Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Combustion cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

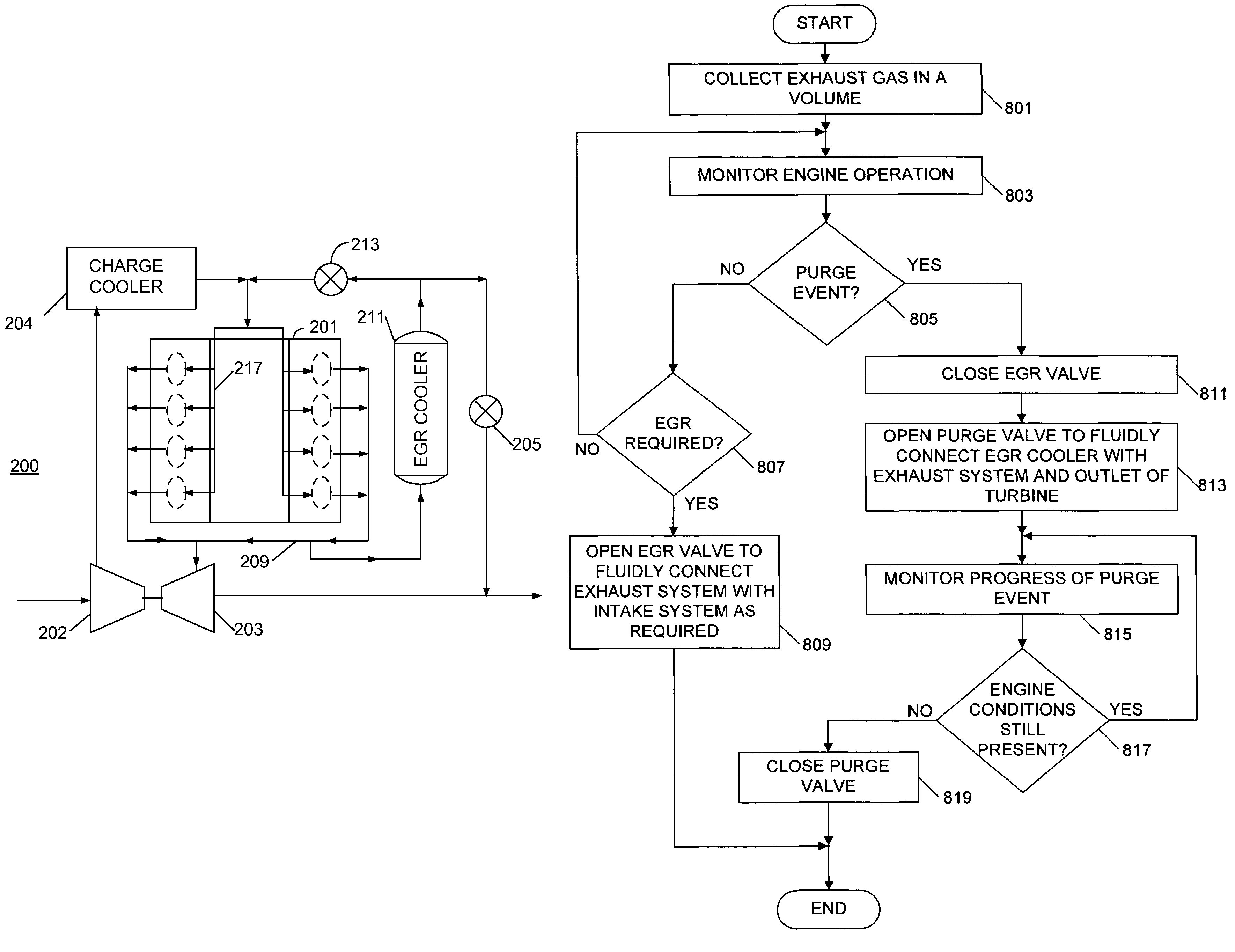

