Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about "Valve control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

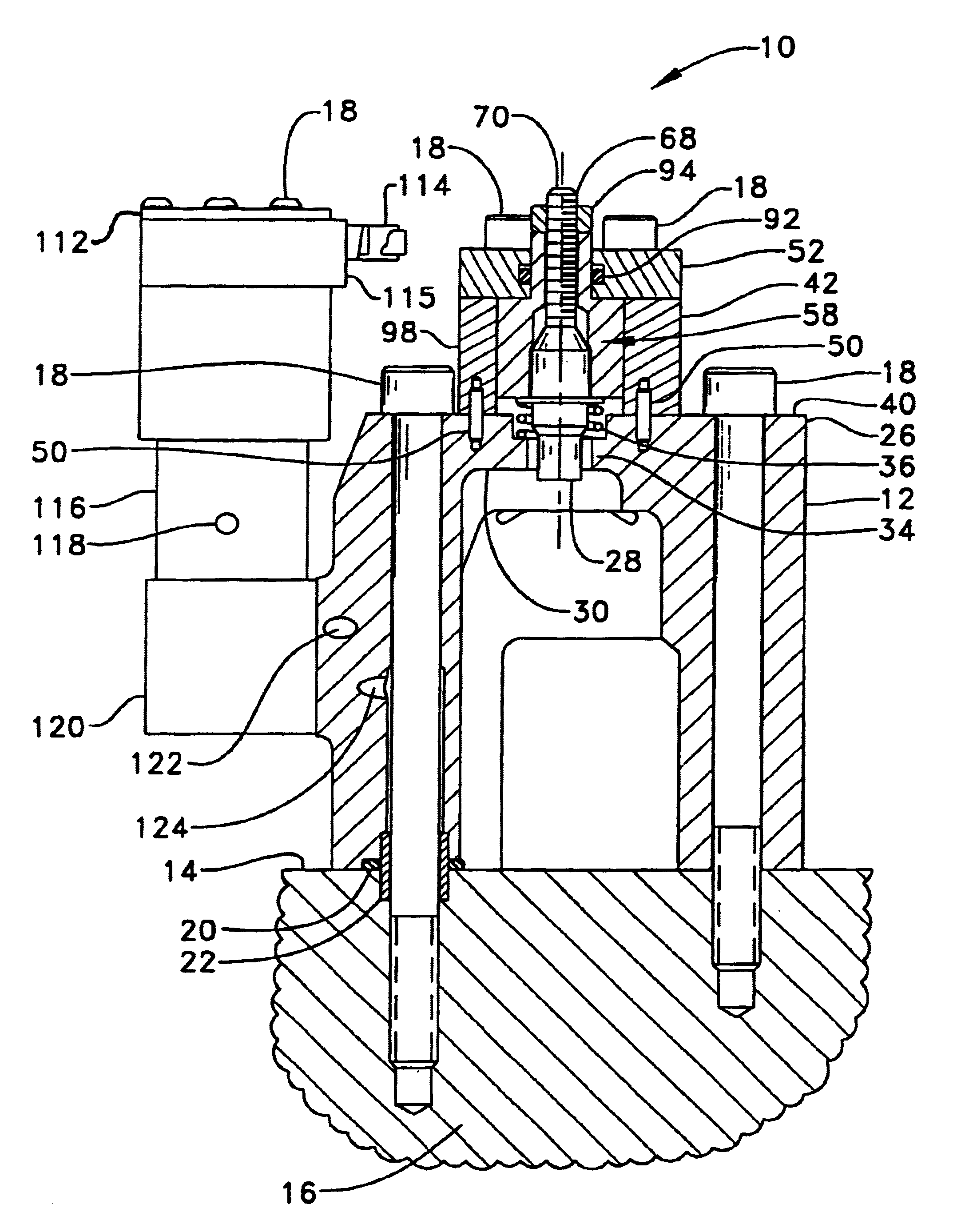

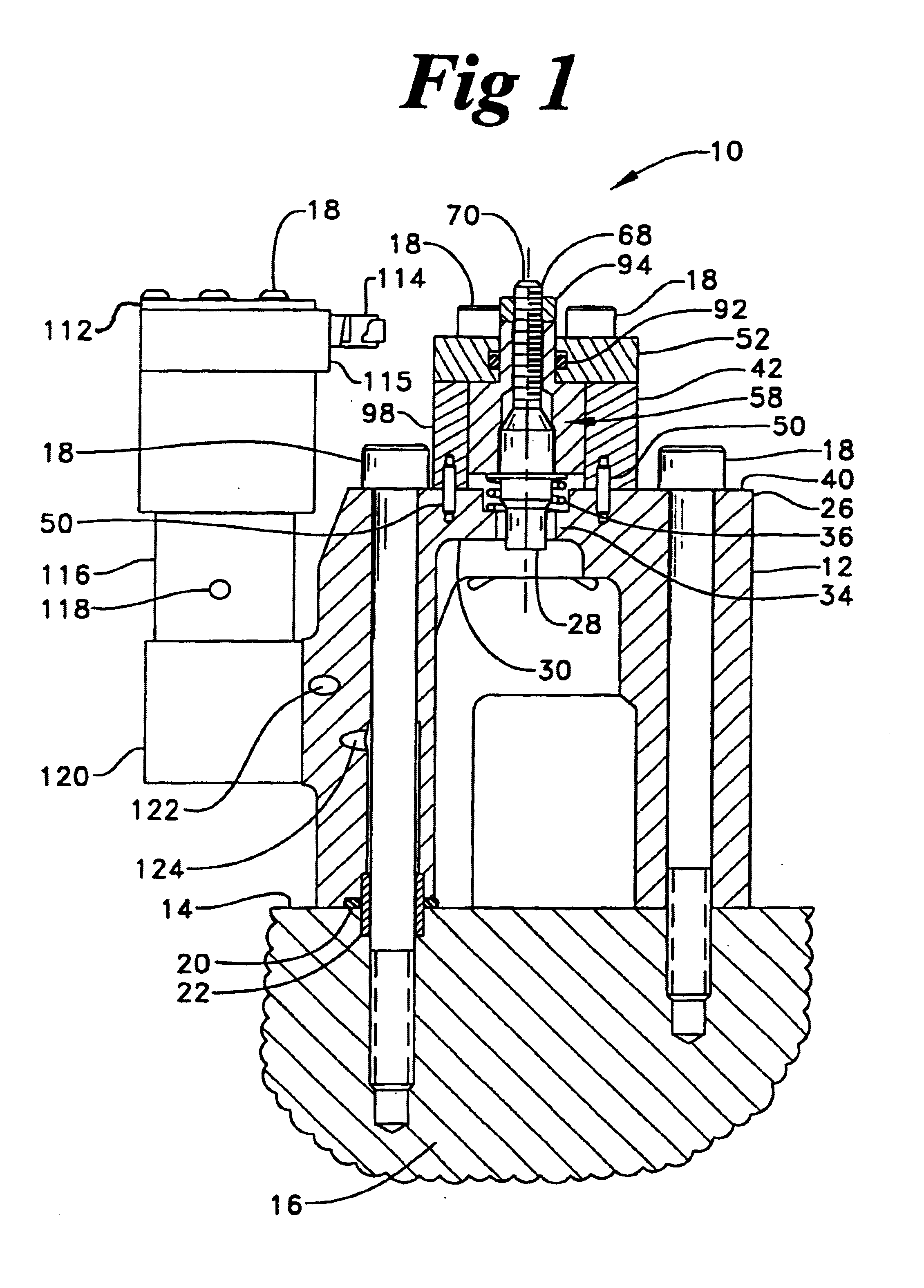

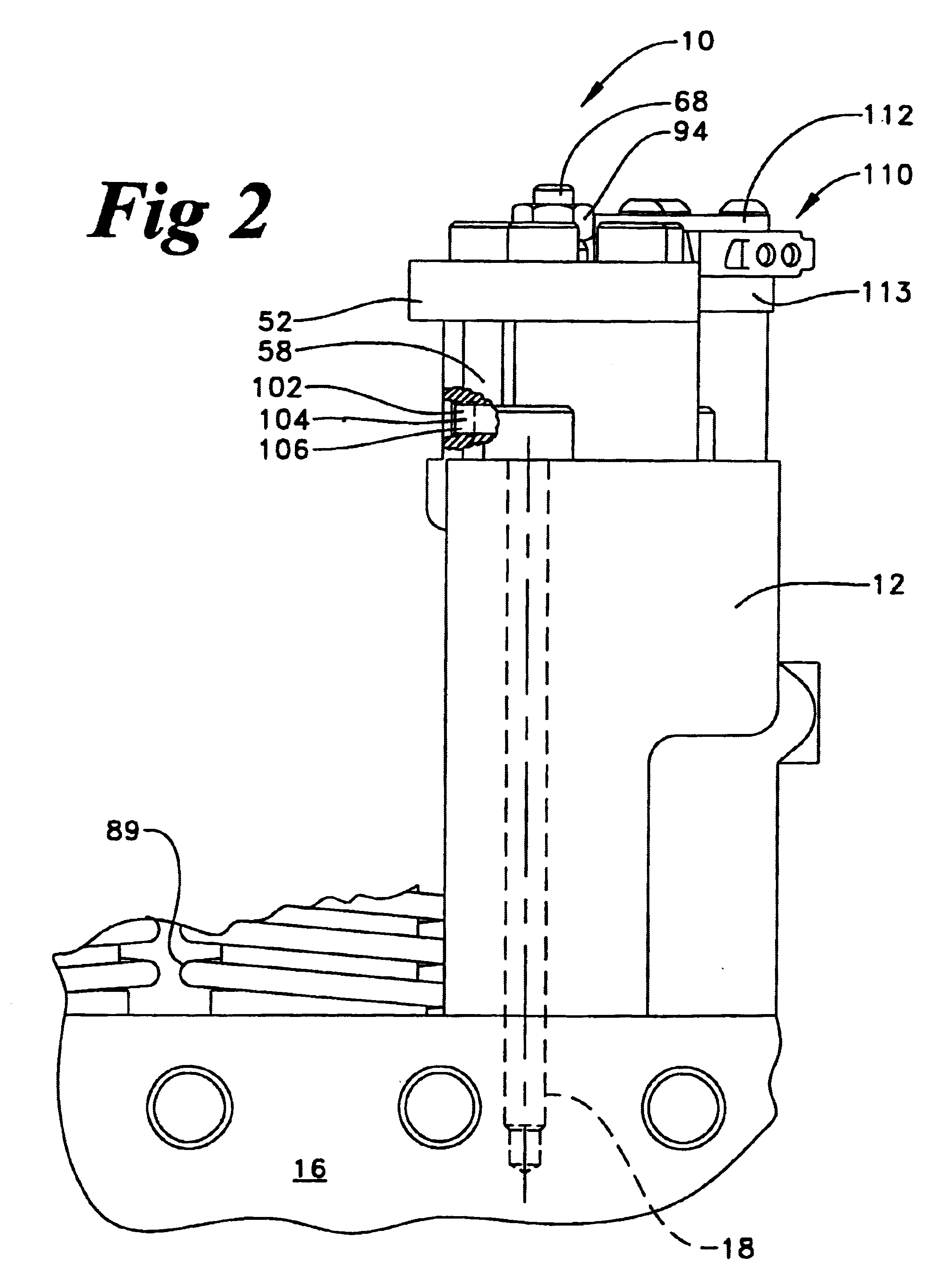

Valve bridge with integrated lost motion system

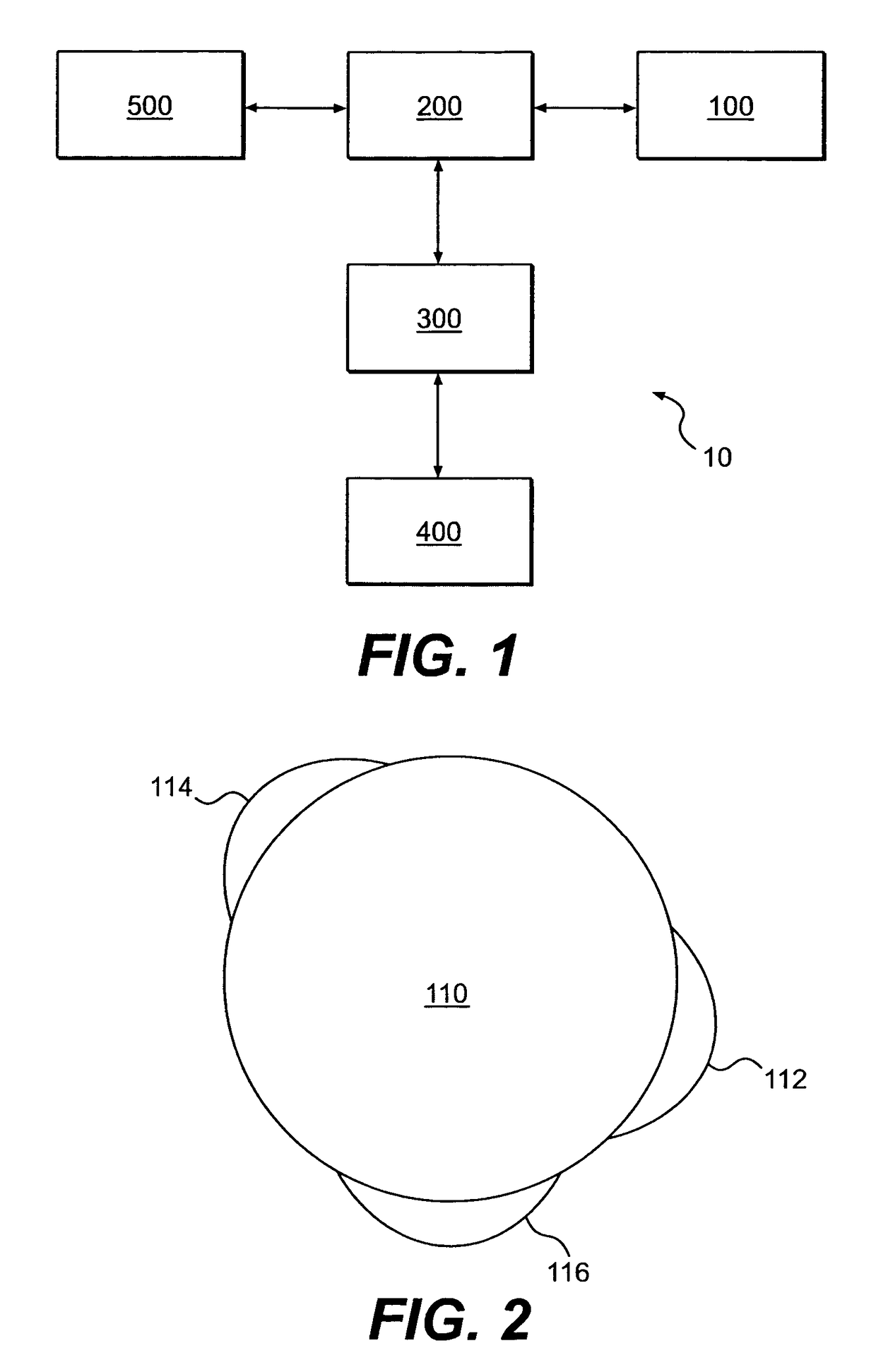

A system and method of actuating one or more engine valves is disclosed. In one embodiment, the system comprises: a valve train element; a rocker arm pivotally mounted on a shaft and adapted to rotate between a first position and a second position, the rocker arm selectively receiving motion from the valve train element; a valve bridge disposed above the one or more engine valves; and a lost motion system disposed in the valve bridge.

Owner:JACOBS VEHICLE SYST

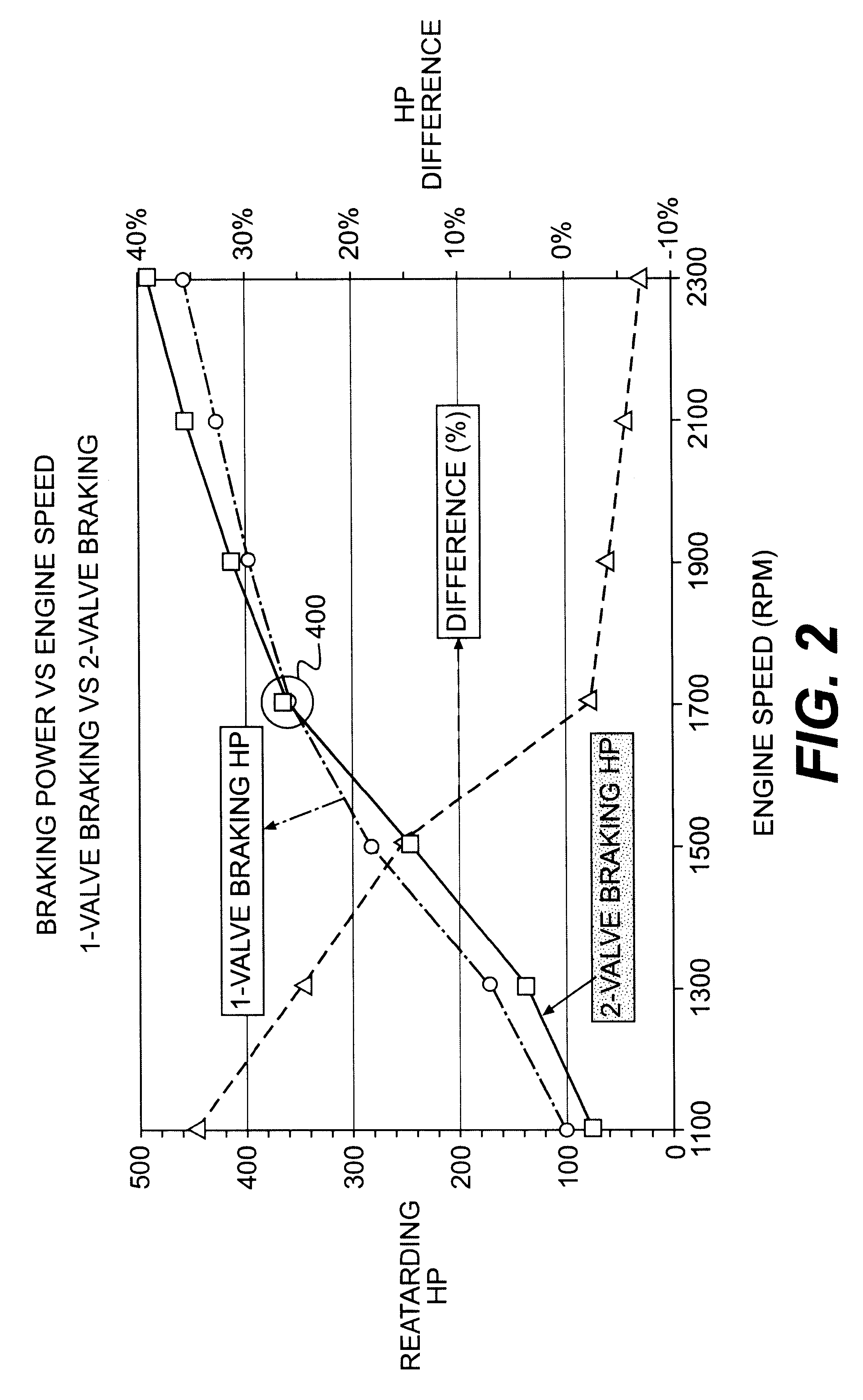

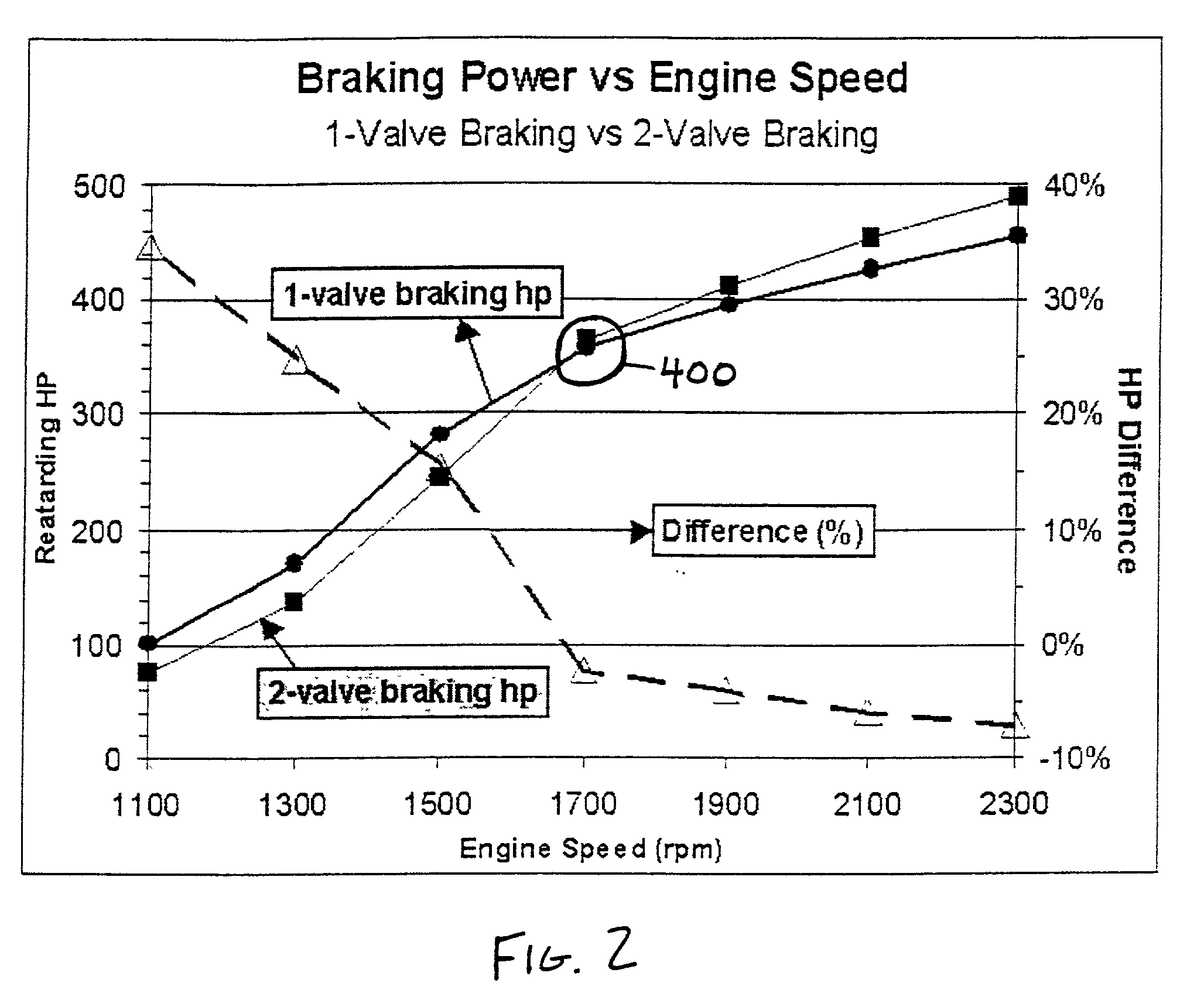

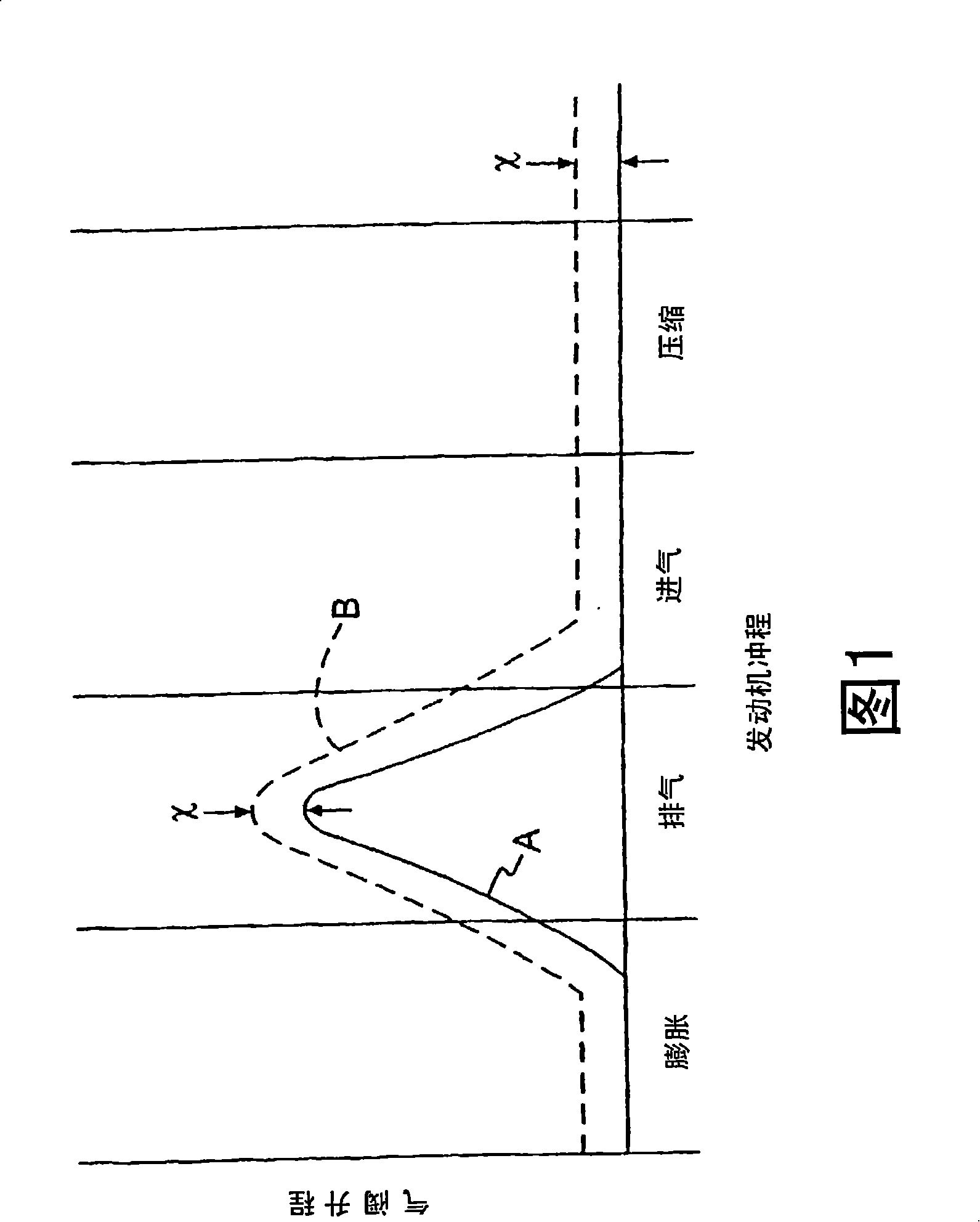

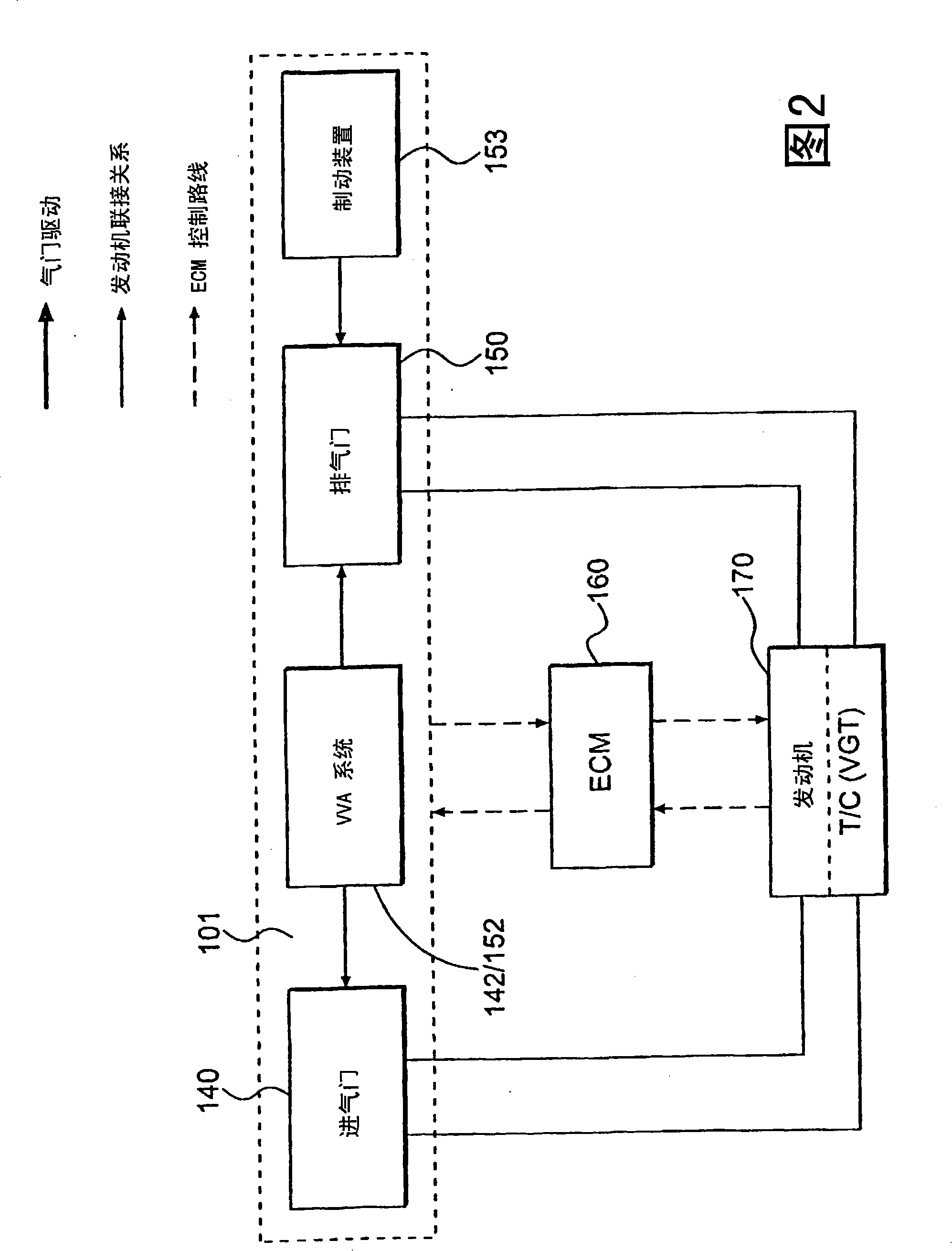

Method and system of improving engine braking by variable valve actuation

InactiveUS6647954B2Improving engine brakingConvenient amountElectrical controlValve drivesLow speedVariable valve timing

The present invention relates to methods of improving engine braking of a reciprocating piston internal combustion engine by variable valve actuation. One embodiment of the present invention enables independent two-valve actuation for each cylinder, and engine braking horsepower can be optimized using two-valve braking at high engine speeds and one-valve braking at low speeds. Another embodiment of the present invention enables better a sequential valve actuation to reduce engine braking load and compliance. Another embodiment of the present invention enables better engine starting and warming up by controlling timing and lift of each valve.

