Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Improved swirl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

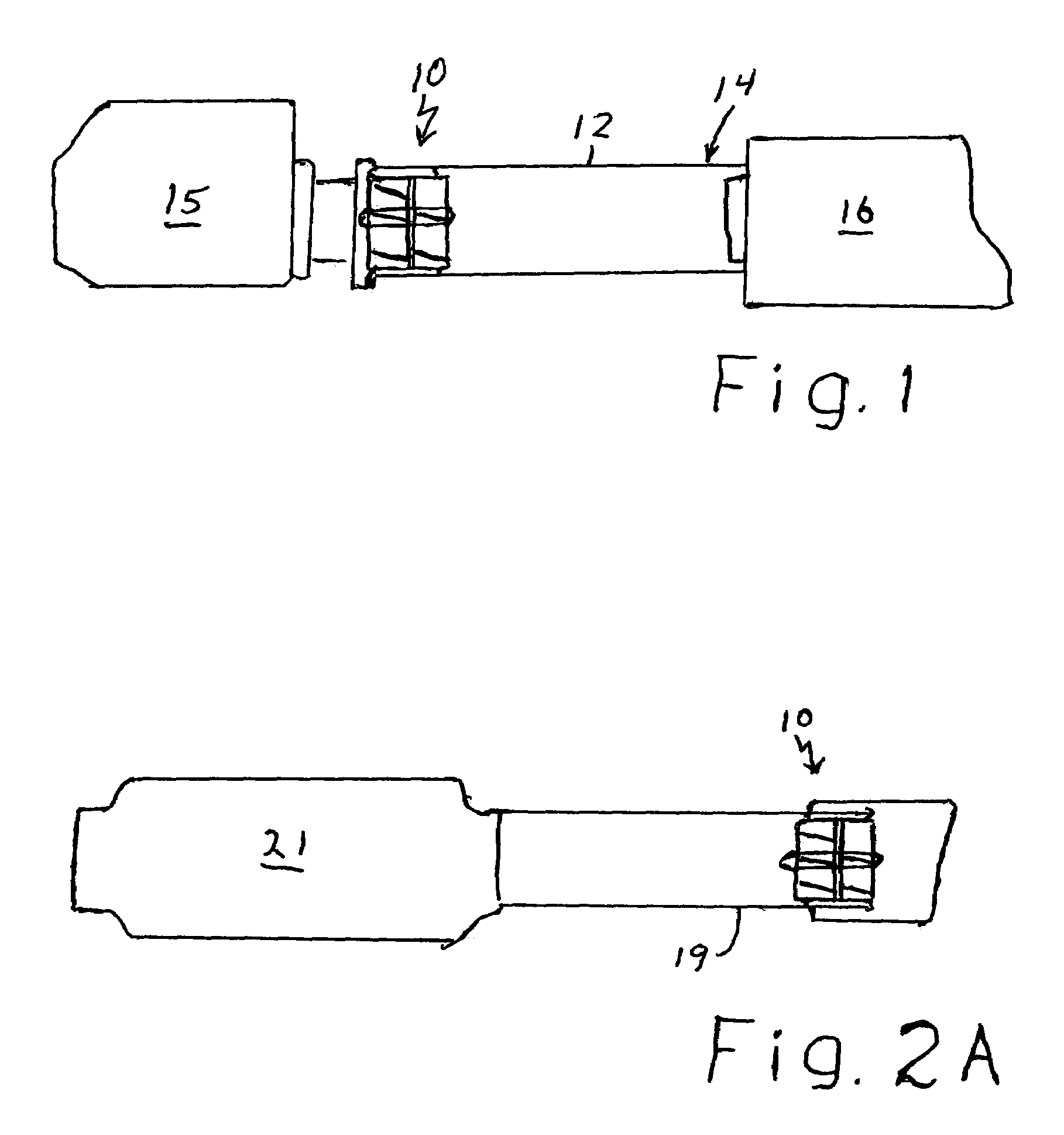

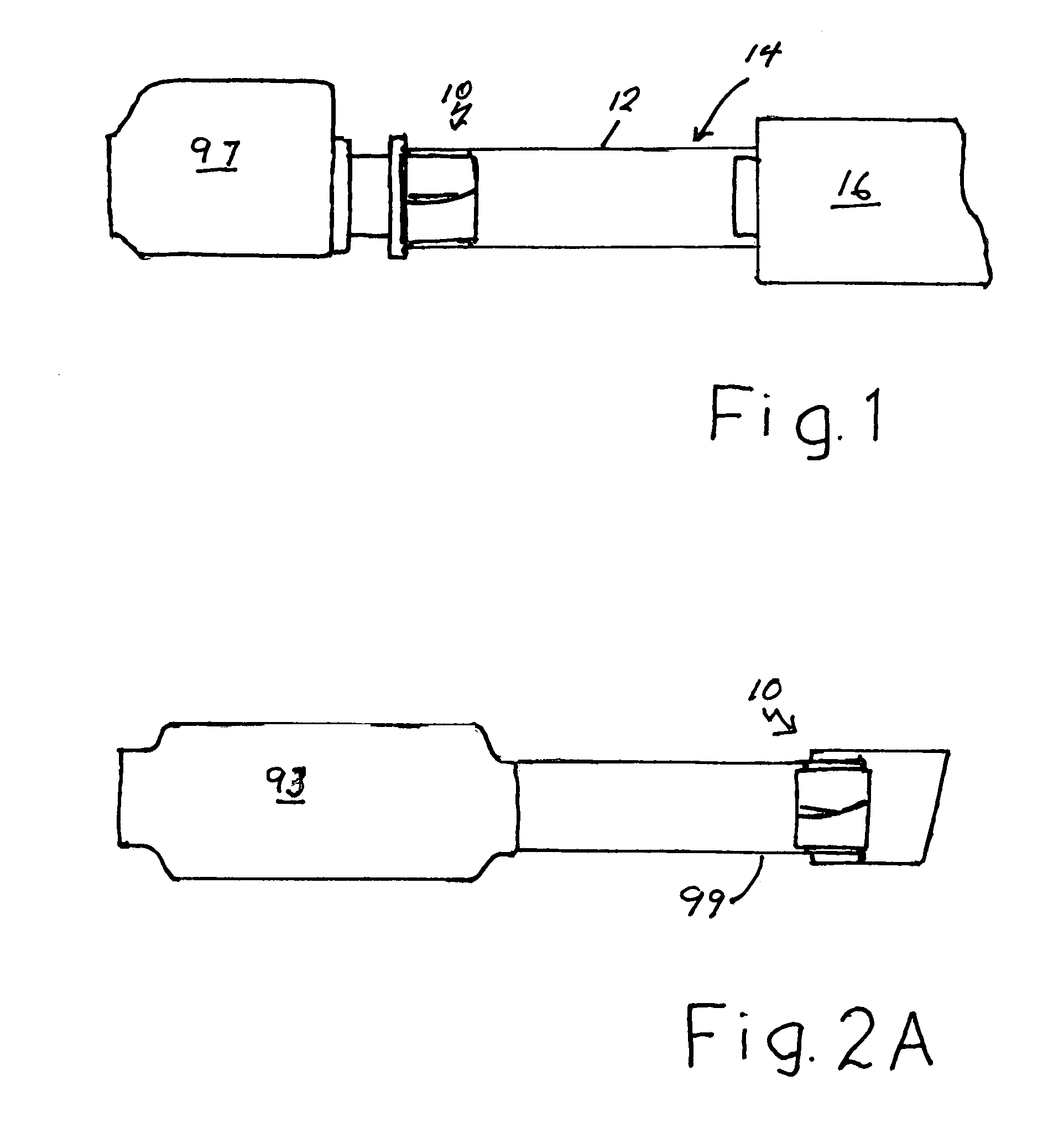

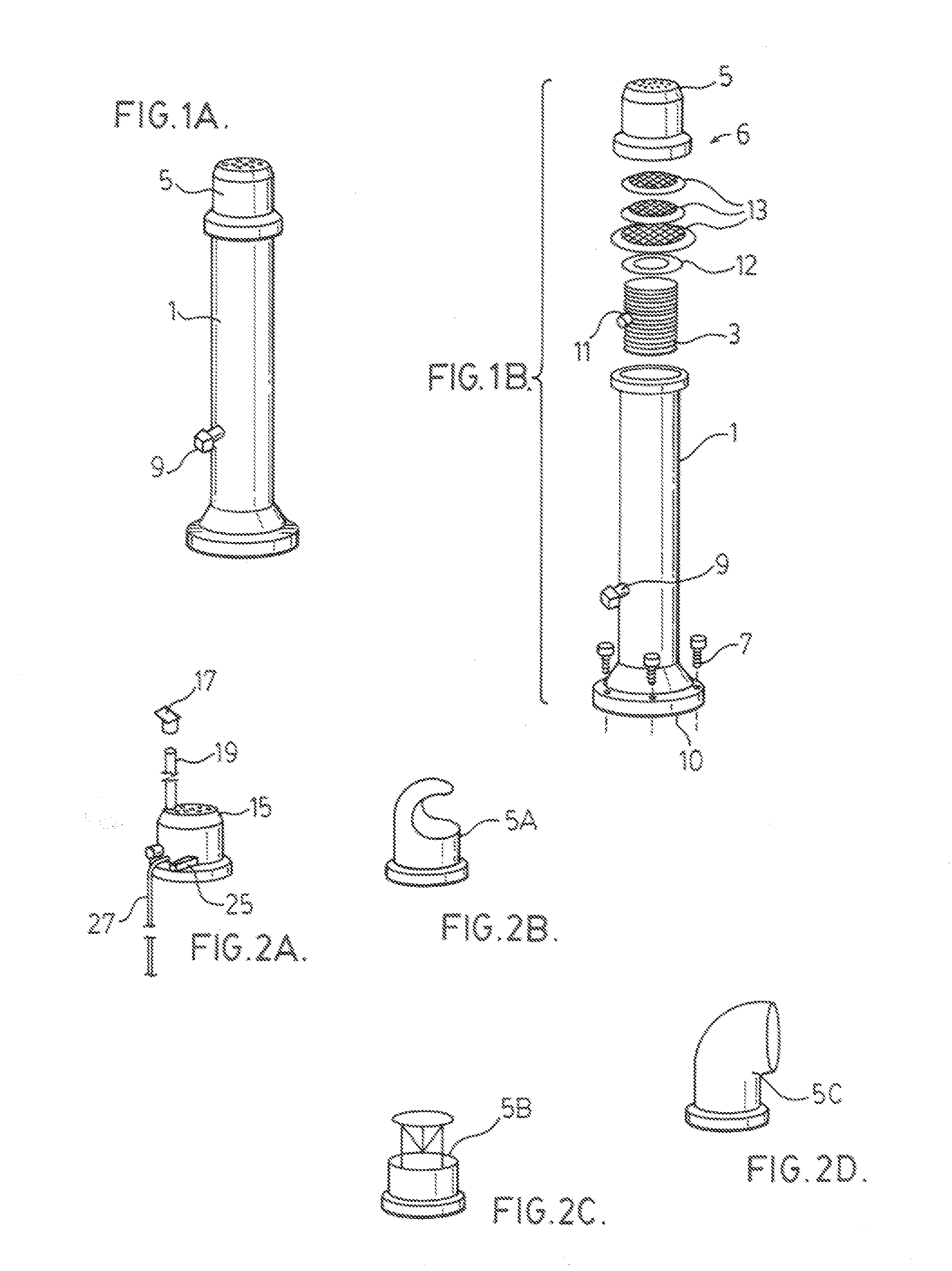

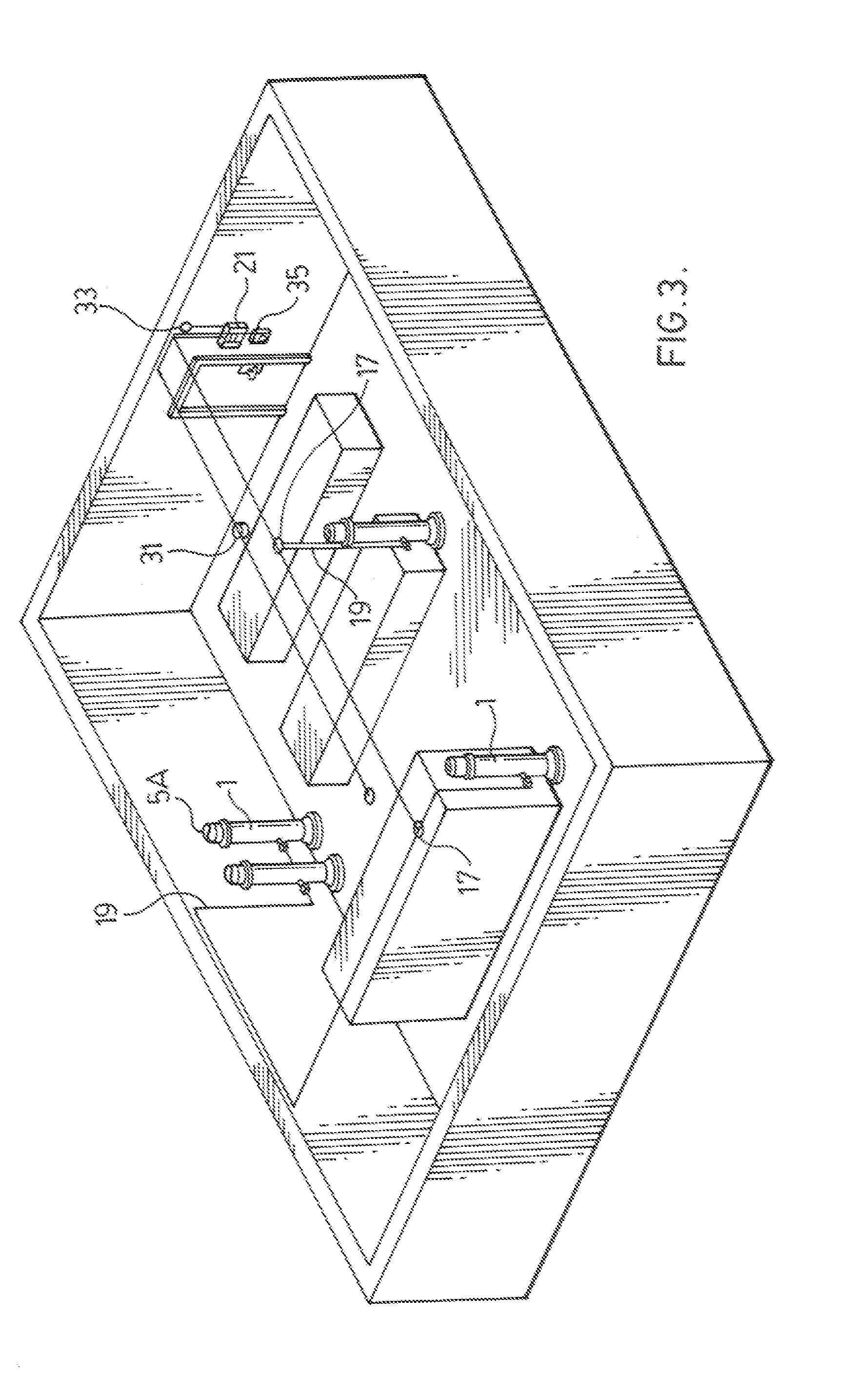

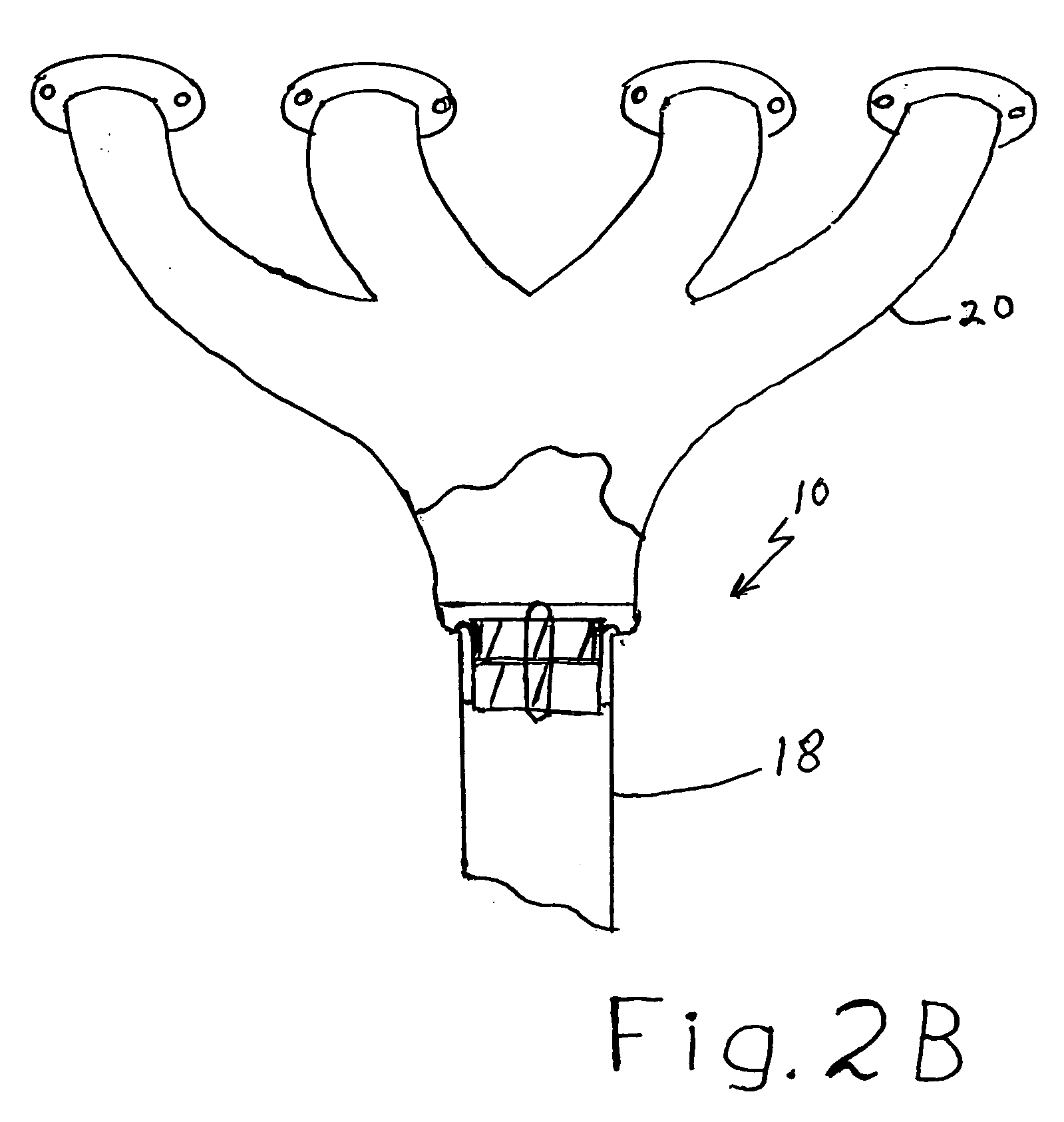

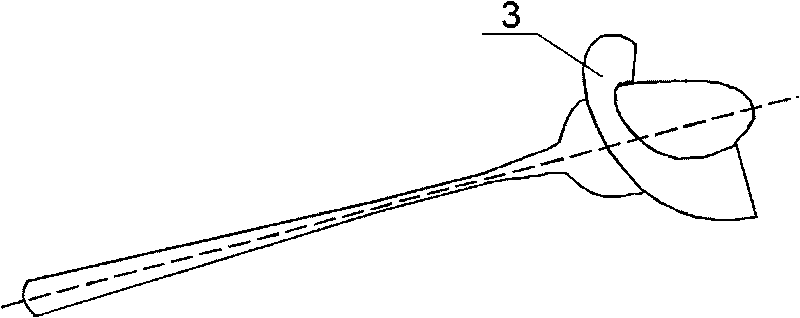

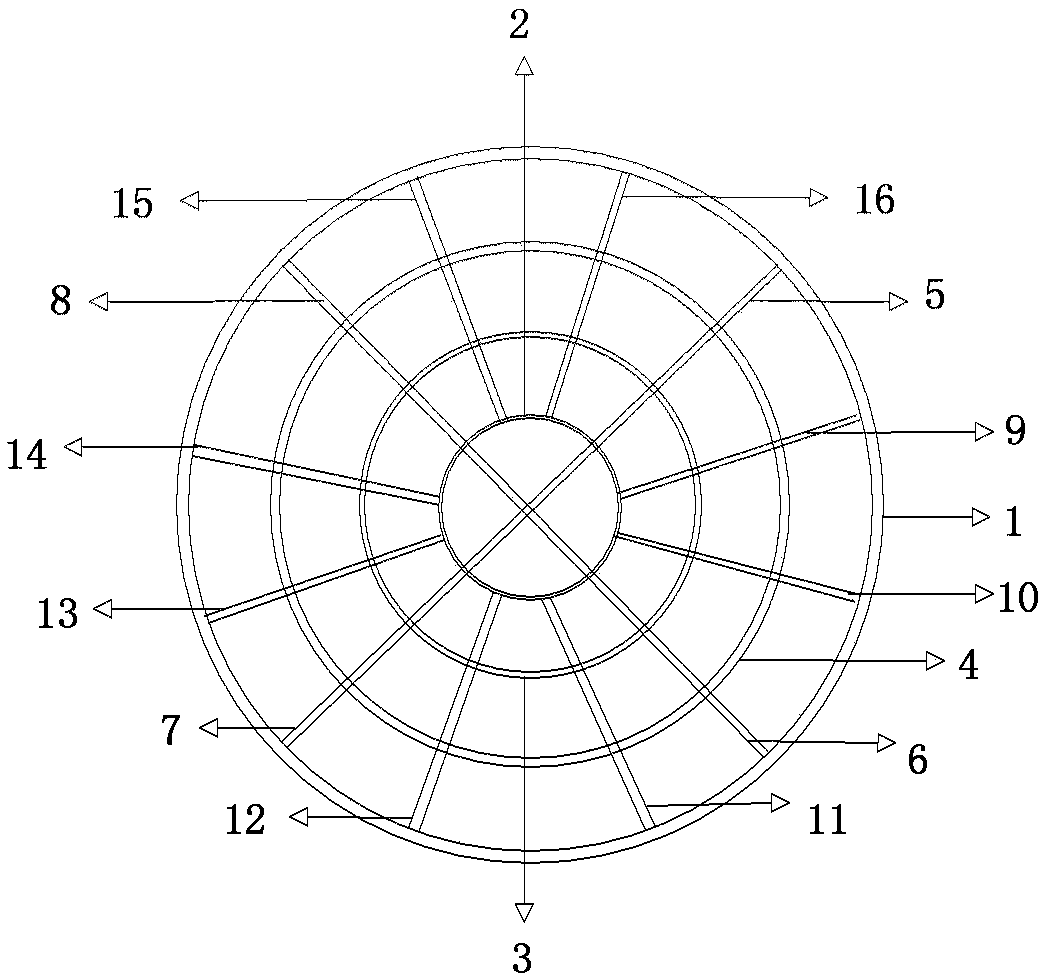

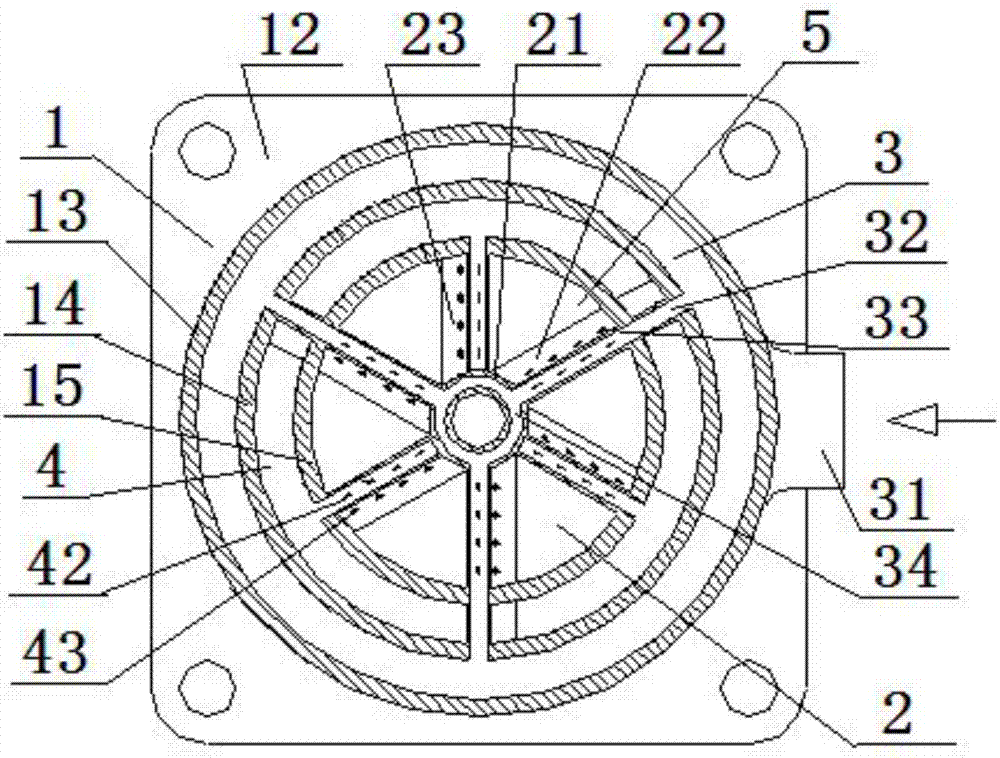

Fluid swirling device having rotatable vanes

InactiveUS7104251B2Improved swirlHigh degreeInternal combustion piston enginesExhaust apparatusEngineeringComplete mixing

The device includes a set of rotatable vanes and a set of stationary vanes which are mounted within a cylindrical housing. The set of rotatable vanes are connected to a post located at the axis of the housing and rotate relative to the post in response to the intake or exhaust fluid impinging on the vanes which are angled relative to the direction of flow of the fluid stream. The set of stationary vanes are rigidly secured to the post and also rigidly secured to the housing walls. The set of stationary vanes are positioned adjacent the set of rotatable vanes and are similarly angled relative to the direction of flow of the fluid stream in order to deflect the fluid stream and impart a swirling motion to the fluid stream in order to provide more complete mixing of the air / fuel mixture of the intake fluid stream or scavenging of the exhaust fluid stream. Tabs which extend radially outwardly from the housing ends secure the device within an intake or exhaust passageway.