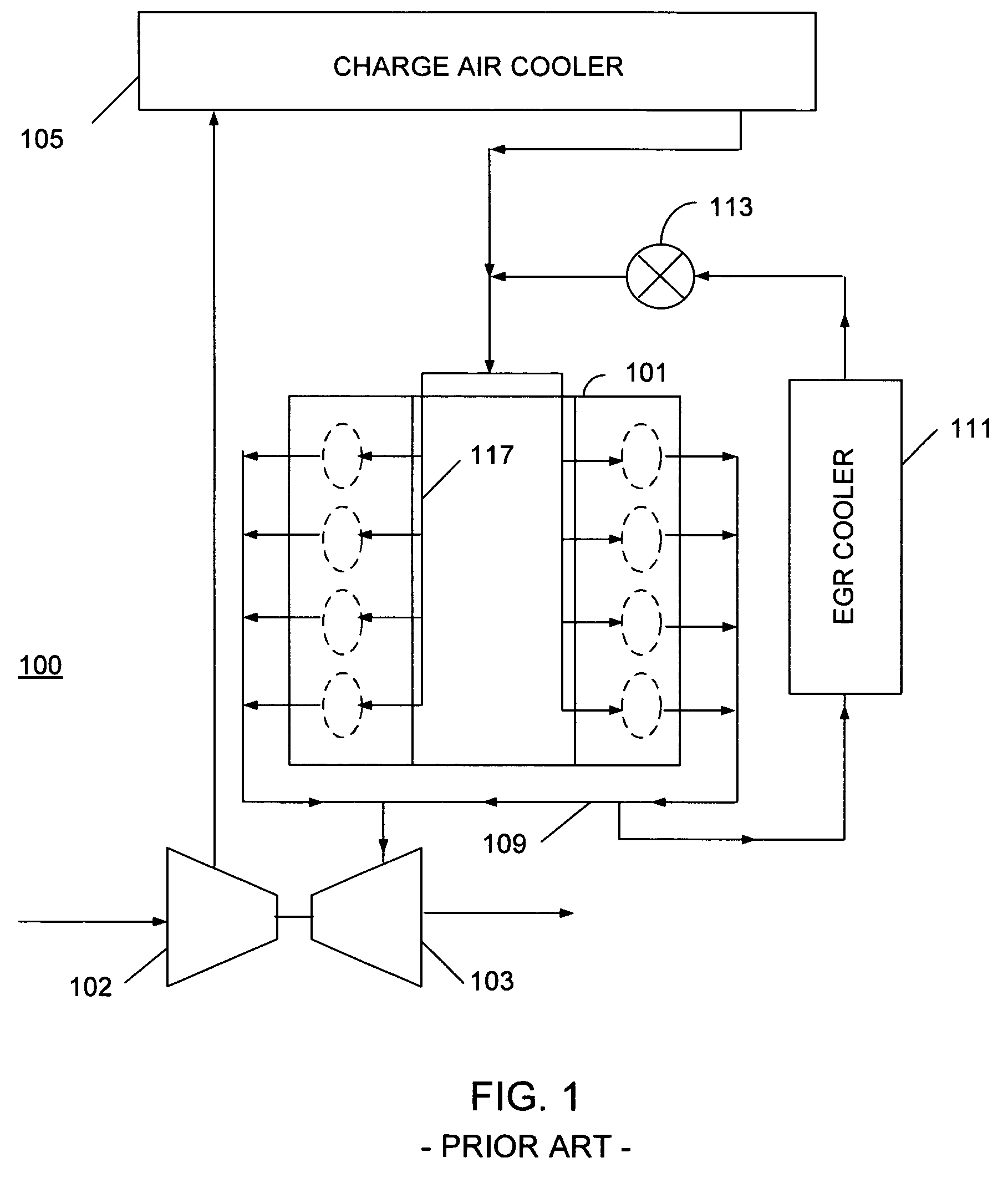

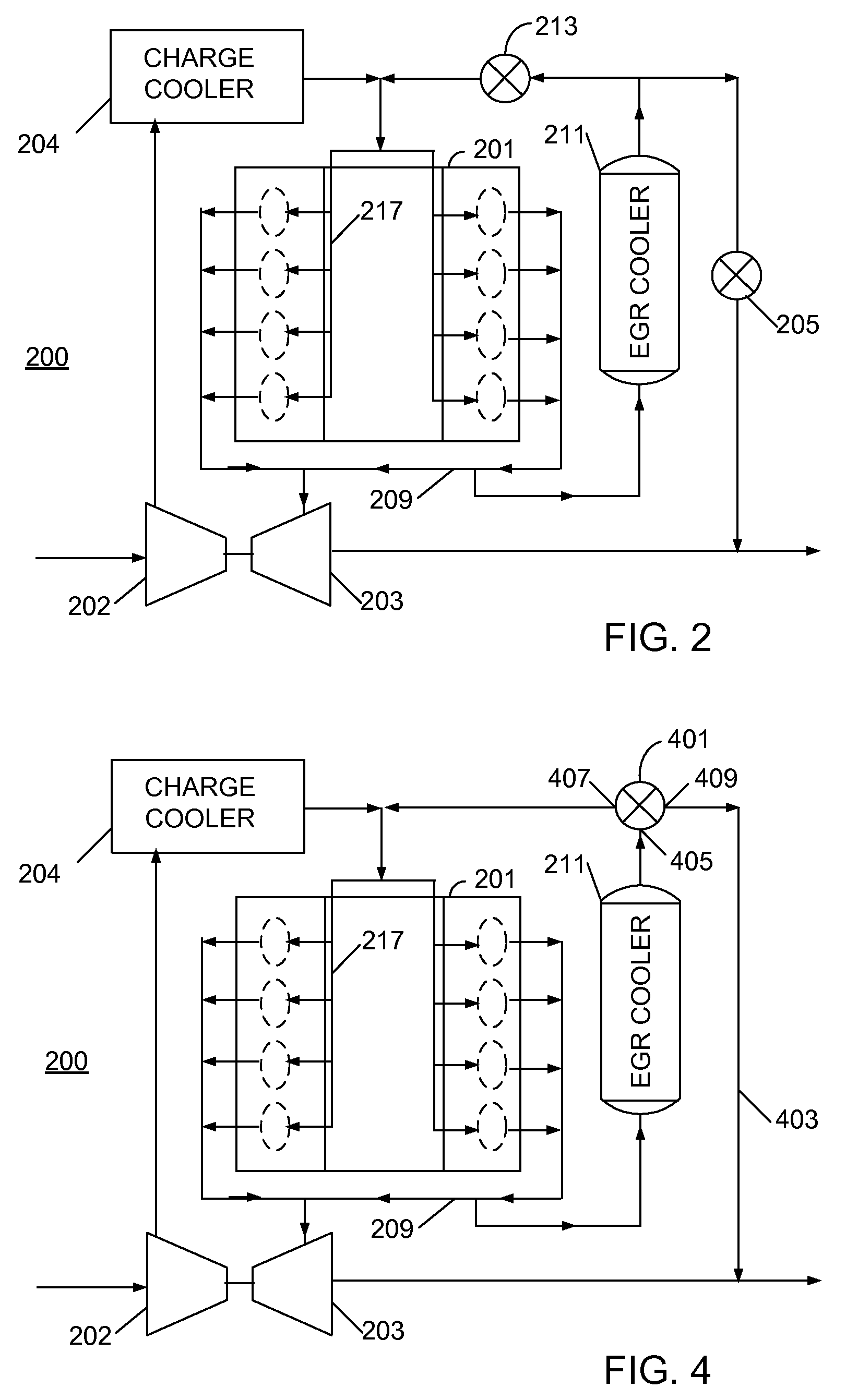

EGR cooler purging apparatus and method

Owner:INT ENGINE INTPROP CO LLC

Detonative cleaning apparatus

InactiveUS7011047B2Pulsating combustionHollow article cleaningCombustionDeflagration to detonation transition