Owner:DIESEL ENGINE RETARDERS

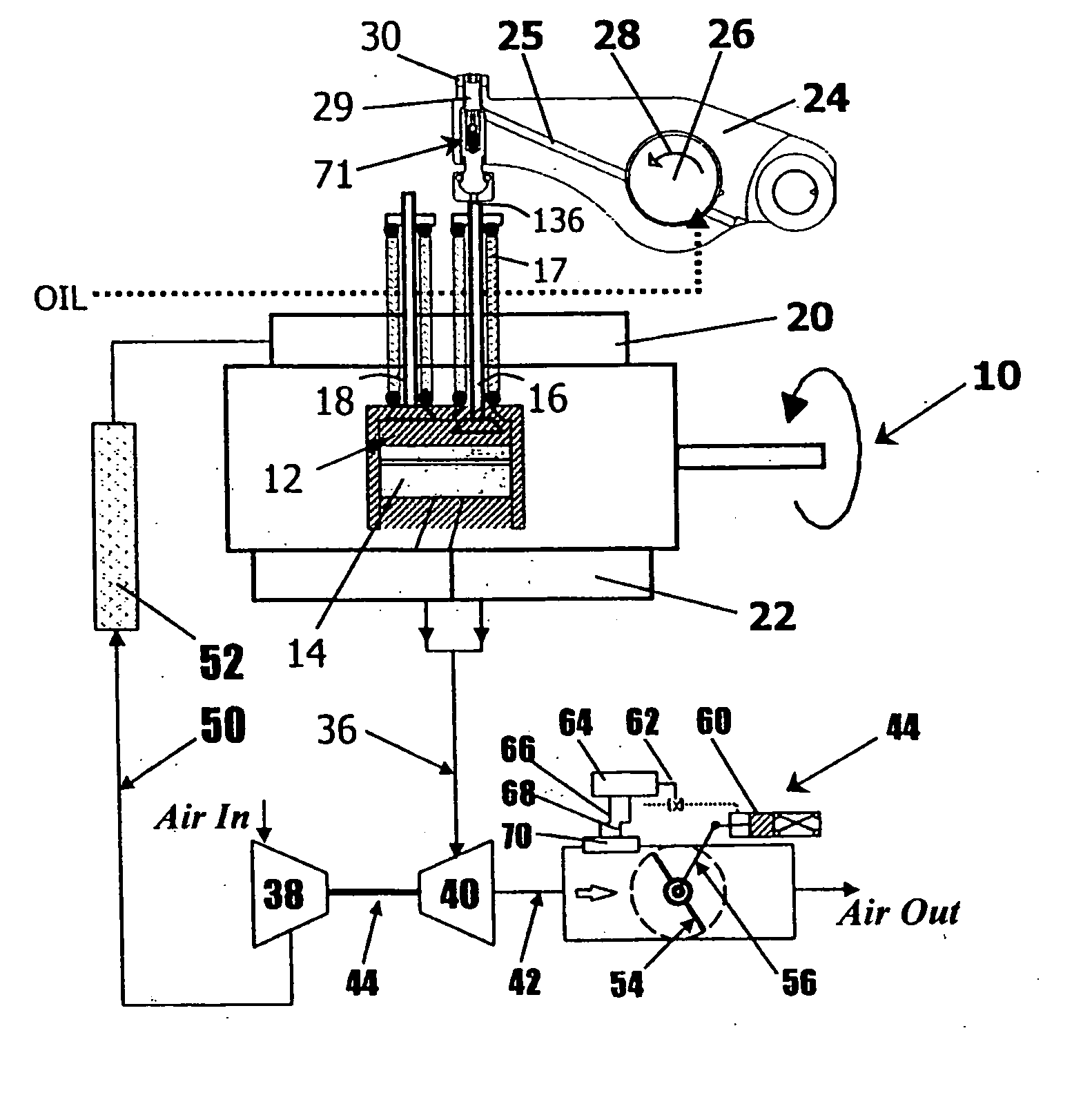

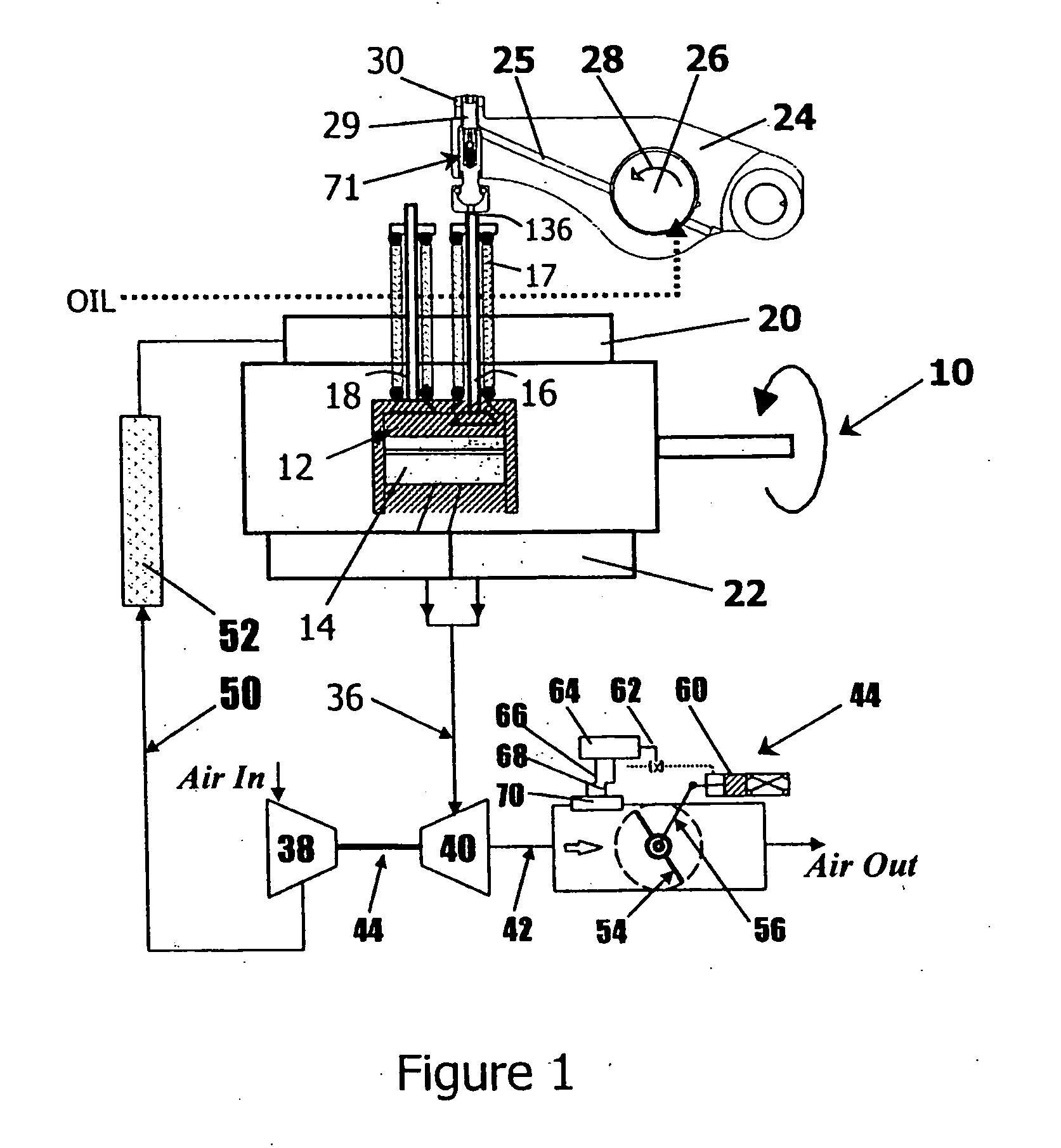

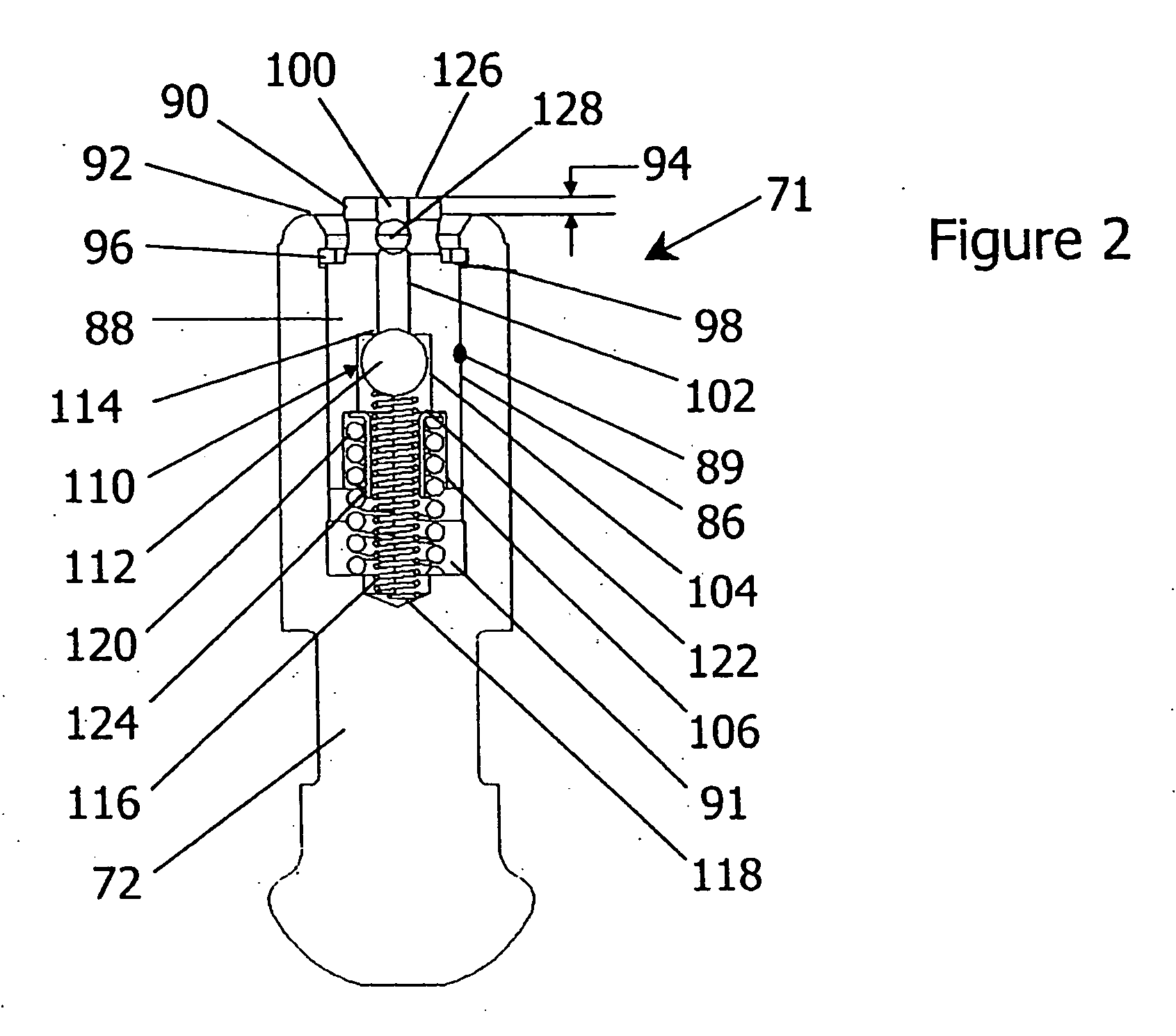

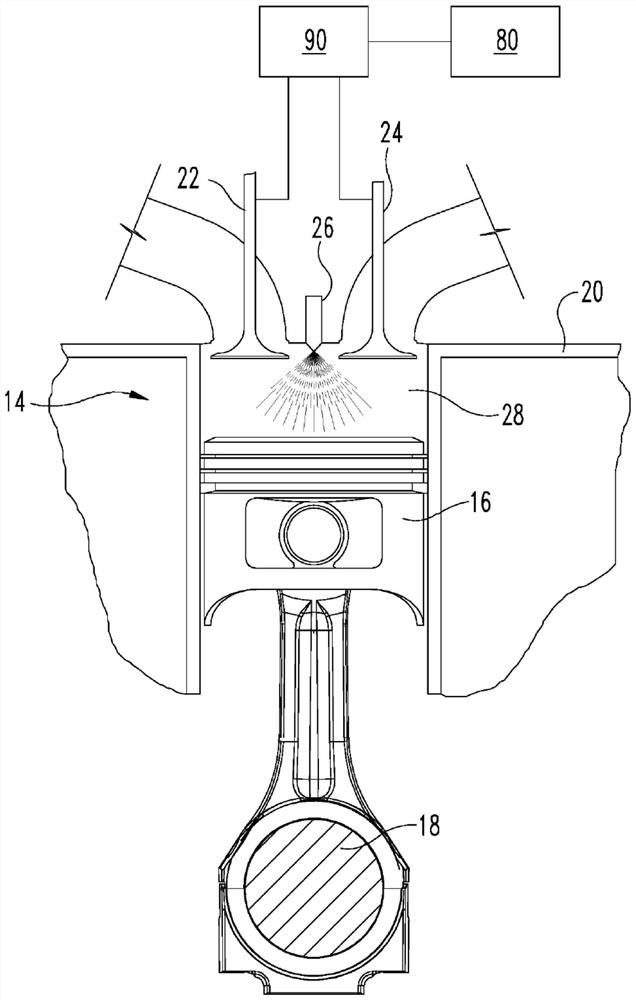

Method and system for engine braking in an internal combustion engine using a stroke limited high pressure engine brake

InactiveUS6866017B2Improve engine performanceImprove performanceElectrical controlInternal combustion piston enginesExternal combustion engineHydraulic circuit

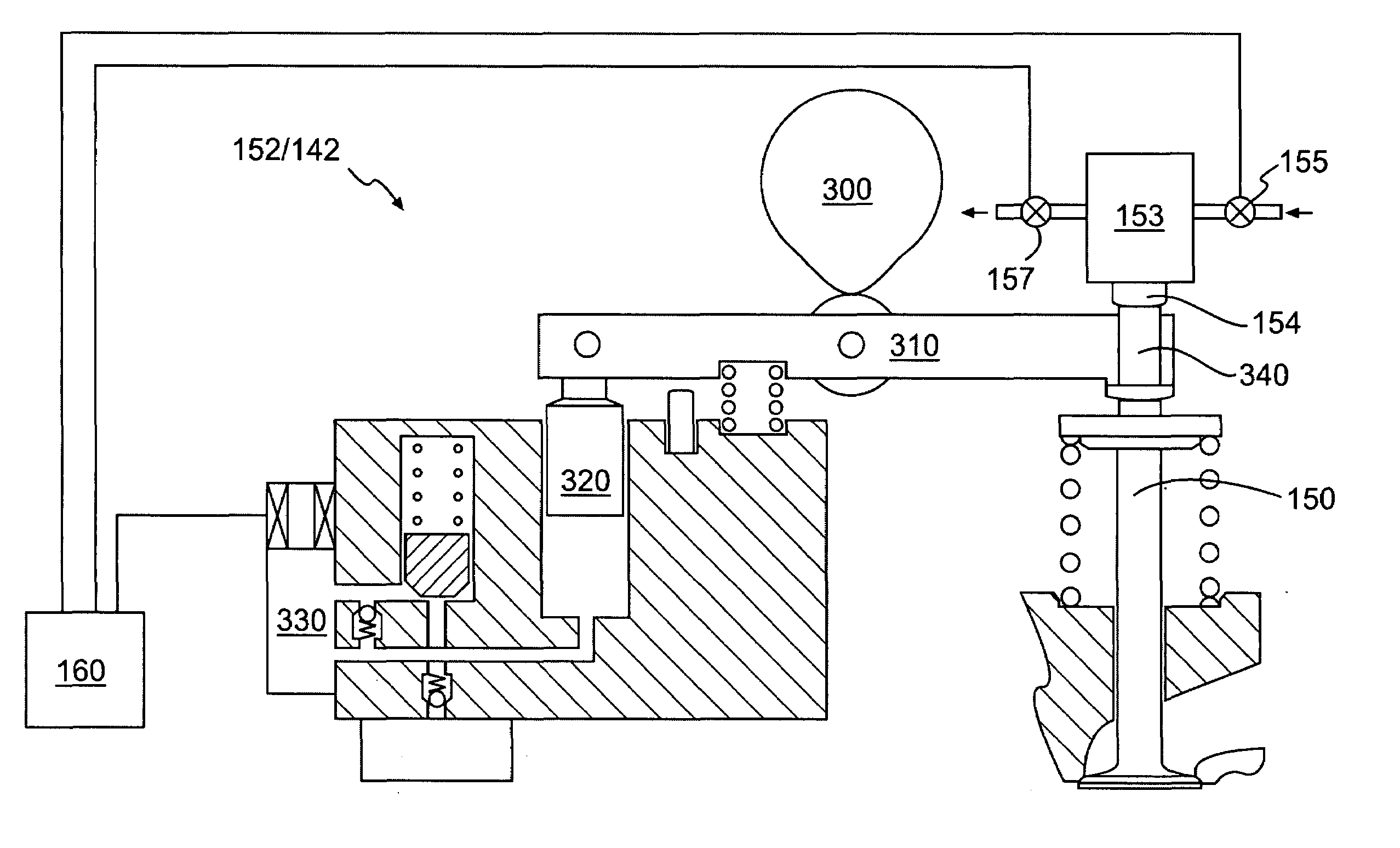

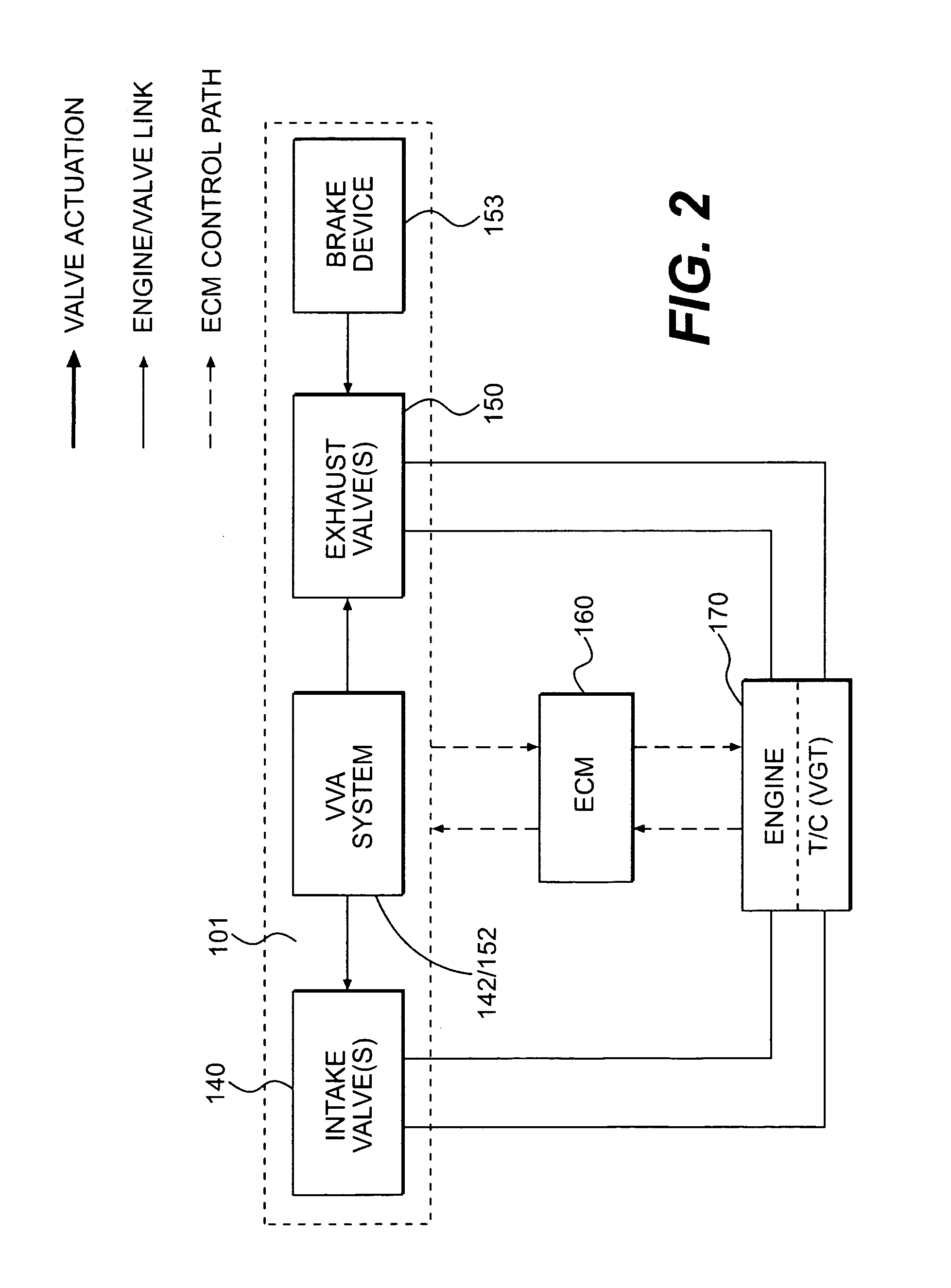

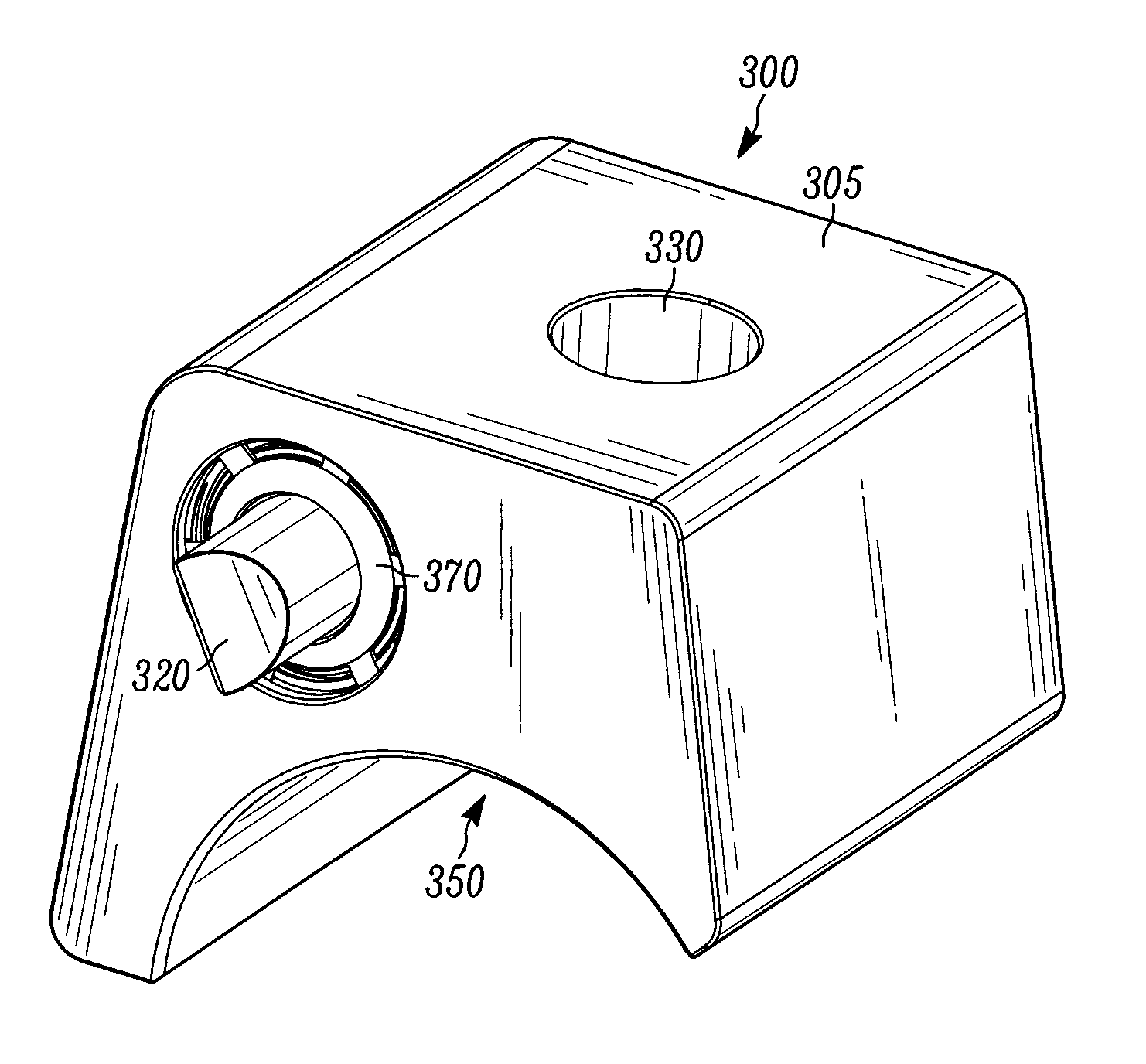

The present invention is directed to an engine braking assembly and method for producing a bleeder braking event in an engine having at least one engine valve, at least one engine cylinder, and intake and exhaust manifolds. The engine braking assembly comprises an engine housing, having a hydraulic circuit formed therein; a high-pressure fluid source adapted to store high-pressure fluid therein; a valve for controlling the flow of the high-pressure fluid, in communication with the high-pressure fluid source through the hydraulic circuit; a control device for selectively controlling the valve; and a valve actuation assembly in communication with the valve through the hydraulic circuit, wherein the valve actuation assembly receives the high-pressure fluid through the valve and wherein the hydraulic force created by the high-pressure fluid actuates and holds open the at least one engine valve to produce the bleeder braking event.

Owner:DIESEL ENGINE RETARDERS

Exhaust valve mechanism in internal combustion engines

InactiveUS6983725B2Avoid increasing overlapLarge back-flowValve drivesOutput powerCombustionExhaust valve

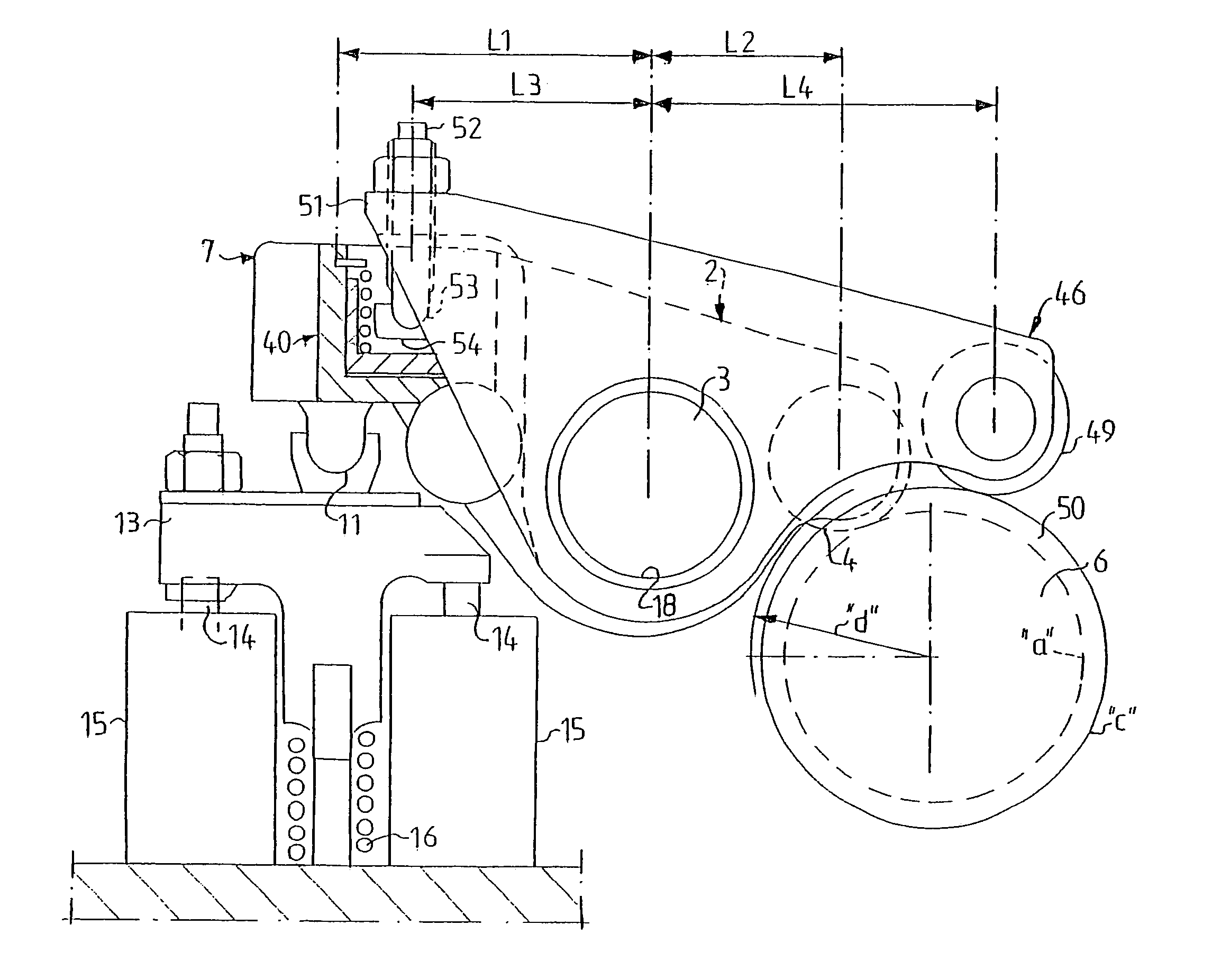

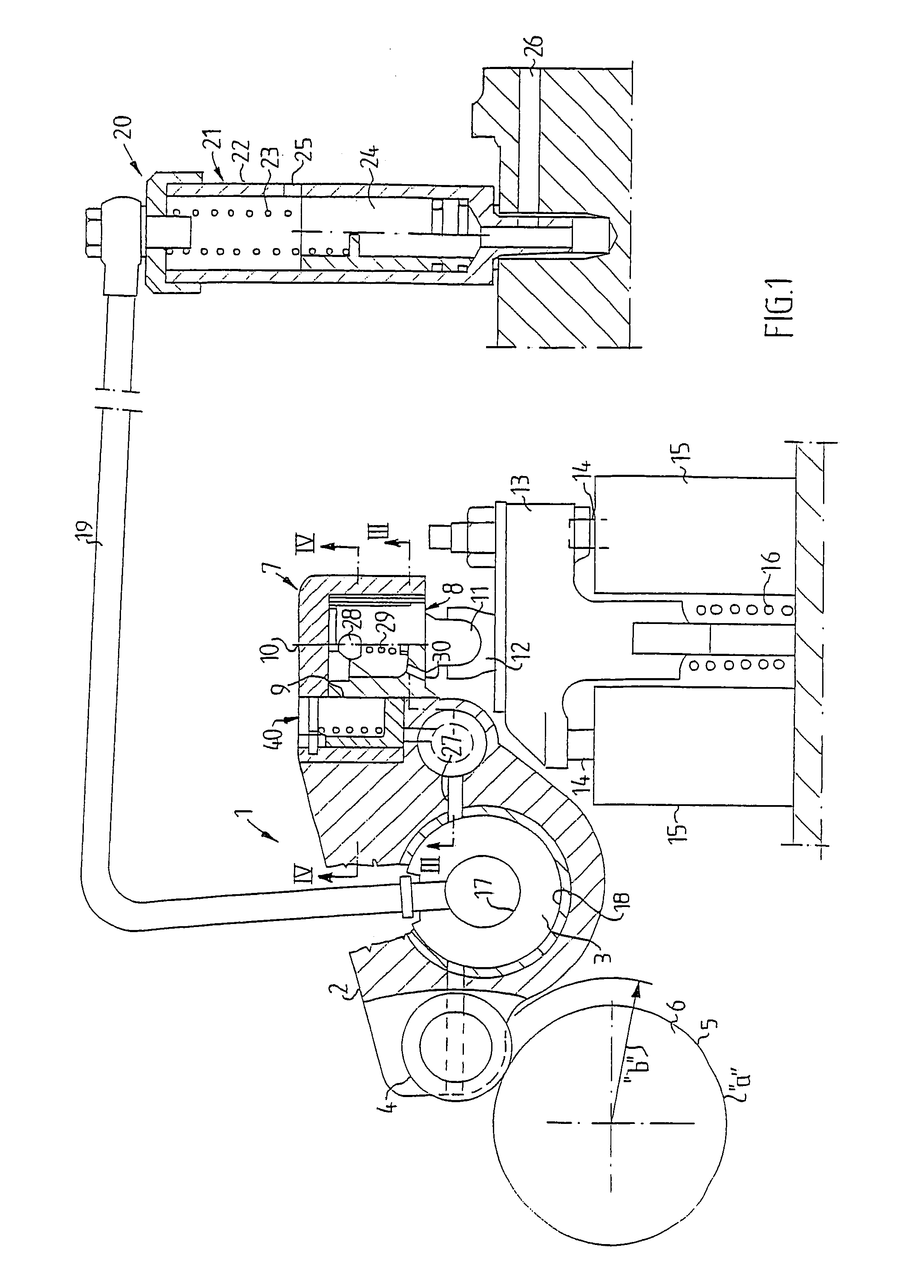

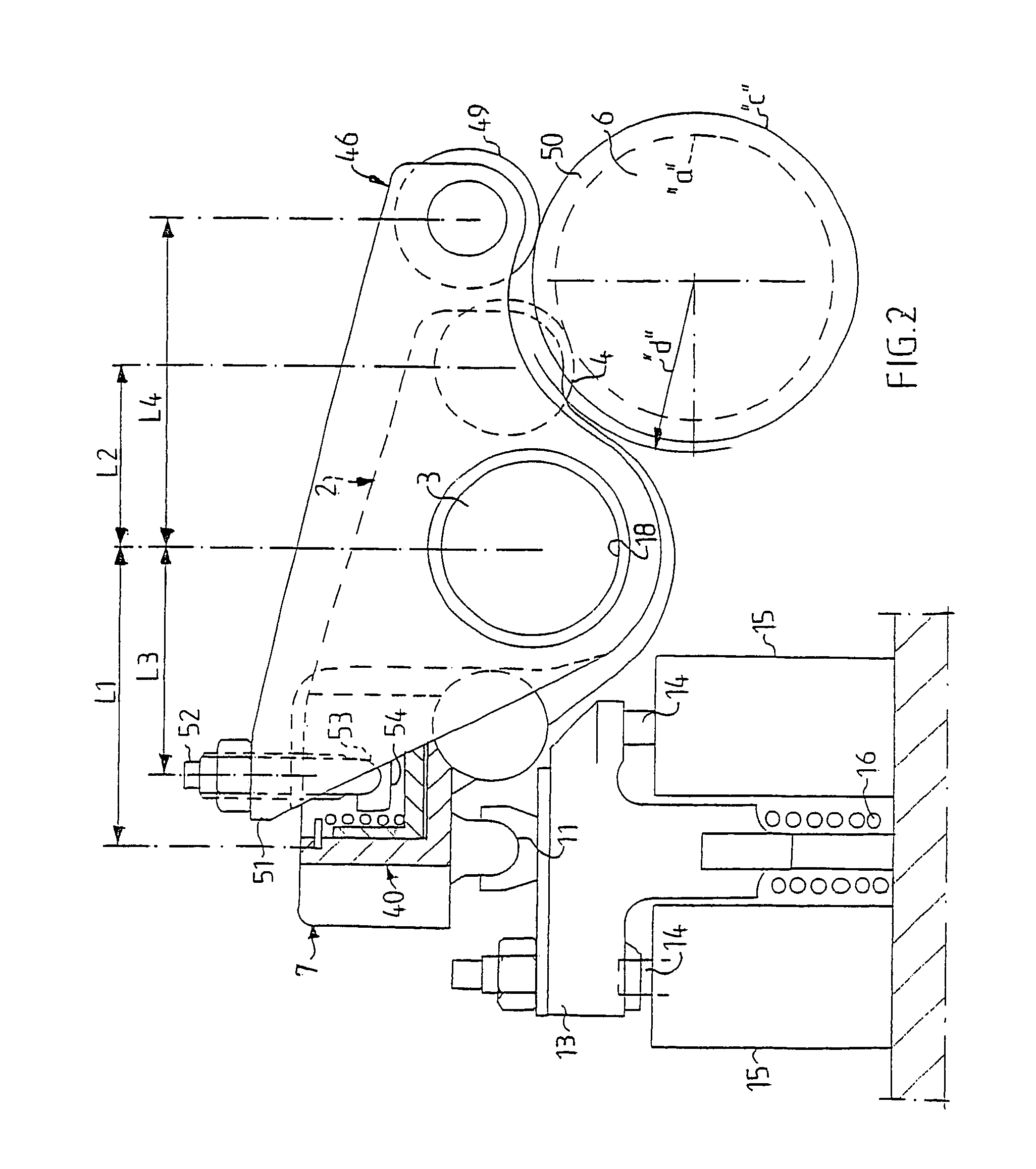

Valve mechanism in an internal combustion engine, includes a valve play-take up mechanism in the form of a piston in a cylinder chamber at one end of an exhaust rocker arm, and a hydraulic circuit with valve elements for supplying or draining off pressure fluid to and from the cylinder chamber. A second cylinder chamber with a piston acting in an opposite direction is arranged in the rocker arm and communicates with the first-mentioned cylinder chamber. A brake rocker arm is mounted on the same rocker arm shaft as the exhaust rocker arm and has an outer end, which acts against the piston in the second cylinder chamber. The brake rocker arm has its own cam element with brake cam lobes to one side of the exhaust rocker arm cam element.

Owner:VOLVO LASTVAGNAR AB

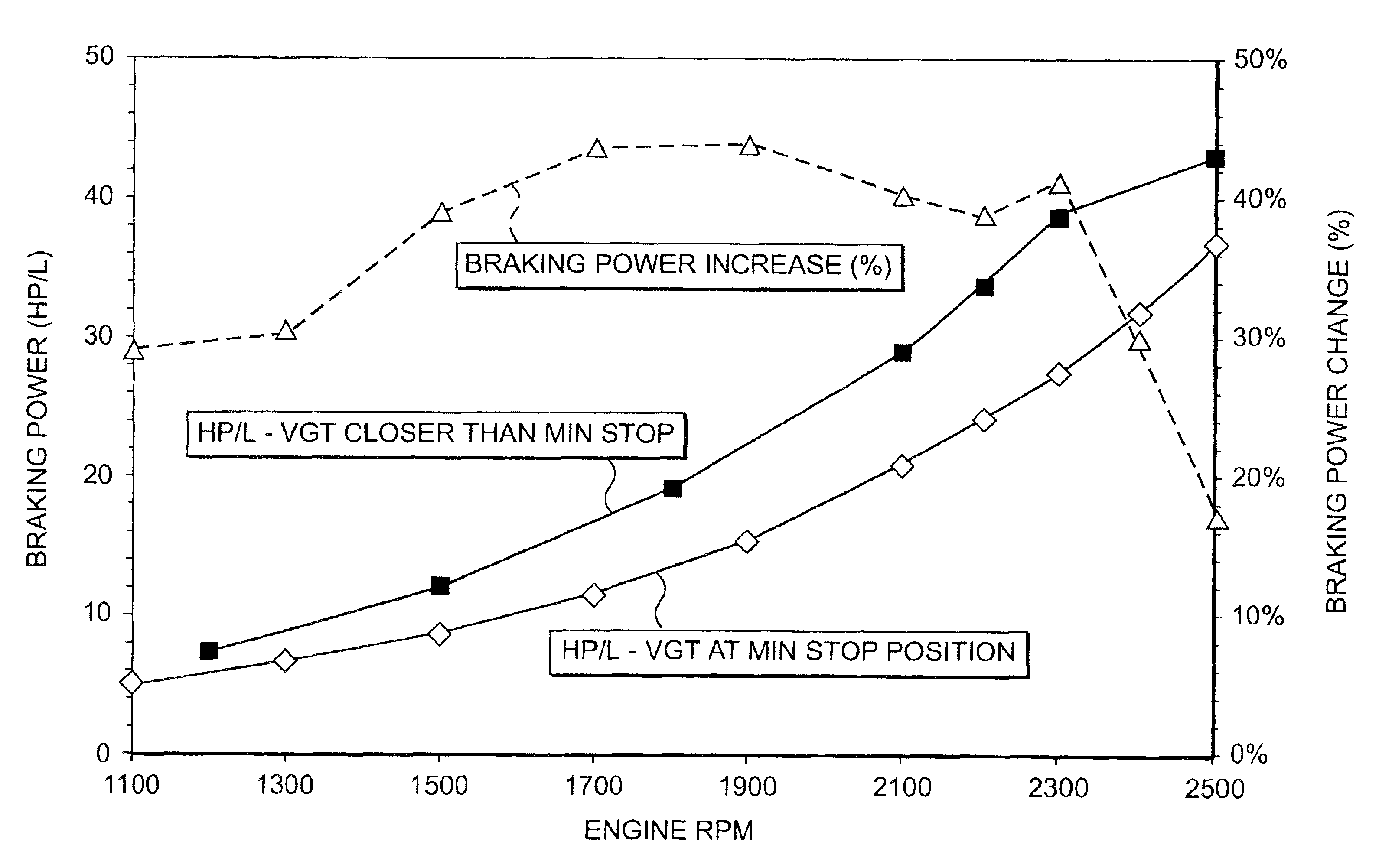

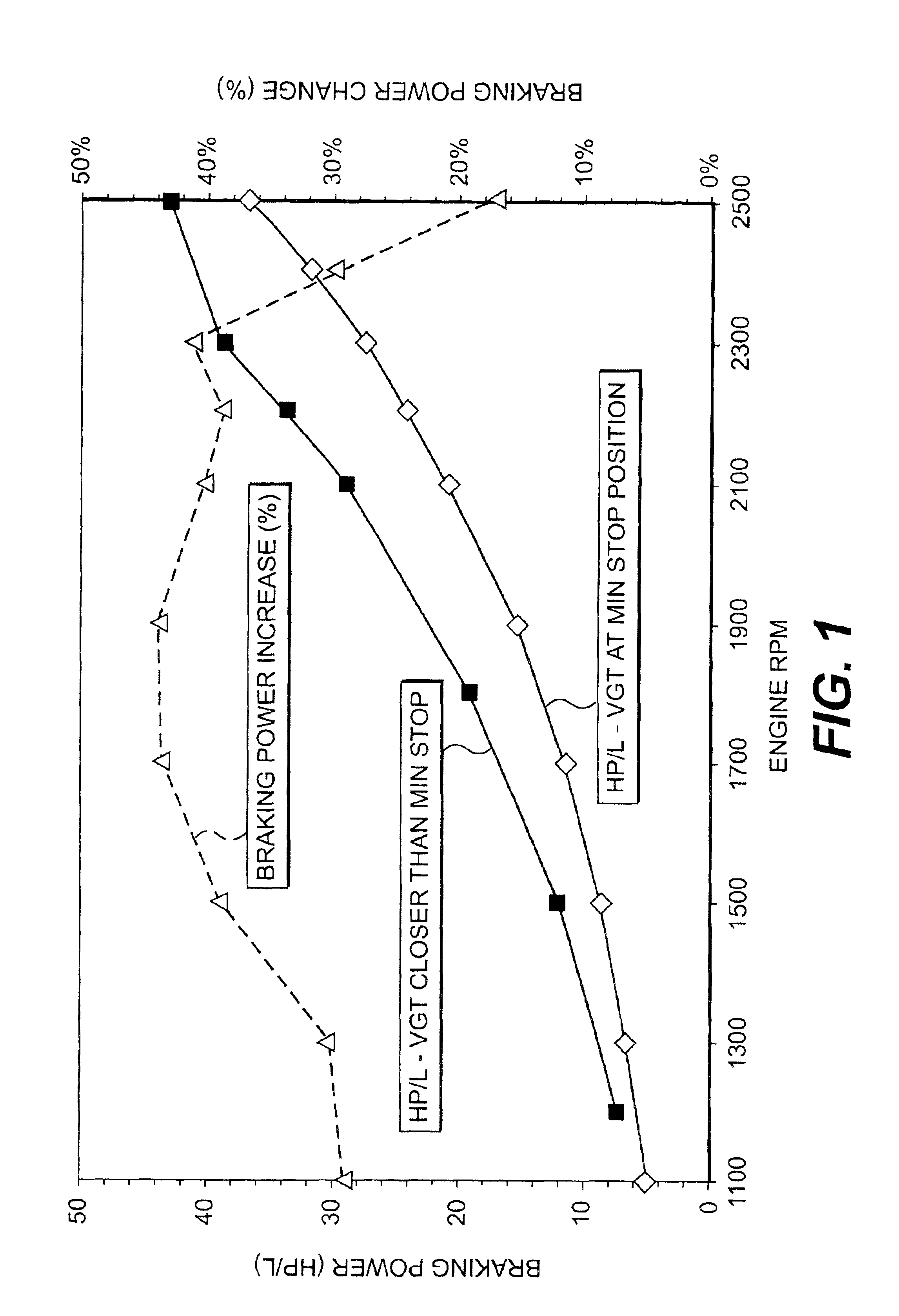

Engine braking methods and apparatus

ActiveUS7162996B2Constant liftNon-fuel substance addition to fuelInternal combustion piston enginesExhaust brakeVariable-geometry turbocharger

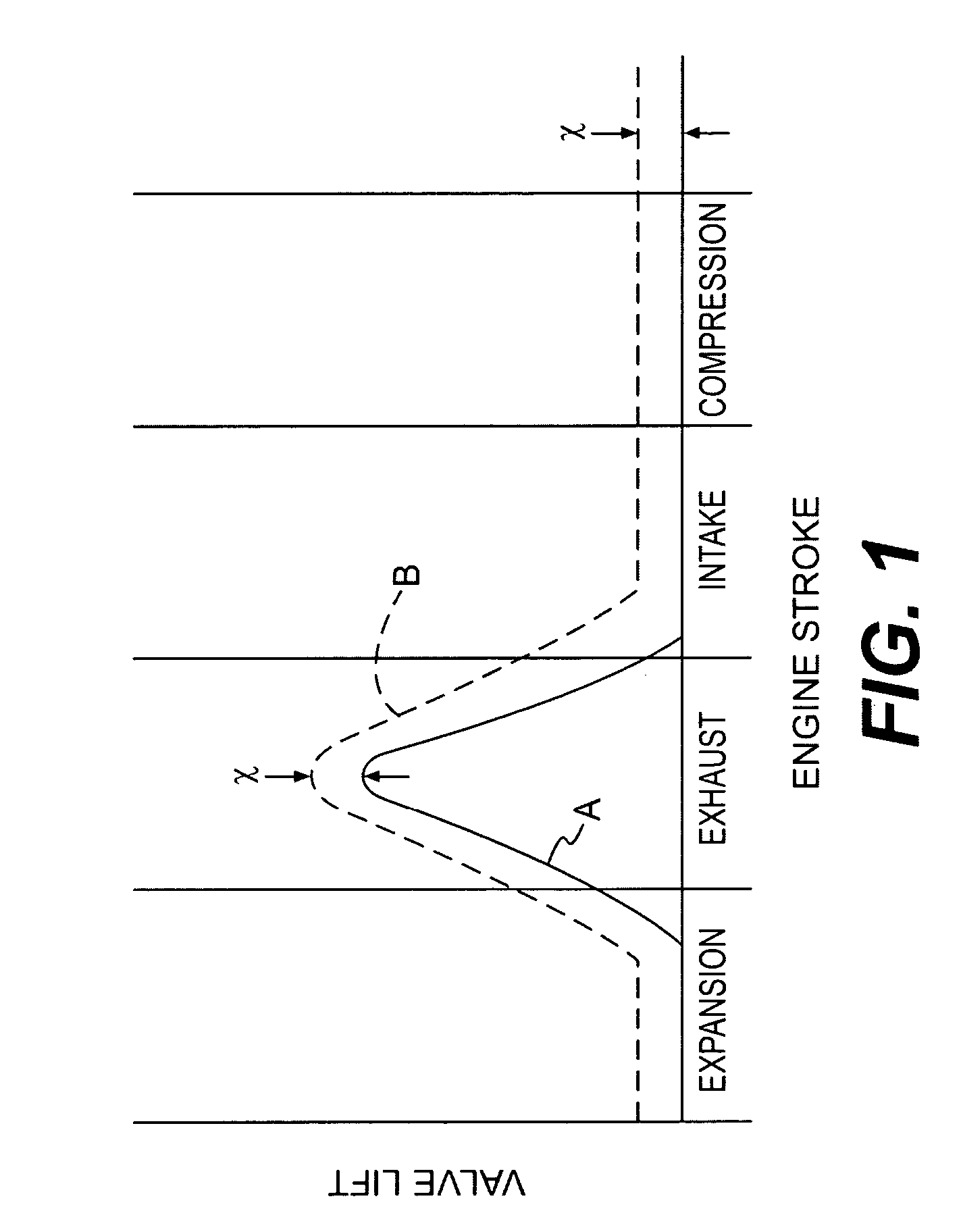

Methods and apparatus for providing bleeder-type and compression-release engine braking in an internal combustion engine are disclosed. For bleeder-type engine braking, the exhaust valve is maintained at a small and relatively constant lift throughout all or much of the engine cycle. The engine braking may be combined with exhaust gas recirculation, variable exhaust brake, and / or operation of a variable geometry turbocharger.