Owner:KIM JAY S

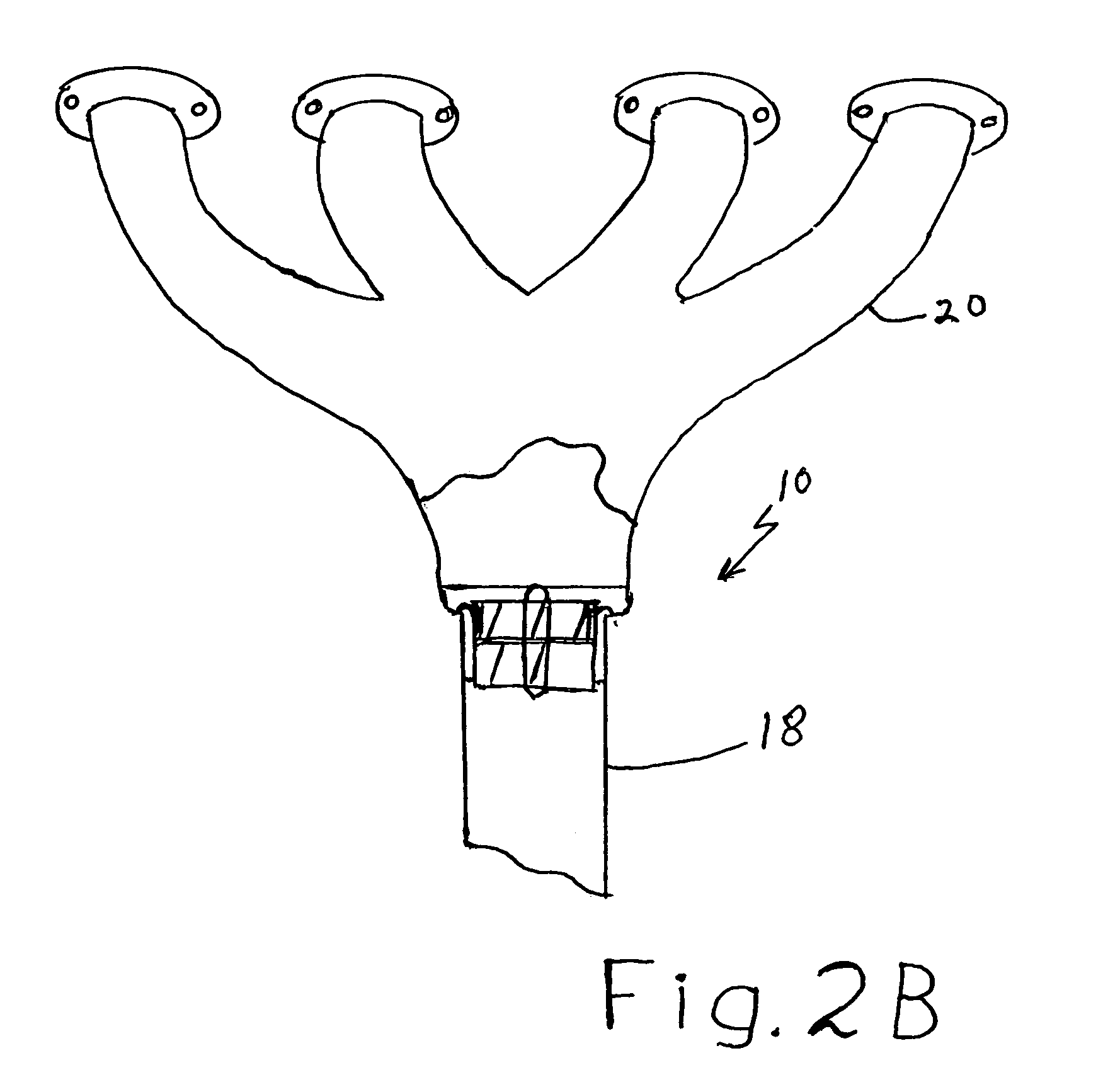

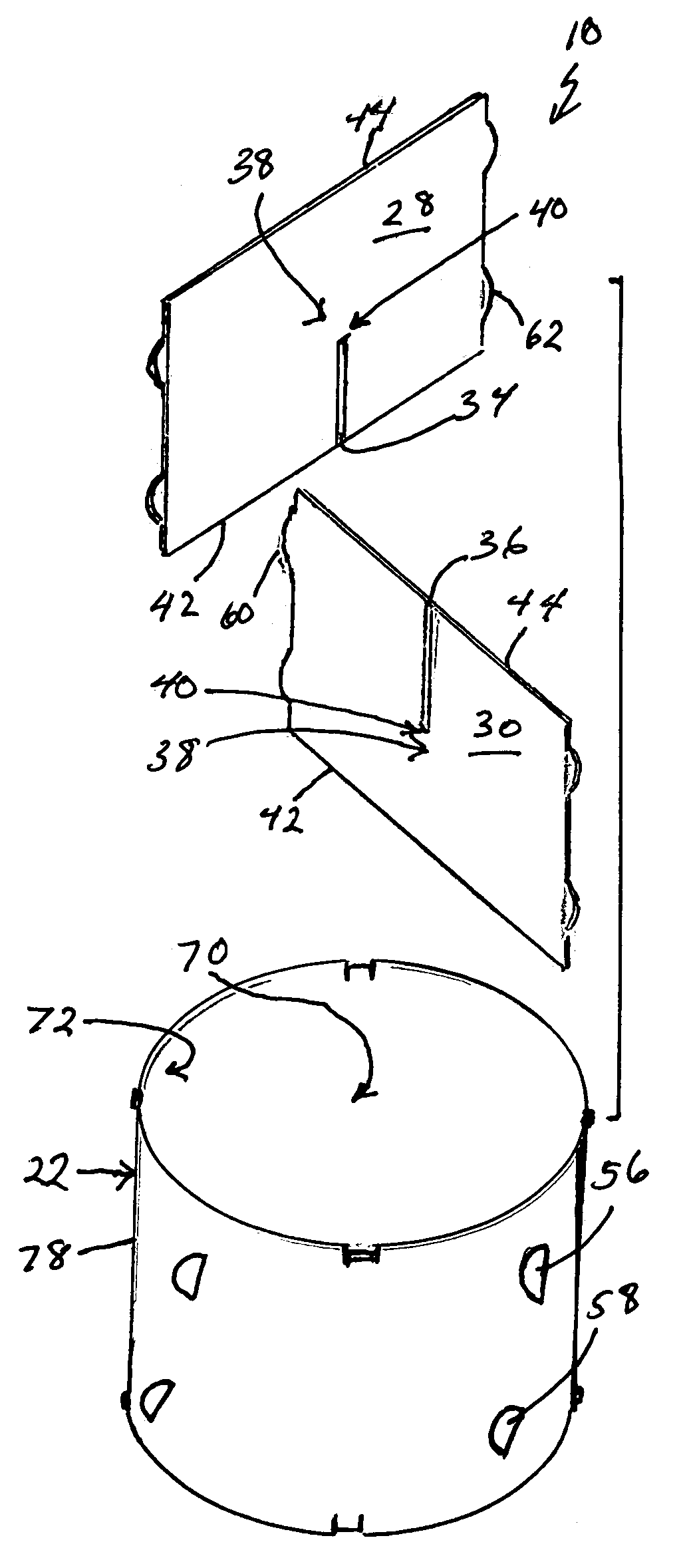

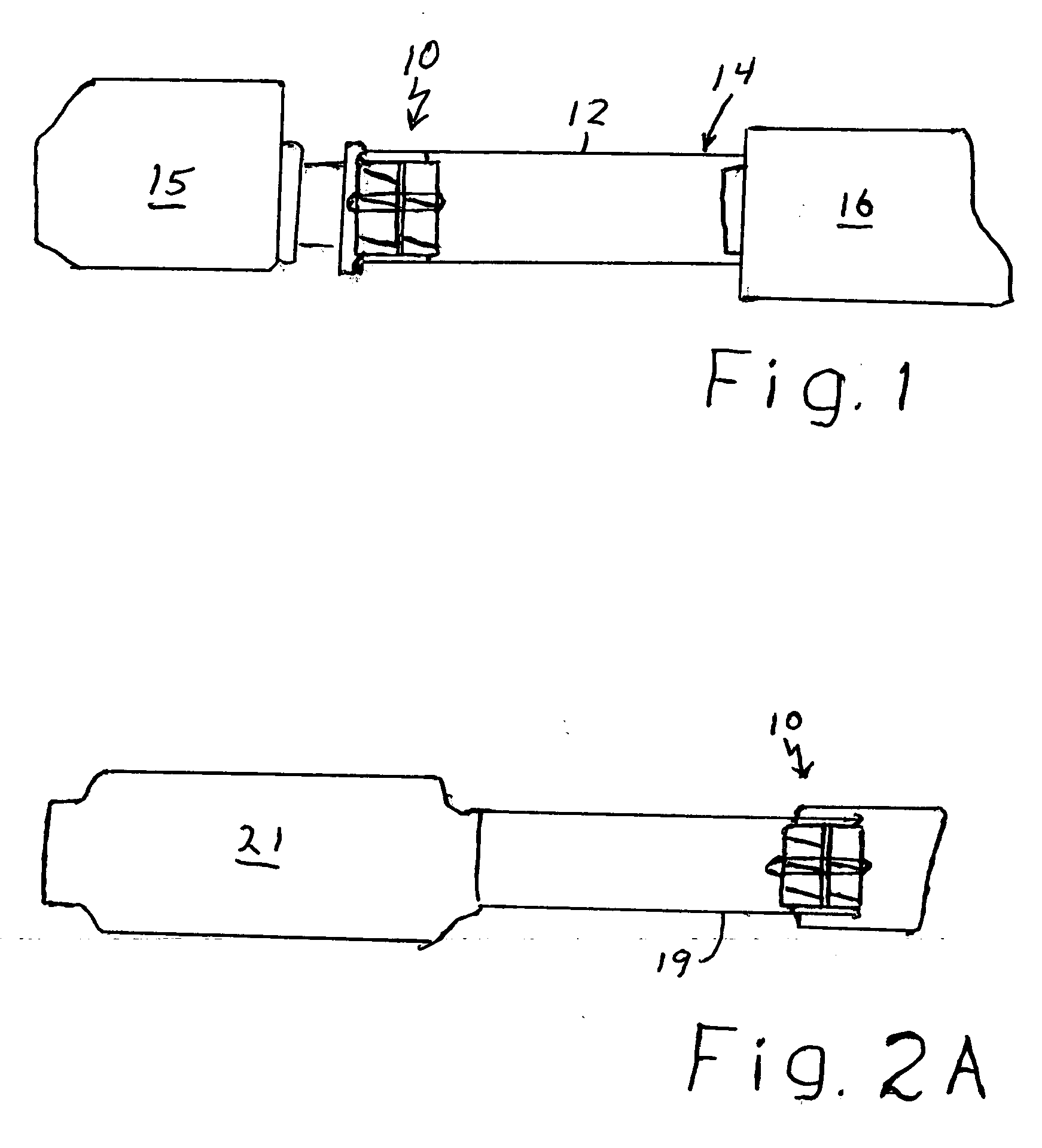

Fluid swirling device

InactiveUS7028663B1Minimizes force actingIncrease airflowInternal combustion piston enginesExhaust apparatusComplete mixingExhaust gas

The device includes a pair of flat planar vanes securely mounted within a cylindrical housing. The vanes have a medial slit extending from the center to a longitudinal end of the vane. The vanes are interconnected at the slits so that they are in criss-cross positioning. The vanes are axially angled so that when positioned in an intake air duct the vanes impart a swirling motion to the air entering the engine providing more complete mixing of the air and fuel and when positioned in an exhaust passageway the vanes impart a swirling motion to the exhaust gases exiting the engine providing scavenging of the exhaust gases.

Owner:KIM JAY S

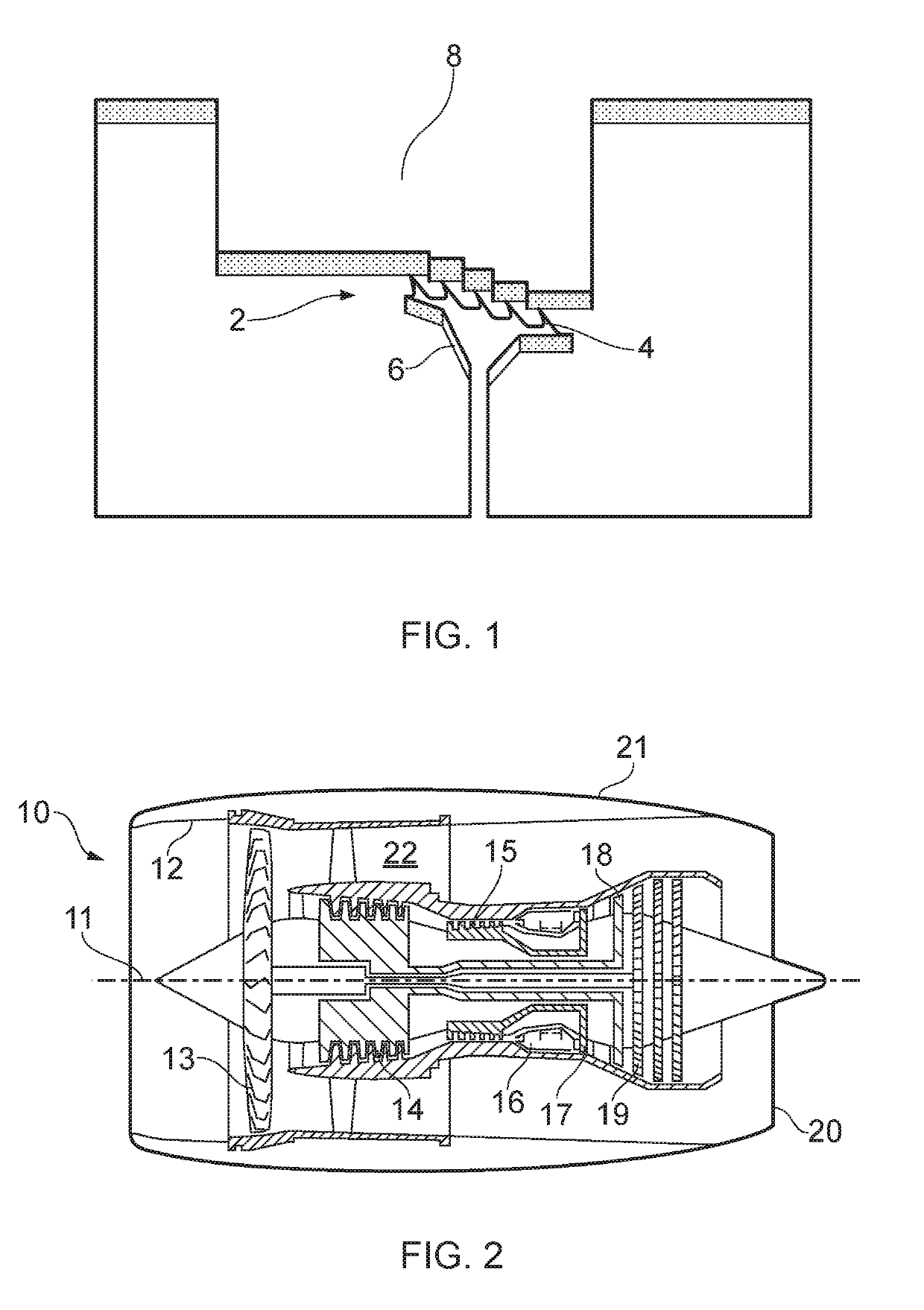

Fuel nozzle having aerodynamically shaped helical turning vanes

ActiveUS20100205971A1High degree of swirlMinimize riskBurnersTurbine/propulsion fuel supply systemsGas turbinesAerodynamics

A fuel nozzle for a gas turbine engine is disclosed which includes a nozzle body having a longitudinal axis, an elongated annular air passage defined within the nozzle body, and a plurality of circumferentially spaced apart axially extending swirl vanes disposed within the annular air passage, wherein each swirl vane has multiple joined leads and a variable thickness along the axial extent thereof.

Owner:ROLLS ROYCE PLC

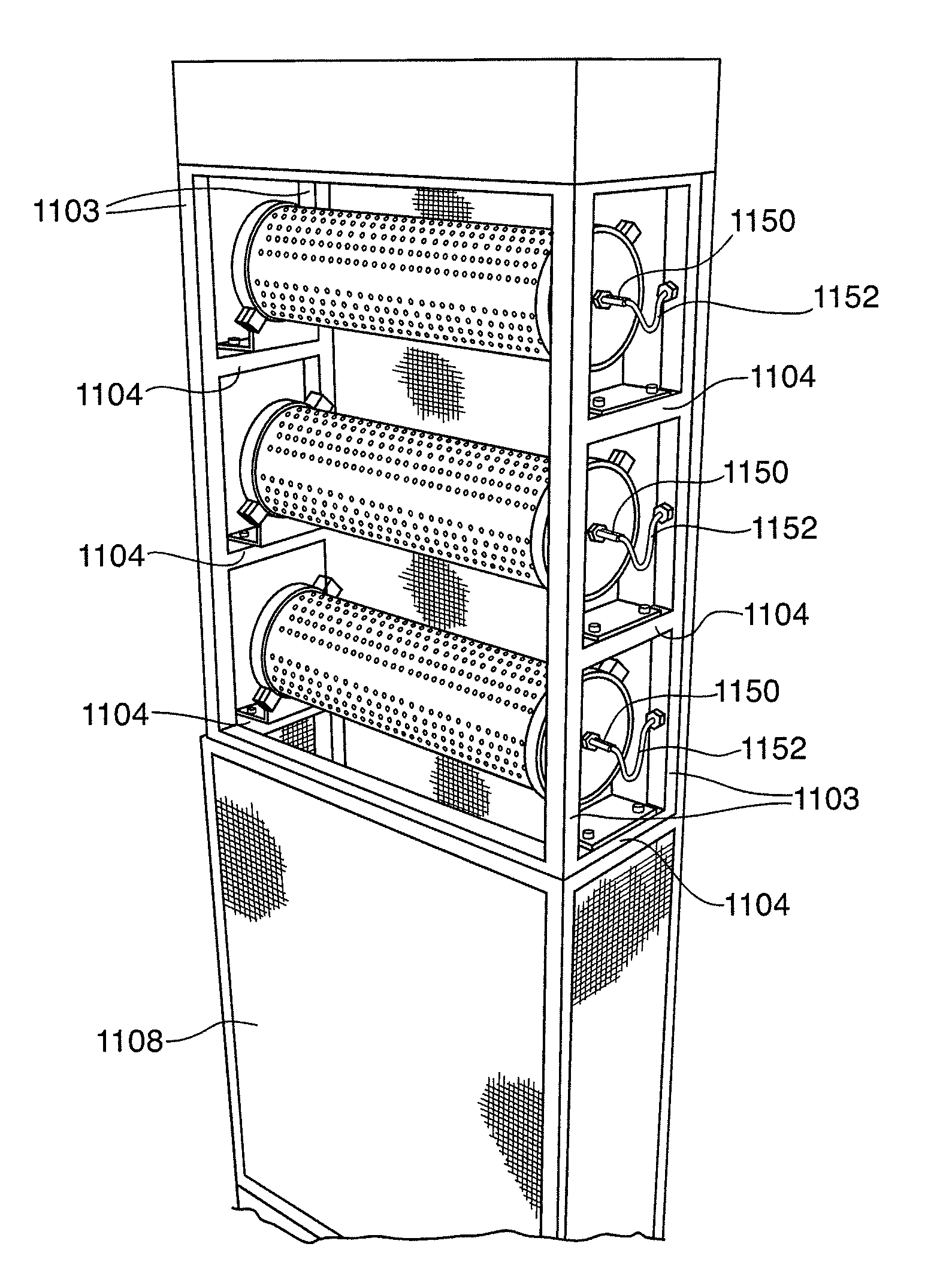

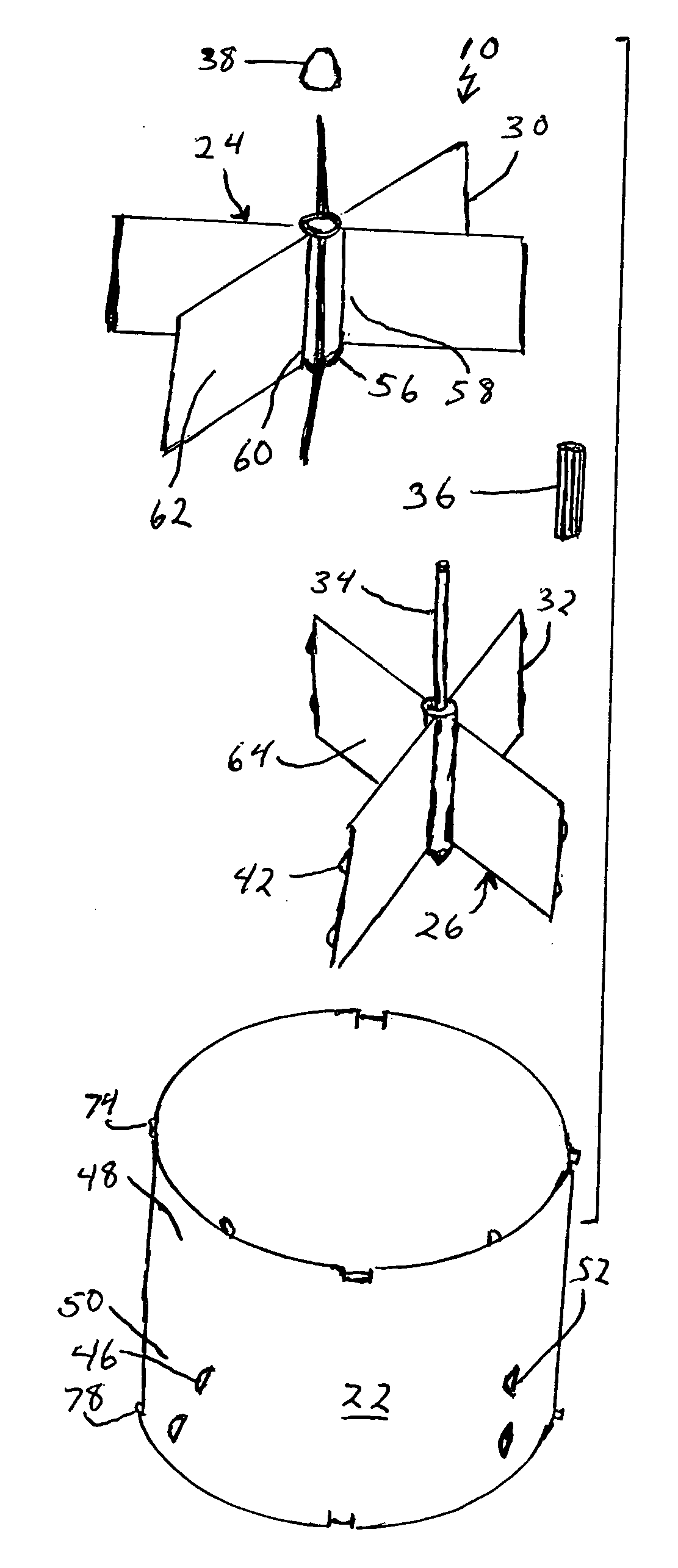

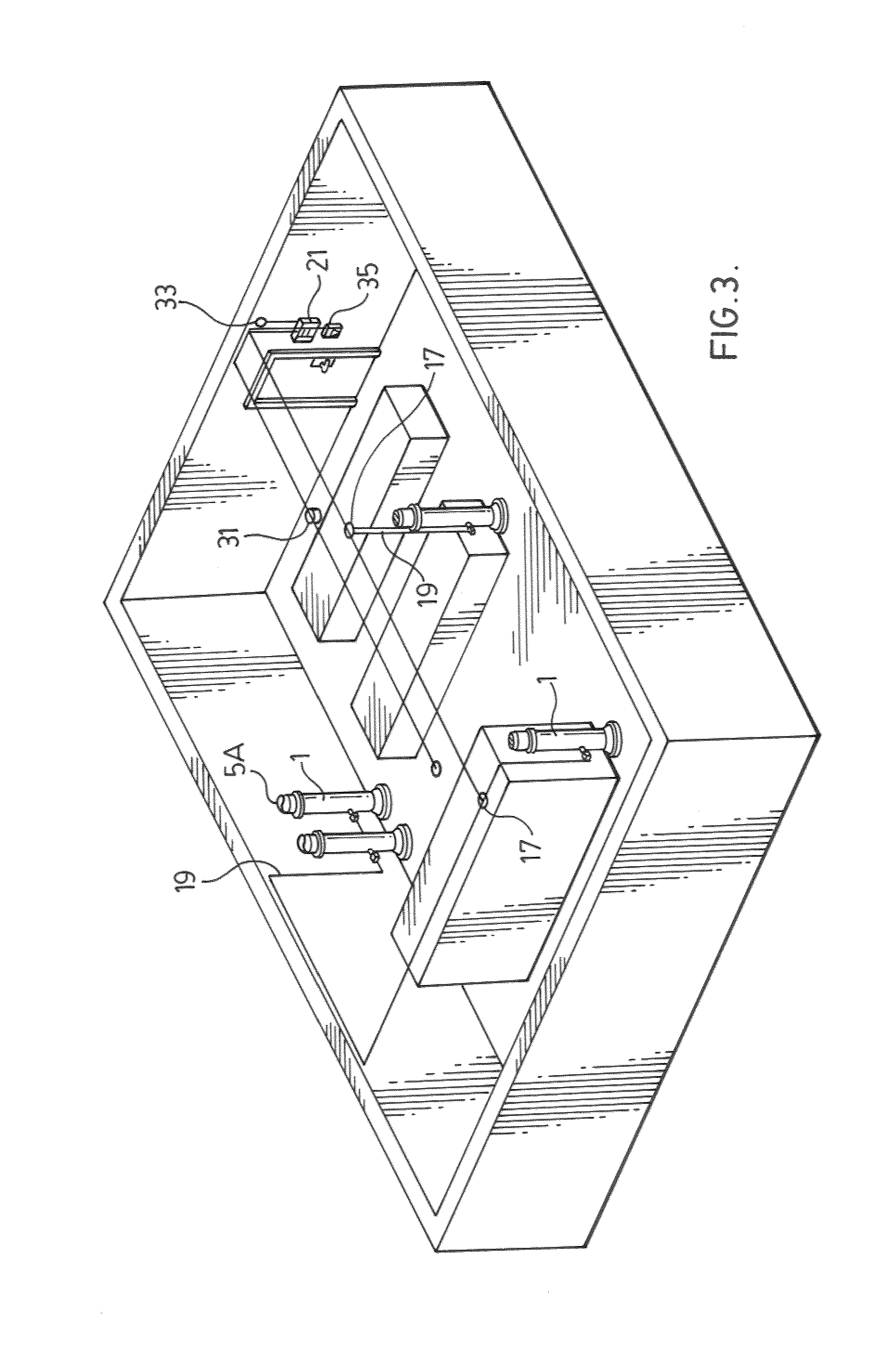

System and method for sodium azide based suppression of fires

A fire suppressing gas generator includes a cylindrical housing comprising an array of discharge ports distributed generally uniformly therearound; a cylindrical filter disposed within the housing and spaced from the interior wall of the housing; a plurality of azide-based propellant grains inside the cylindrical filter; and at least one ignition device associated with the propellant grains. The propellant grains when ignited by the ignition device generate a fire suppressing gas which passes through the filter and out of the discharge ports of the cylindrical housing for delivery into a space.