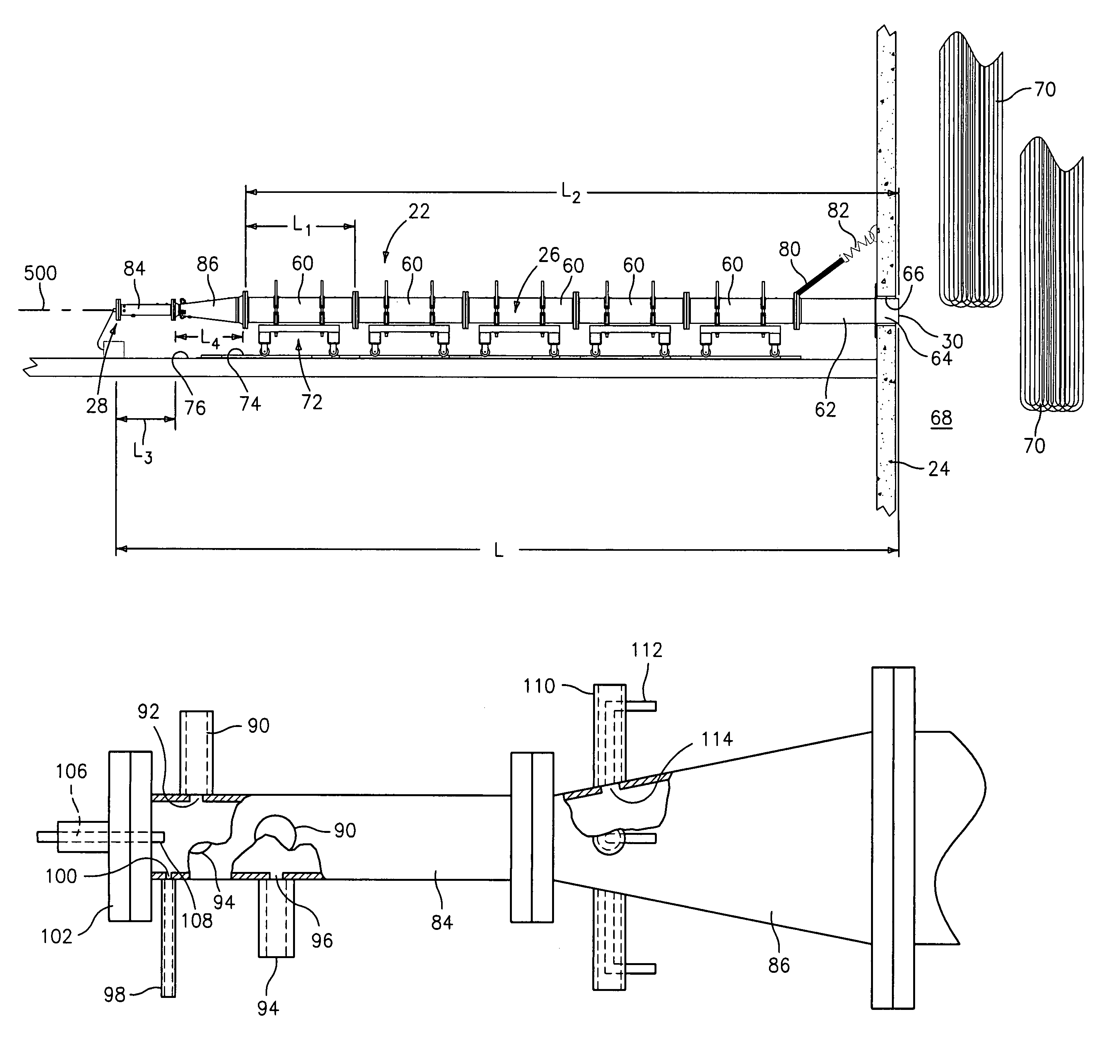

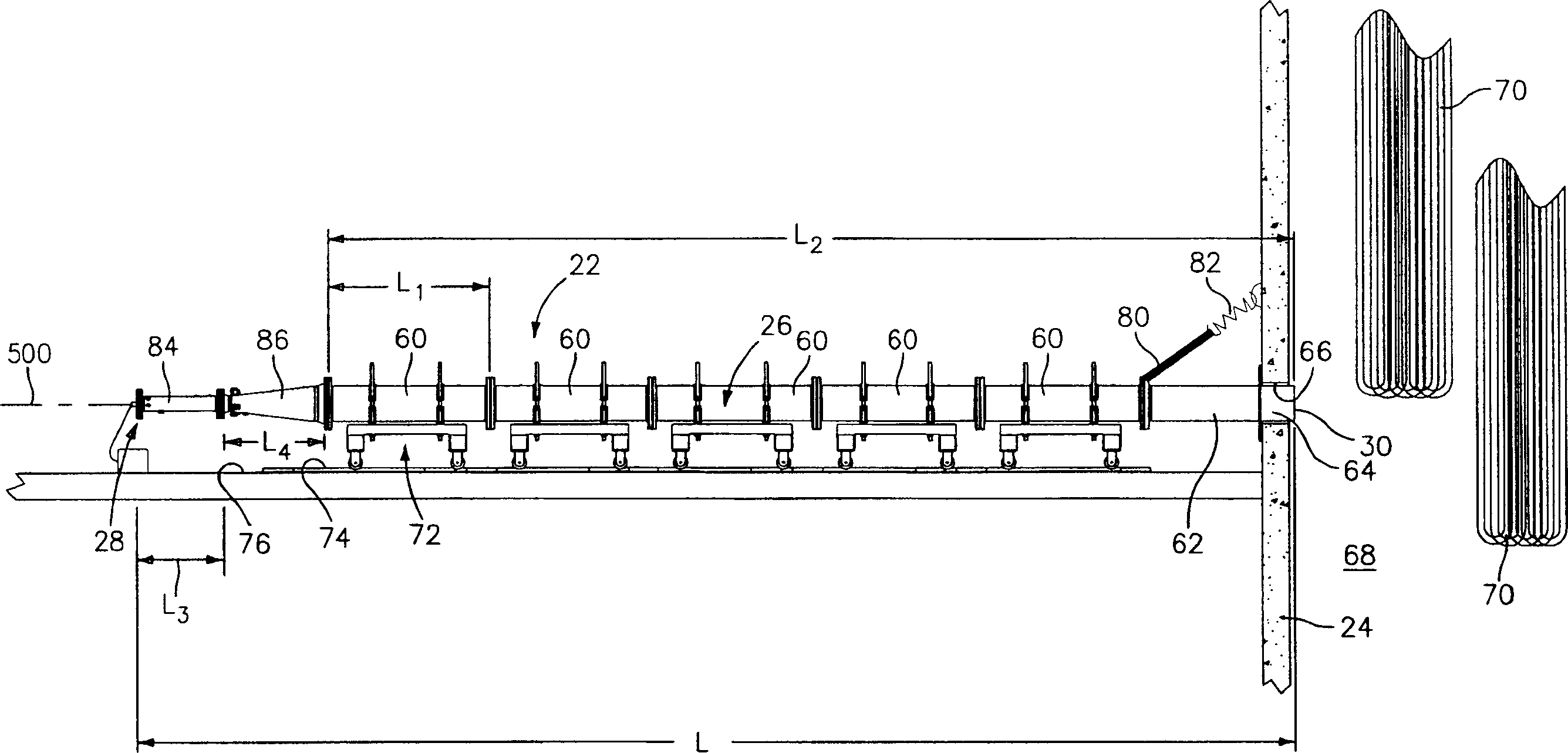