Owner:JACOBS VEHICLE SYST

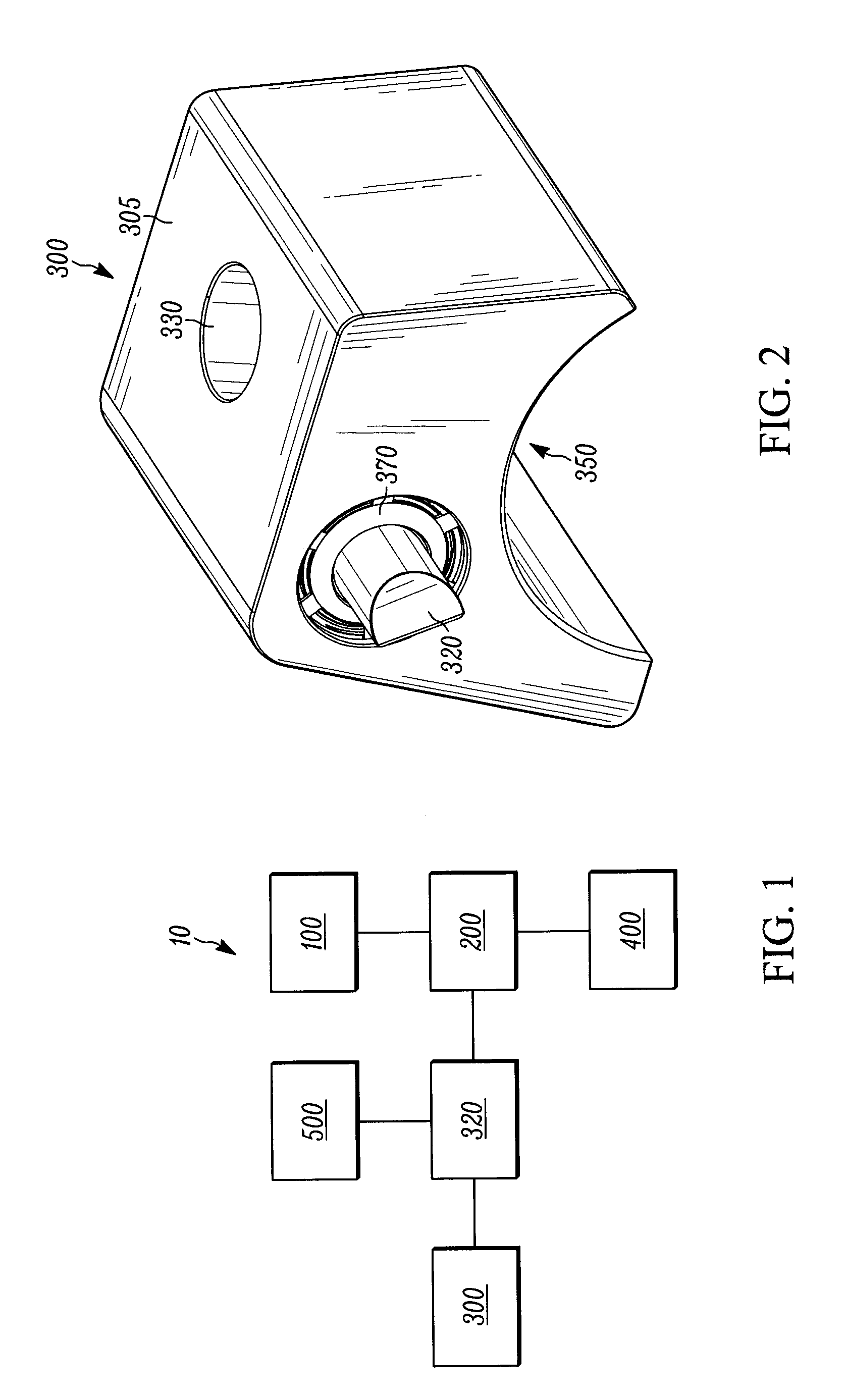

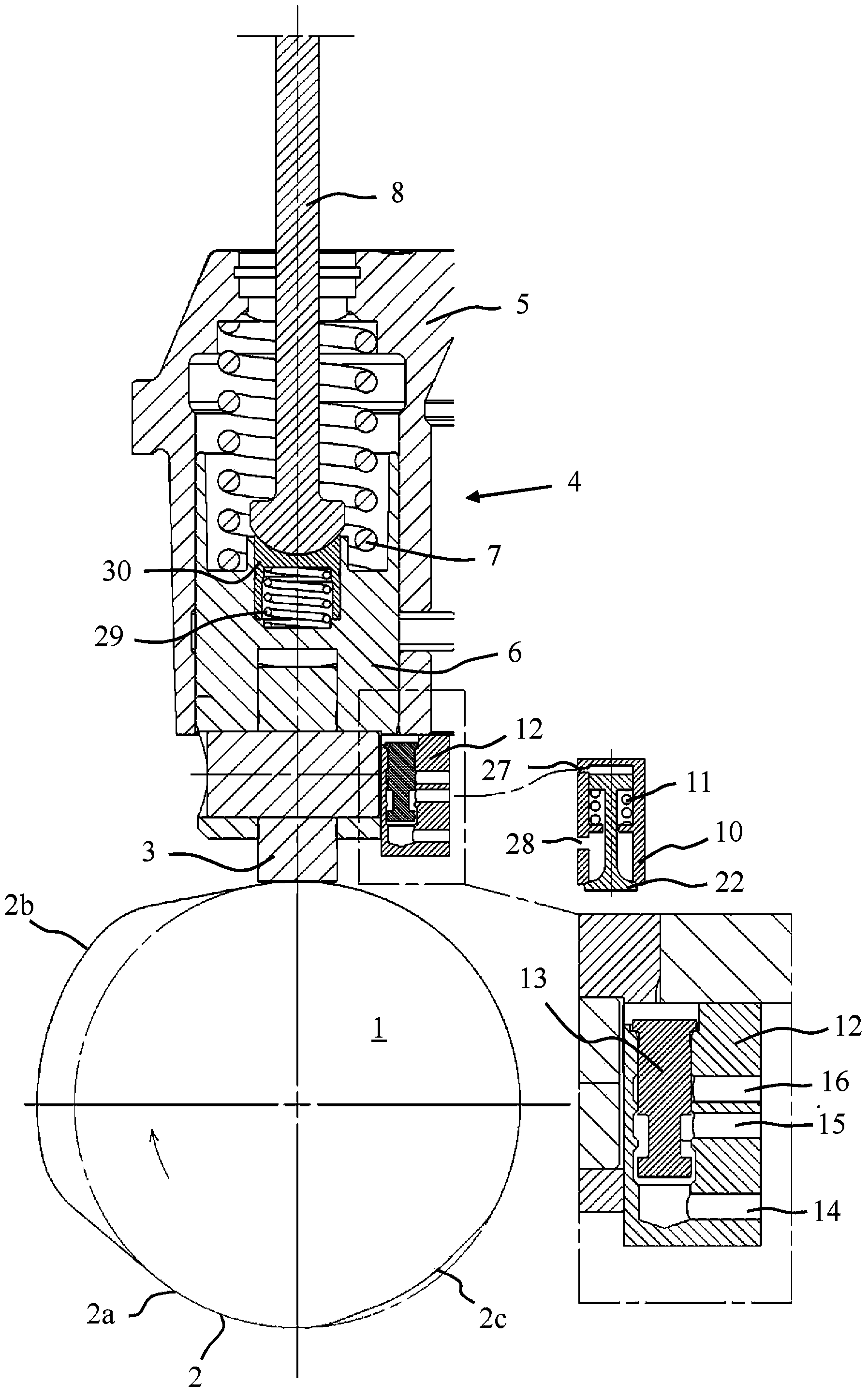

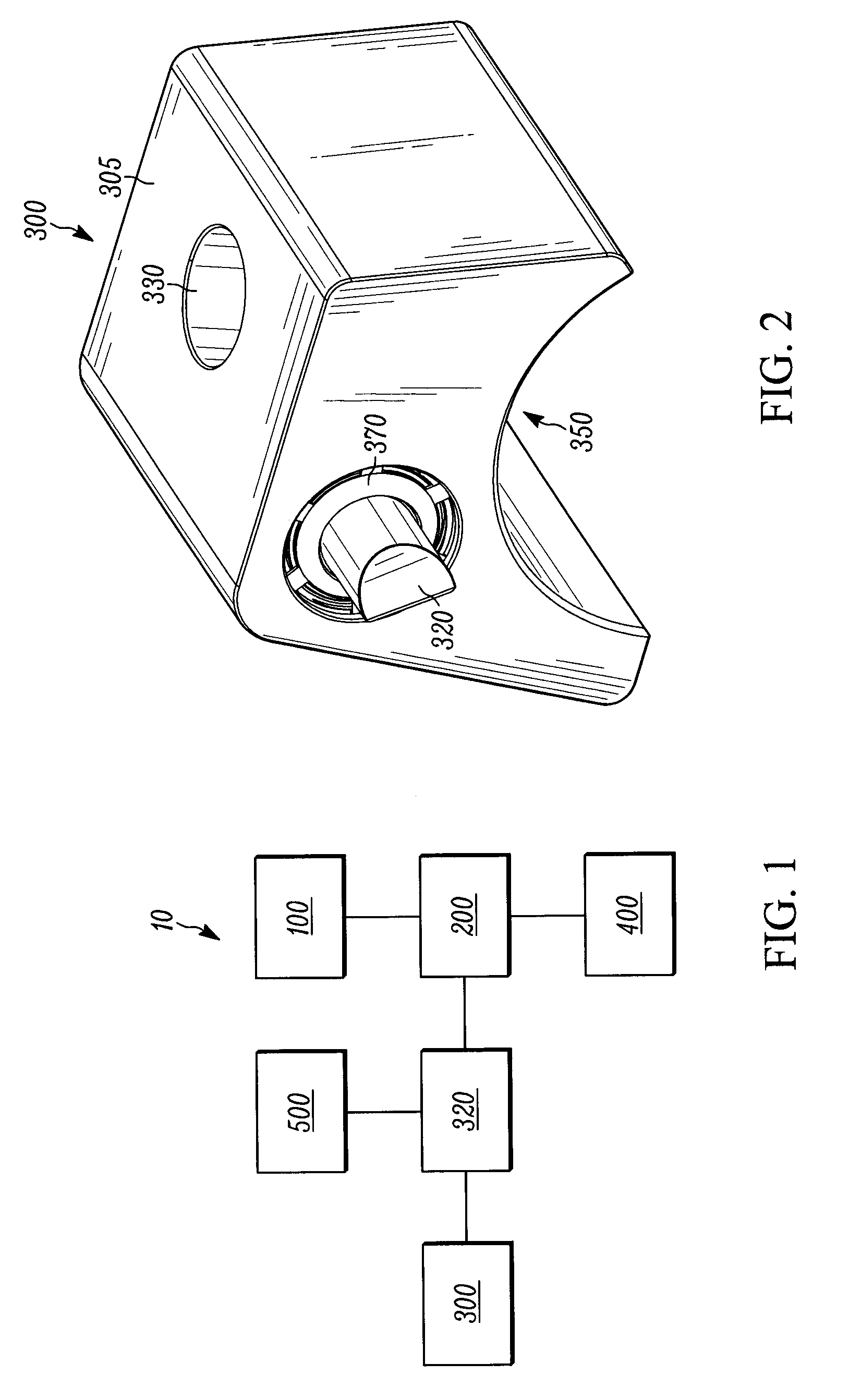

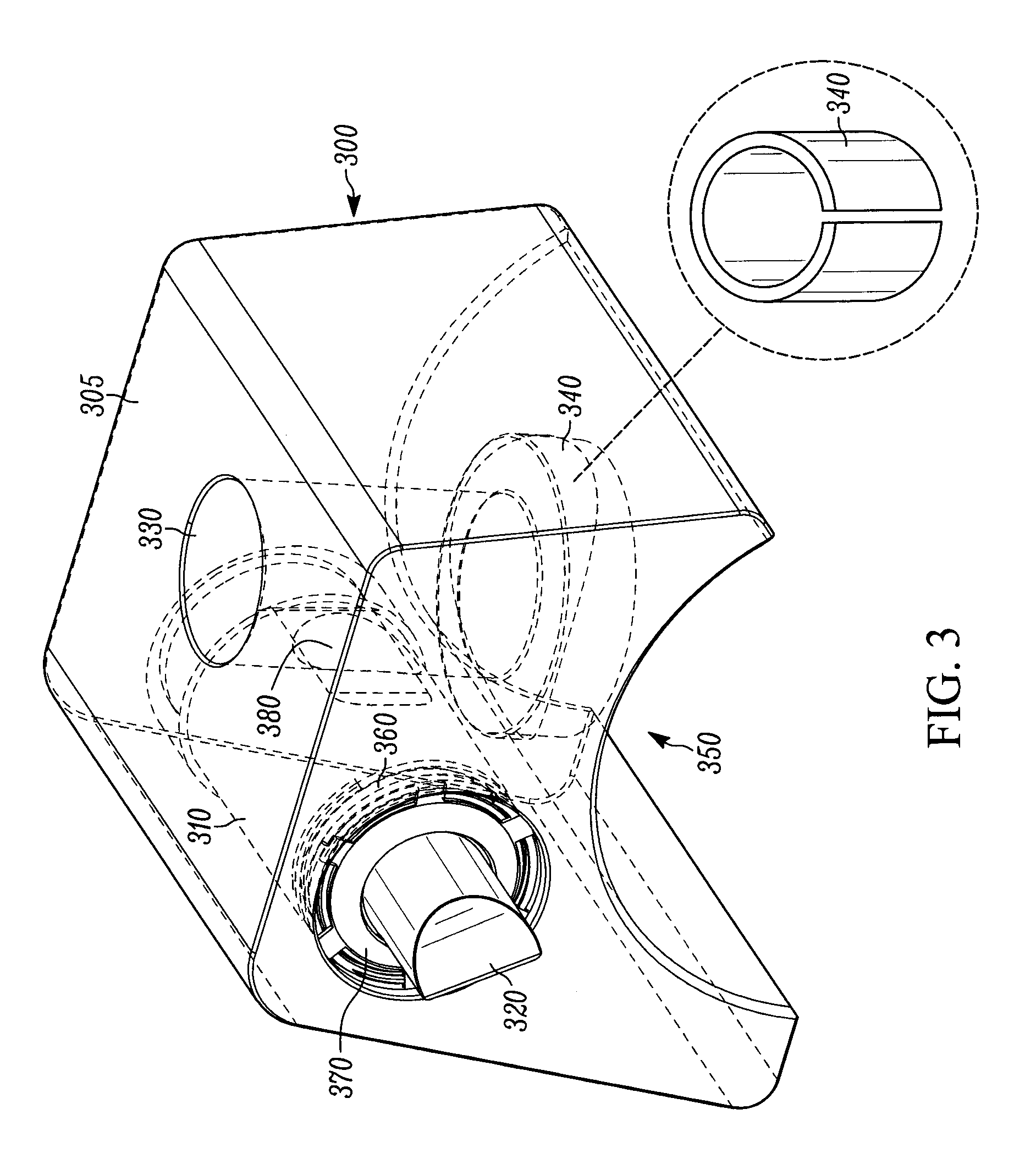

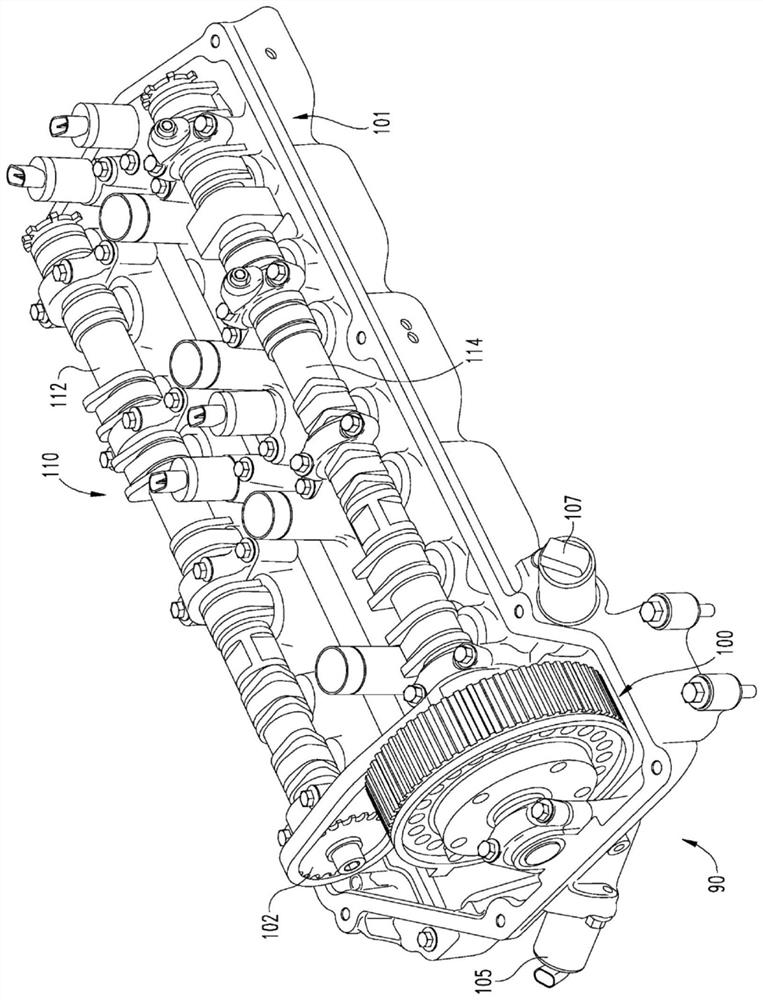

Rocker latch for controlling engine valve actuation

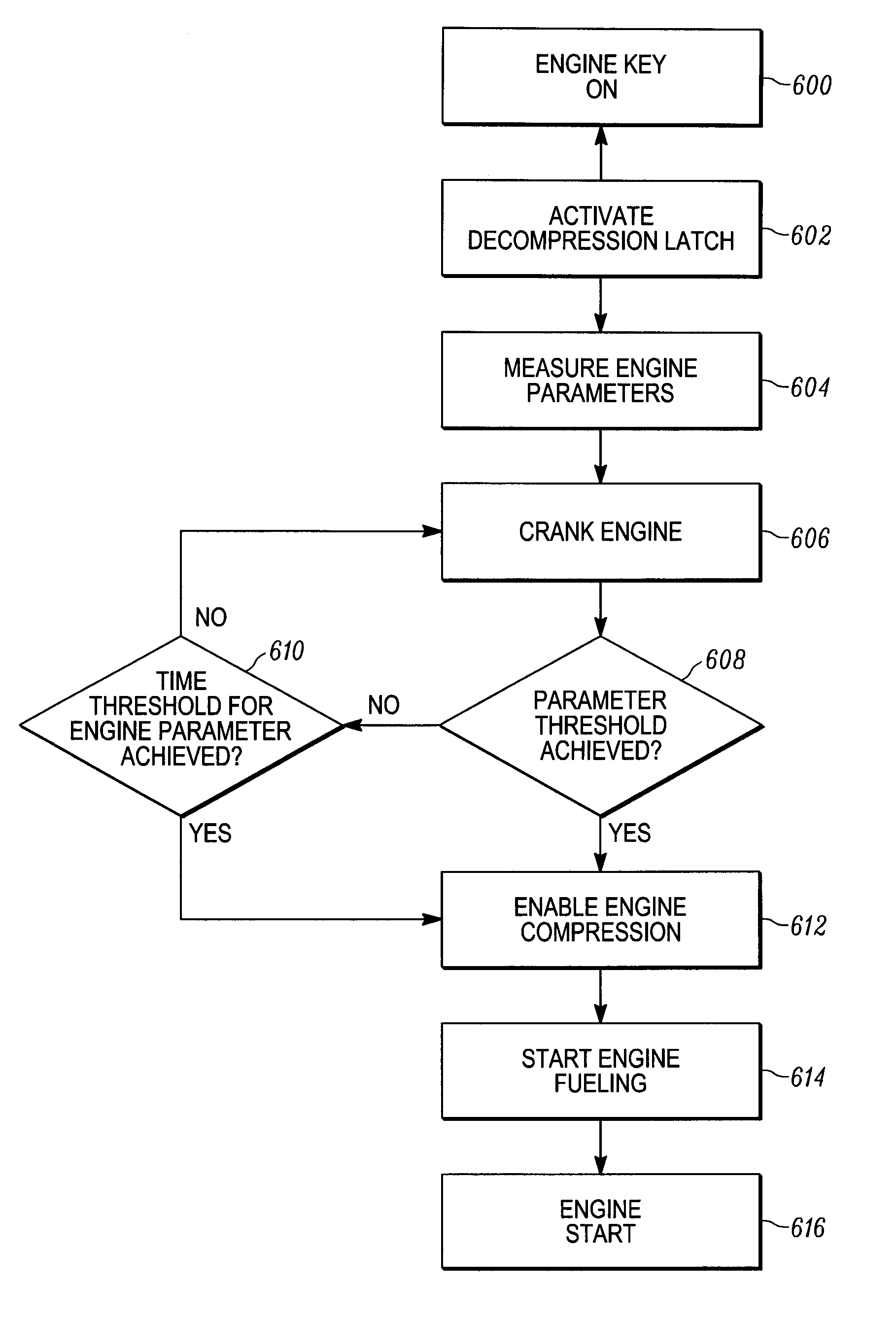

ActiveUS20140182539A1Avoid closingInternal combustion piston enginesOutput powerEngineeringEngine valve

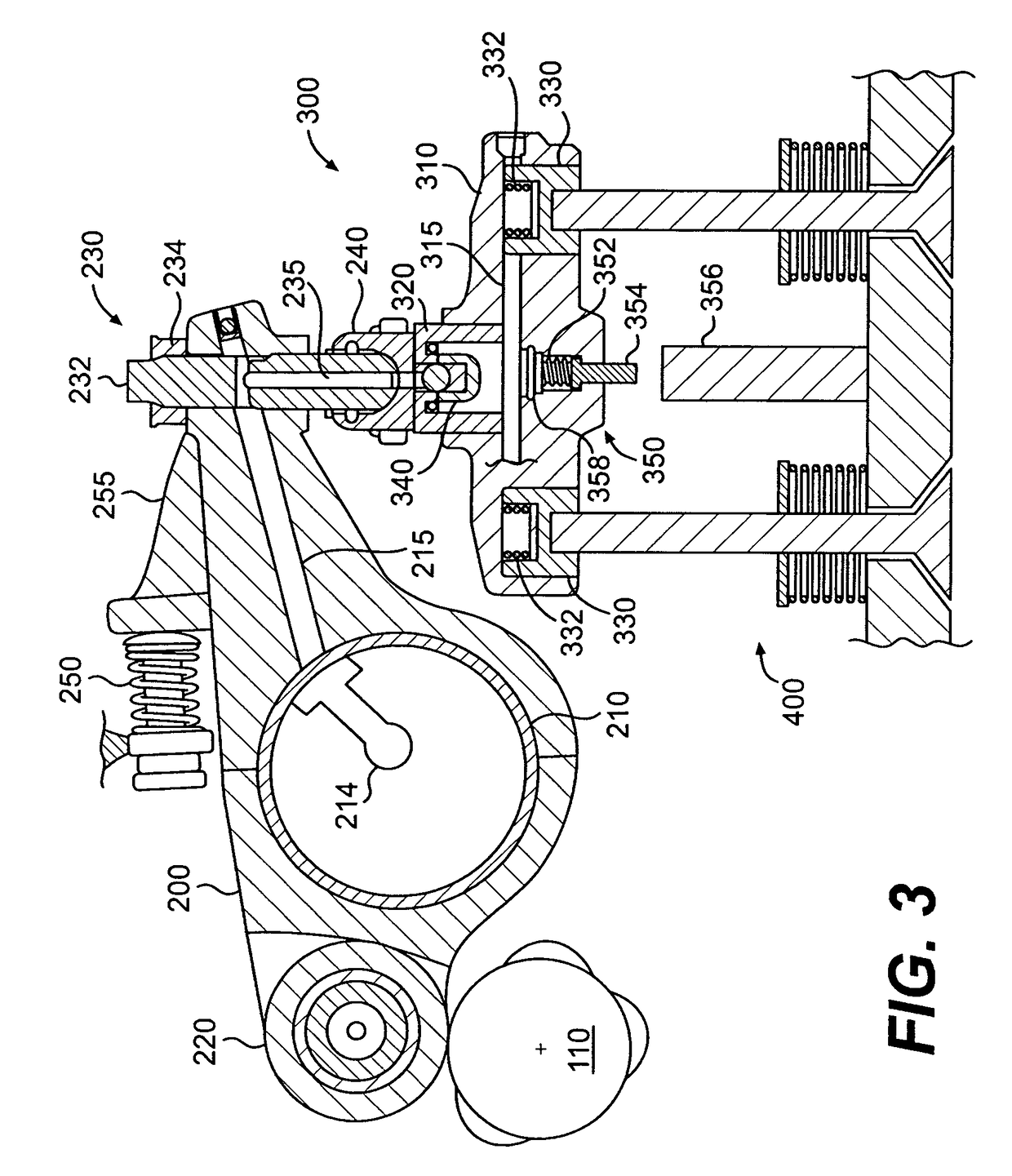

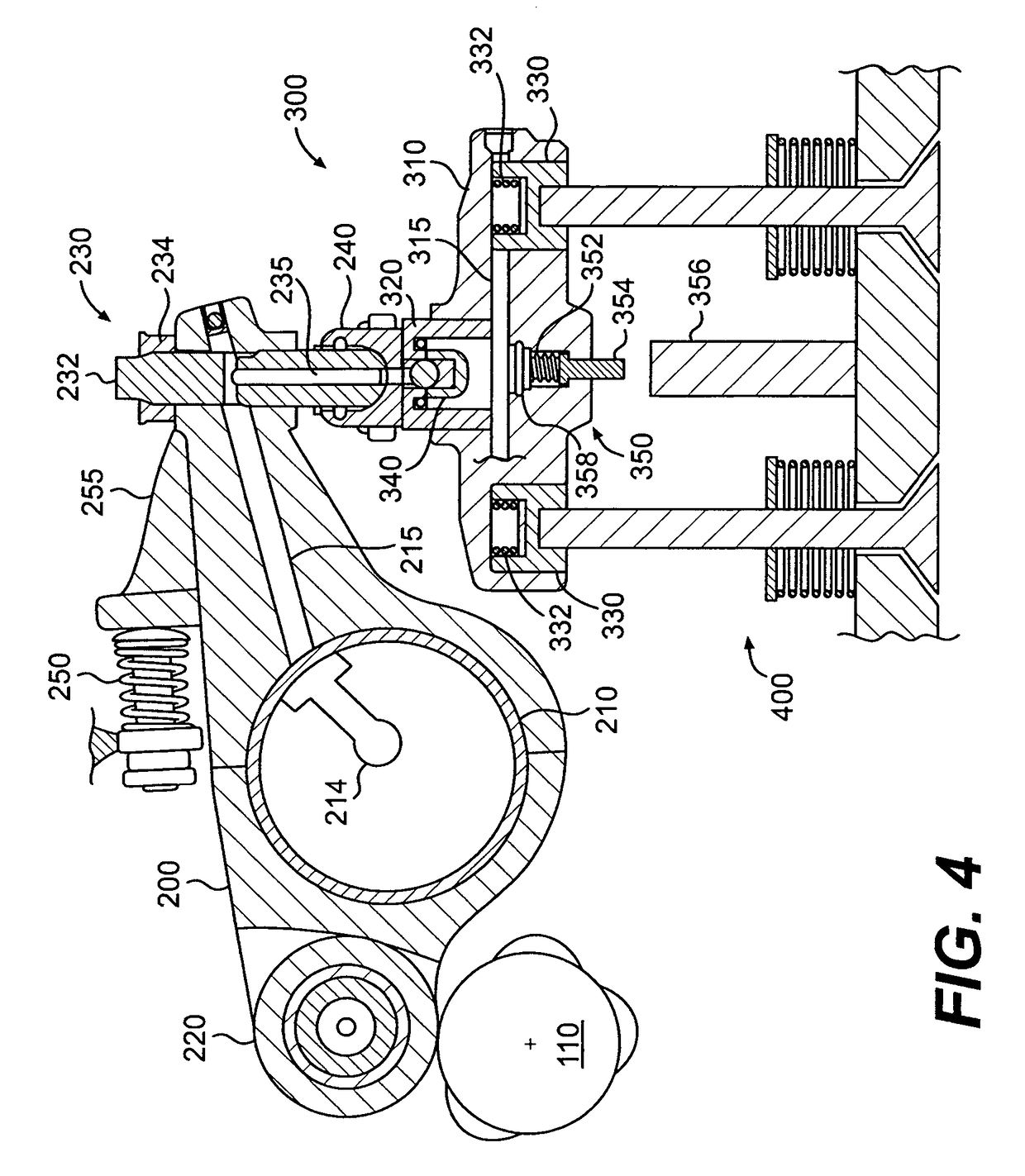

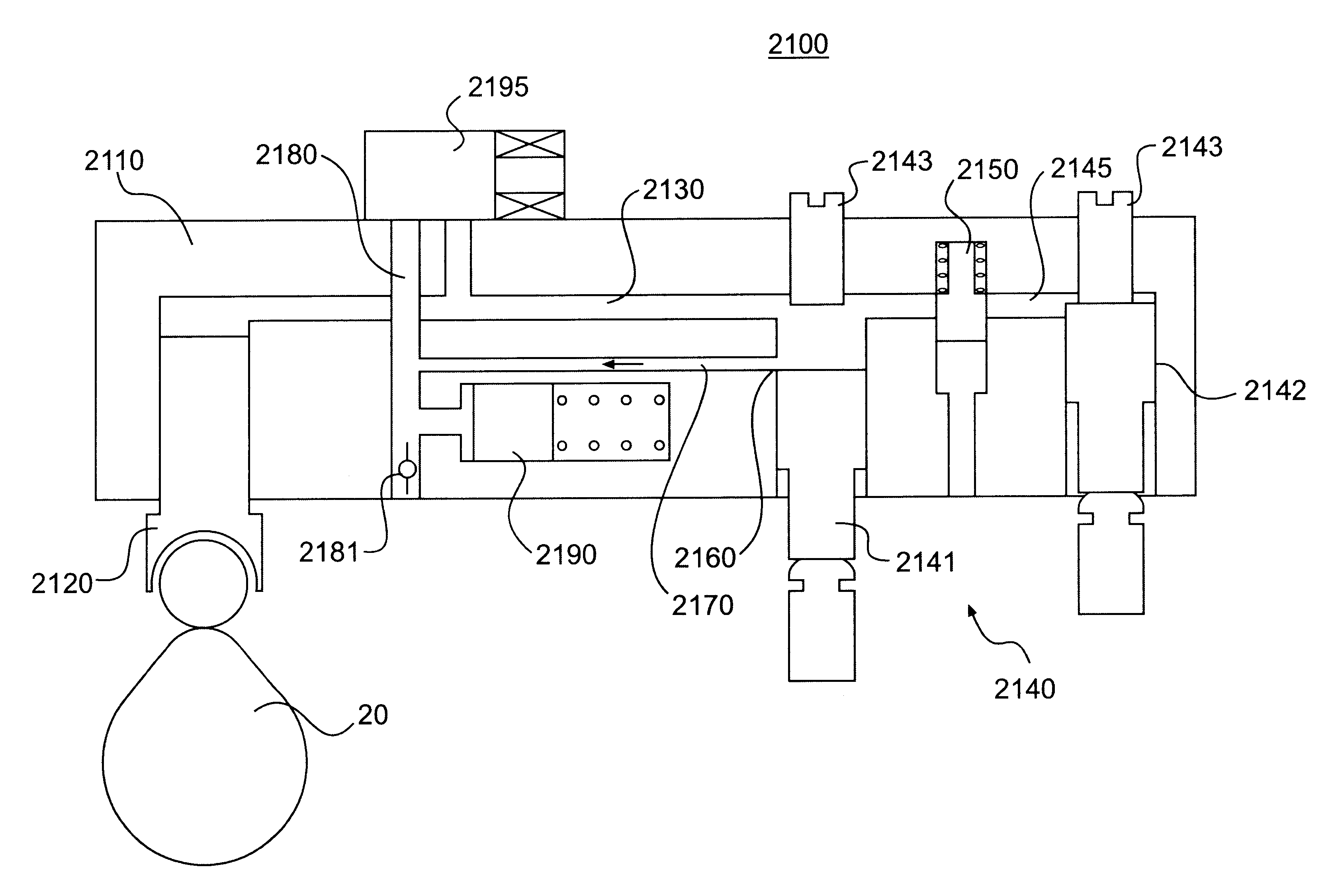

Engine valve actuation systems and methods used to decompress an engine cylinder during engine start-up, shut-down, and for bleeder braking are disclosed. An exemplary system may include a rocker arm pivotally mounted on a rocker shaft, and a structure mounted adjacent to the rocker arm in a fixed position relative to the rocker arm. A latch piston may be slidably disposed between the rocker arm and the structure. The latch piston may be selectively extended to engage both the rocker arm and structure to limit the pivotal motion of the rocker arm and maintain the engine valves in an open condition.

Owner:JACOBS VEHICLE SYST

Method and system of improving engine braking by variable valve actuation

InactiveUS20020056435A1Improved swirlWell mixedElectrical controlValve drivesLow speedVariable valve timing

The present invention relates to methods of improving engine braking of a reciprocating piston internal combustion engine by variable valve actuation. One embodiment of the present invention enables independent two-valve actuation for each cylinder, and engine braking horsepower can be optimized using two-valve braking at high engine speeds and one-valve braking at low speeds. Another embodiment of the present invention enables better a sequential valve actuation to reduce engine braking load and compliance. Another embodiment of the present invention enables better engine starting and warming up by controlling timing and lift of each valve.