Owner:N2 GLOBAL SIA

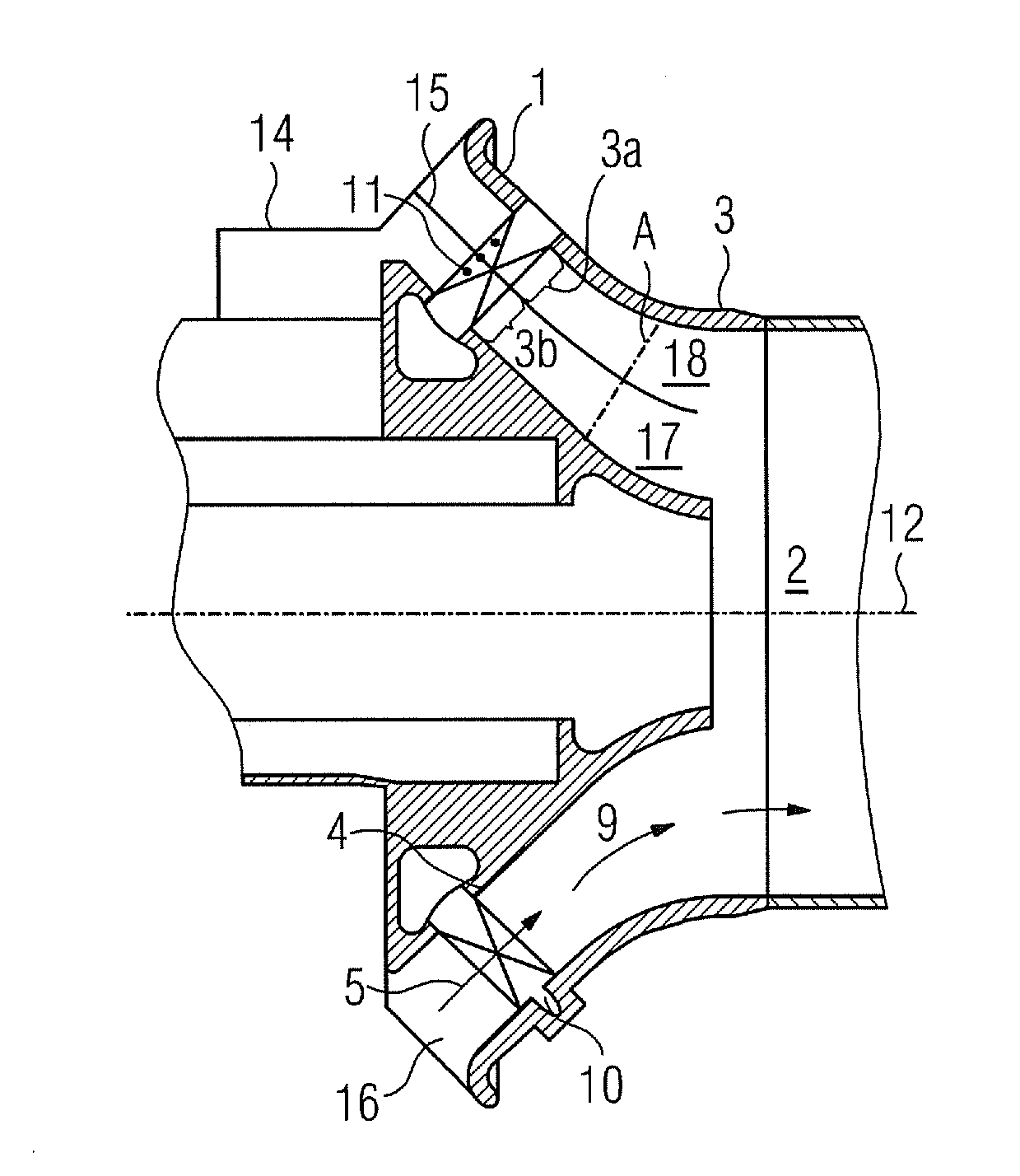

Combustion chamber of a combustor for a gas turbine

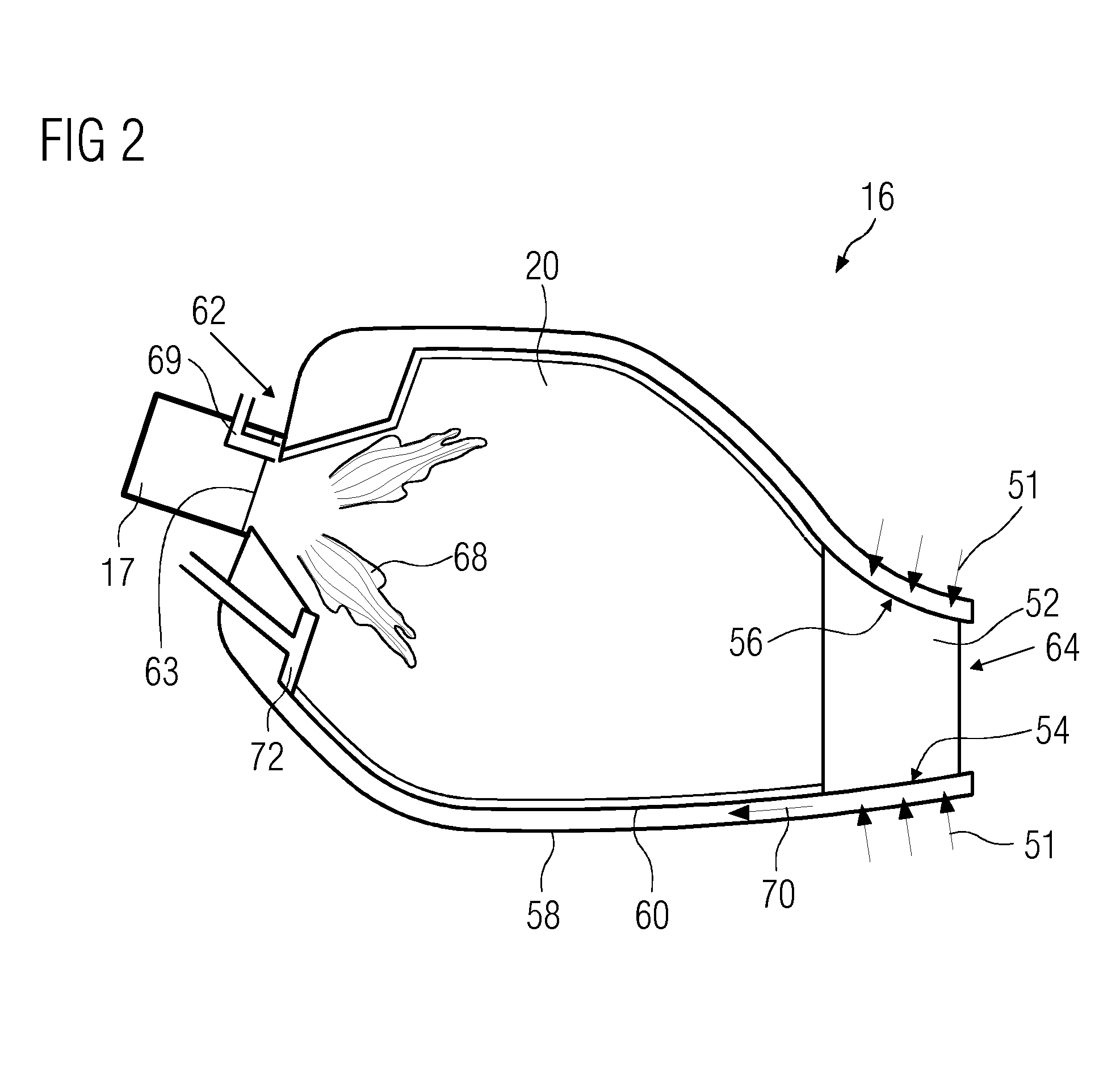

ActiveUS20140373548A1Improved swirlWell mixedContinuous combustion chamberGas turbine plantsCombustorCombustion chamber

A combustion chamber of a combustor for a gas turbine is provided. A combustion chamber includes a plurality of segments arranged annularly about an axis of the combustion chamber, each segment comprising a radial inner wall portion and a radial outer wall portion, a first section comprising an opening for the installation of a burner, and a second section at which at least one airfoil extends between the radial inner wall portion and radial outer wall portion of the segment.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Fluid swirling device having rotatable vanes

InactiveUS20060162690A1Improved swirlHigh degreeInternal combustion piston enginesExhaust apparatusEngineeringMechanical engineering

The device includes a set of rotatable vanes and a set of stationary vanes which are mounted within a cylindrical housing. The set of rotatable vanes are connected to a post located at the axis of the housing and rotate relative to the post in response to the intake or exhaust fluid impinging on the vanes which are angled relative to the direction of flow of the fluid stream. The set of stationary vanes are rigidly secured to the post and also rigidly secured to the housing walls. The set of stationary vanes are positioned adjacent the set of rotatable vanes and are similarly angled relative to the direction of flow of the fluid stream in order to deflect the fluid stream and impart a swirling motion to the fluid stream in order to provide more complete mixing of the air / fuel mixture of the intake fluid stream or scavenging of the exhaust fluid stream. Tabs which extend radially outwardly from the housing ends secure the device within an intake or exhaust passageway.

Owner:KIM JAY S

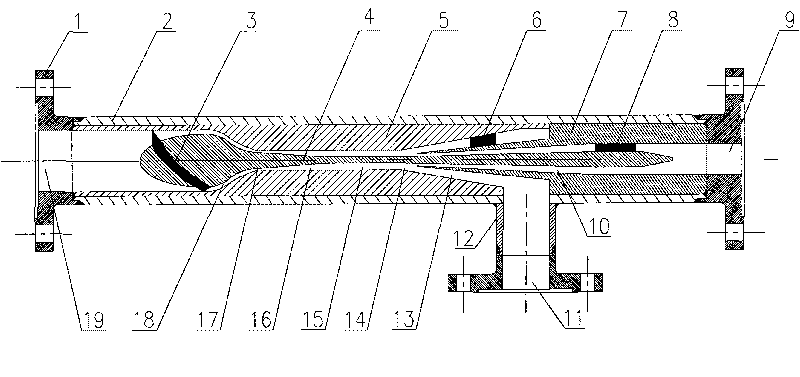

Ultrasonic gas cyclone condensing and separating device

InactiveCN101745246ASolving the Eddy Dissipation ProblemReduce radial velocity gradientDispersed particle separationVapor condensationCycloneNatural gas dehydration

The invention relates to an ultrasonic gas cyclone condensing and separating device applied to the field of gas purification, in particular to the field of natural gas dewatering and heavy hydrocarbon separation. Natural gas generates a cyclone by spiral cyclone blades, enters an Laval nozzle to adiabatically expand to an ultrasonic velocity and form low temperature and low pressure so that water and heavy hydrocarbon in the natural gas are condensed into liquid drops; meanwhile, a higher tangential velocity is generated to fling the water and the heavy hydrocarbon which are condensed to the wall surface under the action of a strong cyclone field; liquid flows into a liquid-collecting cavity from a liquid shunt hole and is discharged from a liquid outlet by a liquid-discharging pipe; and dry gas enters a circular diffuser pipe, is recovered by pressure and is discharged from a dry gas outlet. The shrinking section of the Laval nozzle of the device is designed by using a bicubic curve method to reduce flowing loss; the spiral cyclone blades can enhance the cyclone, generate greater tangential velocity and have good enhance effect. The device has simple structure, easy process and stable and reliable operation without movable parts.

Owner:文闯

Burner and method for operating a burner

InactiveUS9217569B2Low-cost to realizeSimple to realizeContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorEngineering

A burner and a method for operating a burner are provided. The burner includes a channel having a mixing zone and having a feed for an oxidation means, particularly an air feed, and at least one fuel feed for injecting fuel, wherein a separating means which divides the channel over a wide range of the channel into at least two separated channels, namely a first channel and a second channel, is provided in the channel. The method for operating a burner having a channel includes a mixing zone into which an oxidation mass flow and fuel are injected, wherein two substantially separate flow paths are formed by means of a separating means in the channel and the at least two separated first and second channels, formed by the separating means.

Owner:SIEMENS AG

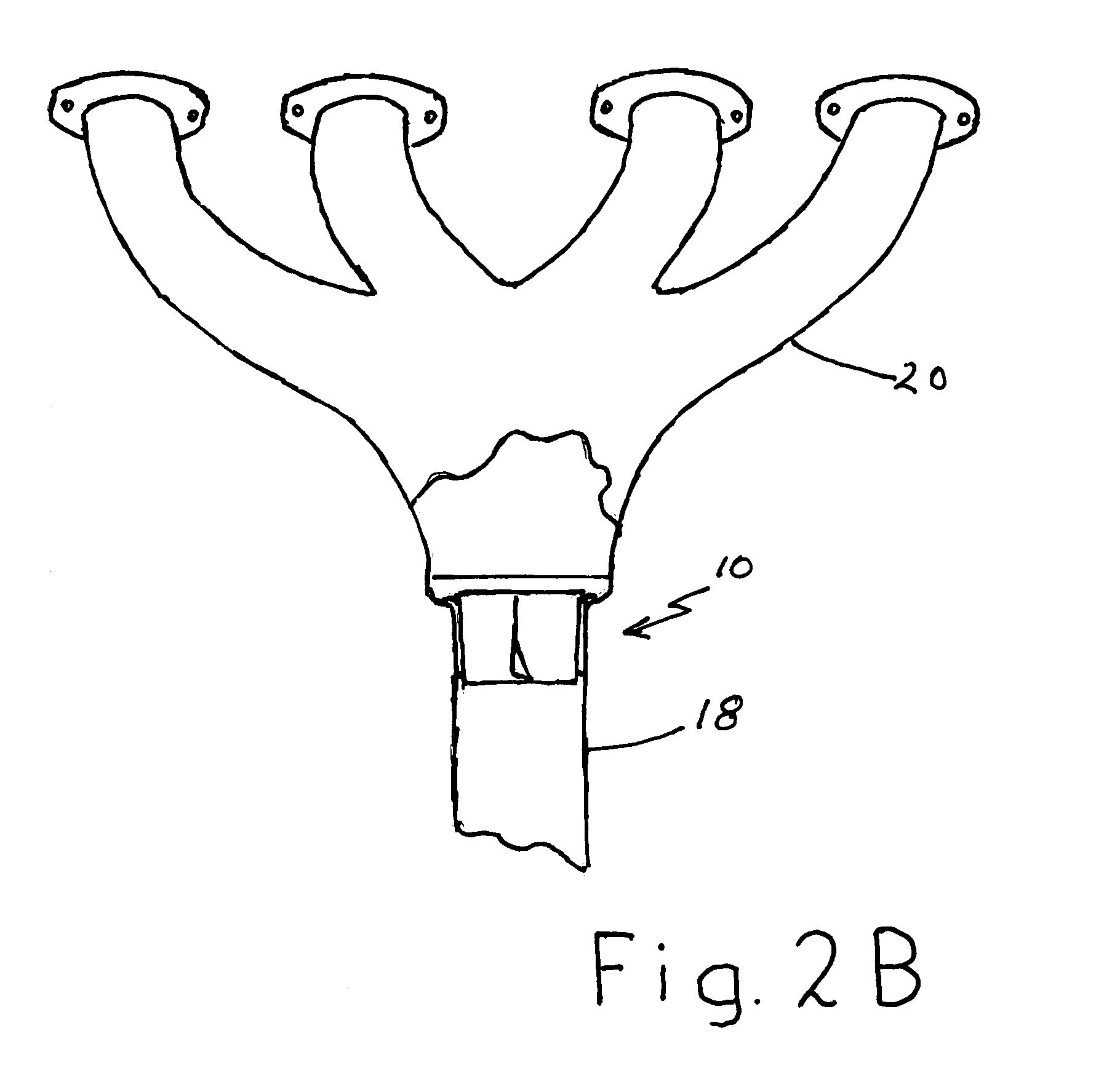

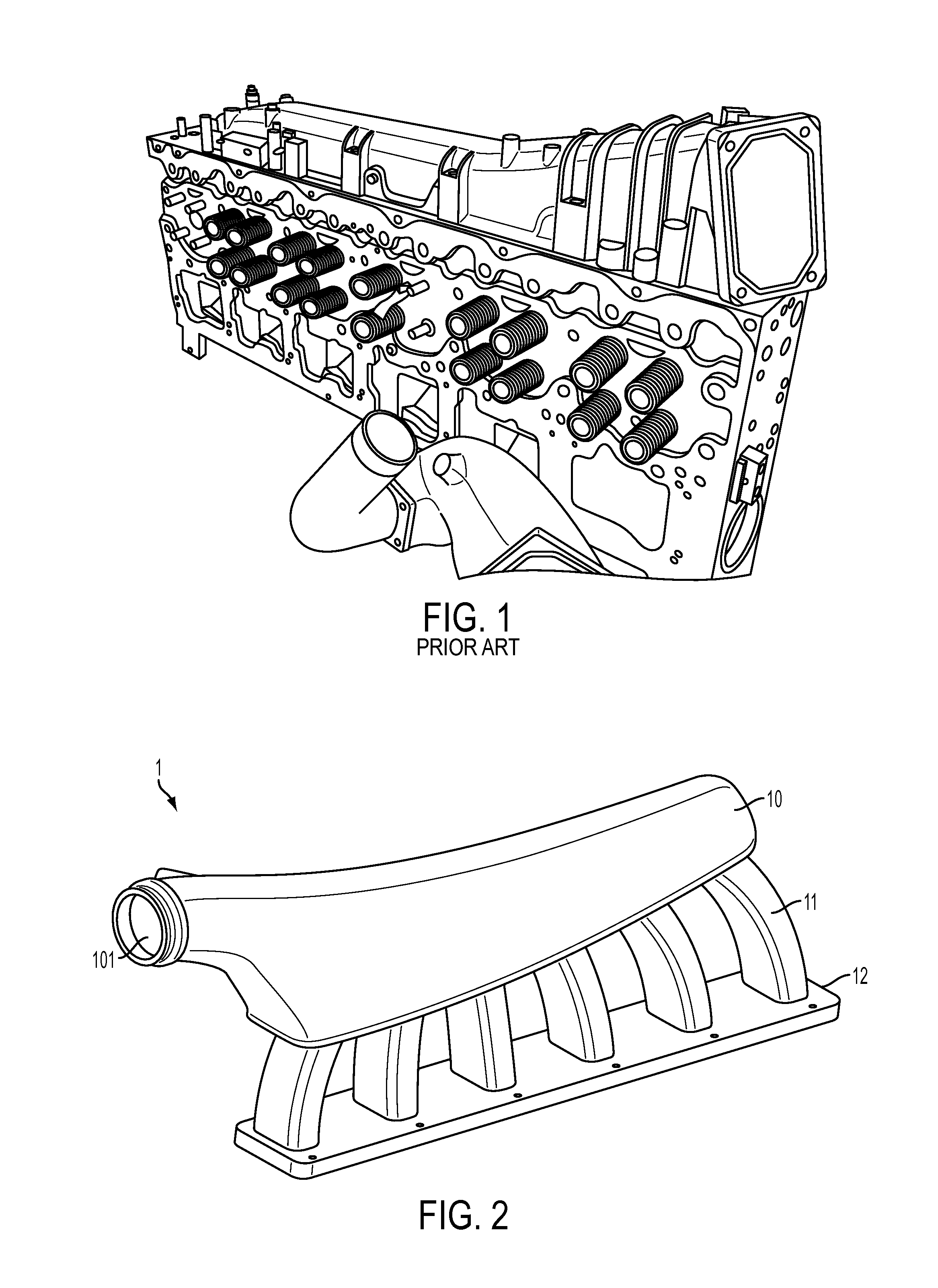

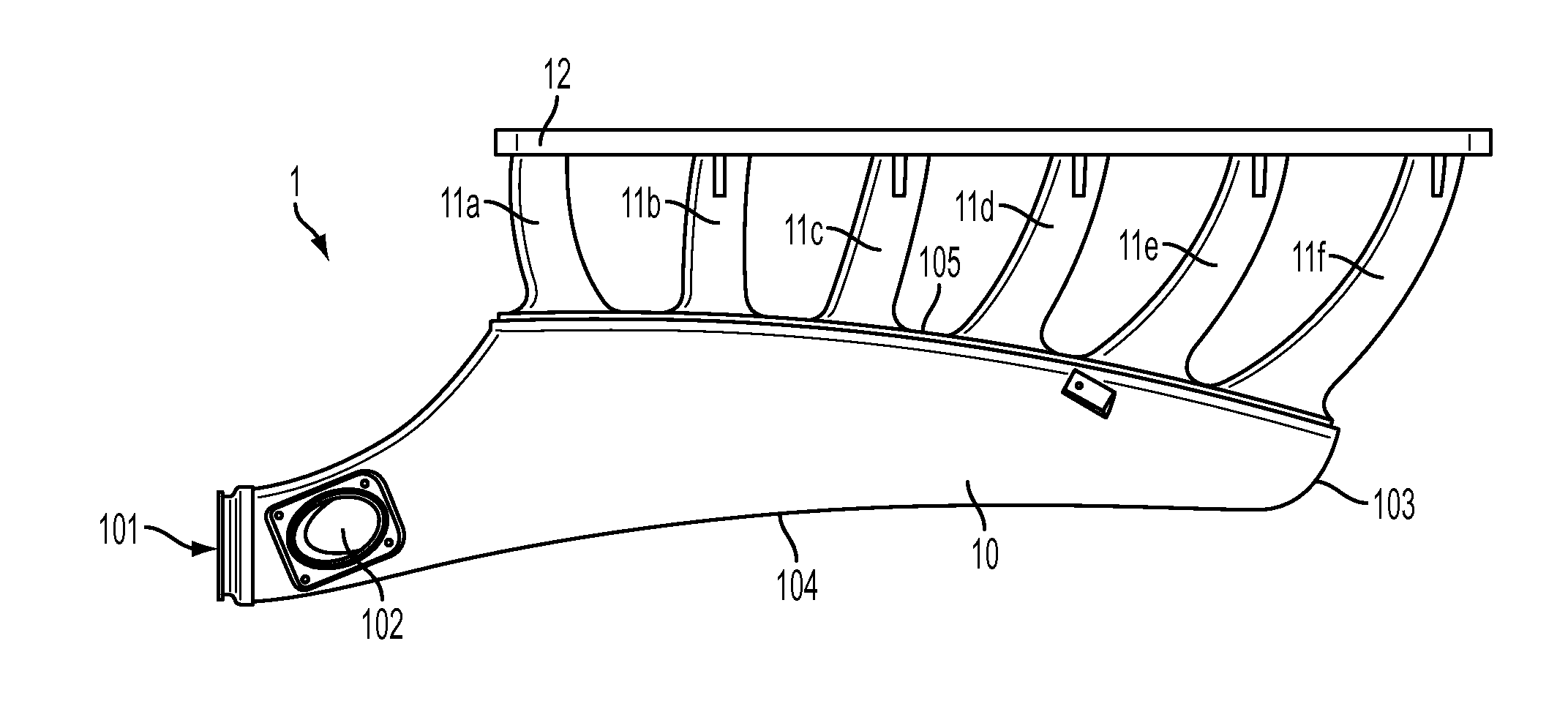

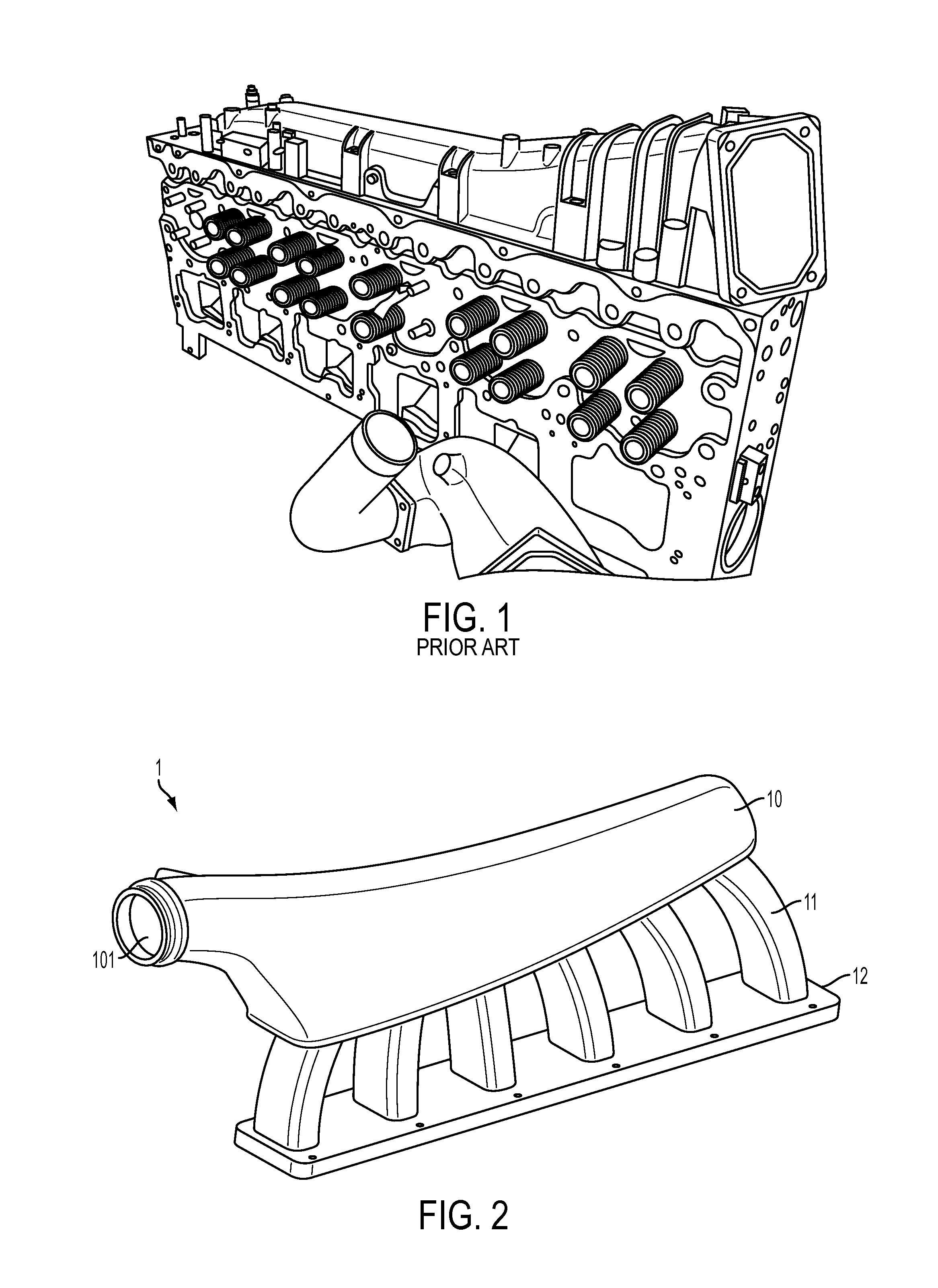

Intake manifold

InactiveUS9273653B2Improve efficiencyHigh outputInternal combustion piston enginesCombustion-air/fuel-air treatmentInterior spaceEngineering

A bolt-on replacement intake manifold has an asymmetrical plenum with a first end including an inlet, a closed terminal end, a concave top surface and a convex bottom surface; a flange; and a plurality of runners extending from the bottom surface of the plenum and terminating at the flange. The plenum defines an interior space in flow communication with the runners. The bottom surface of the plenum is wider than the top surface. The plenum initially widens from the inlet to the first runner and then begins to narrow from the first runner toward the last runner adjacent to the closed terminal end. The runners are tapered, curved, and vary in length. The intake manifold causes air to exit each of the plurality of runners at substantially the same angle. The manifold balances airflow across each runner and increases swirl inside the cylinders enhancing fuel economy, power output, and torque.

