Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Meet handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

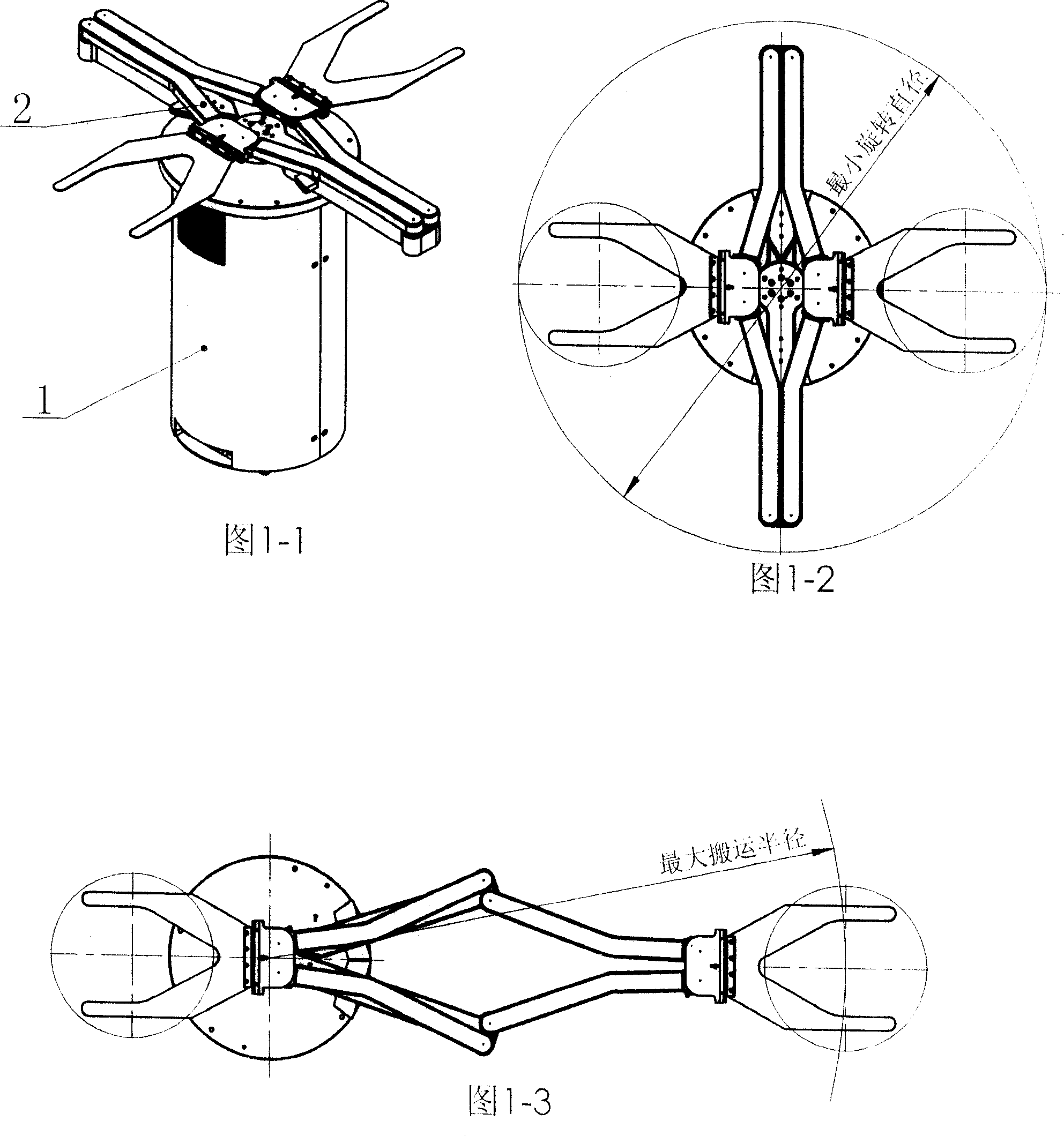

Plane multiple joint robot

The invention relates to a planar multi-joint robot, belonging to a mechanical body of industrial robot, which is suitable for handling objects in an environment with high vacuum degree and cleanliness. The invention comprises an upright column component and an arm component; wherein, the upright column component comprises a lifting driving device, an inner shaft rotary drive unit and outer shaft rotary drive unit, a straight-line guidance, a linear seal, a rotary sealing device and an outer housing; the arm component comprises a link mechanism, an end actuator and an installation adjusting mechanism, and is arranged at one end of the upright column component. The invention has the advantages of light weight, good dynamic controlling performance, and high repetitive positioning accuracy.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

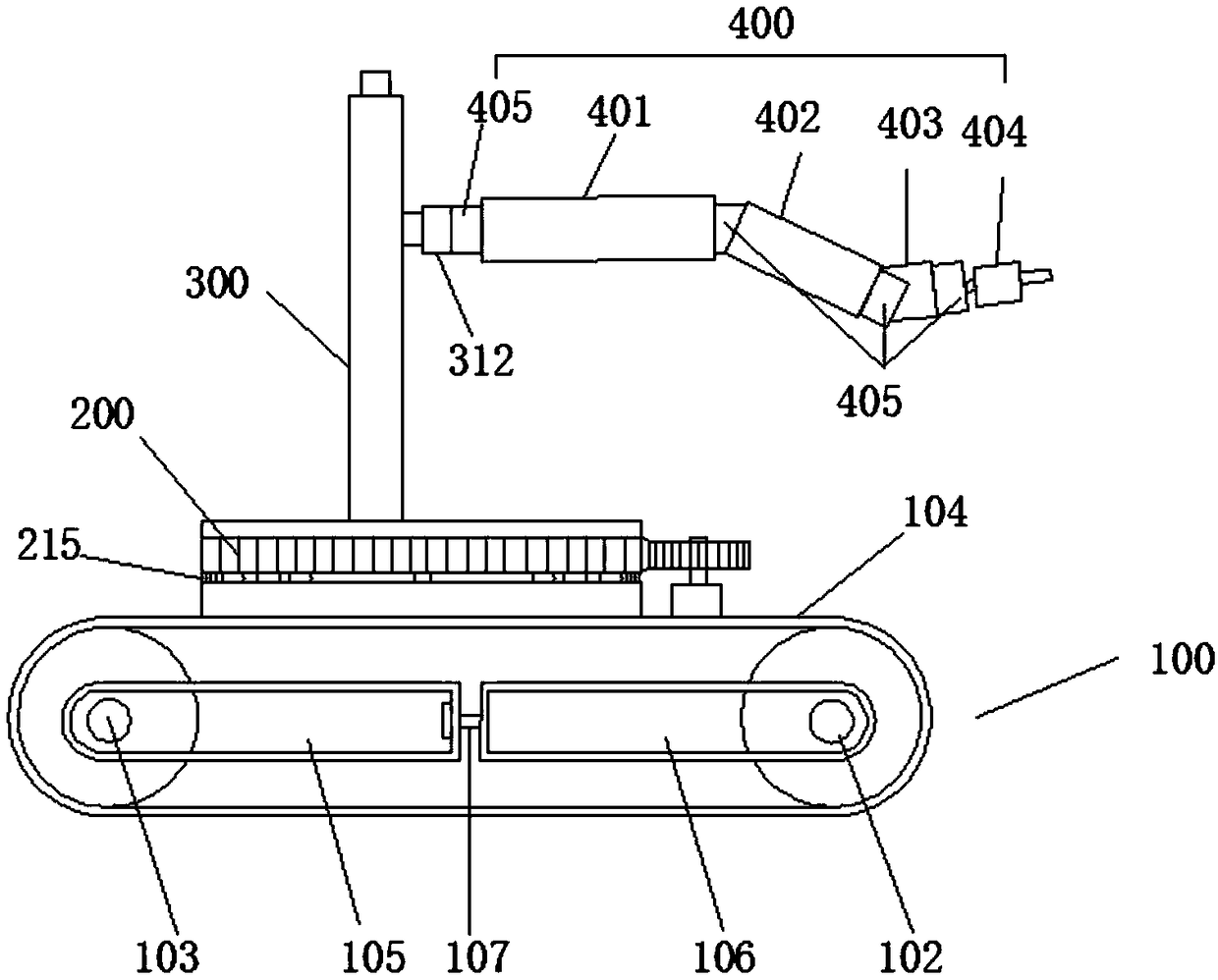

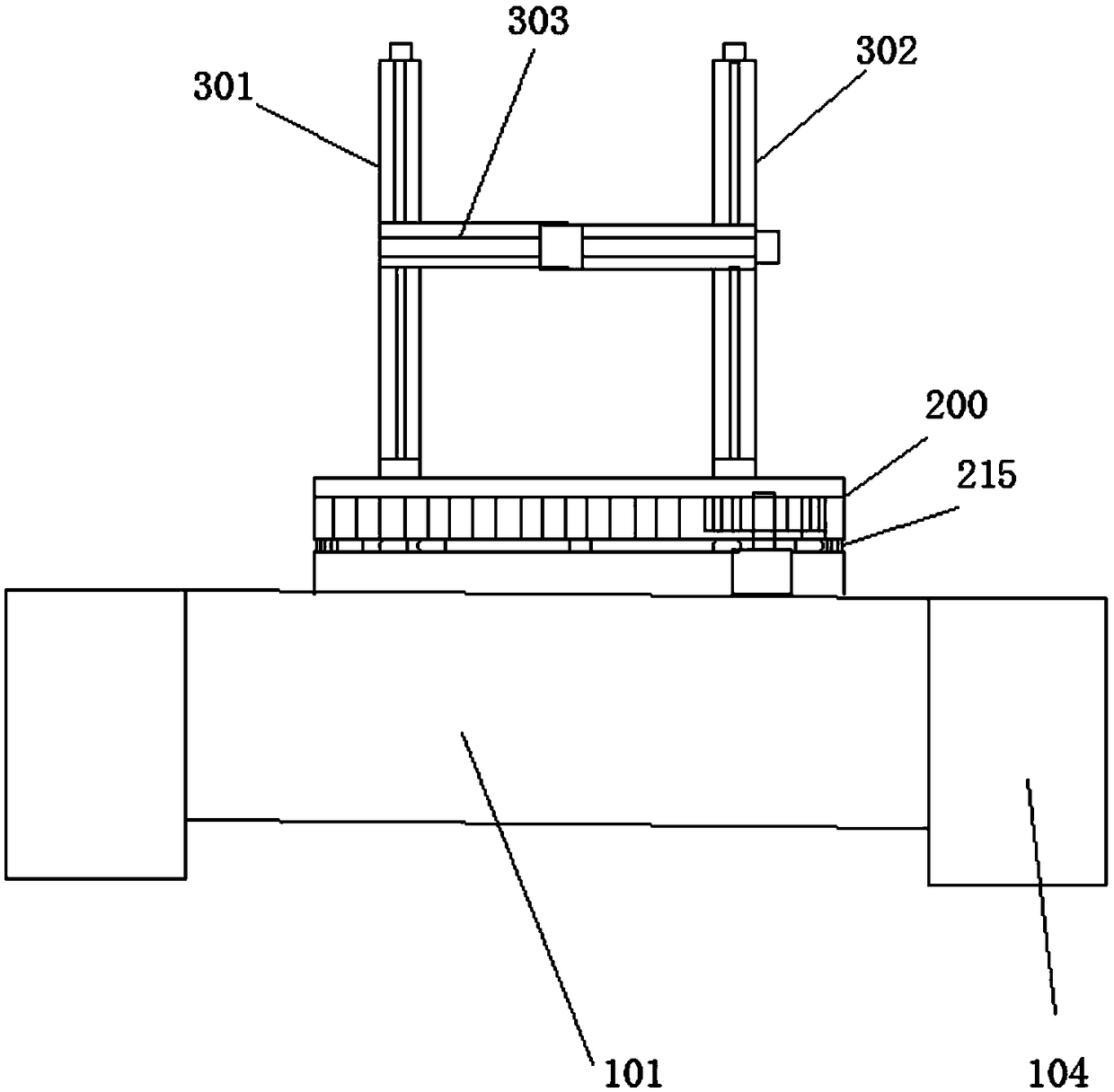

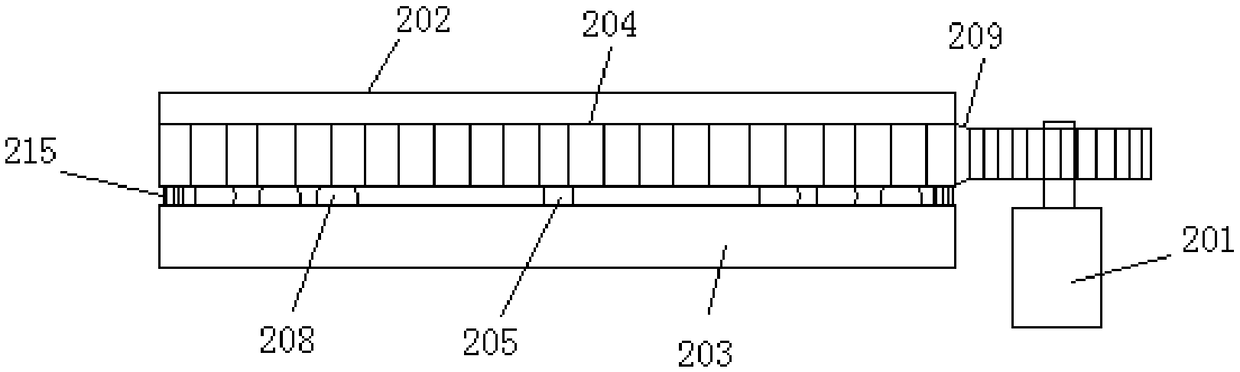

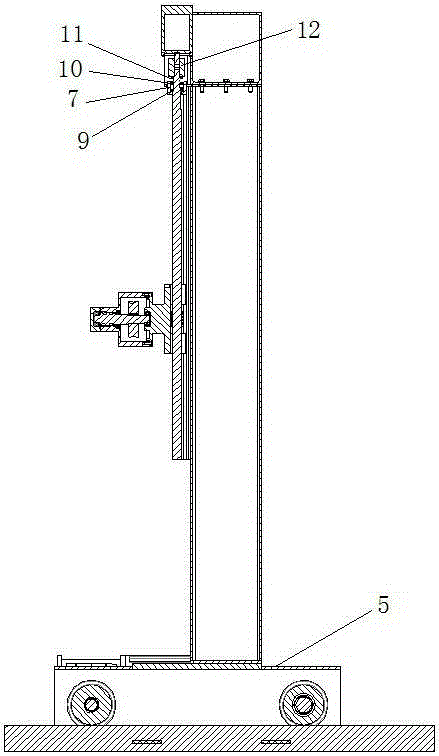

Industrial robot

InactiveCN109015594AImprove weight capacityFully supportedProgramme-controlled manipulatorArmsRobotic armEngineering

The invention provides an industrial robot and belongs to the field of robots. The industrial robot comprises a moving device, a rotating supporting device, a lifting device and a mechanical arm. Therotating supporting device is arranged on the moving device, the lifting device is arranged on the rotating supporting device, and the mechanical arm is connected with the lifting device. The rotatingsupporting device comprises a rotating driving mechanism, a rotating transmission mechanism and a supporting platform. The lifting device comprises a first lifting device body, a second lifting device body and a horizontal moving device. The mechanical arm utilizes a mechanical large arm body, a mechanical small arm body, a wrist joint and a mechanical claw to realize multiple degrees of freedomof movement and realize arranging and carrying of cargos, the cargo arranging efficiency is improved, and a lot of manpower and material resources are saved.

