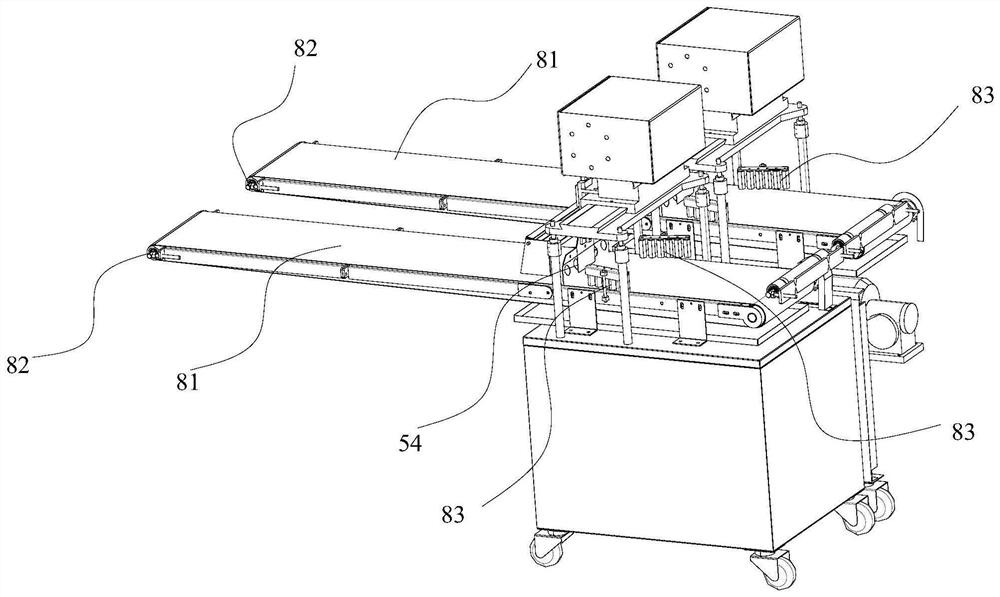

[0019] Biscuit production equipment provided by the invention, such as figure 1 As shown, five noodle-pressing devices 1 are provided, and every two noodle-pressing devices are arranged on a machine platform 2, and the feeding end of the first noodle-pressing device 1 is connected to the feeding device 3 by a conveyor belt, and the feeding device 3 and Flour spreaders 4 are all arranged on the first noodle pressing device 1 . The last noodle pressing device 1 is separately installed on a machine 2, and also includes a cutting device and two disc dividing devices; the unloading end of each noodle pressing device 1 is sequentially connected to the feeding end of the next noodle pressing device 1 through a conveyor belt , the blanking end of the last noodle pressing device 1 is connected to the first cutting group 51, and the second cutting group 52, the flour cleaning brush 53, the splitter device 7 and two third cutting groups arranged side by side are arranged in sequence behi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com