Multi-cylinder piston engine

A piston engine and engine technology, applied in the direction of internal combustion piston engine, engine operation, engine components, etc., can solve the problem of not disclosing how to control, and achieve the effect of simple and reliable control mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

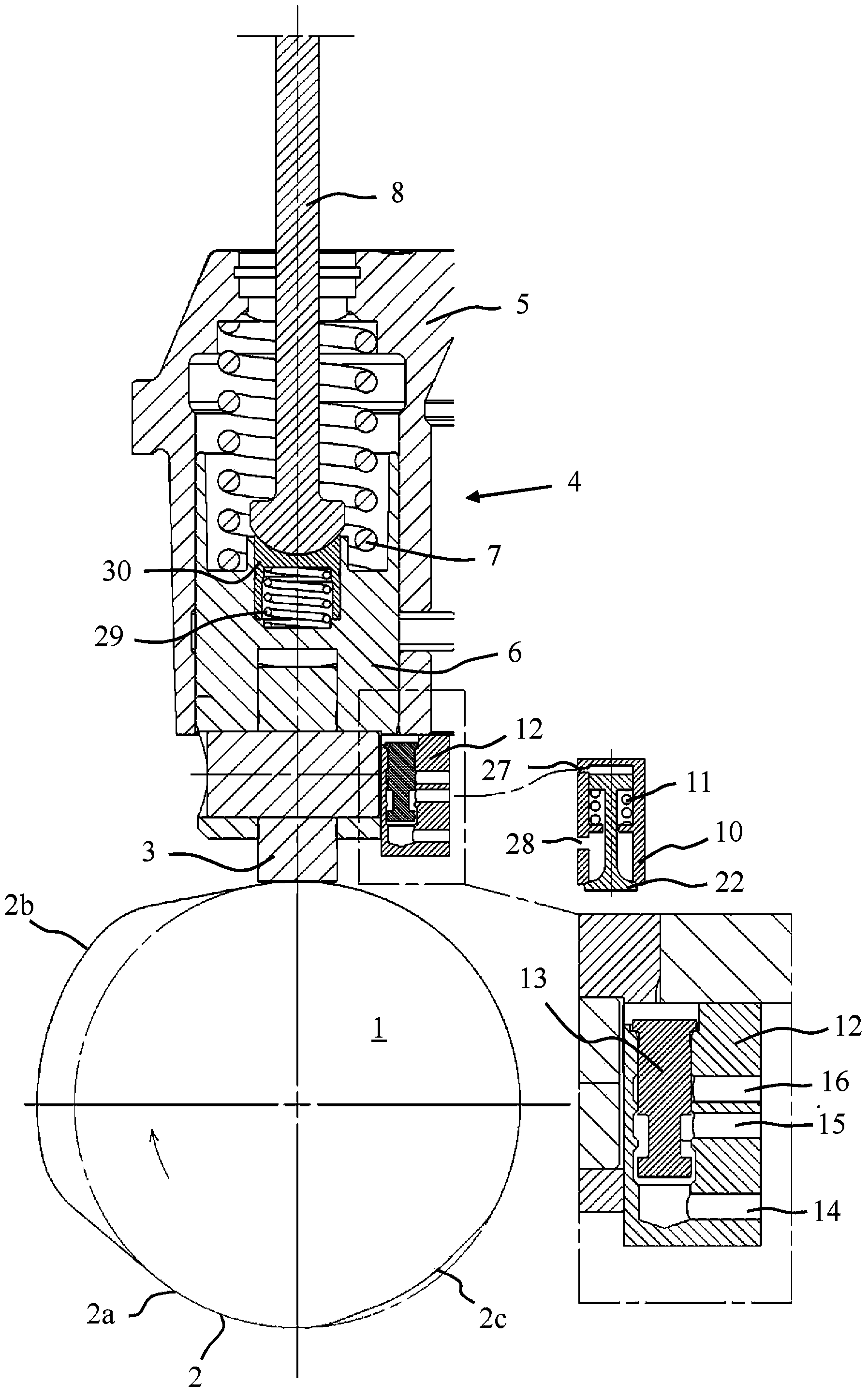

[0022] The embodiments of the present invention will now be described in detail with reference to the drawings.