Owner:李友朋 +1

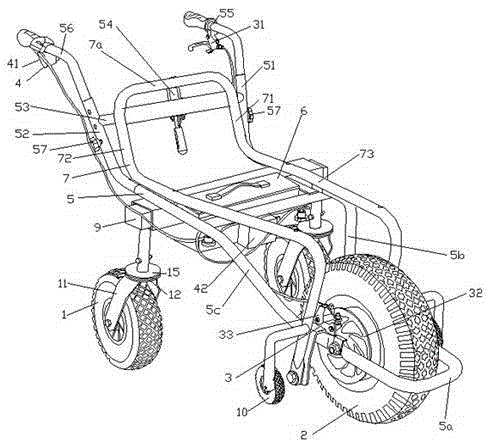

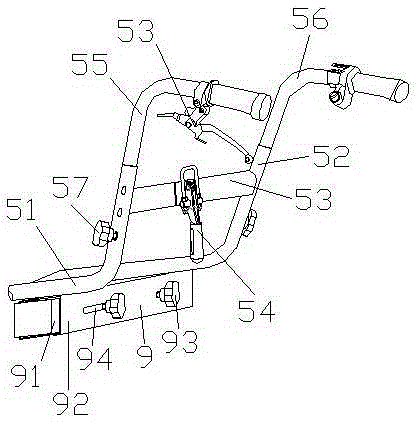

Electric carrying trolley

InactiveCN105346573AEasy to carryEasy to pourHand carts with multiple axesHand cart accessoriesRoad surfaceEngineering

The invention provides an electric carrying trolley. The electric carrying trolley comprises a trolley frame body (5), two rear driven wheels (1) and a front drive wheel (2). The rear end of the trolley frame body (5) is provided with a left armrest (51) and a right armrest (52). The front drive wheel (2) is provided with a brake device (3) and a speed control device (4). The two rear driven wheels (1) are arranged on the rear portion of the trolley frame body (5). A storage battery support (45) is arranged in the trolley frame body (5). A master control circuit (42) is fixed to the storage battery support (45). The electric carrying trolley is characterized in that the distance between the two rear driven wheels (1) can be adjusted within the range from 250 mm to 650 mm. The electric carrying trolley can be adaptive to complex road surfaces and sites and is driven through electric power, time and labor are saved, environment friendliness is achieved, and an operator can carry more objects conveniently by means of the electric carrying trolley.

Owner:HUZHOU DAIXI ZHENHUA IND & TRADE

Sintered brick and preparation method thereof

ActiveCN104150861ASatisfy the production operationMeet handlingSolid waste managementBrickMaterials science

The invention discloses a sintered brick prepared by taking tailings as main raw materials and a preparation method of the sintered brick. According to the method, coal slime and coal gangue are doped into fine grained tailings according to a certain ratio to serve as raw materials, so that the content of SiO2 in the mixture is between 50 and 70 percent, the content of Al2O3 is between 6 and 20 percent, the content of CaO is lower than 6 percent, the content of MgO is lower than 6 percent, and the heating value is controlled to be 1.465-1.780MJ / Kg, and therefore, the mixture is reasonable in grading, and the requirements on plasticity and heating value needed by the sintered brick are met. The sintered brick and the preparation method thereof provided by the invention have the effects that the defects of the tailings, the coal slime and coal gangue respectively serving as raw materials of the sintered brick are overcome due to the mixture, the mineral composition and physical characteristics of the raw materials are optimized, comprehensive utilization of the fine grained tailings is realized, and the cost of the sintered brick is reduced.

Owner:NANJING IRON & STEEL CO LTD

Scaffold steel pipe carrying device

ActiveCN105329291AEasy to moveImprove work efficiencyHand carts with multiple axesFalseworkEngineering

The invention discloses a scaffold steel pipe carrying device. The structure of the device comprises a base, a moveable support, and a fixed support. The fixed support is fixedly connected with the base. The moveable support is slidably connected with the base. The base is provided with a sliding chute. The bottom of the moveable support is connected with a rack. The rack is arranged in the sliding chute. The lower part of the sliding chute is provided with a groove. The groove is internally provided with a gear and a motor. The rack and the gear are connected in a cooperated manner. The gear is connected with the motor. The motor is connected with a controller. The carrying device provides convenience for centralized storage and carrying of steel pipes. Width of the support can be adjusted at will according to differences of the steel pipes, so that the device is suitable for carrying steel pipes in different diameters and lengths. The device saves time and efforts, greatly reduces labor intensity, and improves carrying efficiency.

Owner:STATE GRID SHANDONG JIYANG POWER SUPPLY +1

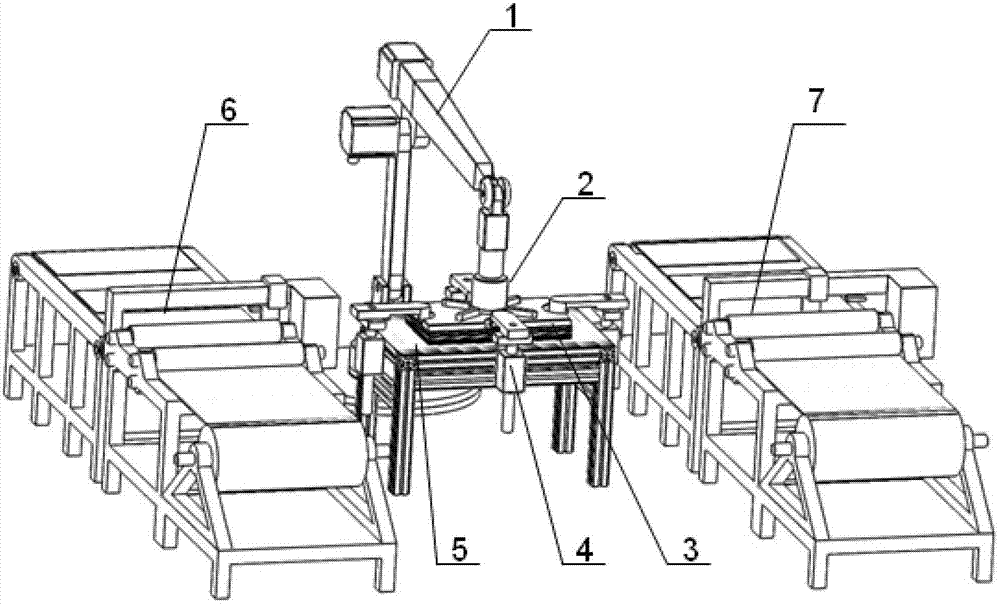

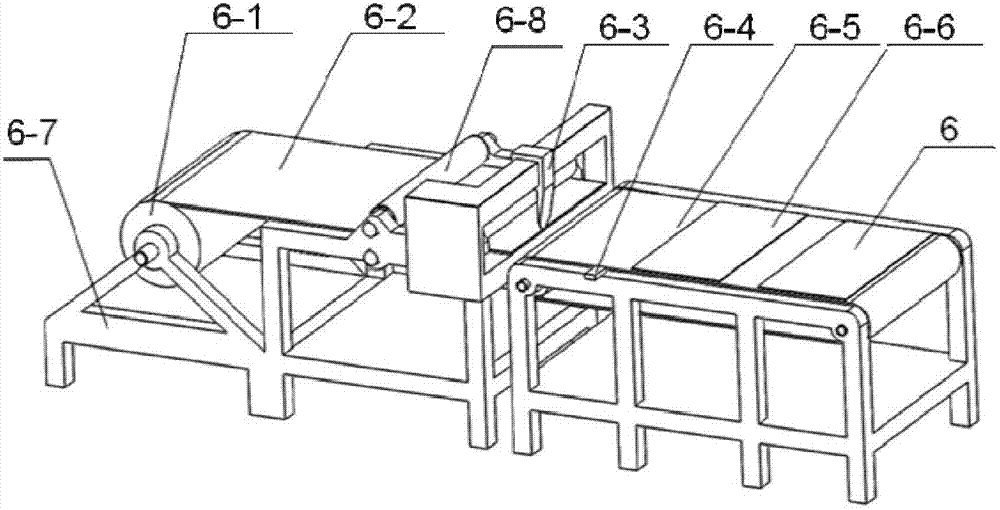

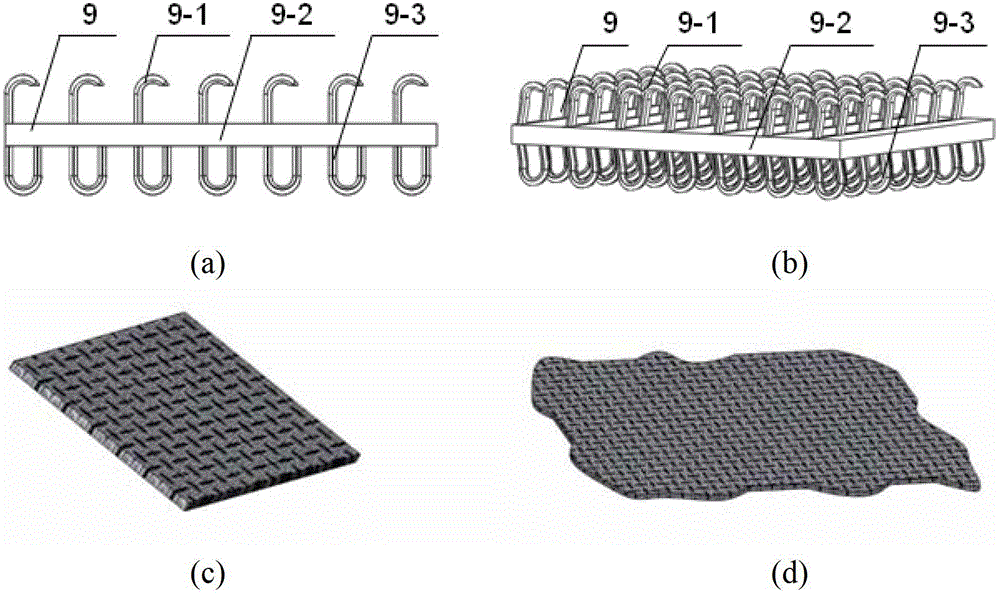

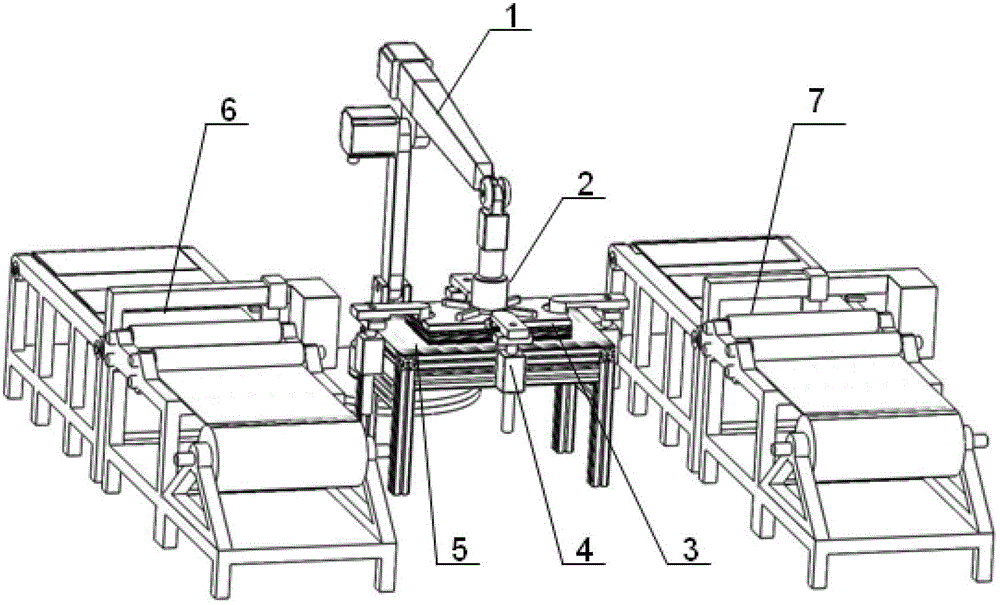

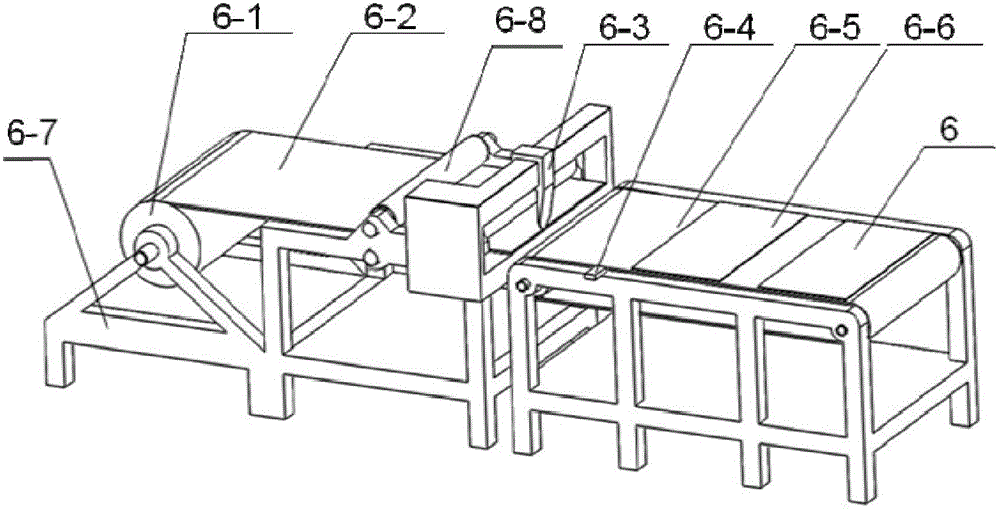

Industrial robot automatic laminating system for fiber sheets

ActiveCN102756921AAutomatic cascading implementationImprove efficiencyStacking articlesDe-stacking articlesFiberEngineering

The invention discloses an industrial robot automatic laminating system for fiber sheets. The system comprises a fiber sheet conveying workbench, a laminating workbench and a mechanical arm, wherein the end part of the mechanical arm is provided with a pick-and-place actuator which is used for picking fiber sheets on the fiber sheet conveying platform and laminating the fiber sheets on the laminating workbench, so that the fiber sheets with different types, different sizes and different shapes can be automatically laminated. The system is suitable for flexible objects, has the advantages of low cost, high laminating efficiency and high flexibility, and can fulfill the requirement of large-scale production. In an optimal technical scheme, a fiber sheet connector can be effectively engaged with a connection element on a fiber sheet, and the flexible objects can be laminated smoothly under the cooperation of an adjustable clamp and the pick-and-place actuator. The system has a simple structure and easy implementation, greatly improves the working efficiency of lamination, and can laminate fiber sheets quickly and effectively in batches, and has excellent application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

