Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Achieving safe mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

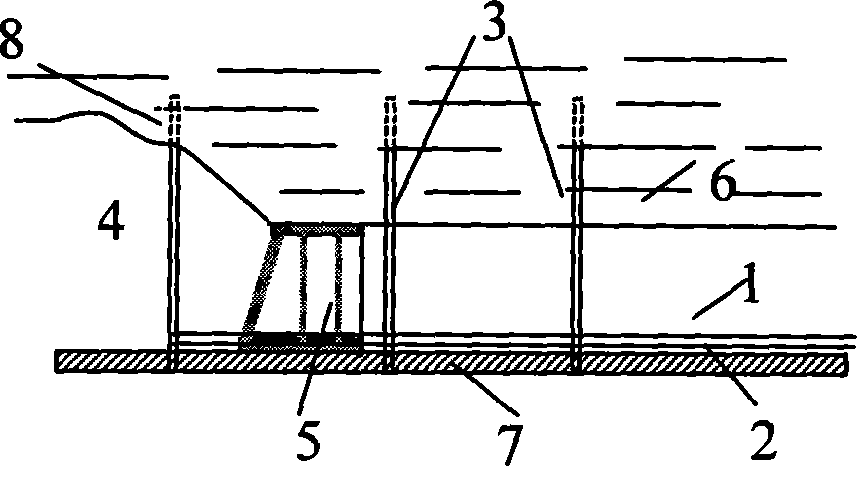

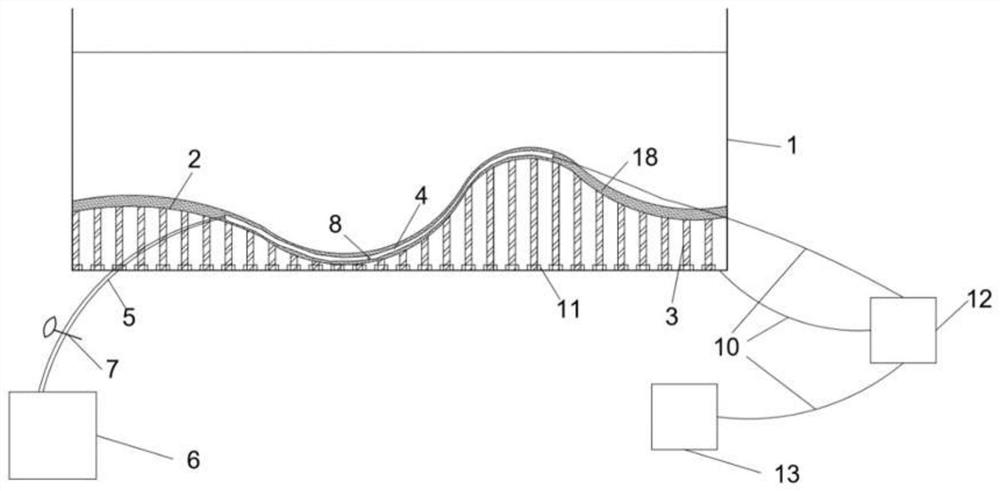

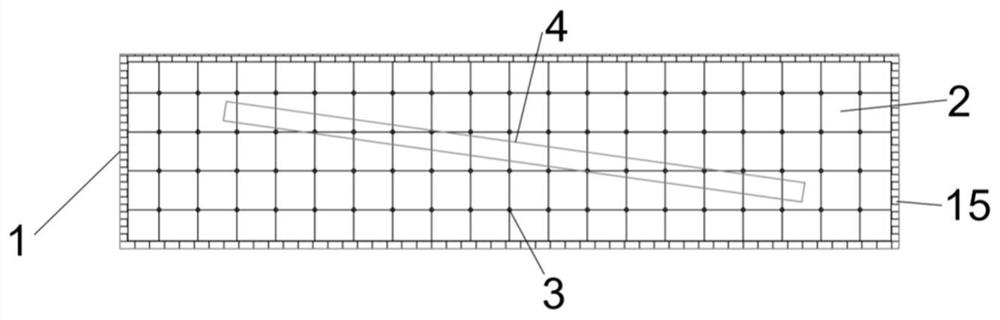

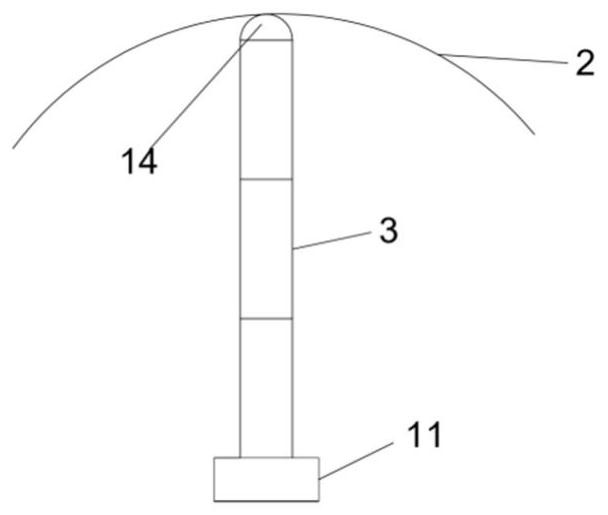

Rib-pillar-free continuous sublevel filling method for mining preparation in medium-thickness slope crushed ore body vein

