Industrial robot automatic laminating system for fiber sheets

An industrial robot and fiber sheet technology, which is applied in the stacking of objects, destacking, transportation and packaging of objects, etc., can solve the problems of inability to complete the stacking of flexible objects, inability to apply flexible objects, etc., and achieve flexible planning of handling paths. , good generalizability, the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

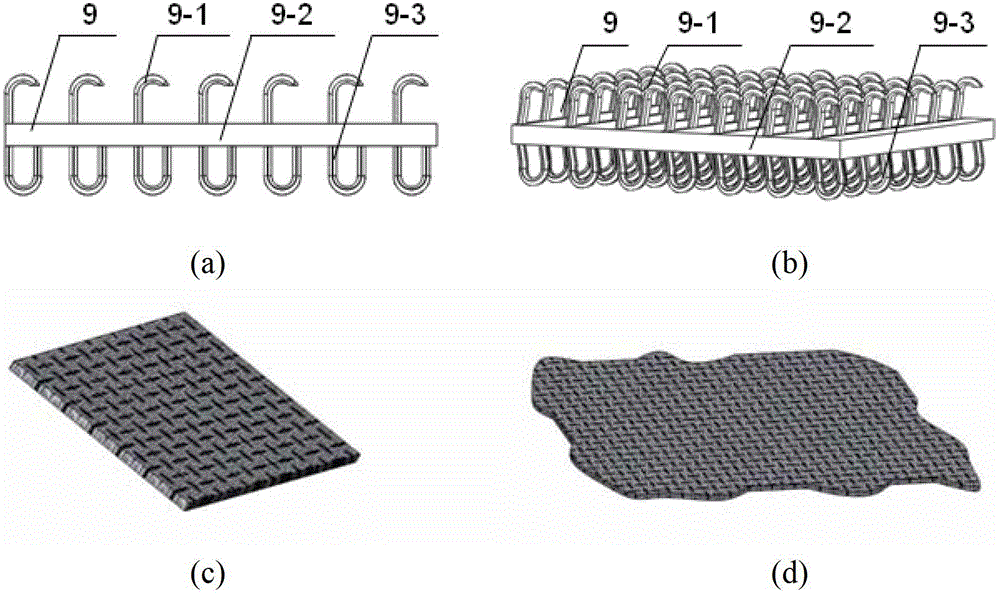

[0031] Such as figure 1 (A), figure 1 (B) shows the current industrial production of fiber sheet 9, including fiber sheet fiber body 9-2, and fiber sheet connection elements (ie, hook 9- 2) fixedly arranged on both sides of the fiber sheet fiber body 9-2 1 and circle 9-3), hook 9-1 can specifically choose fish hook, arrow hook or anchor hook, etc., circle 9-3 can choose net ring, snare ring or group ring, such as figure 1 As shown in (c), the fiber body 9-2 of the fiber sheet has a regular shape, such as figure 1 As shown in (d), the fiber sheet fiber body 9-2 has an irregular shape, and the industrial robot automatic laminating system of the fiber sheet of the present invention can laminate the fiber sheet 9 of regular shape and irregular shape.

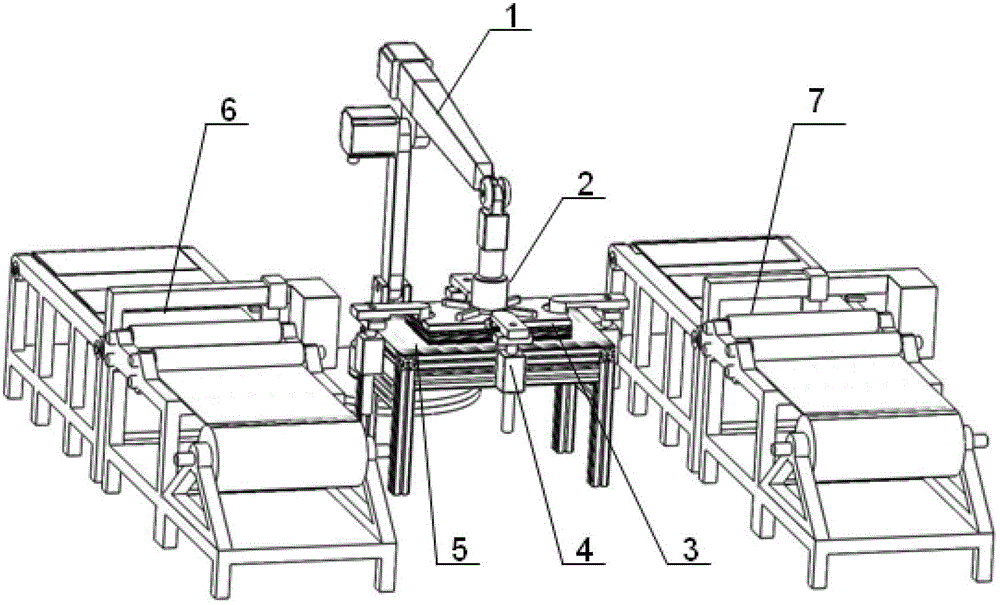

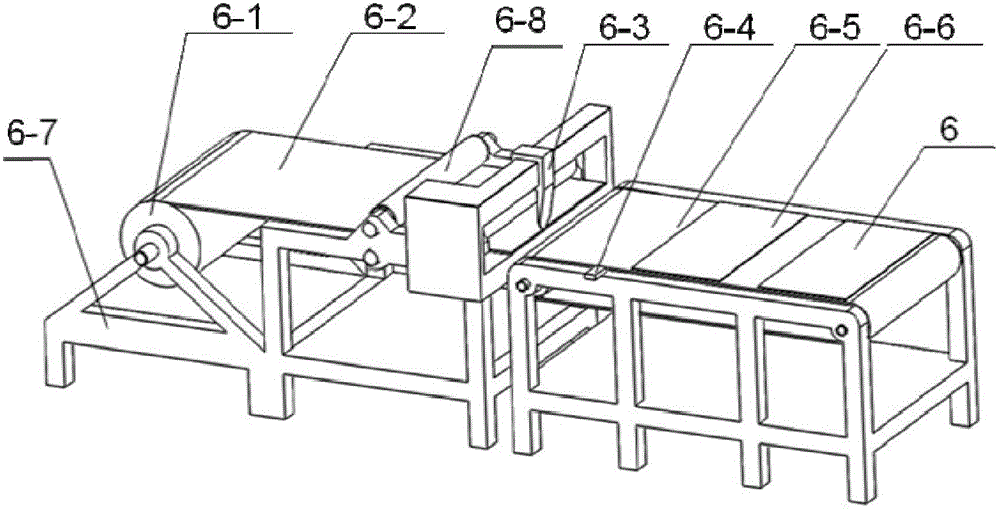

[0032] Such as figure 2 As shown, the industrial robot automatic stacking system for fiber sheets of the present invention includes: a fiber sheet conveying table 6, a fiber sheet conveying table 7, a mechanical arm 1 with a pick-and-pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com