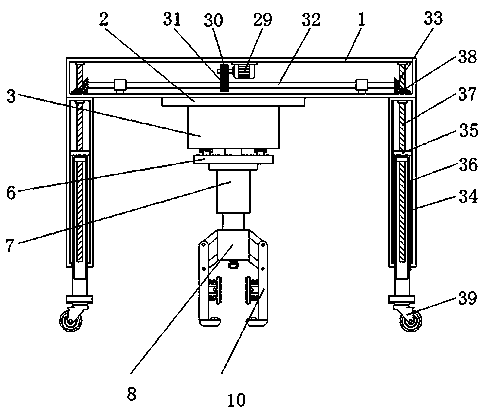

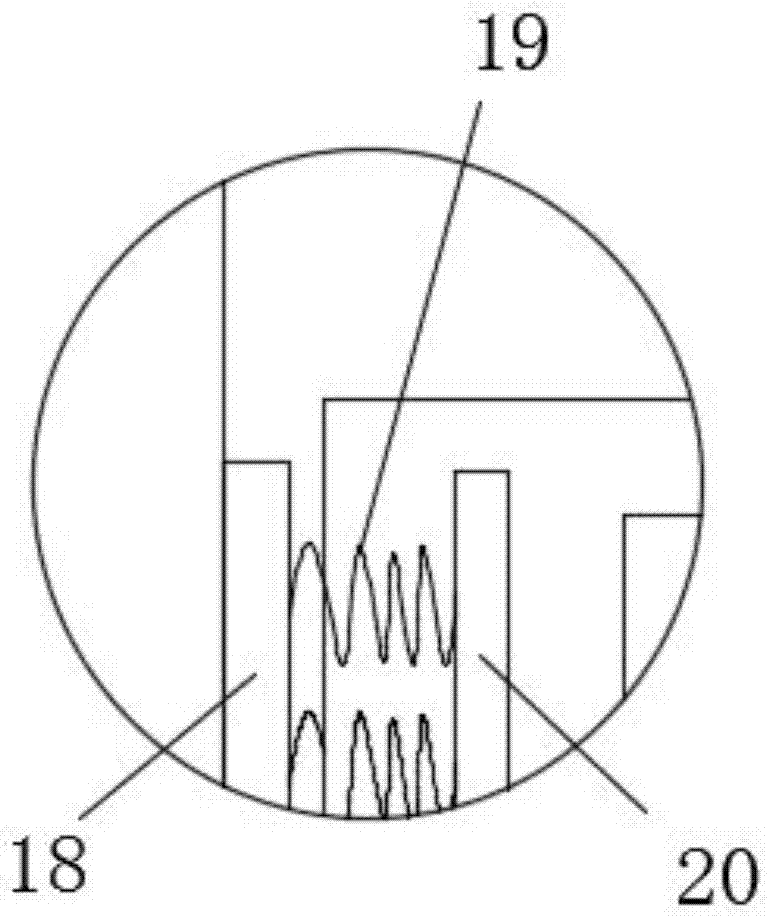

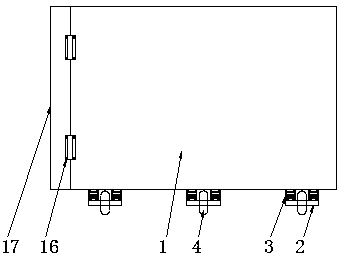

Full-automatic vehicle washing equipment

InactiveCN105212515AMeet handlingMeet sprayingBrush bodiesCleaning apparatus for vehicle exteriorsElectricityEngineering

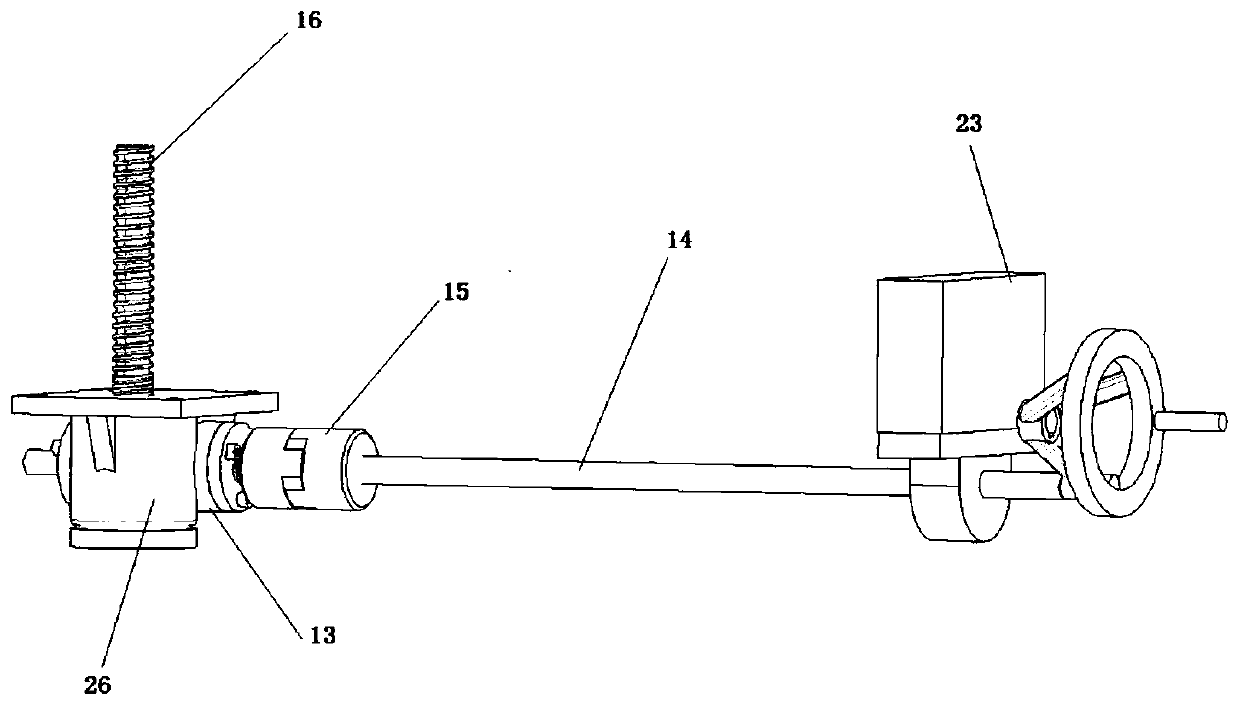

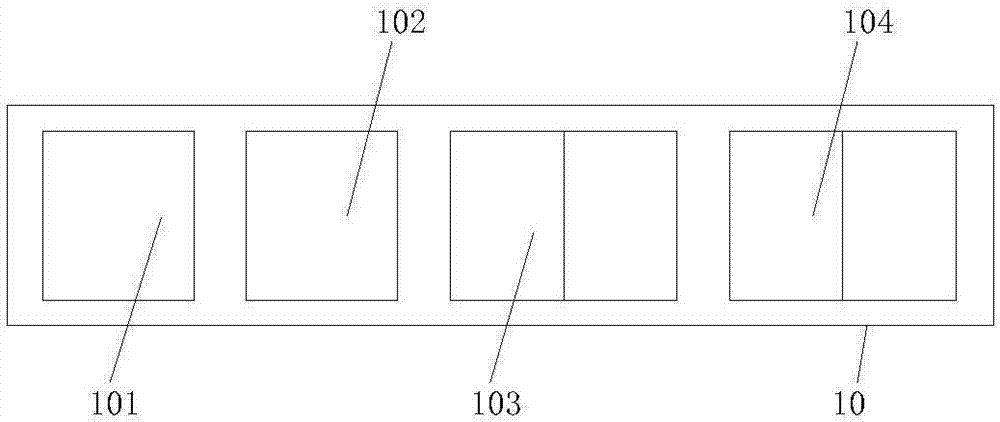

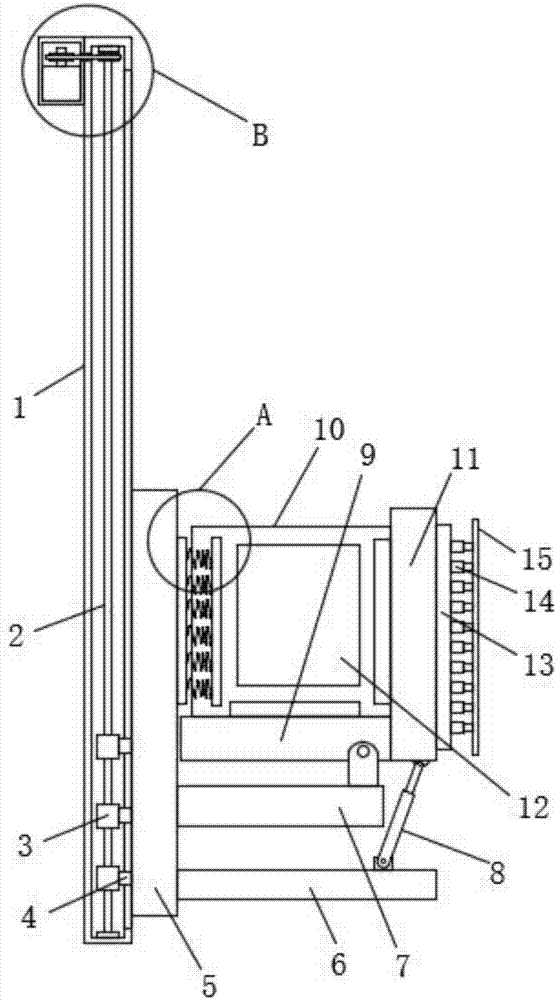

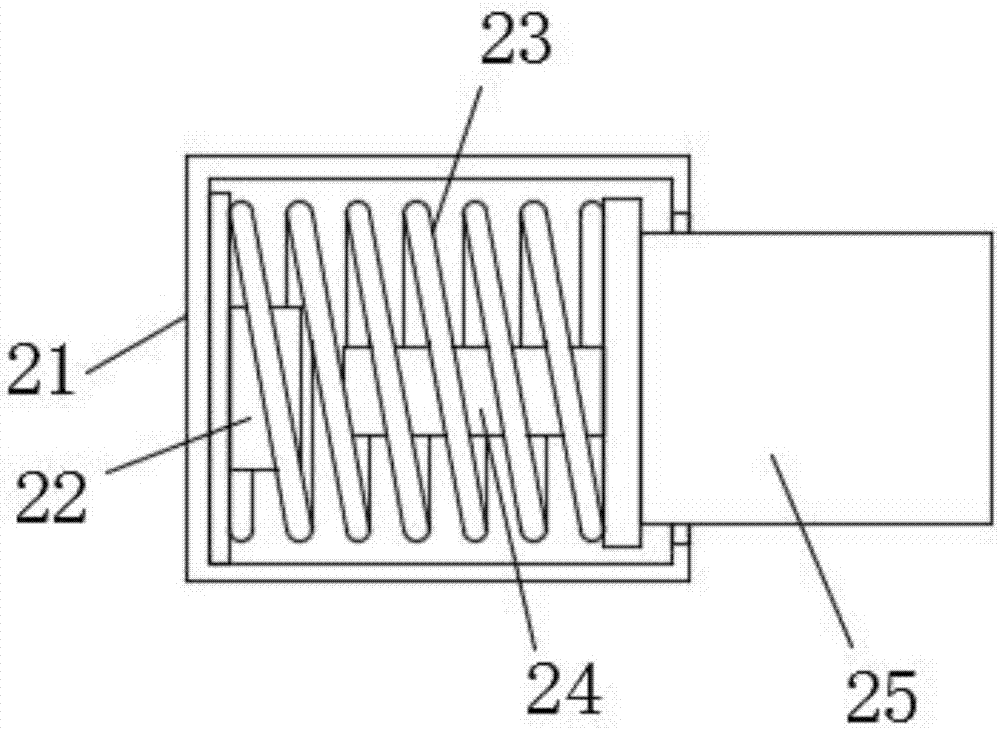

The invention discloses full-automatic vehicle washing equipment. Two T-shaped guide rails (3) are parallel. Stand columns (1) are installed on the T-shaped guide rails (3). A cross beam (2) is installed at the top ends of the stand columns (1). A lead screw stepping motor (8) is fixedly installed on the cross beam (2). Ball lead screws (6) are installed in the stand columns (1). The top ends of the ball lead screws (6) are connected with the lead screw stepping motor (8). A crane gearbox (4) is connected to a base (5). Cylindrical guide rails (18) are installed in the stand columns (1). One ends of large arms (14) are installed on the cylindrical guide rails (18), and the other ends of the large arms (14) are connected with one ends of small arms (15). The other ends of the small arms (15) are connected with rotating heads (16). Brush heads (17) are installed on the rotating heads (16). The equipment is small in occupied site, capable of being placed in a shop front room in a general city, and high in efficiency, operates fully automatically, and saves water and electricity.