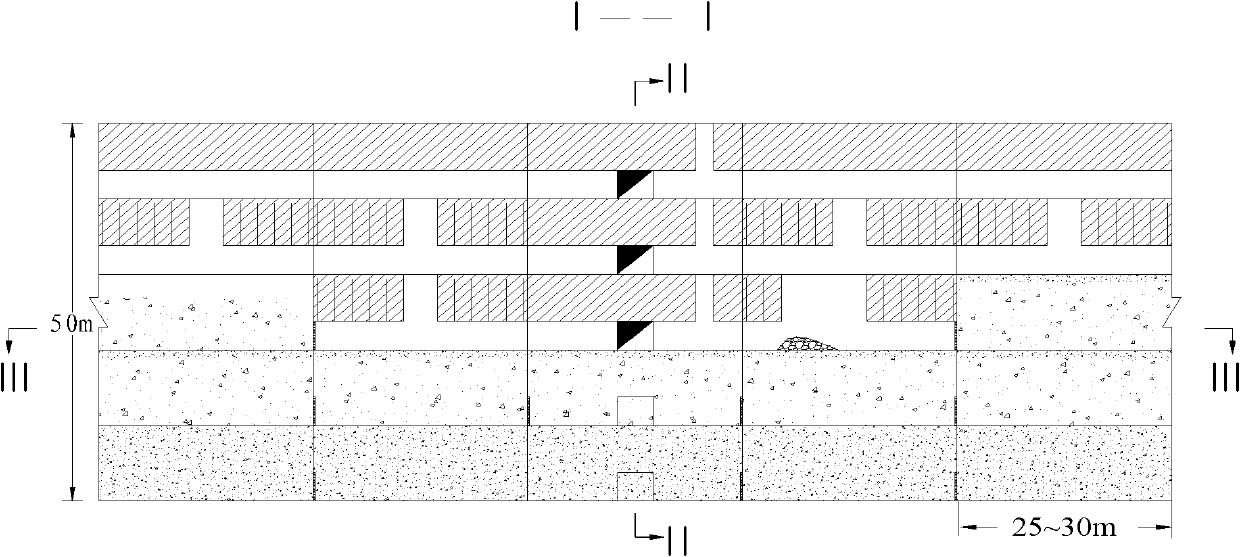

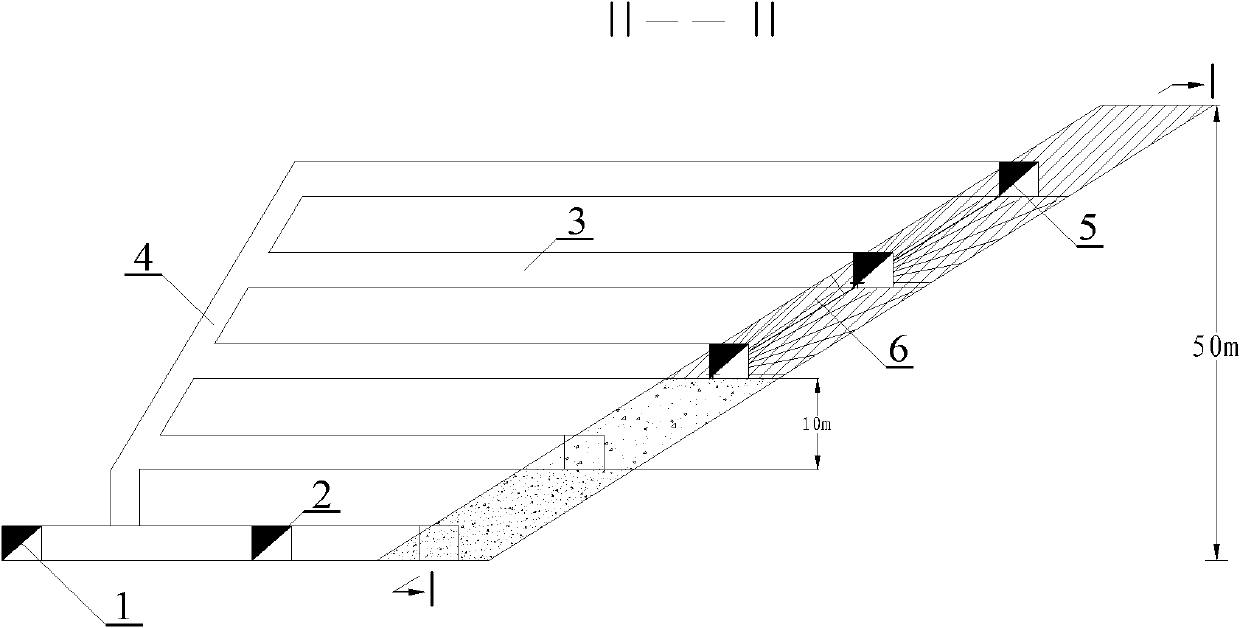

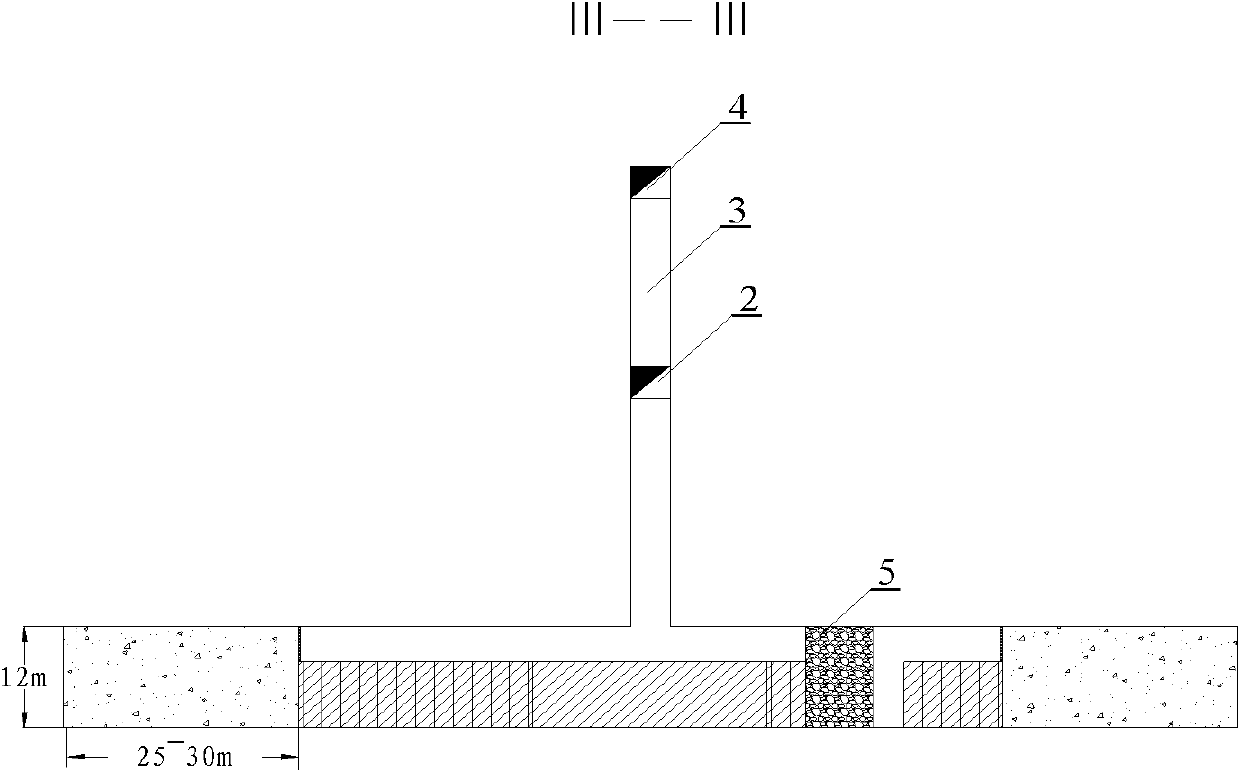

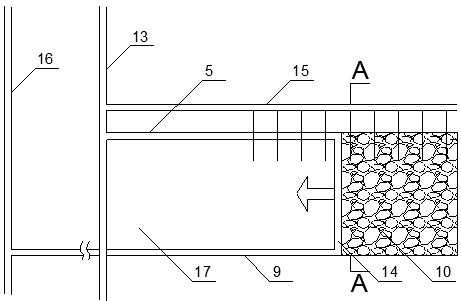

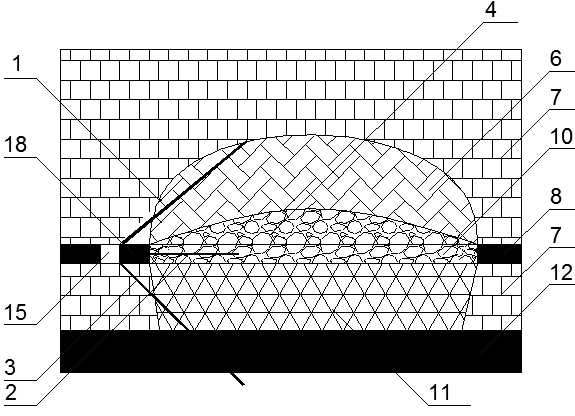

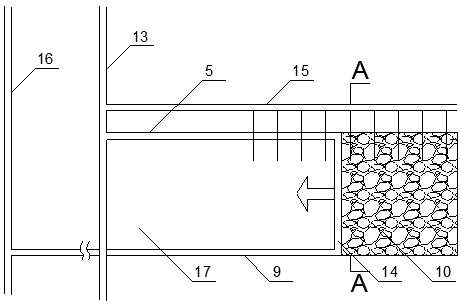

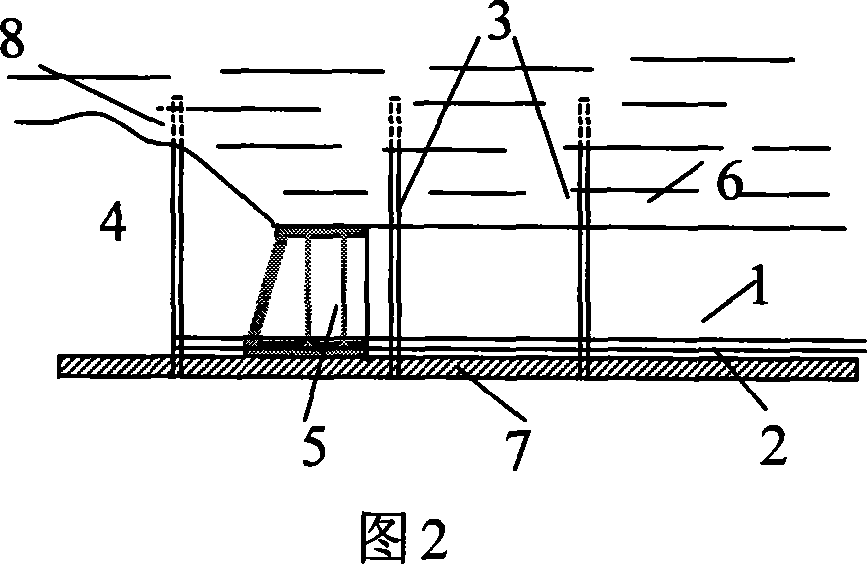

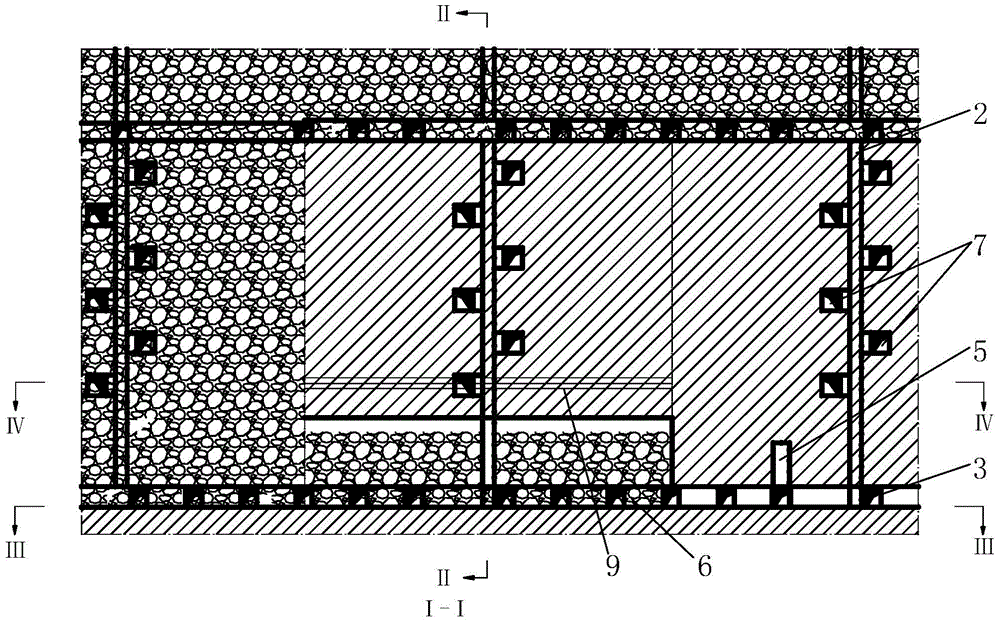

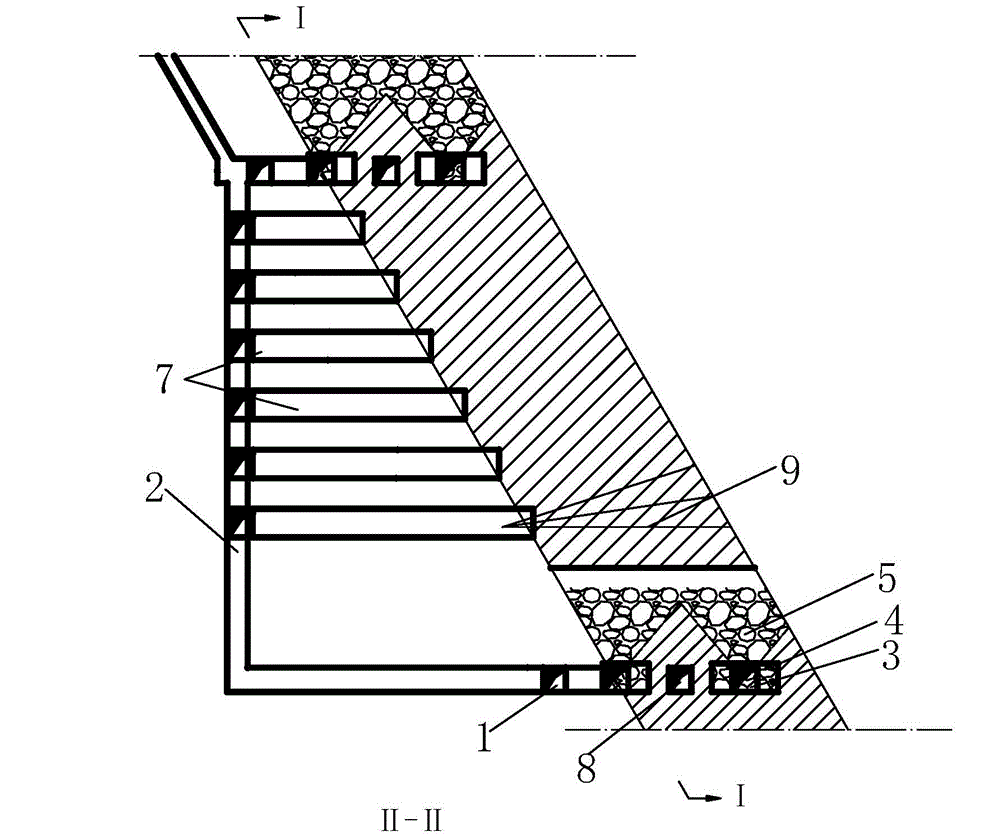

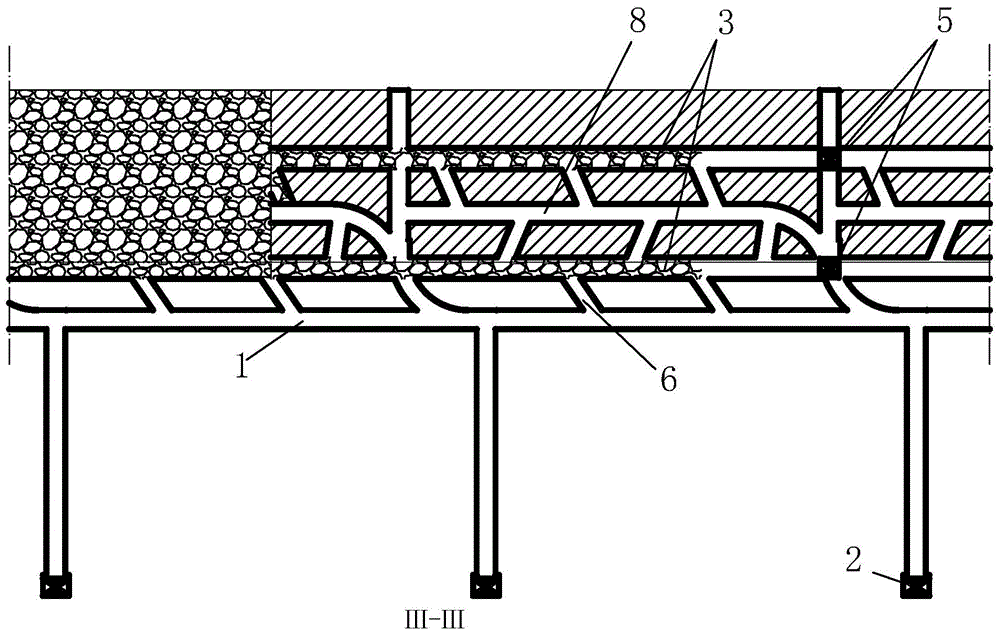

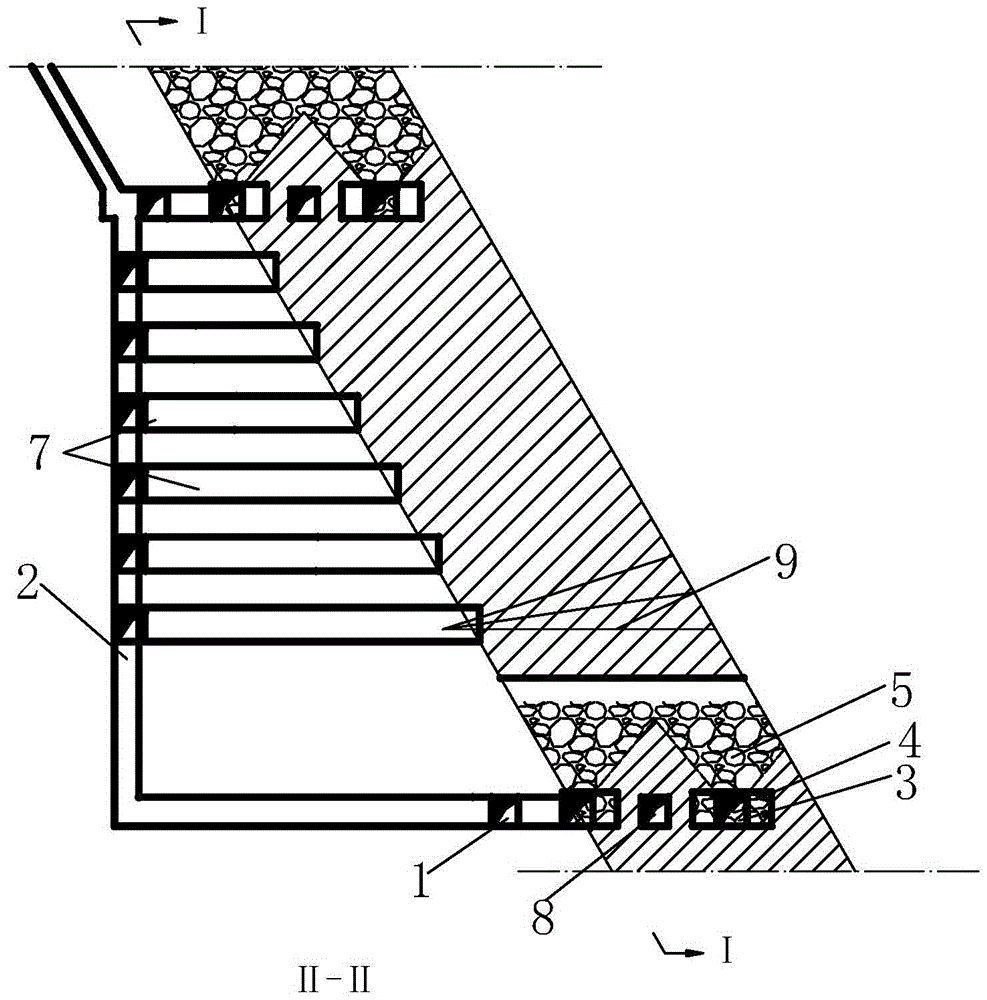

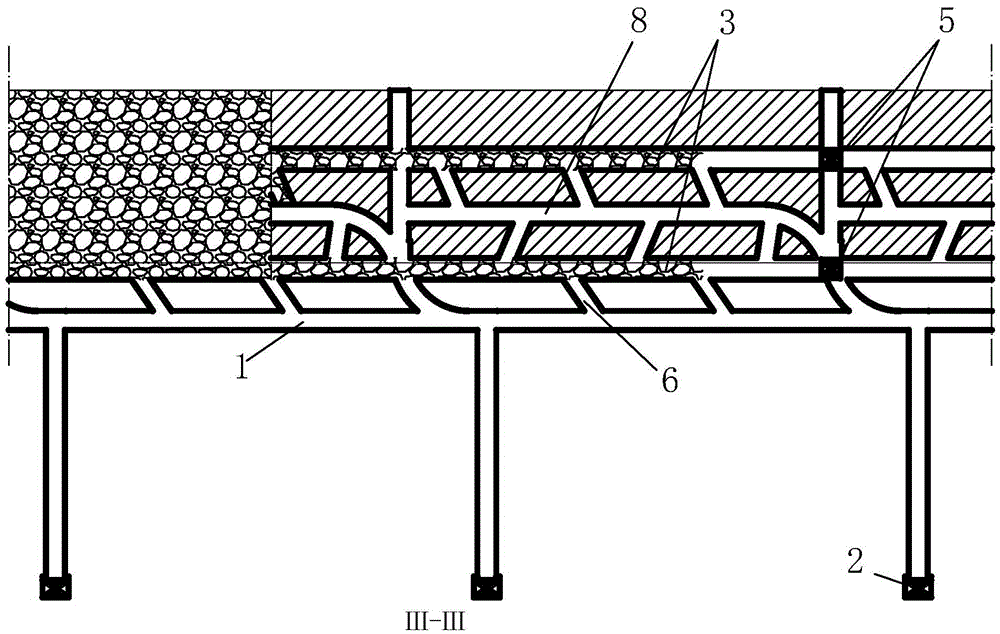

The invention discloses a rib-pillar-free continuous sublevel filling method for mining preparation in a medium-thickness slope crushed ore body vein. The method comprises the following steps of: dividing a mine block into panel structures with a plurality of sections and bunches, namely dividing sections in a panel, not leaving a rib pillar in the sections, and dividing continuous extraction units; arranging a slope ramp of the panel on an ore body hanging wall, and arranging sectional roadways namely rock drilling ore removal gate ways in the vein; making all the sectional roadways in the panel mutually communicated, and the allocation and transportation of trackless equipment flexible and convenient; performing quarry central up cutting before the extraction, and ensuring the deep hole construction in a quarry upward sector in good conditions; performing operation such as multiple-section quarry rock drilling, blasting, supporting, ore removing, filling and paralleling; using a rib-pillar-free continuous extraction way backing from two wings of the panel to the center in the same sectional quarry, wherein an extraction process is performed sequentially; and filling a gob with tailings or waste stones. The invention relates to the rib-pillar-free continuous sublevel filling method suitable for medium-thickness slope crushed ore bodies, which has a low mining preparation ratio, low loss and high efficiency and the extraction is safe.

Owner:CENT SOUTH UNIV +1

Slotting induced-flow pressure-relief anti-reflection method for complicated seam

ActiveCN102966372AAchieving safe miningImprove extraction efficiencyFluid removalGas removalSocial benefitsDesorption

A slotting induced-flow pressure-relief anti-reflection method for a complicated seam is suitable for gas control of high-gas high-ground-stress complicated seam regions, can improve the gas permeability and gas desorption rate of coal, solves the difficult problems of low exhausting and mining efficiencies of coal-bed gas, high drilling construction load and the like, and realizes efficient gas exhausting and mining as well as fast outburst elimination of the complicated seam. High-pressure water is jetted into drilled holes to cut and destroy the coal in a rotary manner, and the coal in the radial direction of the drilled holes is destroyed and disturbed, so that buckling failures of the coal are induced and the coal and the gas are enabled to be spouted out of the drilled holes, as a result, the gas expansion energy of the coal is released, coal cracks are expanded and the exposure surface area of the coal is increased. therefore, the gas exhausting and mining efficiencies of coal are improved, coal and gas burst risks are eliminated, the effective influence range of drilling gas exhausting and mining is improved by 1-3 times, the air permeability coefficient of coal around the drilled holes is improved by 100-200 times, the drilling methane gas exhausting and mining quantity is improved by 2-5 times within hundreds of meters, and the outburst elimination time of the coal bed is shortened by 30-50 percent. The slotting induced-flow pressure-relief anti-reflection method for the complicated seam has very good field application value and social benefits.

Owner:CHINA UNIV OF MINING & TECH

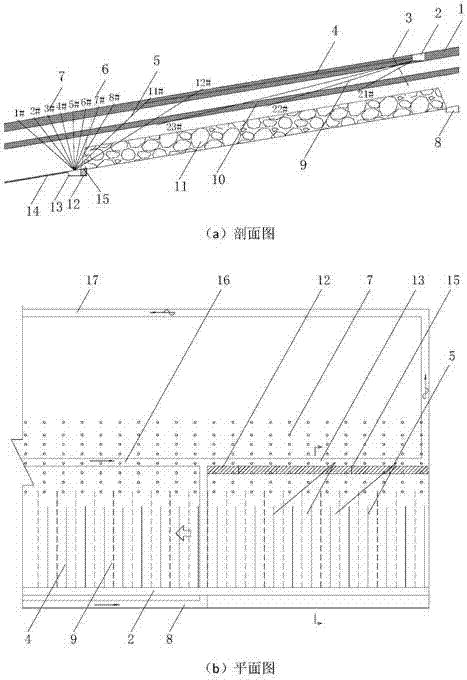

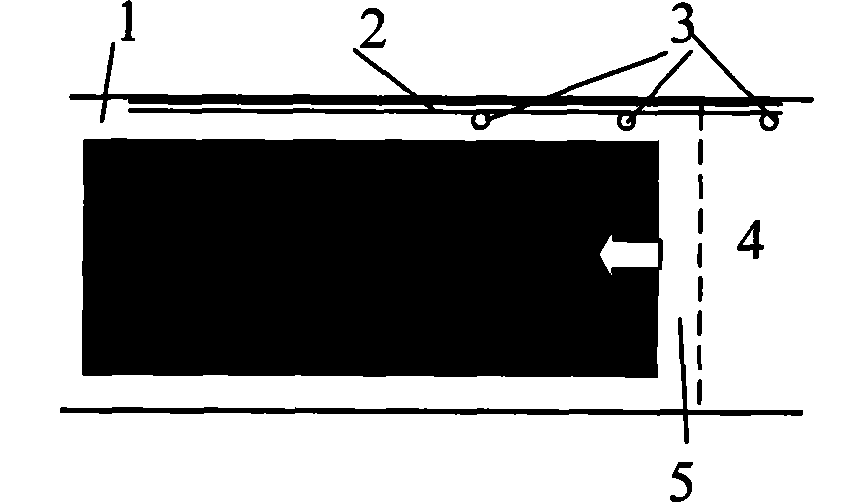

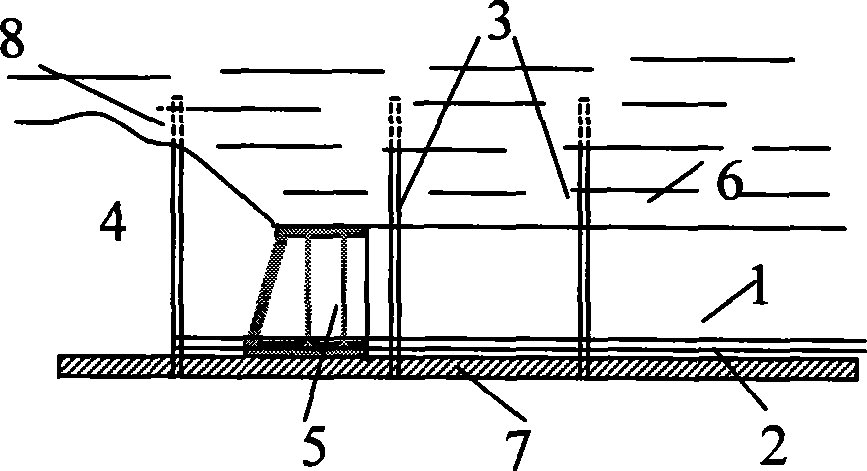

Gas treatment method of rock protection layer working face under near-distance hard roof

ActiveCN106223998APrevent overrunningEliminate outstanding hazardsGas removalEngineeringProtection layer

The invention discloses a gas treatment method of a rock protection layer working face under a near-distance hard roof. When protective seam mining conditions do not exist, weak mudstone of a proper position of an outburst coal seam bottom plate serves as a protective layer, Y-type downward ventilation is adopted on the mudstone working face, and gas of a protected layer and a goaf area is extracted by means of protected layer coal roadways, bedding drilled holes, downward seam penetrating drilled holes, upward seam penetrating drilled holes and hysteretic drilled holes of a mudstone working face roadway, goaf area pipe laying and other modes. The bedding drilled holes and the seam penetrating drilled holes below the bedding drilled holes and adjacent to an outburst coal seam are formed in the pre-constructed coal roadways, and gas of a pressure release seam in an upper section area of the protected area of the mudstone working face is extracted. Pressure release gas of a lower section area corresponding to the protected seam is extracted by means of the hysteretic drilled holes of the mudstone working face, and two hysteretic seam penetrating holes facing the working face are formed in every construction place. Pipes are laid along the top of an abandoned roadway filling wall to extract and control gas in the goaf area. The protected layer coal roadways seal the roadway section by section to extract gas.