Owner:MKC FLOW

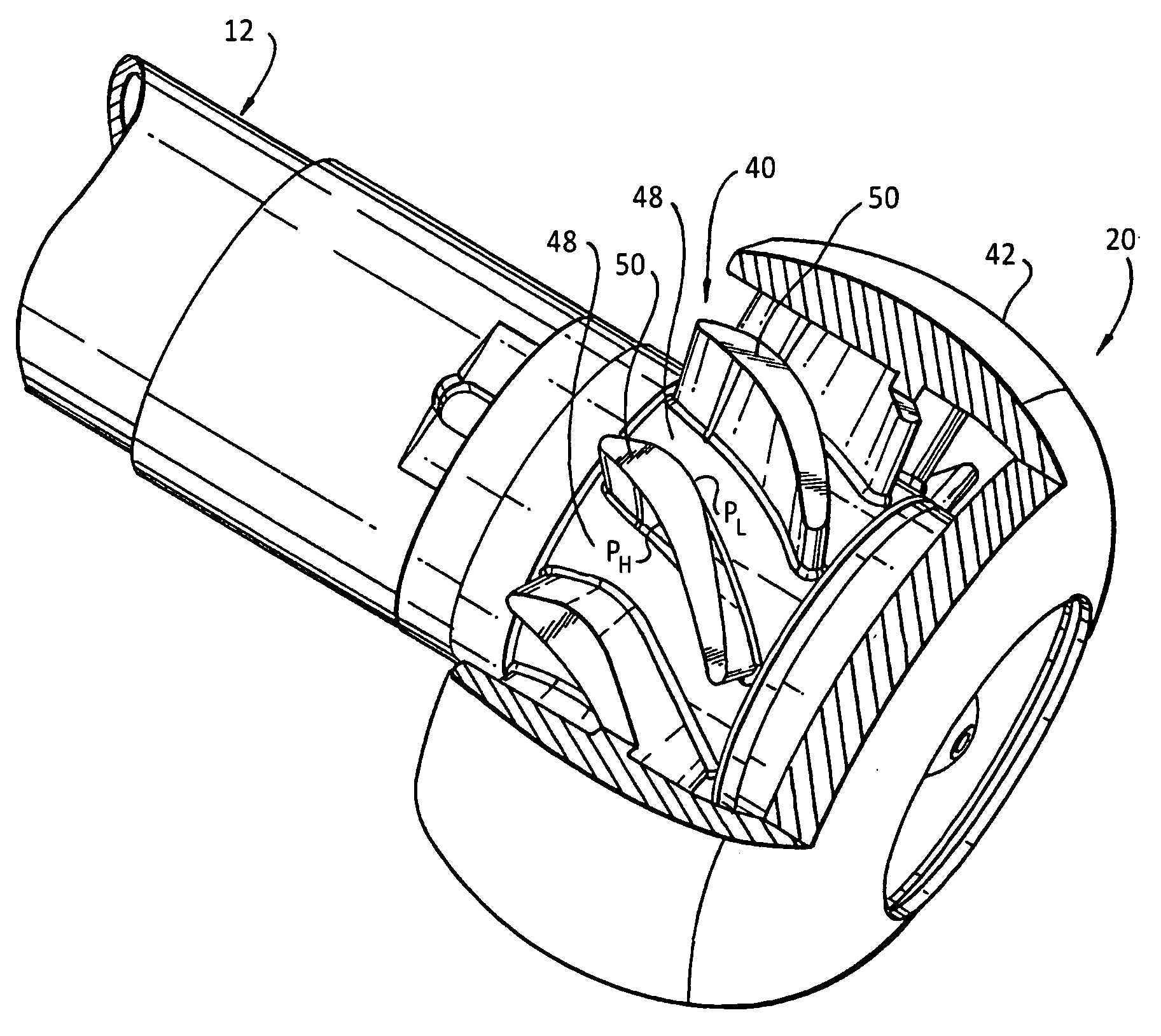

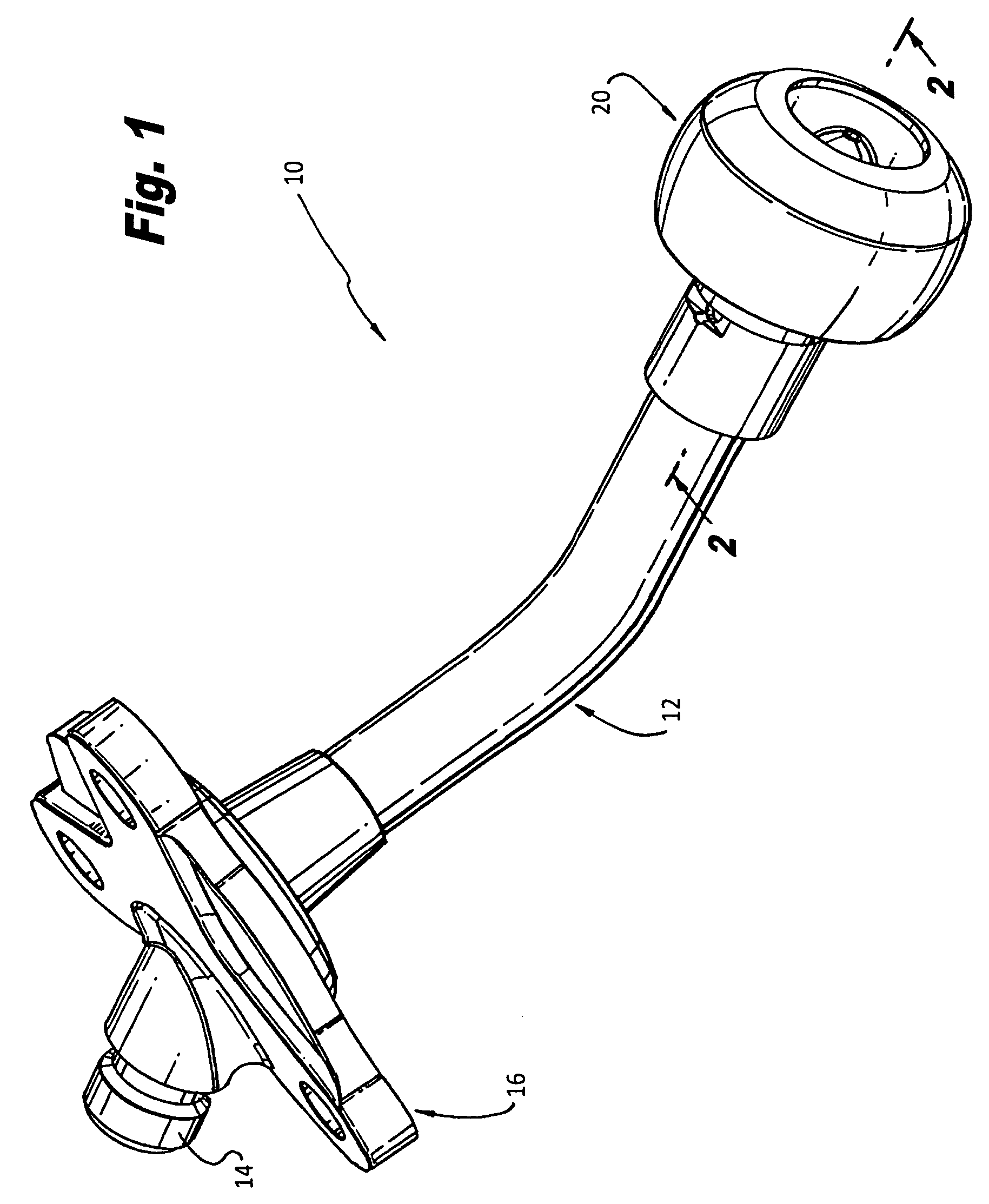

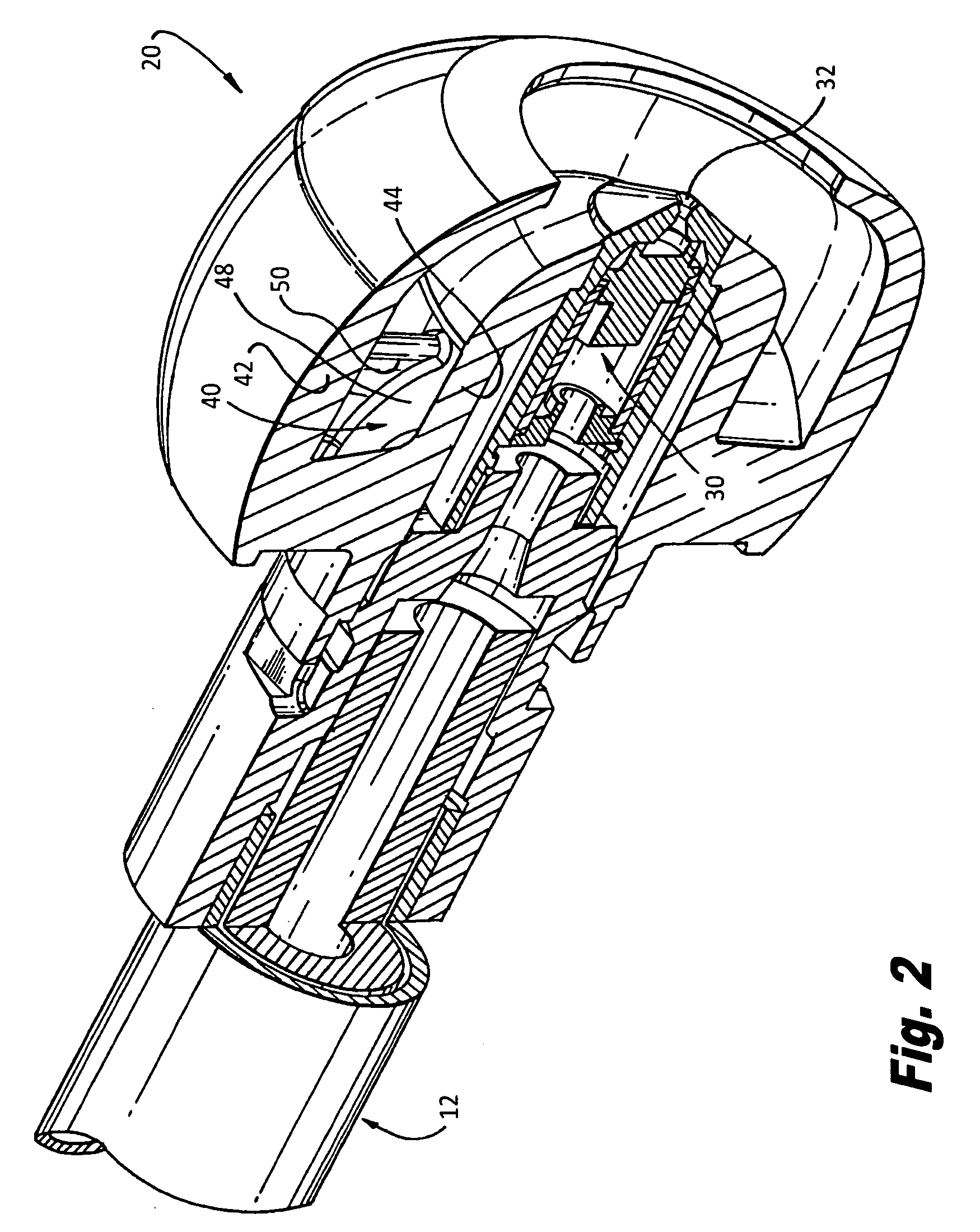

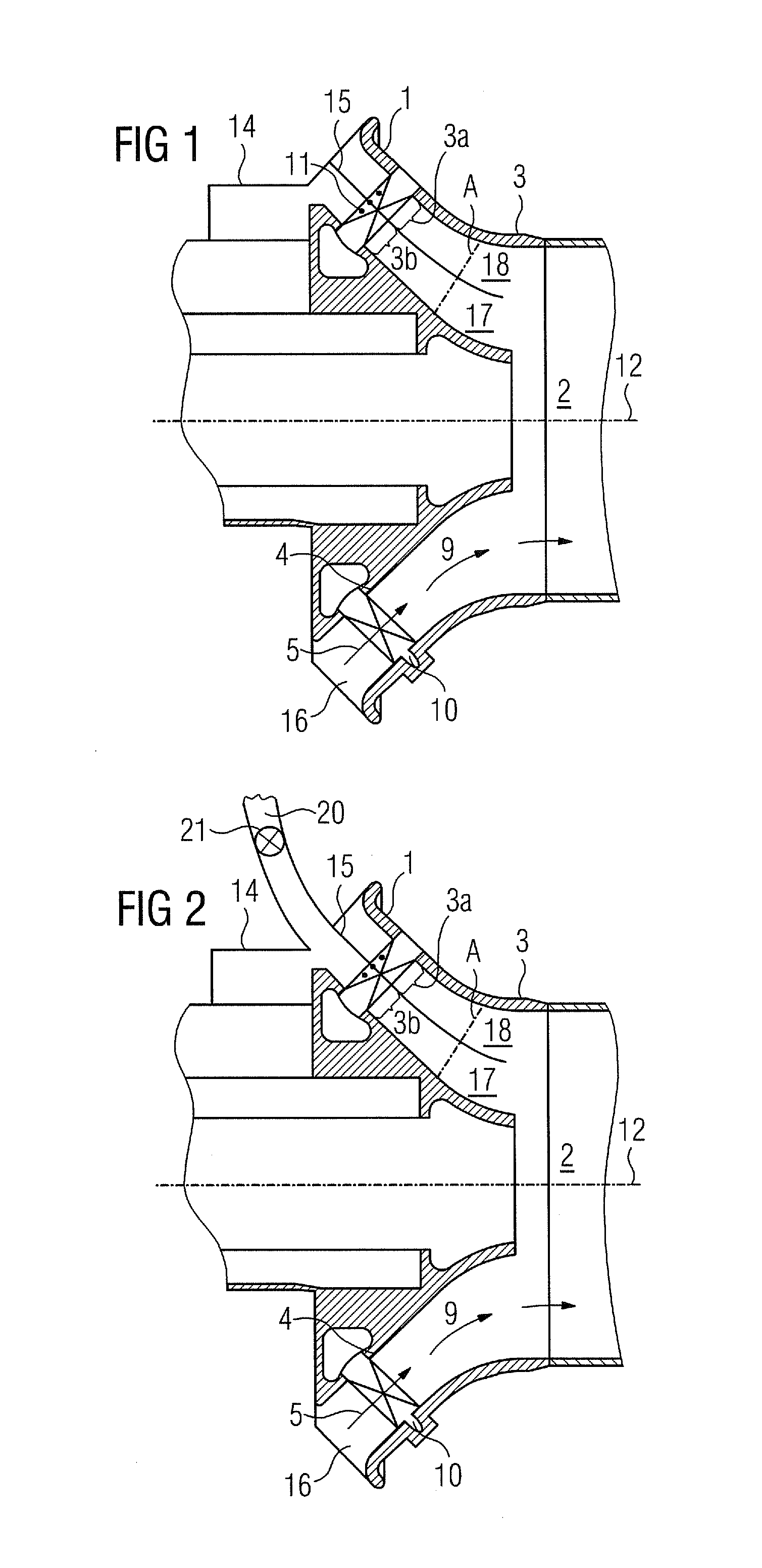

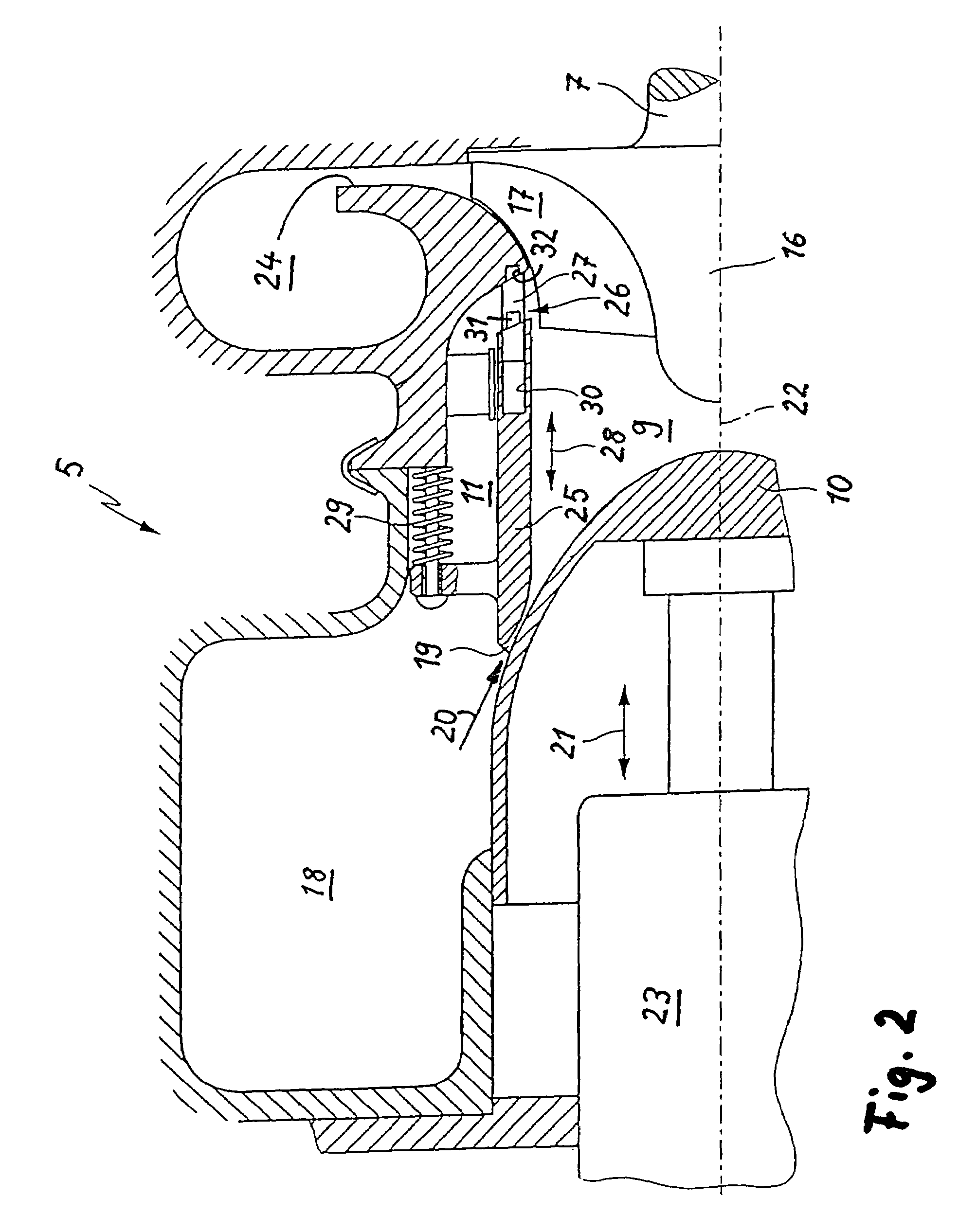

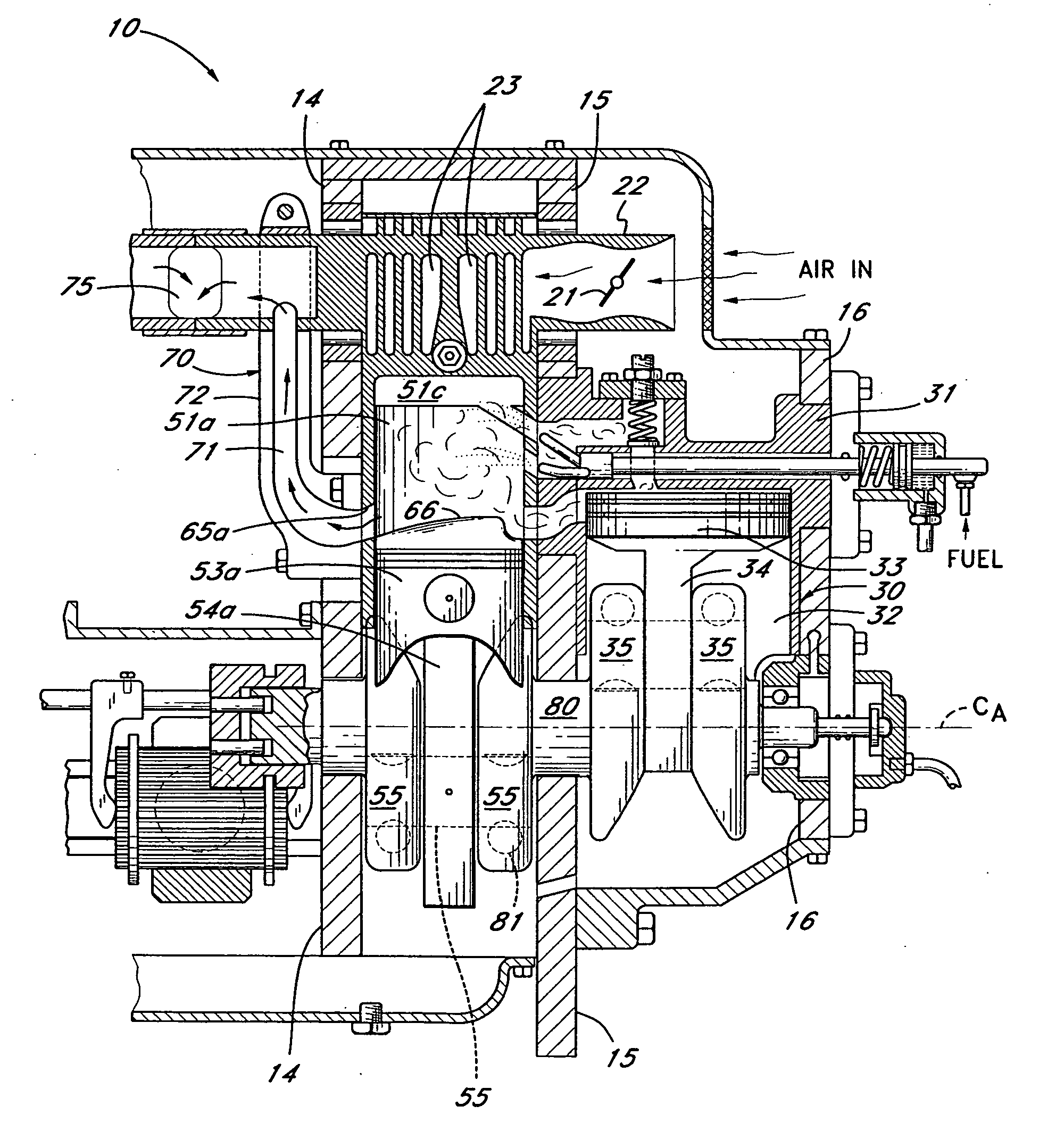

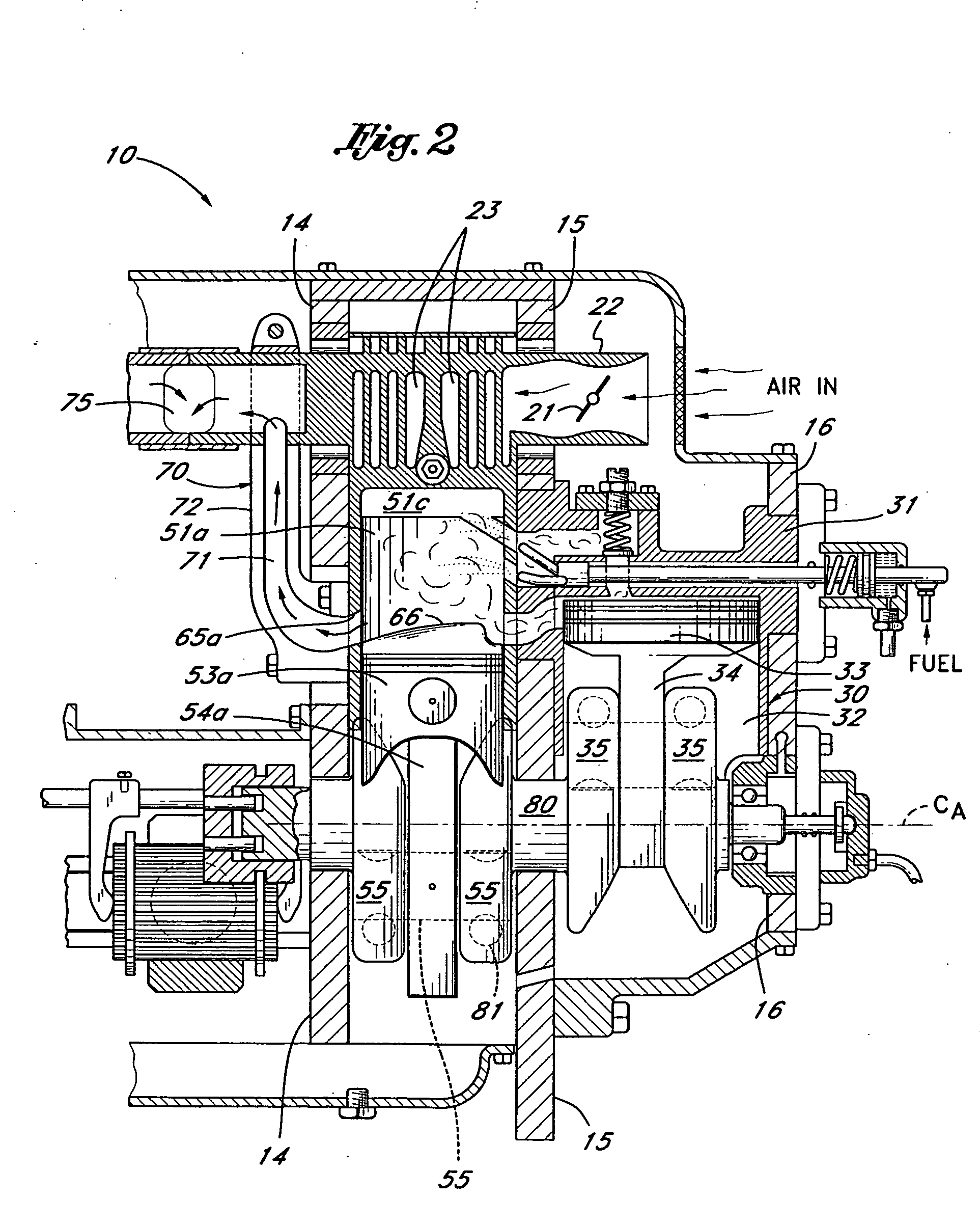

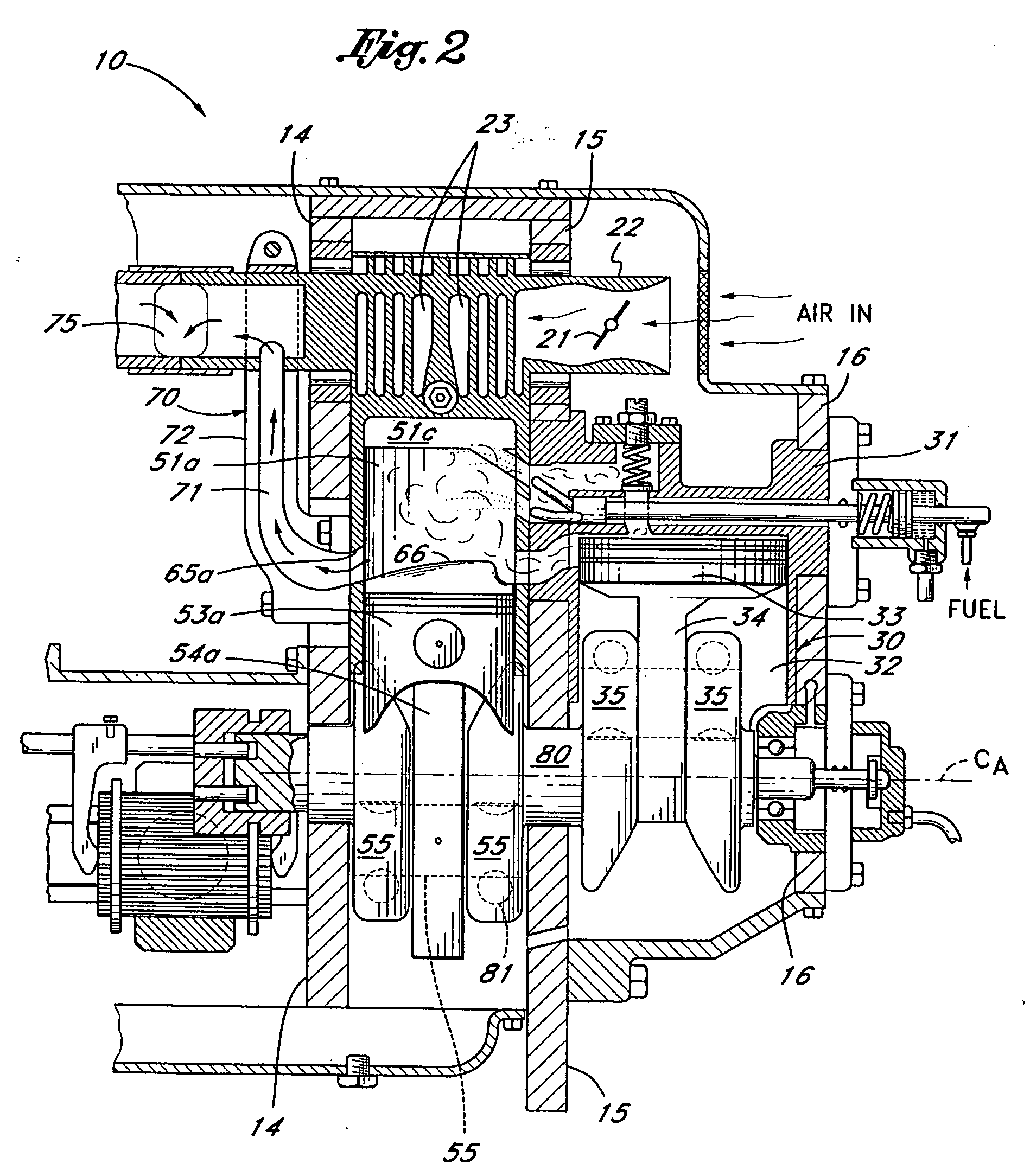

Compressor in the induction tract of an internal combustion engine

InactiveUS7412830B2Increased rotational speed levelReduced flow cross sectionInternal combustion piston enginesWind motor controlImpellerCombustion

In a compressor in the induction tract of an internal combustion engine with a compressor by which combustion air can be compressed to an increased boost pressure and which includes a compressor wheel rotatably mounted in a compressor housing with a main inlet duct in the flow path to the compressor wheel, and an auxiliary inlet duct joining the main inlet duct in the area of the compressor wheel, an adjustable swirl device is provided in the auxiliary intake duct, which comprises two separate, interacting swirl structures with a plurality of guide vanes distributed over the periphery and arranged so that the flow cross-section between the guide vanes of the two swirl structures can be changed by an adjusting motion of at least one swirl structure, the vane height of the guide vanes of the smaller swirl structure being 5% to 35% of the vane height of the guide vanes of the larger swirl structure.

