Drill hole inside secondary grouting leaking stoppage device

A secondary grouting and in-drilling technology, applied in safety devices, earthwork drilling, gas discharge, etc., can solve the problems of high labor intensity, high cost, inconvenient operation, etc., and improve the concentration and purity of gas drainage Quantity, increase the concentration of gas drainage, and ensure the effect of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

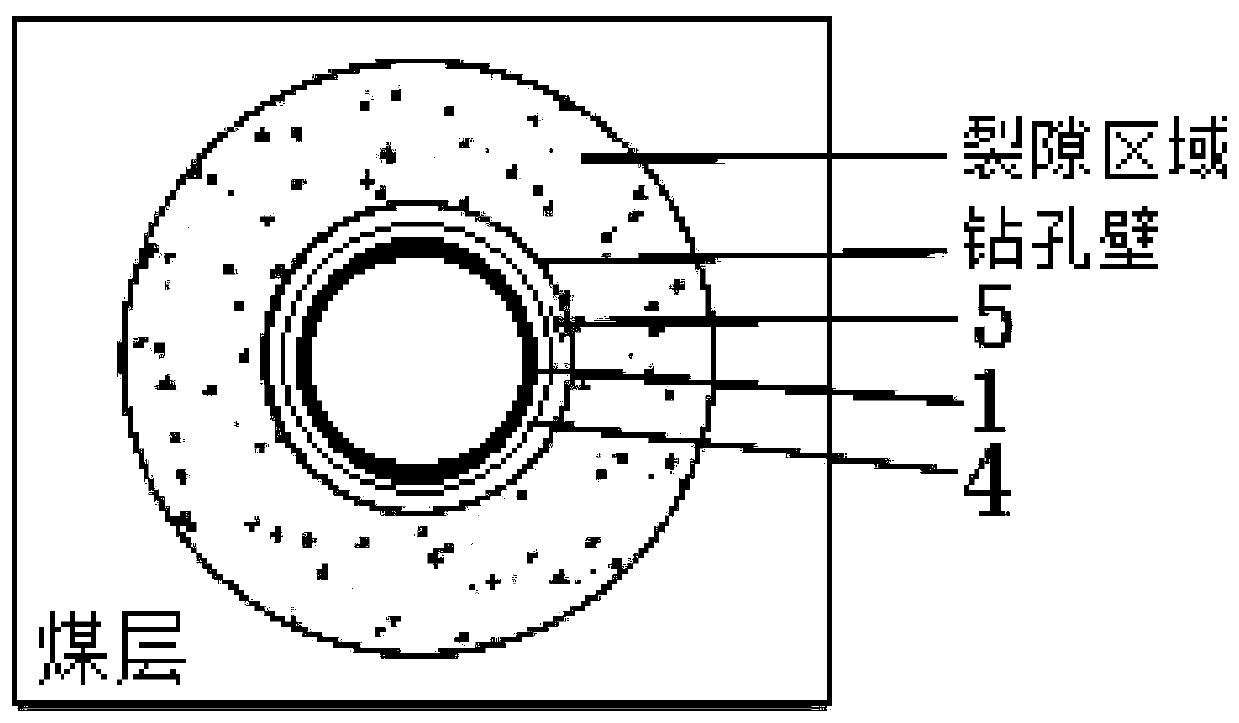

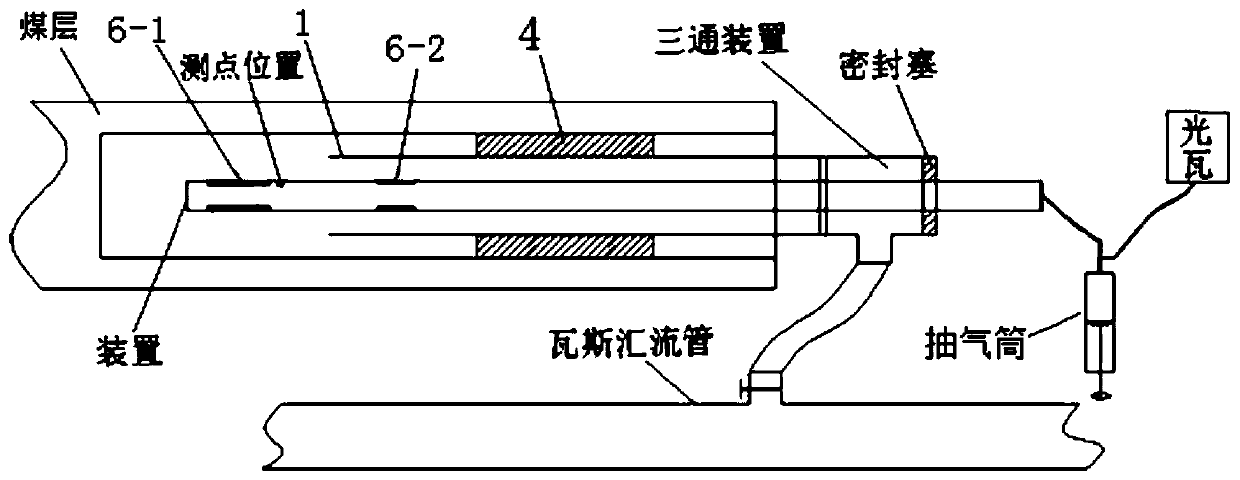

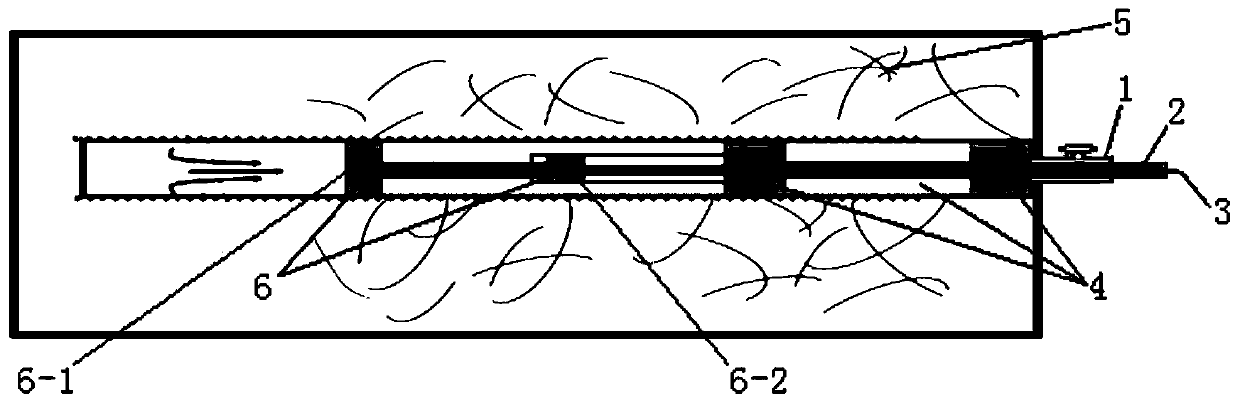

[0021] See Figure 1-Figure 3 The embodiment of the present invention provides a secondary grouting plugging device in a borehole, comprising a plurality of single-section pipes, each single-section pipe includes a gas injection pipe 2 and a grouting pipe 3, and the grouting pipe 3 is sleeved in Inside the gas injection pipe 2, the gap between the two pipes is used as a ventilation channel. A connection piece is fixed between the gas injection pipe 2 and the grouting pipe 3, and the relative position between the two pipes is fixed by the connection piece; the multiple single-section pipes The injection pipes are connected end to end in turn, wherein the grouting pipes 3 of two adjacent single-section pipes are connected, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com