All-in-one machine for imbricated transverse plate deviation-rectifying and welding all-in-one machine and process thereof

An all-in-one machine and deviation correcting machine technology, which is applied to other manufacturing equipment/tools, manufacturing tools, semiconductor devices, etc., can solve problems such as easy jamming, complicated procedures, and long cavity of the suction cup, and meet the requirements of large-scale processing, The process is simple and clear, and the effect of avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

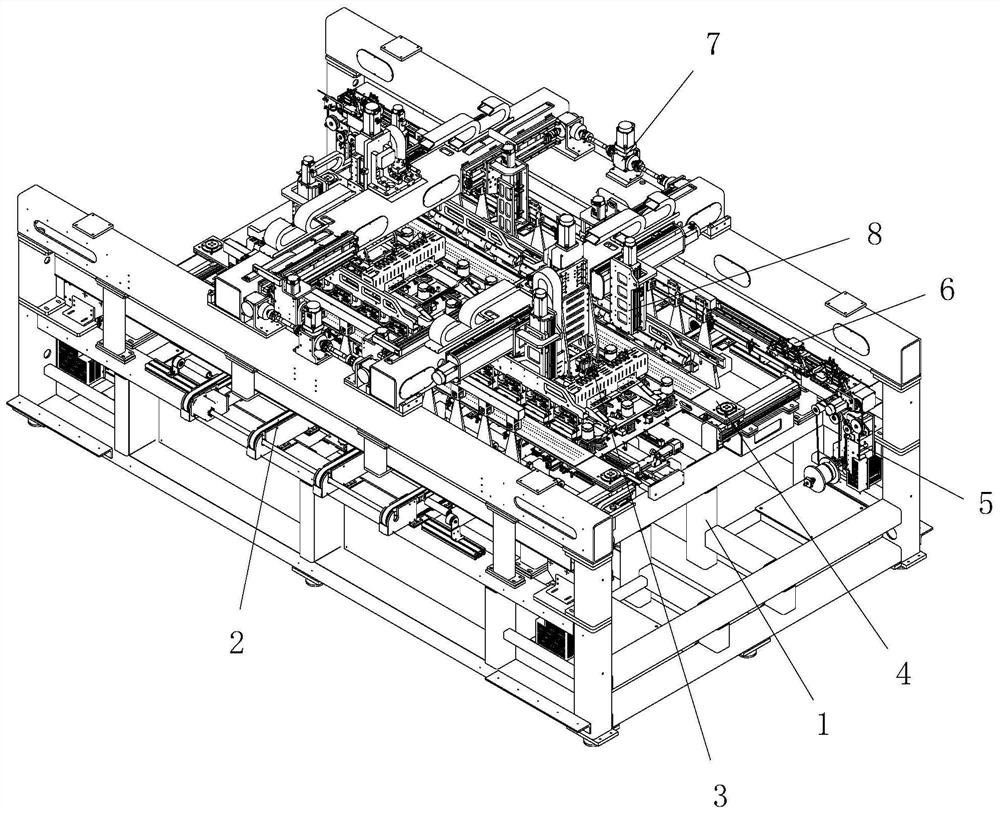

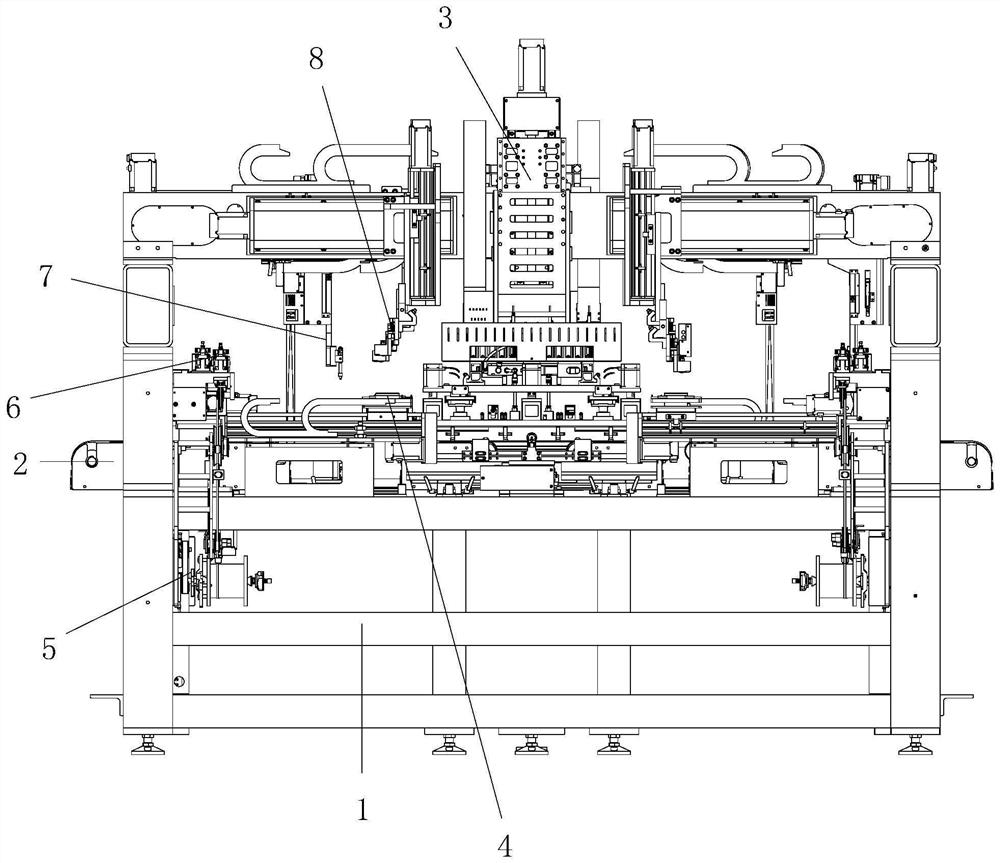

[0034] see Figure 1 to Figure 8 , the embodiment of the present invention includes:

[0035] An integrated machine for rectifying and welding shingled horizontal plates and its technology, including an integrated machine for correcting and welding shingled horizontal plates. , adsorption welding station 4, bus bar feeding device 5, bus bar cutting device 6, bus bar adsorption module 7 and welding manipulator 8, conveying regularizing device 2 is installed on the frame 1, conveying regularizing device 2 The upper docking is equipped with a cell deviation correcting machine 3, the two sides of the conveying regularization device 2 are equipped with adsor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com