Owner:DIESEL ENGINE RETARDERS

Locking multi-mode lever-type variable valve driving system

InactiveCN106545380AMeet operational requirementsMeet the requirements of ventilationValve controlMachines/enginesMature technologyEngineering

The invention discloses a locking multi-mode lever-type variable valve driving system, belonging to the field of engine valve driving. The variable valve driving system mainly comprises a cam shaft, a mode input mechanism, a mode output mechanism, a mode switching mechanism, a valve regulating lever, a valve control mechanism and the like. By using the mode switching mechanism, the switching among multiple modes, including a two-stroke driving mode, a four-stroke driving mode, a two-stroke braking mode, a four-stroke braking mode and the like, of an engine is realized, further, by matching with the valve control mechanism for use, the optimum ventilation under different working conditions of the engine is finally realized, and the aims of comprehensively improving the engine dynamic property, fuel economy, emission performance and braking security are achieved. The invention is proposed by aiming at practical application, the reliability is high, the structure is compact, the requirements of a system on all the mechanisms are reduced, relatively mature technologies are adopted by all the mechanisms, the practical potential of the system in a short time is high, and the application prospect is good.

Owner:DALIAN UNIV OF TECH

Apparatus and method for retarding an engine with an exhaust brake and a compression release brake

An apparatus and method for retarding an engine having a cylinder with an exhaust valve, an intake valve, an intake stroke, an exhaust stroke, a compression stroke and an expansion stroke. The apparatus includes an exhaust brake and a compression release brake. The exhaust brake includes a variable exhaust restrictor, a pressure sensor for sensing pressure of exhaust gases and a controller operatively connected to the pressure sensor and to the exhaust restrictor. Opening of the exhaust restrictor is adjusted during operation of the apparatus so exhaust pressure is sufficient to cause exhaust valve float prior to bottom dead center of intake strokes of the cylinder, thereby enhancing operation of the compression release brake.

Owner:JENARA ENTERPRISES

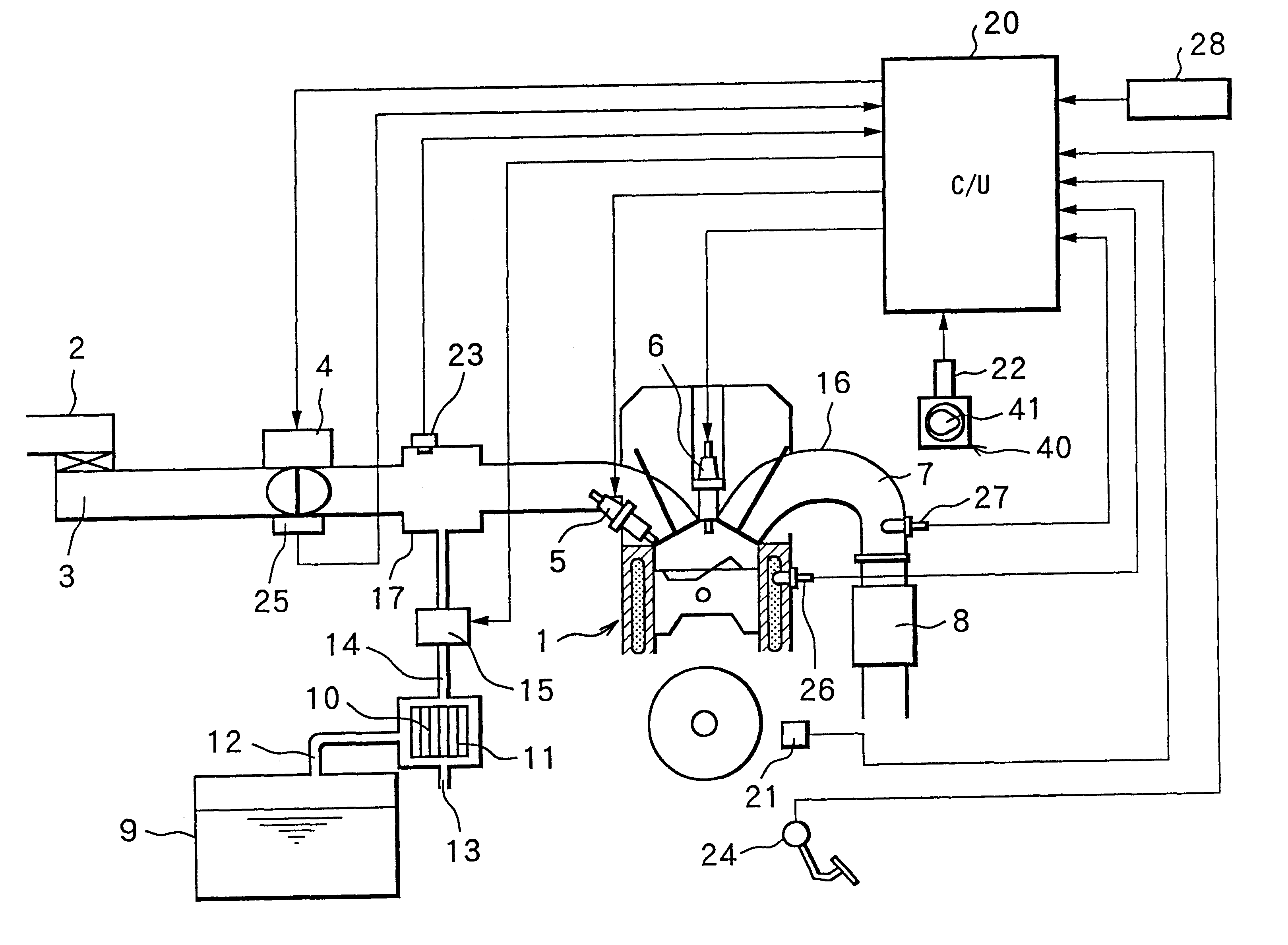

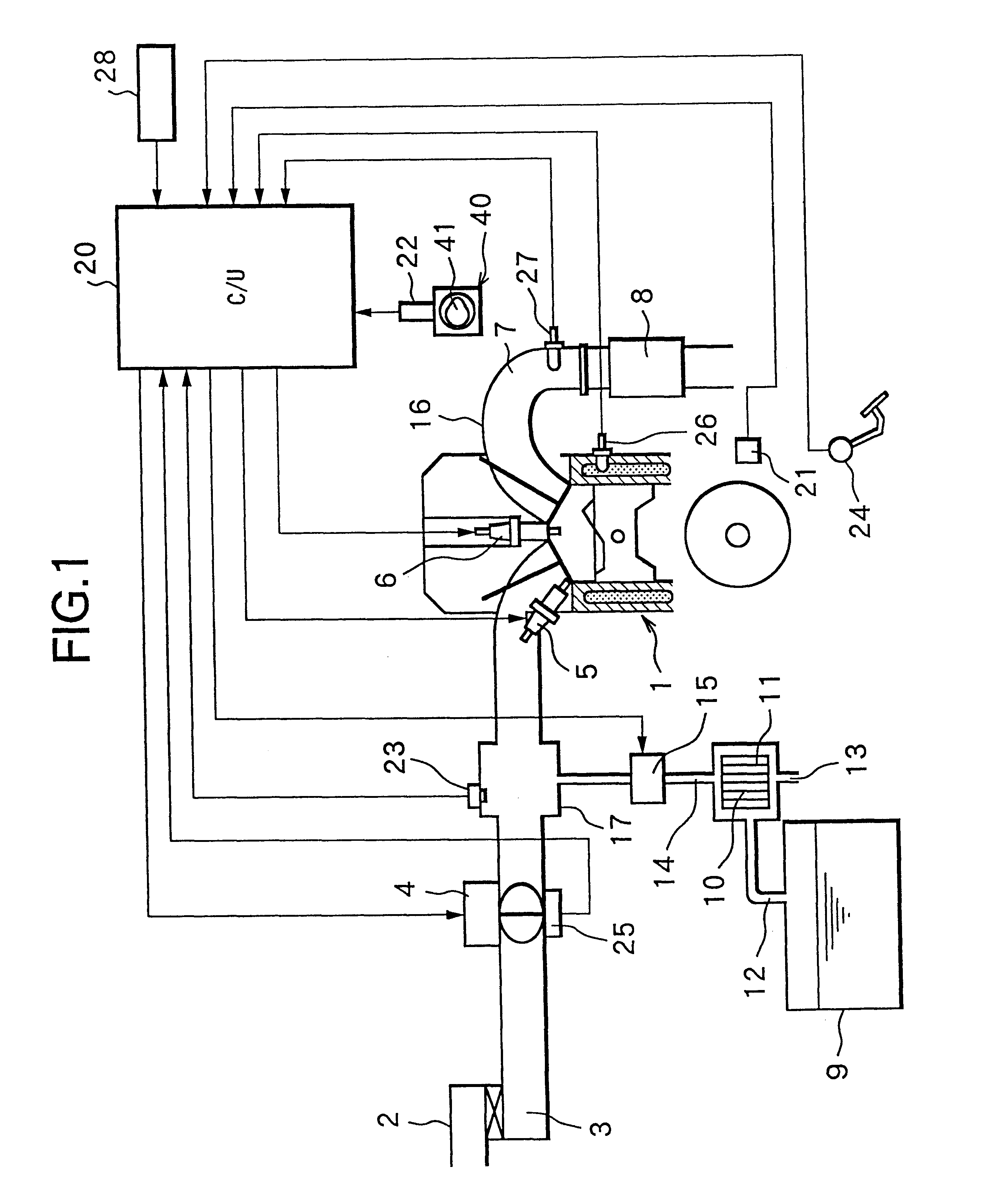

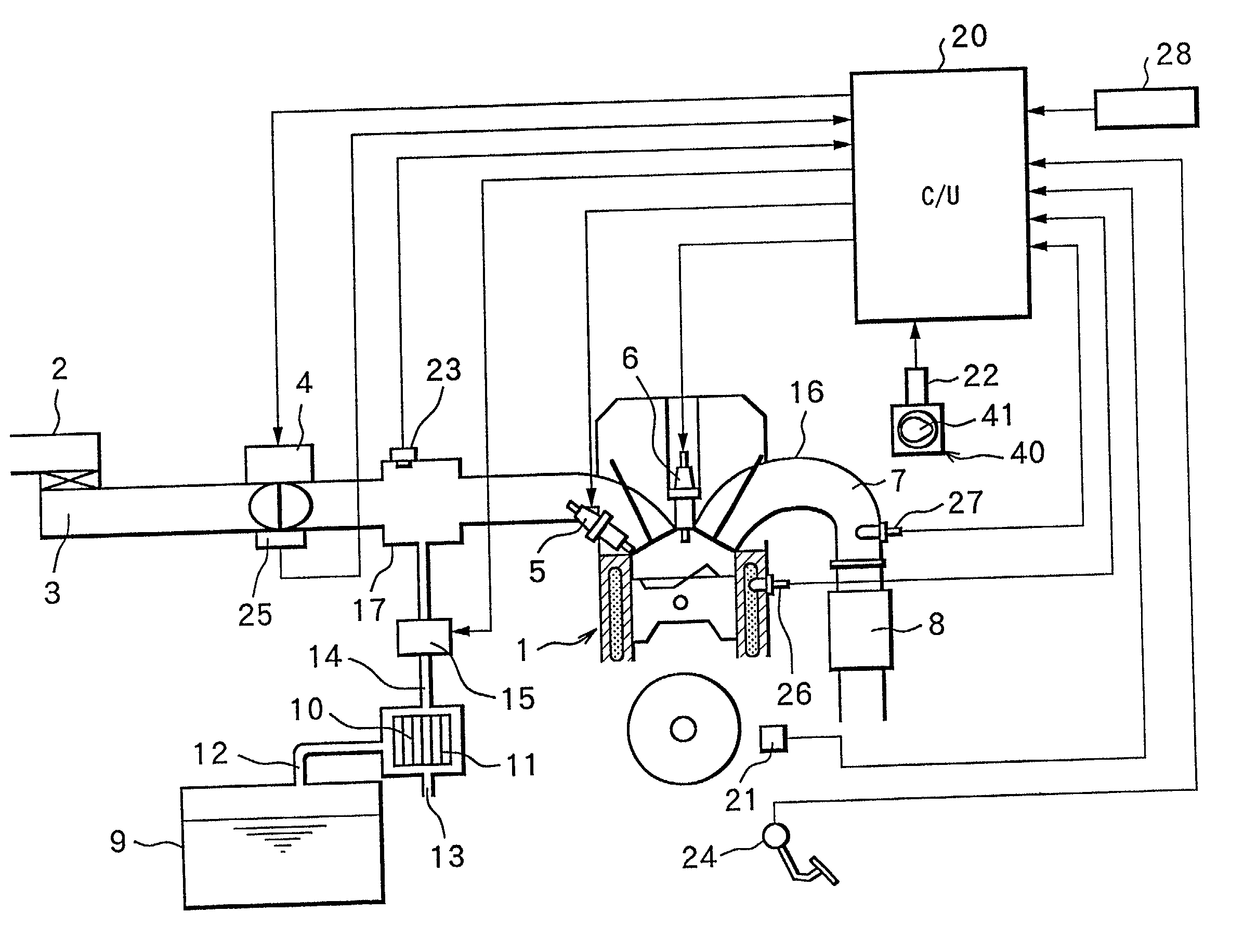

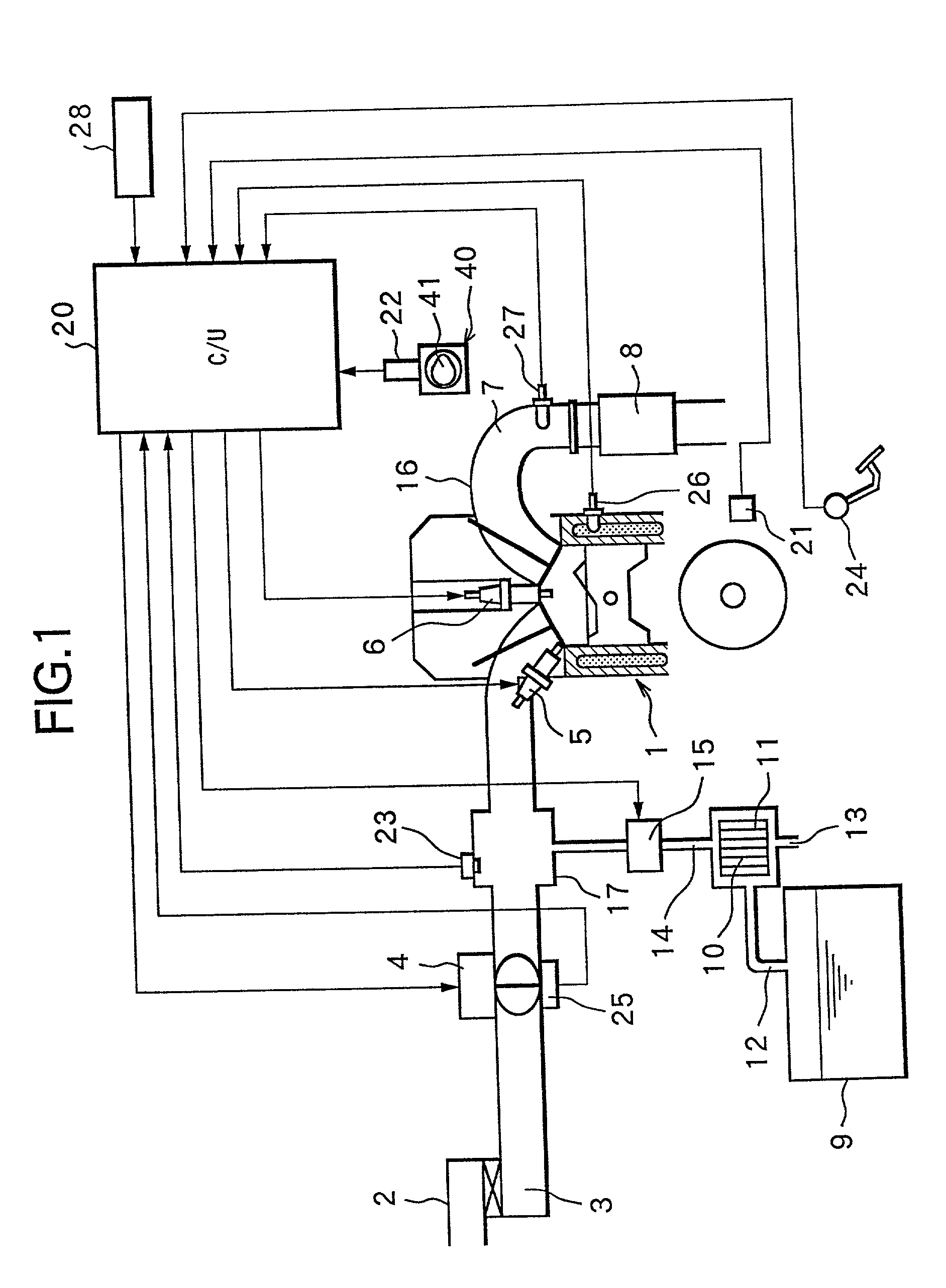

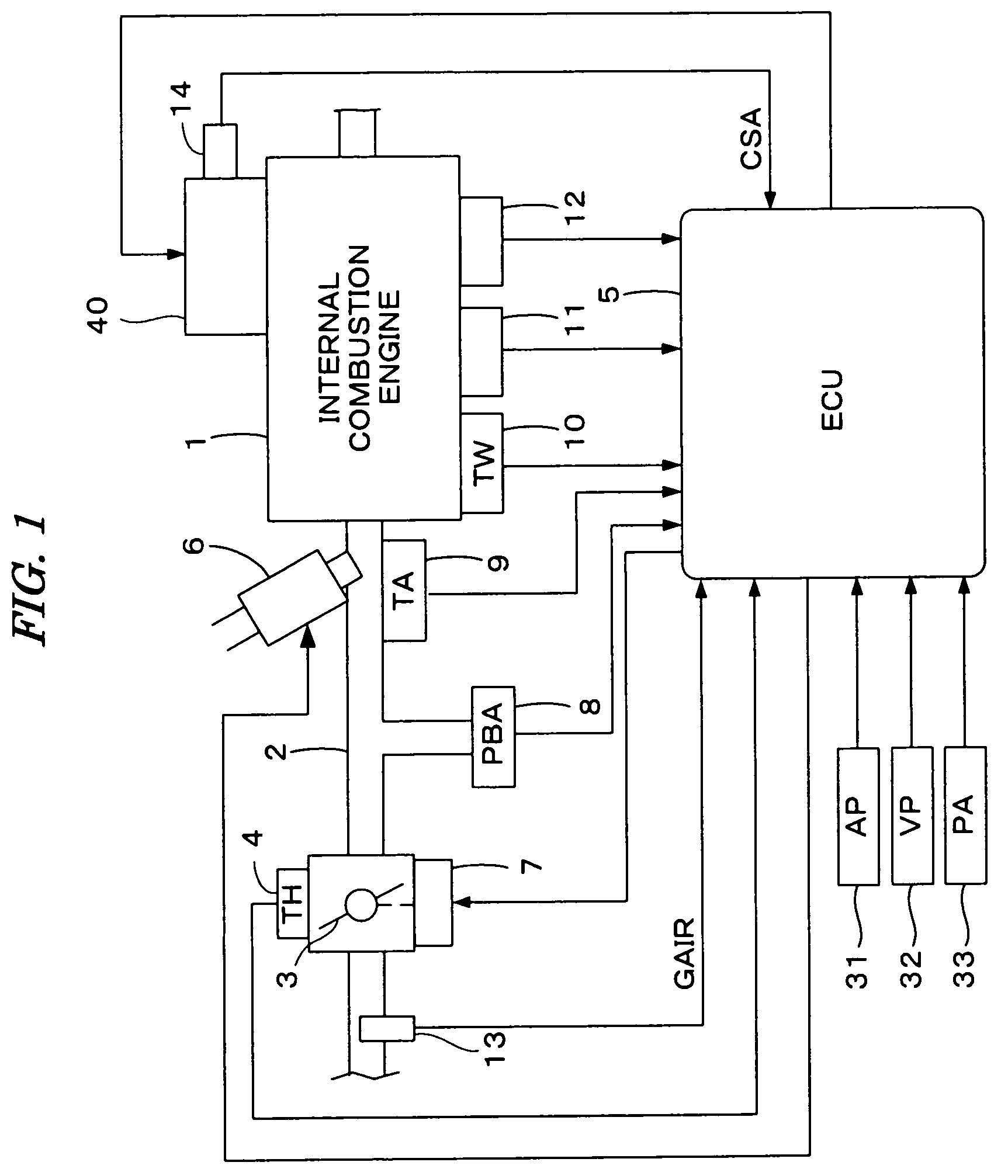

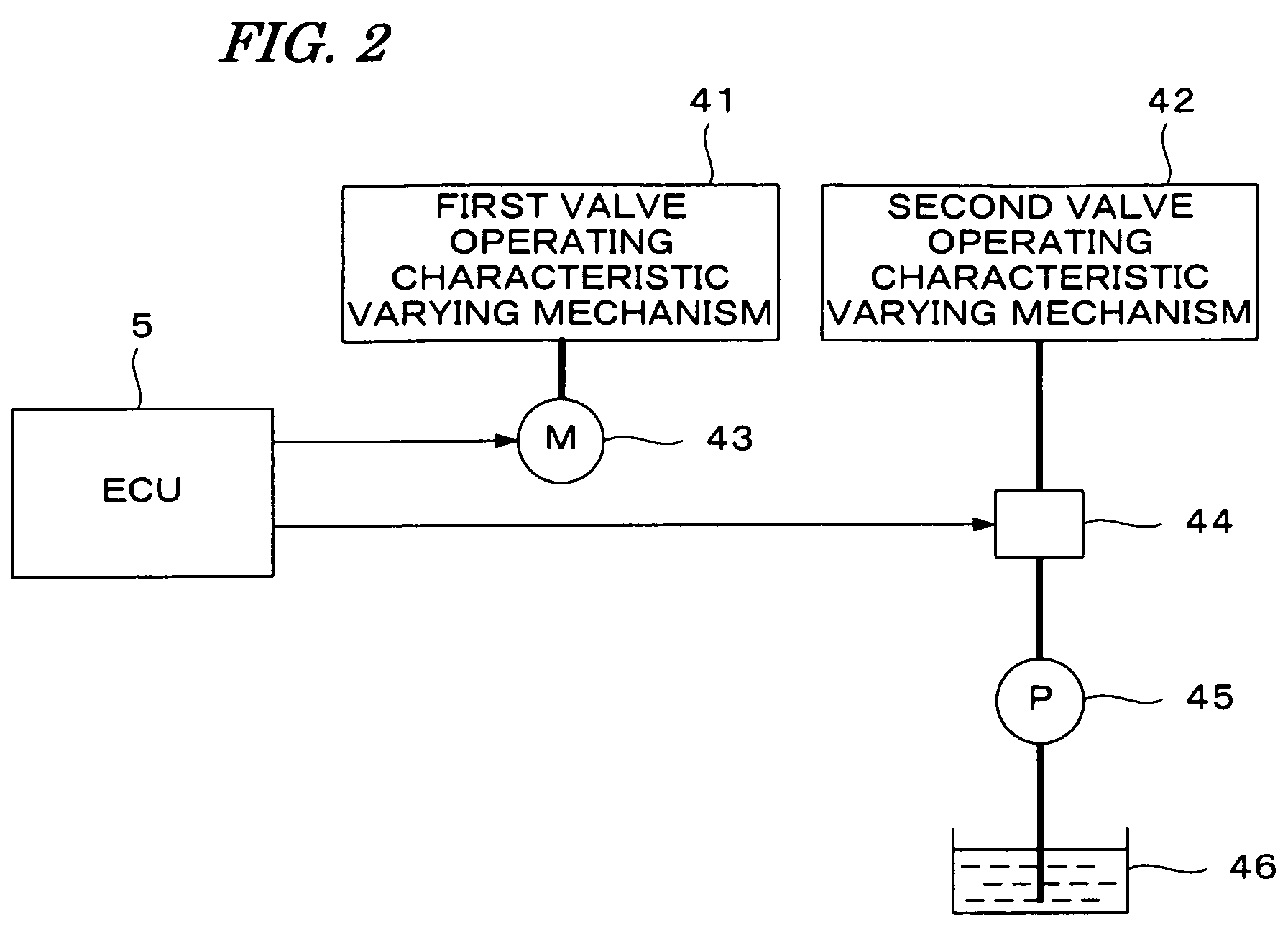

Apparatus and method for controlling internal combustion engine

InactiveUS6584956B2Electrical controlInternal combustion piston enginesExternal combustion engineIntake pressure

In an electronically controlled fuel injection apparatus of a speed density type, a new air intake efficiency correction value for correcting an intake pressure is calculated based on the intake pressure, an engine rotation speed, and an advance angle amount of valve timing.

Owner:UNISIA JECS CORP

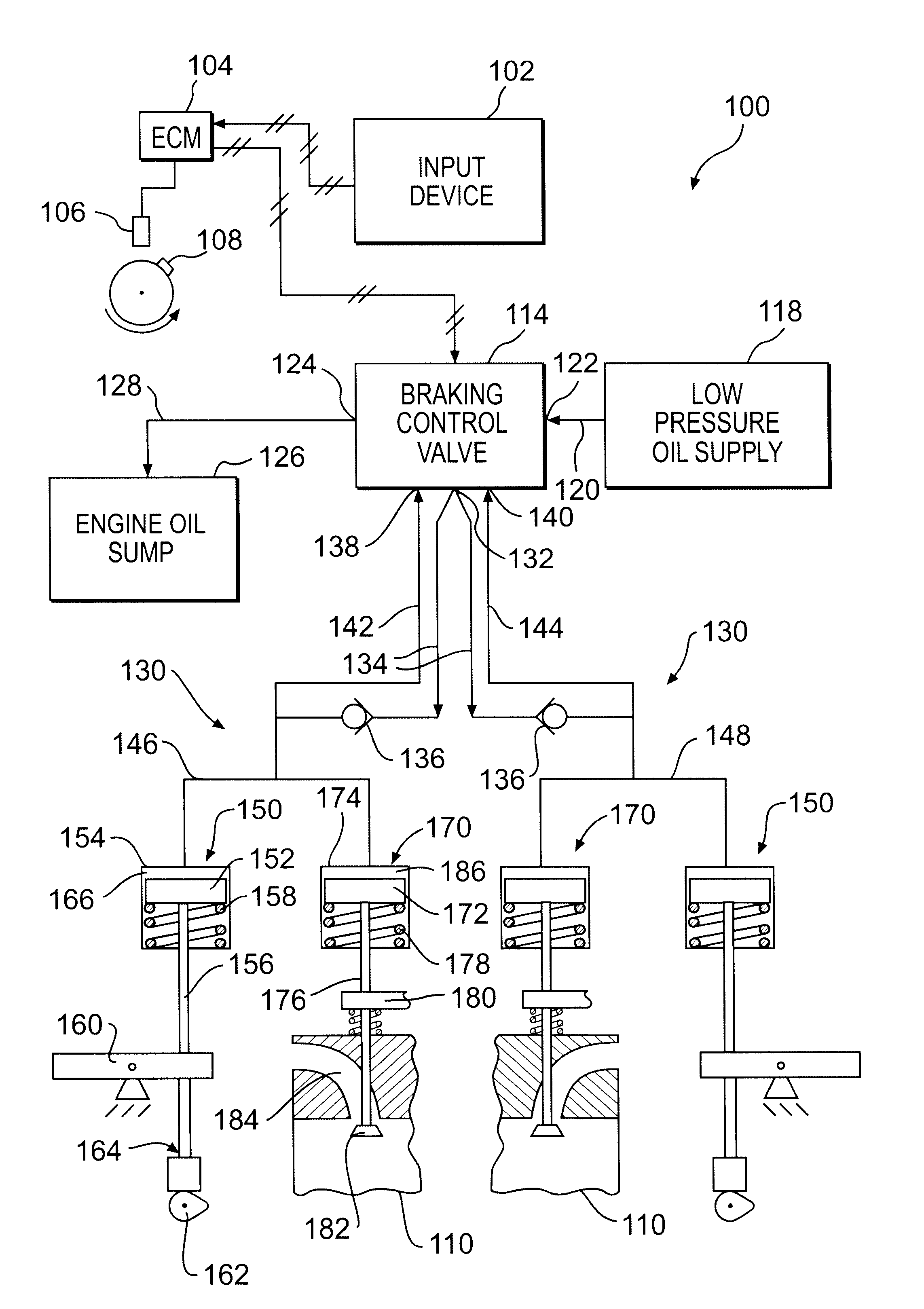

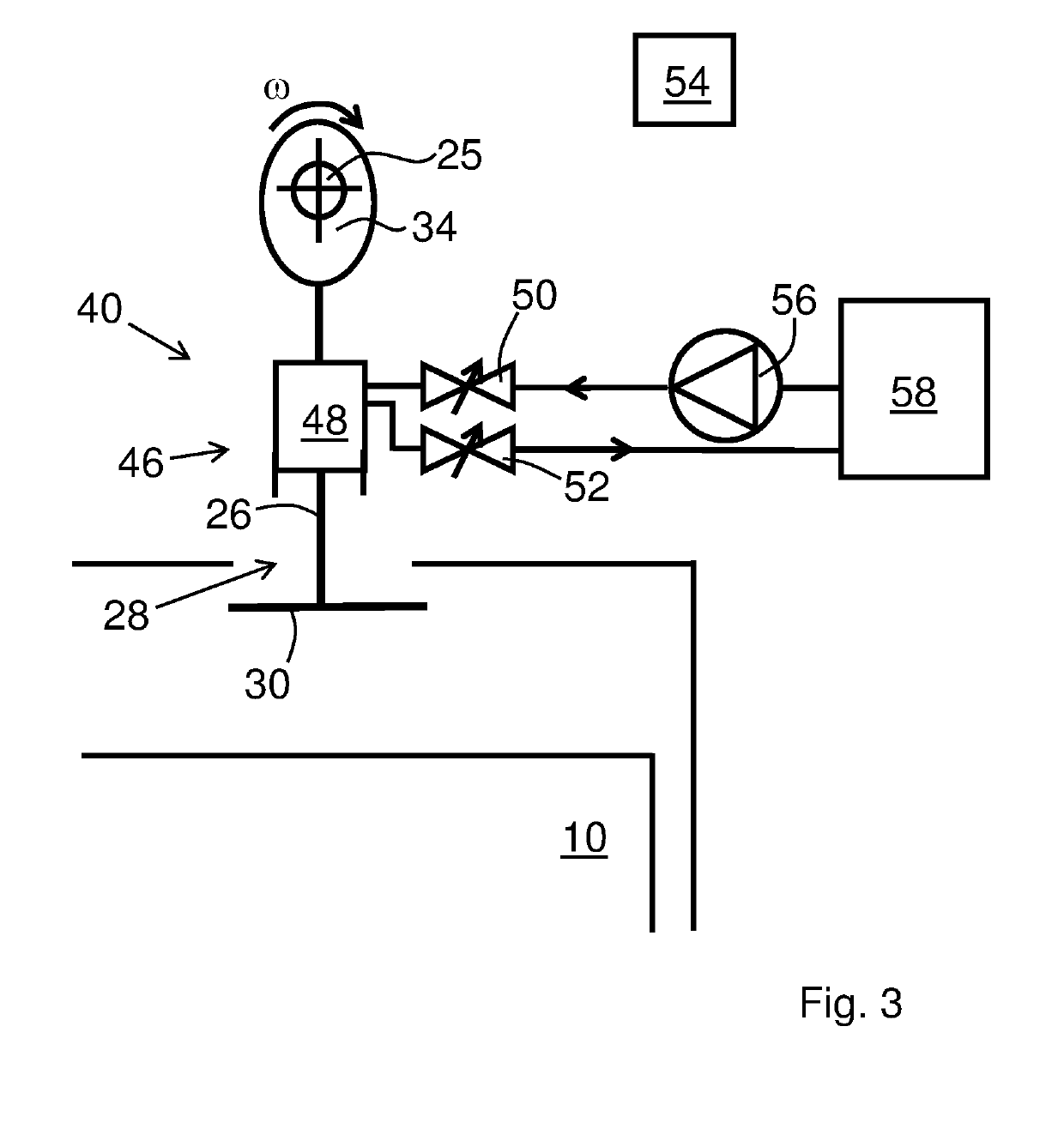

Engine braking system

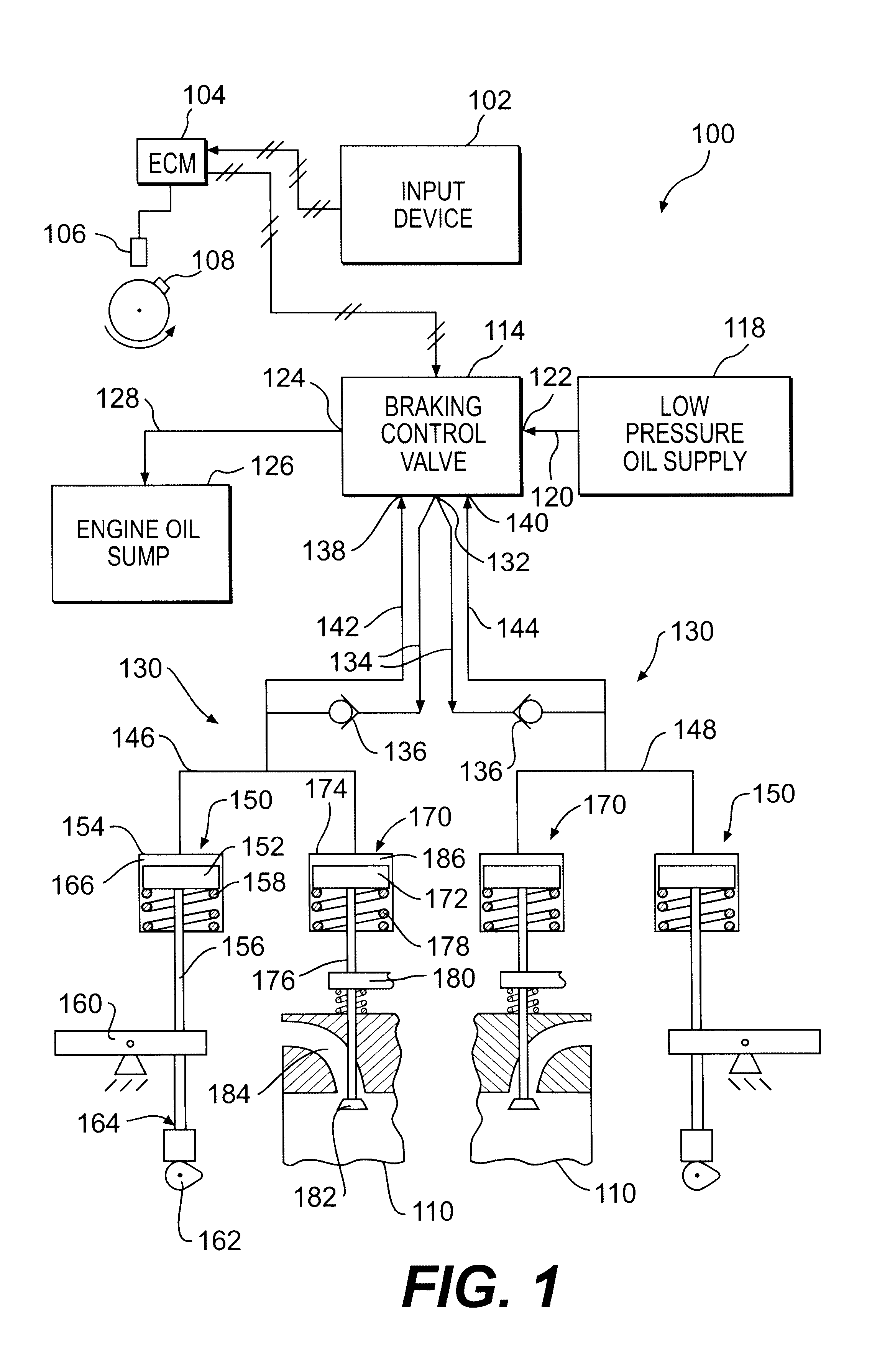

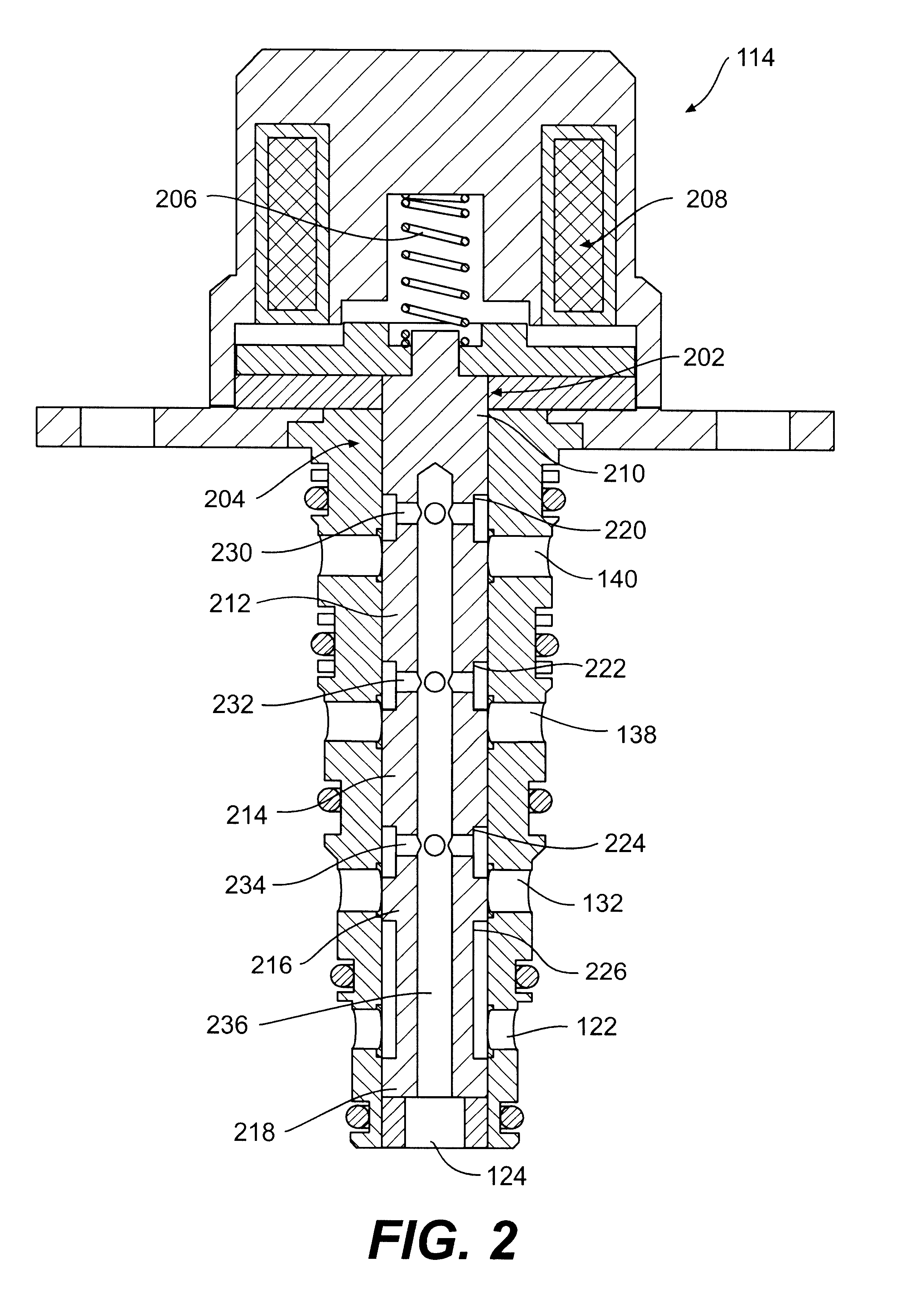

An engine braking system for a multi-cylinder engine includes a supply of low pressure fluid and an engine fluid sump. A plurality of valve actuators are each configured to be alternatively fluidly coupled to the supply of low pressure fluid and the engine fluid sump. Each valve actuator is operably coupled to at least one exhaust valve for a respective cylinder. The system also includes a braking control valve operably coupled to two of the valve actuators. The braking control valve is movable between a first position at which the two valve actuators are fluidly coupled to the engine fluid sump and blocked from the supply of low pressure fluid and a second position at which the two valve actuators are fluidly coupled to the supply of low pressure fluid and blocked from the engine fluid sump.