Owner:HUAIAN RONGSHENG MACHINERY MFG CO LTD

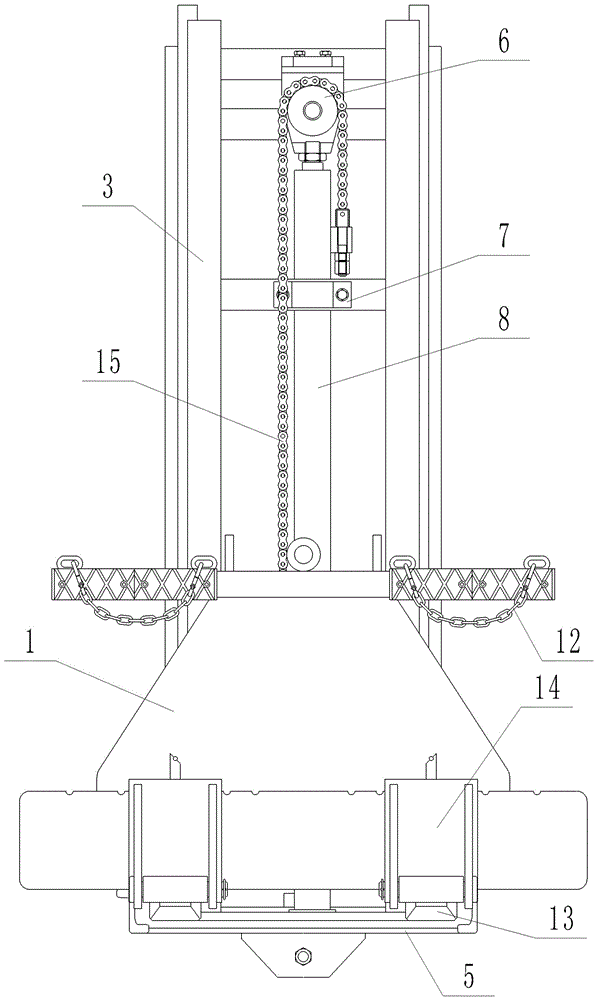

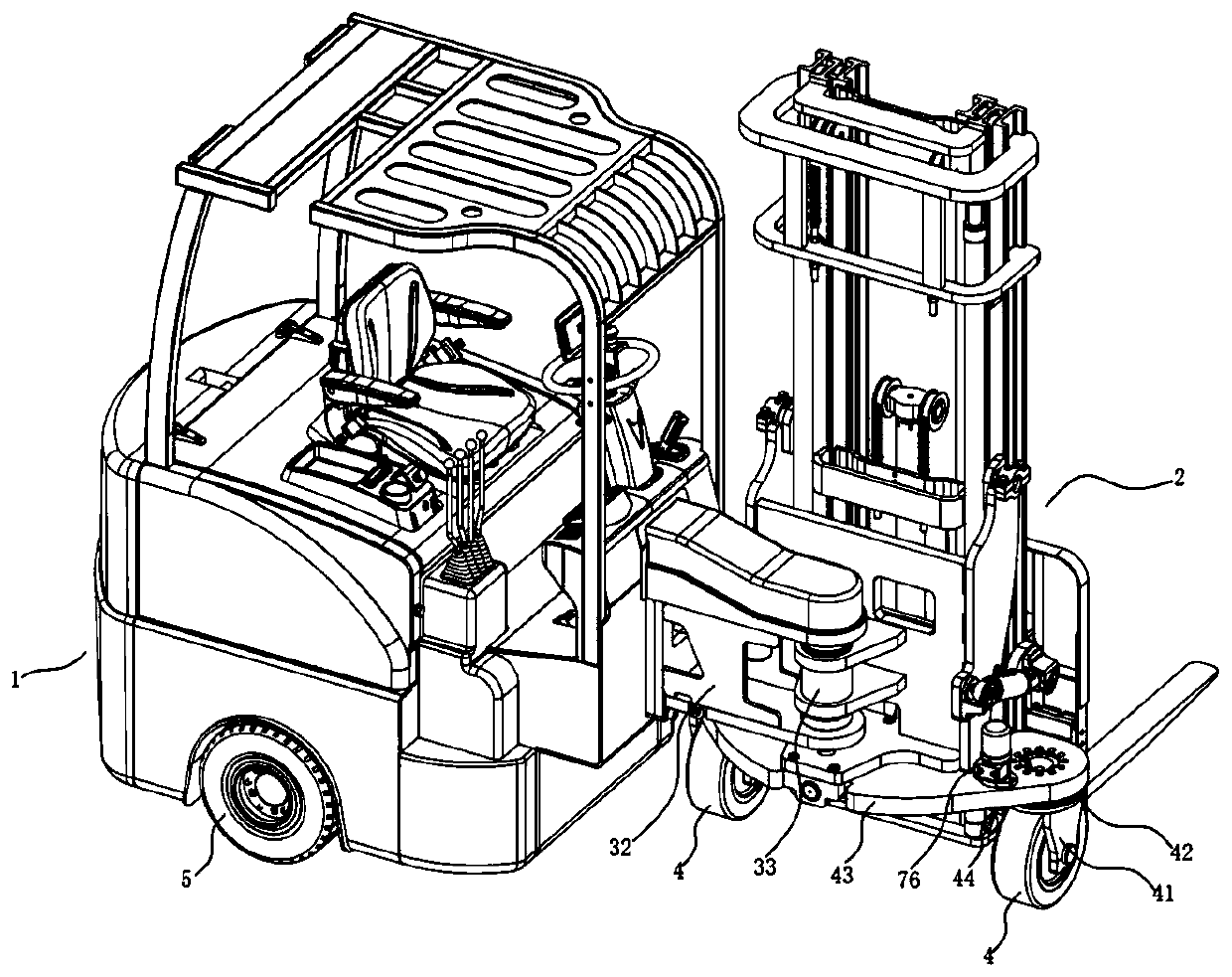

Front fork and portal double-folding device capable of moving forwards and backwards

ActiveCN105858546ALighten the counterweightReduce power usageLifting devicesVehicle framePallet fork

The invention discloses a front fork and portal double-folding device capable of moving forwards and backwards. The front fork and portal double-folding device capable of moving forwards and backwards is characterized in that the device comprises a pallet fork, an inner portal, an outer portal and a guide rail forklift frame; the pallet fork comprises a front fork and a pallet fork carrier; the front fork is rotatably connected with the pallet fork carrier; the inner portal and the outer portal are slidably connected in a matched mode, the inner portal and the outer portal are vertically arranged, and the inner portal and the outer portal can rotate around the lower portion of the outer portal; the guide rail forklift frame is horizontally arranged, and the outer portal and the guide rail forklift frame are slidably connected in a matched mode; and the pallet fork carrier is arranged on the inner portal, and the pallet fork carrier is slidably connected with the inner portal in a matched mode through a lifting assembly. According to a forklift provided with the device, forklift transportation is slightly limited, the weight of the whole forklift is low, and the using cost and transportation cost are low.

Owner:GUILIN FUHUA METAL

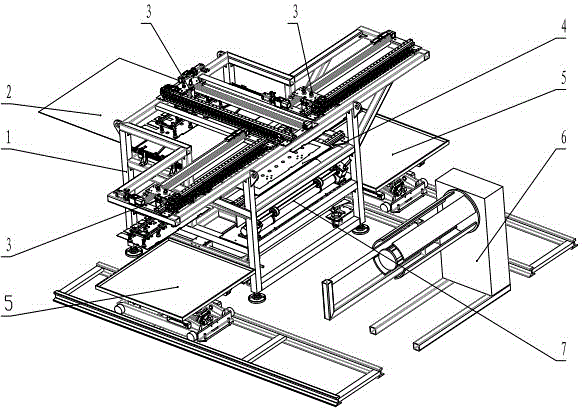

Automatic discharging system used for stamping production line

ActiveCN104815916ARealize automatic blankingEasy to adjustMetal-working feeding devicesPositioning devicesProduction linePunch press

The invention relates to the field of punching machine automation, and particularly relates to an automatic discharging system used for a stamping production line. The automatic discharging system comprises a framework, transportation and adsorption systems, a work-piece transfer system, stacking systems, a waste material traction system and a waste material collection system; the framework is provided with at least three transportation and adsorption systems, the work-piece transfer system and the waste material traction system; a stacking system is respectively arranged below the transportation and adsorption systems which are located at the left side and the right side of the framework. The systems are combined according to the way in the invention, automatic discharging of the stamping production line, including, separation of the work-piece and the waste material, work-piece stacking, waste material collection and the like, can be realized conveniently and rapidly. In the application, only one framework system is needed for separation and transportation of the work-piece waste material, and two-side stacking of the work-pieces can be realized.

Owner:中国东方电气集团有限公司

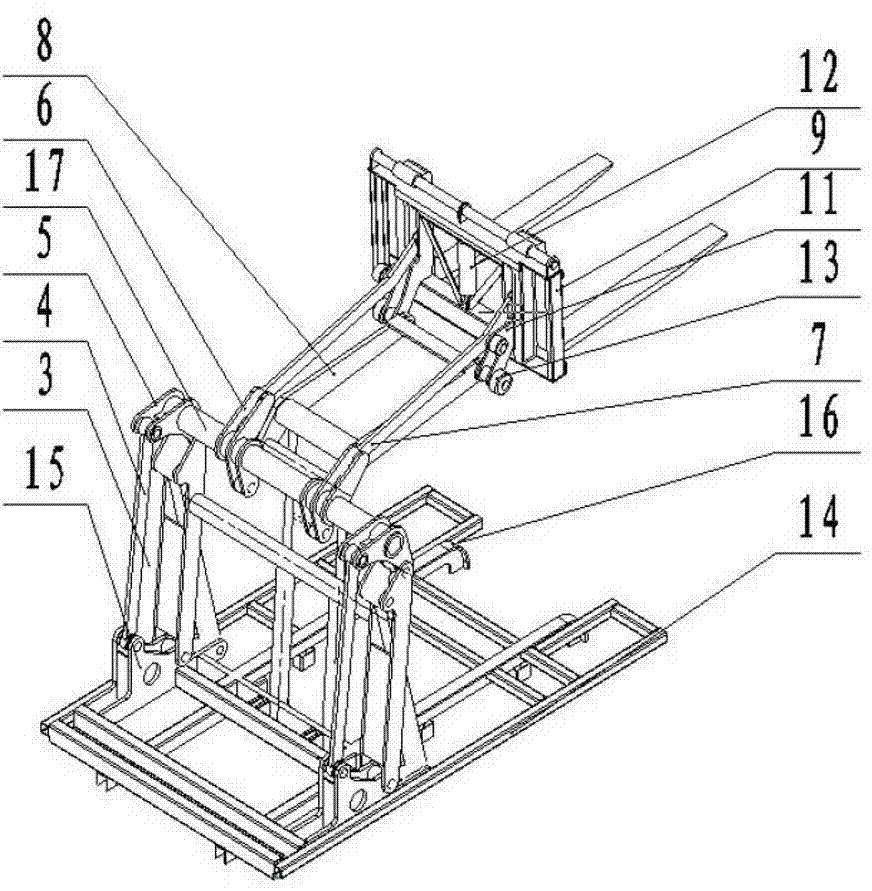

Self-loading operation mechanism of loading machine

The invention relates to a self-loading operation mechanism of a loading machine. The structure of the operation mechanism comprises a fork mechanism which is used for bearing, loading and unloading cargoes, an upper parallel four-rod mechanism which is connected to the fork mechanism through a shaft and is used for controlling the fork mechanism to stretch and lift, a lower parallel four-rod mechanism which is connected to the upper parallel four-rod mechanism through a shaft and is used for controlling the whole operation mechanism to rise and fall and a frame which is hinged with the lower parallel four-rod mechanism and serves as a bearing body of the operation mechanism. Rollers are arranged on the fork mechanism, and sliding rails which are used for bearing the rollers are fixed on the frame. The operation mechanism is flexible in action, convenient to operate, stable in operation, wide in operation application range, suitable to various harsh working terrains and capable of implementing moving operation in a narrow working field and improving the stability of loading operation and convenience of operation.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

Part carrying device for automobile production

Owner:WUHU RUITAI PRECISION MACHINERY

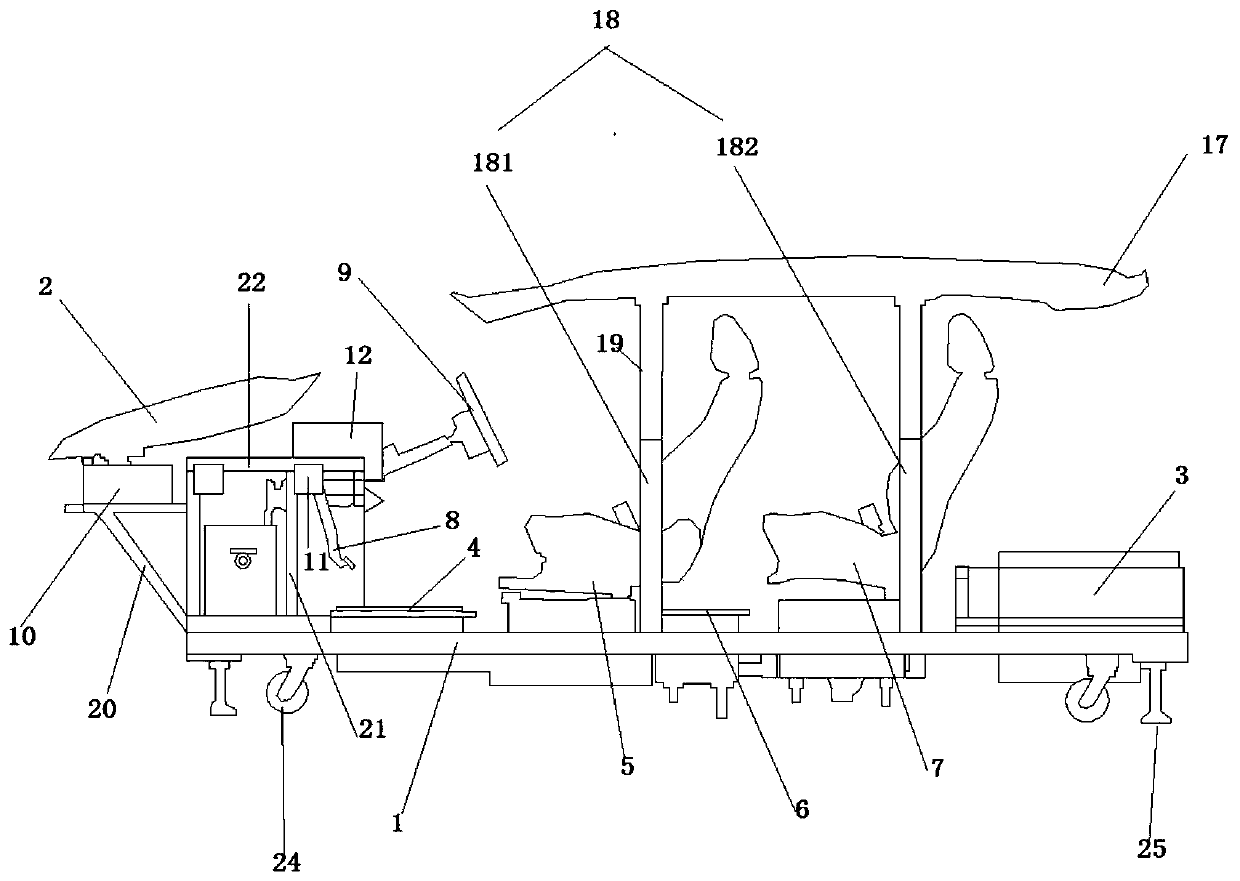

Novel man-machine comfort verification mechanism

InactiveCN110779729AThe test result is accurateTested by real people is true and reliableVehicle testingAutomobile designMan machine

The invention discloses a novel man-machine comfort verification mechanism for the early stage of the automobile design. The invention aims to provide a novel man-machine comfort verification mechanism which is used for improving accuracy of measured data and is low in manufacturing cost. The novel man-machine comfort verification mechanism comprises a bottom plate, an engine hood arranged at thefront end of the bottom plate and a luggage compartment arranged at the rear end of the bottom plate; a front-row floor regulator, a front-row seat regulator, a rear-row floor regulator and a rear-rowseat regulator are sequentially arranged between the engine hood and the luggage compartment and the structures all comprise mounting holes adaptive to the bottom plate; and a front-row floor, a front-row seat, a rear-row floor and a rear-row seat can respectively horizontally move on the front-row floor regulator, the front-row seat regulator, the rear-row floor regulator and the rear-row seat regulator. Compared to an existing man-human comfort verification technology, a model vehicle which is designed and transformed by the novel man-machine comfort verification mechanism and is manufactured according to a true ratio of a prototype vehicle has the advantages of low cost, measurement accuracy and the like.

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

Portable electronic water level thermometer

InactiveCN107966177AMeet the needs of free retractableMeet handlingMeasurement devicesEngineeringSolar power

The invention discloses a portable electronic water level thermometer. The portable electronic water level thermometer comprises a support seat, wherein a first groove is arranged around a bottom portion of the support seat, an electric telescopic rod is fixedly connected with a top end of an inner cavity of the first groove, a roller is movably mounted at a bottom portion of the electric telescopic rod, a third groove is arranged at a middle end of an upper surface of the support seat, and a left end of a top portion of the third groove is movably connected with a cover plate through a hinge.According to the portable electronic water level thermometer, a cable is wound around an outer surface of a wire reel, a probe is fixedly connected with a tail end of the cable, people's need for free pick-up and release of the probe can be satisfied, a solar panel is embedded on an upper surface of a mounting plate, solar power generation capability is realized, most basic requirements for fielddetection is guaranteed, handles are fixedly connected with upper ends of two sides of outer surfaces of a support plate, carrying demands of people for device can be satisfied, and great convenienceis provided for field detection of people.