Owner:ANHUI UNIV OF SCI & TECH

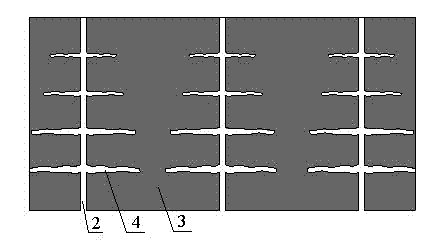

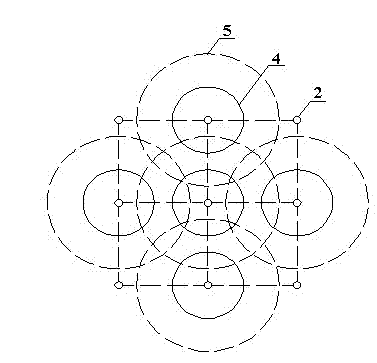

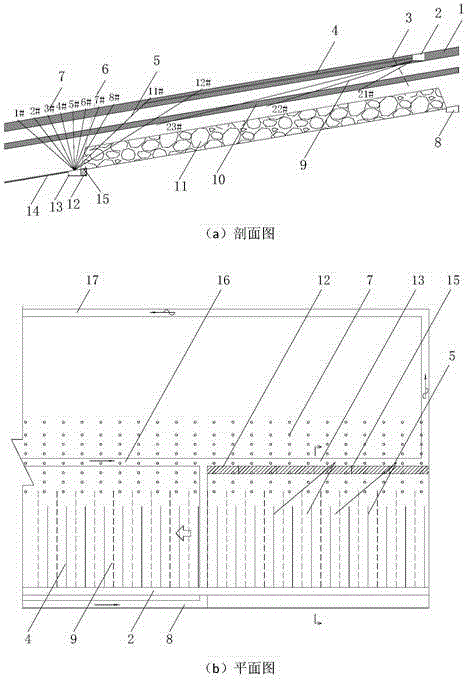

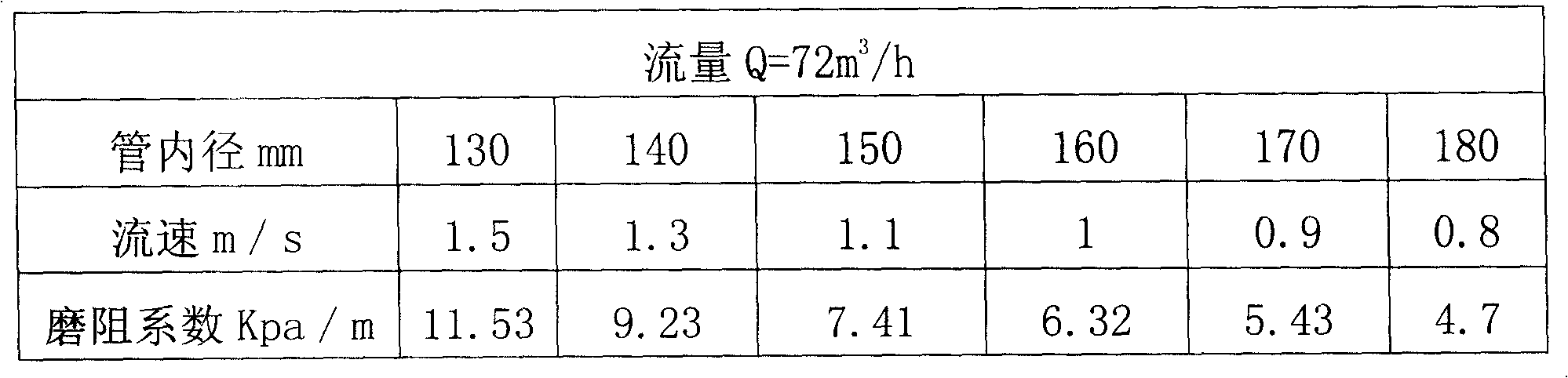

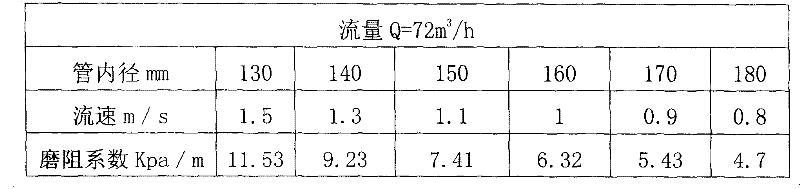

Coal mine consolidated fill technical skill

The invention discloses a coal mine consolidated fill technical skill; the filling material formulation of which is as follows according to the weight percentage: skeletal material: 15-30% of coal tailing coal gangue and / or 15-30% of industrial slag, coarse waste: 10-20% of poor-quality sand discarded by construction trades and / riversand, fine stuff: 25-35% of lime sludge with more than 10% of sandy soil and calcium oxide and / or fly ash; the fill slurry concentration of the filling material processed by batching, watering and stirring is controlled to be 50-85%; the fill slurry is conveyed into a goaf operation surface by an industrial filling pump and a pipeline for filling. The technical skill implements the consolidated fill on an underground dead area, controls underground water burst problem, increases safe coefficient of production, furthest liberates the pressed coal amount, increases recovery ratio, controls ground surface sedimentation, protects environment and ground surface vegetation, prolongs the mining age limit of the mine, and increases the industrial economic benefits.

Owner:赤峰西拉沐沦(集团)公格营子煤业有限公司

Three-dimensional source separated pressure-releasing gas treatment method

The invention discloses a three-dimensional source separated pressure-releasing gas treatment method. The method comprises the following steps of: constructing a gas drainage roadway which is parallel to the return air roadway of a coal face on the outer side of the return air roadway; constructing an elevation borehole from the gas drainage roadway to the direction of a roof crack zone of a maiden area which is positioned in front of the open-off cut of the coal face until the roof crack zone is passed through, constructing a depression borehole which passes through a protected layer to the direction of a bottom crack zone until the bottom crack zone is passed through, and connecting the constructed boreholes with gas drainage pipelines for gas drainage; along with the constant development of the coal face, continually constructing gob boreholes from the gas drainage roadway to a gob which is positioned in the back of the open-off cut of the coal face, and connecting the gas drainage pipelines for the gas drainage until the recovery of the coal face is finished. By draining the gas which is discharged in the pressure releasing process of the protected layer from the elevation borehole on the top of the roadway to the depression borehole at the bottom of the roadway, a separation function is realized, pressure-released gas is prevented from flowing into a protective layer working face, a great amount of air flow is prevented from carrying the gas from the gob to an upper corner, and the gas emission amount of the upper corner is reduced.

Owner:CHINA UNIV OF MINING & TECH +1

Long standpipe gas extraction in worked-out section

InactiveCN101029574AIncrease extraction concentrationThe extraction concentration is reducedUnderground miningSurface miningEngineeringGas concentration

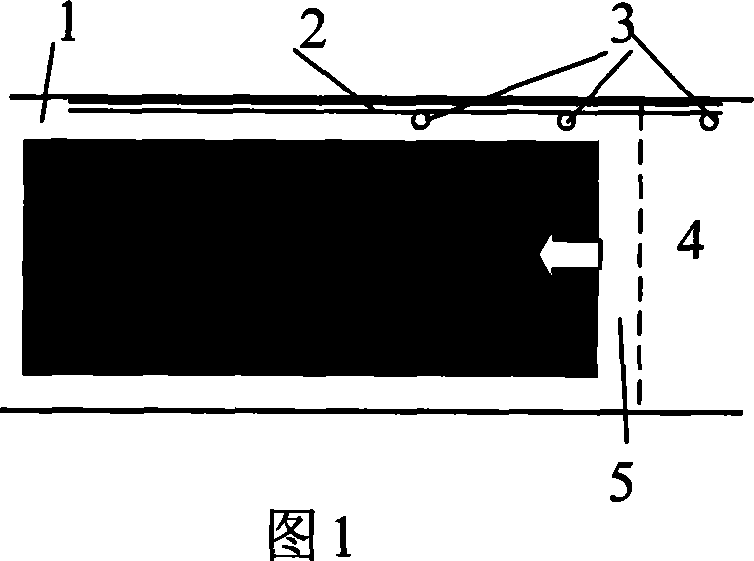

This is a gas extraction method via a long vertical pipe at goaf zone. Two holes are made on the top and bottom board of the air gallery at the working face. Sectional metal pipes are linked together to form a long vertical pipe, with the top sealed and inserted into the hole on the top board, and the bottom inserted into the bottom board and concreted. Small holes distributes on the pipe wall and been wrapped with pack. The pipe is connected to the extraction network. With 5m of the pipe getting into the goaf zone, start extraction; with the previous pipe getting into the goaf zone at 30m, and the following one at 5m, shut the previous pipe and open the following one. So realize a continuous extraction and decrease the gas concentration at the solid angle. The gas concentration could be controlled under 0.6%.

Owner:淮北矿业股份有限公司祁南煤矿 +1

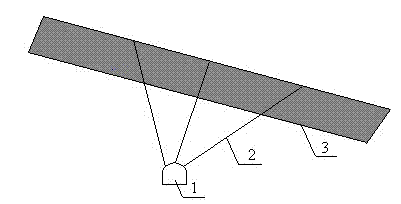

Sub-level shrinkage caving method

InactiveCN104481543ASolve construction difficultiesSolve the costUnderground miningSurface miningMineralogyGround pressure

The invention relates to a sub-level shrinkage caving method. According to the sub-level shrinkage caving method, no large-area mined-out space appears in an extraction process, a hanging wall rock is supported by utilizing a caved ore in the early stage of extraction, and an upper overburden rock downwards moves to fill a mined-out space to control ground pressure along with bottom ore removal in the later stage of the extraction, so that safe and high-efficiency extraction is achieved; ores are aggregated in a bottom trench in a bottom structure, and the bottom trench is connected with a travelling roadway by adopting a herringbone non-track ore loading feed path, so that the sub-level ore removal is realized; when undercutting work is carried out, only a part of caved ores are discharged, fragmented rock mass in an ore block keeps that the hanging wall rock is not collapsed and ensures that a sufficient free compensating space is enough for upper ore dropping, the dropped ore is discharged from the non-track ore loading feed path, and then is put into a mine car to leave from a stope, then ore dropping is carried out again, the process is circulated till the ores contained in the ore block all drop in a blasting way, and finally large-scale ore removal is carried out; and the overburden rock continuously moves downwards to fill a mining area to control the ground pressure along with the continuous extraction of the ores during the large-scale ore removal.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

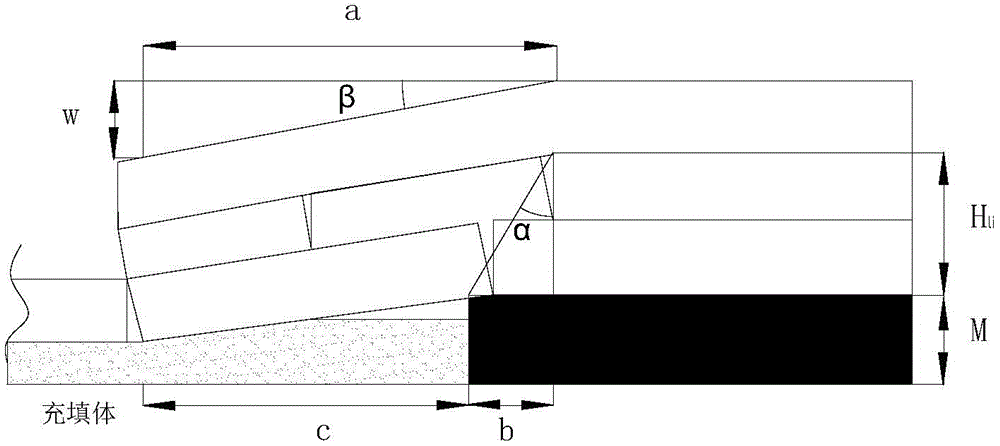

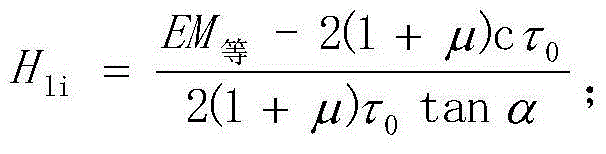

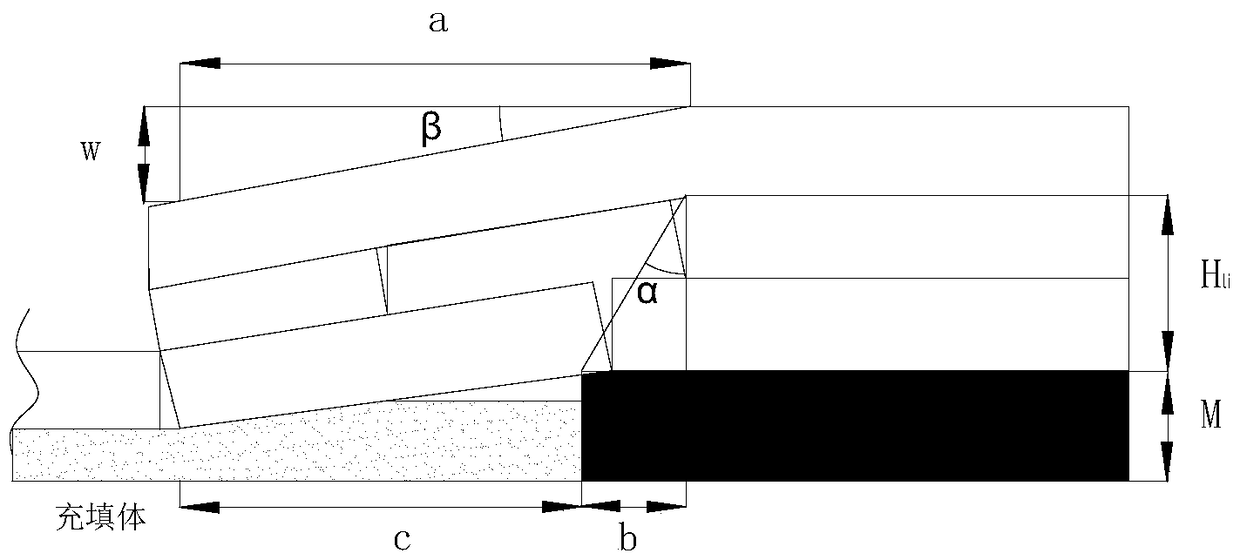

Method for predicting maximum height of filling mining diversion fissure zone

The invention discloses a method for predicting maximum height of a filling mining diversion fissure zone. Supposing a precondition that no caving zone is generated and only a fissure zone and a sagging zone are generated in the advancing process of a working face, a mathematical model which is used for predicting the maximal height of the filling mining diversion fissure zone; a critical value of top board deformation is used for determining the strata failure low of an over-limit stress limited space; and whether the strata fails is determined according to the critical value of the top board deformation. Therefore, compared with the prior art, the method has advantages of more direct calculation and higher convenience. A calculation formula for predicting the maximum height of the filling mining diversion fissure zone can be simply and accurately obtained. Furthermore the parameters in the formula can be easily acquired, and higher accuracy of the calculation process can be realized. Simple and direct calculation can be obtained. The method can quickly, effectively and accurately predict the maximum height of the diversion fissure zone and is suitable for guidance for actual production, thereby realizing safe mining under water body.