Owner:CATERPILLAR INC

Engine braking methods and apparatus

InactiveCN101180459ANon-fuel substance addition to fuelInternal combustion piston enginesWork cycleVariable geometry

The present invention discloses a method and apparatus for implementing blower type engine braking and compression-release type engine braking on an internal combustion engine. With blower-type engine braking, the exhaust valve is held at a relatively constant low lift during all or most of the engine's operating cycle. Engine braking may be combined with operation of exhaust gas recirculation, variable exhaust brake operation, and / or operation of a variable geometry turbocharger.

Owner:JACOBS VEHICLE SYST

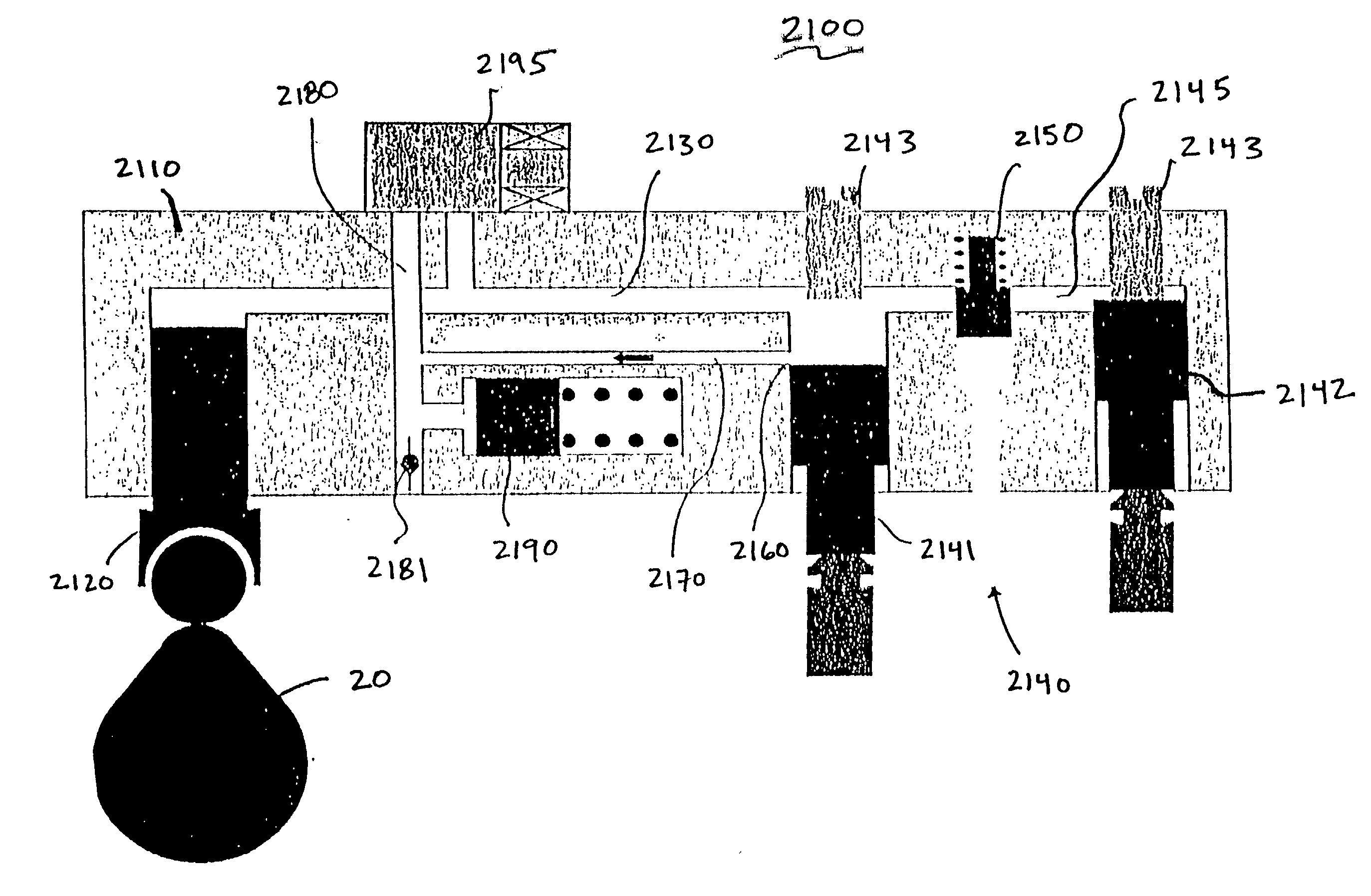

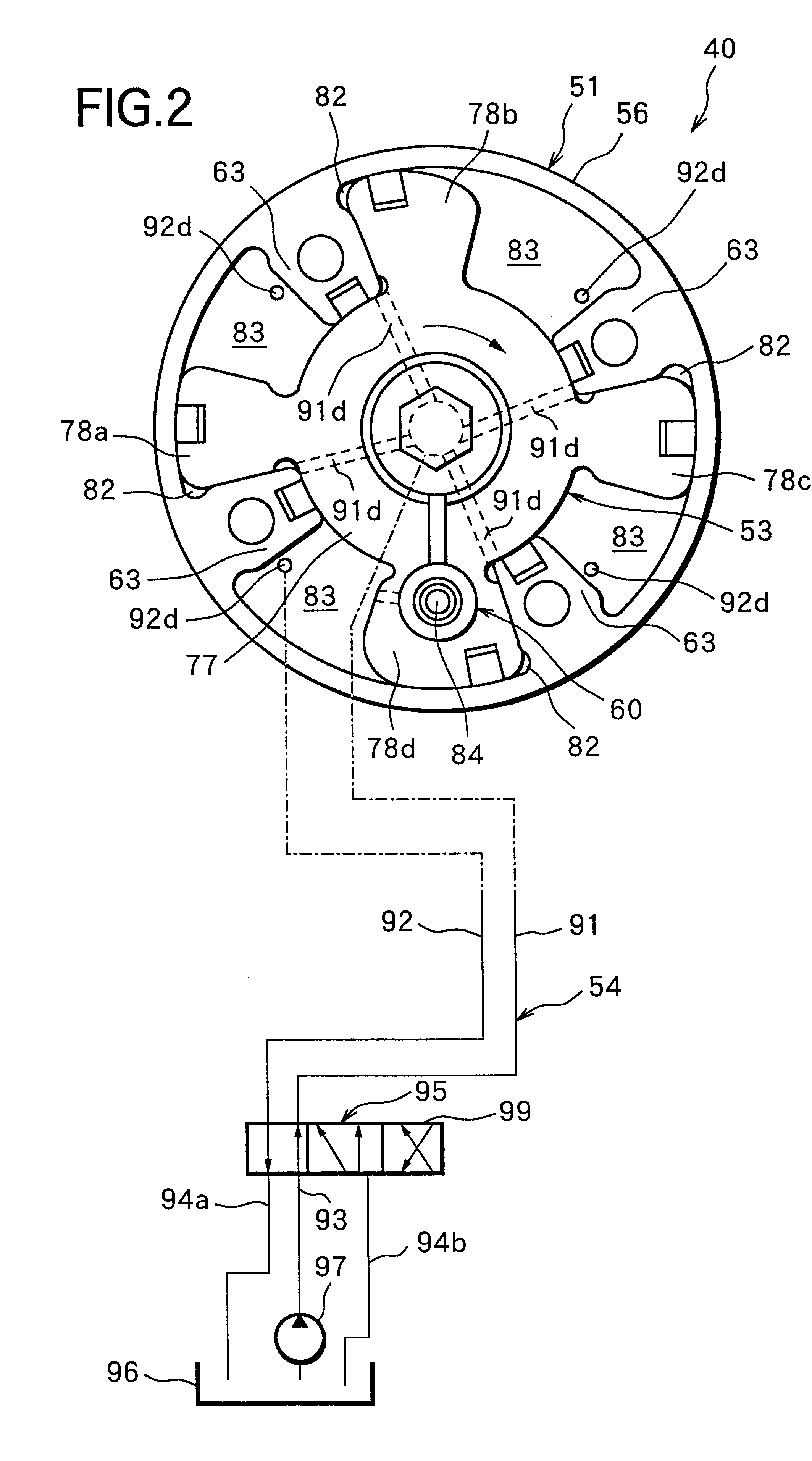

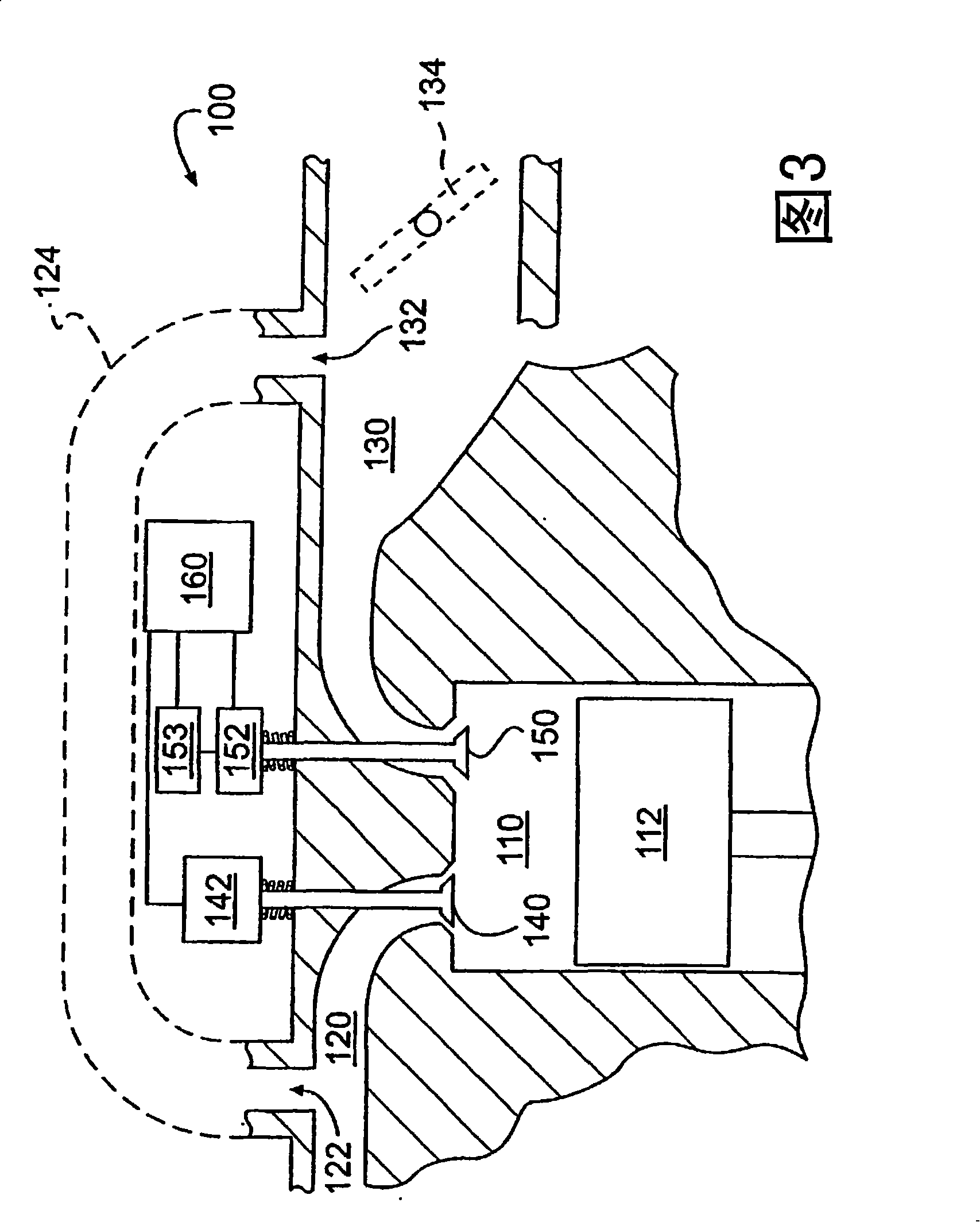

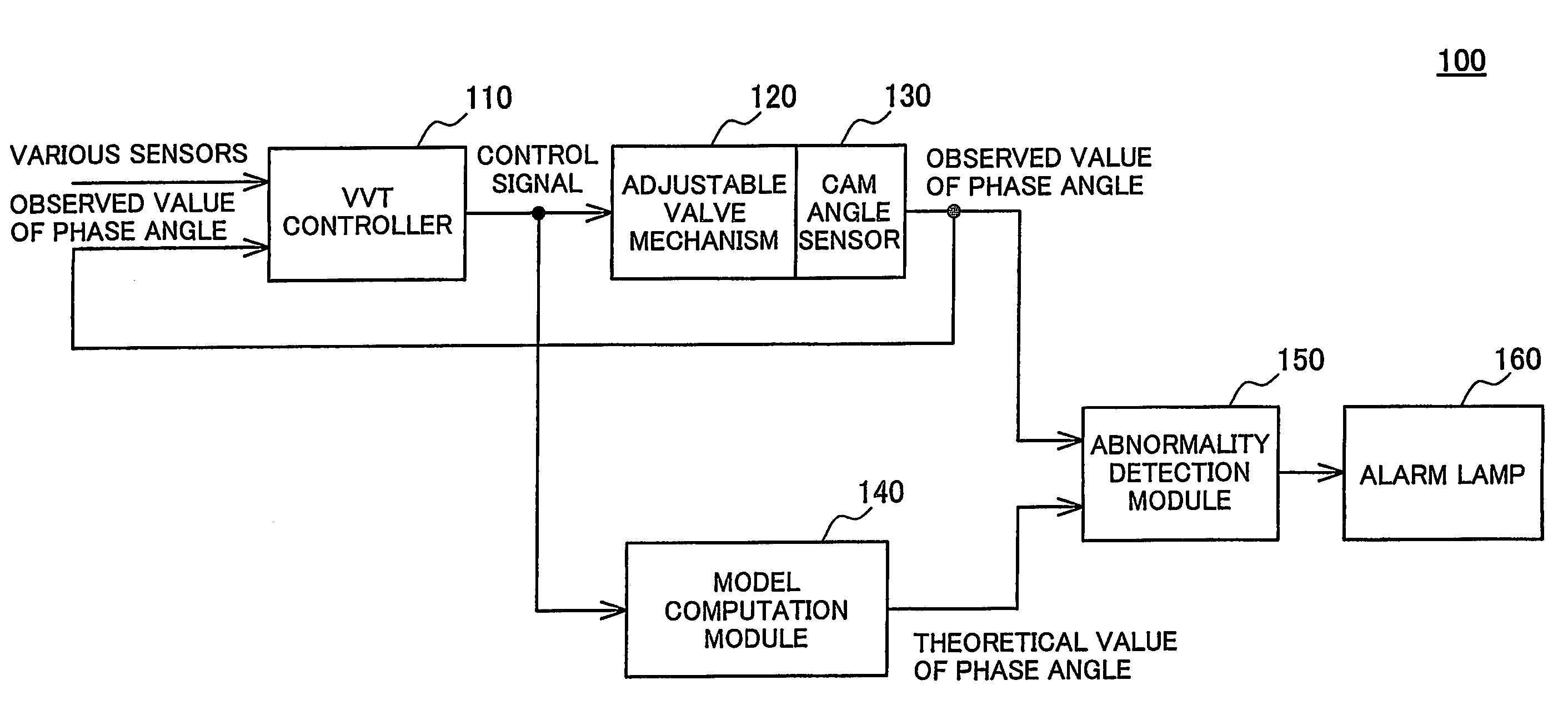

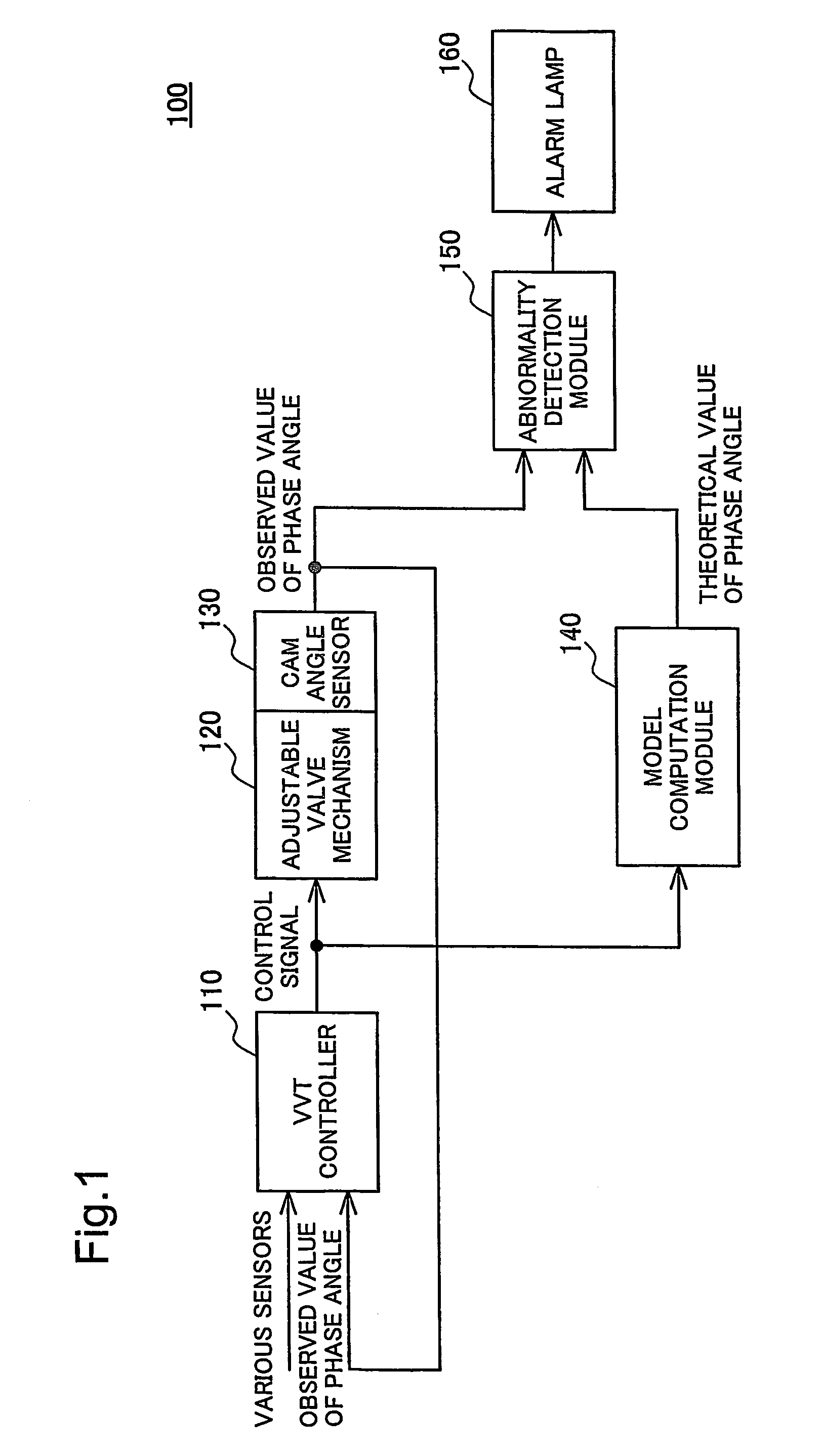

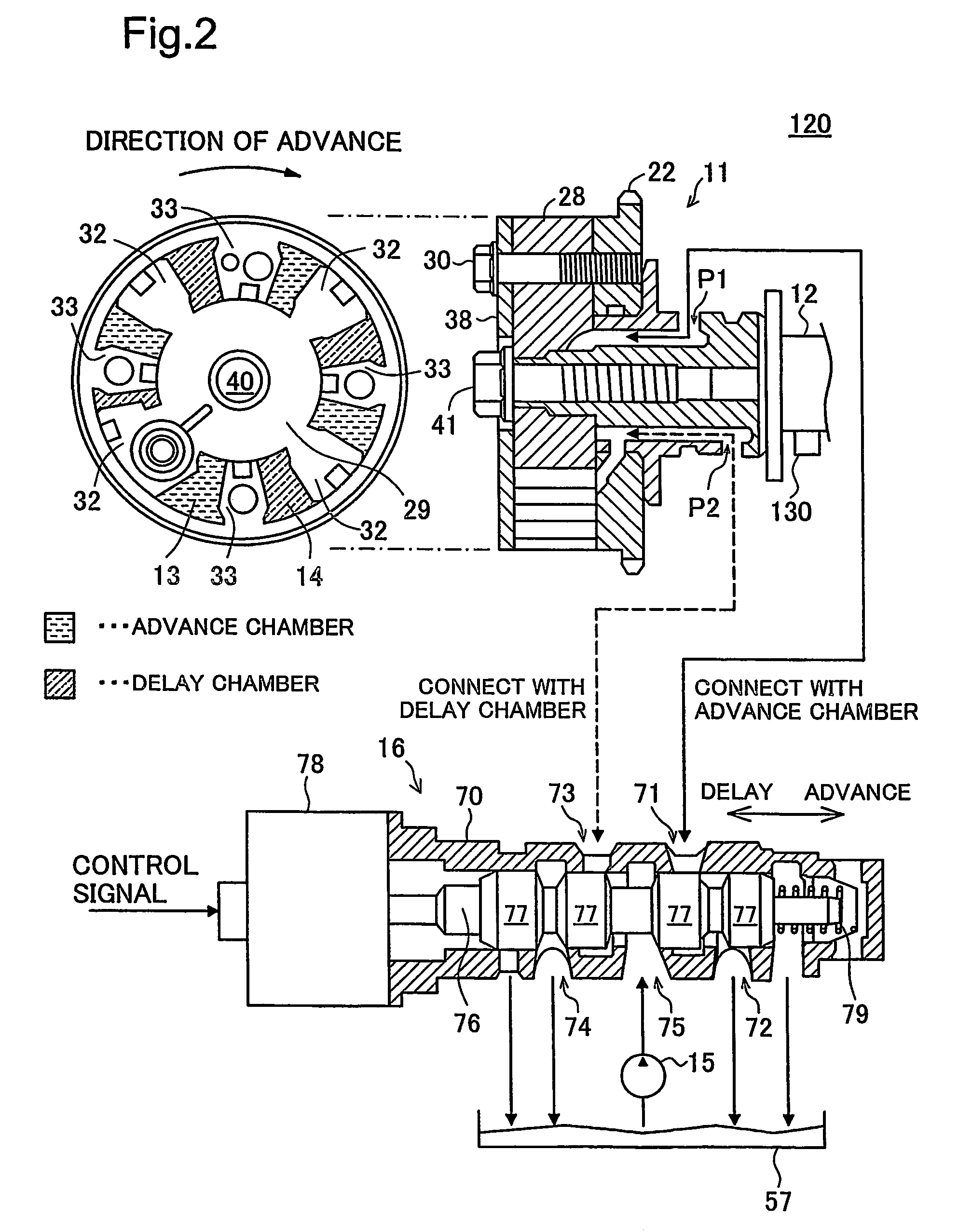

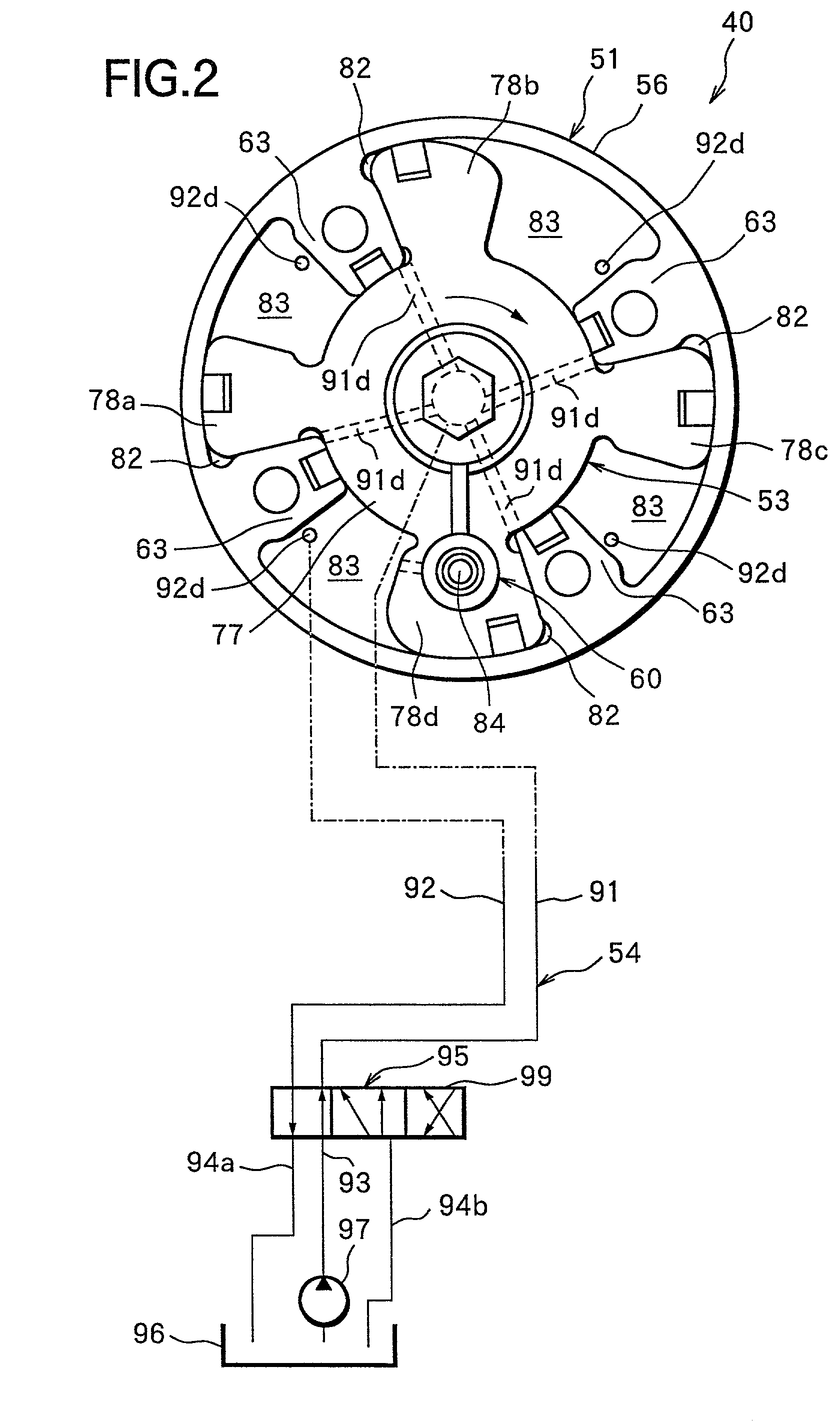

Apparatus for abnormal diagnosis of variable valve timing mechanism

InactiveUS7343887B2Analogue computers for vehiclesElectrical controlVariable valve timingControl signal

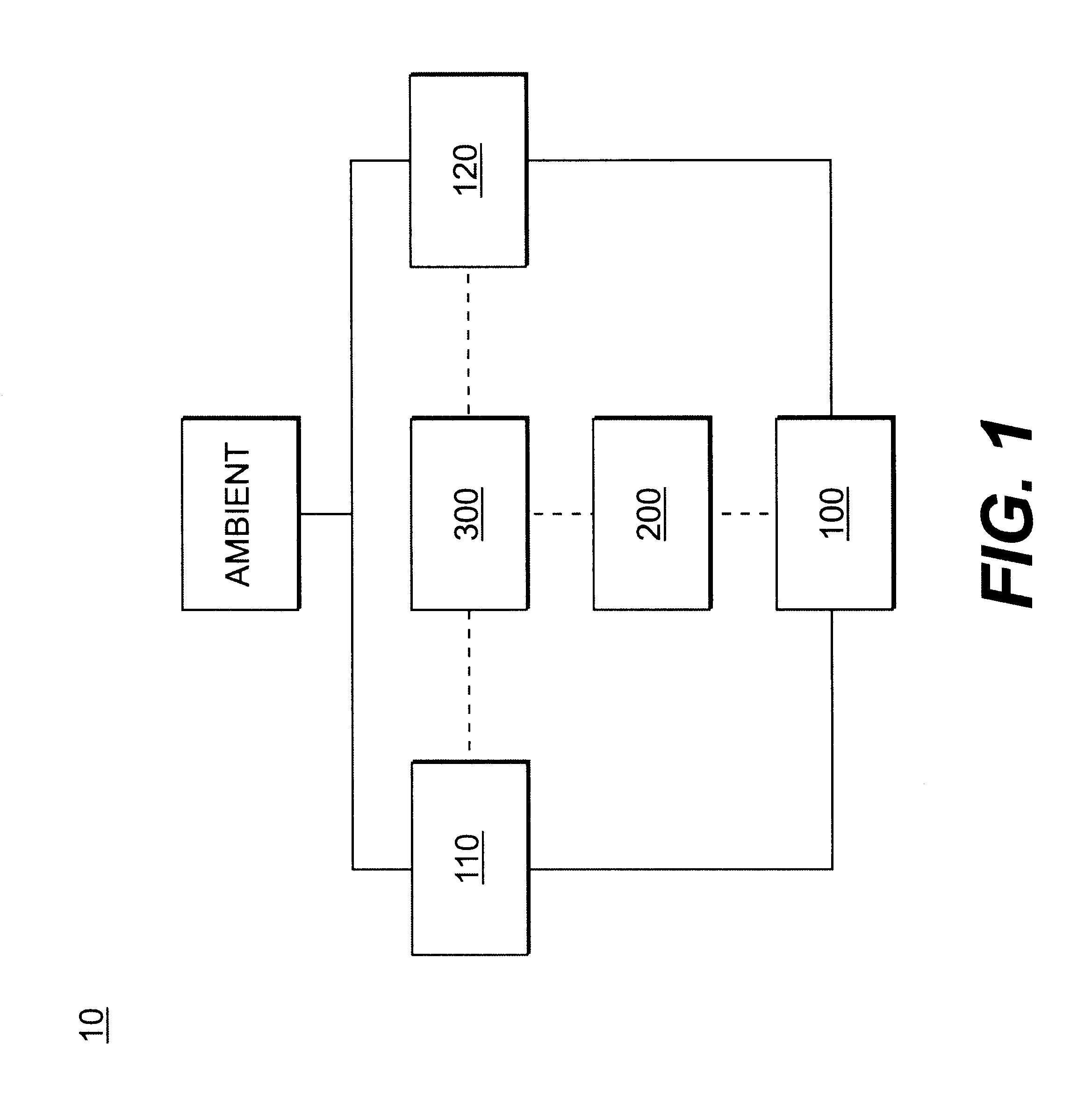

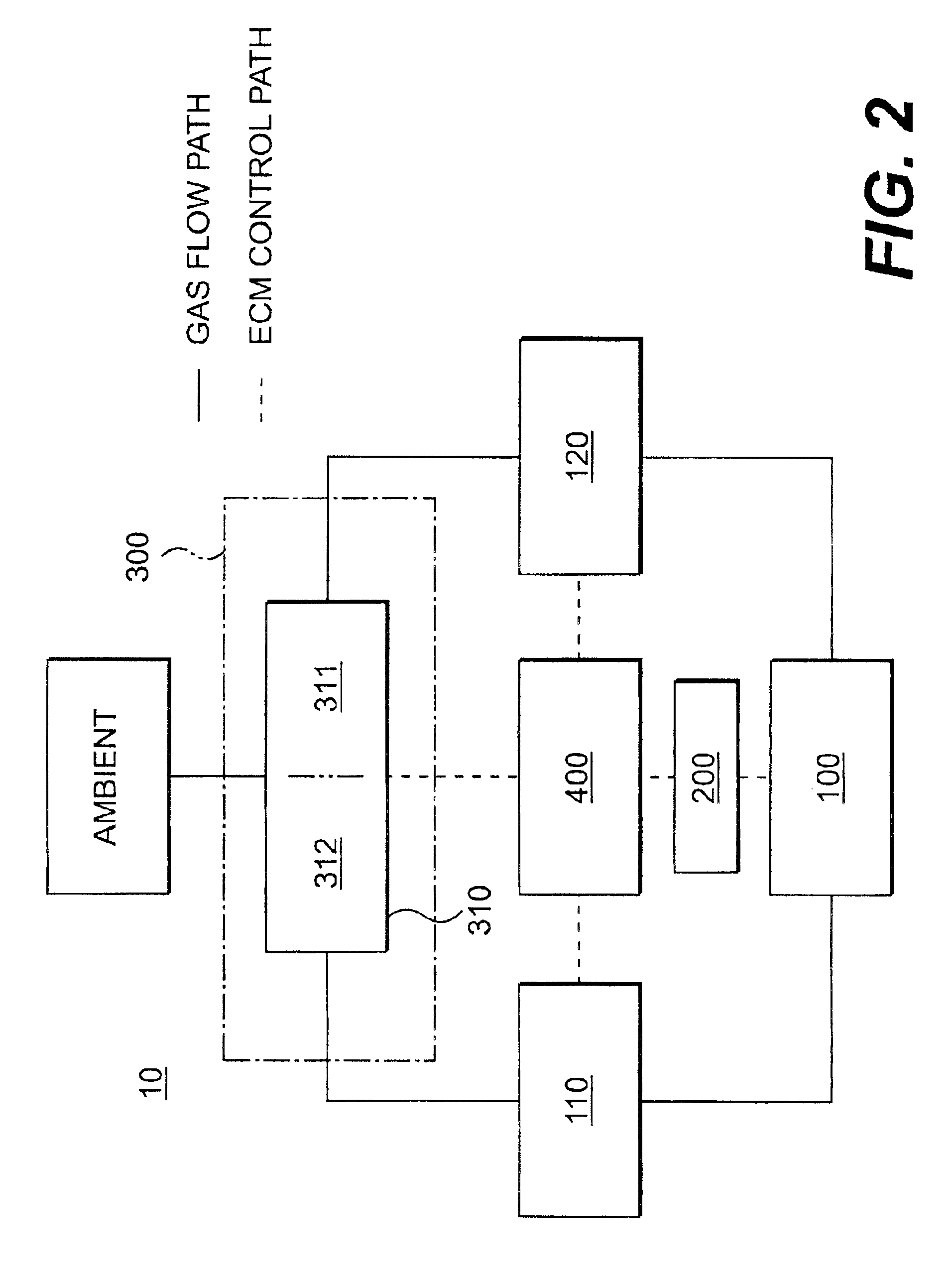

An abnormality diagnosis system 100 includes a VVT controller 110, an adjustable valve mechanism 120, a cam angle sensor 130, a model computation module 140, an abnormality detection module 150, and an alarm lamp 160. The adjusable valve mechanism 120 advances or delays a phase angle of an intake cam shaft relative to a crankshaft, thereby varying an open-close timing of a valve. The model computation module 140 computes a physical behavior of the adjustable valve mechanism 120 according to a physical model, in response to a control signal input from the VVT controller 110. The abnormality detection module 150 determines whether the adjustable valve mechanism 120 is abnormal or normal, based on a difference between a theoretical value of phase angle calculated according to the physical model and an observed value of phase angle measured with the cam angle sensor 130. The arrangement of the invention ensures highly accurate abnormality diagnosis of the adjustable valve mechanism 120.