Owner:DAIMLER AG

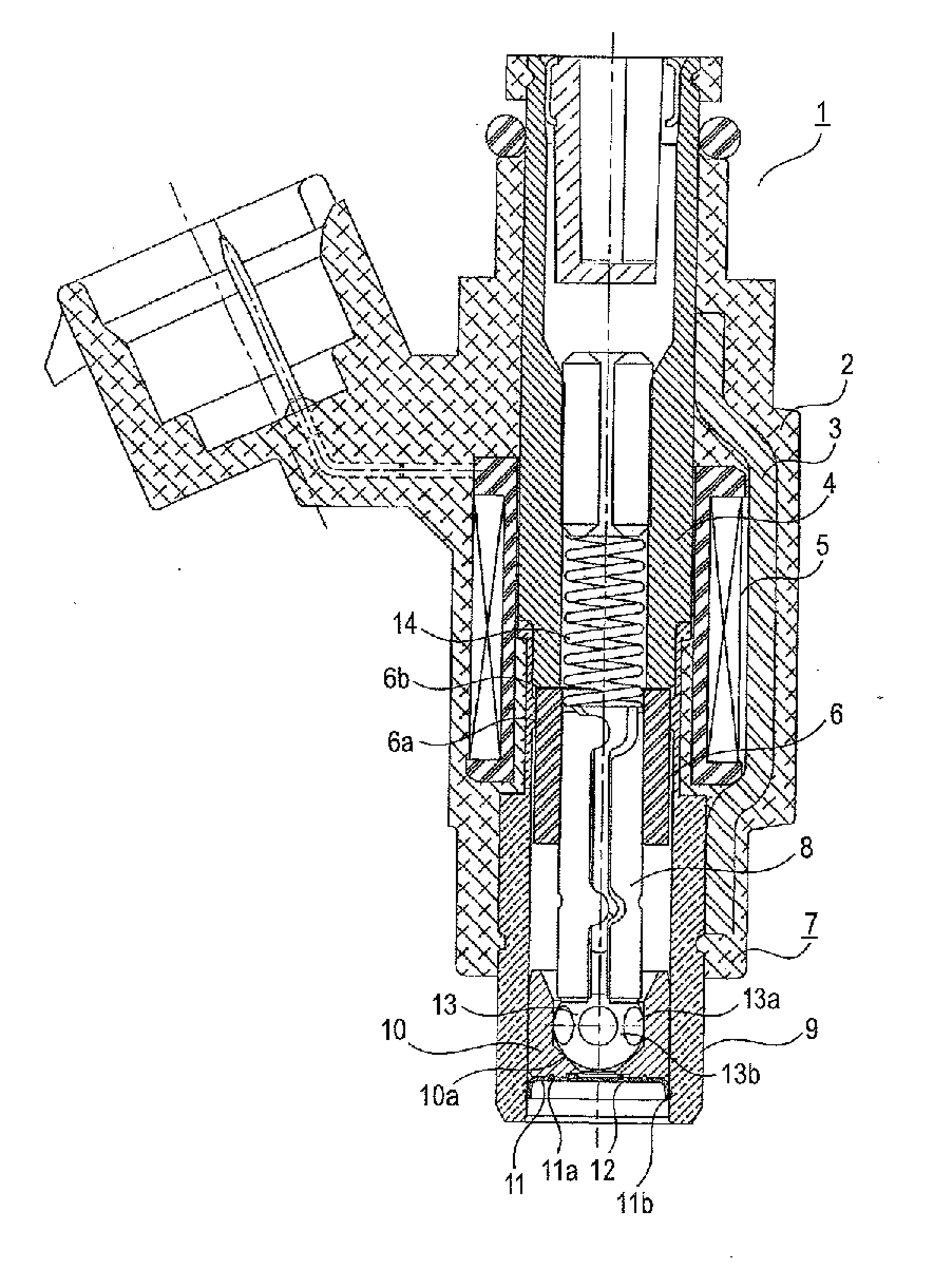

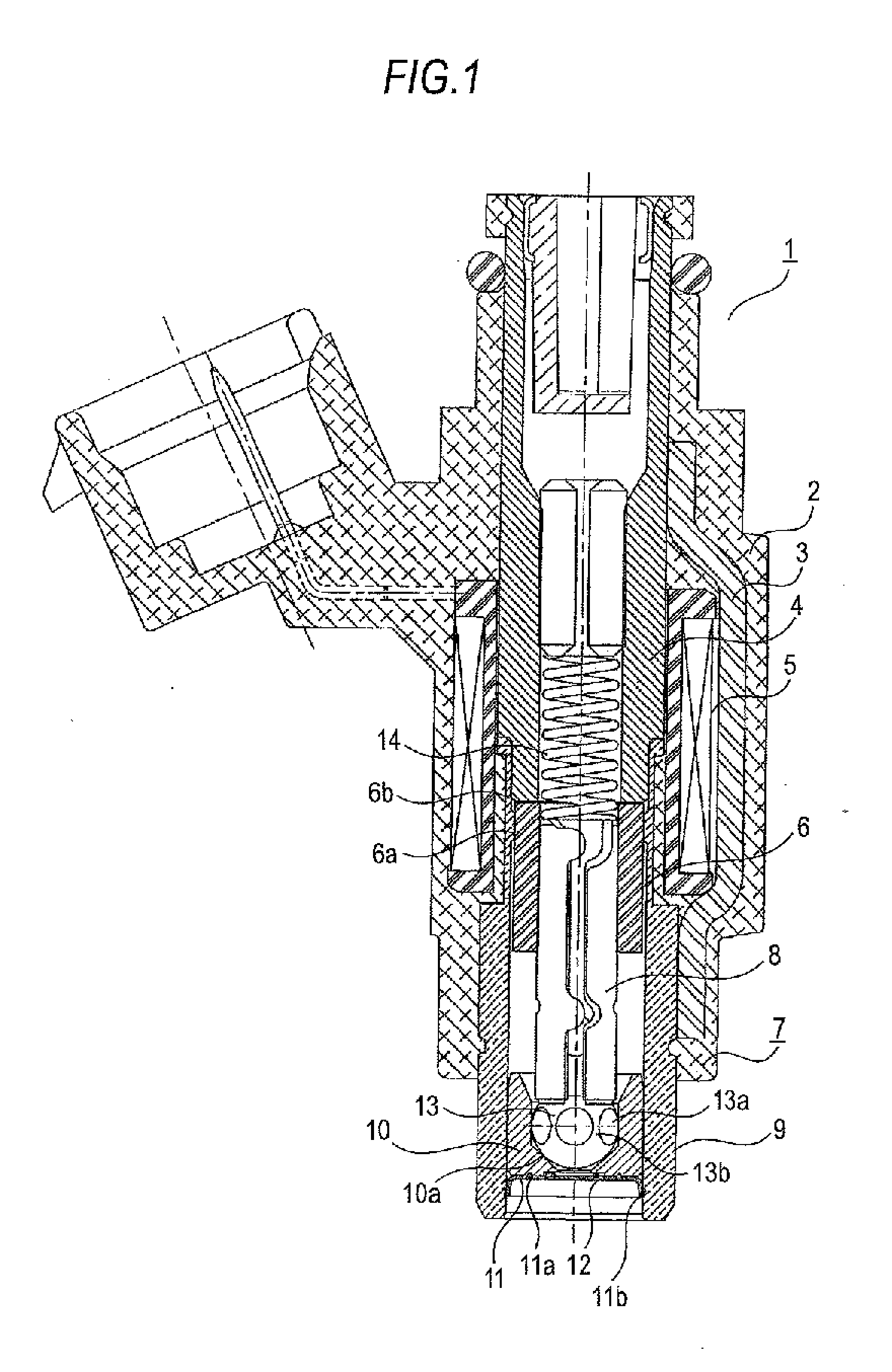

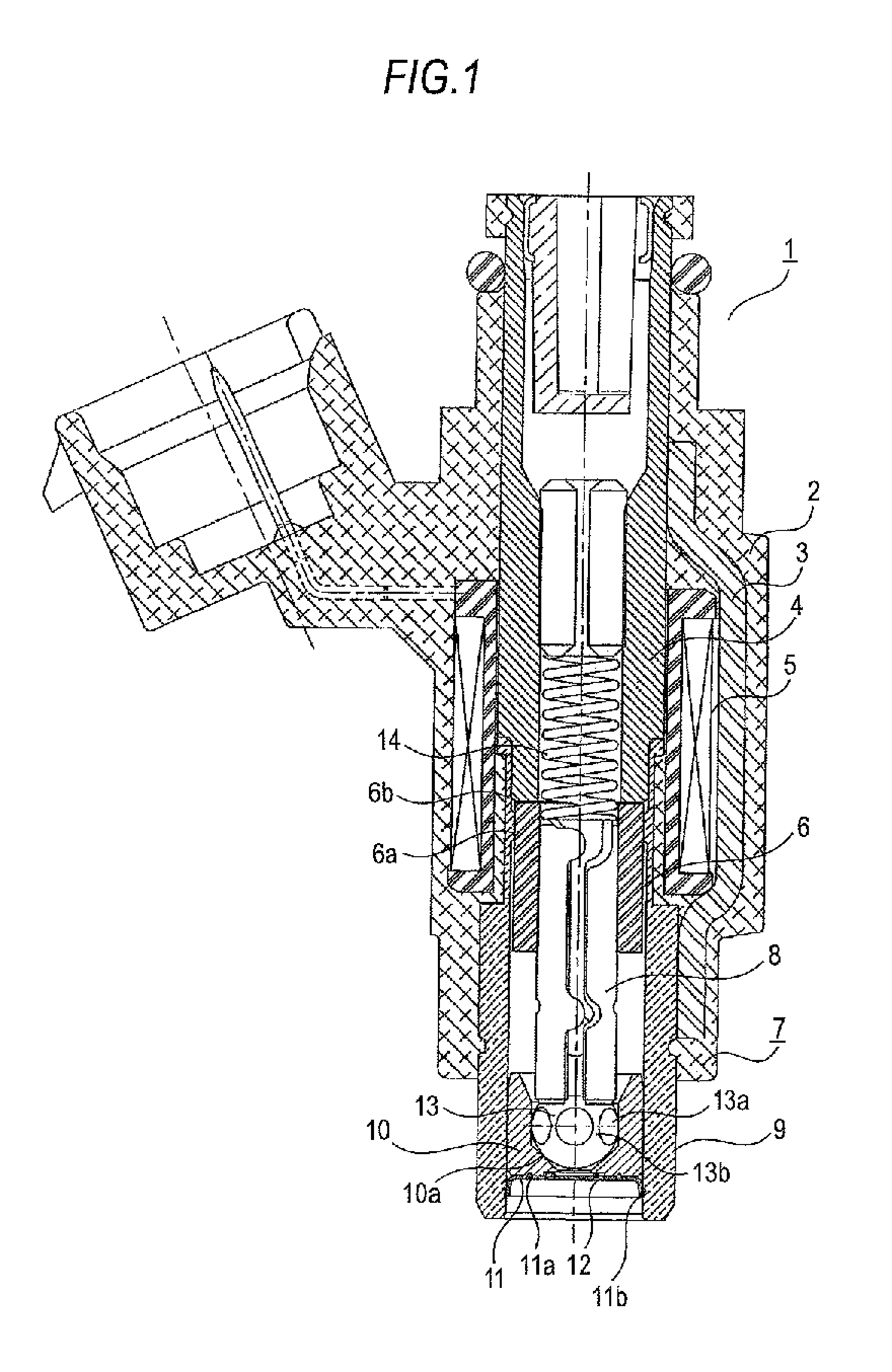

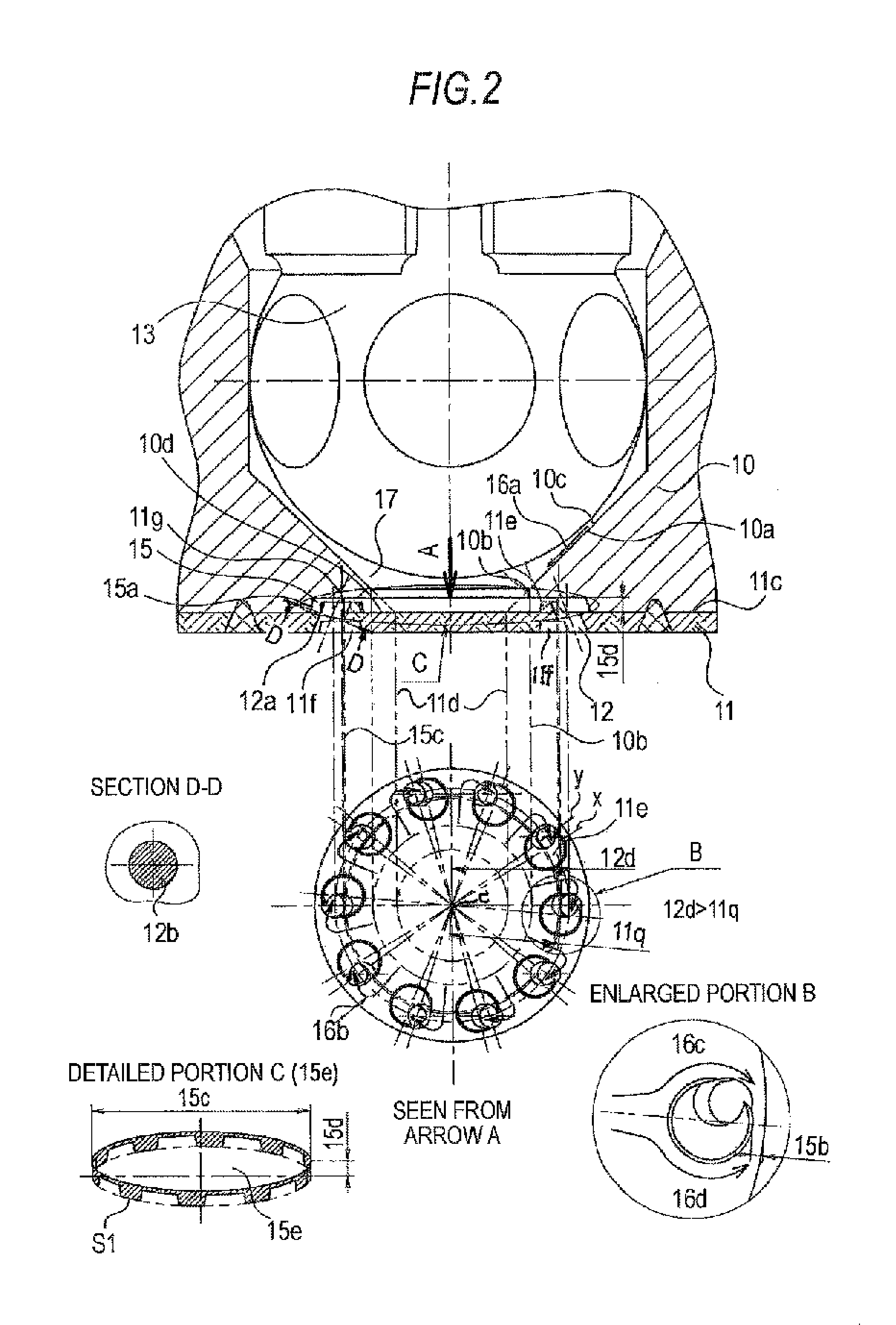

Fuel injection valve

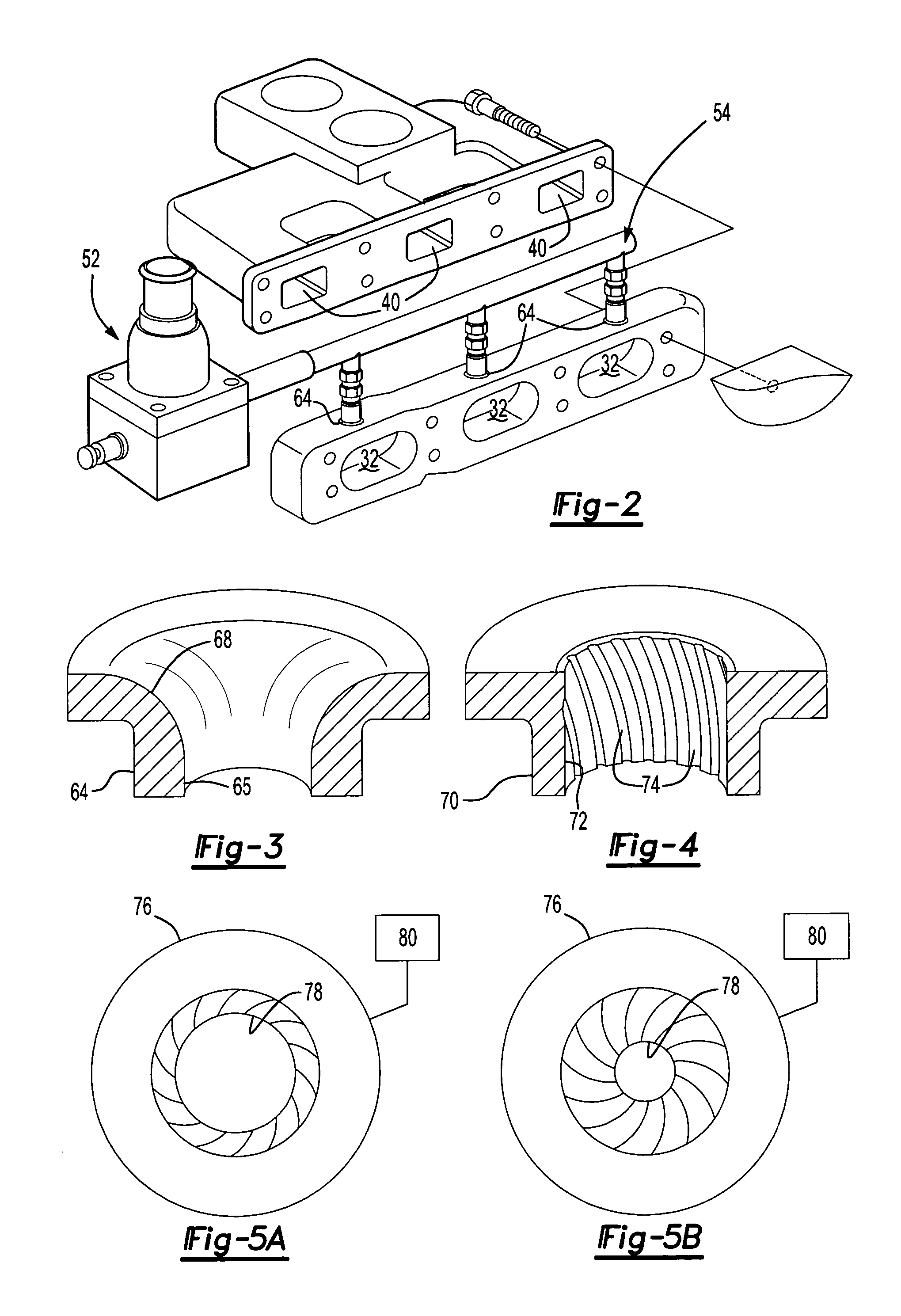

InactiveUS20110253812A1Avoid cloggingChange flow characteristicsFuel injection apparatusMachines/enginesEngineeringFuel injection

A plate convex is formed on the upstream side of the injection hole plate and a plate concave is formed on the downstream side of the injection hole plate so as to form a pair together, a minimum of one set of the plate convexes and the plate concaves are formed, and the injection holes are arranged so that the radial centerline which connects the centerline of the plate convex from the axial center of the fuel injection valve does not overlap the center of the injection hole on an upstream flat surface of the injection hole plate, and the plate convex is arranged so as to straddle the injection hole on the upstream flat surface of the injection hole plate, and the top surface of the plate convex.

Owner:MITSUBISHI ELECTRIC CORP

Intake Manifold

InactiveUS20150247477A1Improve fuel efficiencyIncrease power outputInternal combustion piston enginesAir intakes for fuelInterior spaceEngineering

A bolt-on replacement intake manifold has an asymmetrical plenum with a first end including an inlet, a closed terminal end, a concave top surface and a convex bottom surface; a flange; and a plurality of runners extending from the bottom surface of the plenum and terminating at the flange. The plenum defines an interior space in flow communication with the runners. The bottom surface of the plenum is wider than he top surface. The plenum initially widens from the inlet to the first runner and then begins to narrow from the first runner toward the last runner adjacent to the closed terminal end. The runners are tapered, curved, and vary in length. The intake manifold causes air to exit each of the plurality of runners at substantially the same angle. The manifold balances airflow across each runner and increases swirl inside the cylinders enhancing fuel economy, power output, and torque.

Owner:MKC FLOW

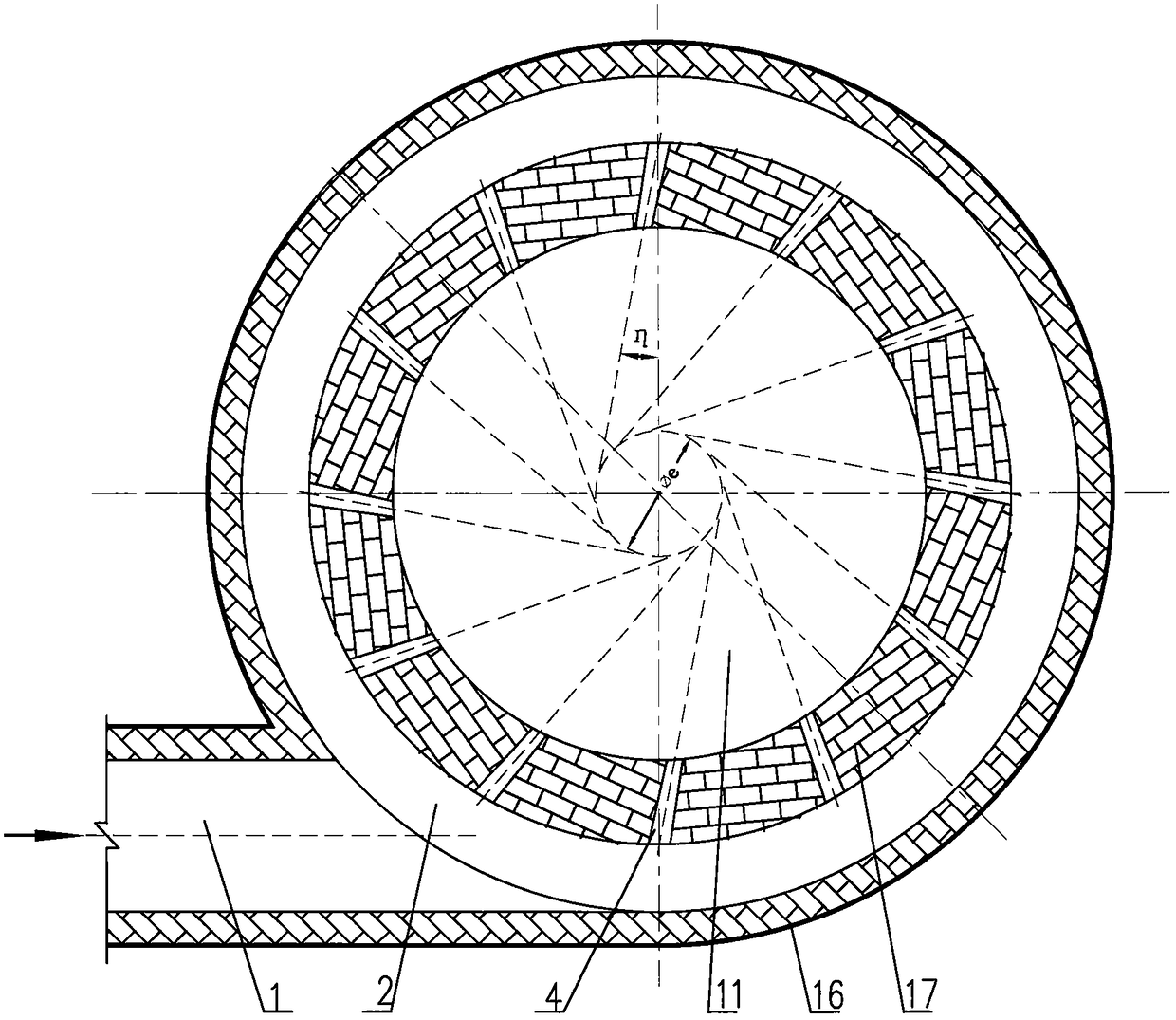

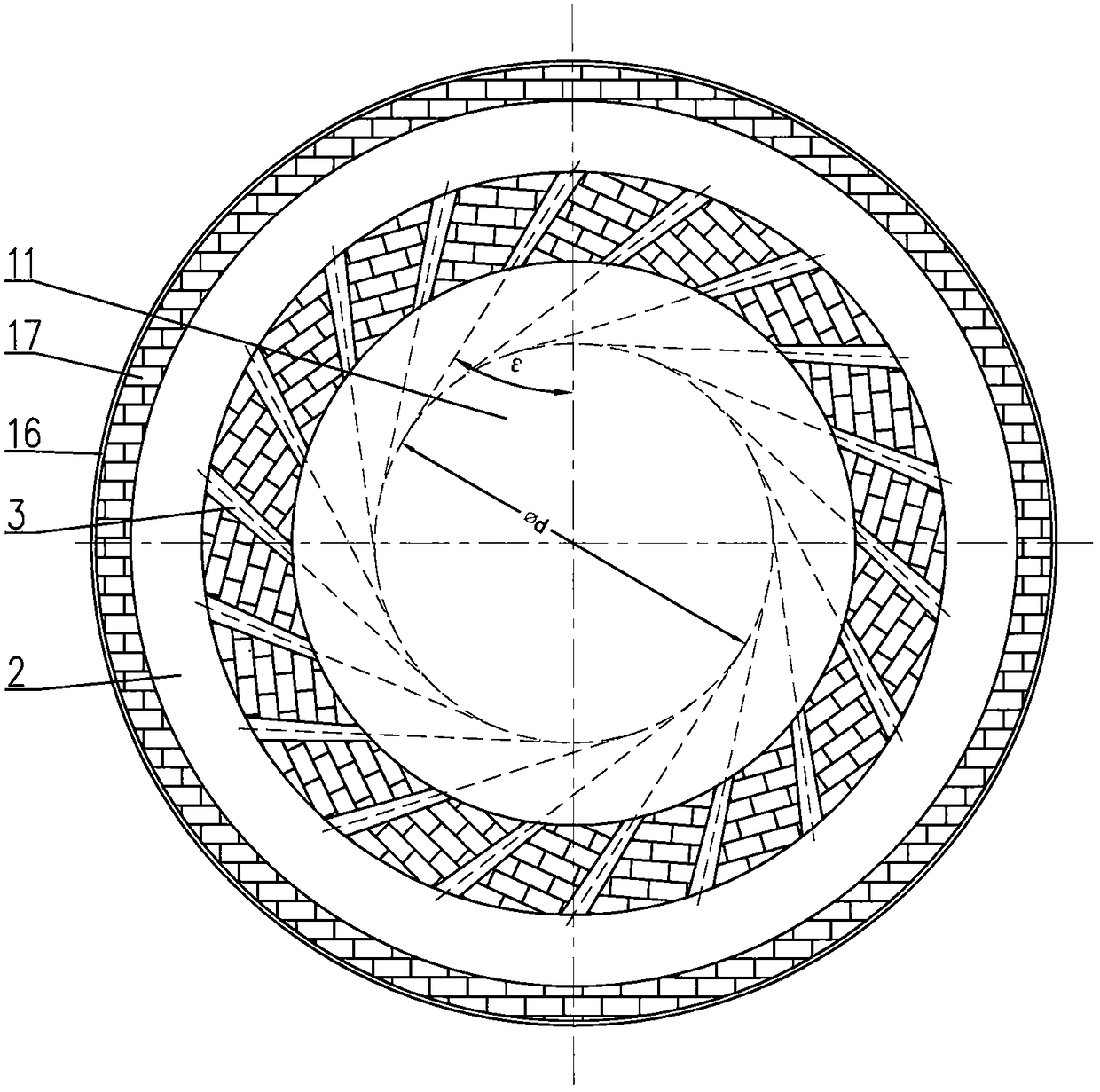

Novel multi-blade centrifugal fan

ActiveCN105508265AImprove work efficiencyReduce speed differencePump componentsRadial flow pumpsAir volumeEngineering

The invention discloses a novel multi-blade centrifugal fan. The novel multi-blade centrifugal fan comprises a volute, a volute tongue and a plurality of fan blades fixed in the volute, wherein one lateral side of the volute tongue is fixed on the inner lateral side of the air outlet of the volute, the other lateral side of the volute tongue is a concave face, a plurality of air guide grooves are formed in the concave face, the two end faces of each fan blade are arc-shaped faces, a zigzag structure is arranged on one arc-shaped face of each fan blade, a bionic non-smooth structure is arranged on the other arc-shaped face of each fan blade, and airflow sequentially passes the bionic non-smooth structures and the zigzag structures and then is discharged from the air outlet of the volute. The novel multi-blade centrifugal fan has the advantages that the air quantity and air pressure of the fan are increased effectively, the noise of the fan is lowered effectively, and the efficiency of the fan is increased effectively.

Owner:XI AN JIAOTONG UNIV

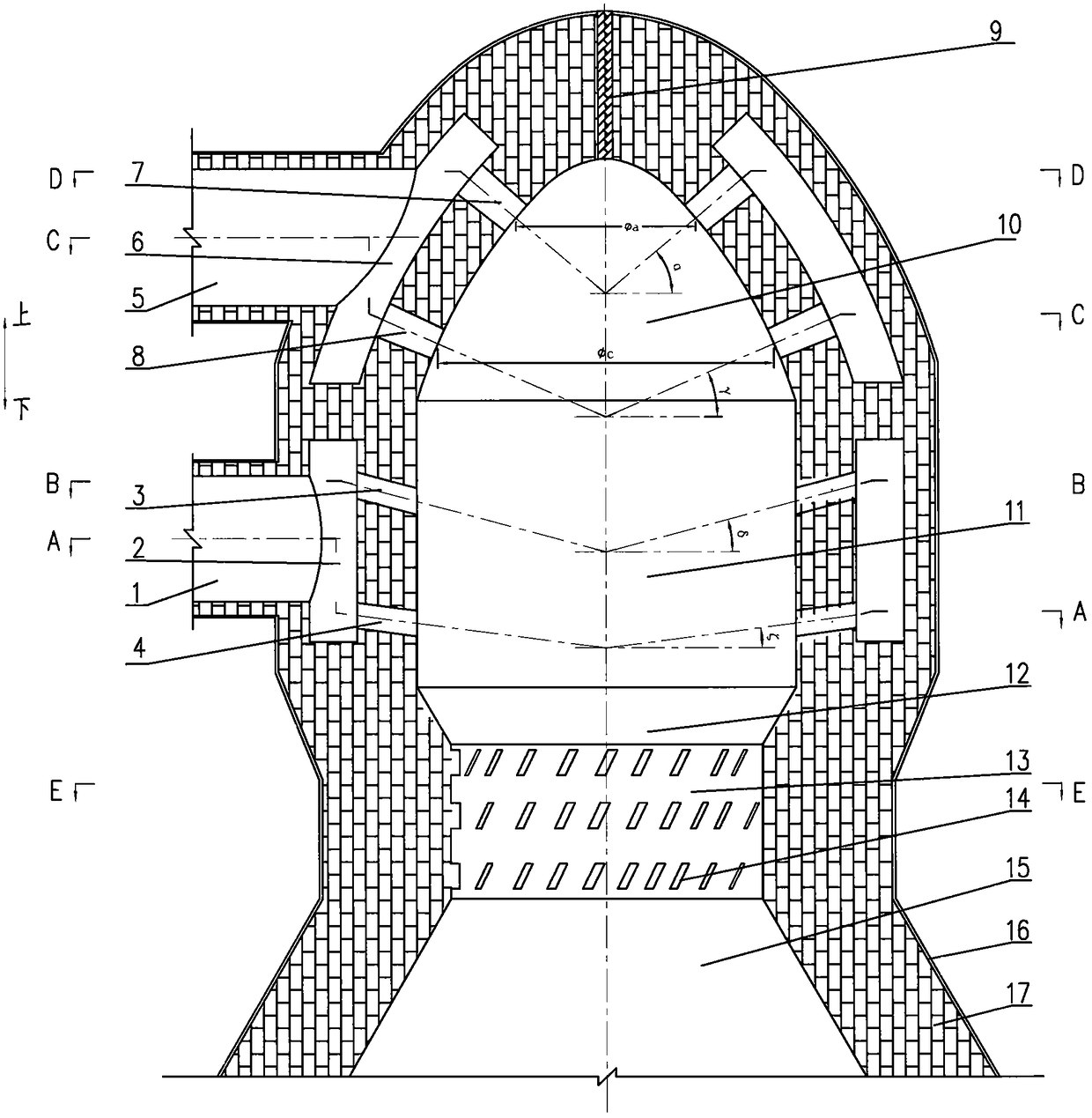

Three-dimensional vortex burner

InactiveCN108662581AEasy to adjustAvoid damageNon-combustible gases/liquids supplyGaseous fuel burnerThermal energyNitrogen oxide

The invention relates to a three-dimensional vortex burner and belongs to the technical field of thermal power engineering. The three-dimensional vortex burner is primarily characterized by being provided with an air inlet and a coal gas inlet entering tangentially, a catenary convoluted rectifying room, a primary air nozzle and a secondary air nozzle which are arranged in layers and different indirection and a diversion trench reinforcing throat, so that air is supplied to form conical spiral vortexes to inject the coal gas to fit an extremely low coal gas pressure and staged burning and thick and light burning are achieved to reduce emission of nitric oxide. The three-dimensional vortex burner is full in burning and small in resistance loss, and is particularly suitable for various industrial kilns which are high in power, low in coal gas calorific value, low in coal gas pressure, great in pressure fluctuation and high in demand on emission of nitric oxide. Energy conservation and emission reduction are achieved.