Owner:SHANDONG UNIV OF SCI & TECH

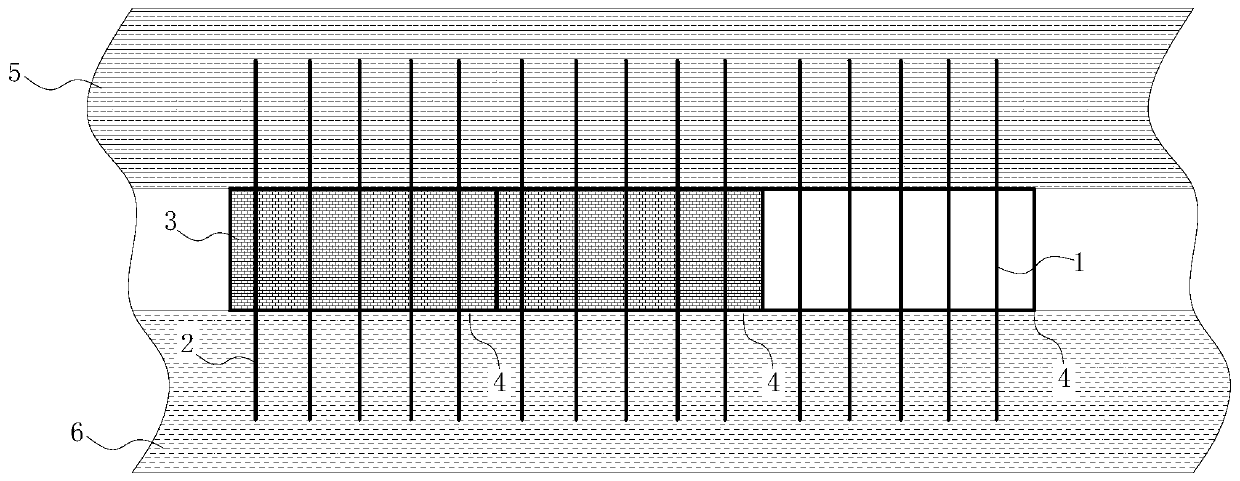

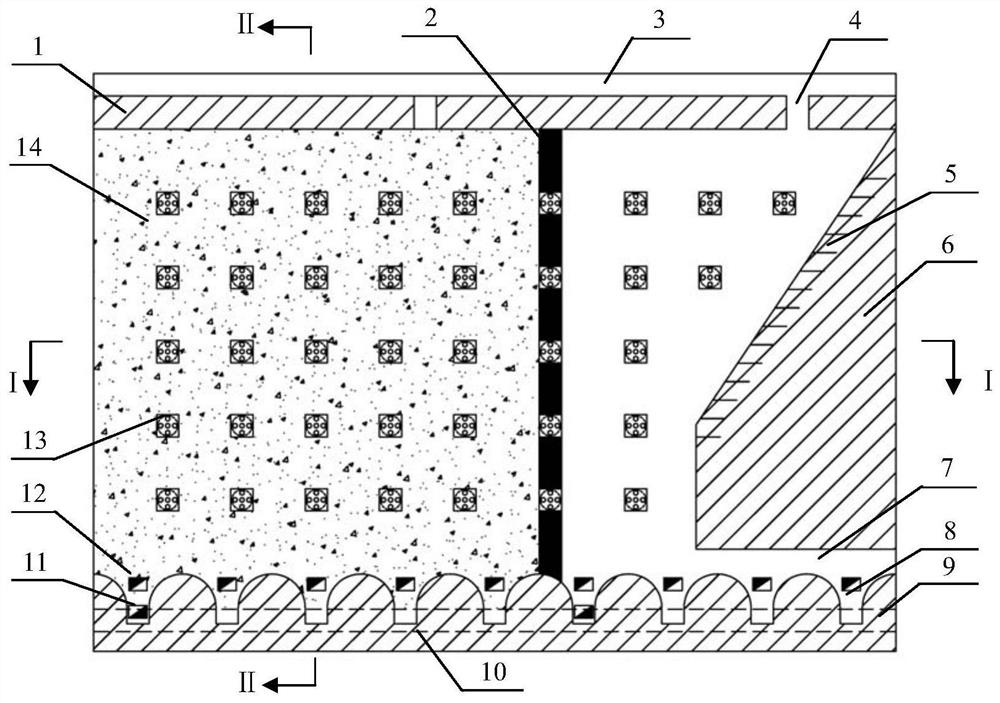

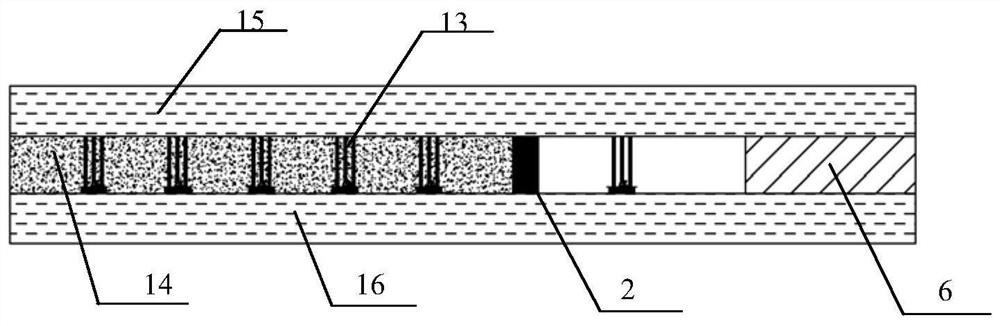

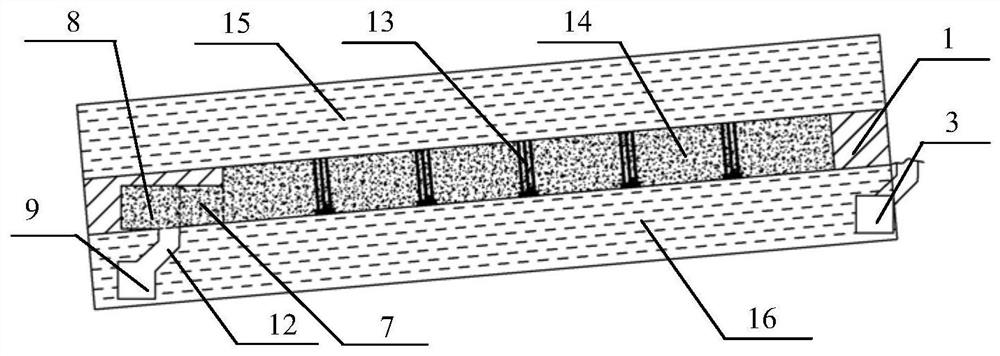

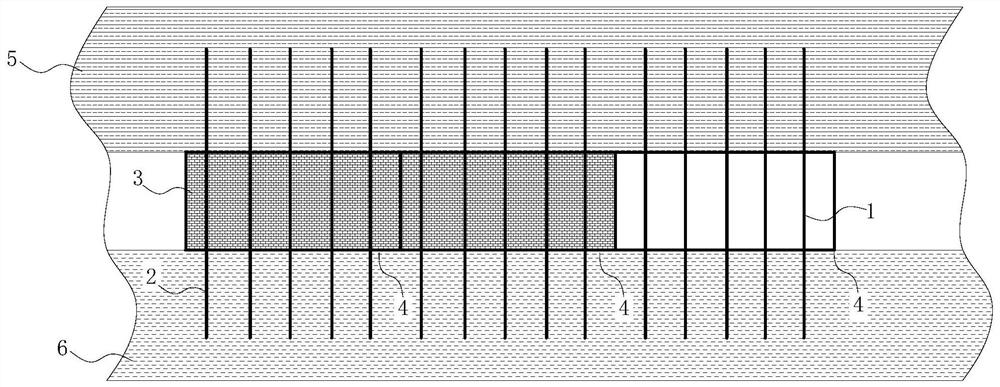

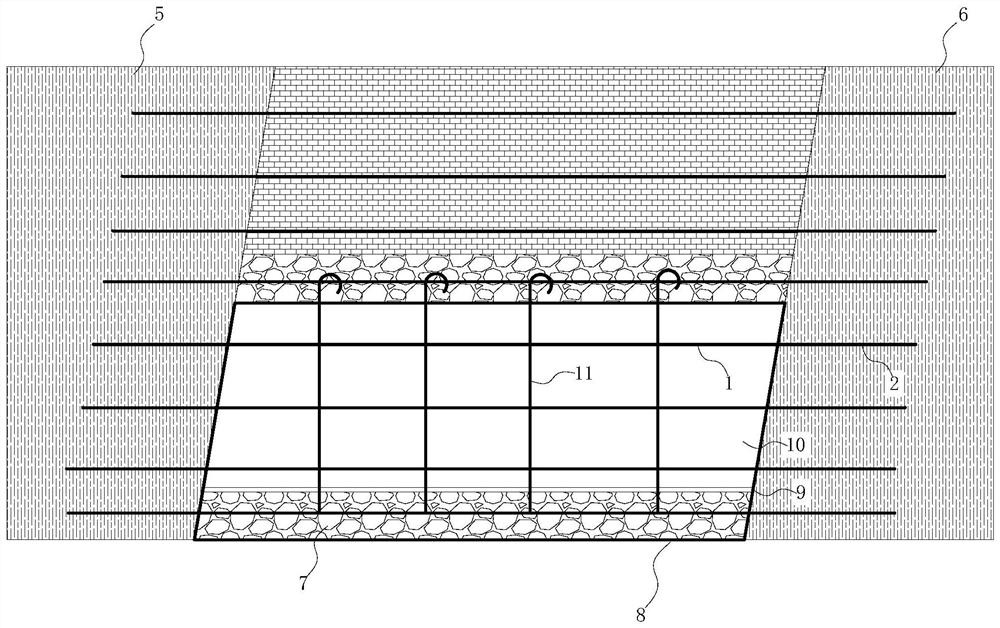

Studding-free method of maintaining stability of filled mat of downward single access

ActiveCN111456735AReduce lossesGuarantee mining safetyUnderground chambersUnderground miningMining engineeringPre stress

The invention provides a studding-free method of maintaining stability of a filled mat of a downward single access and relates to the technical field of mining engineering. The method comprises the following steps of recovering a stope room by using a downward access layered segment-free roadway filling mining method and carrying out manual flat fielding immediately after layering the recovered stope room; constructing an ultra-long pre-stressed anchor rod to surrounding rocks of upper and lower discs vertical to an ore body and carrying out supporting in an anchoring-screening-spraying way; welding and fixing an exposed end of the anchor rod close to a bottom plate, and paving a crushed ore cushion and an isolating layer; suspending a longitudinal bar of a bar-mat reinforcement to a reinforcing steel bar hook reserved in a previous branched layer and welding the lower end of the longitudinal bar to a horizontal reinforcing steel bar at the bottom of the branched layer; carrying out cemented filling to a goaf, and recovering a lower branched layer after a filling body is stabilized till recovering all the branched layers; and repeating the steps till recovering all stope rooms. Themethod maintains the stability of the filled mat by means of the ultra-long anchor rod in the surrounding rocks of the upper and lower discs and the longitude and latitude bar-mat reinforcement in the goaf and studdings are not reserved, so that the loss of ores is reduced.