Owner:TOYOTA JIDOSHA KK

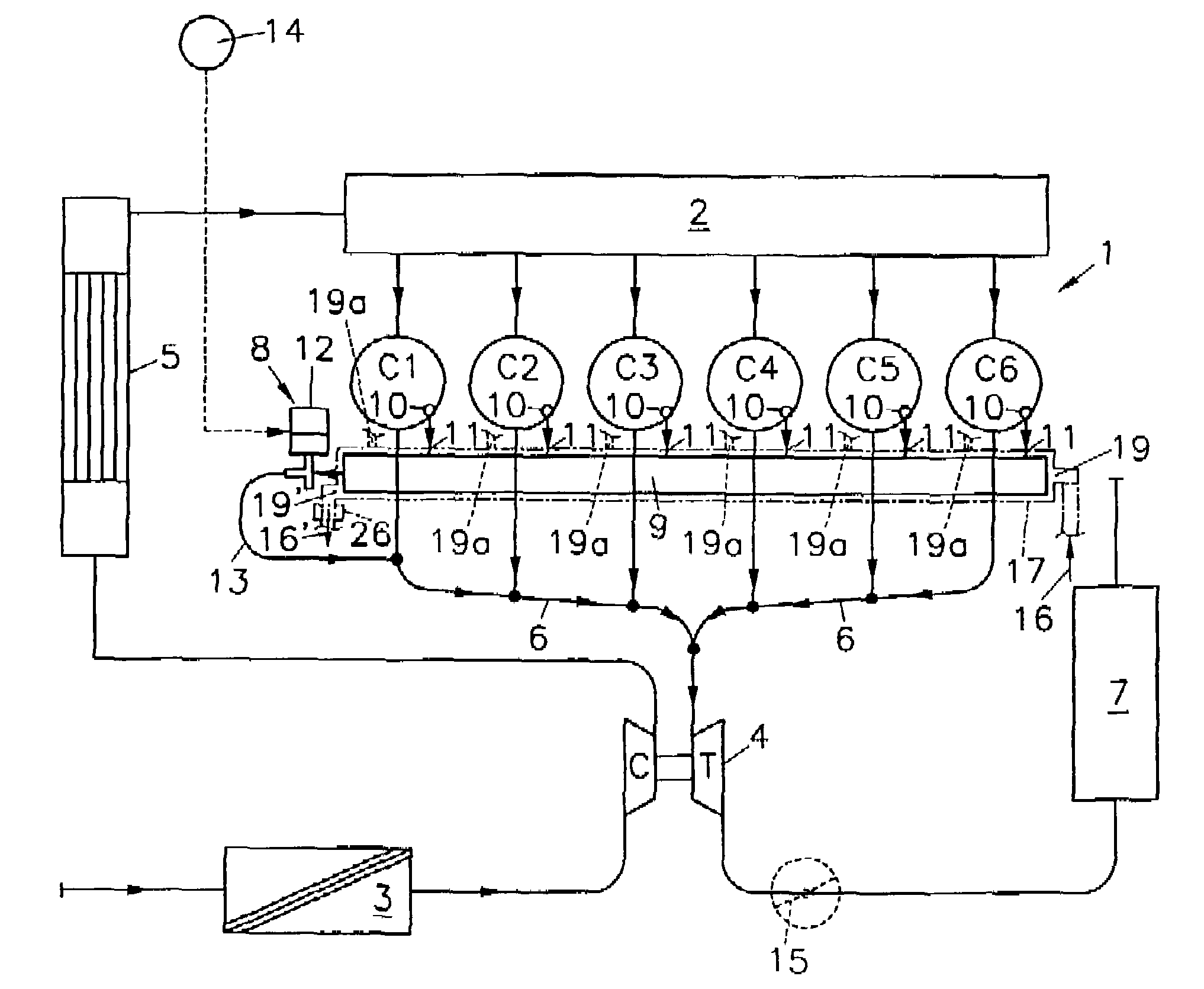

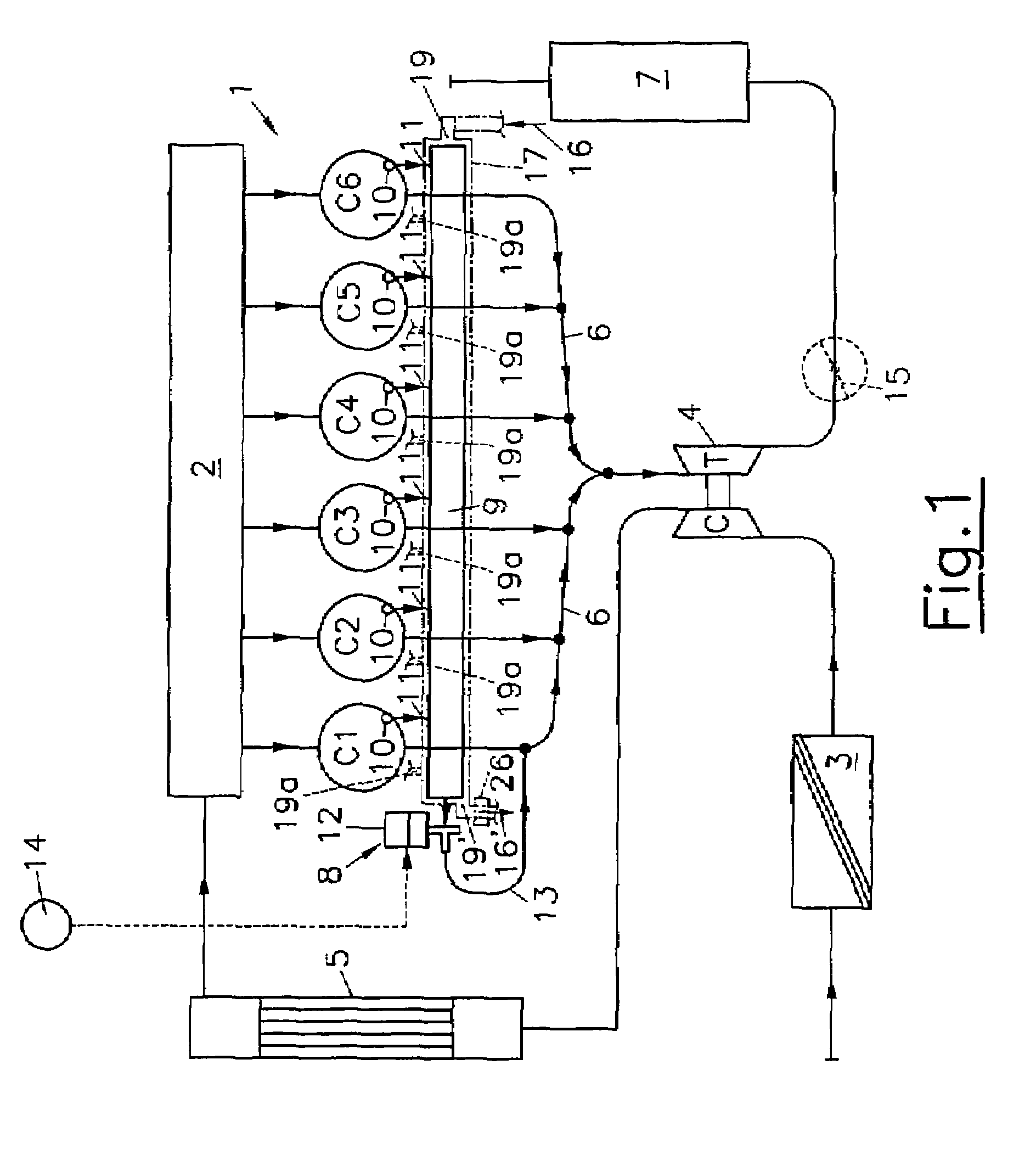

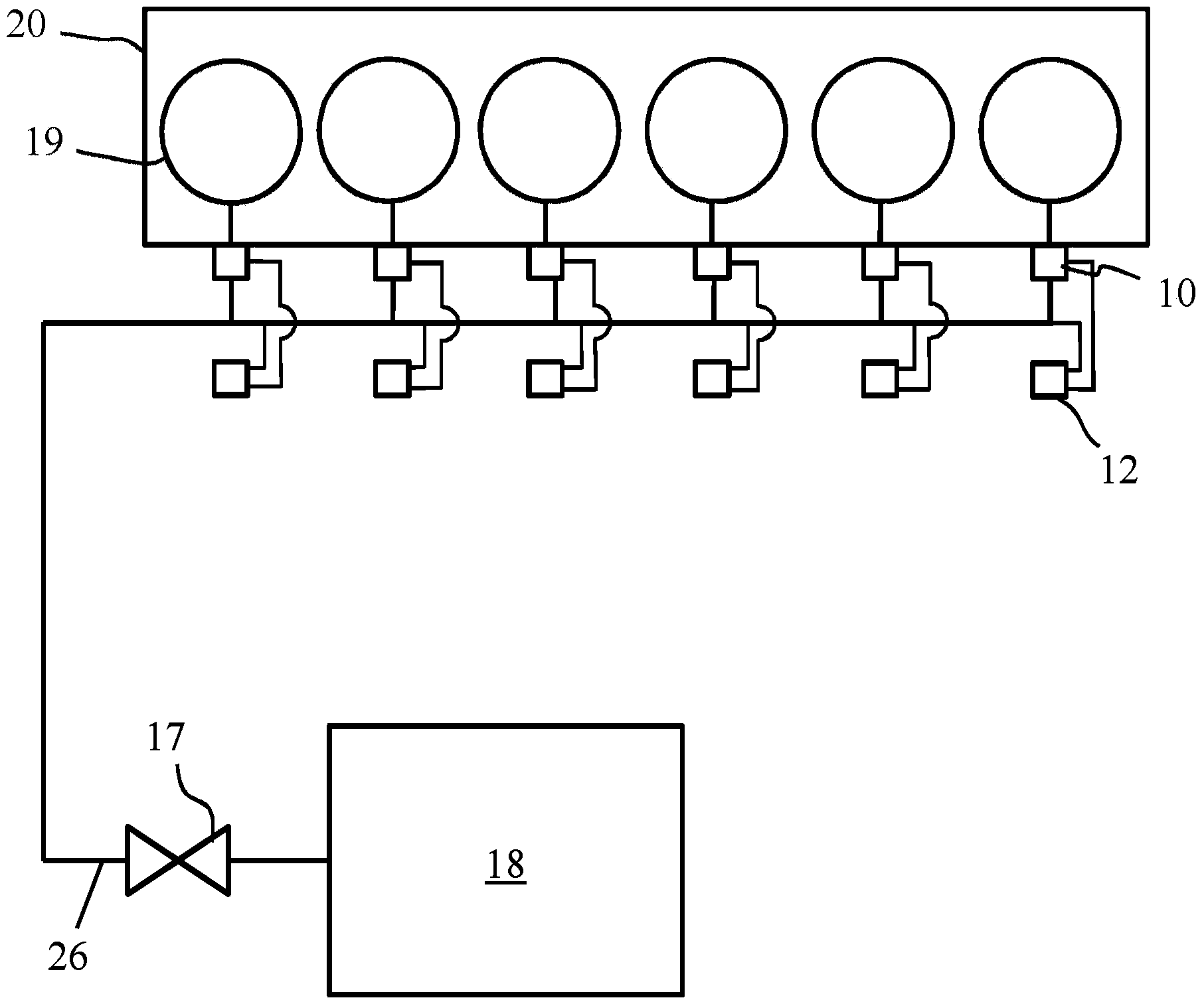

Engine brake system of a multicylinder internal combustion engine comprising a cooled intermediate pipe for exchanging gas between cylinders during engine braking

InactiveUS7314037B2Increases thermally conductive surfaceImprove heat transfer performanceInternal combustion piston enginesAir coolingExhaust valveInlet valve

The invention relates to a multicylinder internal combustion engine (1) comprising intake valves and exhaust valves that are provided with at least one additional valve (10) for each cylinder (C1, C2, C3, C4, C5, C6), a preferably tubular pressure container (9) with a gas chamber (90) into which extend ducts (11) originating from the valves (10) such that gas can be exchanged between individual cylinders (C1, C2, C3, C4, C5, C6) when the valves (10) are actuated. The pressure container (9) is provided with a device (17) for cooling the quantities of gas exchanged between individual cylinders (C1, C2, C3, C4, C5, C6). In order to increase the cooling capacity, the cooling device (17) encompasses at least one cooling pipe (17) which is axially inserted into the pressure container (9) and is penetrated by coolant. The outer jacket (171) of the cooling pipe (170) borders the gas chamber (90), the gas that is exchanged between individual cylinders (C1, C2, C3, C4, C5, C6) flowing around said outer jacket (171).

Owner:AVL LIST GMBH

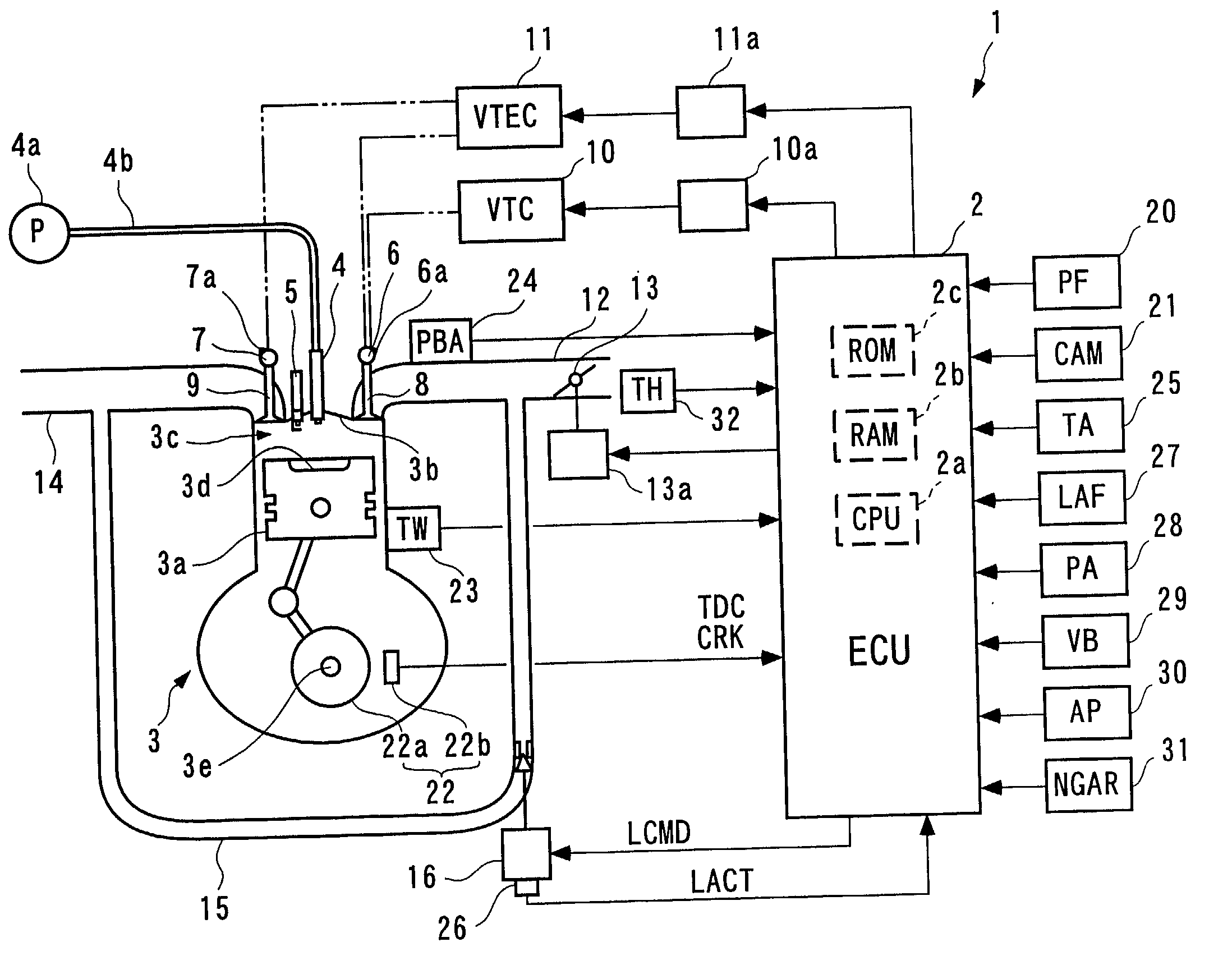

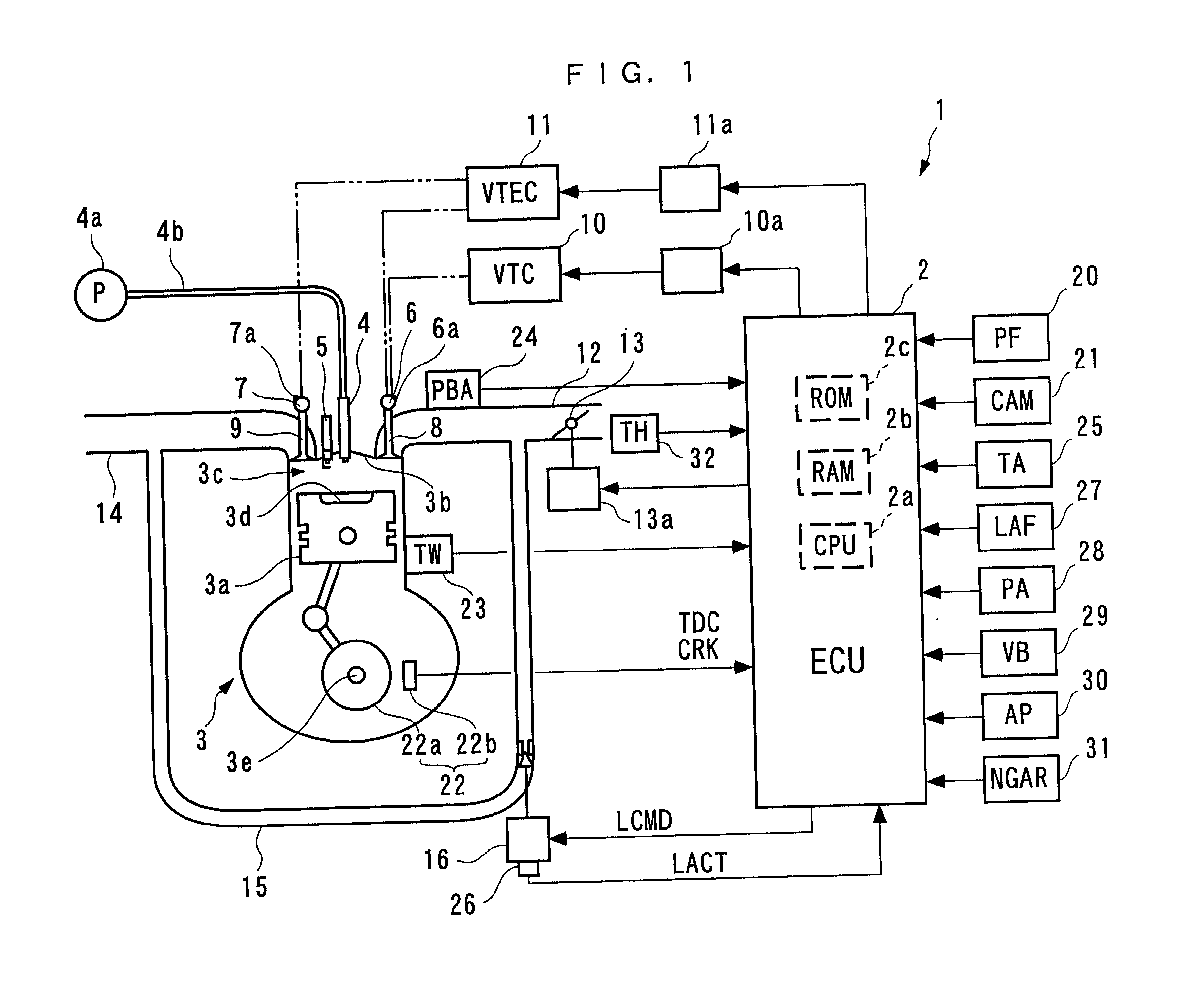

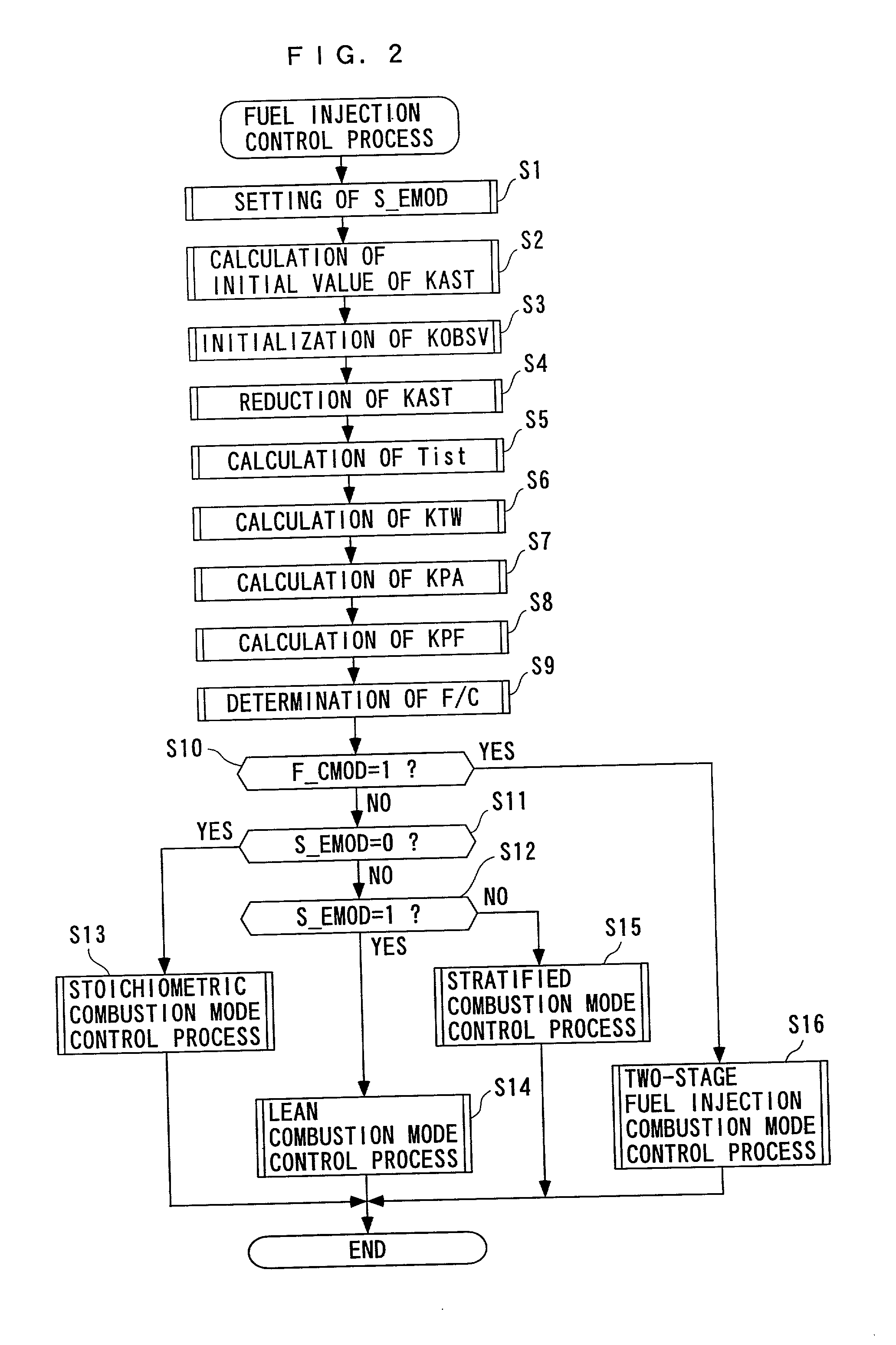

Fuel injection control system and method and engine control unit for internal combustion engine

InactiveUS20020059919A1Significant valueHigh profileElectrical controlInternal combustion piston enginesLow speedExternal combustion engine

There are provided a control system and method and an engine control unit for an internal combustion engine including two types of variable valve mechanisms capable of changing a camp phase and a cam profile, respectively, which system is capable of determining an amount of fuel to be injected as a value suited to charging efficiency at the time by simplified calculation processing, thereby performing the fuel injection control properly in a simplified manner. The fuel injection control system includes an ECU. The ECU searches a map for a multiplier term Ati for a high-speed cam or low-speed cam based on the rotational speed of the engine and the cam phase, and a map for an addend term Bti for the high-speed cam or the low-speed cam based on the rotational speed of the engine and the cam phase. The ECU calculates a basic fuel injection time period Tibase as the sum of the product of an intake pipe absolute pressure PBA and the multiplier term Ati and the addend term Bti (Ati.times.PBA+Bti).