Owner:姜凤山

Throttling element, differential pressure type pulmonary function parameter monitoring device and flow rate confirming method

ActiveCN108577845AEasy to useLow costDiagnostic signal processingSensorsDifferential pressureEngineering

The invention provides a throttling element, a differential pressure type pulmonary function parameter monitoring device and a flow rate confirming method. The porous throttling element comprises a pipe and a throttling porous plate, wherein an airflow channel is formed via the pipe; the throttling porous plate is arranged in the pipe, and the throttling porous plate comprises a plurality of firstcomponents and a plurality of second components; the plurality of first components are distributed in a mode of being coaxial with the pipe; the plurality of second components are distributed in thepipe in a radial form; therefor, a plurality of tubular throttling holes are formed in the airflow channel via the plurality of first components and the plurality of second components. The throttlingelement, the differential pressure type pulmonary function parameter monitoring device and the flow rate confirming method provided by the invention are simple in structure and low in cost; a requirement on the length of a straight-pipe section is reduced and a measuring range is widened; vortex, which appears under a high-flow-rate condition in an expiration / inspiration process, is effectively improved; airflow balance is realized; and repeatability and reliability are improved.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

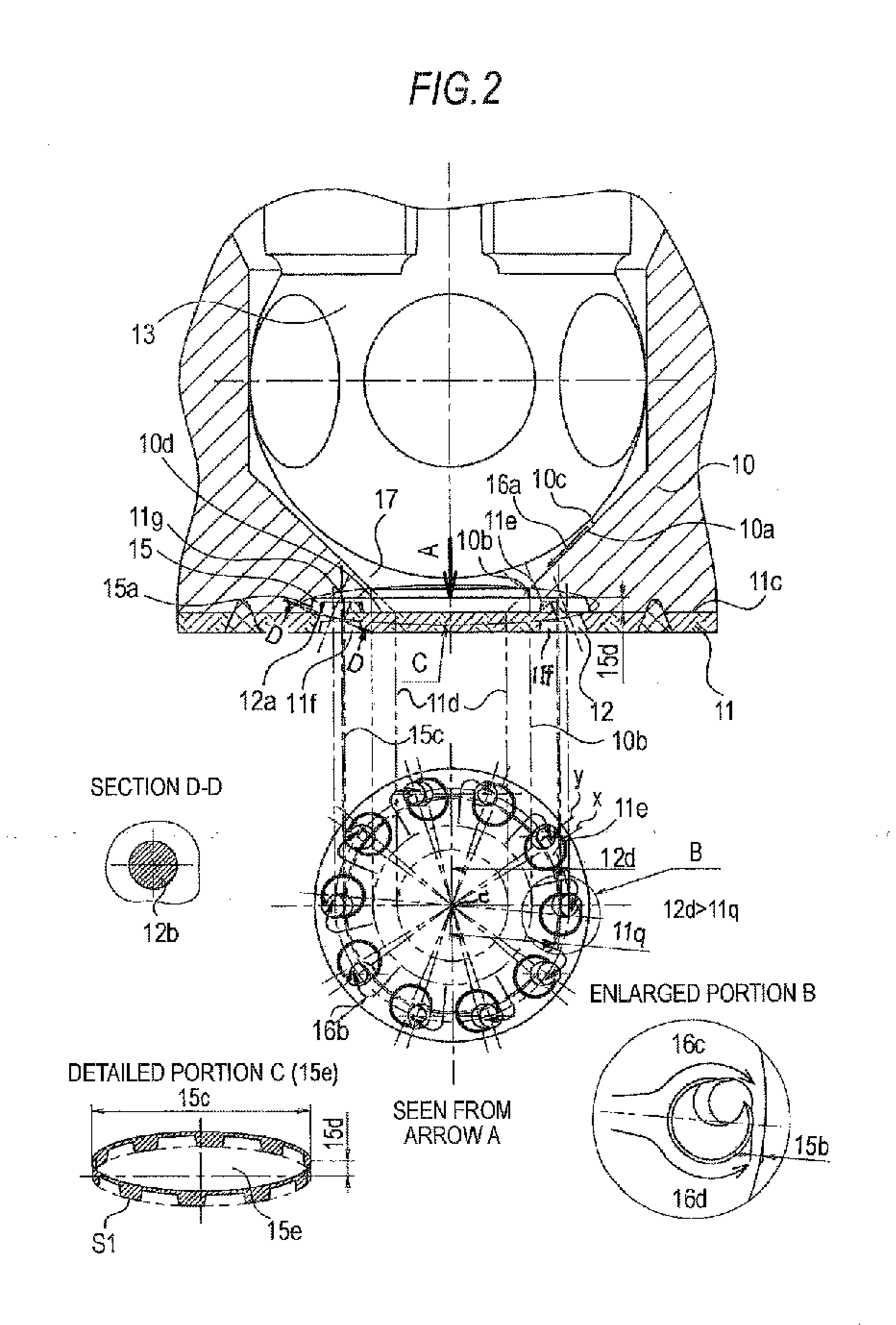

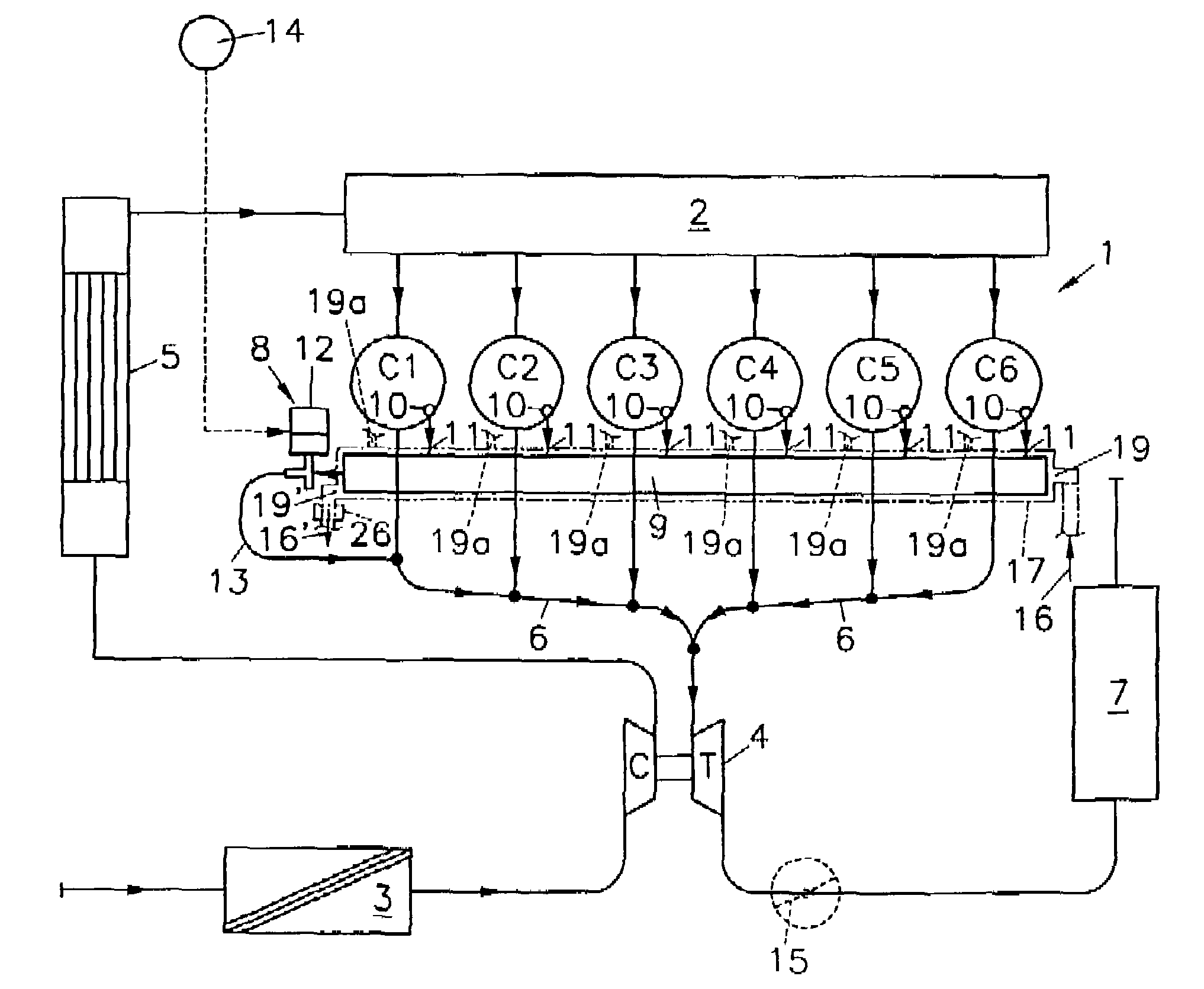

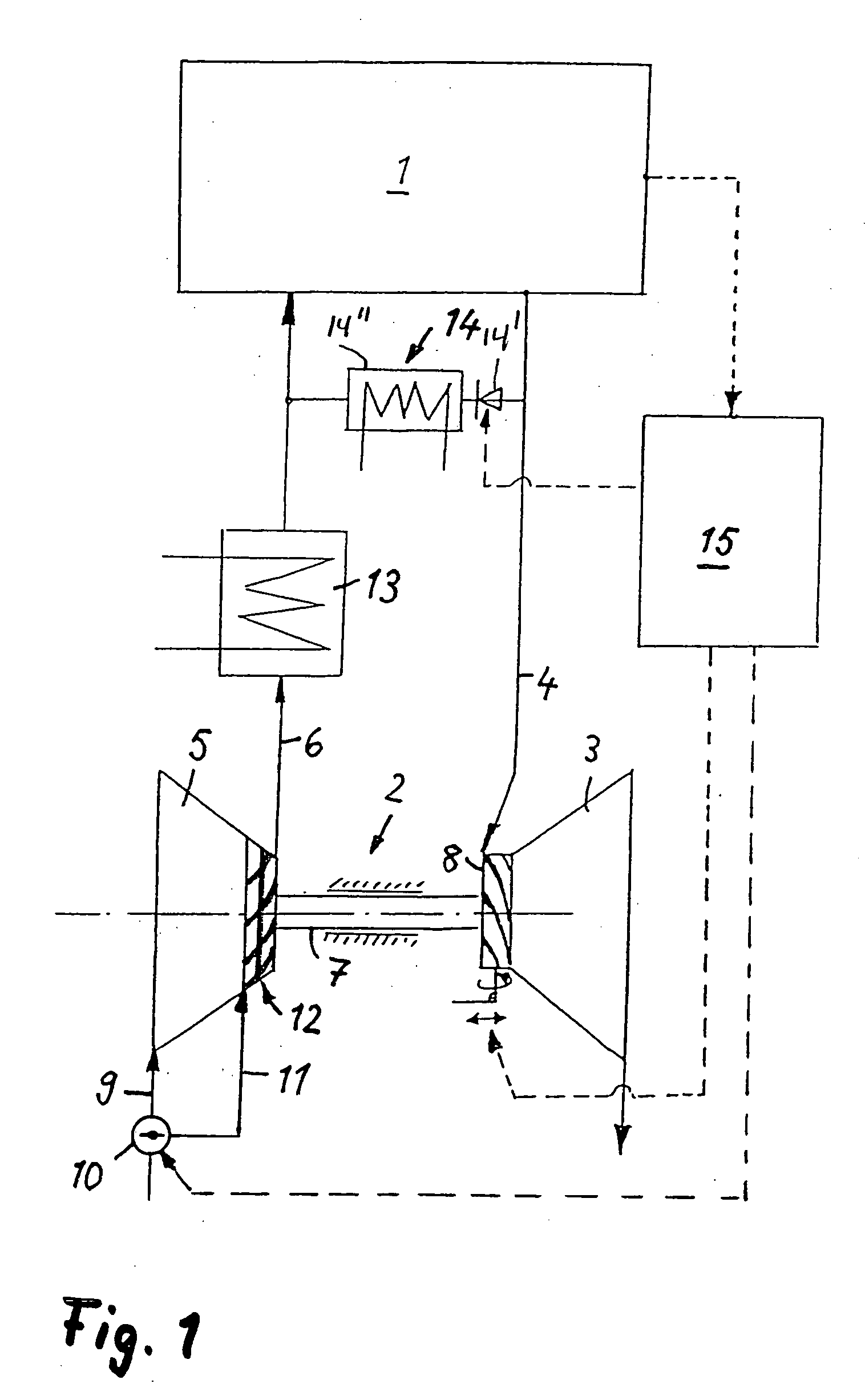

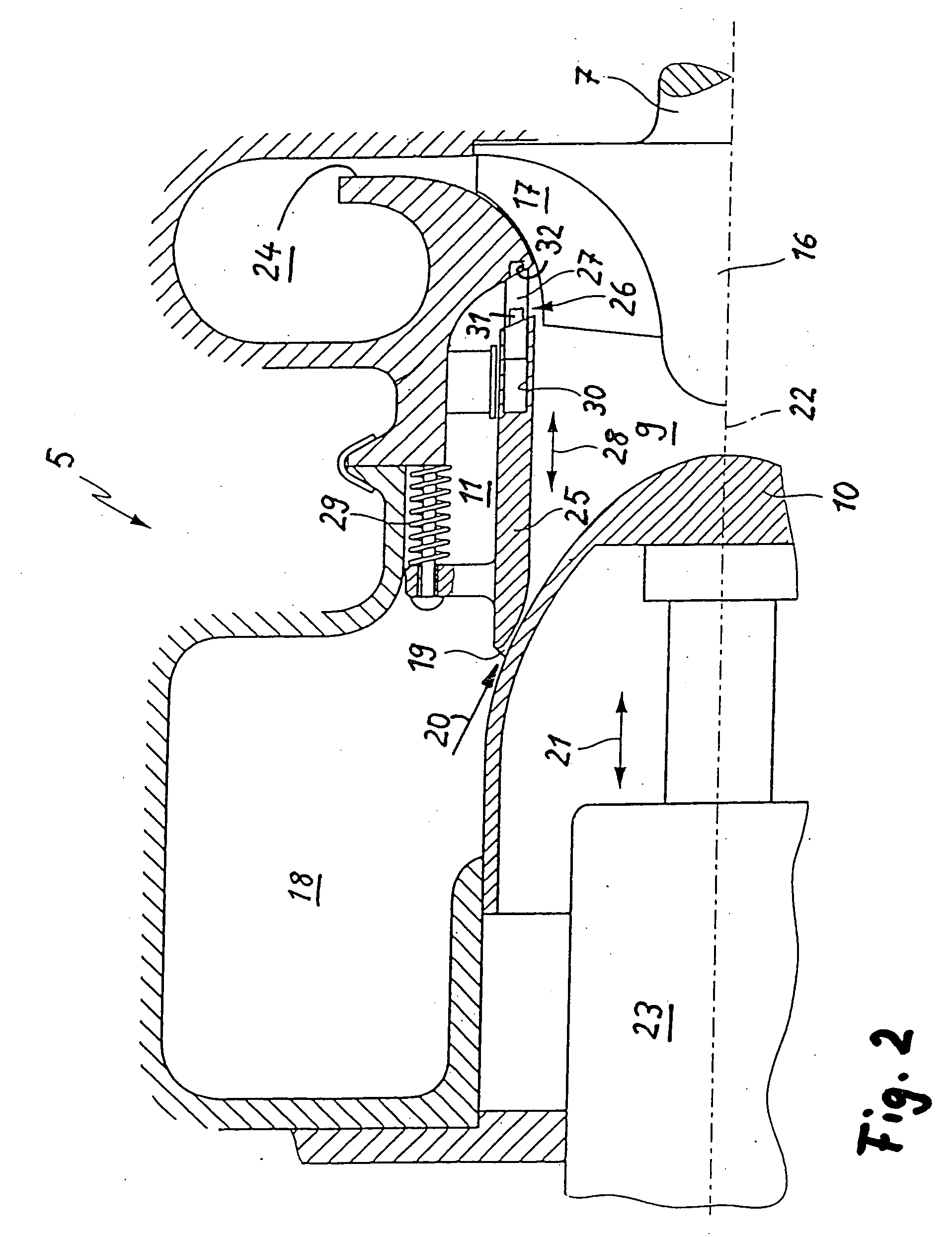

Engine brake system of a multicylinder internal combustion engine comprising a cooled intermediate pipe for exchanging gas between cylinders during engine braking

InactiveUS7314037B2Increases thermally conductive surfaceImprove heat transfer performanceInternal combustion piston enginesAir coolingExhaust valveInlet valve

The invention relates to a multicylinder internal combustion engine (1) comprising intake valves and exhaust valves that are provided with at least one additional valve (10) for each cylinder (C1, C2, C3, C4, C5, C6), a preferably tubular pressure container (9) with a gas chamber (90) into which extend ducts (11) originating from the valves (10) such that gas can be exchanged between individual cylinders (C1, C2, C3, C4, C5, C6) when the valves (10) are actuated. The pressure container (9) is provided with a device (17) for cooling the quantities of gas exchanged between individual cylinders (C1, C2, C3, C4, C5, C6). In order to increase the cooling capacity, the cooling device (17) encompasses at least one cooling pipe (17) which is axially inserted into the pressure container (9) and is penetrated by coolant. The outer jacket (171) of the cooling pipe (170) borders the gas chamber (90), the gas that is exchanged between individual cylinders (C1, C2, C3, C4, C5, C6) flowing around said outer jacket (171).