Owner:SHANDONG UNIV OF SCI & TECH

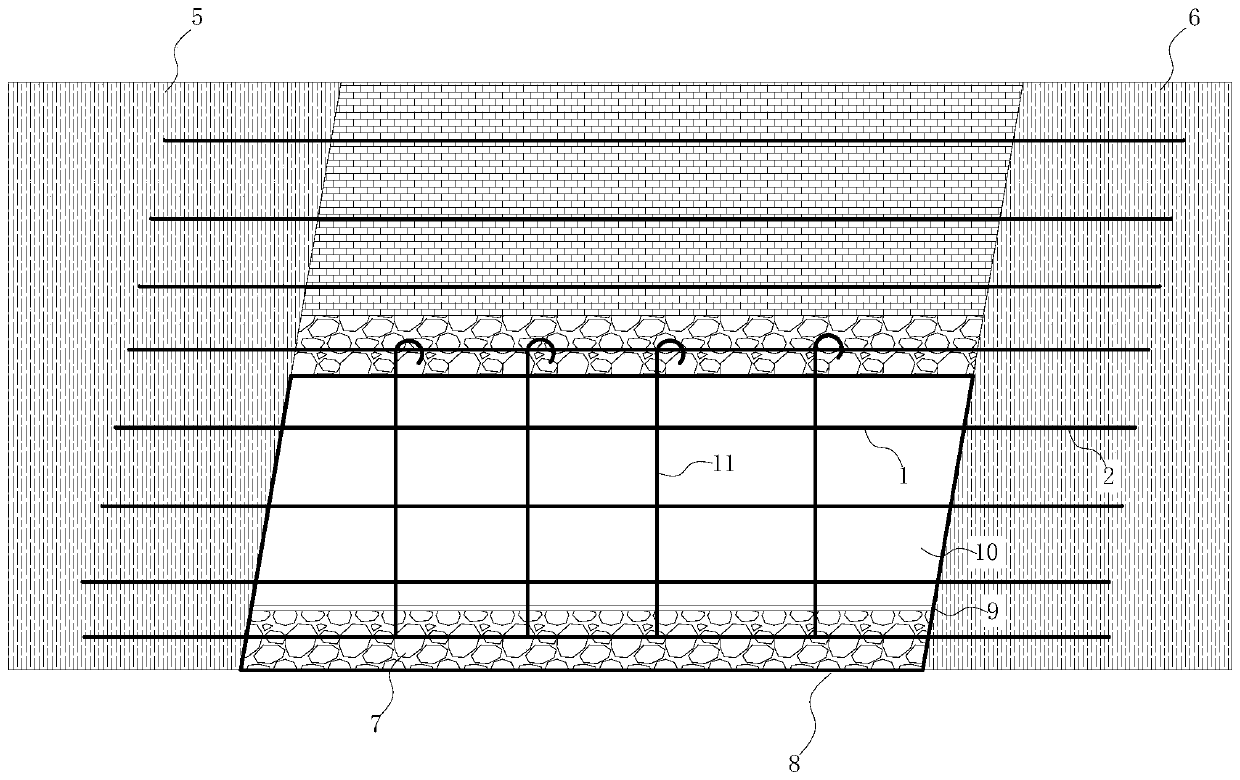

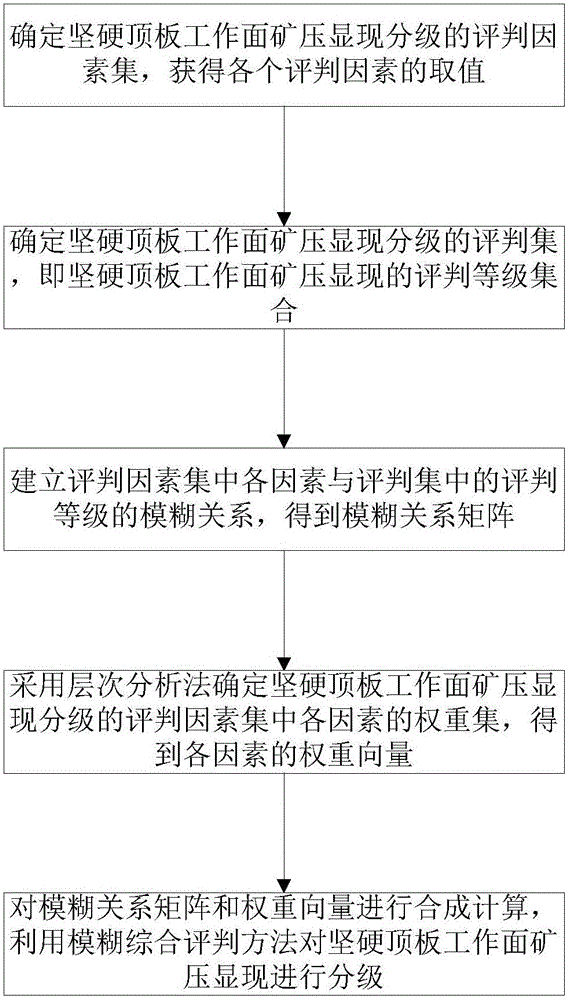

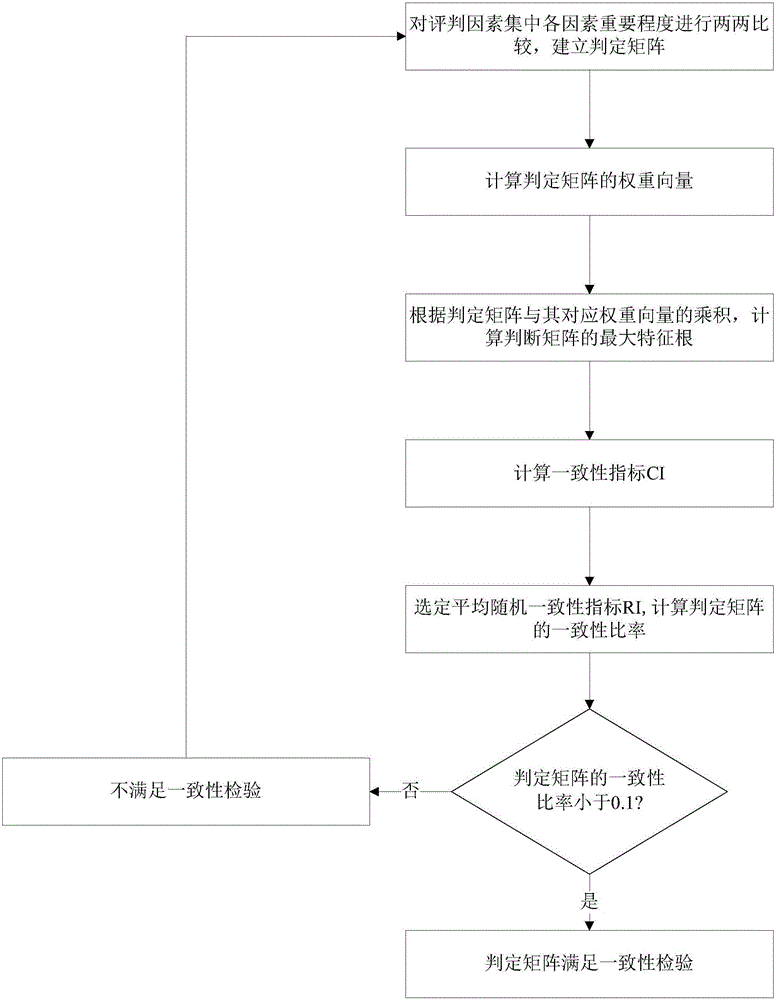

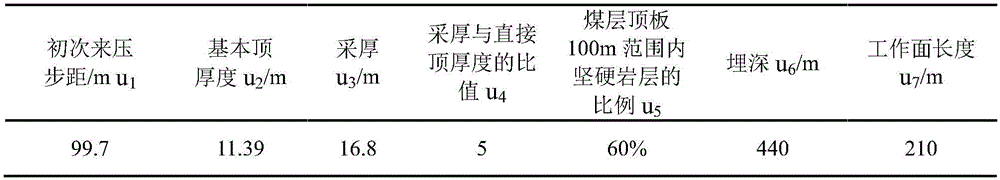

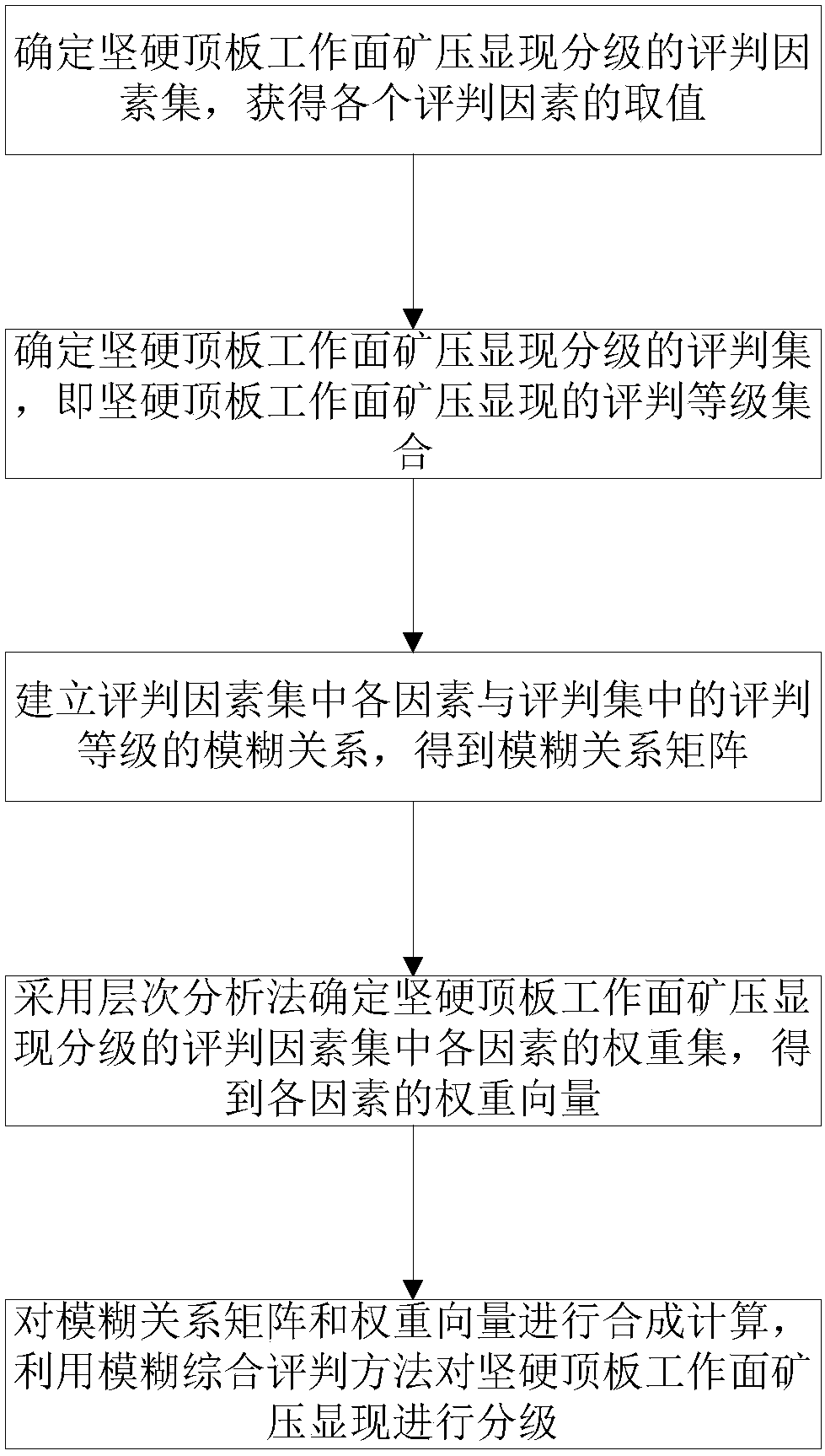

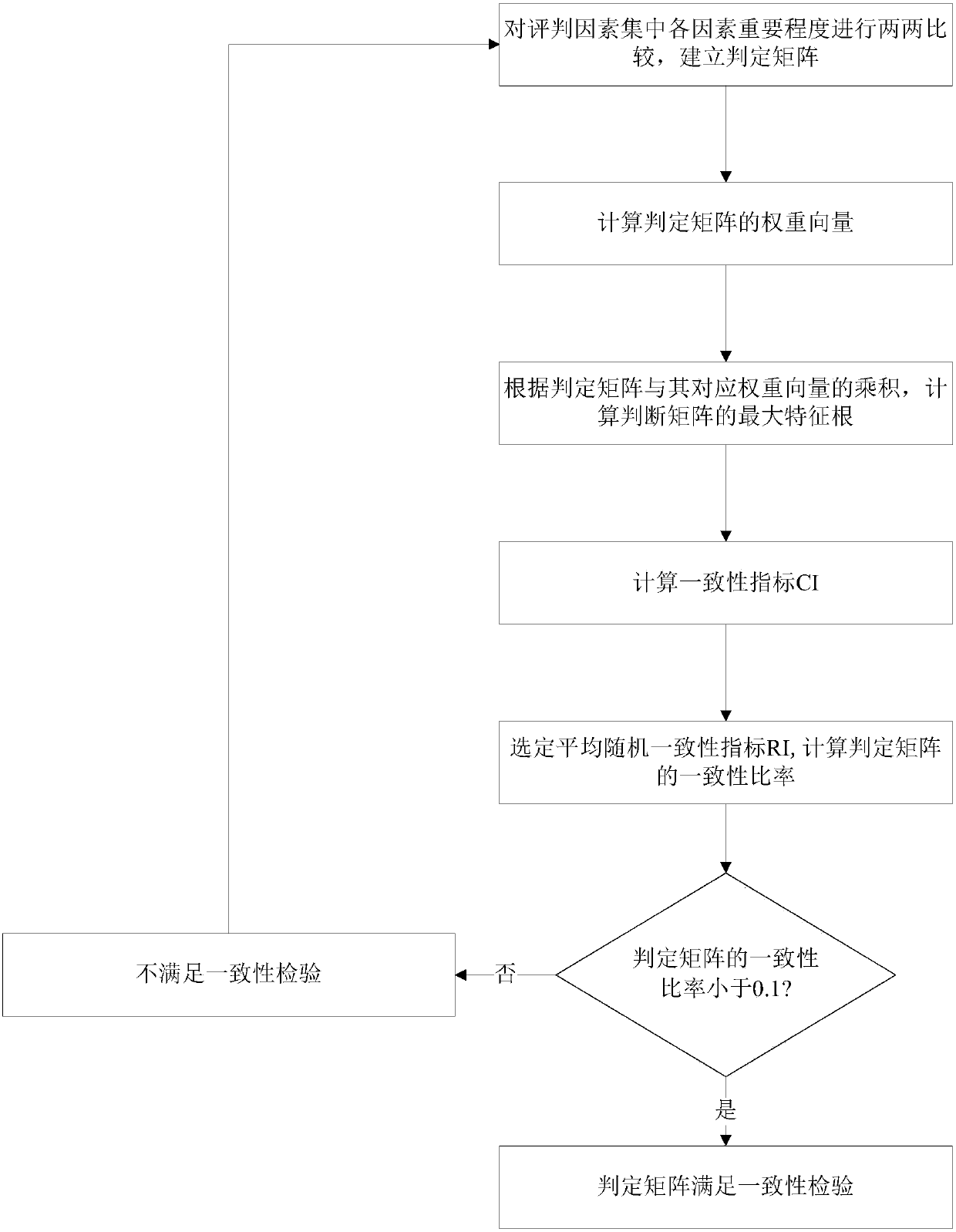

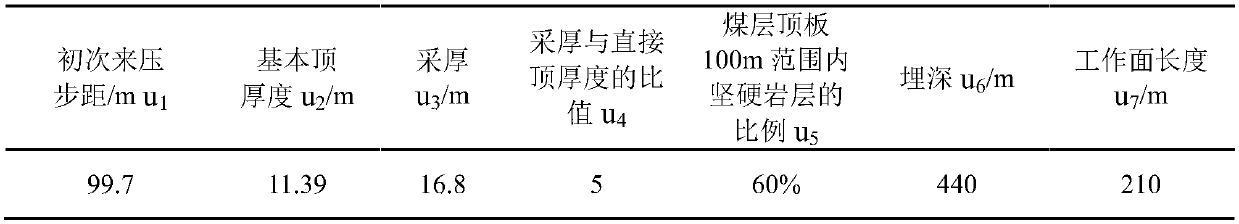

Hard roof working face strata pressure behavior classification method

The invention provides a hard roof working face strata pressure behavior classification method. The hard roof working face strata pressure behavior classification method comprises the steps that an evaluation factor set of the hard roof working face strata pressure behavior classification is determined, and various evaluation factor values are obtained; an evaluation set of the hard roof working face strata pressure behavior classification is determined, namely the evaluation grade set of the hard roof working face strata pressure behaviors; fuzzy relations between all factors in the evaluation factor set and the evaluation grades in the evaluation set are built to obtain a fuzzy relation matrix; a weight set of each factor in the evaluation factor set of the hard roof working face strata pressure behavior classification is determined to obtain a weight vector of the factor; and the fuzzy relation matrix and the weight vectors are subjected to composite calculation, and the hard roof working face strata pressure behaviors are classified. According to the mechanics properties and inherent conditions of a hard roof, the working face strata pressure behavior intensity is classified, effective prediction of the working face strata pressure behavior intensity under the condition of the hard roof is achieved, a support scheme of a working face and a mining roadway is adopted in a targeted mode, and safe mining of the working face is achieved.

Owner:LIAONING TECHNICAL UNIVERSITY

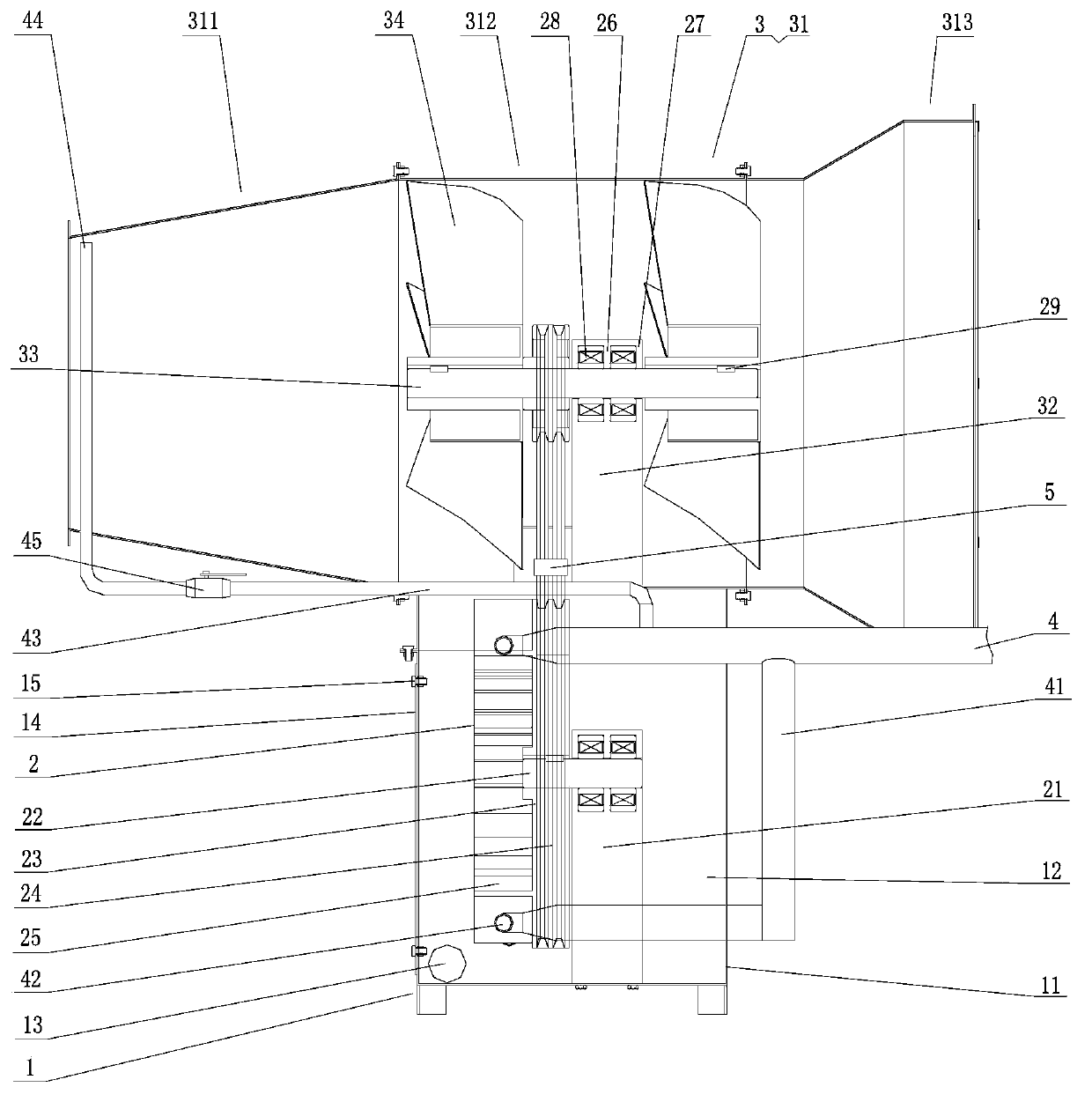

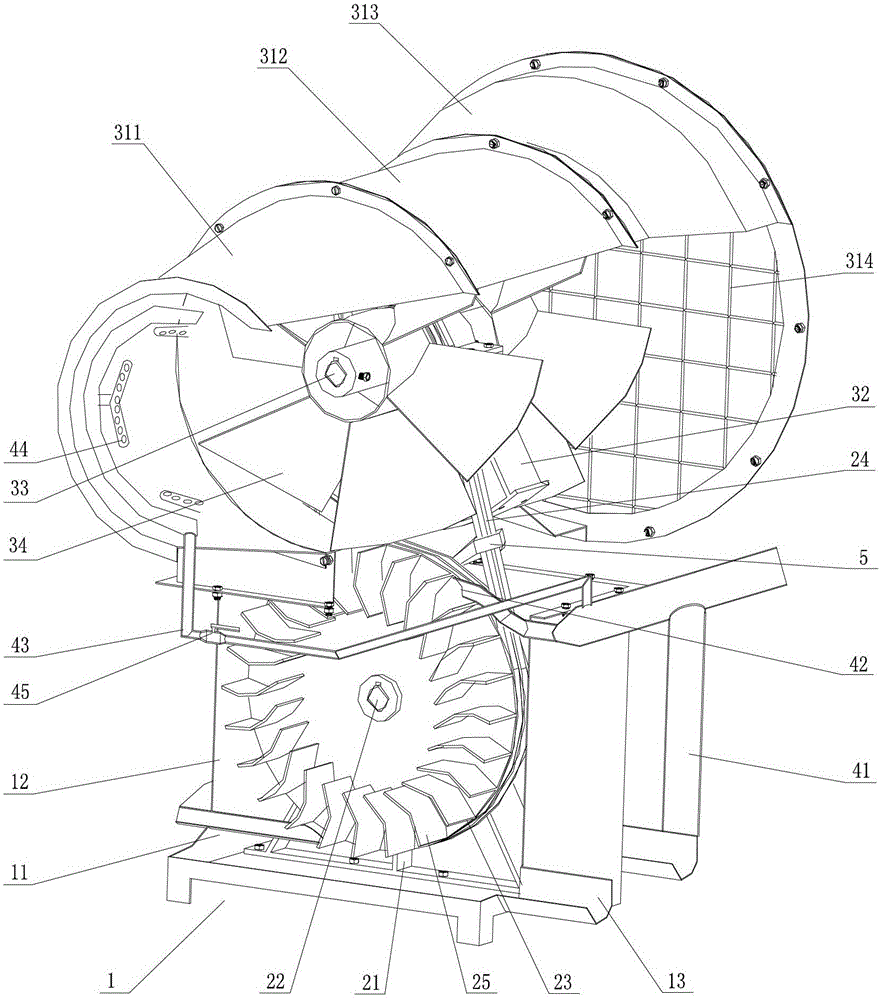

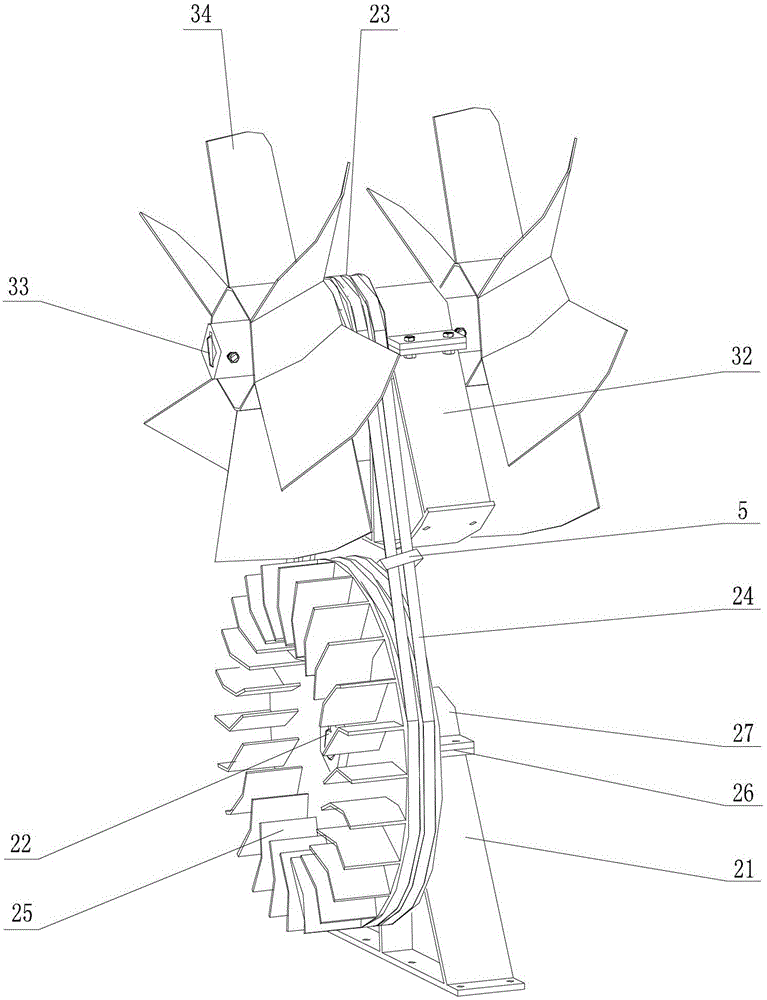

Spraying environment-friendly energy-saving anti-explosion fan based on shaft sump water source

ActiveCN103362832AAvoid security issuesSave money on energy consumptionDust removalFire preventionWater wheelWater source

A spraying environment-friendly energy-saving anti-explosion fan based on a shaft sump water source comprises a water tank substrate; a water wheel device is arranged on the water tank substrate and is connected with a wind wheel device by a belt; a high-pressure water spraying device is connected with the water wheel device and the wind wheel device; the technical scheme of taking the shaft sump water source as a power source and combining the functions of wind feeding and spraying of a high-pressure water spraying device, the water wheel device and the wind wheel device is adopted; the defects of high frequency of gas and coal dust explosion caused by electric sparks of a motor, high investment cost, complete demand on the system auxiliary project, large machine noise, poor radiating performance, short service life, low production efficiency, severe production labor environment, easily caused occupational diseases of operation staff and severe coal source waste of the existing coal-mining equipment used for the high-gas shaft are overcome; and the spraying environment-friendly energy-saving anti-explosion fan based on the shaft sump water source is suitable for various ventilation equipment for mine excavation, particularly the ventilation equipment for excavation of the high-gas protruded shaft coal layer.