Owner:惠州伊尚生活科技有限公司

Anti-collision carrying device of robot

InactiveCN107879280AAvoid damageEasy to unloadSafety devices for lifting equipmentsLifting framesEngineeringSlide plate

The invention discloses an anti-collision handling device for a robot, which comprises a mounting cylinder vertically arranged on the side of the robot, a vertical threaded rod is movably installed on the inner wall of the mounting cylinder, and the lower part of the threaded rod is equidistantly threaded and socketed. There are three threaded sleeves, one side of the threaded sleeve is fixed with a sliding block, the side of the sliding plate is fixed with an overturning plate, the top of the overturning plate is hinged on the side away from the sliding plate with a bottom plate, and both sides of the bottom plate are fixed with a first side plate , the side of the two first side plates away from the sliding plate is fixed with a second side plate, and the lower end of the second side plate is fixed on the top side of the bottom plate, and the other end of the push rod motor is hinged on the bottom of the second side plate, The side of the second side plate away from the sliding plate is fixed with a mounting plate, the side of the mounting plate away from the second side plate is uniformly fixed with an anti-collision device, and the end of the anti-collision device away from the mounting plate is fixed with an anti-collision plate. The invention has unique structure, ingenious design, high creativity and is suitable for popularization.

Owner:王静静

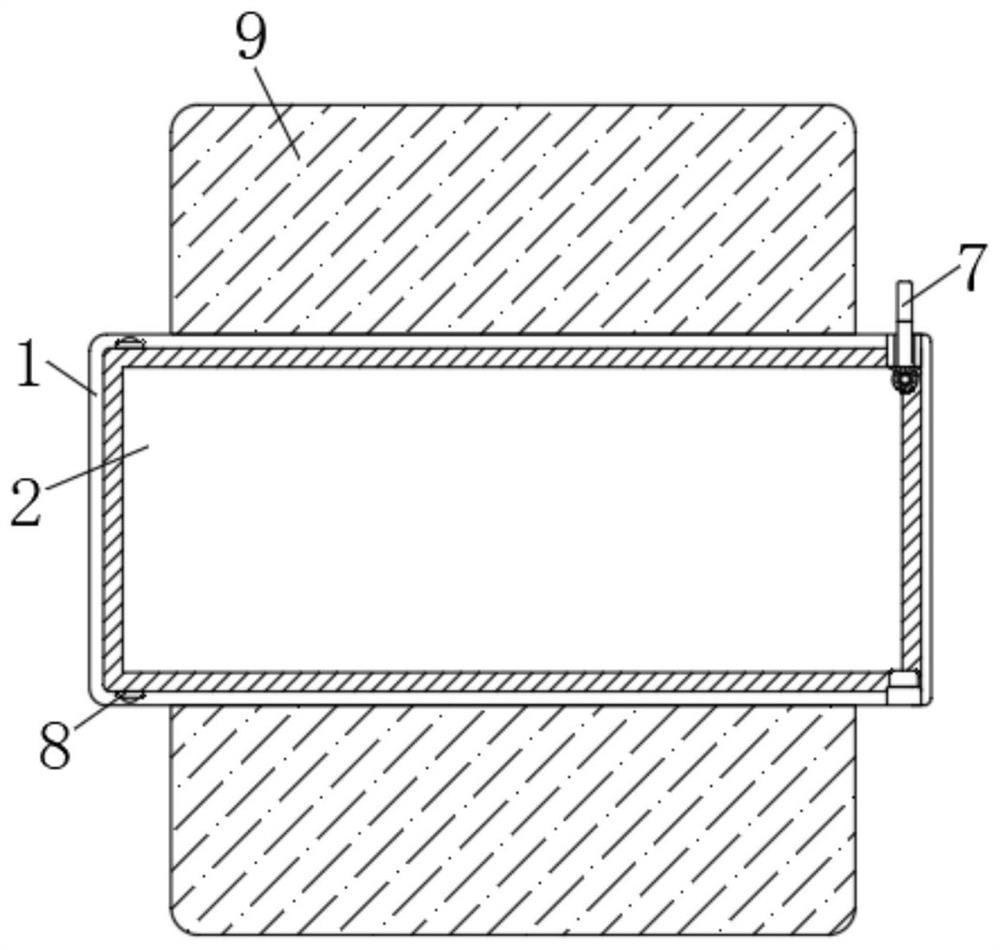

Aero seat transporting box

InactiveCN108839927AImprove seismic performanceMeet handlingLidsNon-removalbe lids/coversAviationSlide plate

The invention discloses an aero seat transporting box which comprises a box body. Spring columns are mounted on the outer wall of the bottom of the box body; universal wheels are mounted in supports;sliding rails are mounted on the outer wall of the bottom of the inner side of the box body; the sliding rails are connected with a sliding plate through pulleys; side pulleys are mounted on the outerwalls of the left side and the right side of the sliding plate; the sliding plate is connected with side sliding rails through the side pulleys; a cushion is arranged on the outer wall of the upper portion of the sliding plate; and supporting plates are arranged on the upper portions of the inner walls of the left side and the right side of the box body, and electric telescopic rods are mounted in the supporting plates. According to the aero seat transporting box, by arranging the supporting plates and the electric telescopic rods, the electric telescopic rods are fixed to the inner wall of the box body through the supporting plates, during using, pushing plates can fix a seat into the box body through rubber blankets by controlling the electric telescopic rods to automatically stretch out and draw back to work, and thus the situation that in the transporting process, the seat collides with the inner wall of the box body to generate the appearance quality problem of scratching, and consequently using performance is affected is avoided.

Owner:苏州频聿精密机械有限公司

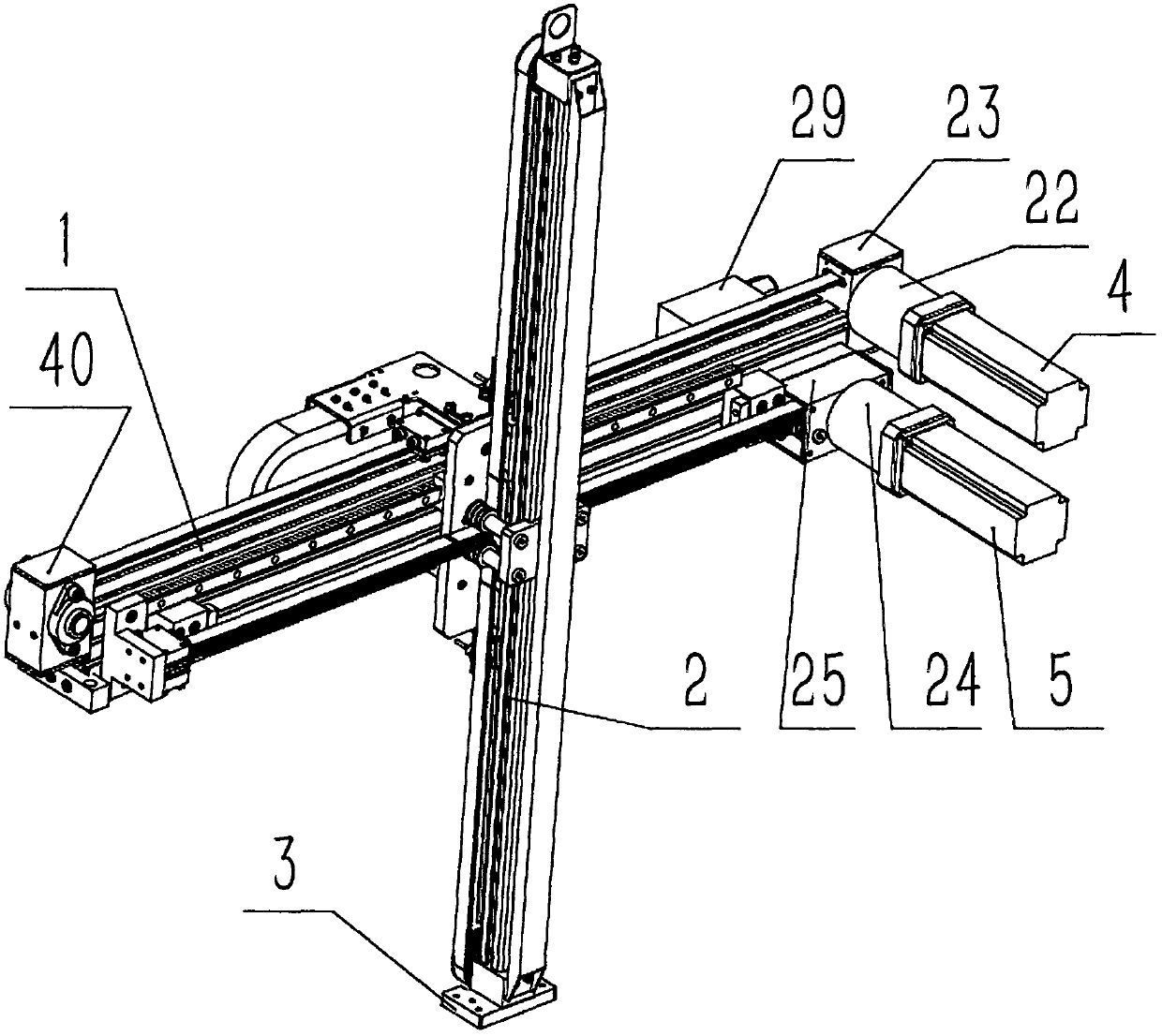

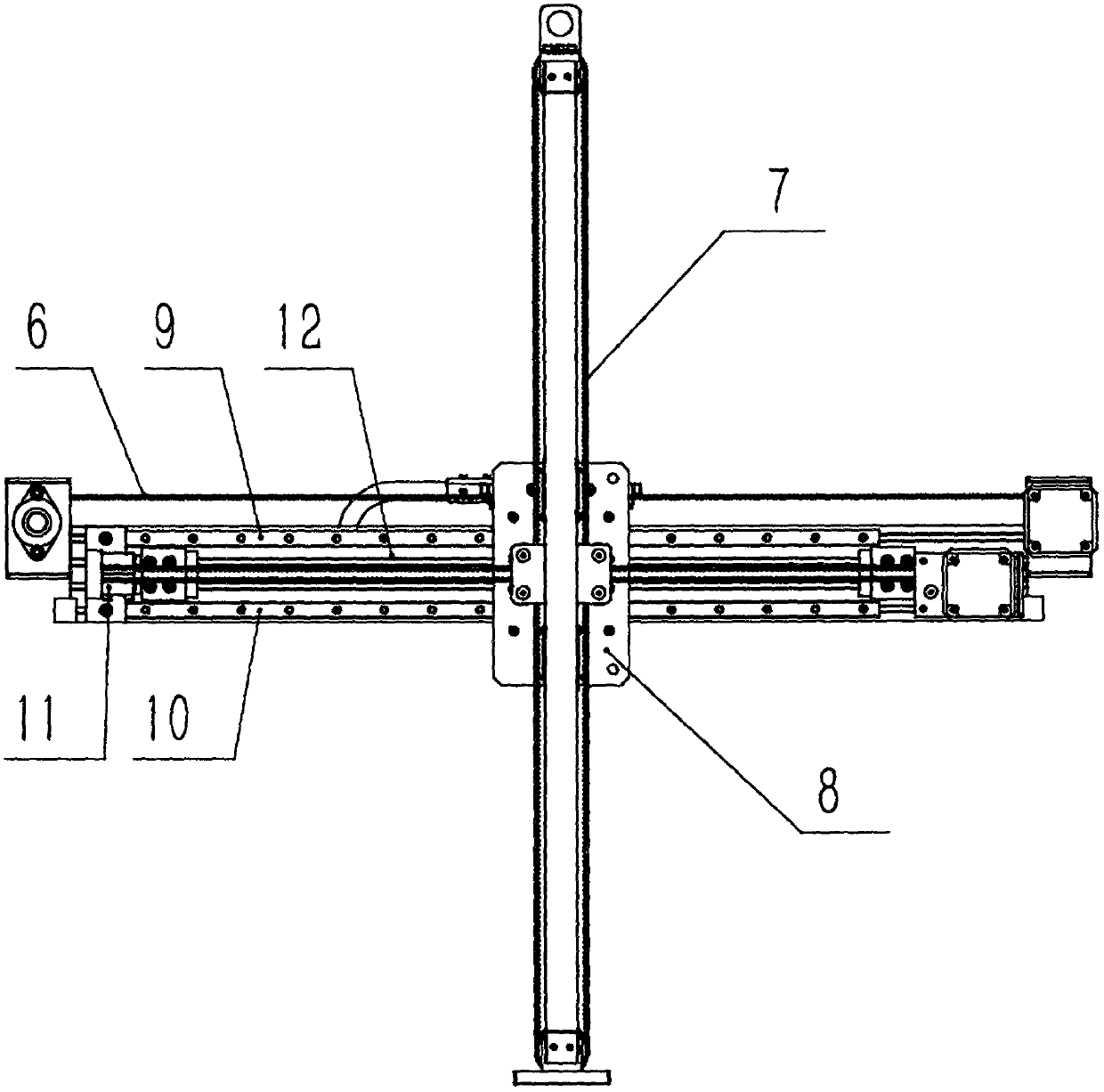

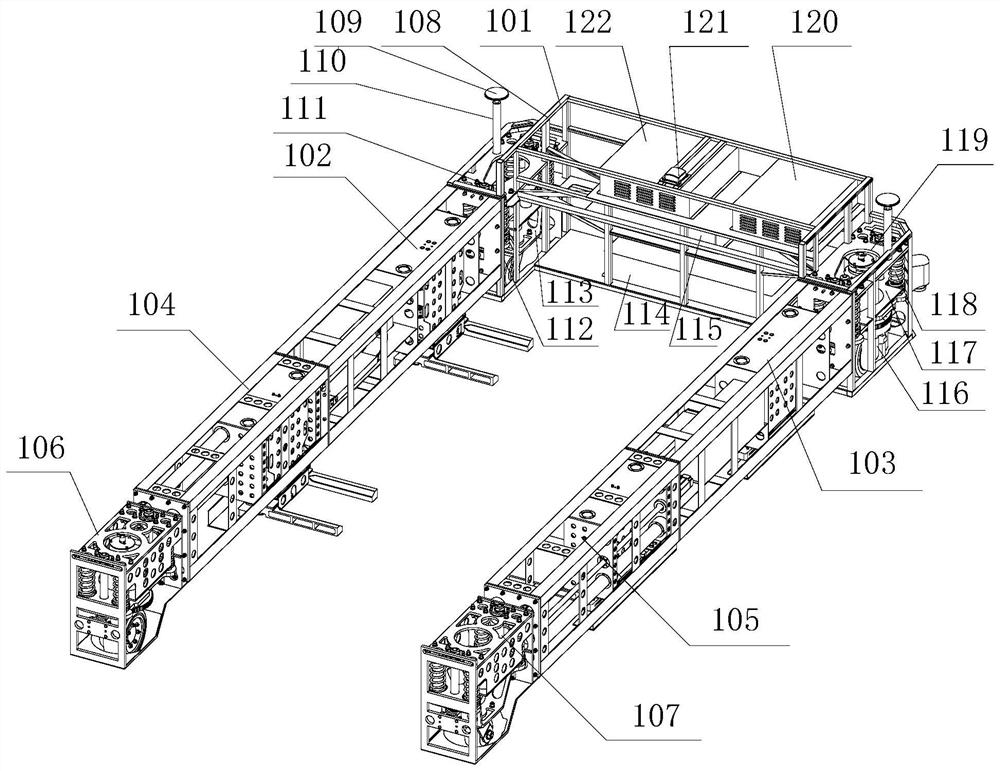

T-axis robot

PendingCN110142749AMeeting exercise needsMeet handlingProgramme-controlled manipulatorQuality of workReducer

The invention relates to the fields of object transferring, grabbing, assembling and the like, in particular to a T-axis robot which is used for object transferring, grabbing, assembling and the like.The T-axis robot comprises a servo motor, a speed reducer, a sliding block mounting plate, a tail end mounting plate, an X-axis moving device and a Y-axis moving device, wherein the X-axis moving device and the Y-axis moving device are driven by the motor to move. The T-axis robot is an integrated robot and can move in the horizontal direction and in the vertical direction, parameters, such as the moving speed and distance, of the T-axis robot can be adjusted, and the T-axis robot is high in intellectualization and digitization; the tail end mounting plate is arranged at the bottom of the Y-axis moving device, and thus, the T-axis robot can adapt to various manipulators used for equipment; and the T-axis robot is simple and practical, has good flexibility and adaptability, and is high inbearing capacity, and the working efficiency and the working quality are effectively improved.

