Mechanism capable of automatically feeding paper into paper box

A transmission mechanism and carton technology, applied in the field of transmission technology, can solve the problems of high labor intensity and easy leakage, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

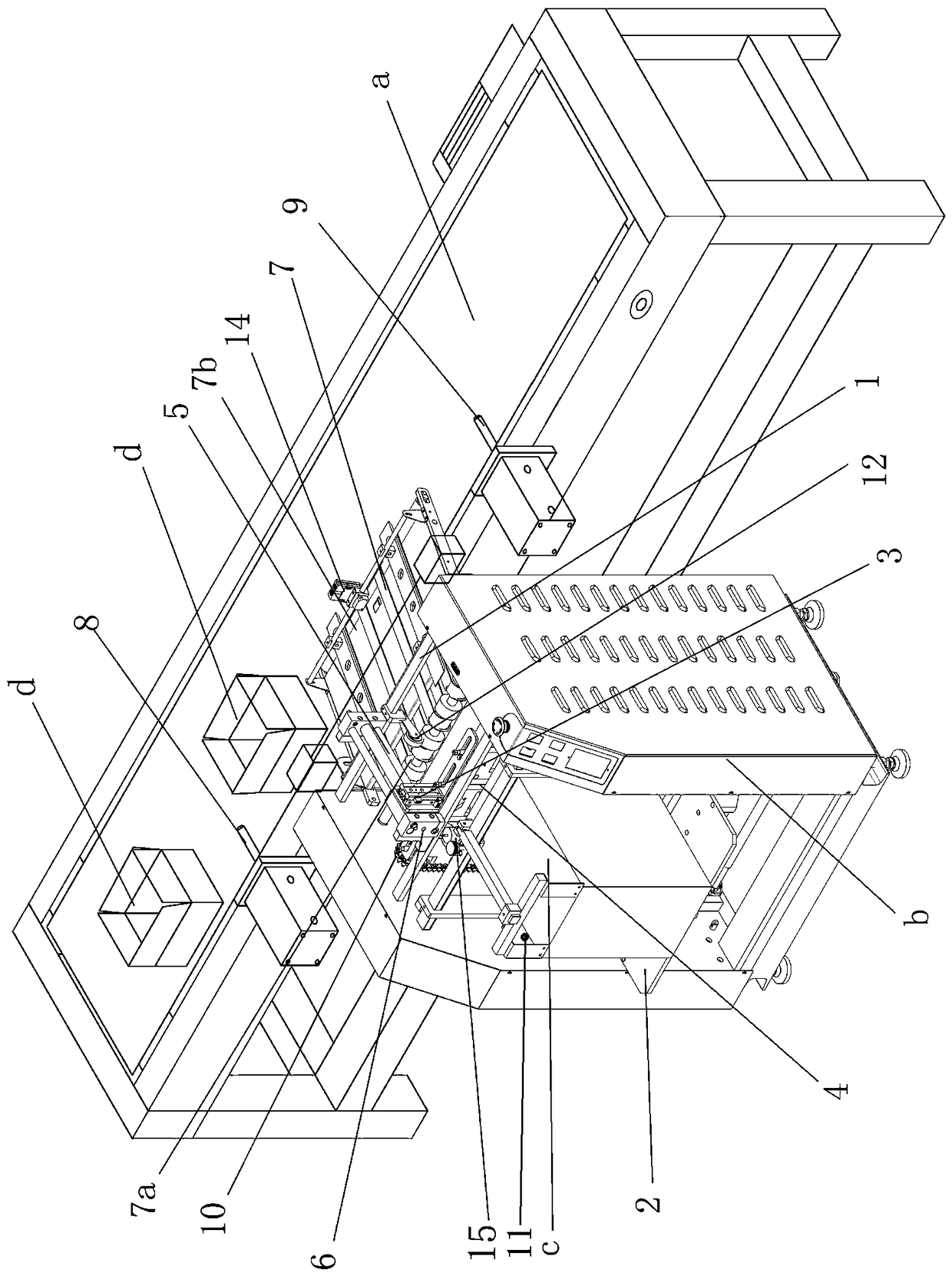

[0010] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

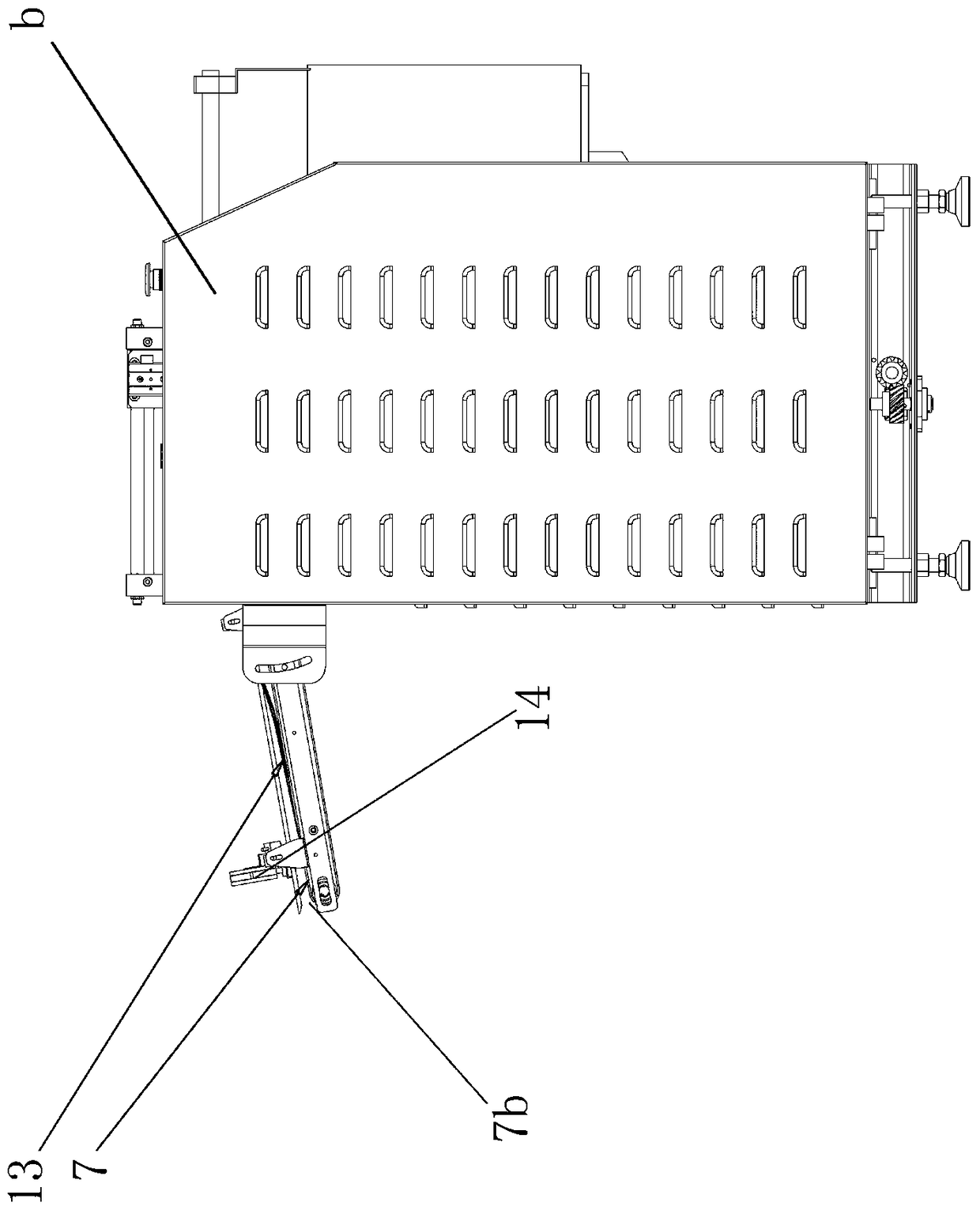

[0011] Such as figure 1 As shown, the present invention includes a carton conveying mechanism a, a cardboard conveying mechanism b arranged next to the carton conveying mechanism a, and the cardboard conveying mechanism b includes a frame 1, a cardboard storage bin 2 arranged outside the frame 1, and a cardboard storage bin 2 The upper suction cup driven by the up and down power moving mechanism (cylinder) 3, the front and rear power moving mechanism (cylinder) 6 set on the frame 1 that drives the up and down power moving mechanism 3 to move back and forth along the guide rail 5 on the frame 1, The power transmission belt or the power transmission roller group 7 arranged on the frame 1 are respectively provided with a front carton stop mechanism 8 and a rear carton stop mechanism 9 at the front and rear of the carton transmission mechanism a.

[0012] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com