Owner:永州市亿达自动化机械有限公司

Fluidized cooperative mining method for deep mine geothermal energy and coal resources

ActiveCN111997612AAchieve source assuranceEfficient cycle developmentUnderground miningGeothermal energy generationMining engineeringThermal water

The invention discloses a fluidized cooperative mining method for deep mine geothermal energy and coal resources. The fluidized cooperative mining method comprises the following steps of adopting a deep in-situ unmanned intelligent shield tunneling machine to perform coal resource excavating operation, and transmitting excavated pulverized coal to the ground through a spiral conveyor and a pipeline system in a fluidized mode; adopting partial extraction methods such as a strip belt type extraction method and a room column type extraction method, utilizing the deep in-situ unmanned intelligentshield tunneling machine to mine a thin coal line adjacent to a coal bed or a relatively weak geothermal energy reservoir, and constructing a geothermal energy storage space; adding cementing materials such as coal ash and cement into rock powder of the mined geothermal energy reservoir to obtain a mixture, transmitting the mixture to a worked-out section of a coal bed working face to perform filling operation through a pumping pipeline in the fluidized mode; after the geothermal energy storage space is constructed, paving a cold water re-filling and hot water extracting pipeline, and constructing an area isolating partition wall, thereby forming a geothermal energy circulatory mining system and achieving the fluidized cooperative mining purpose of deep mine geothermal energy and coal resources. The fluidized cooperative mining method can realize fluidized comprehensive development of deep mine resources, and has a wide application prospect.

Owner:CHINA UNIV OF MINING & TECH

Method for preventing and treating rock burst during exploiting of working face in fault zone

InactiveCN106401588AReduce workloadReduce manufacturing costUnderground miningSurface miningRock burstCoal

The invention discloses a method for preventing and treating rock burst during exploiting of a working face in a fault zone. The method includes the steps that after a mining area roadway is constructed and before the working face is exploited, the two sides of the fault zone in the mining area roadway are each provided with a row of energy release holes towards coal seams within the scopes 100 m away from fault surfaces; when the working face is advanced to the starting positions of the energy release holes, exploiting needs to be stopped if it is found that impact risks still exist between the energy release holes, a row of pressure release blastholes is constructed towards each coal seam along the mining area roadway, energy is released again after detonation, and therefore risks of the rock burst of the fault zone are accordingly eliminated, and the working face can safely pass through the fault zone. According to the method, as for the fault zone and a deep rock burst mine, safe exploiting of the fault zone can be achieved; and pressure release is achieved through two steps according to the conditions, the workload is reduced, and the production cost is saved.

Owner:SHANDONG UNIV OF SCI & TECH

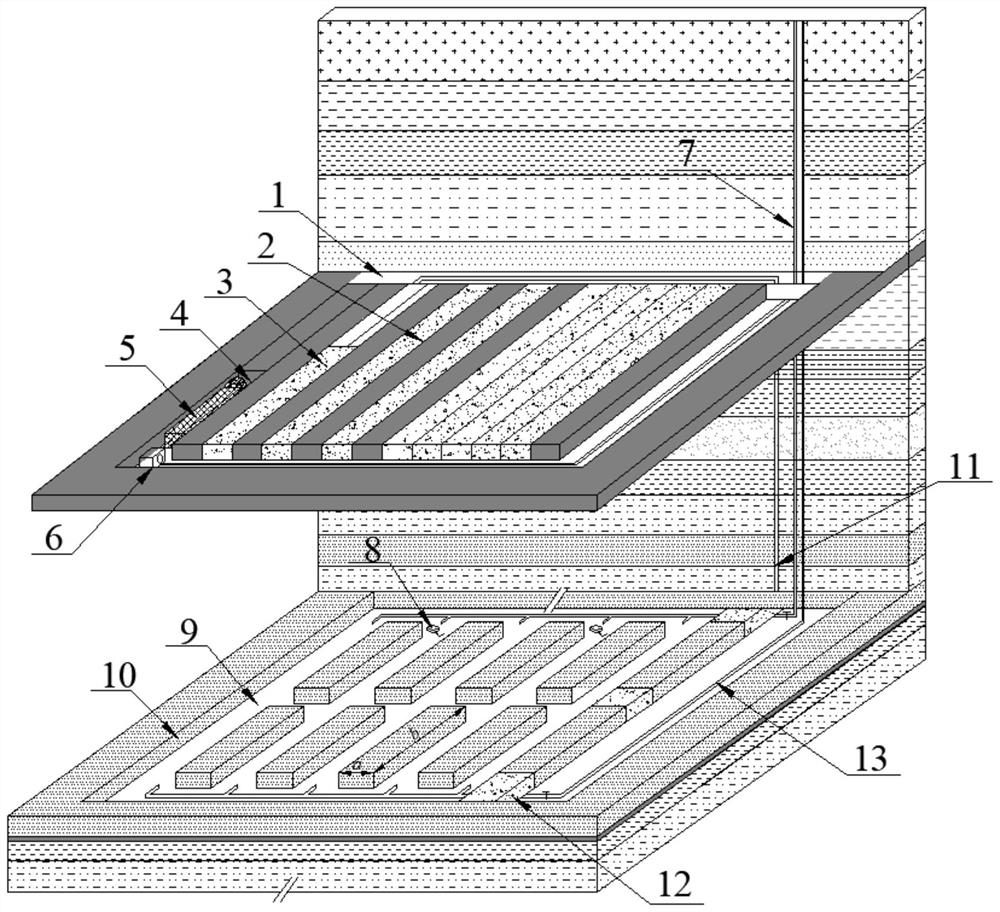

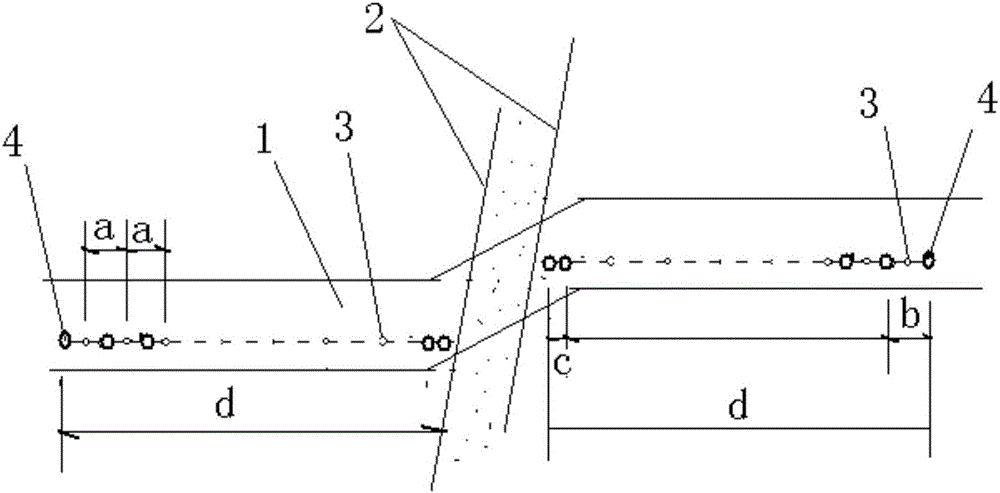

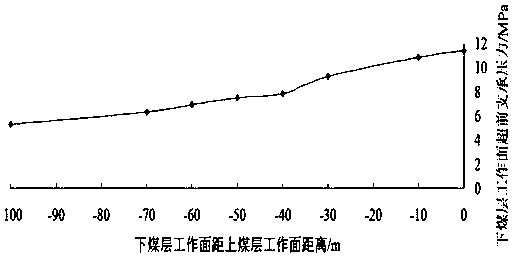

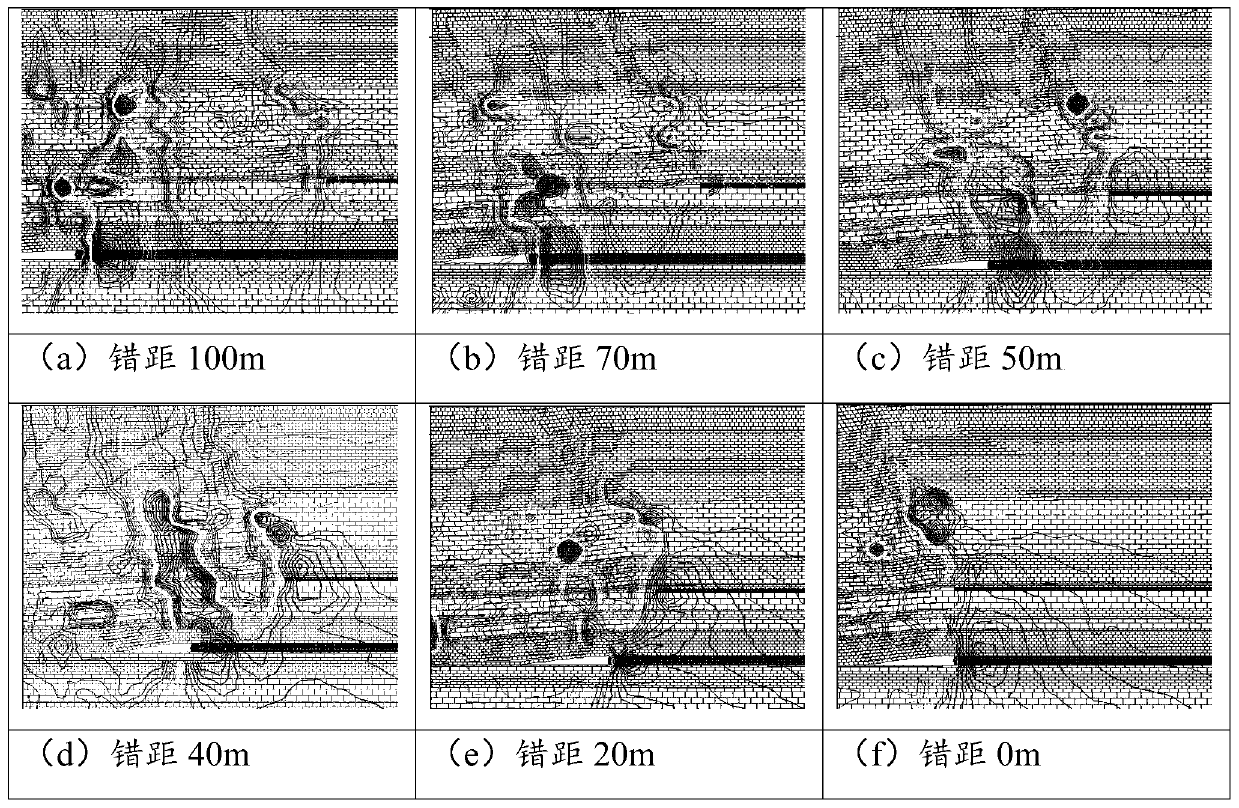

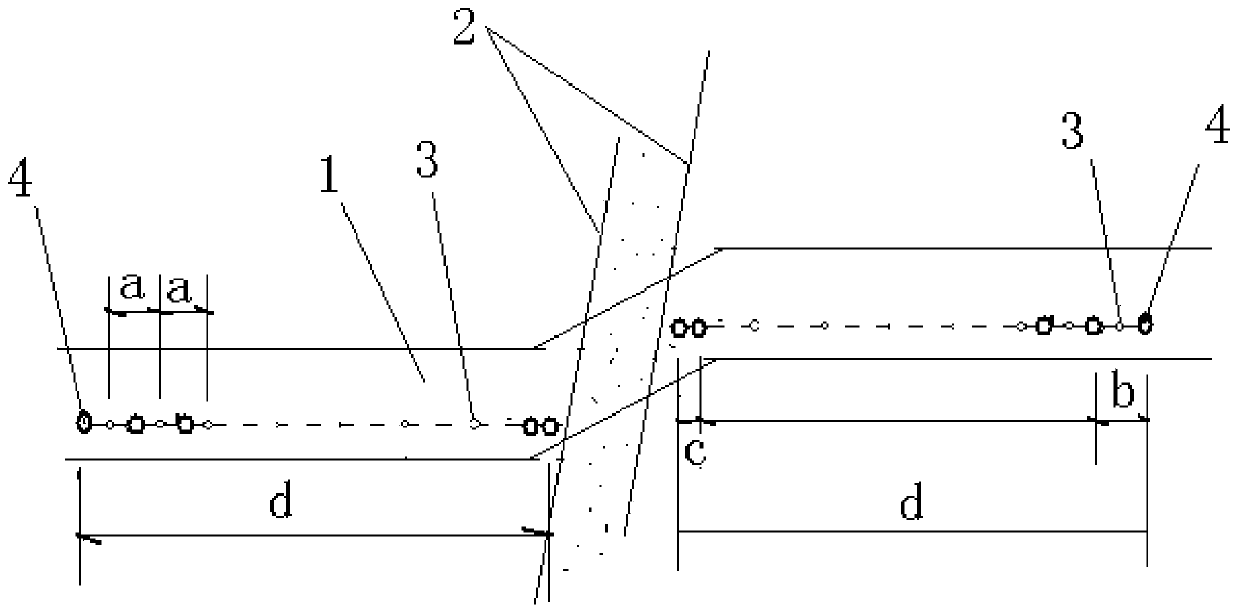

Method for determining staggered distance between dual coal seam upper-lower simultaneous mining working faces in propelling direction

InactiveCN110630268AEnsure safetyAchieving safe miningUnderground miningSurface miningMechanical modelsMaximum depth

The invention provides a method for determining the staggered distance between dual coal seam upper-lower simultaneous mining working faces in the propelling direction, and belongs to the technical field of coal mining. The method comprises the steps that the ideal staggered distance range is found out and obtained; according to the ideal staggered distance range, an ultimate bearing capacity computational formula during plastic slip of rock and soil is utilized to obtain a computational formula of the maximum depth H<max> of an upper coal seam bottom plate destruction region under the ultimate bearing pressure condition, and thus a computational formula of the maximum horizontal distance L<max> of an upper coal seam bottom plate broken rock stratum is obtained; a pressure-stabilizing mechanical model and a pressure-reducing mechanical model for the propelling direction of upper-lower coal seam working face simultaneous mining of dual coal seam mining are established, thus the maximumhorizontal distance of the upper coal seam bottom plate broken rock stratum, the bottom plate stress transfer angle and the spacing between an upper coal seam and a lower coal seam are obtained, and acomputational formula of the staggered distance in the pressure-stabilizing propelling direction and the pressure-reducing propelling direction is determined; and the computational result in the step3 is corrected. According to the method, the mine pressure strength of the lower coal seam working face and the earth surface damage degree during simultaneous mining of the dual coal seam superposition regions can be effectively lowered, and efficient and environment-friendly mining of the dual coal seams is achieved.

Owner:XIAN UNIV OF SCI & TECH

Double-trench flat-bottom mining method for ores difficult to mine

InactiveCN105525922AAchieving safe miningIncrease the mining area of the stopeUnderground miningSurface miningInlet channelCutoff grade

The invention provides a double-trench flat-bottom mining method for ores difficult to mine. The method includes the process steps that firstly, based on a sublevel caving method without sill pillars, three inlet channels are classified into one stoping unit, a transverse ore outlet channel is made from the middle inlet channel to the inlet channels on the two sides, and a bottom structure for double-trench ore falling and flat-bottom ore discharging is formed; secondly, in the stoping process, just like the inlet channels conducted through the sublevel caving method without sill pillars, for the trenches in the two sides, row-by-row blast hole blasting is conducted for mining retract, the ores do not stop being discharged until a driver of a scooptram does not enter an open stope and the ores cannot be discharged, and the caved ores which fall into the open stope and the ores which fall after roof hanging are discharged through the transverse ore outlet channel; thirdly, stoping is conducted at the two trenches at the same time, and the continuous mined-out area span is formed and exceeds the critical falling span of the hanging roof ores and roof surrounding rock, so that the roof surrounding rock falls naturally along with falling of the ores, and a covering layer is formed; and fourthly, the ores stop being discharged after the ores discharged from the transverse ore outlet channel reach the cutoff grade, an ore outlet roadway is formed through row-by-row caving in an inlet channel mining retract manner according to the sublevel caving method without sill pillars, and ridge residual bodies are recovered.