Owner:邯郸市海拓机械科技有限公司

Four-fulcrum multi-steering narrow roadway articulated forklift

InactiveCN110626995AMeet handlingRealize handlingLifting devicesSteering for vehicles in tandemDrive wheelRotation function

The invention discloses a four-fulcrum multi-steering narrow roadway articulated forklift. The four-fulcrum multi-steering narrow roadway articulated forklift comprises a pair of front wheels, a pairof rear wheels, and a steering device; wherein the front wheels are driven wheels with independent steering functions, and the front wheels are symmetrically arranged on two sides of a lifting body; the pair of rear wheels are in power connection with a driving device, and the rear wheels are symmetrically arranged on a vehicle body; and the steering device connects the lifting body with the vehicle body, and a power system is arranged on the steering device. According to the four-fulcrum multi-steering narrow roadway articulated forklift, a articulated mechanism with an independent rotation function is arranged between the vehicle body and the lifting body, and at the same time, the front wheels with steering functions are arranged on the lifting body, so that two steering modes of articulated steering and front wheel steering are formed, carrying requirement of conventional goods can be met, and carrying of the ultra-long goods in the narrow roadway can be achieved; meanwhile, a four-fulcrum bridge type structure is used, so that the contact area between the wheels and the ground is effectively increased, the problem of driving slipping is solved, and the adaptability of the forklift to the ground is improved.

Owner:BANYITONG SCI & TECH DEVING

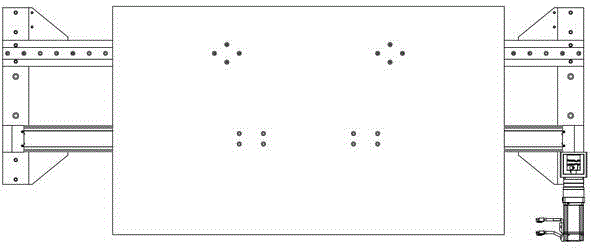

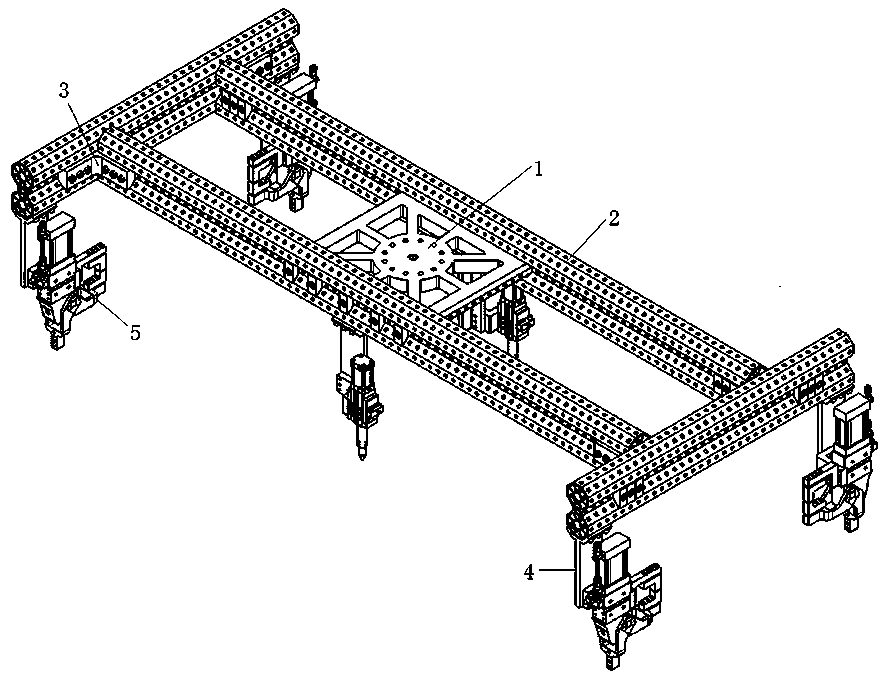

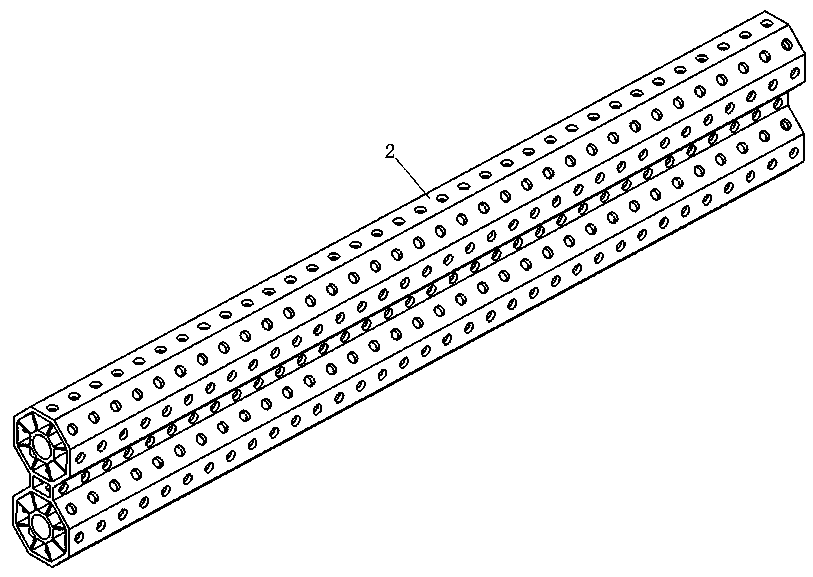

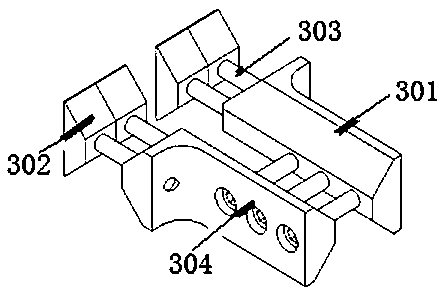

Double-row octagonal pipe gripping apparatus

PendingCN109304704AFirmly connectedOptimize the installation positionProgramme-controlled manipulatorGripping headsEngineeringUltimate tensile strength

The invention discloses a double-row octagonal pipe gripping apparatus. The double-row octagonal pipe gripping apparatus comprises a connecting plate, four double-row octagonal pipes, connecting assemblies, connecting pieces and a plurality of clamping units. A frame is defined by the four double-row octagonal pipes, and the four corners of the frame are fixed through the connecting assemblies. The connecting plate is located at the center position of the frame, and the two ends of the connecting plate make contact with the two double-row octagonal pipes correspondingly. The multiple clampingunits are fixed to the lower ends of the four corners of the frame and the lower end of the connecting plate through the connecting pieces. The double-row octagonal pipe gripping apparatus can conveniently grip workpieces and can be flexibly mounted, demounted and adjusted. The stability and the strength of the frame of the gripping apparatus can be effectively improved, and the safety of the equipment is improved.

Owner:上海企可机械自动化技术有限公司

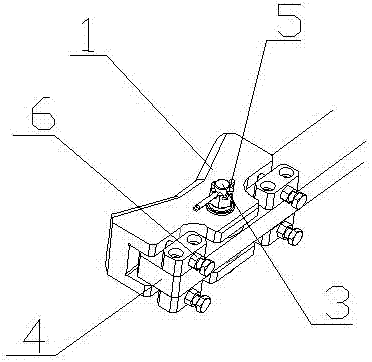

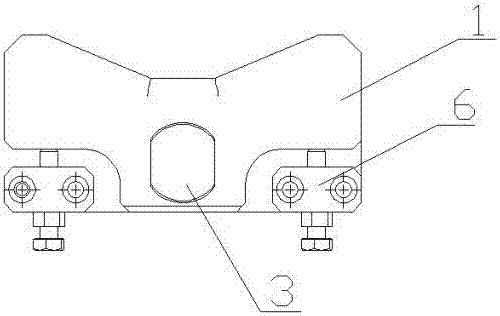

Carrying clamping grasping block special for aluminum alloy forged hub

Disclosed is a carrying clamping grasping block special for an aluminum alloy forged hub. The carrying clamping grasping block special for the aluminum alloy forged hub consists of a V-shaped block (1), a lubrication copper sleeve (2), a fixed shaft (3), a mechanical arm (4), a locking nut (5) and limiting bolts (6). The carrying clamping grasping block special for the aluminum alloy forged hub is characterized in that the mechanical arm (4) is arranged below the V-shaped block (1), the fixed shaft (3) penetrates through installing holes of the V-shaped block (1) and the mechanical arm (4), the locking nut (5) locks the fixed shaft (3) on the mechanical arm (4), and the V-shaped block (1) rotates around the fixed shaft (3). According to the carrying clamping grasping block special for the aluminum alloy forged hub, a product is clamped through a V-shaped trough in the V-shaped block, lubrication is conducted during using the lubrication copper sleeve, the combination of the V-shaped block and the lubrication copper sleeve makes an object with the heavy weight and the high temperature be clamped by the aluminum alloy forged hub carrying clamping grasping block in a long term.

Owner:江苏天宏智能装备有限公司

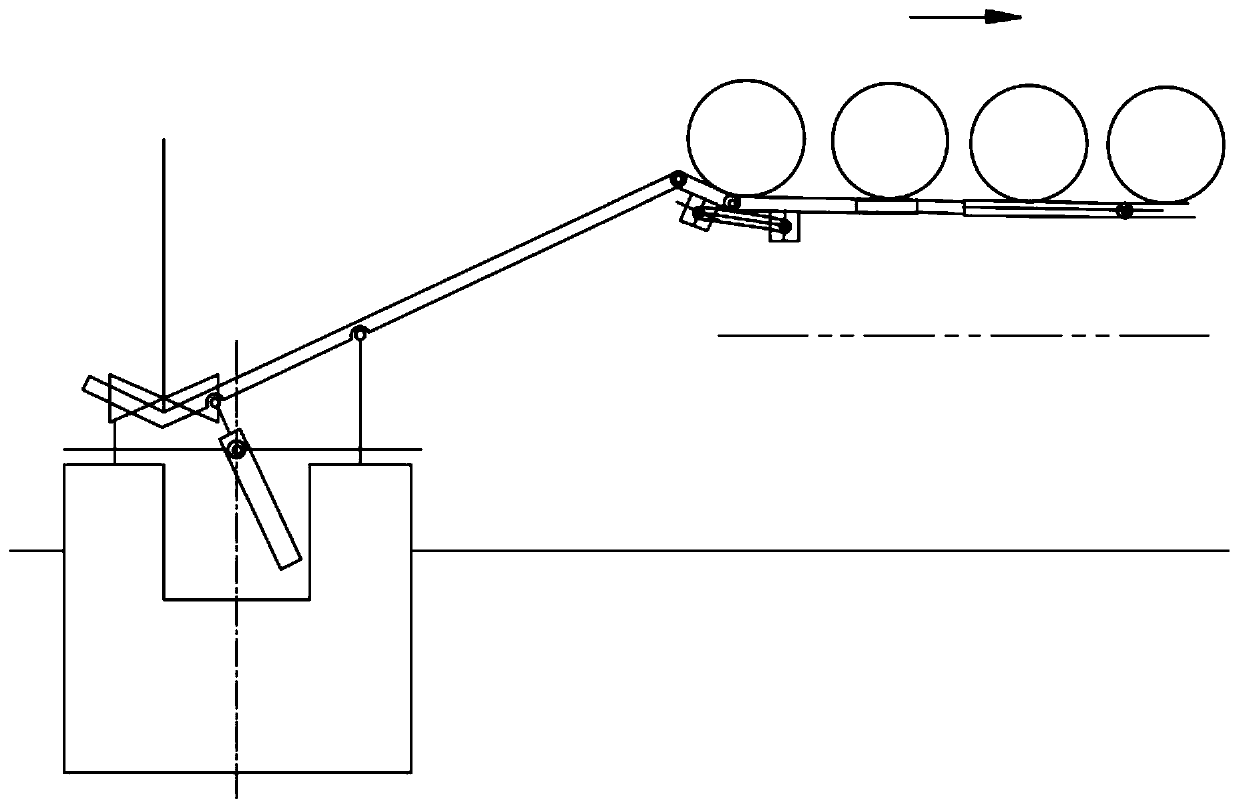

Adaptive steel pipe conveying system and operating method thereof

PendingCN111422607AMeet handlingReduce vibrationConveyorsRollersHydraulic cylinderClassical mechanics

The invention relates to the field of steel pipe conveying equipment, in particular to an adaptive steel pipe conveying system and an operating method thereof. The adaptive steel pipe conveying systemis characterized by comprising a pipe pulling arm, an angle adjusting rod, a length adjusting rod, a second pipe pulling arm, a second angle adjusting rod and a second length adjusting rod, wherein the pipe pulling arm, the angle adjusting rod and the length adjusting rod are arranged at the position of a certain production procedure, the second pipe pulling arm, the second angle adjusting rod and the second length adjusting rod are arranged at the position of another production procedure, and the length adjusting rod and the second length adjusting rod are connected through a middle ramp; and a hydraulic cylinder capable of adjusting the pipe pulling arm to be overturned relative to a pipe pulling arm hinge frame is arranged between a pipe pulling arm foundation and the pipe pulling arm.Compared with the prior art, the adaptive steel pipe conveying system and the operating method thereof have the beneficial effects that 1), steel pipe carrying between large-fall procedures can be achieved, the stability and the safety of the conveying system are improved, and the transportation journey is shortened; 2), vibration generated in the steel pipe transportation process can be buffered, and the service life of the conveying system is prolonged; 3), the influences caused by abrasion and deformation of the ramp in the conveying process can be eliminated; and 4), a roller bed roller can be reused after being finished, so that the production cost is reduced advantageously.

