A control device for a robot

A control device and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of single action of the manipulator and shorten the processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

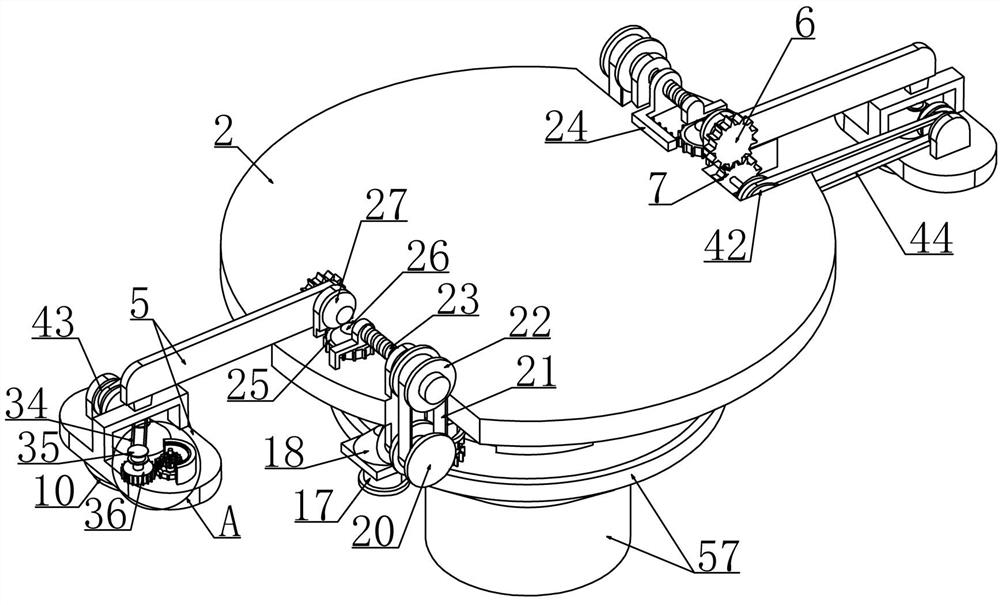

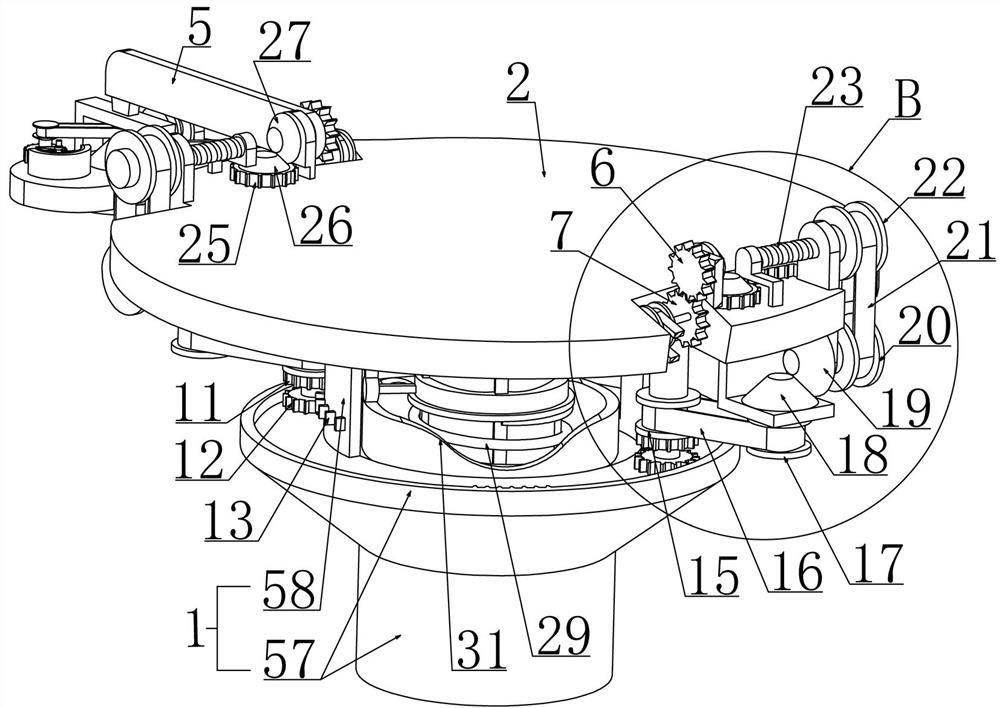

[0033] Embodiment 1, this embodiment provides a control device for a robot, which includes a base 1, referring to the attached Figure 4 As shown, a support plate 2 is rotatably installed on the base 1 and the support plate 2 is driven by a motor 3 fixedly installed on the base 1. The motor 3 is connected to an external power supply and is electrically connected to the microcontroller, and In this embodiment, the microcontroller controls the motor 3 to start intermittently, that is, the motor 3 will drive the supporting plate 2 to rotate intermittently, and two rotating shafts 4 are installed on the lateral sides of the lower end surface of the supporting plate 2, and the lower ends of the two rotating shafts 4 It is connected with a rotating shaft drive device, through which the forward and reverse rotation of the rotating shaft 4 can be controlled, and the rotating shaft 4 is connected with a transmission mechanism, through which the power of the rotating shaft 4 is changed, ...