Owner:HONDA MOTOR CO LTD

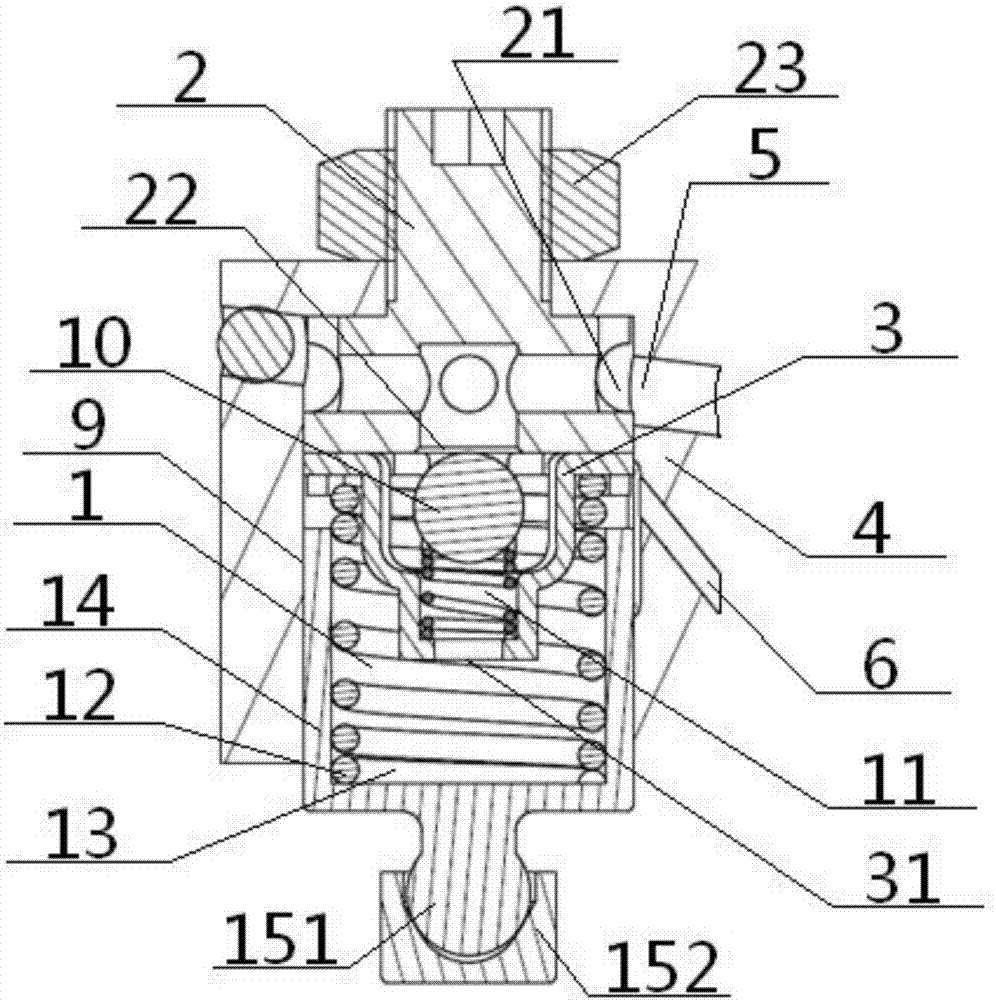

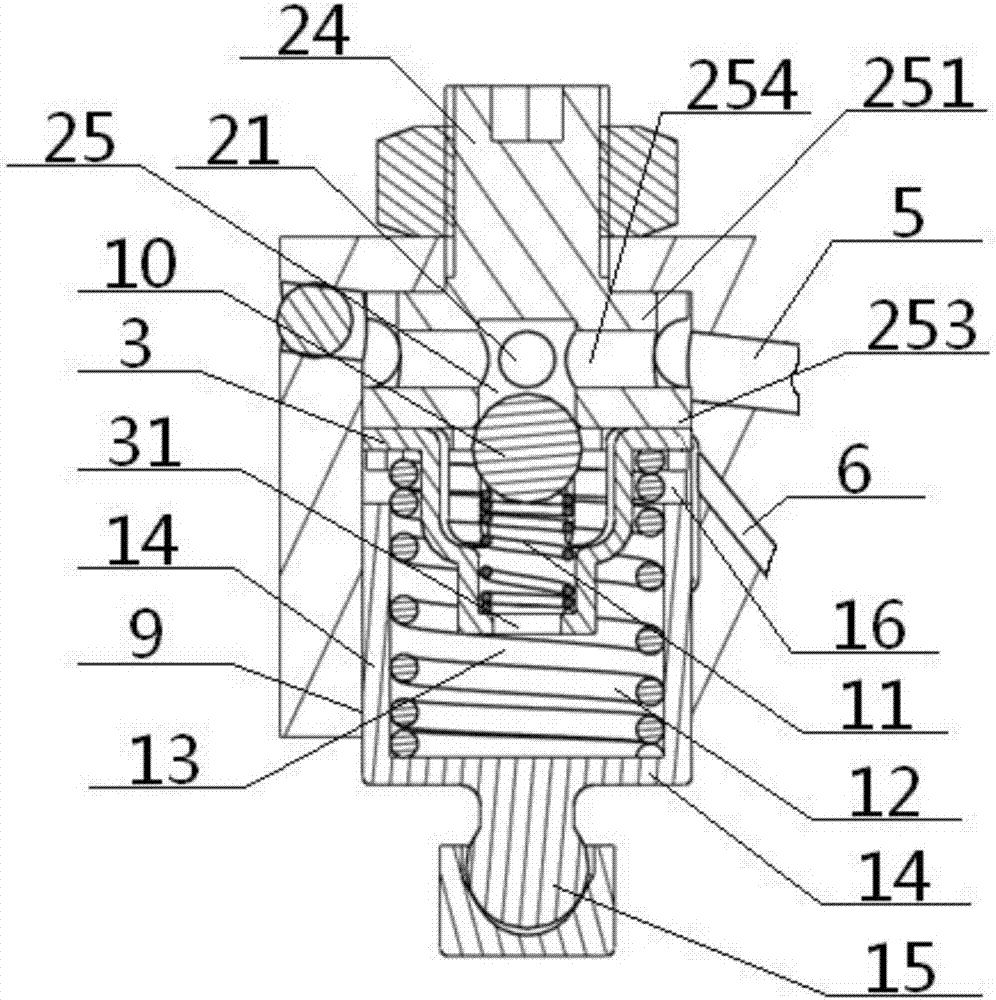

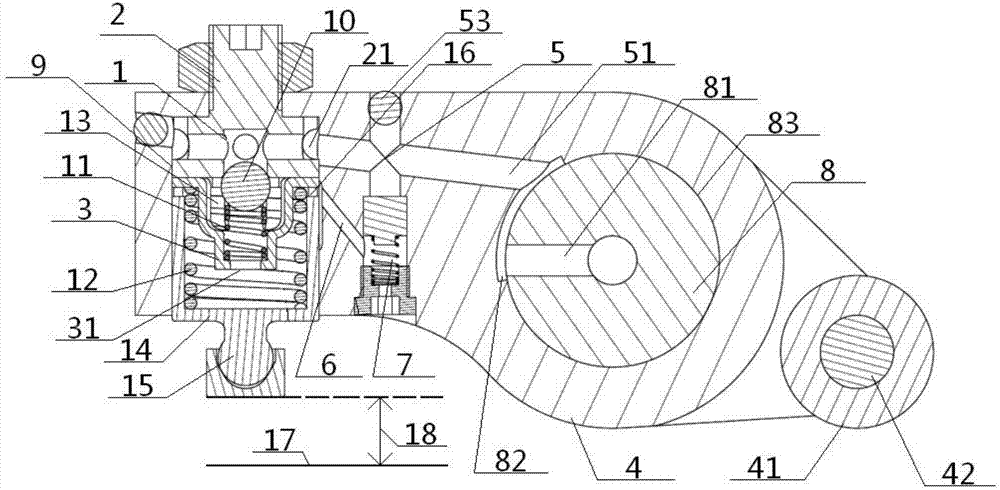

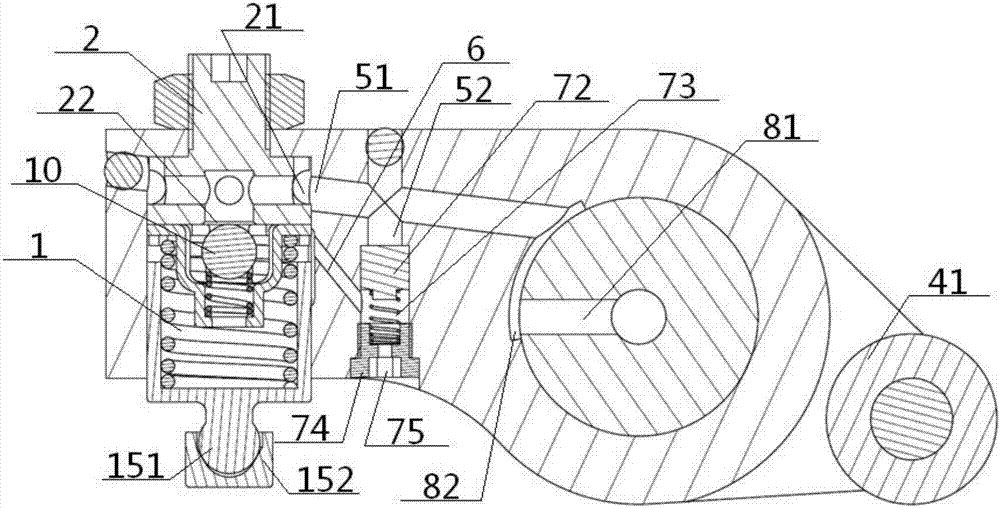

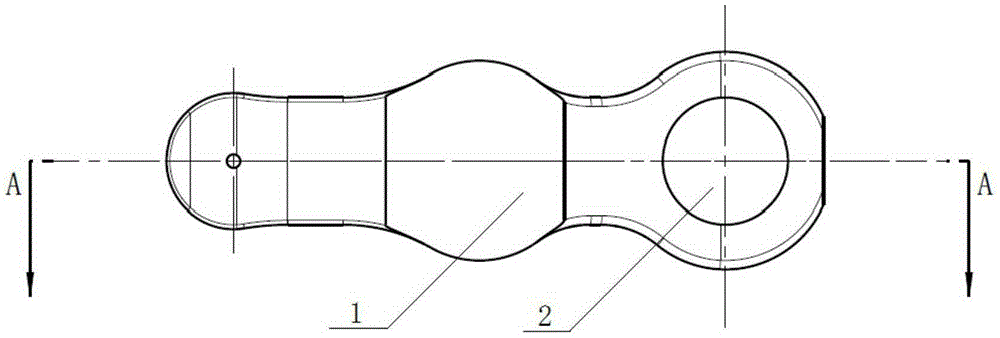

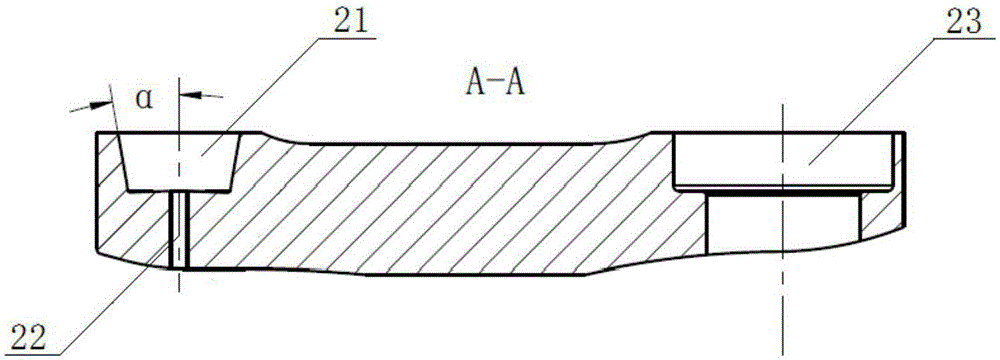

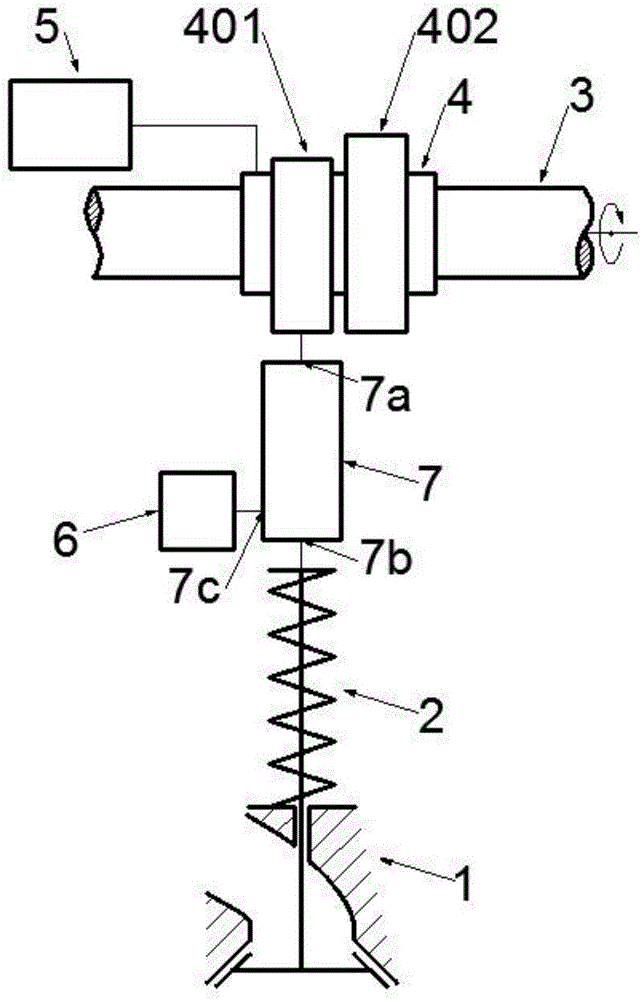

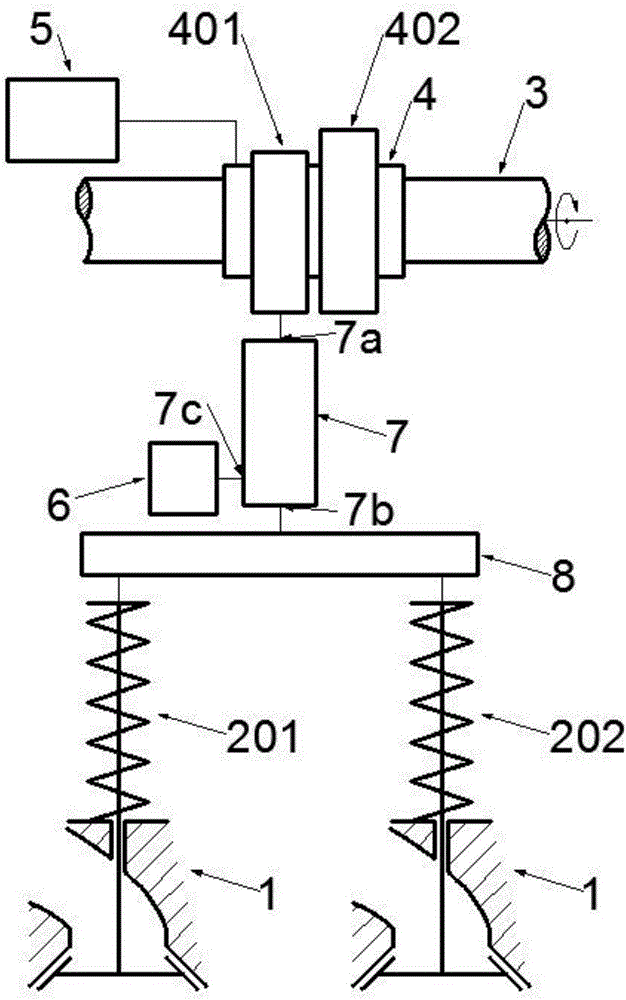

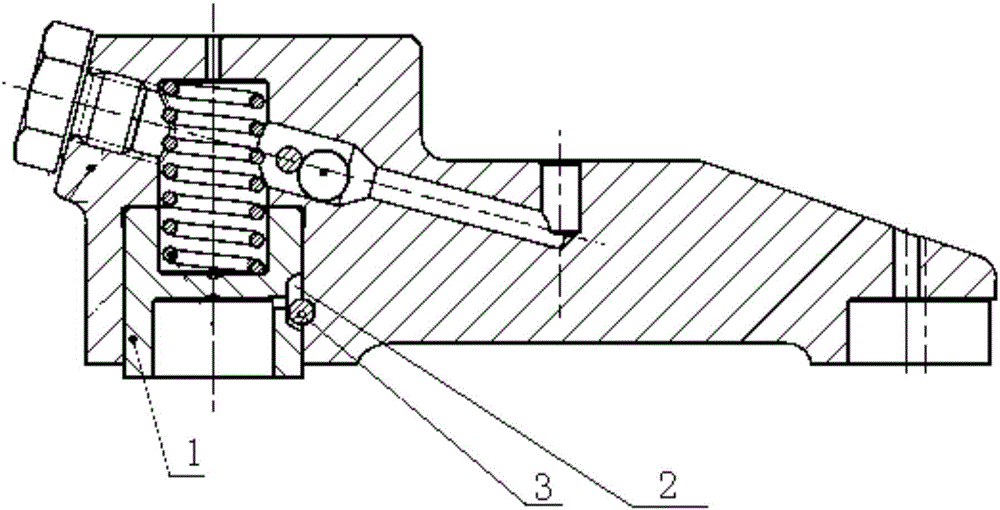

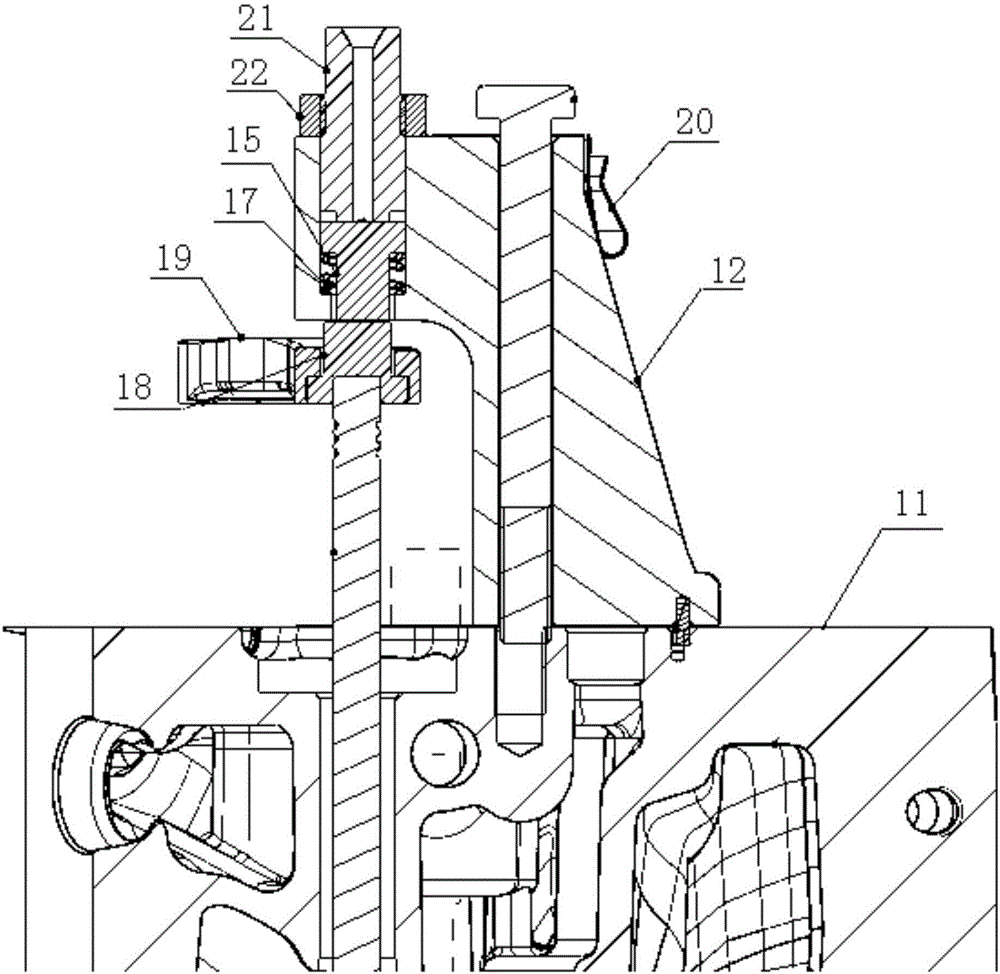

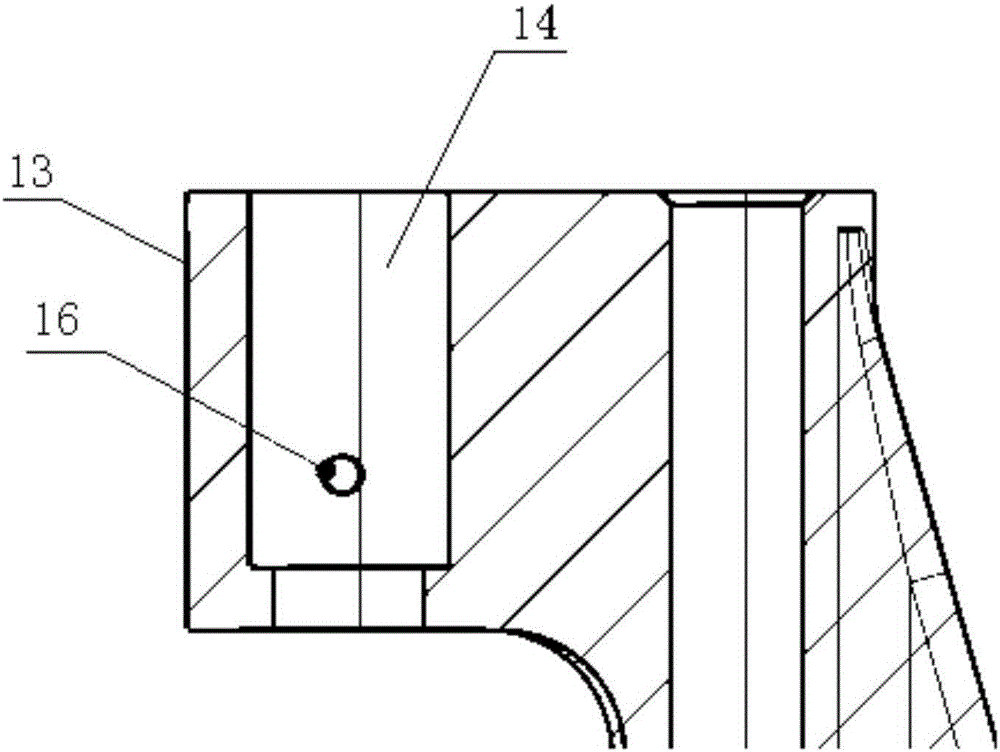

Braking execution mechanism used for engine braking oil way and using method of braking execution mechanism

ActiveCN106968753AEasy to controlFacilitate the realization of brakingOutput powerValve controlHigh pressureCounterforce

A braking execution mechanism used for an engine braking oil way comprises a brake chamber, a brake oil cavity, an adjusting bolt, a ball valve, a ball valve spring, a ball valve spring seat, a brake spring and a brake piston, wherein the brake oil cavity, the adjusting bolt, the ball valve, the ball valve spring, the ball valve spring seat, the brake spring and the brake piston are arranged in the brake chamber; engine oil sequentially passes through a side face oil hole and a bottom face oil hole which are formed in the adjusting bolt and then flows into the brake oil cavity; the bottom face oil hole, the ball valve and the ball valve spring are arranged up and down; the bottom end of the ball valve spring is connected with a spring seat bottom hole in the bottom of the ball valve spring. The brake spring arranged outside the ball valve spring seat in a sleeving mode is sleeved with the brake piston which slides up and down along the inner wall of the brake chamber; and an air valve gap is formed between the bottom of a ball socket in an elephant foot connected to the bottom of the brake piston and an air valve yoke. During application, through closing of an oil discharging way, counterforce of a rocker to the brake oil cavity and closing of the brake oil cavity, the brake oil cavity forms a high-pressure cavity, and braking is started. The design is good in braking effect and high in stability and sensitivity, and noise of the mechanism during operation is lowered advantageously.

Owner:DONGFENG COMML VEHICLE CO LTD

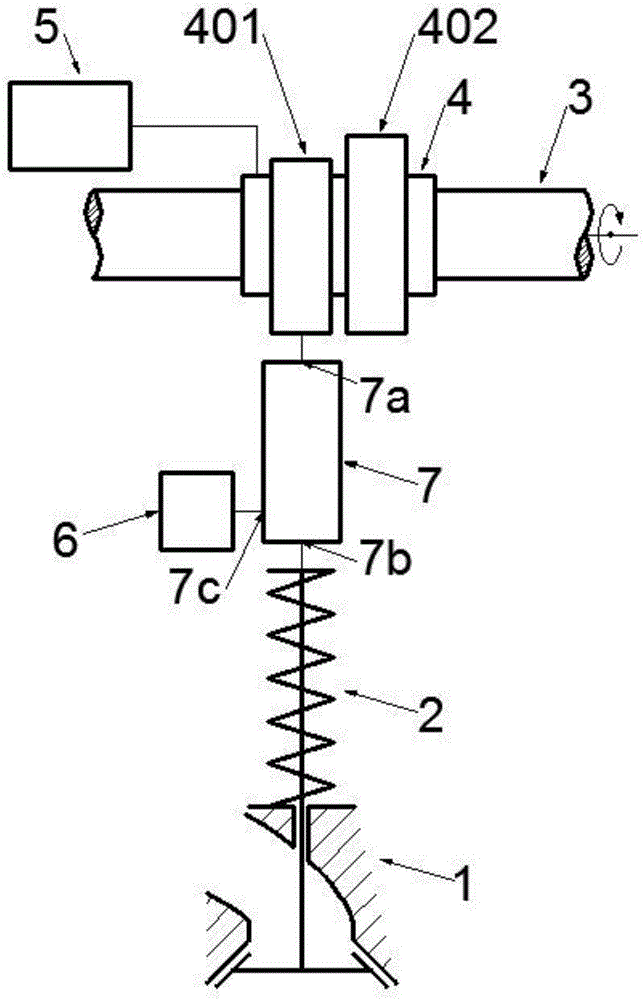

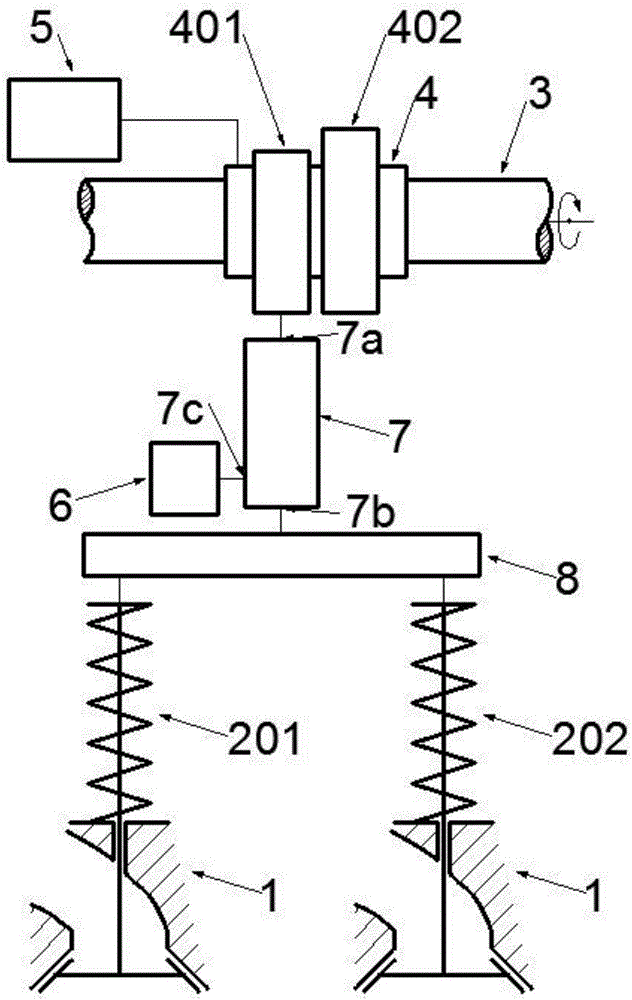

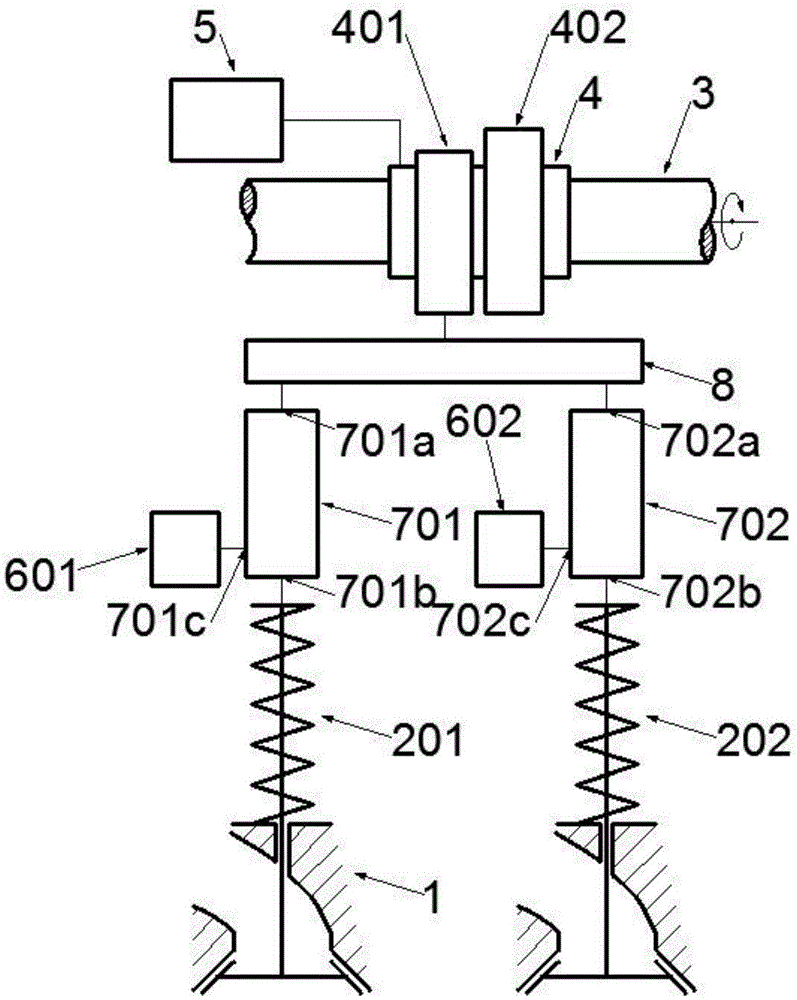

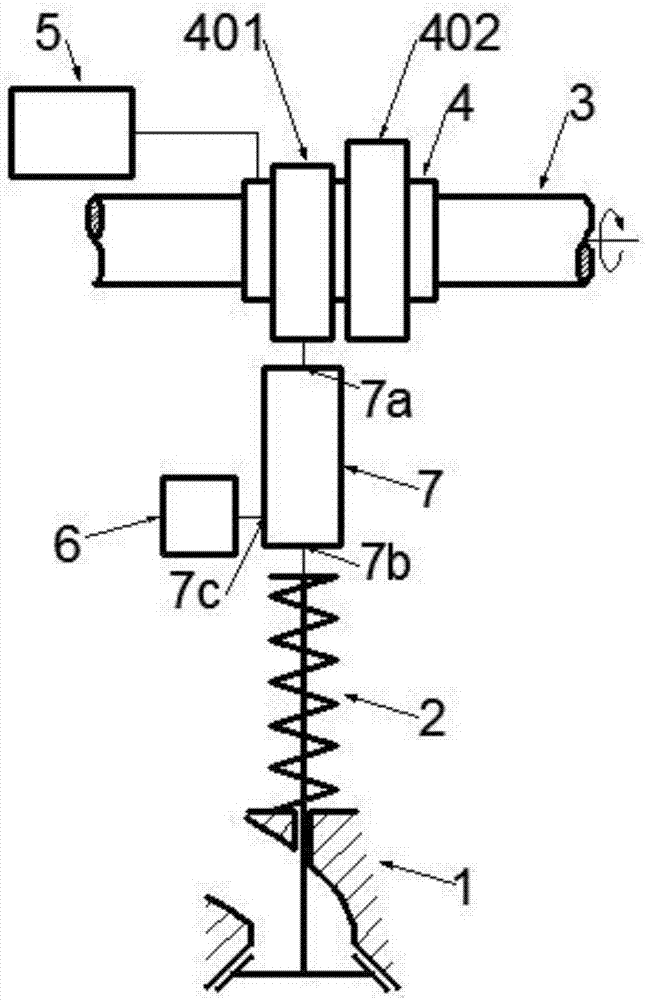

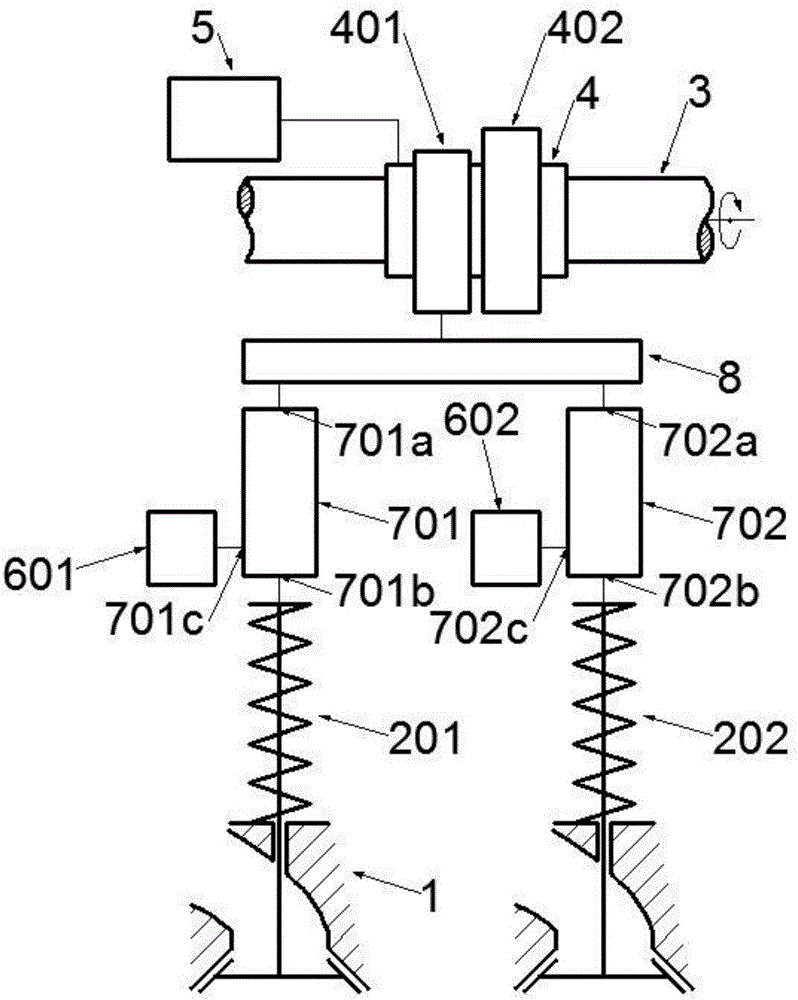

Axially-moving multi-mode four-rod variable valve driving system

InactiveCN106545381AGood flexibilityImprove powerValve controlMachines/enginesMature technologyEngineering

The invention provides an axially-moving multi-mode four-rod variable valve driving system and belongs to the field of engine valve driving. The axially-moving multi-mode four-rod variable valve driving system mainly comprises a cam shaft, a cam shaft sleeve, an axially-moving mechanism, a valve adjustment mechanism, a valve control mechanism and the like. The cam shaft sleeve is at least provided with a first cam and a second cam, and switching between multiple modes such as a two-stroke driving mode, a four-stroke driving mode, a two-stroke brake mode and a four-stroke brake mode of an engine is achieved through the axially-moving mechanism; and furthermore, optimal ventilation of the engine under different work conditions is finally achieved through cooperative use of the axially-moving mechanism and the valve control mechanism, and the purposes of comprehensively improving the power performance, the fuel economy, the emission performance and the brake safety of the engine are achieved. The axially-moving multi-mode four-rod variable valve driving system is provided for the practical application and is high in reliability and compact in structure, the requirements of the system for all the mechanisms are lowered, all the mechanisms adopt relatively mature technologies, and the system is high in practical utilization potential in a short time and has good application prospects.

Owner:DALIAN UNIV OF TECH

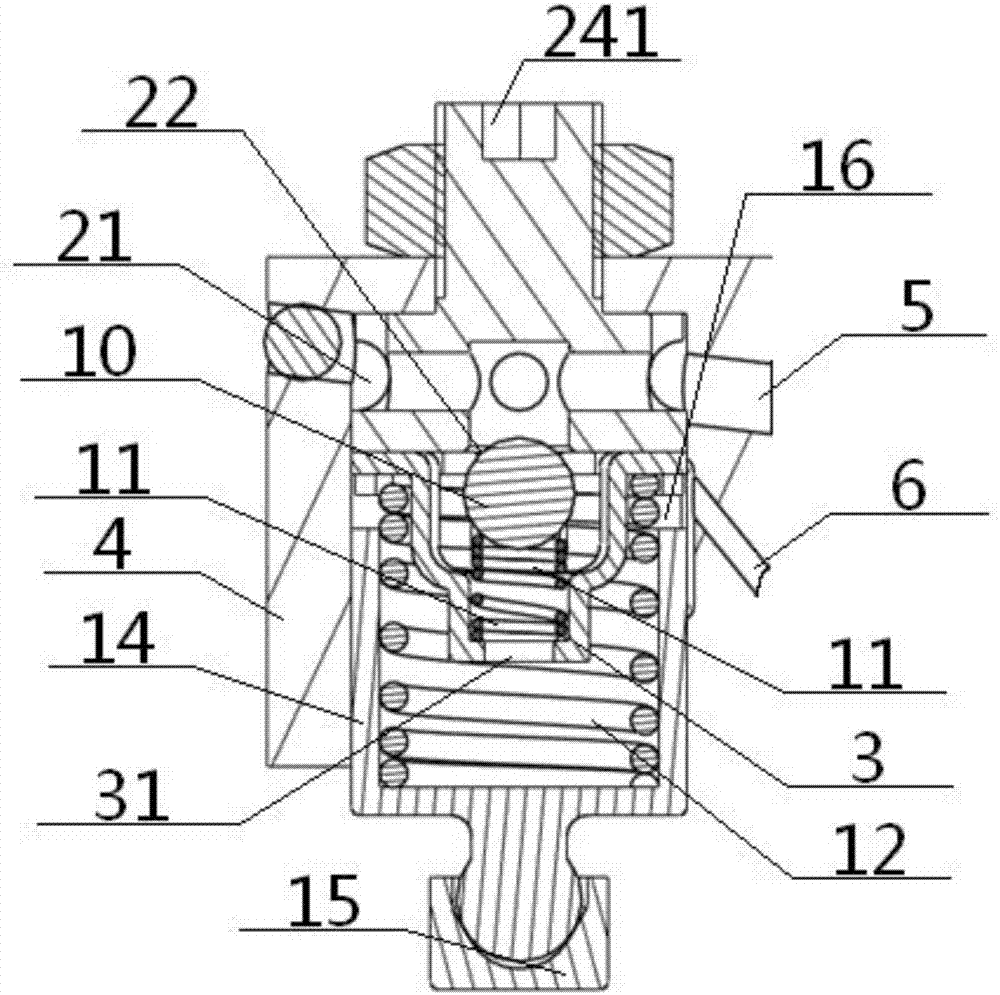

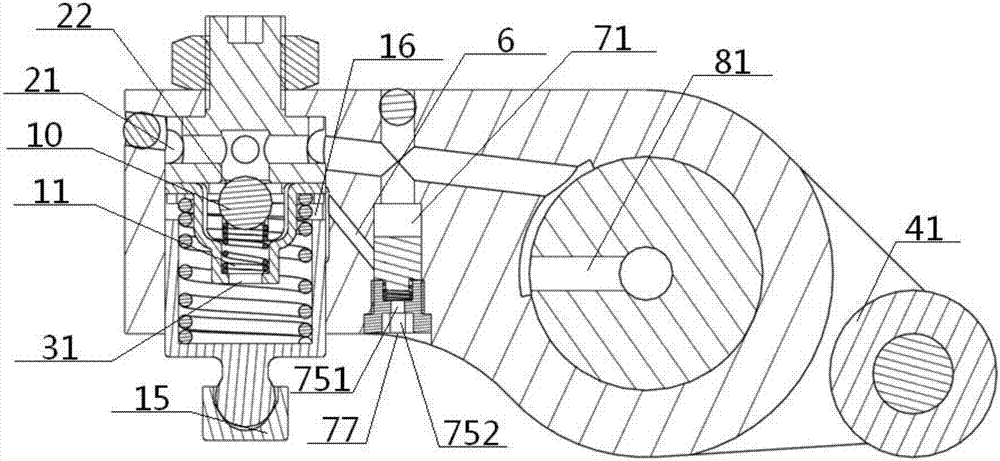

Engine brake oil way control device and usage method thereof

ActiveCN107035460AStructure is clear and easy to understandImprove braking effectOutput powerValve controlEngineeringControl room

An engine brake oil way control device comprises a rocker, a brake performing mechanism, a control valve, a slant oil way and a longitudinal oil way. The brake performing mechanism and the control valve are arranged on the rocker. The slant oil way and the longitudinal oil way intersect. A control piston, a control spring and a control spring seat are arranged in the control valve sequentially from top to bottom. A control oil discharge hole is formed in the control spring seat. The part, located between the control piston and the control spring seat, on the side wall of a control chamber communicates with the side part of a brake oil cavity through an oil discharge way. The top end of the control chamber communicates with the bottom of the longitudinal oil way. The top of the longitudinal oil way penetrates through the slant oil way and then extends to be above the slant oil way, and a shaft-in oil way of a rocker shaft communicates with the brake oil cavity in the brake performing mechanism through the slant oil way. During usage, opening or closing of the oil discharge way is achieved through change of engine oil pressure by means of the control valve, and thus the brake condition is started or relieved. Therefore, the engine brake oil way control device is good in brake effect, high in stability, good in clearance adjustment effect, low in production cost, and capable of lowering noise during mechanism operation.

Owner:DONGFENG COMML VEHICLE CO LTD

Apparatus and method for controlling internal combustion engine

InactiveUS20020017276A1Electrical controlInternal combustion piston enginesExternal combustion engineVolumetric Mass Density

In an electronically controlled fuel injection apparatus of a speed density type, a new air intake efficiency correction value for correcting an intake pressure is calculated based on the intake pressure, an engine rotation speed, and an advance angle amount of valve timing.

Owner:UNISIA JECS CORP

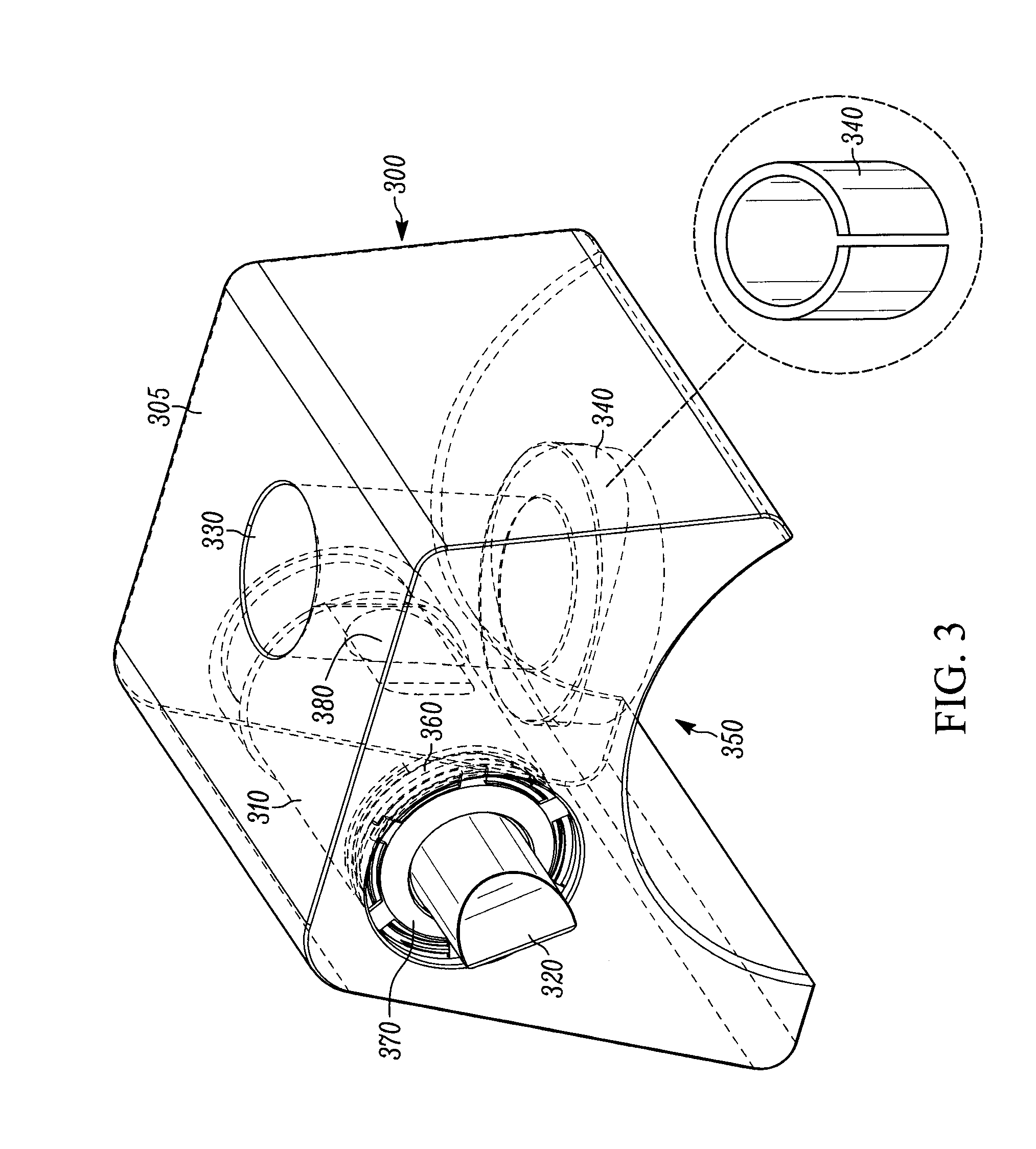

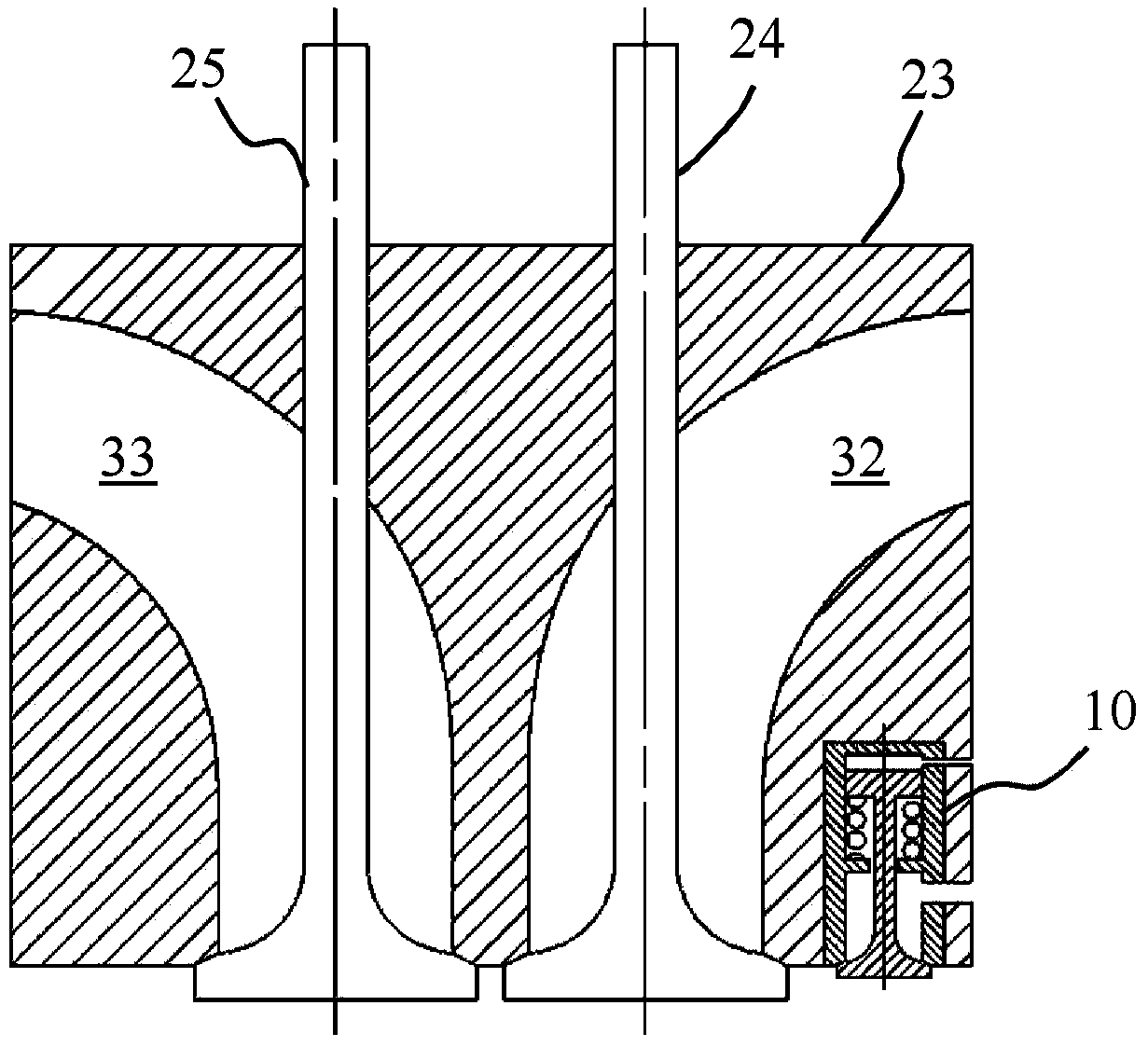

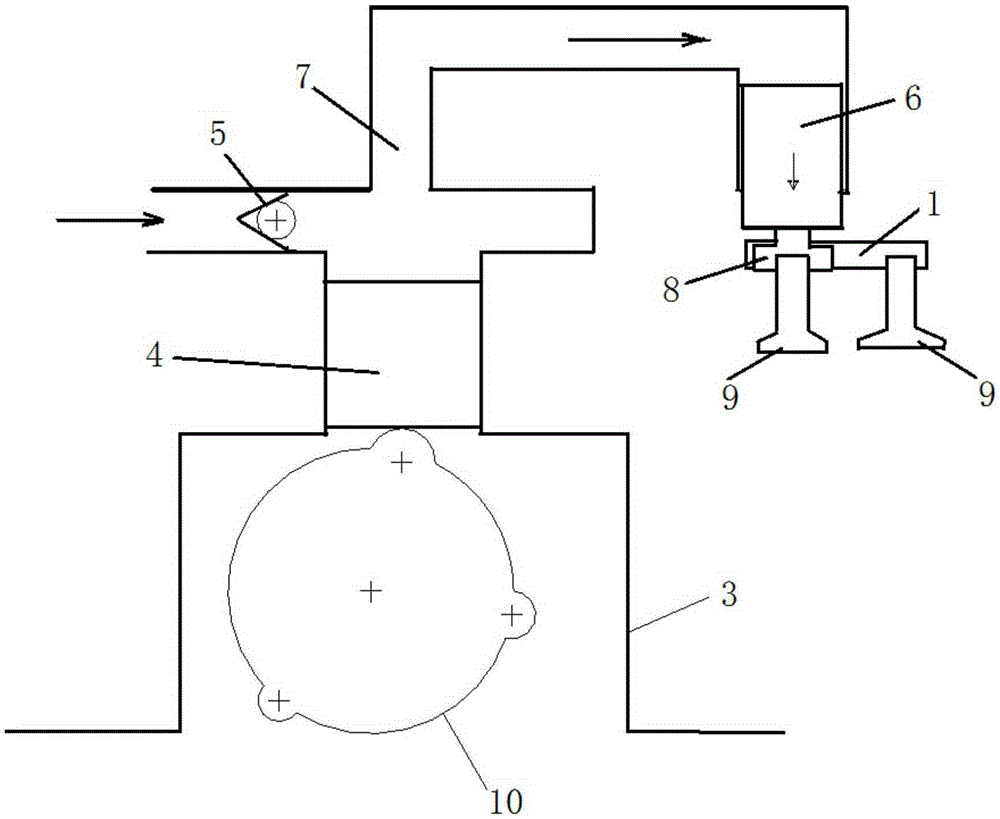

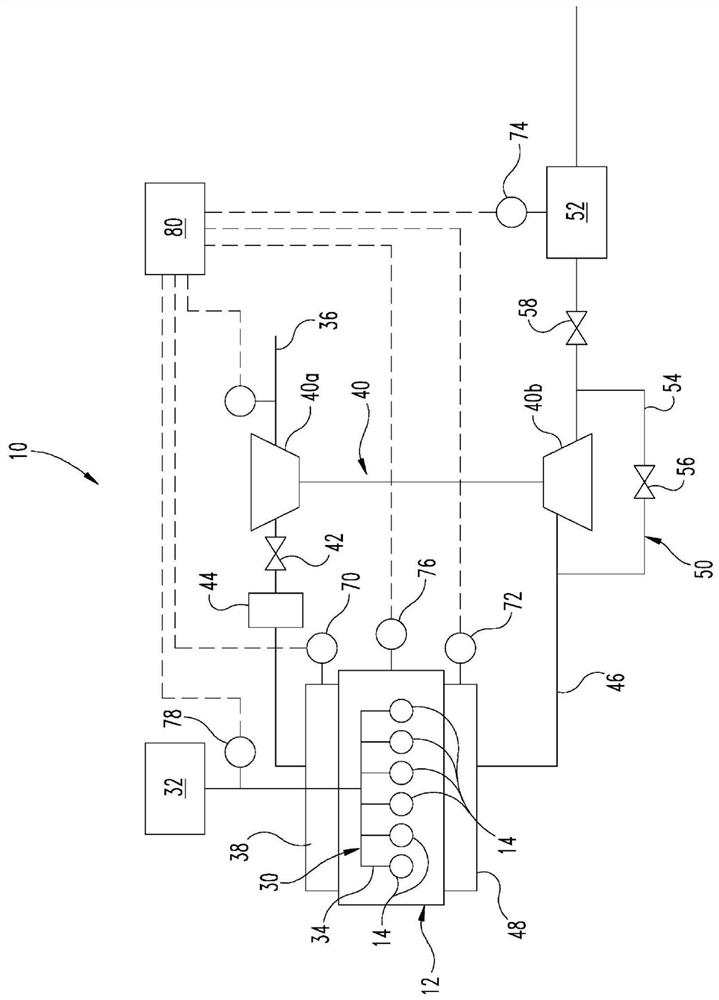

Multi-cylinder piston engine

ActiveCN103608558AControl injectionPower operated startersInternal combustion piston enginesCombustionGas exchange

The multi-cylinder piston engine (20) comprises means (24) for introducing combustion air into the cylinders (19) of the engine (20) and at least one cam-operated valve lifting device (4) for each cylinder (19) of the engine (20), the valve lifting device (4) being arranged to open a gas exchange valve (24, 25). The engine (20) further comprises an arrangement for injecting additional oxygen containing gas into the cylinders (19) of the engine (20), the arrangement comprising a pressure medium source (18) for supplying the additional oxygen containing gas,an injection valve (10) in connection with each cylinder (19), means (21) for connecting the pressure medium source (18) to the injection valves (10), and a control valve (12) for each cylinder (19) of the engine (20) for controlling the operation of the injection valve (10). Each control valve (12) is arranged to be operated by a gas exchange cam (1) of the respective cylinder (19).