Owner:五矿邯邢矿业有限公司西石门铁矿

Three-dimensional source separated pressure-releasing gas treatment method

The invention discloses a three-dimensional source separated pressure-releasing gas treatment method. The method comprises the following steps of: constructing a gas drainage roadway which is parallel to the return air roadway of a coal face on the outer side of the return air roadway; constructing an elevation borehole from the gas drainage roadway to the direction of a roof crack zone of a maiden area which is positioned in front of the open-off cut of the coal face until the roof crack zone is passed through, constructing a depression borehole which passes through a protected layer to the direction of a bottom crack zone until the bottom crack zone is passed through, and connecting the constructed boreholes with gas drainage pipelines for gas drainage; along with the constant development of the coal face, continually constructing gob boreholes from the gas drainage roadway to a gob which is positioned in the back of the open-off cut of the coal face, and connecting the gas drainagepipelines for the gas drainage until the recovery of the coal face is finished. By draining the gas which is discharged in the pressure releasing process of the protected layer from the elevation borehole on the top of the roadway to the depression borehole at the bottom of the roadway, a separation function is realized, pressure-released gas is prevented from flowing into a protective layer working face, a great amount of air flow is prevented from carrying the gas from the gob to an upper corner, and the gas emission amount of the upper corner is reduced.

Owner:CHINA UNIV OF MINING & TECH +1

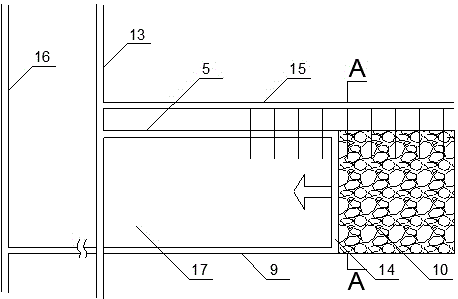

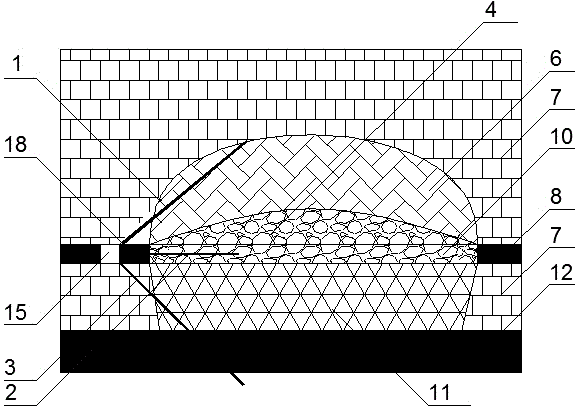

Deep gentle dip narrow vein ore-pillar-free continuous exploitation method

ActiveCN111852476AReduce lossesSolve the problem of not being able to support the stope roof for a long timeMining devicesUnderground miningInfraredMining engineering

A deep gentle dip narrow vein ore-pillar-free continuous exploitation method comprises the steps that a zoning band in the ore direction in a segment at a certain span is adopted as an extraction unit, and continuous exploitation is carried out from one side to the other side; a V-shaped work face is formed on the upper portion of the zoning band, and dip pushing is carried out from top to bottom;after exploitation of certain space, a prestress expansion strut supporting top plate is erected, a filling curtain is constructed on the boundary of the zoning band, and the goaf is filled with milltailings or low-strength cemented filler; and a pressure sensor, an infrared displacement monitor and a ground pressure deformation data collector are mounted through prestress expansion struts, and ground pressure evolution and top plate sinking of the stope are monitored. The method has the advantages that no studding or original rock pillar is left in the stope, and core losses can be reduced;the ground pressure of the area stope can be effectively controlled and balanced, and the work safety conditions are improved; by means of the V-shaped work face, the ore carrying workloads can be reduced; and ground pressure disaster precise early warning can be achieved.

Owner:NORTHEASTERN UNIV

A gas control method for working face of rock protective layer under close hard roof

ActiveCN106223998BPrevent overrunningEliminate outstanding hazardsGas removalEngineeringProtection layer

The invention discloses a gas treatment method of a rock protection layer working face under a near-distance hard roof. When protective seam mining conditions do not exist, weak mudstone of a proper position of an outburst coal seam bottom plate serves as a protective layer, Y-type downward ventilation is adopted on the mudstone working face, and gas of a protected layer and a goaf area is extracted by means of protected layer coal roadways, bedding drilled holes, downward seam penetrating drilled holes, upward seam penetrating drilled holes and hysteretic drilled holes of a mudstone working face roadway, goaf area pipe laying and other modes. The bedding drilled holes and the seam penetrating drilled holes below the bedding drilled holes and adjacent to an outburst coal seam are formed in the pre-constructed coal roadways, and gas of a pressure release seam in an upper section area of the protected area of the mudstone working face is extracted. Pressure release gas of a lower section area corresponding to the protected seam is extracted by means of the hysteretic drilled holes of the mudstone working face, and two hysteretic seam penetrating holes facing the working face are formed in every construction place. Pipes are laid along the top of an abandoned roadway filling wall to extract and control gas in the goaf area. The protected layer coal roadways seal the roadway section by section to extract gas.

Owner:ANHUI UNIV OF SCI & TECH

A collaborative mining method of geothermal energy and coal resources fluidization in deep mines

ActiveCN111997612BAchieve source assuranceEfficient cycle developmentUnderground miningGeothermal energy generationMining engineeringThermal water

The invention discloses a method for collaborative mining of geothermal energy and coal resources fluidization in deep mines, which includes adopting a deep in-situ unmanned intelligent shield machine for mining operations of coal resources, and the mined coal powder passes through a screw conveyor and a pipeline system Fluid transmission to the surface; partial mining methods such as strip type and room-and-pillar type are adopted, and deep in-situ unmanned intelligent shield machines are used to mine coal seams adjacent to thin coal lines or weaker geothermal energy reservoirs to build geothermal energy storage space After mining, the rock powder of the geothermal energy reservoir is added with cementing materials such as fly ash and cement, and is fluidized and transported to the goaf of the coal seam working face through the pumping pipeline system for filling operation; after the space of the geothermal energy reservoir is constructed, Lay cold water recharge and hot water extraction pipelines, build regional isolation retaining walls, and form a geothermal energy cycle mining system; thus achieving the purpose of fluidized coordinated mining of deep mine geothermal energy and coal resources. The invention can realize the fluidized comprehensive development of deep mine resources, and has wide application prospects.

Owner:CHINA UNIV OF MINING & TECH

Prevention and control method of rock burst during mining in working face in fault zone

InactiveCN106401588BAchieving safe miningReduce workloadUnderground miningSurface miningDetonationEngineering

Owner:SHANDONG UNIV OF SCI & TECH

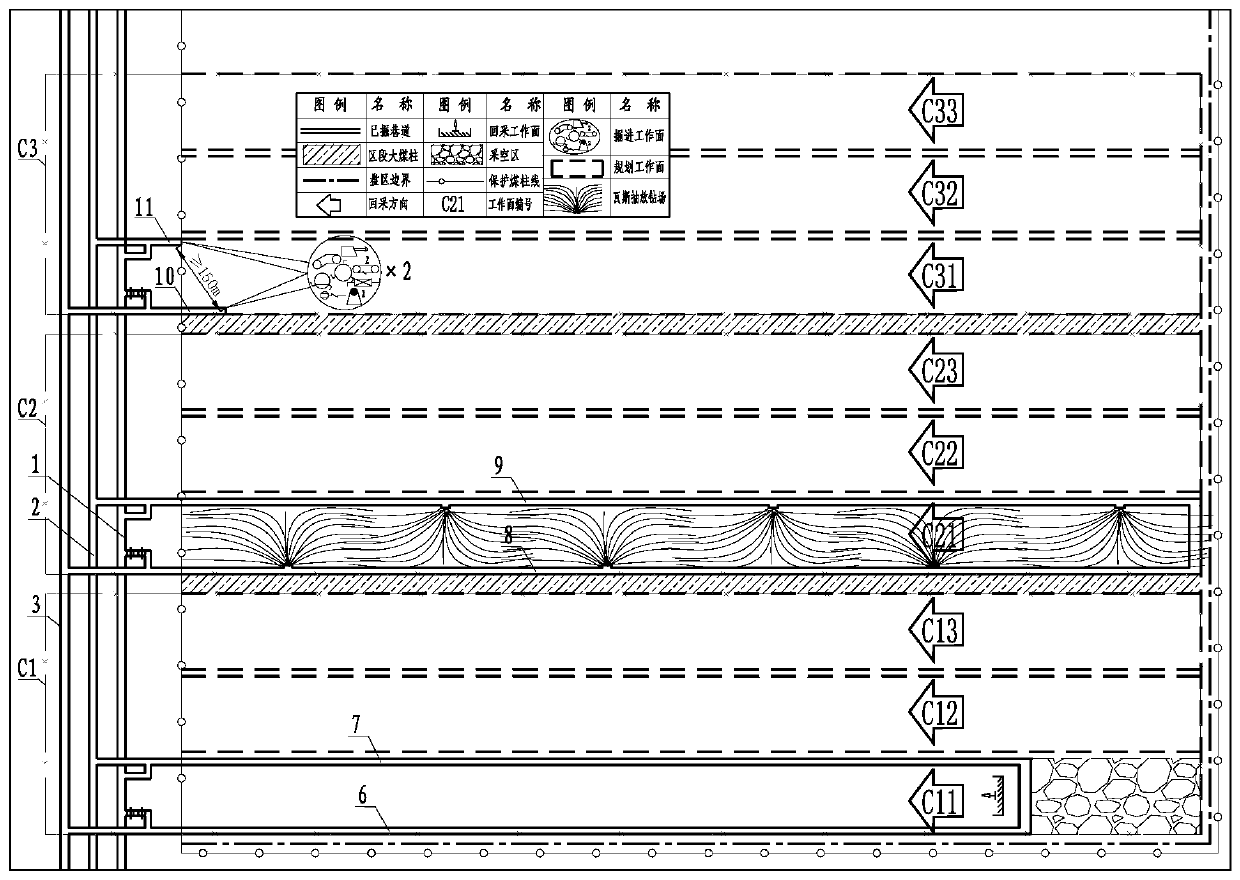

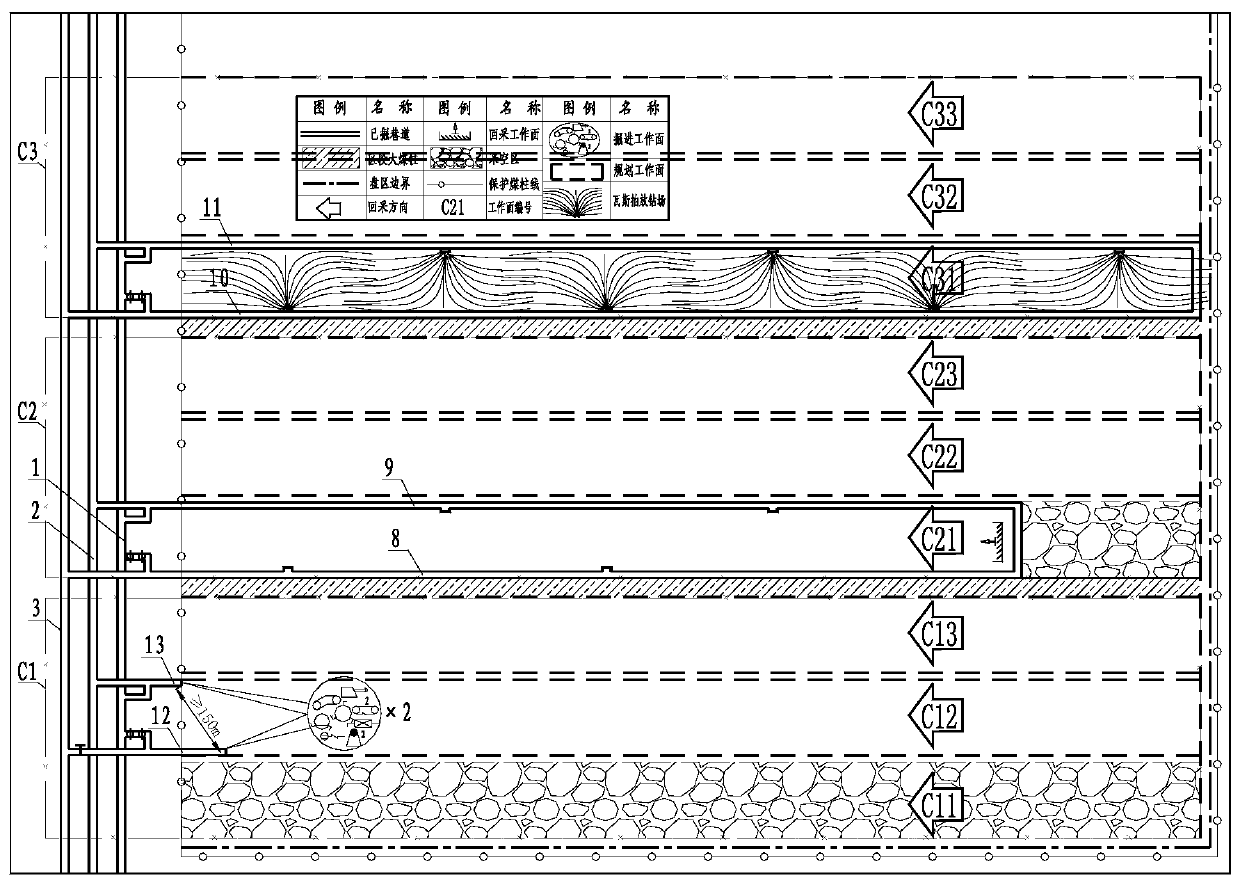

A method for continuous arrangement of working face in mining area of rock burst and high gas mine

ActiveCN108590658BConducive to cost reduction and efficiency increaseAchieving safe miningUnderground miningSurface miningStopped workStoping

The invention discloses a method for continued arrangement of a working face in a mining area of rock burst and high gas mine. The method comprises the following steps that the mining area is selectedand is divided into three zones, each zone is divided into a plurality of sections, and the mining sequence of the sections is determined; a first zone primary mining working face is mined firstly, and at the same time the second zone primary mining working face and third zone primary mining working face are separately subjected to gas pre-drainage and heading work; after stoping of the first zone primary mining working face is completed, a heading end of the third zone is moved to a second face of the first zone, and the roadway heading is carried out; the stoping of the second zone primarymining working face is carried out; the third zone primary mining working face is subjected to gas pre-drainage; and so on, the heading, pre-drainage and stoping work are separately carried out simultaneously in the three zones, and cycling is carried out until the next mining area continues. Linkage of mining, heading and pumping in the mining area is achieved, the method for continued arrangement of the working face in the mining area of rock burst and high gas mine has the advantages of less development (preparation), less investment, concentrated production, less occupancy of personnel andequipment, and the contradiction between rock burst and tight connection in the high gas mine can be can effectively alleviated.

Owner:中煤西安设计工程有限责任公司

A classification method for mine pressure appearance in working face with hard roof

ActiveCN106121721BAchieving safe miningGood effectMining devicesMining engineeringClassification methods

The present invention provides a method for grading mine pressure appearance in a hard roof working face, comprising: determining a set of evaluation factors for grading mine pressure appearance in a hard roof working face, and obtaining the values of each evaluation factor; determining the evaluation set for grading the appearance of rock pressure in a hard roof working face , that is, the set of evaluation grades for rock pressure appearance on hard roof working faces; establish the fuzzy relationship between each factor in the evaluation factor set and the evaluation grades in the evaluation set, and obtain a fuzzy relationship matrix; The weight set of each factor is obtained to obtain the weight vector of each factor; the fuzzy relationship matrix and weight vector are synthesized and calculated, and the mine pressure appearance of the hard roof working face is classified. According to the mechanical properties and occurrence conditions of the hard roof, the present invention classifies the strength of the mine pressure on the working face, realizes the effective prediction of the strength of the mine pressure on the working face under the condition of the hard roof, and can take targeted support for the working face and the mining roadway scheme to realize safe mining at the working face.

Owner:LIAONING TECHNICAL UNIVERSITY

Long standpipe gas extraction in worked-out section

InactiveCN101029574BIncrease extraction concentrationThe extraction concentration is reducedUnderground miningSurface miningEngineeringGas concentration

This is a gas extraction method via a long vertical pipe at goaf zone. Two holes are made on the top and bottom board of the air gallery at the working face. Sectional metal pipes are linked together to form a long vertical pipe, with the top sealed and inserted into the hole on the top board, and the bottom inserted into the bottom board and concreted. Small holes distributes on the pipe wall and been wrapped with pack. The pipe is connected to the extraction network. With 5m of the pipe getting into the goaf zone, start extraction; with the previous pipe getting into the goaf zone at 30m, and the following one at 5m, shut the previous pipe and open the following one. So realize a continuous extraction and decrease the gas concentration at the solid angle. The gas concentration could be controlled under 0.6%.