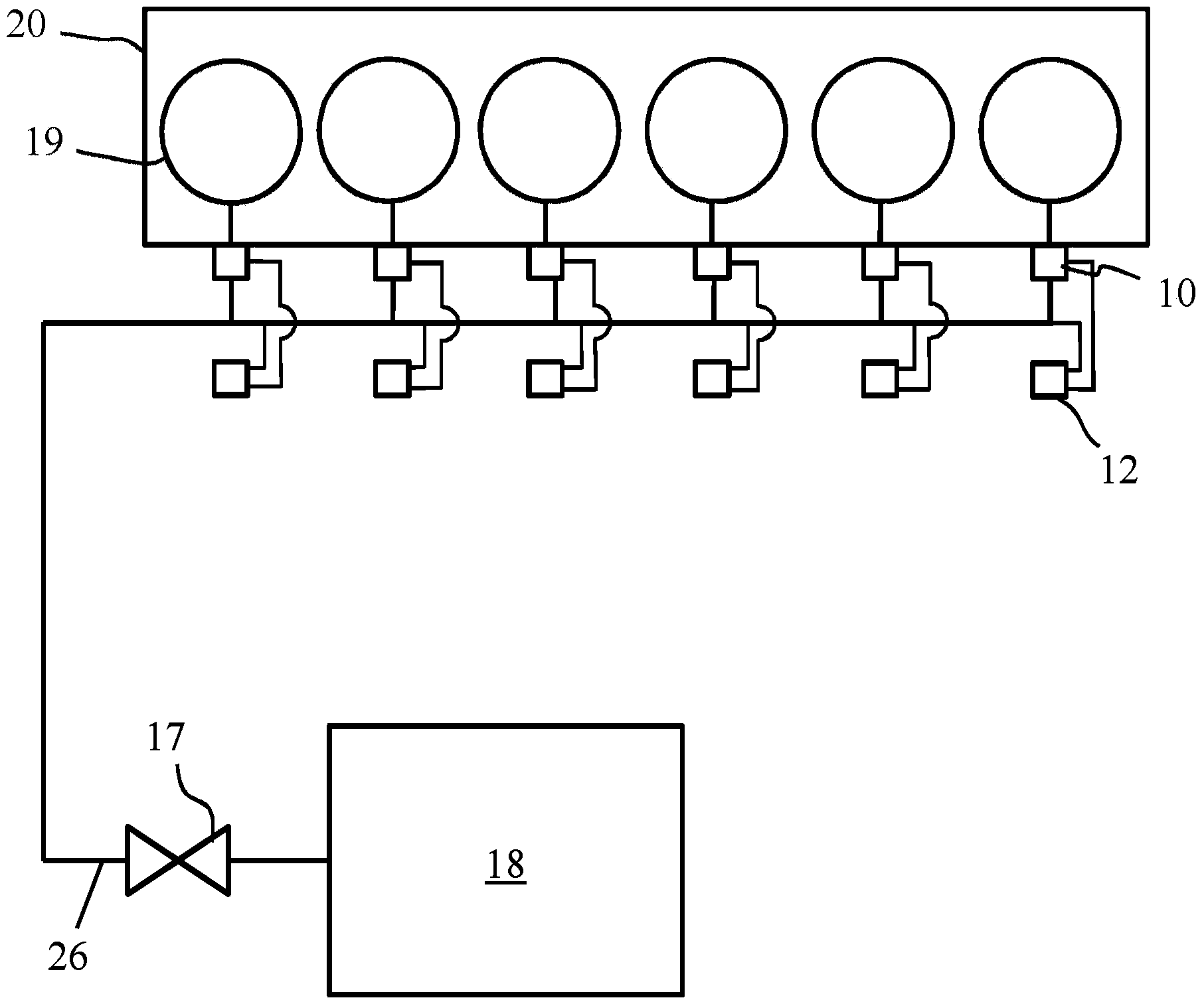

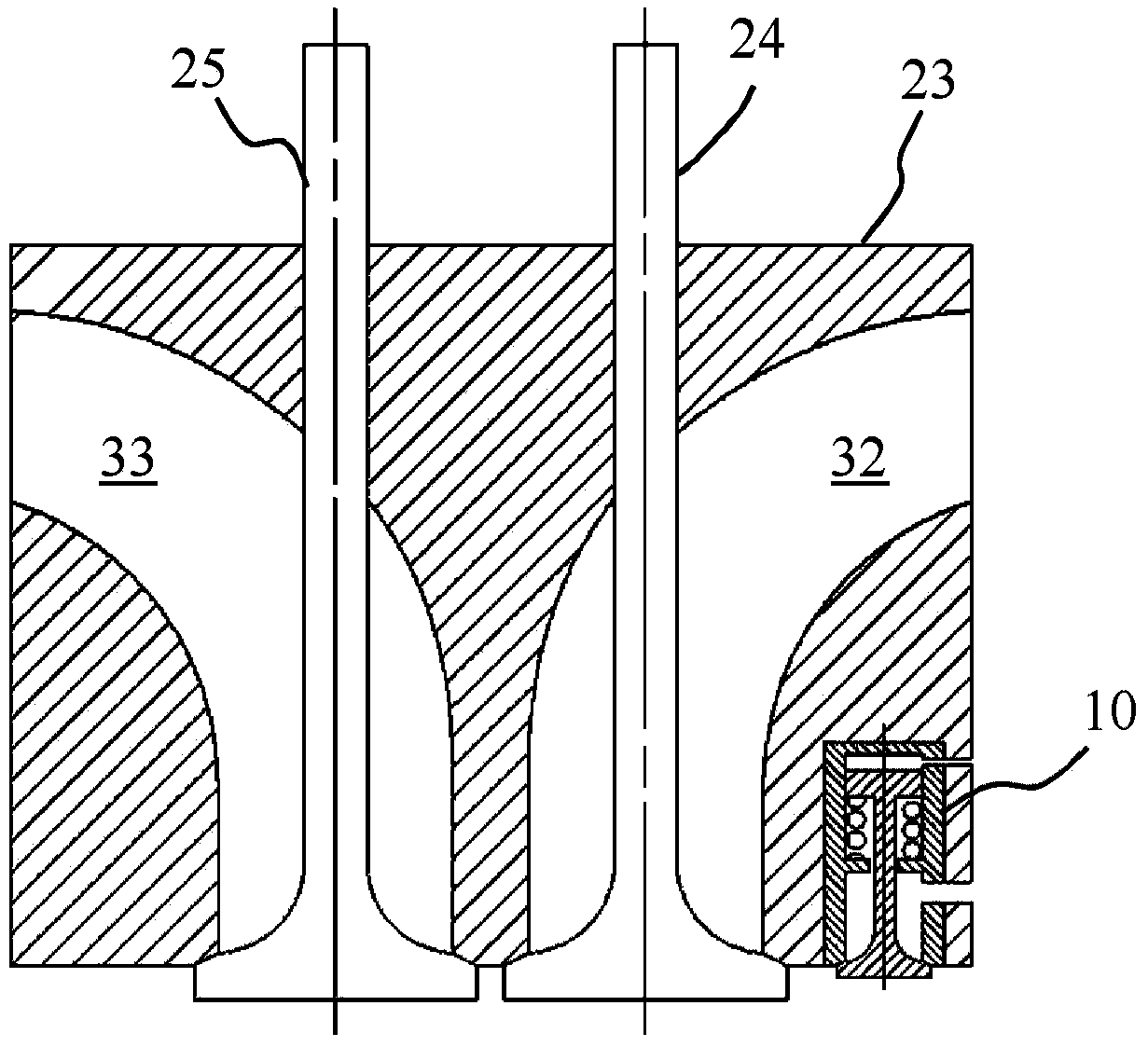

[0023] figure 1 A piston engine 20 with an introduction device for introducing additional oxygen-containing gas into the cylinder 19 of the engine 20 is schematically shown. The additional oxygen-containing gas is a pressure medium that is introduced into the cylinder 19 of the engine 20 before ignition and after the normal air intake is completed. In a four-stroke engine, this means that the pressure medium is introduced into the cylinder 19 after the intake valve of the cylinder 19 is closed. The pressure medium can be, for example, pressurized air or pure oxygen. Charge air can be produced by a compressor, so it is suitable for many applications. In this specification, the term "extra combustion air" is used for the pressure medium. However, the present invention is not limited to the use of air as the pressure medium.

[0024] in figure 1 In the example, the eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com