Long standpipe gas extraction in worked-out section

A gas extraction and riser technology, which is applied in gas discharge, surface mining, mining equipment, etc., can solve the problems of over-limit gas concentration in the upper corner, low extraction concentration, affecting the normal production of the working face, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the embodiment in the accompanying drawings, the present invention will be further described:

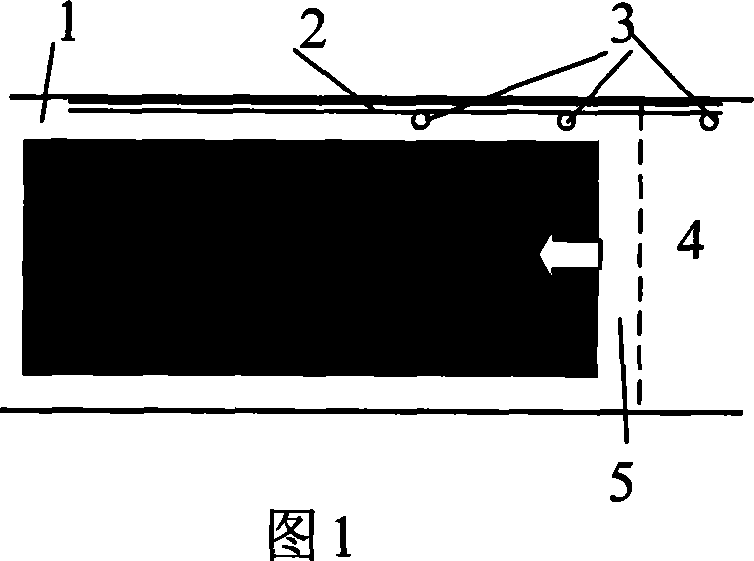

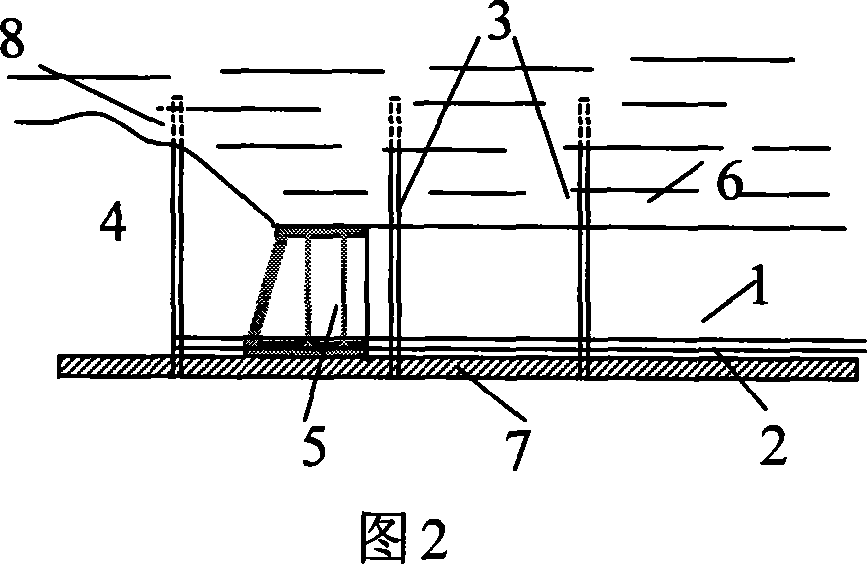

[0017] In the goaf long standpipe gas extraction method of the present invention, the position of the suction port is determined according to the movement law of the coal seam roof rock layer and the height of the caving zone, and the main pipe 2 and the branch pipe are laid along the bottom plate of the wind tunnel 1 near the upper side. The gas drainage connecting pipe network composed of gate valves, the main pipe is provided with a variable diameter tee every 25m, and the branch pipe is a steel pipe with a diameter of 108mm and a length of 30m. There is a control gate valve near the section; the main pipe is a steel pipe with a diameter of 216mm. Use a drilling rig to drill vertically downward to the bottom plate 7 of the air tunnel in the coal mining face, with a drilling depth of 1.5-2m and a diameter of 150mm; drill holes vertically upward at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com