Owner:WARTSILA FINLAND OY

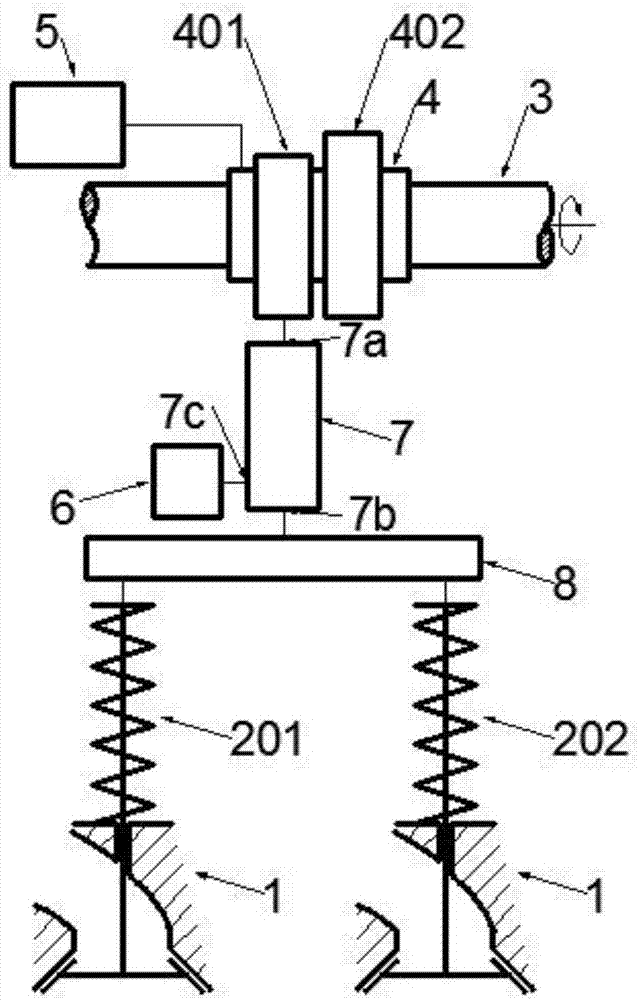

Axial moving type multi-mode variable valve drive system

InactiveCN106968752AGood flexibilityMeet the requirements of ventilationValve controlMachines/enginesMature technologyAir exchange

The invention relates to an axial moving type multi-mode variable valve drive system, and belongs to the field of engine valve drive. The axial moving type multi-mode variable valve drive system mainly comprises a cam shaft, a cam shaft sleeve, an axial moving mechanism, a valve adjusting mechanism, a valve control mechanism and the like. The cam shaft sleeve is at least provided with a first cam and a second cam. Through usage of the axial moving mechanism, conversion among multiple modes of the engine two-stroke drive mode, the four-stroke drive mode, the two-stroke braking mode, the four-stroke braking mode and the like is achieved. Through further cooperated usage of the axial moving type multi-mode variable valve drive system and the valve control mechanism, optimal air exchange of the engine under different work conditions is finally achieved, and the purposes of comprehensively improving the dynamic property, fuel economical efficiency, emission performance and braking safety of the engine are achieved. The axial moving type multi-mode variable valve drive system is provided for actual application and is high in reliability and compact in mechanism, the requirement of the system for various mechanisms is lowered, the mature technology is adopted in the mechanisms, the practical potential of the system within the short period is high, and good application prospects are achieved.

Owner:DALIAN UNIV OF TECH

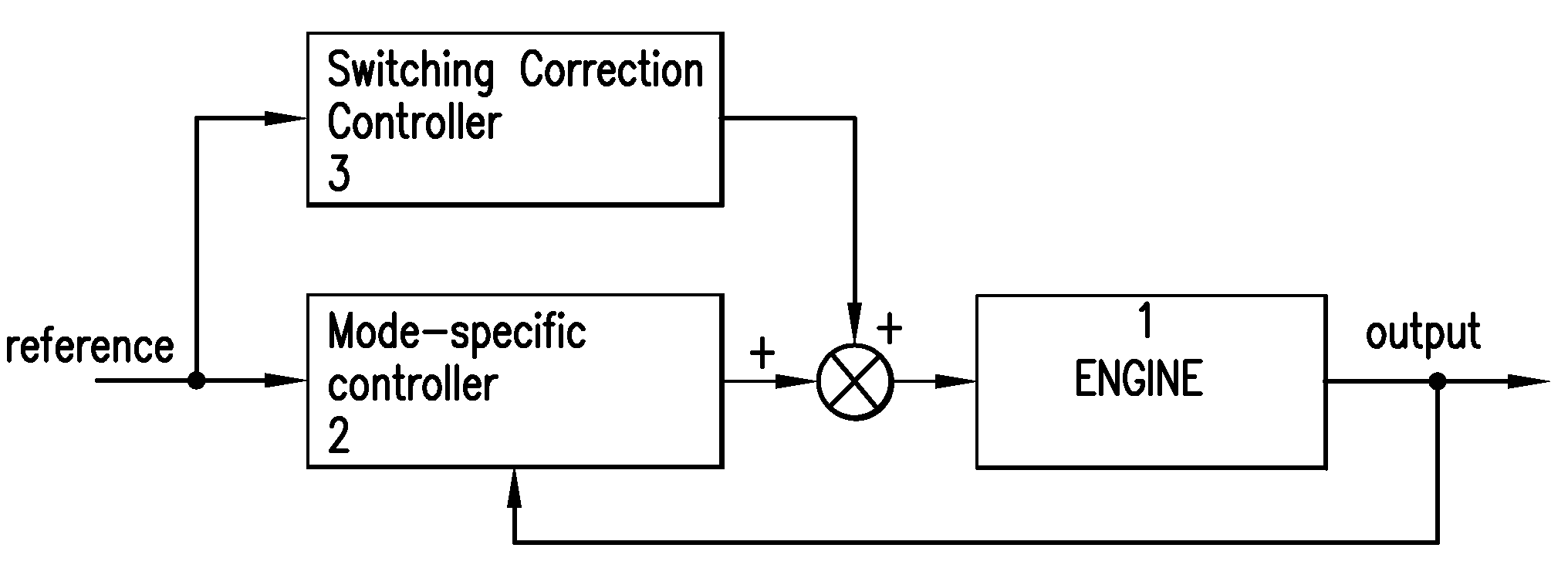

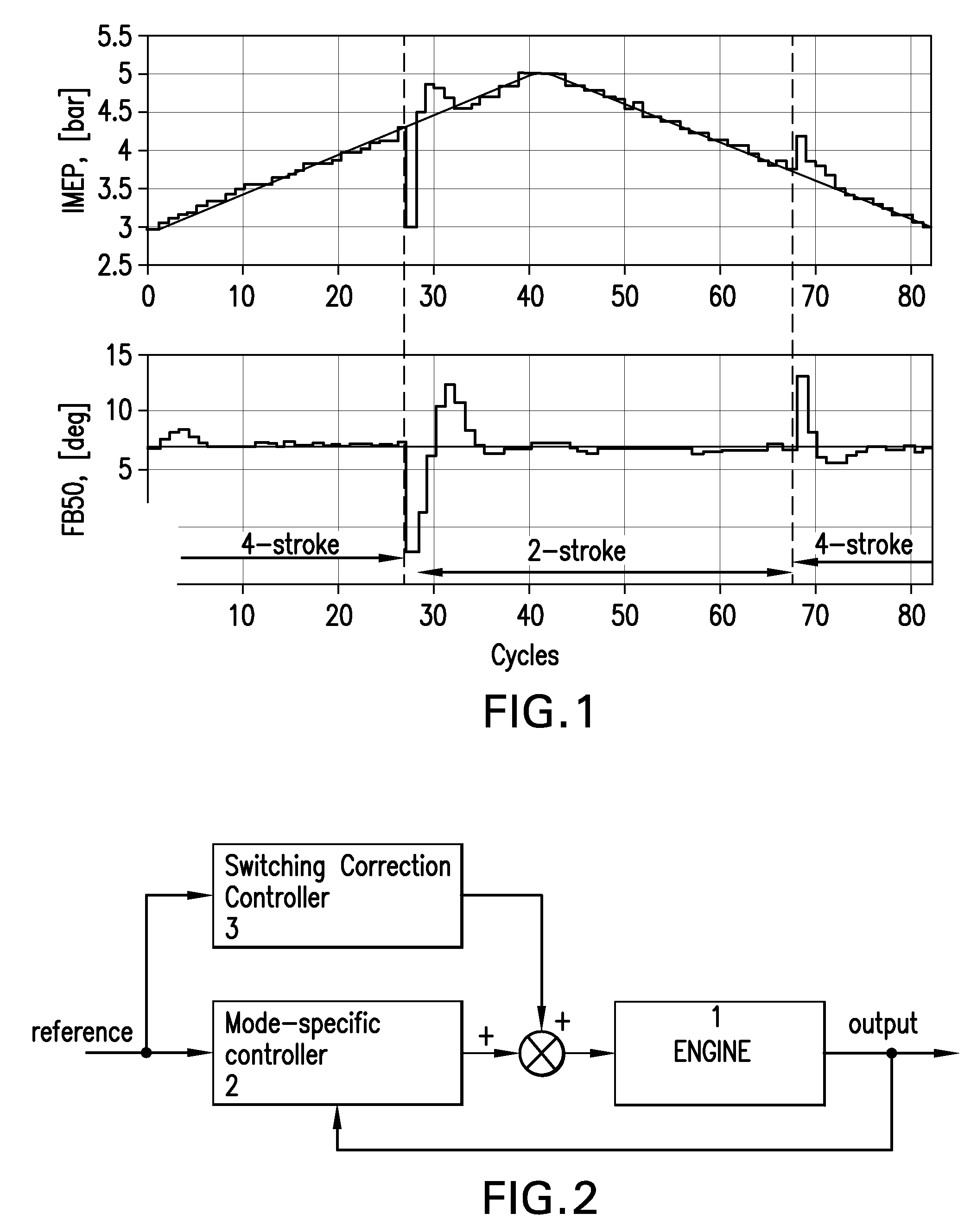

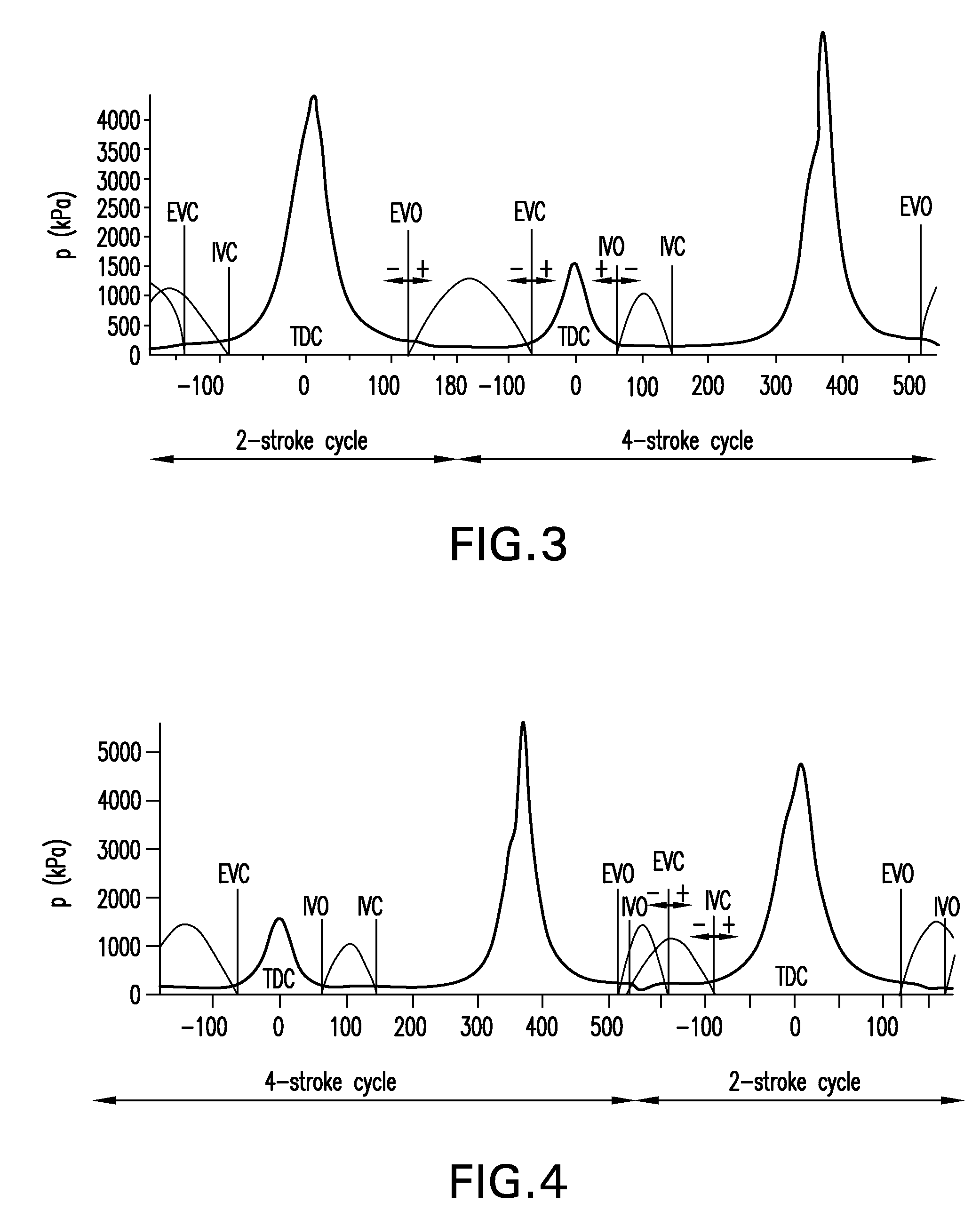

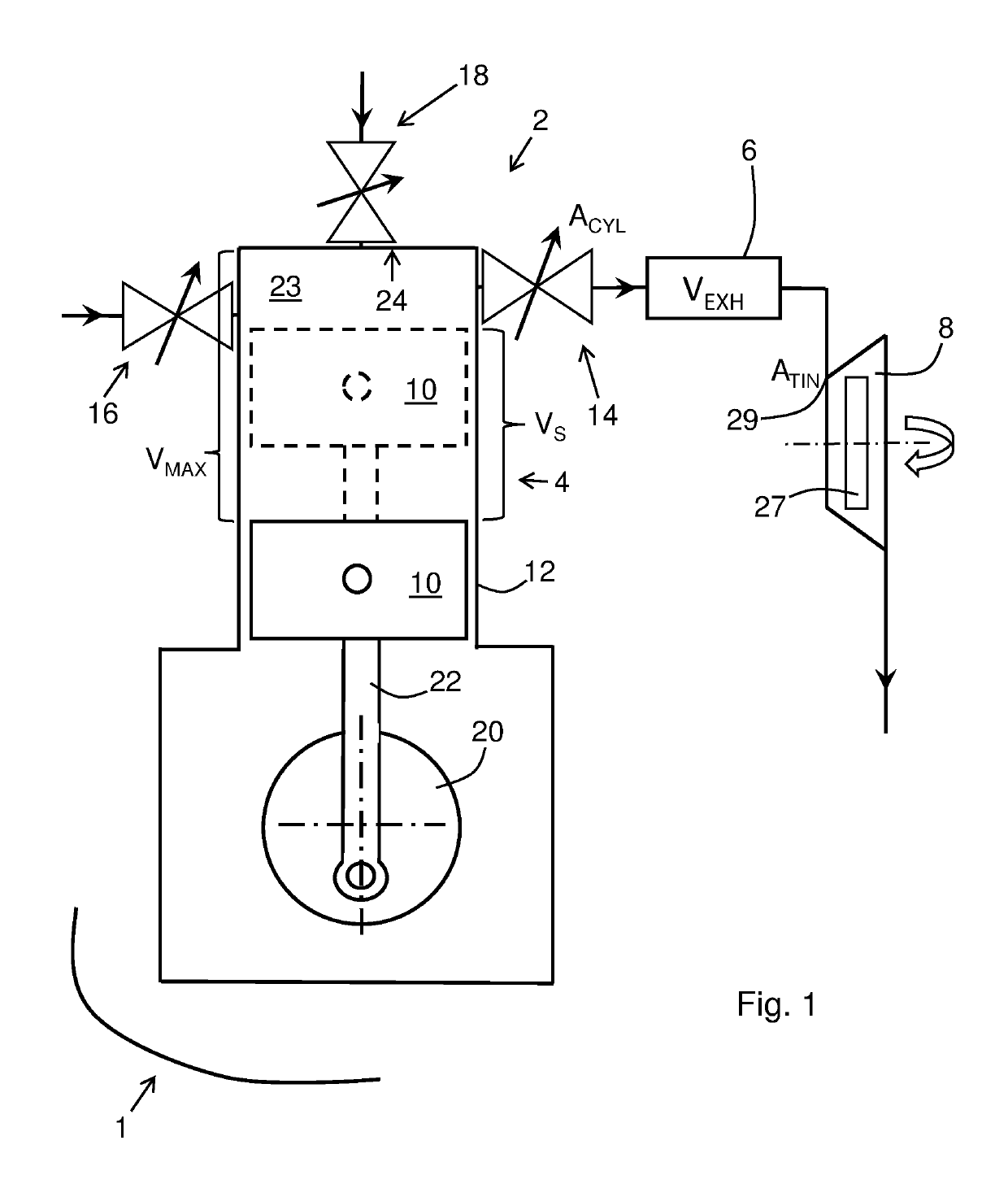

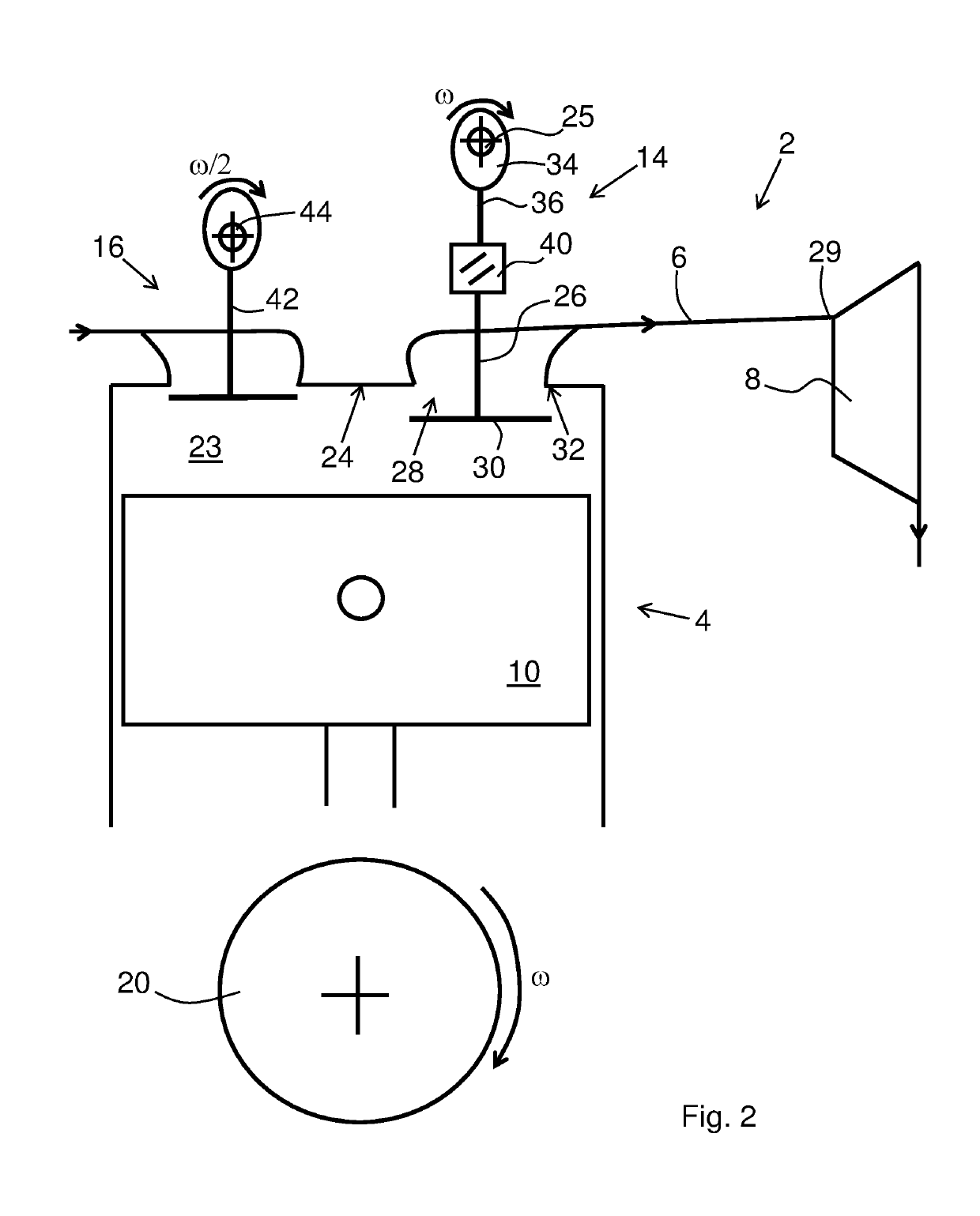

Control architecture and optimal strategy for switching between 2-stroke and 4-stroke modes of HCCI operation

ActiveUS20100275860A1Smooth transitionAnalogue computers for vehiclesElectrical controlLinear engineSystem model

Engine correction inputs to control oscillation in an engine output in a transition between 2-stroke and 4-stroke engine cycle modes of an HCCI engine are determined as follows: for each mode, valve timings which modify the engine output the most upon switching are determined, and a linear engine system model is defined at least partially based on the determined valve timings, which model provides mappings relating initial conditions of the engine and the engine correction inputs to outputs of the engine; initial conditions of the engine corresponding to a switching point for switching between the two modes are determined; desired engine output conditions upon switching between the two modes are specified; and the engine correction inputs are determined by using the determined initial conditions, the desired engine output conditions, and the linear engine system model corresponding to the engine cycle mode in effect upon switching.

Owner:ROBERT BOSCH GMBH

Four stroke internal combustion engine and thereto-related method

InactiveUS20190153906A1Available energyElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

Provided is a four stroke internal combustion engine comprising at least one cylinder arrangement, a crankshaft, a camshaft, and a turbine. The camshaft is synchronized with the crankshaft to rotate at a same rotational speed as the crankshaft. A linkage arrangement is configured to prevent the motion of the valve head every alternate rotation of the camshaft, such that the exhaust opening remains closed during a compression stroke of the piston. Also a method for controlling a four stroke internal combustion engine is disclosed.

Owner:SCANIA CV AB

Motor brake system

The invention relates to the field of motor braking, and discloses a motor brake system, which comprises a motor body and further comprises a brake pump assembly, a valve bridge assembly and a brake piston; the brake pump assembly and the valve bridge assembly are arranged on the motor body; the brake pump assembly comprises a pump body connected with the brake piston by a master oil pipe and provides hydraulic oil for the brake piston; a cam is arranged in an inner cavity of the pump body; a plunger is arranged above the cam and is driven to move up and down by the rotation of the cam; the valve bridge assembly comprises a valve bridge body, an execution pin and a valve rod; the valve bridge body is provided with a guide hole; the valve rod is arranged in the guide hole by the execution pin positioned below the brake piston. High oil pressure can be created by the brake pump arranged on the motor so as to drive the brake piston to open the brake valve, a high load generated during braking is transferred and the problem of wear of a cam shaft and a tappet in an air distribution mechanism is solved.

Owner:WEICHAI POWER CO LTD

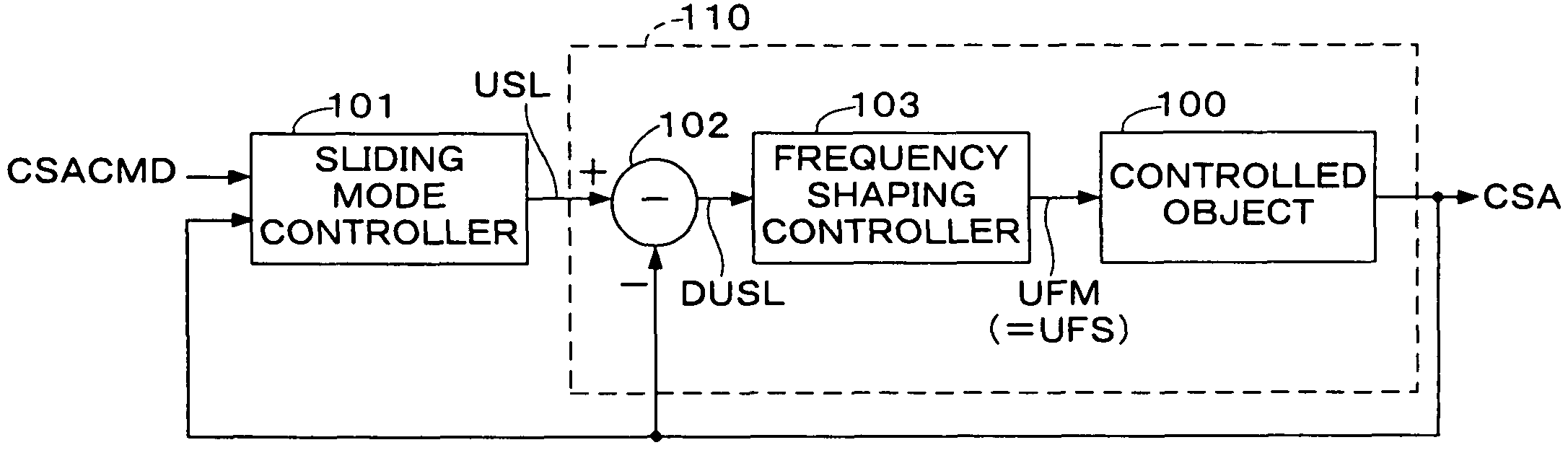

Control system for plant

InactiveUS7826956B2Sufficient robustness and stabilityOvercome the lack of robustnessAnalogue computers for vehiclesElectrical controlControl systemFeedback control

A control system for a plant, including a sliding mode controller and a transfer characteristic adjusting module. The sliding mode controller calculates a feedback control input with a sliding mode control so that an controlled output of the plant coincides with a target value. The transfer characteristic adjusting module is connected to an output of the sliding mode controller, and has a transfer characteristic set according to a transfer function of a controlled object model which is obtained by modeling the plant. A control input to the plant is set to an output of the transfer characteristic adjusting module. The transfer characteristic of the transfer characteristic adjusting module is set so that a composite transfer function indicative of a transfer characteristic which is obtained by combining the transfer characteristic of the transfer characteristic adjusting module and a transfer characteristic of the controlled object model, coincides with a desired target transfer function.

Owner:HONDA MOTOR CO LTD

Rocker latch for controlling engine valve actuation

Engine valve actuation systems and methods used to decompress an engine cylinder during engine start-up, shut-down, and for bleeder braking are disclosed. An exemplary system may include a rocker arm pivotally mounted on a rocker shaft, and a structure mounted adjacent to the rocker arm in a fixed position relative to the rocker arm. A latch piston may be slidably disposed between the rocker arm and the structure. The latch piston may be selectively extended to engage both the rocker arm and structure to limit the pivotal motion of the rocker arm and maintain the engine valves in an open condition.

Owner:JACOBS VEHICLE SYST

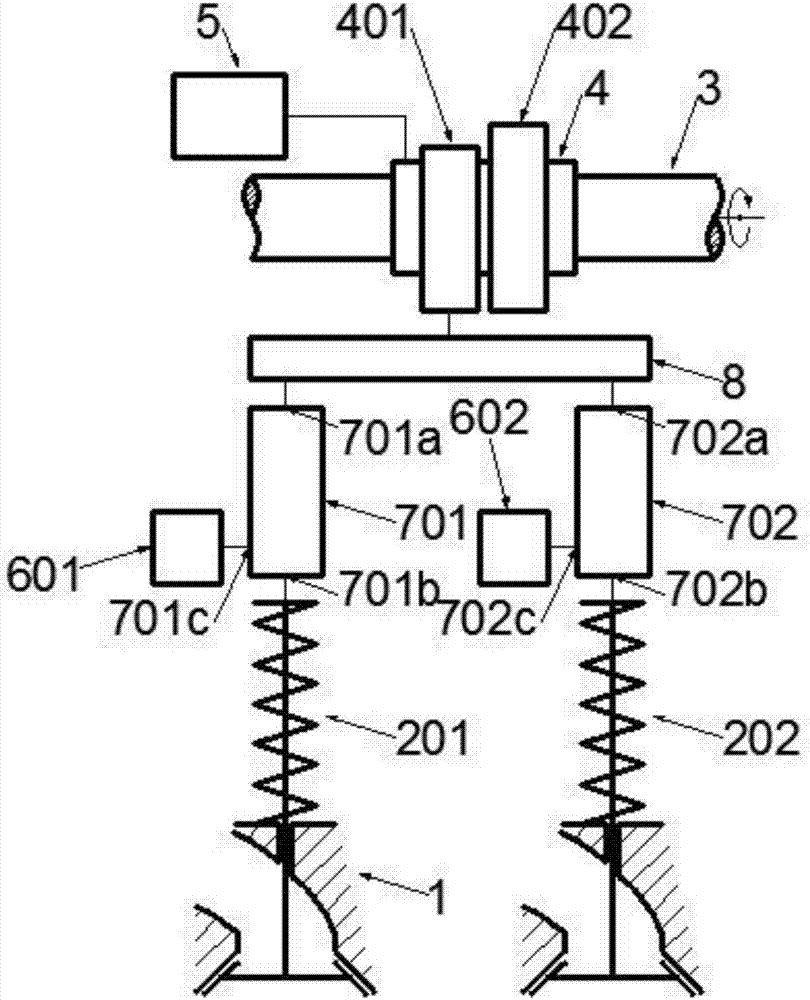

Axial-moving multi-mode level type variable valve driving system

InactiveCN106762010AImprove powerImprove fuel economyValve controlMachines/enginesMature technologyEngineering

The invention belongs to the field of engine valve driving and discloses an axial-moving multi-mode level type variable valve driving system. The system mainly comprises a cam shaft, a cam shaft sleeve, an axial moving mechanism, a valve adjusting level, a valve control mechanism and the like. At least a first cam and a second cam are arranged on the cam shaft sleeve. By adoption of the axial moving mechanism, shifting among various mode including a two-stroke driving mode, a four-stroke driving module, a two-stroke braking mode, a four-stroke braking mode and the like of an engine is realized, and further, by joint use with the valve control mechanism, optimal aeration of the engine under different working conditions is finally realized, and comprehensive improvement of engine dynamic properties, fuel economy, emission performance and braking safety is realized. The system is provided aiming at practical application and is high in reliability and compact in structure, and requirements of the system on each mechanism are reduced; due to adoption of mature technologies for each mechanism, the system is high in short-term practical potential and has a promising application prospect.

Owner:DALIAN UNIV OF TECH

Valve train with cylinder deactivation and compression release

An internal combustion engine system includes an engine with a plurality of pistons housed in respective ones of a plurality of cylinders, an air intake system to provide air to the plurality of cylinders through respective ones of a plurality of intake valves, an exhaust system to release exhaust gas from the plurality of cylinders through respective one of a plurality of exhaust valves. A valvetrain is provided for cylinder deactivation of a first part of the plurality of cylinders and compression release braking on a second part of the plurality of cylinders.

Owner:CUMMINS INC

Integral lash adjustor for hydraulic compression engine brake

Engine compression release brakes include some degree of lash between the brake actuation portion and the engine exhaust valve portion. The disclosed apparatus and method provides an integral lash adjuster that includes an adjusting screw that is threadably received by a slidable plunger. Rotation of the adjusting screw causes the plunger to slide relative to a plunger cavity and responsively modify the amount of lash.

Owner:CATERPILLAR INC

Engine brake execution mechanism and engine

InactiveCN106321183AThere will be no problem of limitation failureValve controlMachines/enginesPulp and paper industryPiston

The invention discloses an engine brake execution mechanism and an engine. The engine brake execution mechanism comprises a support fixed to a cylinder cover of the engine, the support comprises an extending portion extending to the position above an air valve, the extending portion is provided with a through hole allowing the extending portion to penetrate in the vertical direction, an execution piston is arranged in the through hole in a sliding manner, the upper end of the execution piston is communicated with a pressure oil supply pipeline, the lower end of the execution piston is connected with a linkage part for controlling the lift of the air valve, and an elastic part is arranged between the wall of the through hole and the execution piston; an oil draining hole is formed in the side wall of the through hole, and when the execution piston displaces to the preset position downwards, the pressure oil is communicated with the oil draining hole, the execution piston stops downward displacement, and the lift of the air valve reaches the maximum. According to the arrangement, the engine brake execution mechanism can avoid limiting failures of the execution piston.

Owner:WEICHAI POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com