Braking execution mechanism used for engine braking oil way and using method of braking execution mechanism

An engine braking and actuator technology, applied in engine control, engine components, machines/engines, etc., can solve problems such as weak stability and poor braking effect, and achieve strong stability, good braking effect, and a wide range of applications. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

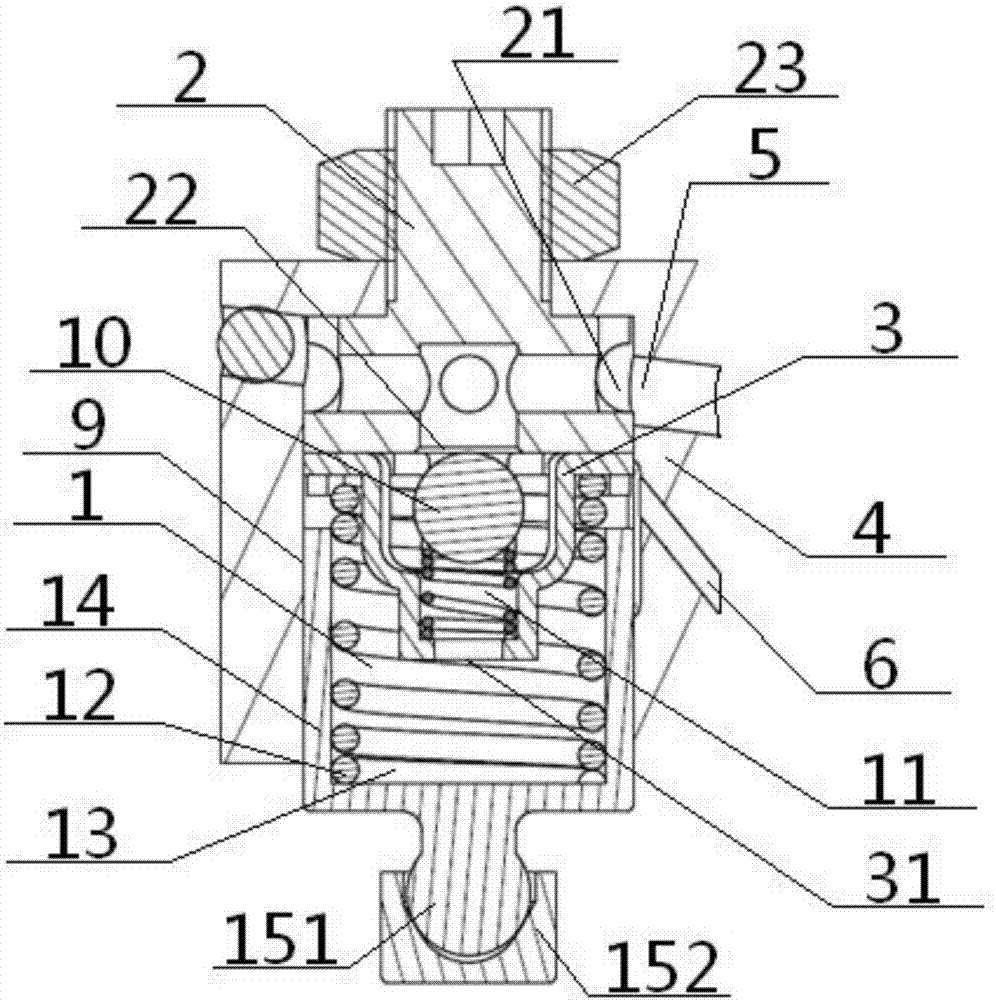

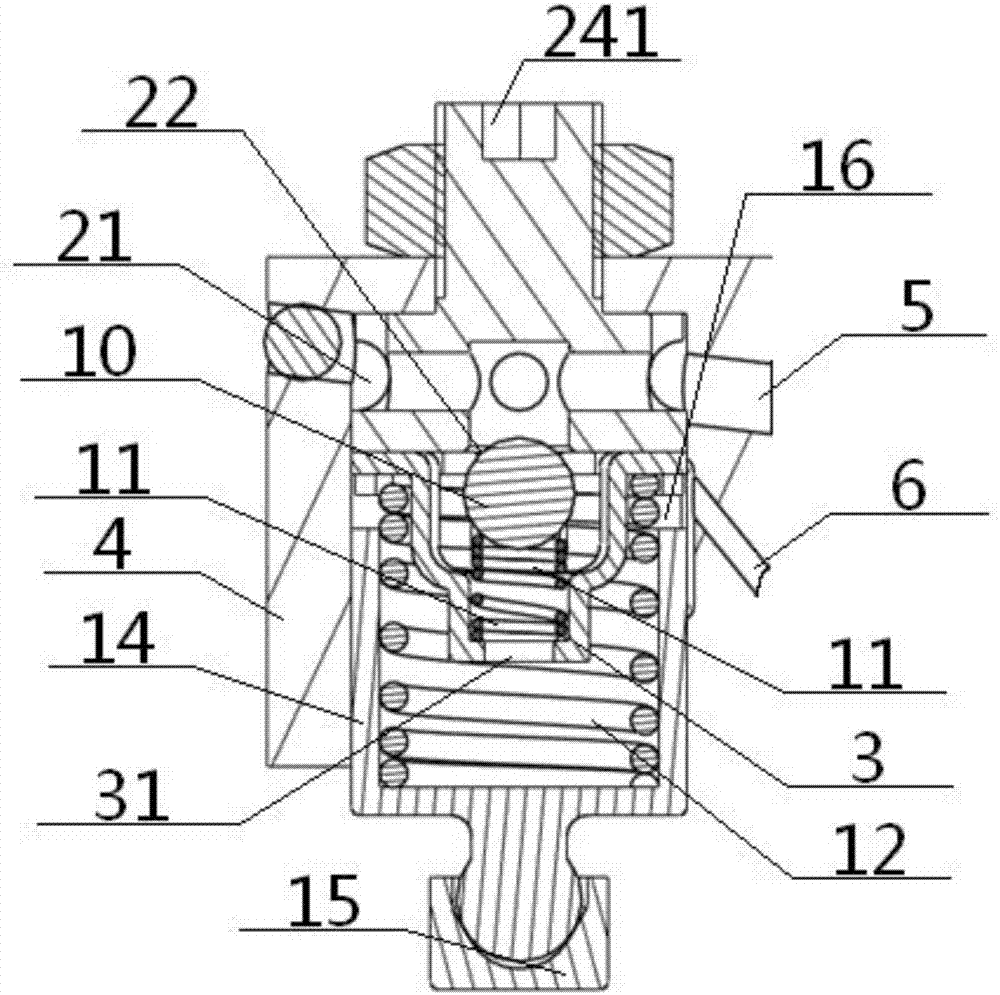

[0053] see Figure 1 to Figure 8 , a brake actuator for the engine brake oil circuit, including a brake chamber 9 and a brake oil chamber 13 and a brake piston 14 arranged inside, the side of the brake oil chamber 13 and the rocker arm The brake oil passage 5 and the oil discharge passage 6 in 4 communicate with each other, the bottom of the brake piston 14 is connected with the elephant foot 15 directly below it, and the bottom of the ball socket 152 in the elephant foot 15 is connected with the air valve directly below it. A valve gap 18 is formed between the yokes 17; the brake actuator also includes an adjustment bolt 2, a ball valve 10, a ball valve spring 11, a ball valve spring seat 3 and a brake spring 12, and the bottom end of the adjustment bolt 2 is located at the brake Inside the chamber 9, the top of the adjustment bolt 2 passes through the brake chamber 9 and the rocker arm 4 in turn and is fixedly connected with the outer wall of the rocker arm 4. The side and b...

Embodiment 2

[0058] Basic content is the same as embodiment 1, the difference is:

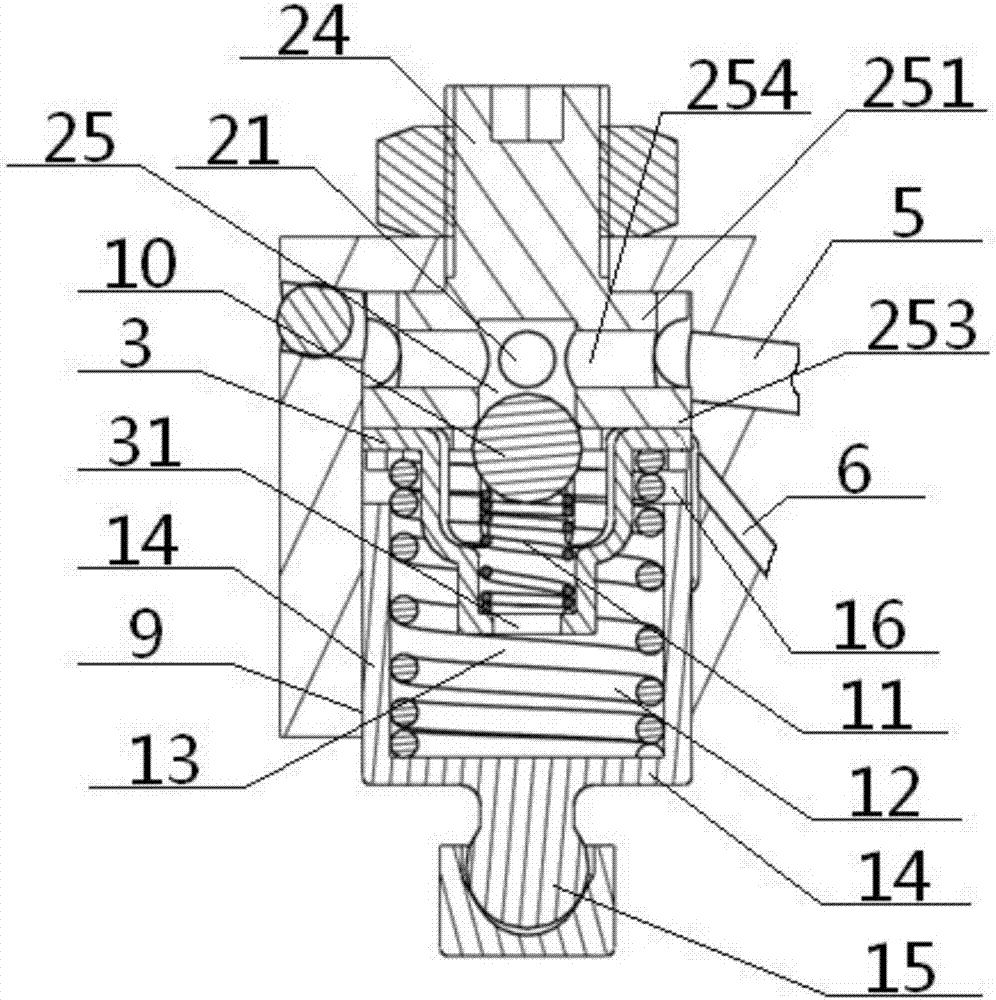

[0059] The adjusting bolt 2 is a T-shaped structure, including a screw fixing part 24 and a screw oil part 25 perpendicular to each other; the screw oil part 25 is a waist structure, including an oil-through top 251 and an oil-through waist 252 connected in sequence Connect with the oil-through bottom 253, the top surface of the oil-through top 251 is vertically connected with the bottom of the screw fixing part 24, and the bottom surface of the oil-through top 251, the top surface of the oil-through bottom 253 and the oil-through waist 252 form a semi-open ring altogether Type oil groove 254, at least two side oil holes 21 are uniformly opened on the oil waist 252 to communicate with the bottom oil hole 22 provided inside the screw oil portion 25. The top of the bottom oil hole 22 is set higher than the side oil hole 21, the bottom of the bottom oil hole 22 is flush with the bottom surface of the oil botto...

Embodiment 3

[0061] Basic content is the same as embodiment 2, the difference is:

[0062] The oil passage top 251 is provided with an oil passage gap 26 corresponding to the side oil hole 21, the inner bottom edge 261 of the oil passage gap 26 is located directly above the corresponding side oil hole 21, and the side oil hole 21 The bottom is connected to the top surface of the oil-through bottom 253 , and a gap 27 is formed between the junction of the side oil hole 21 , the oil-through bottom 253 and the side wall of the oil-through bottom 253 . The side wall of the screw fixing part 24 near its top is provided with an external thread to be threadedly connected with the adjustment nut 23, and the inside of the top of the screw fixing part 24 is provided with a screw connection hole 241, and the screw connection hole 241 The cross section is polygonal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com