Owner:AVL LIST GMBH

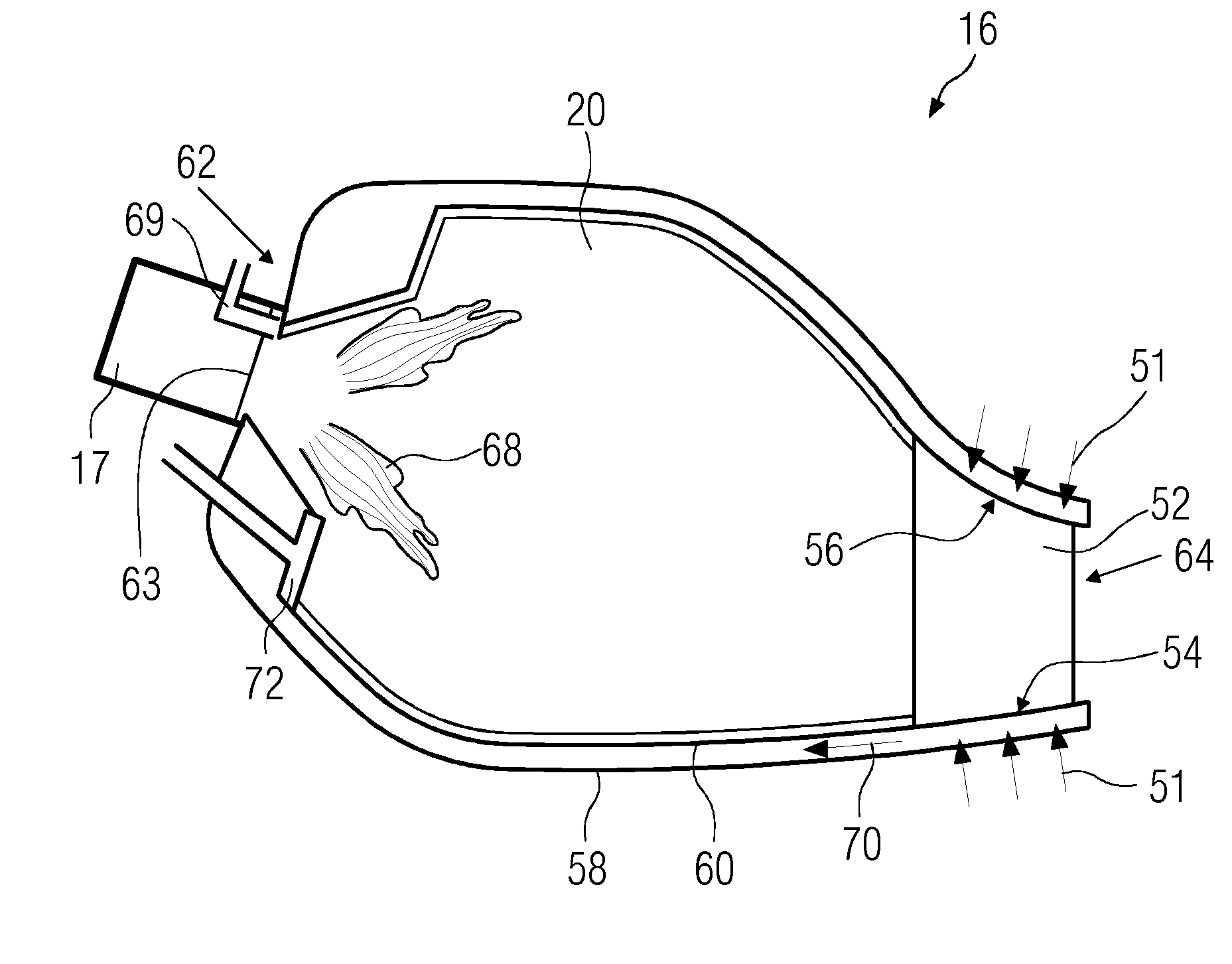

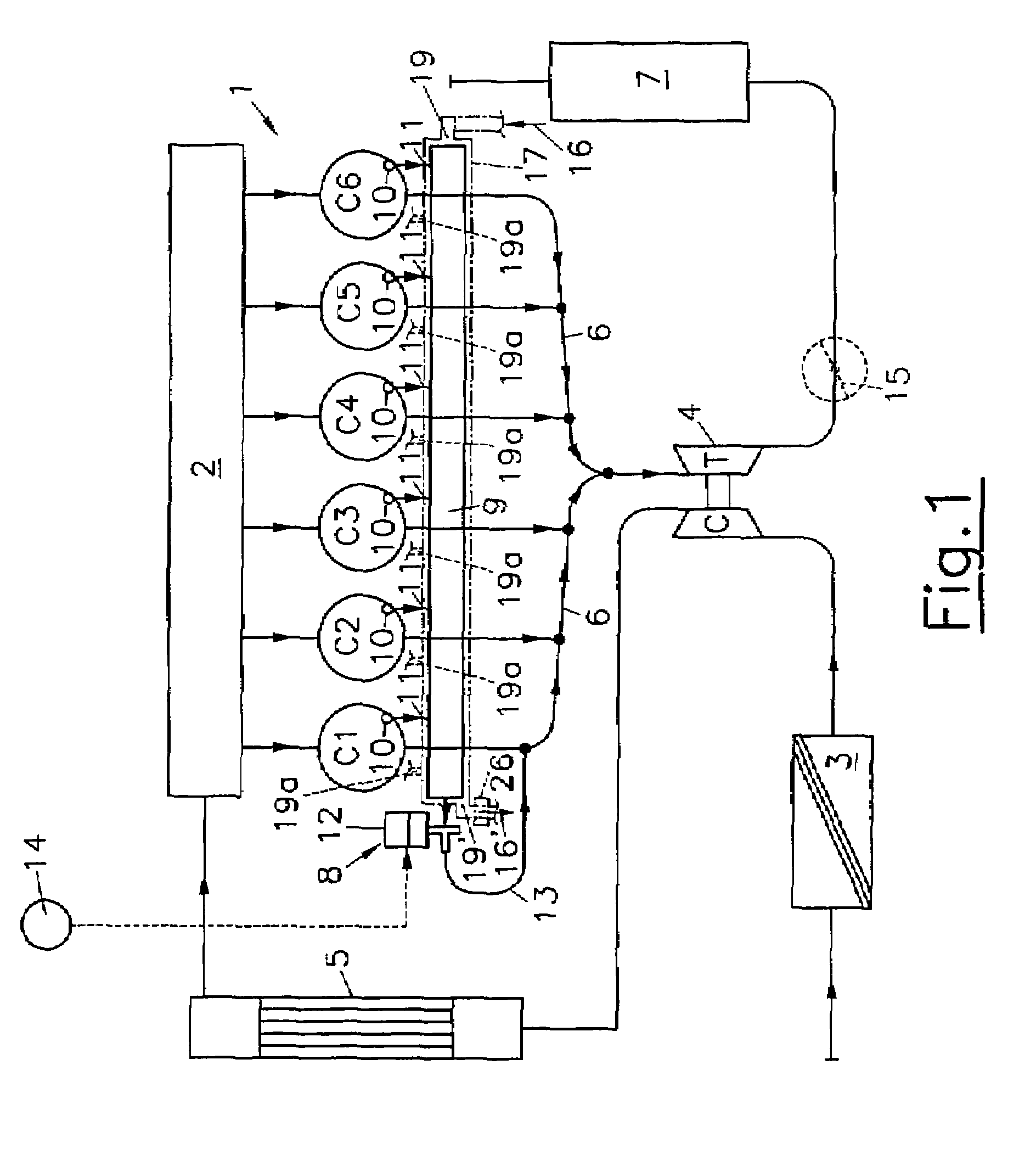

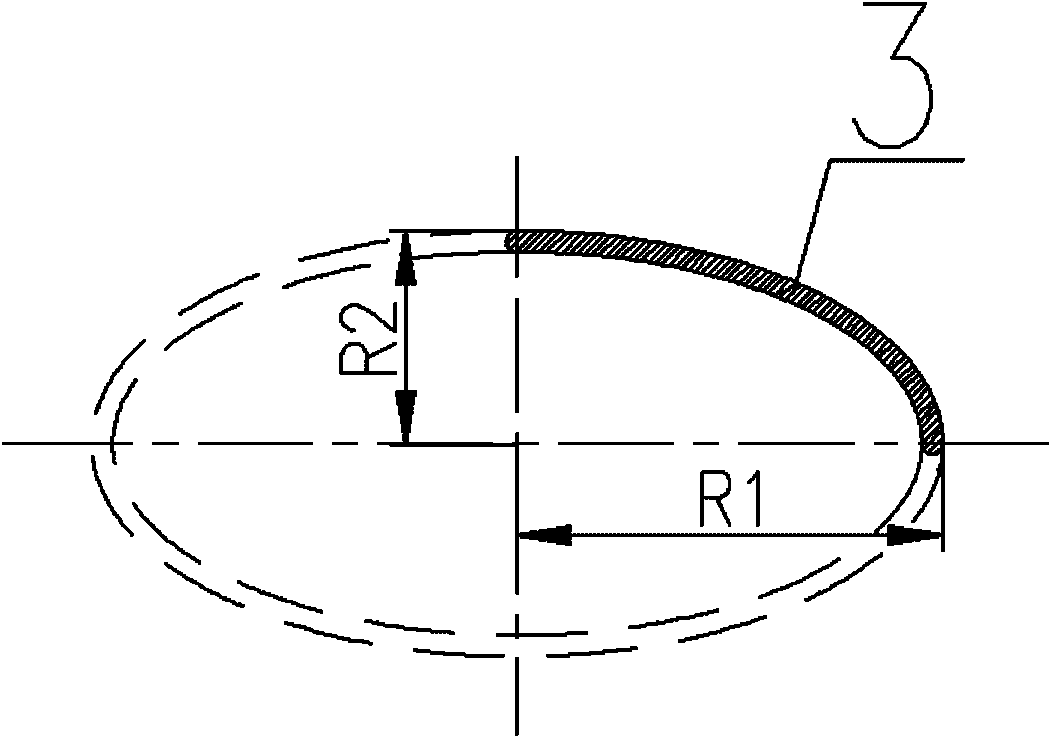

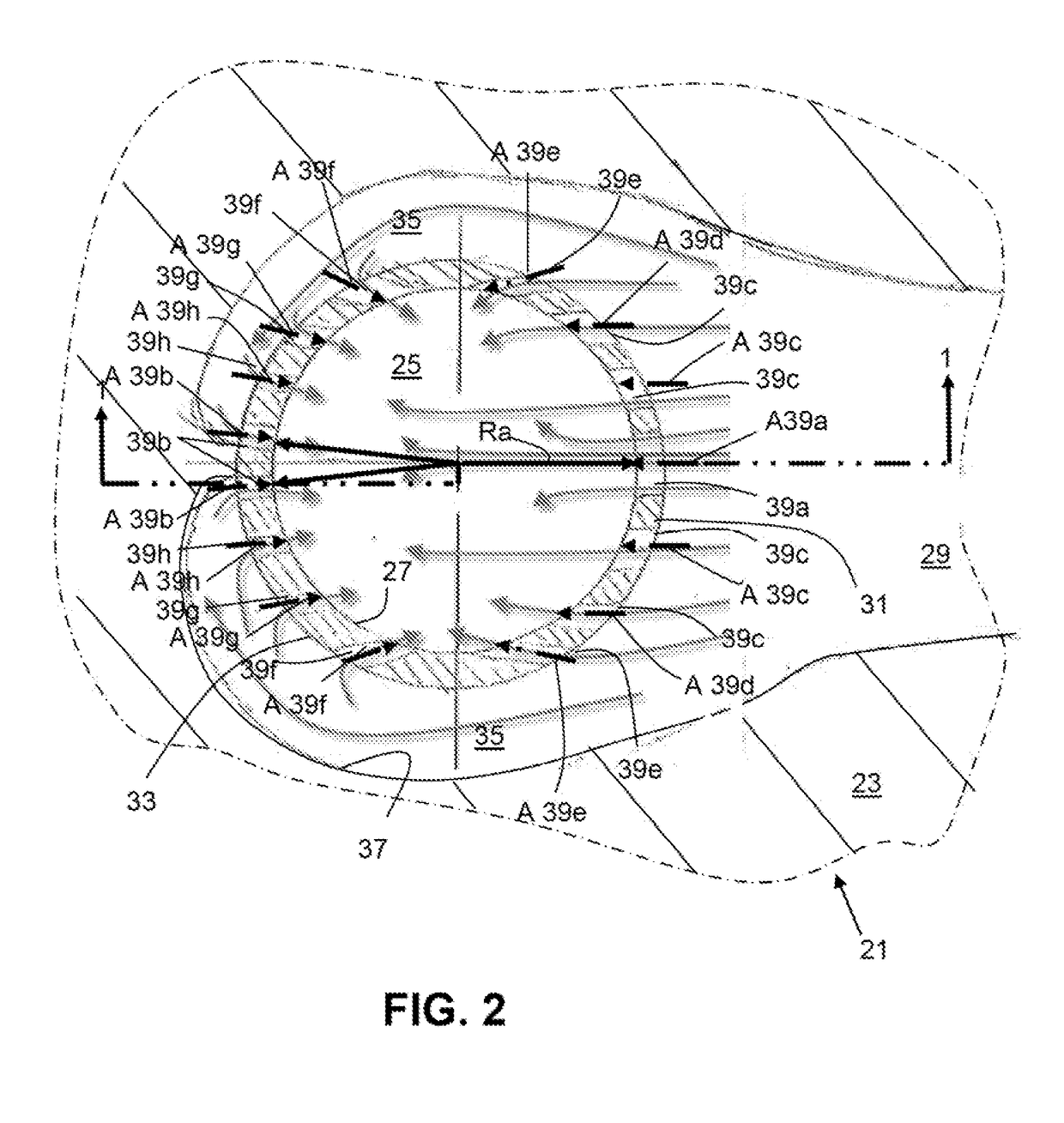

Fluid seal

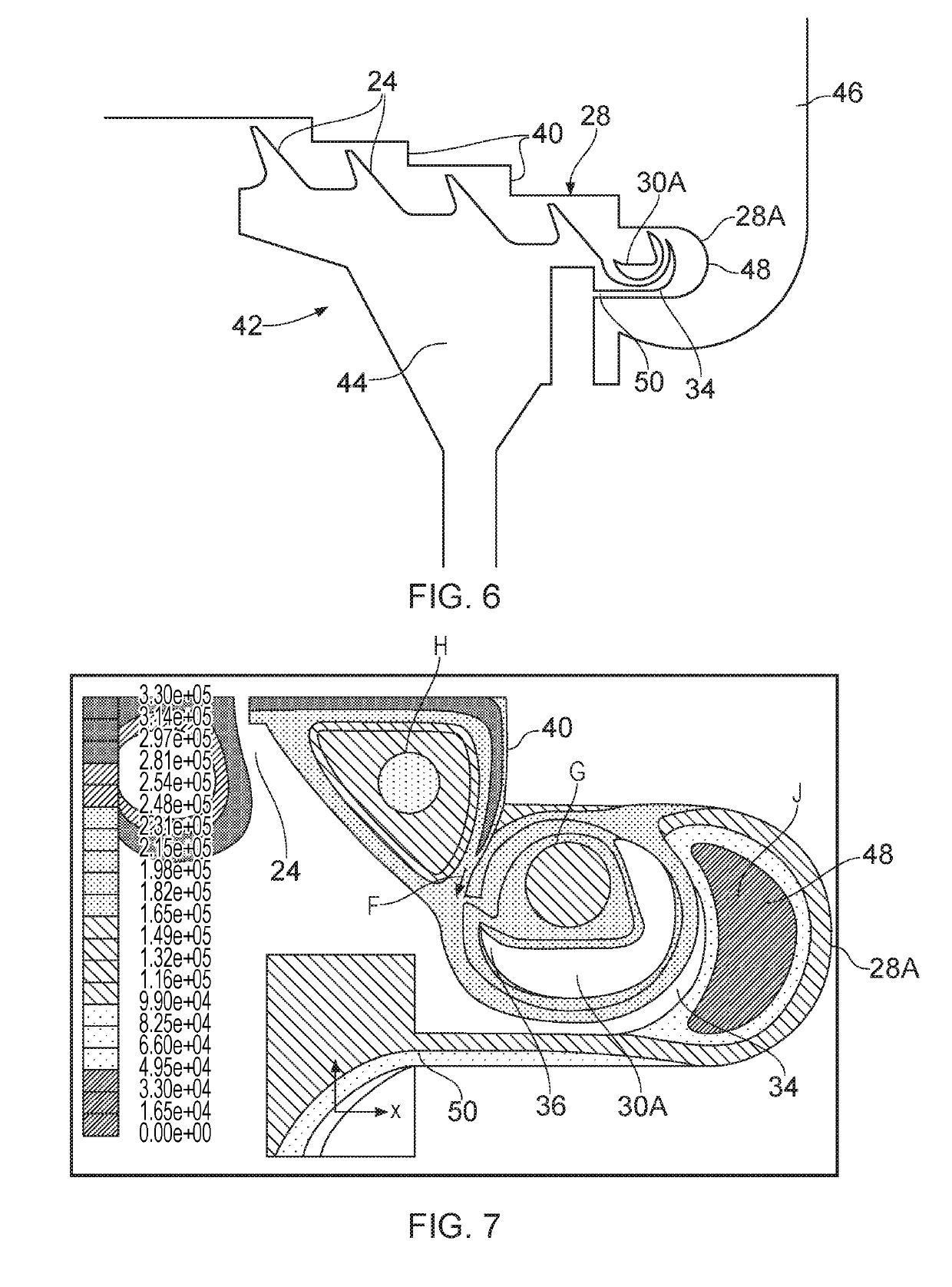

InactiveUS20190112939A1Reduction in leakage quantityImproved swirlEngine manufacturePump componentsStatorEngineering

This invention concerns a flow seal (42) for location between opposing components of a fluid flow machine, such as rotor (44) and stator (46) components of a turbomachine (10). The seal (42) has an upstream fin (24) depending from one of components (44) towards an opposing surface (28) of the other (46) of the components and a wall (26) downstream of the fin (24) defining a flow cavity between the fin (24) and wall (26). The fin (24) terminates at a fin tip (24A) so as to define a gap between the fin tip (24A) and the opposing surface (28), through which a leakage flow enters the flow cavity in use. The seal (42) also has a flow guide member (30A) located in the cavity, the flow guide member (30A) being arranged to define a flow path that promotes a vortical flow regime in the cavity. The flow cavity geometry is altered to promote a desired vortical flow regime, such as by way of a projection (39) in an intermediate wall portion of the flow cavity. The vortical flow regime may hinder flow leakage.

Owner:ROLLS ROYCE PLC

System and method for sodium azide based suppression of fires

A fire suppressing gas generator includes a cylindrical housing comprising an array of discharge ports distributed generally uniformly therearound; a cylindrical filter disposed within the housing and spaced from the interior wall of the housing; a plurality of azide-based propellant grains inside the cylindrical filter; and at least one ignition device associated with the propellant grains. The propellant grains when ignited by the ignition device generate a fire suppressing gas which passes through the filter and out of the discharge ports of the cylindrical housing for delivery into a space.

Owner:N2 GLOBAL SIA

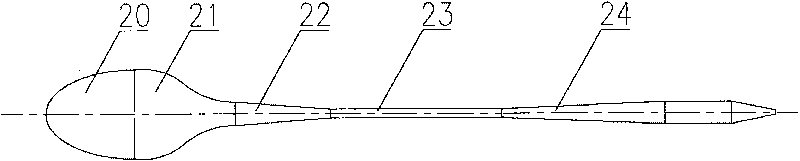

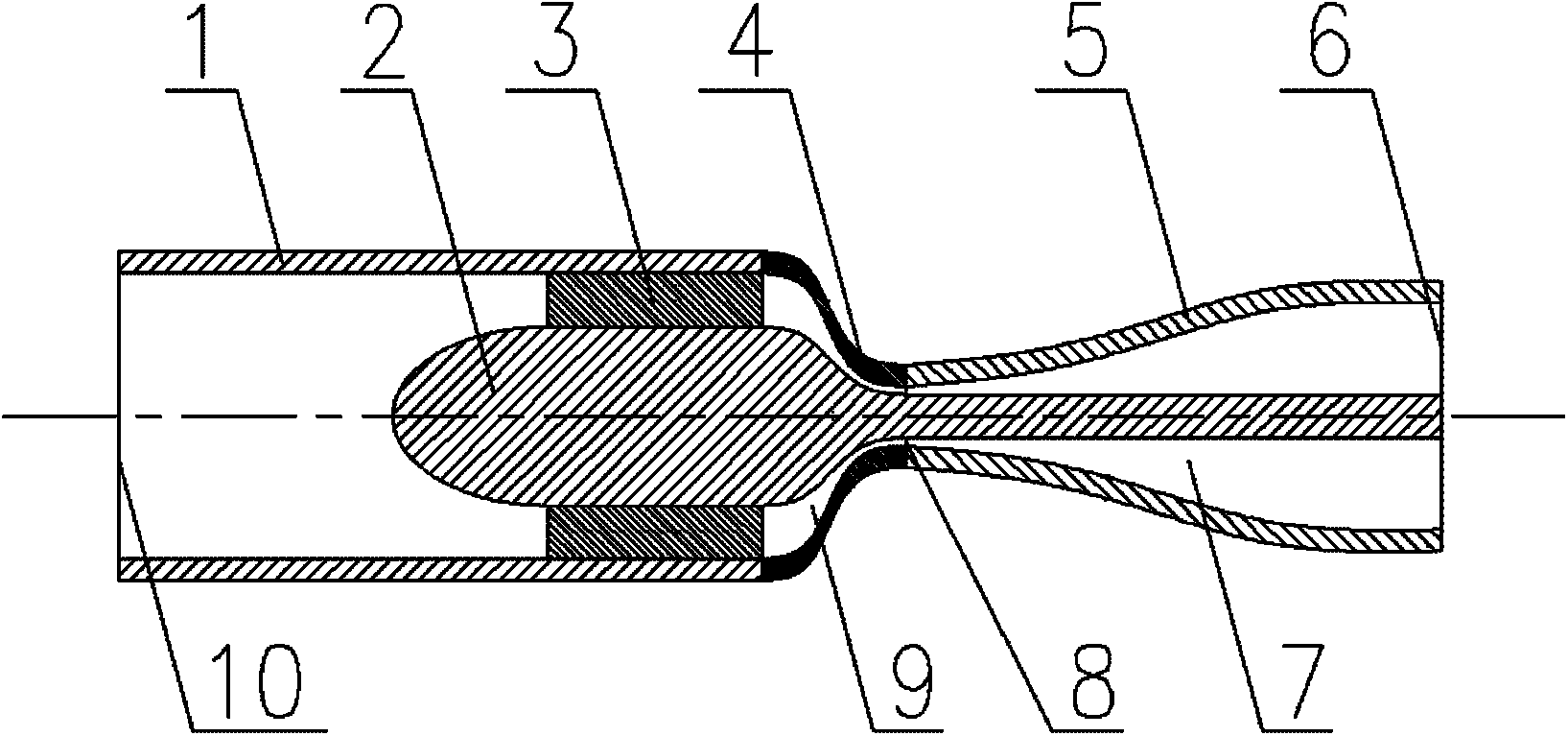

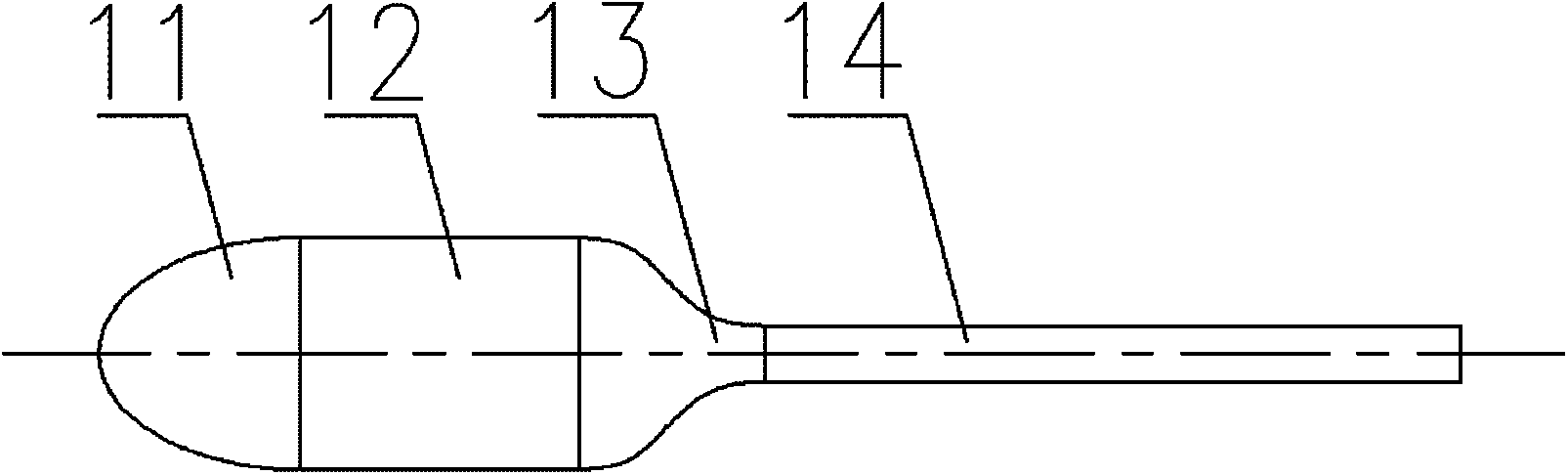

Air supersonic-velocity condensation and cyclone separation spray pipe

InactiveCN102489081AStrong swirl abilitySwirl enhancement and stabilizationGaseous fuelsDispersed particle separationCycloneOffshore oil and gas

The invention relates to an air supersonic-velocity condensation and cyclone separation spray pipe. The air supersonic-velocity condensation and cyclone separation spray pipe mainly comprises a central body, a cyclone blade, a contraction section and an expansion section, and is mainly applied to air purification, particularly the field of natural gas dehydration and heavy hydrocarbon separation.The cyclone blade is designed by an elliptical blade method, and can effectively strength cyclone; the central body can effectively reduce eddy dissipation, and the curve of the contraction section can guarantee that the velocity of air flow can be stably increased to sound velocity; the contraction section has a gradually expanded structure, and simple linear design in the conventional device isabandoned; and the curve design can avoid the influence of expansion waves, and the spray pipe is good in aerodynamic performance. In the spray pipe, the velocity of the air flow is supersonic velocity, the residence time is very short, hydrate is avoided, and chemical agents and relative recovery systems are not needed to be added. Moreover, the spray pipe has the advantages of supporting unmanned operation, along with no movement component, compact structure, small occupied space and the like, is particularly suitable for development of oil and gas fields of boundary and desert, and offshore oil and gas fields, and has a wide application range.

Owner:文闯

Uniflow engine with fluid flow arrangement

ActiveUS20170335752A1Minimize turbulenceMinimize heat transferInternal combustion piston enginesCylinder headsInlet channelEngineering

A uniflow engine includes a cylinder having a cylinder wall, an inlet channel, an extension of a central axis of the inlet channel first intersecting the cylinder wail in a first portion of the cylinder and next intersecting the cylinder wail in a second portion of the cylinder opposite the first portion of the cylinder, an intake air gallery, the intake air gallery having a gallery wall and being in flow communication with the inlet channel, and a plurality of intake ports extending between the cylinder wail and the gallery wall, at least some of the intake ports having different areas at the cylinder wall measured perpendicular to longitudinal axes of the intake ports, and wherein an area of at least one in take port in the first portion of the cylinder is larger than an area of at least one intake port in the second portion of the cylinder.

Owner:VOLVO LASTVAGNAR AB

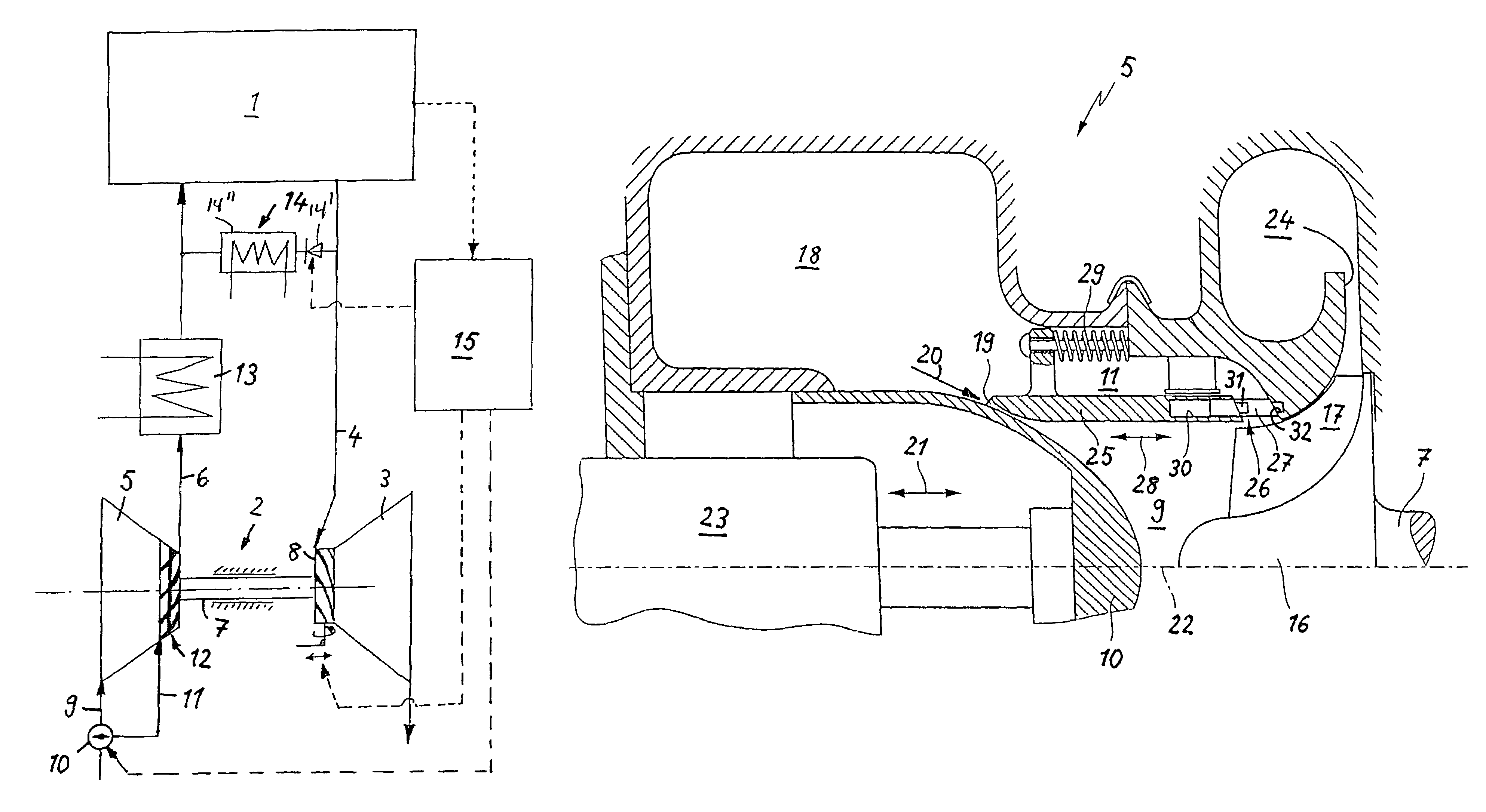

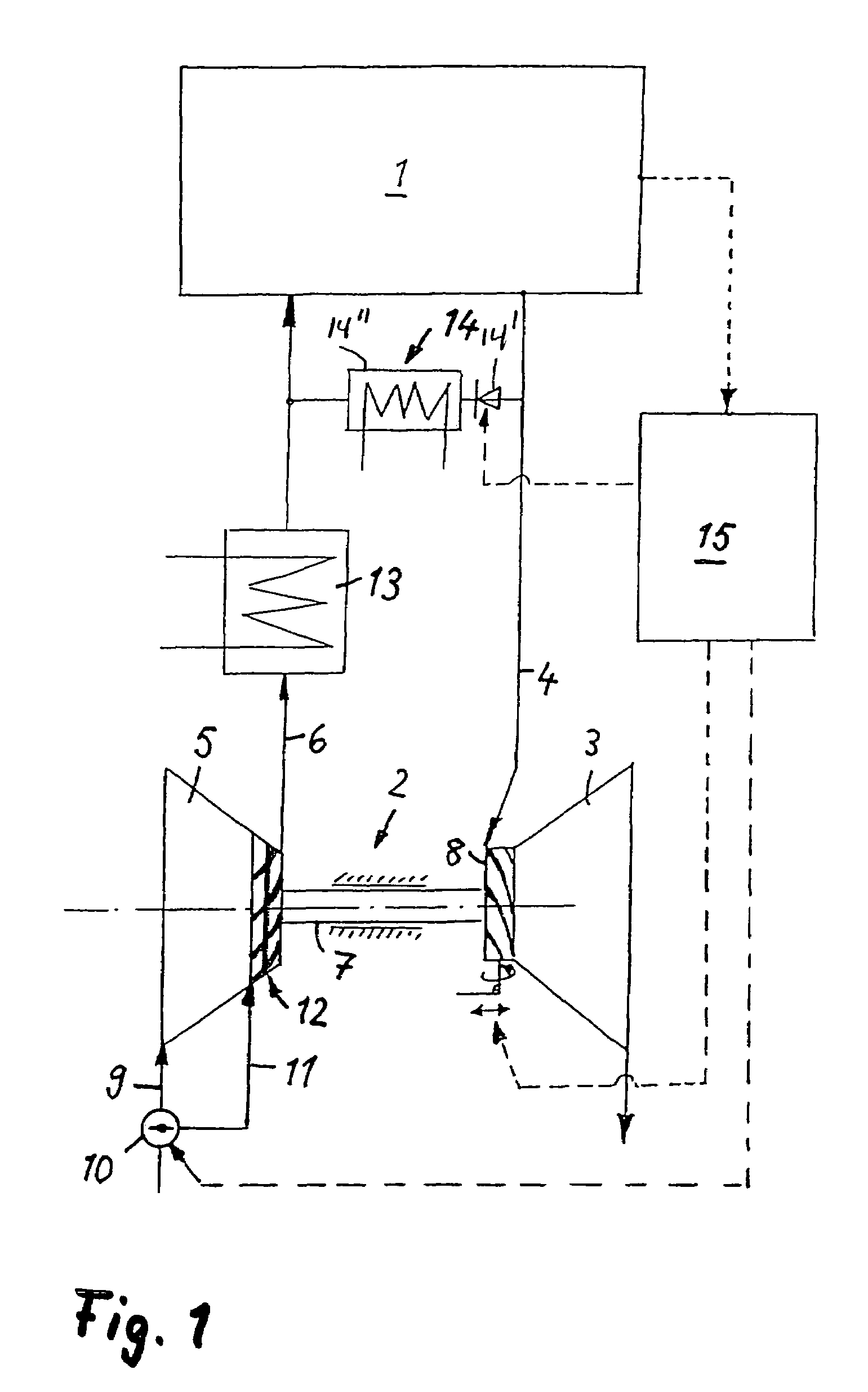

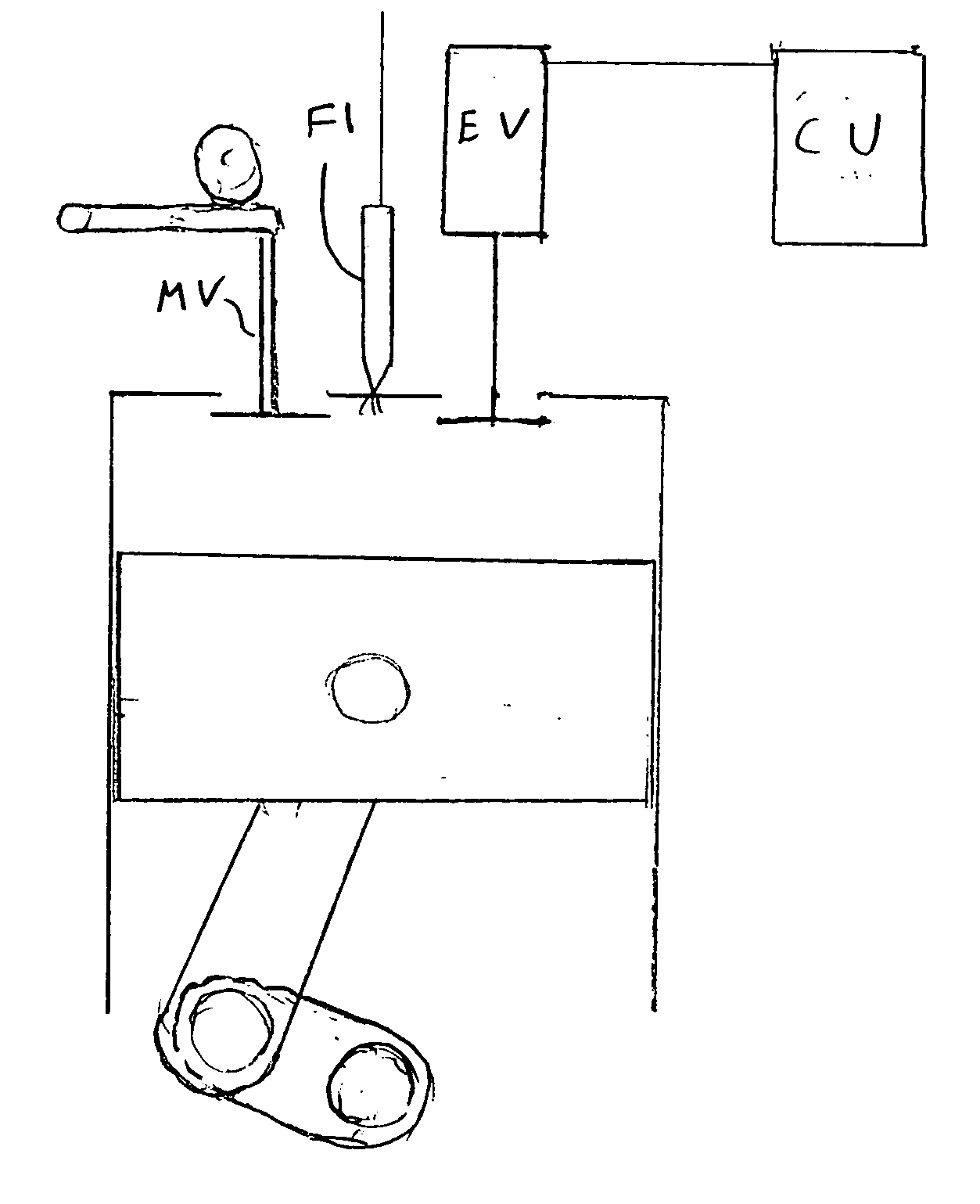

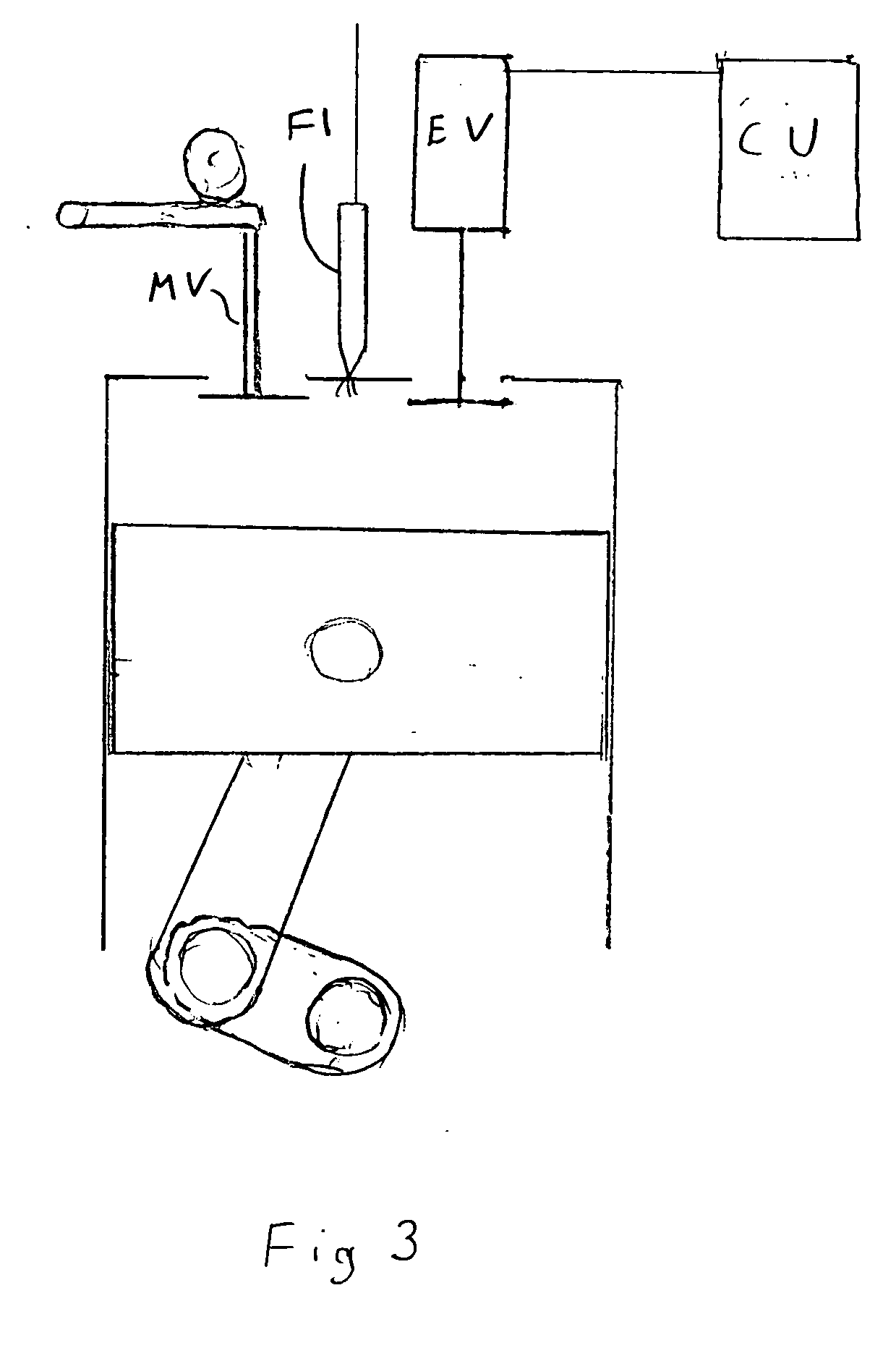

Method for controlling an inlet valve of an internal combustion engine

InactiveUS20060185646A1Simple and cost-effective designSave installation spaceInternal combustion piston enginesOutput powerInlet valveInternal combustion engine