Owner:淮北矿业股份有限公司祁南煤矿 +1

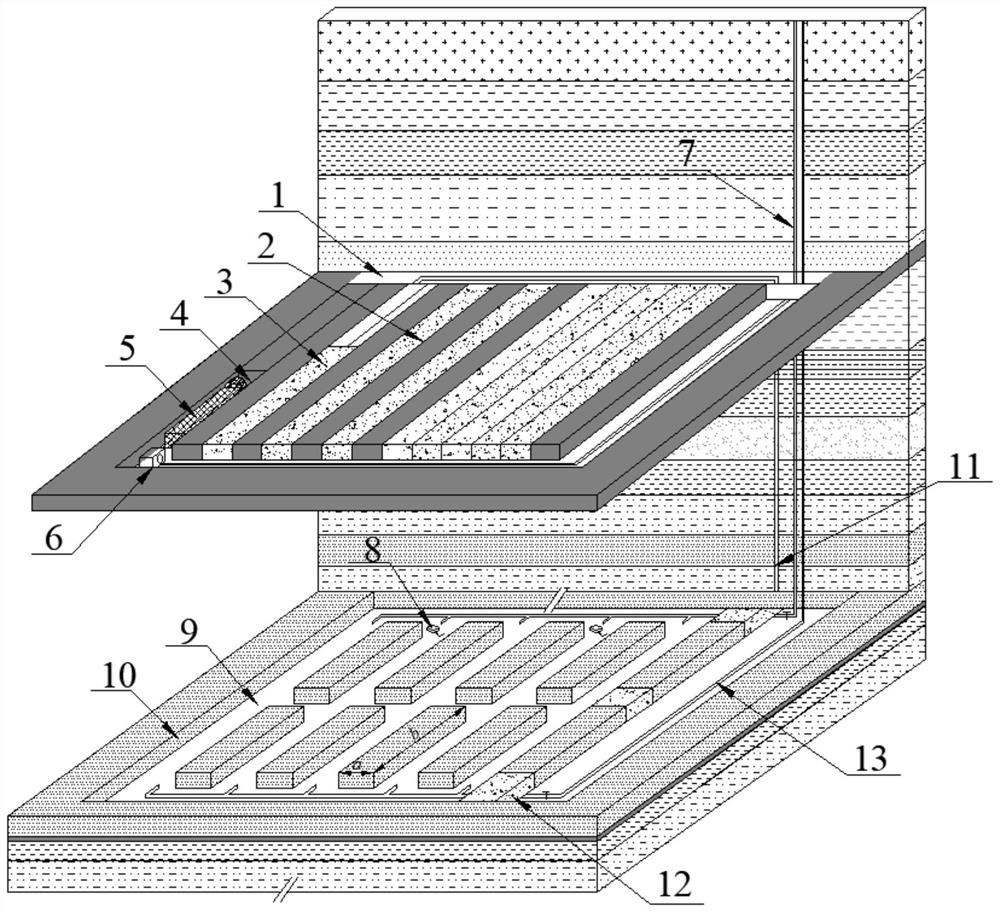

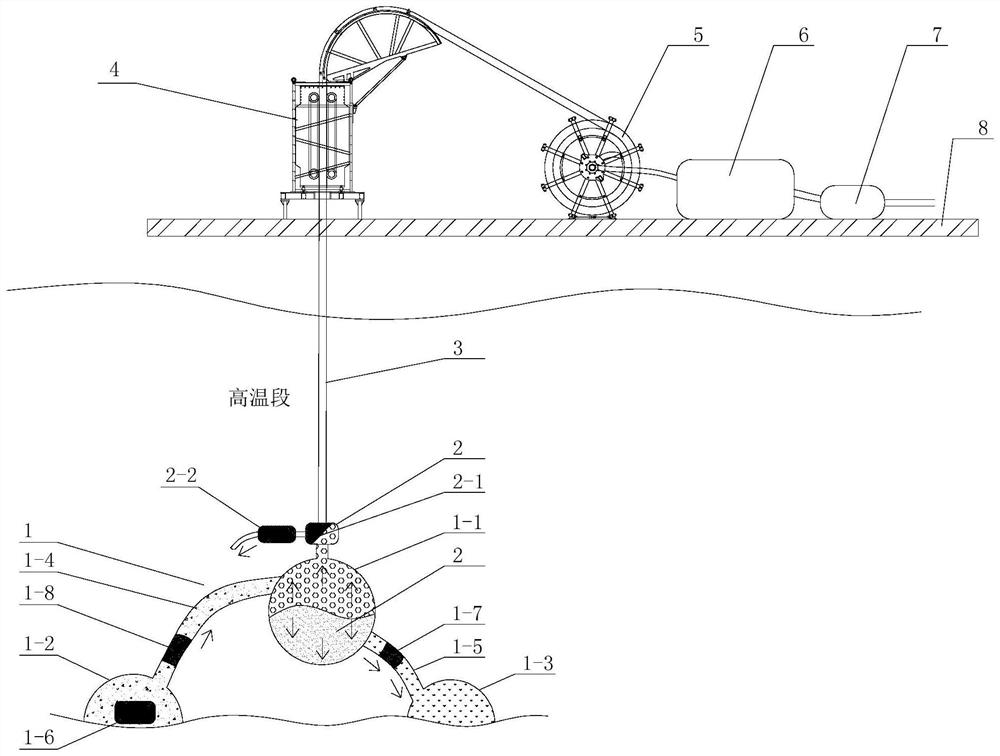

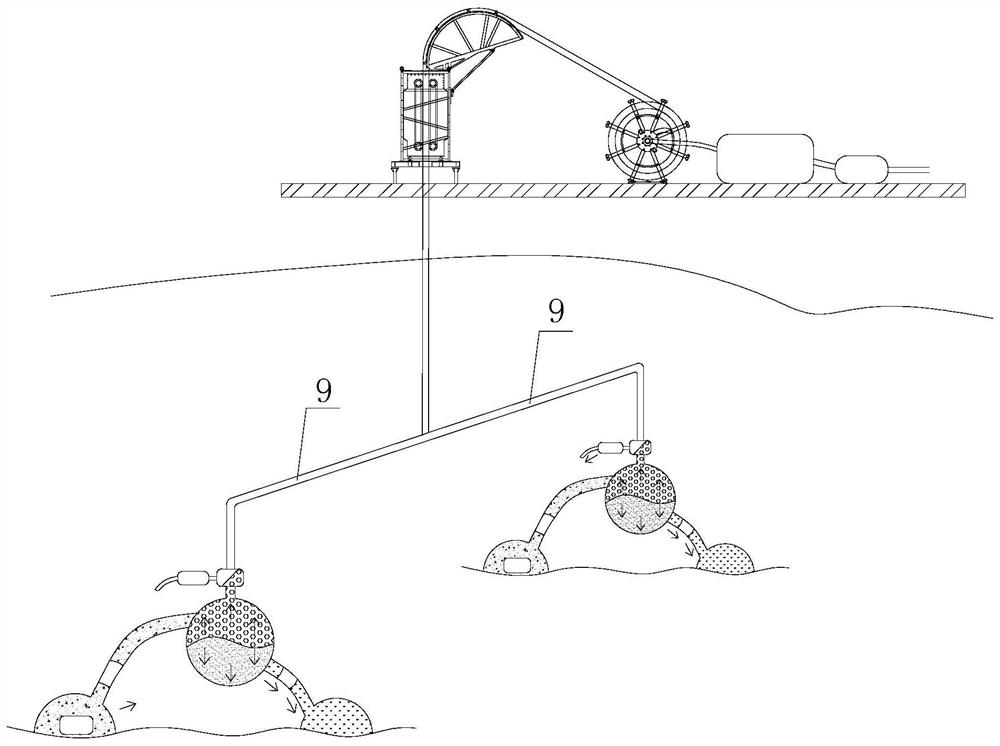

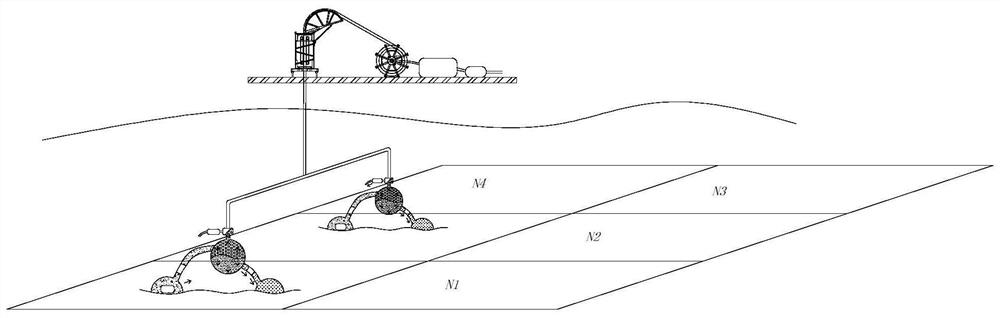

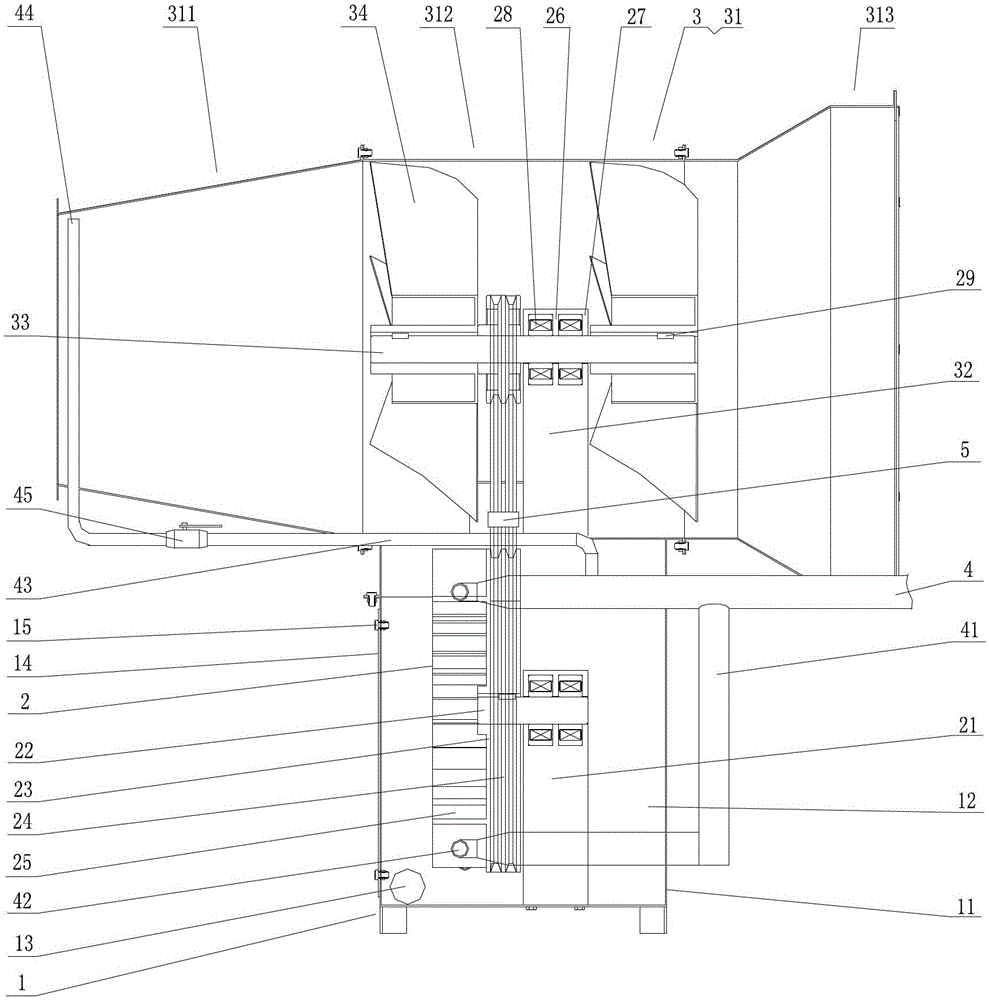

Mining system and method for seabed combustible ice

ActiveCN108547599BNo damage to high pressure and low temperature conditionsNo escapeConstructionsFluid removalNew energyCoiled tubing

The invention discloses an exploiting system for seabed combustible ice, and further discloses an exploiting method for the seabed combustible ice. The exploiting system comprises a seabed exploitingmechanism. The seabed exploiting mechanism is connected with the lower end of a composite coiled tubing through a downhole joint. The composite coiled tubing passes through a coiled tubing injection lifting mechanism. The upper end of the composite coiled tubing is fixedly connected with a coiled tubing extending-retracting mechanism. The composite coiled tubing is wound around a winding disc of the coiled tubing extending-retracting mechanism. The upper end of the composite coiled tubing is connected with a gaseous combustible ice liquefying furnace through a gaseous combustible ice conveyingpipeline. The gaseous combustible ice liquefying furnace is connected with a liquid combustible ice conveying pipeline. The coiled tubing injection lifting mechanism, the coiled tubing extending-retracting mechanism and the gaseous combustible ice liquefying furnace are arranged on a combustible ice offshore exploiting platform. According to the exploiting system, safety exploiting of the seabedcombustible ice can be achieved, and human makes it possible to take the seabed combustible ice as a new energy source for utilization; and the problem of shortage of earth energy is completely solved.

Owner:SHANGHAI FB OIL EQUIP TECH

An experimental device and method for simulating the destabilization of submarine slopes caused by the decomposition of combustible ice under complex terrain conditions

ActiveCN111594157BTemperature controlAchieving safe miningConstructionsBorehole/well accessoriesTerrainLandform

The invention discloses an experimental device and method for simulating the destabilization of a seabed slope caused by the decomposition of combustible ice under complex terrain conditions. The experimental device includes a support system, a landslide induction system, a simulated stratum for the decomposition of combustible ice, a temperature control system and a control system: The support system changes the ups and downs of the inner surface of the water tank through the telescopic lifting rod to achieve the purpose of simulating the real topography of the seabed. The landslide induction system sprays gas similar to the decomposition of combustible ice through small holes, and the temperature control system is used to control the gas similar to the decomposition of combustible ice. The overall control system automatically realizes the change of the height of the telescopic lifting rod through computer control, so as to drive the change of the surface layer inside the water tank to simulate the change of the terrain. The cooperative work of each system can accurately simulate the decomposition of combustible ice due to the change of environmental conditions. The whole process of submarine landslide.

Owner:ZHEJIANG UNIV

Environmental protection and energy-saving explosion-proof fan based on water source of underground water tank

ActiveCN103362832BAvoid security issuesSave money on energy consumptionDust removalFire preventionWater sourceAgricultural engineering

A spraying environment-friendly energy-saving anti-explosion fan based on a shaft sump water source comprises a water tank substrate; a water wheel device is arranged on the water tank substrate and is connected with a wind wheel device by a belt; a high-pressure water spraying device is connected with the water wheel device and the wind wheel device; the technical scheme of taking the shaft sump water source as a power source and combining the functions of wind feeding and spraying of a high-pressure water spraying device, the water wheel device and the wind wheel device is adopted; the defects of high frequency of gas and coal dust explosion caused by electric sparks of a motor, high investment cost, complete demand on the system auxiliary project, large machine noise, poor radiating performance, short service life, low production efficiency, severe production labor environment, easily caused occupational diseases of operation staff and severe coal source waste of the existing coal-mining equipment used for the high-gas shaft are overcome; and the spraying environment-friendly energy-saving anti-explosion fan based on the shaft sump water source is suitable for various ventilation equipment for mine excavation, particularly the ventilation equipment for excavation of the high-gas protruded shaft coal layer.

Owner:永州市亿达自动化机械有限公司

A Prediction Method for Maximum Height of Water Conducting Fracture Zone in Filling Mining

Owner:SHANDONG UNIV OF SCI & TECH

Coal Mine Cemented Filling Technology

Owner:赤峰西拉沐沦(集团)公格营子煤业有限公司

stage caving mining method

InactiveCN104481543BSolve construction difficultiesSolve the costUnderground miningSurface miningMineralogyGround pressure

The invention relates to a sub-level shrinkage caving method. According to the sub-level shrinkage caving method, no large-area mined-out space appears in an extraction process, a hanging wall rock is supported by utilizing a caved ore in the early stage of extraction, and an upper overburden rock downwards moves to fill a mined-out space to control ground pressure along with bottom ore removal in the later stage of the extraction, so that safe and high-efficiency extraction is achieved; ores are aggregated in a bottom trench in a bottom structure, and the bottom trench is connected with a travelling roadway by adopting a herringbone non-track ore loading feed path, so that the sub-level ore removal is realized; when undercutting work is carried out, only a part of caved ores are discharged, fragmented rock mass in an ore block keeps that the hanging wall rock is not collapsed and ensures that a sufficient free compensating space is enough for upper ore dropping, the dropped ore is discharged from the non-track ore loading feed path, and then is put into a mine car to leave from a stope, then ore dropping is carried out again, the process is circulated till the ores contained in the ore block all drop in a blasting way, and finally large-scale ore removal is carried out; and the overburden rock continuously moves downwards to fill a mining area to control the ground pressure along with the continuous extraction of the ores during the large-scale ore removal.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A method for filling false roofs without interstitial columns and maintaining the stability of downward single approach filling

ActiveCN111456735BReduce lossesGuarantee mining safetyUnderground chambersUnderground miningMining engineeringPre stress

The invention provides a method for maintaining the stability of filling a false roof in a single approach downwards without interstitial columns, and relates to the technical field of mining engineering. The steps include: returning to the mining room by adopting the mining method of layering and non-segmented roadway filling in the downward direction, and performing artificial leveling immediately after the layering of the mining room. Construction of ultra-long prestressed bolts on the surrounding rocks of the upper and lower walls perpendicular to the ore body trend is supported by means of anchor-net-spray. The exposed end of the anchor near the bottom plate is fixed by steel bar welding, and the crushed ore cushion and isolation layer are laid. The longitudinal bars of the steel mesh are hung on the steel bar hooks reserved in the previous layer, and their lower ends are welded to the horizontal steel bars at the bottom of the layer. The goaf is cemented and filled, and after the filling body is stabilized, the lower layer is mined until all layered mining is completed. Repeat the above steps until all mines are mined. This method maintains the stability of the filling false roof with the help of super-long bolts in the surrounding rock of the upper and lower walls and the warp and weft steel mesh in the goaf, and does not need to leave spacers, reducing the loss of ore.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com