Owner:中冶辽宁德龙钢管有限公司

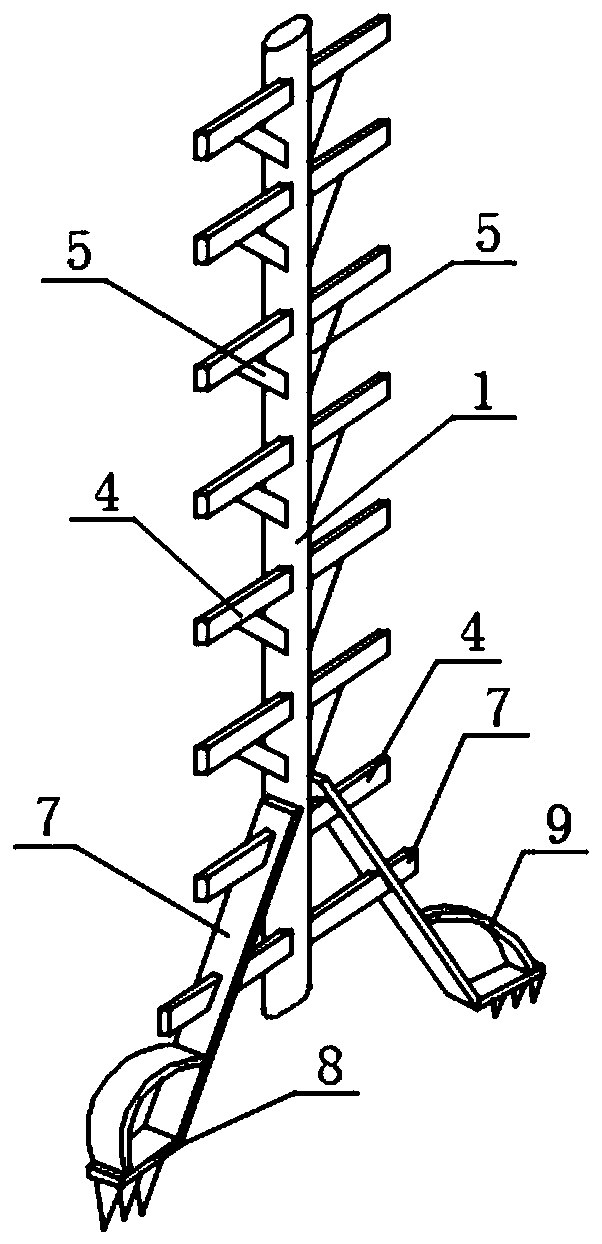

Special climbing ladder for nut picking

The invention provides a special climbing ladder for nut picking. The special climbing ladder is characterized by comprising a main supporting frame, wherein an auxiliary supporting frame is assembledto the top of the main supporting frame; the main supporting frame and the auxiliary supporting frame adopt cylindrical structures; the pore diameter of the auxiliary supporting frame is greater thanthat of the main supporting frame; spacing holes are formed in the surfaces of the main supporting frame and auxiliary supporting frame; a pedal is arranged in the spacing hole; the spacing hole andthe pedal adopt rectangular structures; a base is arranged at the bottom of the main supporting frame; a bottom plate is arranged at the tail end of the base; a plurality of groups of fixed pieces aredownward vertically arranged at the bottom of the bottom plate; a tension piece is arranged between the bottom plate and the base. The special climbing ladder can meet the requirements on different heights when nuts, such as Chinese torreya, pecans and Chinese chestnuts, are picked through the assembly of the main supporting frame and the auxiliary supporting frame according to variable landforms, such as mountains and sloping lands, in which nut trees mainly grow, is simple in design structure and convenient to carry and dismount, can effectively enhance the self stability and firmness through a single column structure, guarantees the picking safety, and deserves promotion.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