In a method for controlling an inlet valve of an internal combustion engine having at least one cylinder with at least a first inlet valve and a second inlet valve, wherein the closing time of the first inlet valve is adjustable and the first inlet valve is so controlled that, at a first engine speed, the first inlet valve is closed before the closing of the second inlet valve and, at a second engine speed which is higher than the first engine speed, the first inlet valve is closed after the closing time of the second inlet valve.

Owner:DAIMLER AG

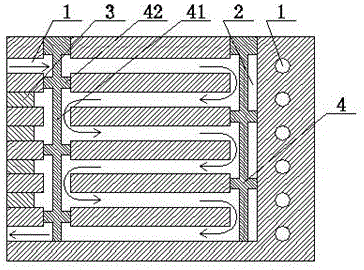

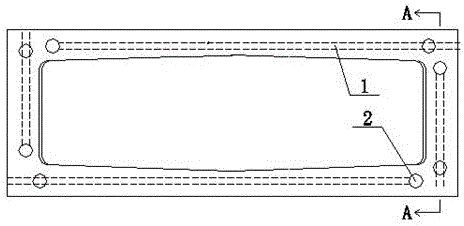

Bright oxygen-free copper flat profile crystallizer

The invention discloses a bright oxygen-free copper flat profile crystallizer which comprises a crystallizer body composed of a plurality of side walls. A crystallizing channel is formed by the side walls in a surrounded mode, and each side wall is provided with a cooling channel. The cooling channels comprise multiple horizontal cooling channels and two vertical cooling channels. The cooling channels further comprise horizontal through hole plugging columns for sealing the horizontal cooling channels and vertical through hole plugging columns for sealing the vertical cooling channels. Each vertical through hole plugging column comprises a fixed-connection column body and a through hole sealing plug block arranged on the fixed-connection column body. The section shape of the horizontal through hole plugging columns is identical with that of the horizontal cooling channels, and the section shape of the through hole sealing plug blocks is identical with that of the vertical cooling channels. According to the bright oxygen-free copper flat profile crystallizer provided by the invention, the mechanical strength of the bright oxygen-free copper flat profile crystallizer is improved, the cooling channels can be evenly distributed, and thus the adverse influences that hot spots occur or local temperature gradient is too high for the crystallizer and cast blanks are reduced.

Owner:ANHUI XINXU NEW MATERIALS LTD BY SHARE LTD

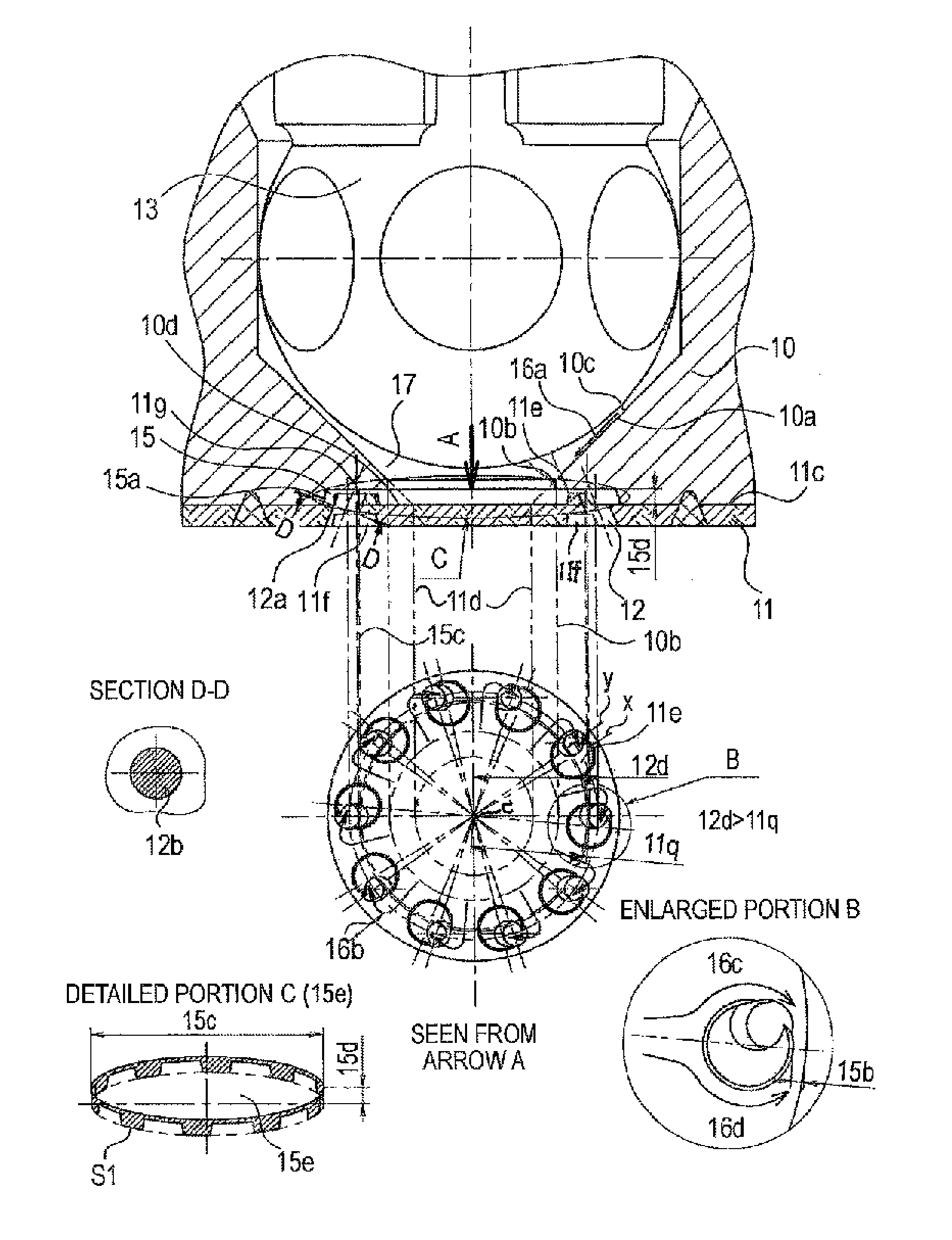

Fuel injection valve

InactiveUS8657213B2Improved swirlLarge centrifugal forceSpray nozzlesMachines/enginesEngineeringFuel injection

Owner:MITSUBISHI ELECTRIC CORP

Internal combustion engine with actuating oscillating cylinders

InactiveUS20060180104A1Improved swirlPromotes even distributionInternal combustion piston enginesCombustion chamberVaporization

An internal combustion engine having one or more modules each employing fluidly-communicating, oscillating, power cylinder and air cylinder. The power and air cylinders oscillate about separate, individually supporting sets of trunnions positioned non-linearly with respect to each other and permitting the passage of air therethrough. The air cylinder includes a pre-combustion chamber for the purpose of withholding the delivery of a portion of compressed air to the power cylinder until all spent gases have been evacuated from the power cylinder. Means for enhancing fuel dispersion and / or vaporization is provided whereby cavities are provided in the cap of both the air cylinder and the power cylinder that are in selective synchronous fluid communication. A blower is provided to not only assist in the elimination of exhaust from the combustion chamber but also purge the combustion piston cap cavity of exhaust backflow prior to the delivery of fresh charge

Owner:SPRINGER

Anti-blocking molten iron blowing desulfurization spray gun with multi-strand cyclone dispersion function

InactiveCN105331773AGuarantee unimpededGuaranteed sealing performanceLiquid spraying apparatusCycloneRefractory

The invention discloses an anti-blocking molten iron blowing desulfurization spray gun with a multi-strand cyclone dispersion function. The anti-blocking molten iron blowing desulfurization spray gun is composed of a connection section, a gun body section and a blowing section, wherein the connection section is composed of a connection flange and a composite gun core in sequence, and the outer walls of the gun body section and the blowing section are a refractory material gun lining formed through pouring a refractory material; and a gun body outer diameter D of the blowing section is greater than a gun body outer diameter d of the gun body section, the composite gun core sequentially comprises an inner insertion tube, a main tube and a reinforcing tube from the inside to the outside, an inner insertion tube connector is installed on the inner wall of the bottom end of the reinforcing tube, the bottom end surface of the inner insertion tube is level with the bottom end surface of a graphite blowing tube, and wrapped with the refractory material gun lining to form a spray gun nozzle, and grooves are formed at the nozzle. According to the invention, the inherent shortages of poor reaction kinetics performance and high blocking frequency of a nozzle existing in a conventional spray gun are effectively solved through said structural design and optimization for the related structural dimensions; and meanwhile, the anti-damage capacity of the blowing section and the gun body section of the spray gun is effectively reinforced, and the purpose of prolonging the service life of the spray gun is achieved.

Owner:武汉钢铁有限公司

Compressor in the induction tract of an internal combustion engine

InactiveUS20060218921A1Increased rotational speed levelReduced flow cross sectionInternal combustion piston enginesWind motor controlImpellerInternal combustion engine

In a compressor in the induction tract of an internal combustion engine with a compressor by which combustion air can be compressed to an increased boost pressure and which includes a compressor wheel rotatably mounted in a compressor housing with a main inlet duct in the flow path to the compressor wheel, and an auxiliary inlet duct joining the main inlet duct in the area of the compressor wheel, an adjustable swirl device is provided in the auxiliary intake duct, which comprises two separate, interacting swirl structures with a plurality of guide vanes distributed over the periphery and arranged so that the flow cross-section between the guide vanes of the two swirl structures can be changed by an adjusting motion of at least one swirl structure, the vane height of the guide vanes of the smaller swirl structure being 5% to 35% of the vane height of the guide vanes of the larger swirl structure.

Owner:DAIMLER AG

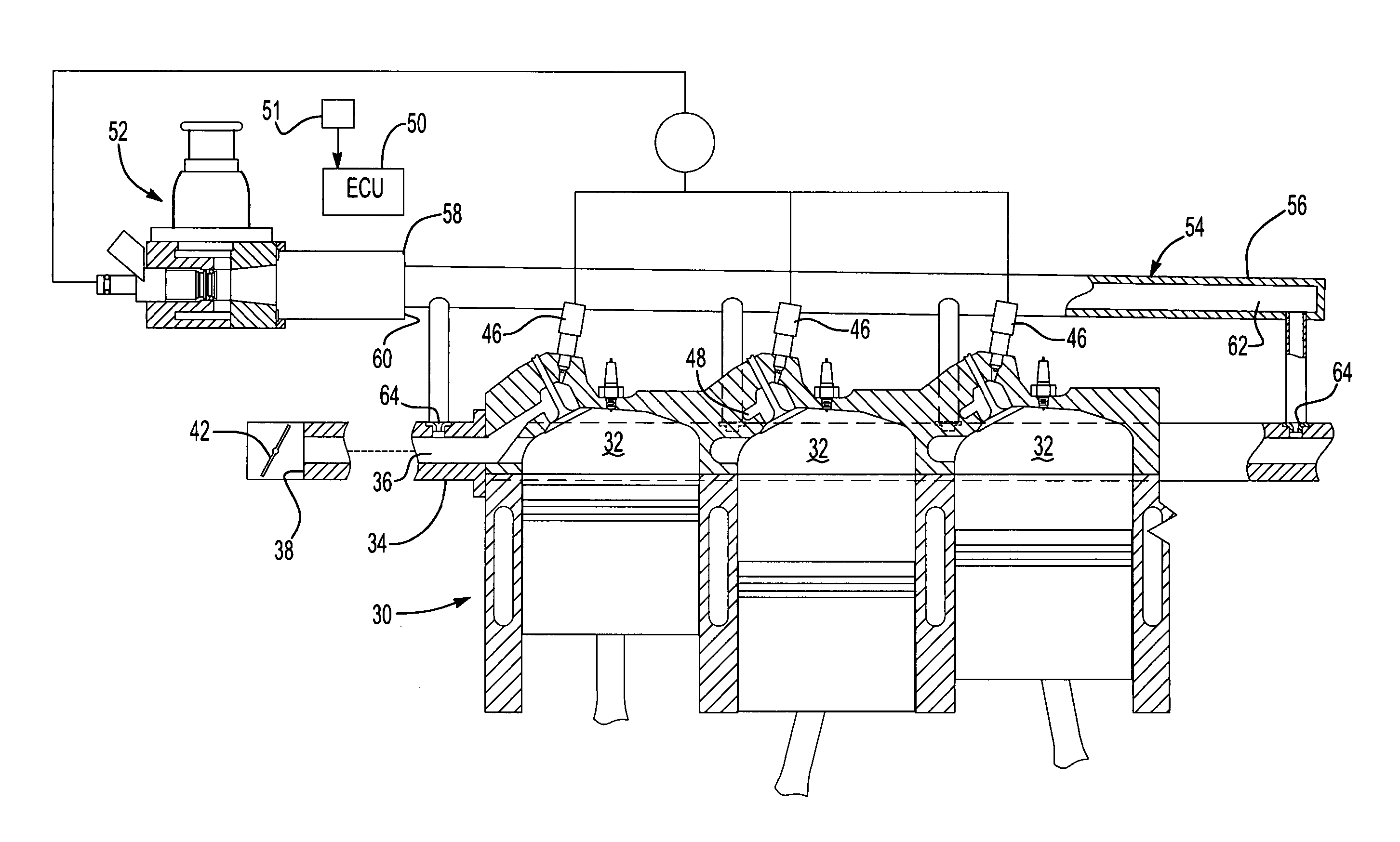

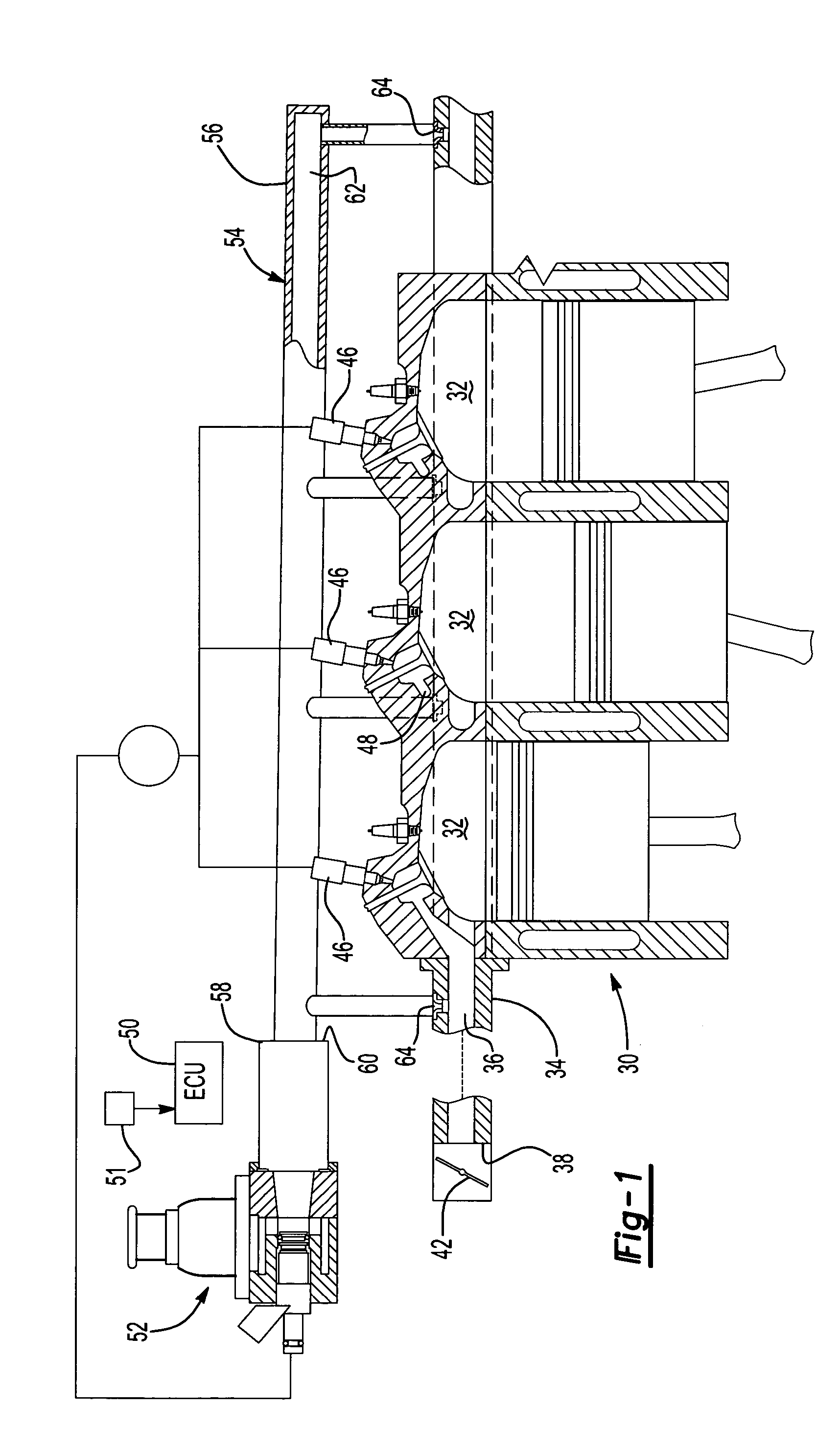

Fuel control system

InactiveUS20040003790A1Minimize the possibilityQuicker engine startingElectrical controlInternal combustion piston enginesCombustion chamberControl system

A cold start fuel control system is disclosed for use with an internal combustion engine having a plurality of combustion chambers, a source of fuel and an intake manifold having an inlet and an outlet port connected to each combustion chamber. The system includes a cold start fuel injector assembly having an inlet and an outlet to provide a vapor fuel charge during a cold start engine condition. The cold start fuel injector assembly inlet is fluidly connected to the source of fuel. An auxiliary intake manifold has an internal chamber and the cold start fuel injector assembly outlet is fluidly connected to the auxiliary intake manifold chamber. The auxiliary intake manifold chamber is then fluidly connected through a control orifice to each of the combustion chambers at a position downstream from the inlet of the primary intake manifold. A control circuit optionally controls the area of the control orifice to minimize noxious emissions from the engine and a shroud is optionally associated with each control orifice to enhance mixing of the vapor fuel with the inducted airflow to also minimize noxious emissions from the engine.

Owner:HITACHI LTD

Multi-fluid mixer

ActiveCN107131080ACompact structureHighly integratedExhaust gas recirculationMachines/enginesEngineeringCavity wall

The invention relates to a multi-fluid mixer which comprises a gas mixing base and a mixing core. The mixing core is arranged inside the gas mixing base; the gas mixing base comprises a top plate and a bottom plate, an outer cavity wall, a middle cavity wall and an inner cavity wall are coaxially arranged between the top plate and the bottom plate, a first fluid cavity is formed between the outer cavity wall and the middle cavity wall, a second fluid cavity is formed between the middle cavity wall and the inner cavity wall, and a gas mixing cavity is formed inside the inner cavity wall; and the mixing core comprises a middle support, a first fluid gas mixing blade and a second fluid gas mixing blade, one end of the first fluid gas mixing blade is fixedly connected with the outer wall of the middle support, the other end of the first fluid gas mixing blade (22) penetrates the inner cavity wall to be fixedly connected with the middle cavity wall, one end of the second fluid gas mixing blade is fixedly connected with the outer wall of the middle support, and the other end of the second fluid gas mixing blade is fixedly connected with the inner cavity wall. By means of the design, mixing of three kinds of fluid can be achieved, and the uniform mixing integration level is high.

Owner:DONGFENG COMML VEHICLE CO LTD

Internal combustion engine with actuating oscillating cylinders

InactiveUS20060180105A1Guaranteed to workEasy to reciprocateInternal combustion piston enginesCombustion chamberVaporization

An internal combustion engine having one or more modules each employing fluidly-communicating, oscillating, power cylinder and air cylinder. The power and air cylinders oscillate about separate, individually supporting sets of trunnions positioned non-linearly with respect to each other and permitting the passage of air therethrough. The air cylinder includes a pre-combustion chamber for the purpose of withholding the delivery of a portion of compressed air to the power cylinder until all spent gases have been evacuated from the power cylinder. Means for enhancing fuel dispersion and / or vaporization is provided whereby cavities are provided in the cap of both the air cylinder and the power cylinder that are in selective synchronous fluid communication. A blower is provided to not only assist in the elimination of exhaust from the combustion chamber but also purge the combustion piston cap cavity of exhaust backflow prior to the delivery of fresh charge

Owner:SPRINGER JOSEPH E

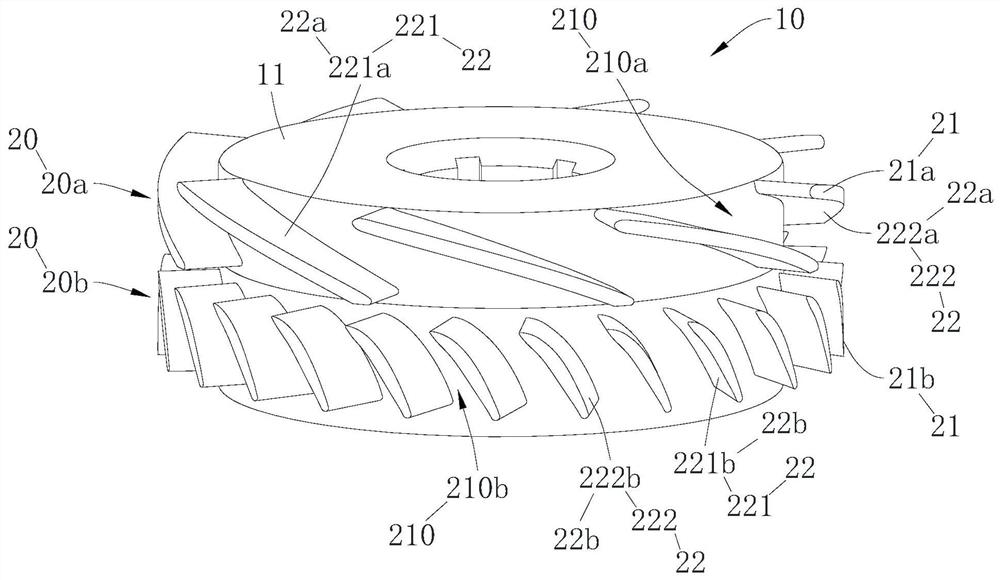

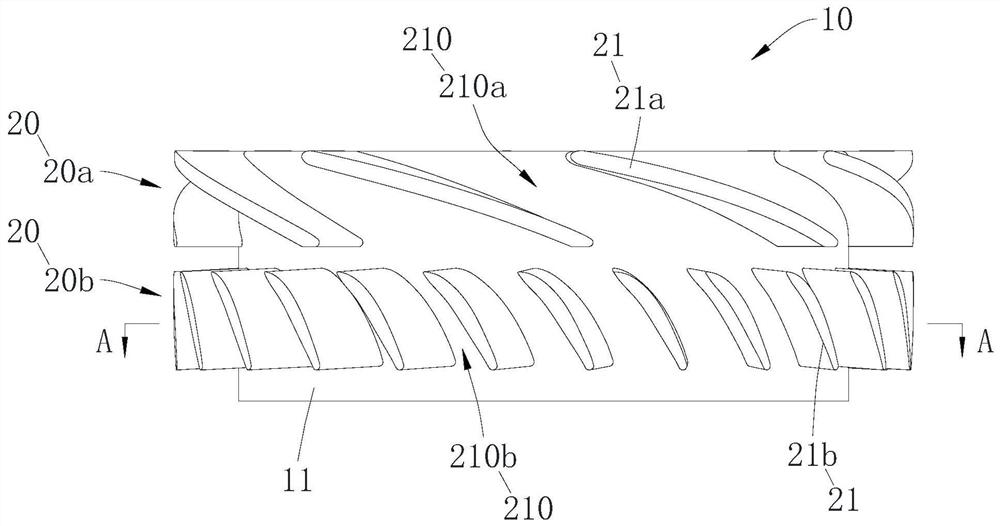

Diffusion device, fan and dust collector

ActiveCN113074138AReduce absolute speedReduce unevennessPump componentsSuction cleanersEngineeringMechanical engineering

The invention provides a diffusion device, a fan and a dust collector. The diffusion device comprises a base and a plurality of stationary blades, wherein the multiple stationary blades are sequentially arranged in multiple rows in the axial direction of the base, multiple stationary blades are arranged in each row, the multiple stationary blades in each row are arranged in the circumferential direction of the base, the cross section of the base is circular, and the thickness of each stationary blade in at least one row of stationary blades in the multiple rows of stationary blades is not constant from the head part to the tail part of the stationary blade. According to the diffusion device, by arranging the multiple rows of stationary blades in the circumferential direction of the base, airflow is gradually guided through the multiple rows of stationary blades, the absolute speed of the airflow is reduced, and then the pressurization effect is improved; and the thickness of each stationary blade in at least one row of stationary blades in the multiple rows of stationary blades is not constant from the head part to the tail part of the stationary blade, so that the flow separation can be relieved, the flow separation loss can be reduced, the diffusion effect can be improved, and the pneumatic noise can be lowered.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com