Embodiment 2

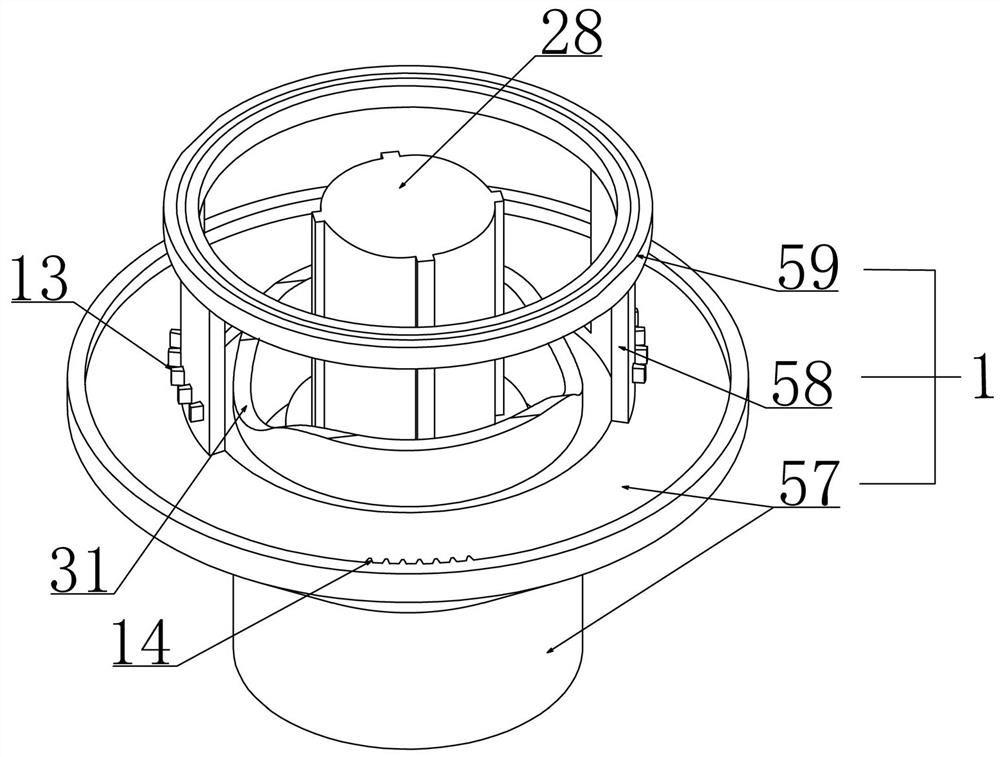

[0035] Embodiment 2, on the basis of embodiment 1, with reference to appended figure 2 As shown, the base 1 includes a fixed cylinder 57 fixedly connected to the foundation, and two arc-shaped plates 58 are fixedly installed on the upper end of the fixed cylinder 57 close to the inner circular surface, and these two arc-shaped plates 58 are radially symmetrical to the fixed cylinder 57 , and the upper ends of the two arc-shaped plates 58 are fixedly installed with a mounting ring 59 , and the supporting plate 2 is rotatably mounted on the upper end surface of the mounting ring 59 .

Embodiment 3

[0036] Embodiment 3, on the basis of Embodiment 2, in order to ensure that the support rod 5 can realize positive and negative rotation during the rotation of the support plate 2, a rotating shaft driving device is provided on the rotating shaft 4, refer to the attached Figure 7 As shown, the rotating shaft driving device includes a forward rotating helical gear 11 and a reverse rotating helical gear 12 which are vertically spaced at the lower end of the rotating shaft 4. Refer to the attached figure 2 As shown, a first helical gear train 13 corresponding to the forward-rotating helical gear 11 is provided on the arc-shaped plate 58. When the forward-rotating helical gear 11 meshes with the first helical gear train 13, it will drive the rotating shaft 4 to rotate forward. Moreover, a second helical gear train 14 corresponding to the reverse helical gear 12 is provided between the two arc-shaped plates 58 on the outer surface of the upper end surface of the fixed cylinder 57. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com