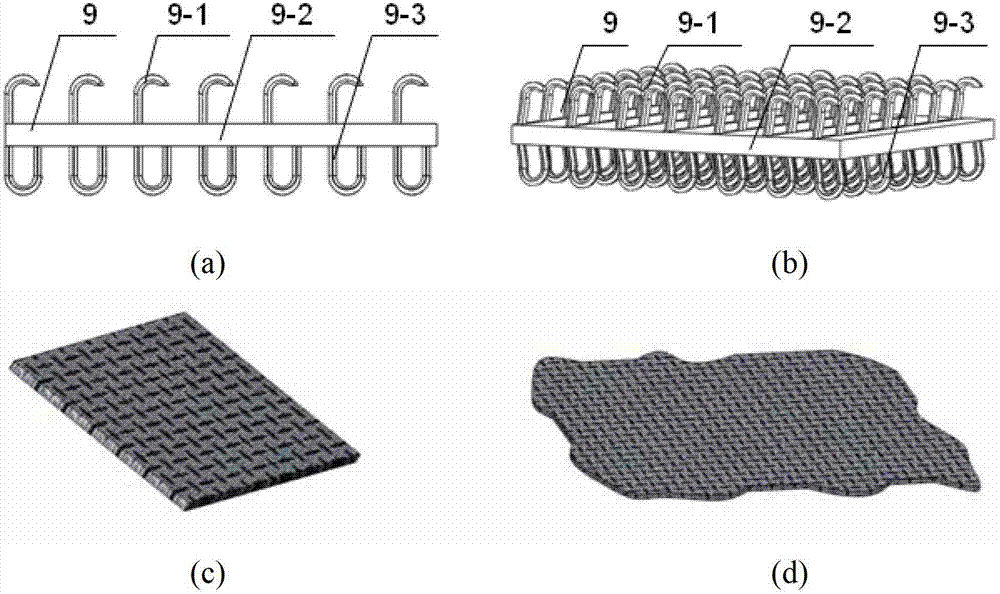

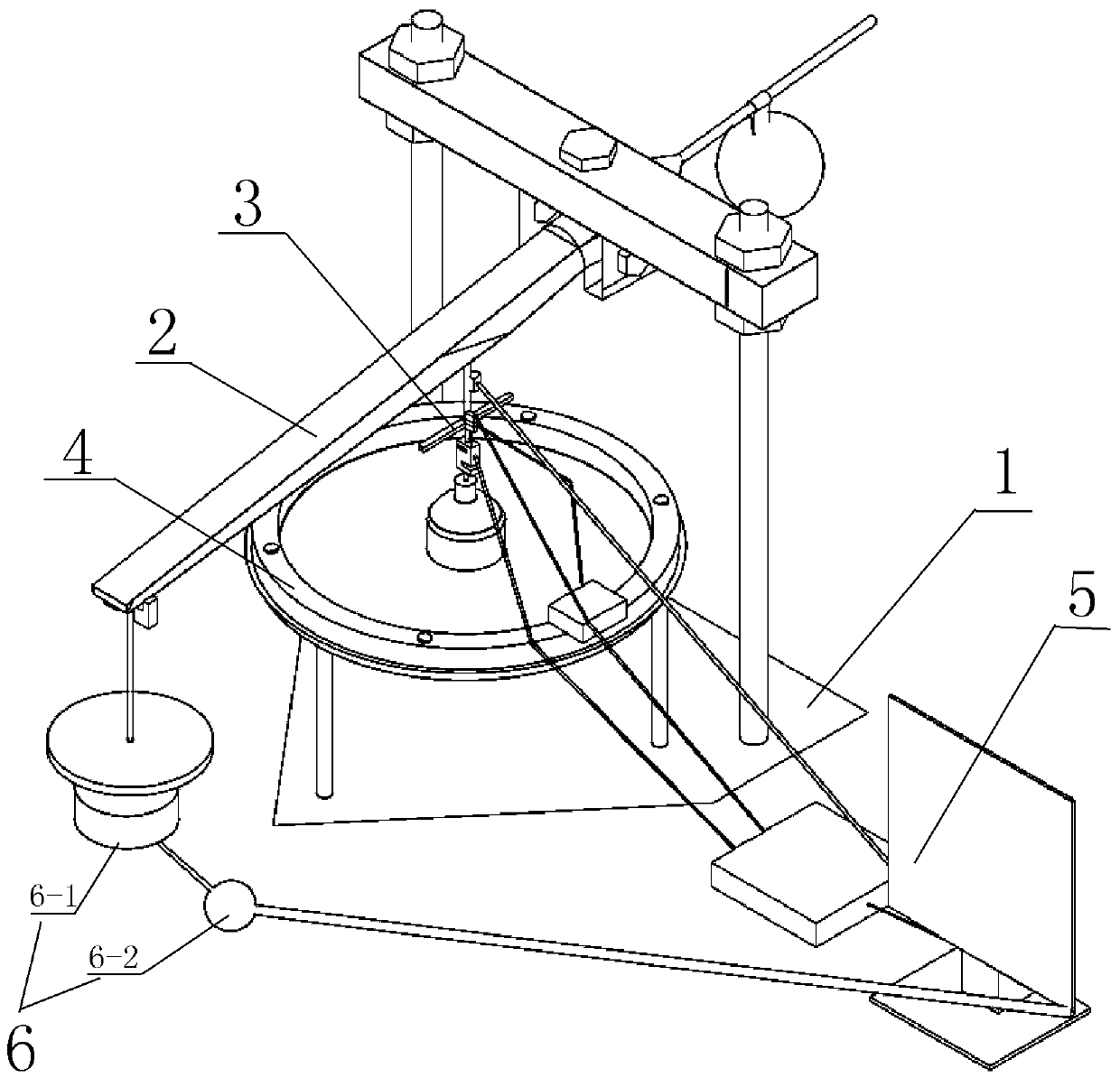

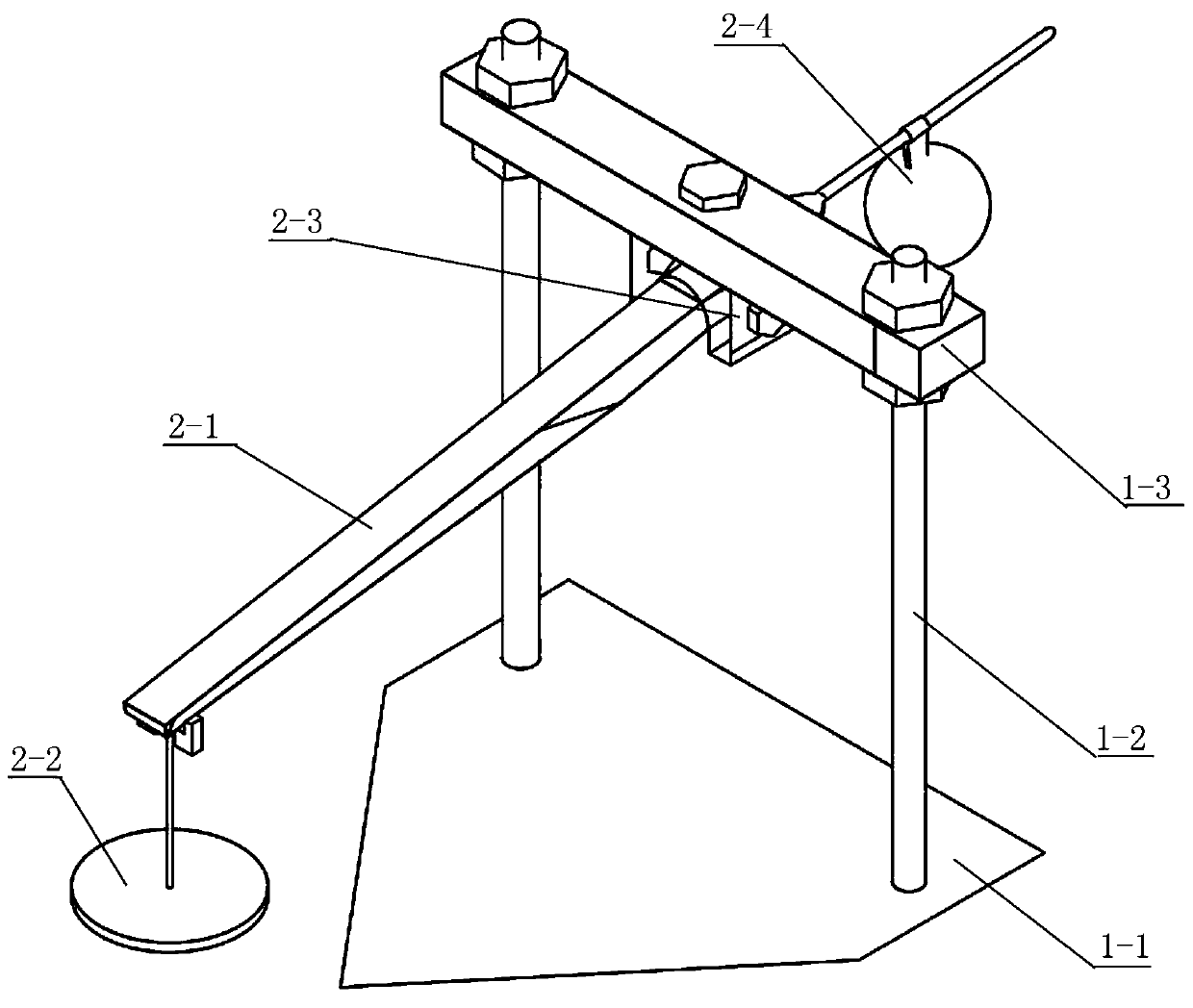

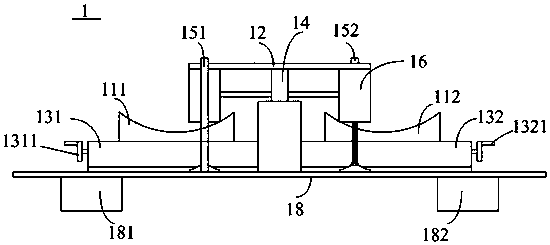

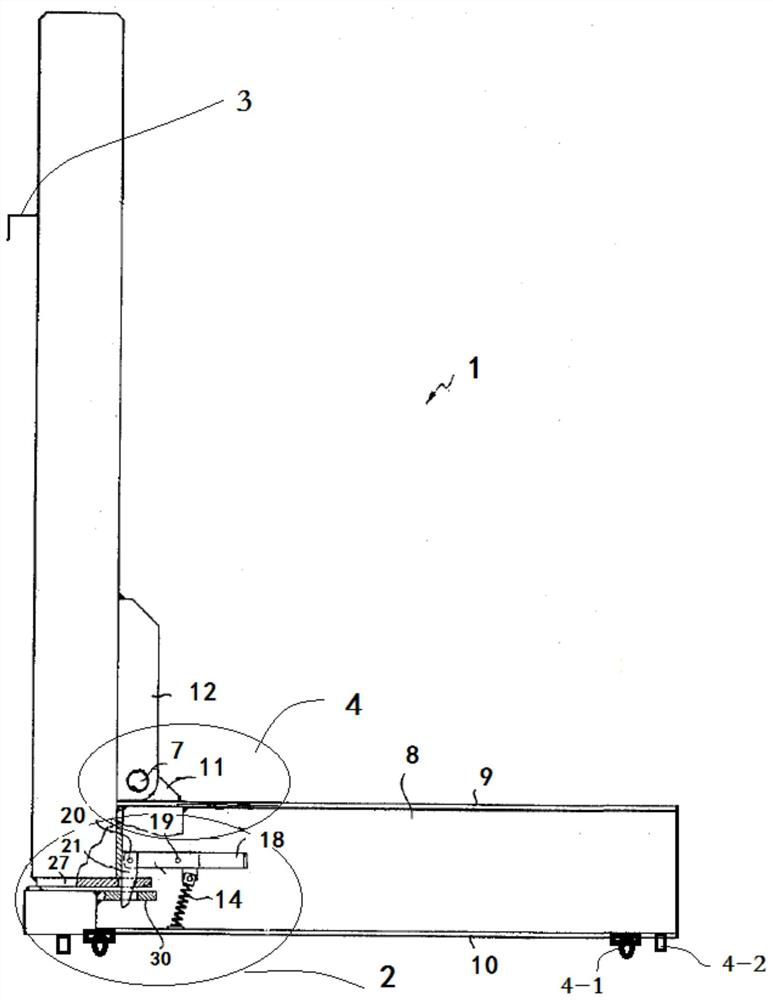

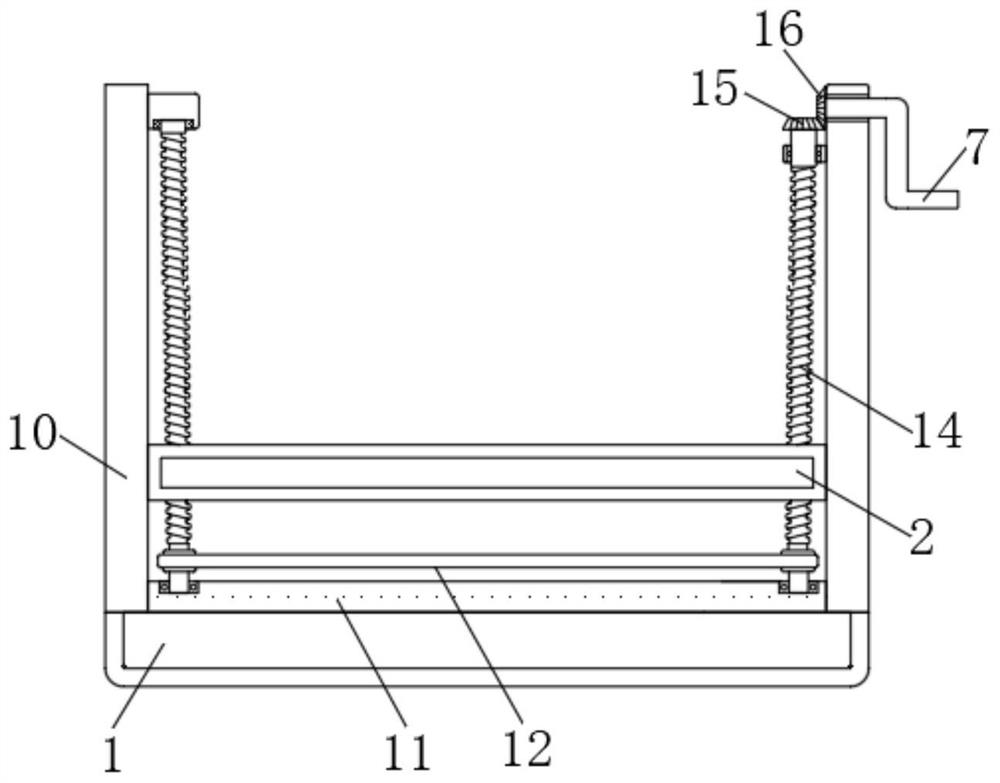

Geosynthetic material jacking creep test device

PendingCN109932246ANo stress concentrationThe experimental data is accurateMaterial strength using tensile/compressive forcesSynthetic materialsData acquisition

The invention discloses a geosynthetic material jacking creep test device. The device comprises a workbench, a suspension part, a guide part, a clamp part, a control part and a counterweight part. Theworkbench comprises a base, a lever suspension frame and a stabilizing cross beam, and plays a role in stabilizing the whole device. The suspension part comprises a lever, a weight frame, a pressinghammer and a lever holder, and can achieve the effect of pressing the geotechnical cloth after leveling. The guide part comprises a jacking block, a pressure sensor, a rotating force direction indicator, a directional barrel and a connecting rod, and enables the forces acting on a geosynthetic material to be kept in the same vertical direction all the time. The clamp part comprises a clamp cover,a bracket and a quincunx nail and is used for fixing the geosynthetic material. The control part comprises a data acquisition workstation, a displacement sensor, an electromagnetic fixing instrument,a sensor switching station and an SIS426 digital biaxial tilt angle sensor and is used for data acquisition, processing, storage, output and the like. The counterweight part comprises a water level leveling vessel and an intelligent water supply pump, so that the force acting on the geosynthetic material is kept constant.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Crane trolley set carrying and fixing device

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

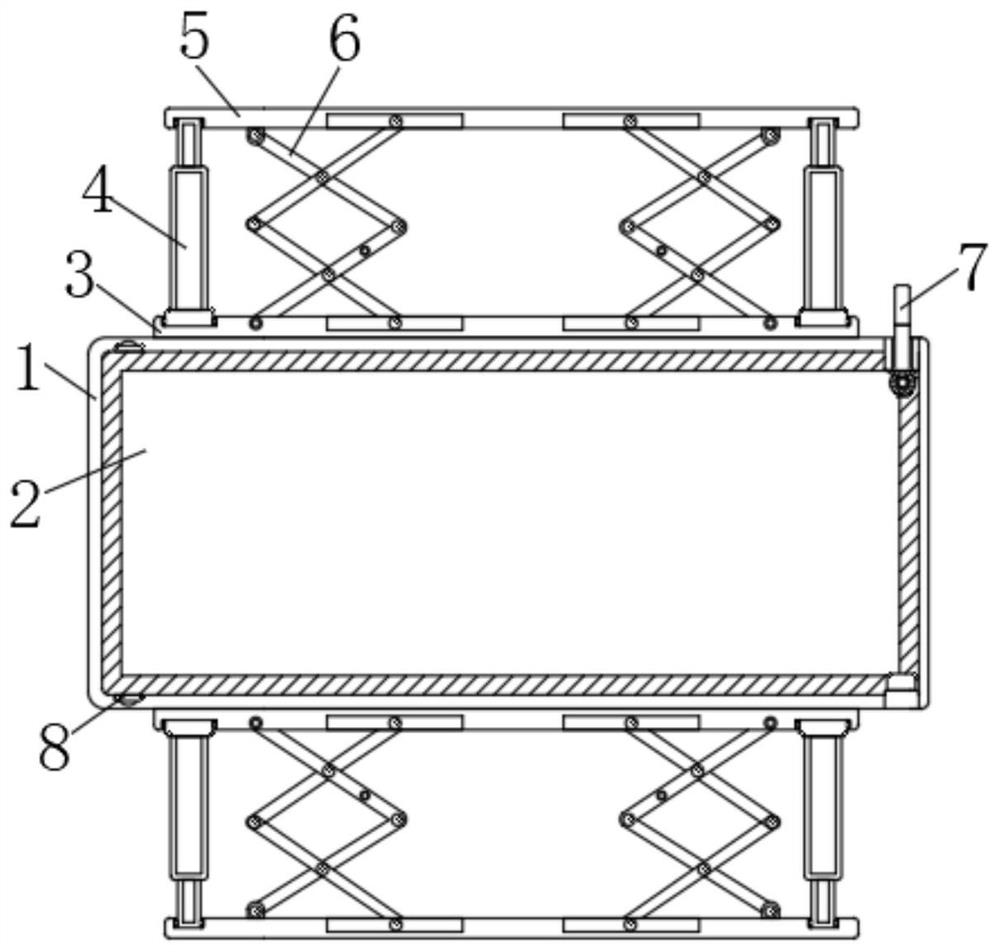

Automobile carrying AGV

ActiveCN112723243AReduce control difficultyLow costLifting devicesVibration suppression adjustmentsControl theoryWheelbase

The invention provides an automobile carrying AGV, and relates to the field of intelligent carrying. The automobile carrying AGV comprises a control unit, a frame unit, a lifting unit, a variable shaft unit, a supporting rod unfolding unit and a wheel train unit. The control unit is used for controlling the AGV to complete an automobile carrying task. The frame unit comprises a first frame module and second frame modules and is used for providing support for an AGV body. The first frame module is arranged in front of the AGV running direction and used for carrying the control unit. The second frame modules are arranged on the two sides of the first frame module and comprise fixed cabin sections and variable shaft cabin sections which are arranged front and back. The lifting unit is used for lifting and putting down an automobile. The variable shaft unit is used for adjusting the AGV carrying wheel base. The supporting rod unfolding unit is used for obtaining the tire position so as to calculate the automobile wheel base and complete clamping of automobile tires. The wheel train unit is arranged at the bottom of the frame unit and used for AGV running and shock absorption. The provided automobile carrying AGV is adjustable in wheel base and good in passing performance.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Medicament transfer trolley for clinical laboratory

InactiveCN113212511ASave spaceImprove reliability and service lifeStorage devicesHand carts with multiple axesProcess engineeringBiology

The invention discloses a medicament transfer trolley for a clinical laboratory. The medicament transfer trolley is provided with a trolley general structure part, a releasable mechanism, a push-pull auxiliary structure and a corner part, and the releasable fixing mechanism is provided with a fitting sealing mechanism. According to the trolley, the storage space of the trolley can be saved, the requirement for carrying medicine during storage can be met, meanwhile, the reliability of equipment is improved, the maintenance cost is reduced, and the service life is prolonged.

Owner:赵振文

A car handling agv

ActiveCN112723243BReduce control difficultyLow costLifting devicesVibration suppression adjustmentsGear trainAutomobile handling

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

An intelligent material handling device for underground logistics

ActiveCN111762491BEasy to carryConvenient dropConveyorsStorage devicesLogistics managementStructural engineering

The invention discloses an intelligent material handling device for underground logistics, which comprises a moving mechanism and a telescopic rod. Both sides of the screw are provided with a belt mechanism, and the surface of the screw is provided with a placement plate, and the left side of the placement plate is hinged with a first fixed block, and the right top of the screw is provided with a second A conical wheel, and the surface of the first conical wheel engages with the surface of the second conical wheel. The intelligent material handling device for underground logistics of the present invention can be adjusted according to the need to transport different quantities of materials, and the materials on the surface of the placing board can be conveniently lowered by tilting the placing board, and the materials on the surface of the placing board can be conveniently transported.

Owner:JIAOZUO UNIV

Industrial robot automatic laminating system for fiber sheets

ActiveCN102756921BAutomatic cascading implementationImprove efficiencyStacking articlesDe-stacking articlesFiberEngineering

The invention discloses an industrial robot automatic laminating system for fiber sheets. The system comprises a fiber sheet conveying workbench, a laminating workbench and a mechanical arm, wherein the end part of the mechanical arm is provided with a pick-and-place actuator which is used for picking fiber sheets on the fiber sheet conveying platform and laminating the fiber sheets on the laminating workbench, so that the fiber sheets with different types, different sizes and different shapes can be automatically laminated. The system is suitable for flexible objects, has the advantages of low cost, high laminating efficiency and high flexibility, and can fulfill the requirement of large-scale production. In an optimal technical scheme, a fiber sheet connector can be effectively engaged with a connection element on a fiber sheet, and the flexible objects can be laminated smoothly under the cooperation of an adjustable clamp and the pick-and-place actuator. The system has a simple structure and easy implementation, greatly improves the working efficiency of lamination, and can laminate fiber sheets quickly and effectively in batches, and has excellent application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of fired brick and preparation method thereof

ActiveCN104150861BSatisfy the production operationMeet handlingSolid waste managementFire brickHeat generation

The invention discloses a production of sintered bricks with tailings as the main raw material and a preparation method thereof. The invention uses fine-grained tailings and mixes a certain proportion of coal slime and coal gangue as raw materials, so that the SiO2 content in the mixture is between 50 -70%, the content of Al2O3 is between 6-20%, the content of CaO is less than 6%, the content of MgO is less than 6%, and its calorific value is controlled at 1.465-1.780MJ / Kg, so that the mixture gradation is reasonable and meets the requirements of sintered bricks. The required plasticity and heat generation requirements. The invention has the effect that the mixture overcomes the defects of tailings, coal slime and coal gangue as raw materials for sintered bricks, optimizes the mineral composition and physical properties of raw materials, realizes the comprehensive utilization of mine fine tailings, and is also beneficial Reduce the cost of fired bricks.

Owner:NANJING IRON & STEEL CO LTD

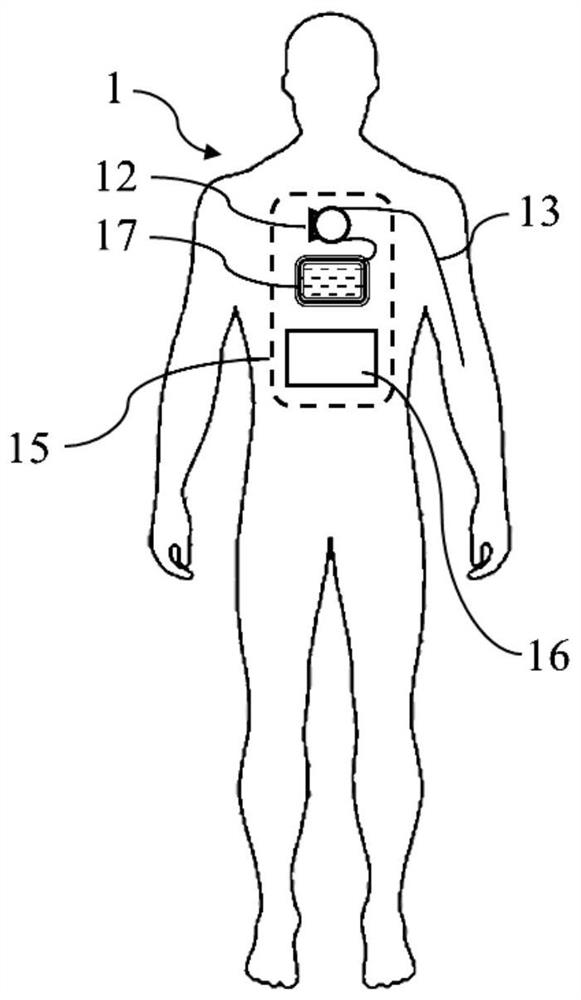

Hemostasis training system and simulated human body model for battlefield rescue training

InactiveCN112201130AHuman body is highly realisticMeet the needs of compression hemostasis trainingEducational modelsHuman bodyPhysical medicine and rehabilitation

The invention provides a hemostasis training simulation system. The hemostasis training simulation system comprises a blood bag, a blood transfusion tube, a pump and a controller, wherein the blood bag is used for containing red liquid, the blood bag is connected to the input end of the pump through the blood transfusion tube and leads to the outside through the blood transfusion tube via the output end of the pump so as to output the red liquid to the outside through the pump, and the controller receives an external instruction and controls and adjusts starting and stopping of the pump and the rotating speed of the pump according to the instruction, so that the speed of outputting the red liquid outwards through the blood transfusion tube is controlled. The invention further provides a simulated human body model for battlefield rescue training provided with the hemostasis training simulation system and a control method of the simulated human body model. The hemostasis training simulation system and the simulated human body model are high in human body trueness, can meet field training requirements, and can meet tourniquet pressurization hemostasis training requirements.

Owner:TONGFANG INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com