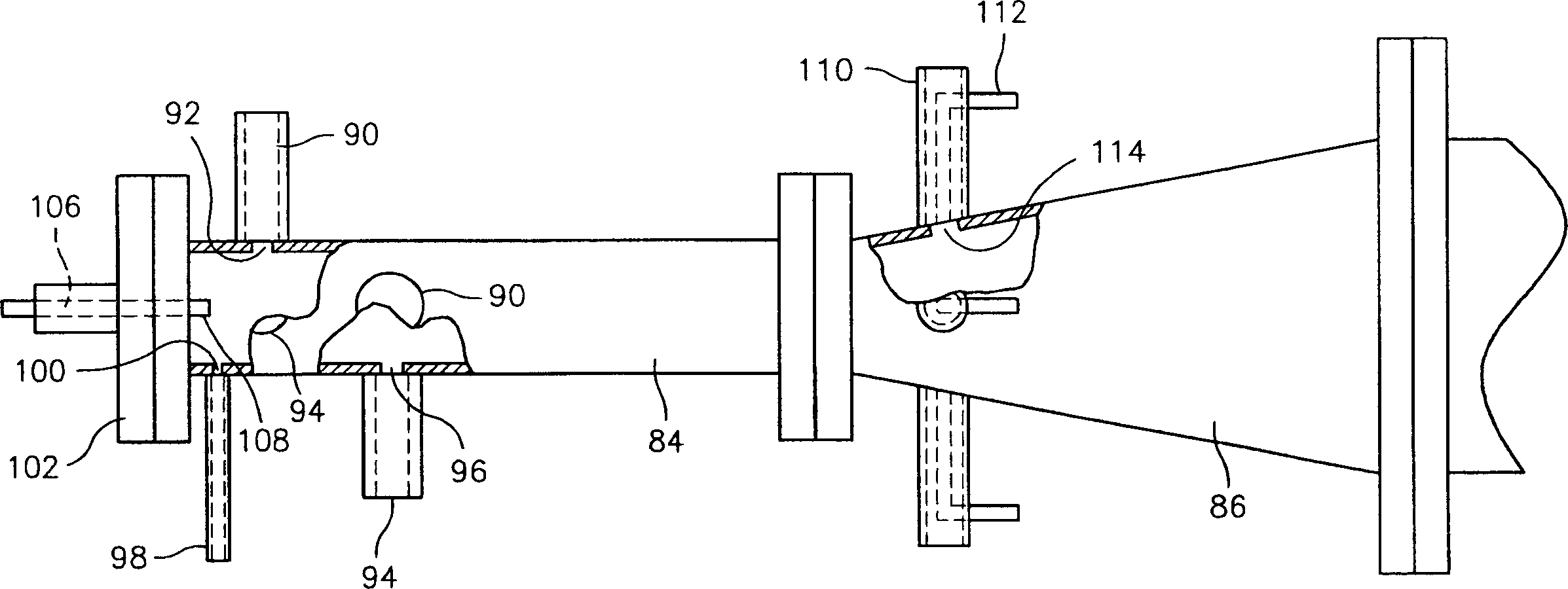

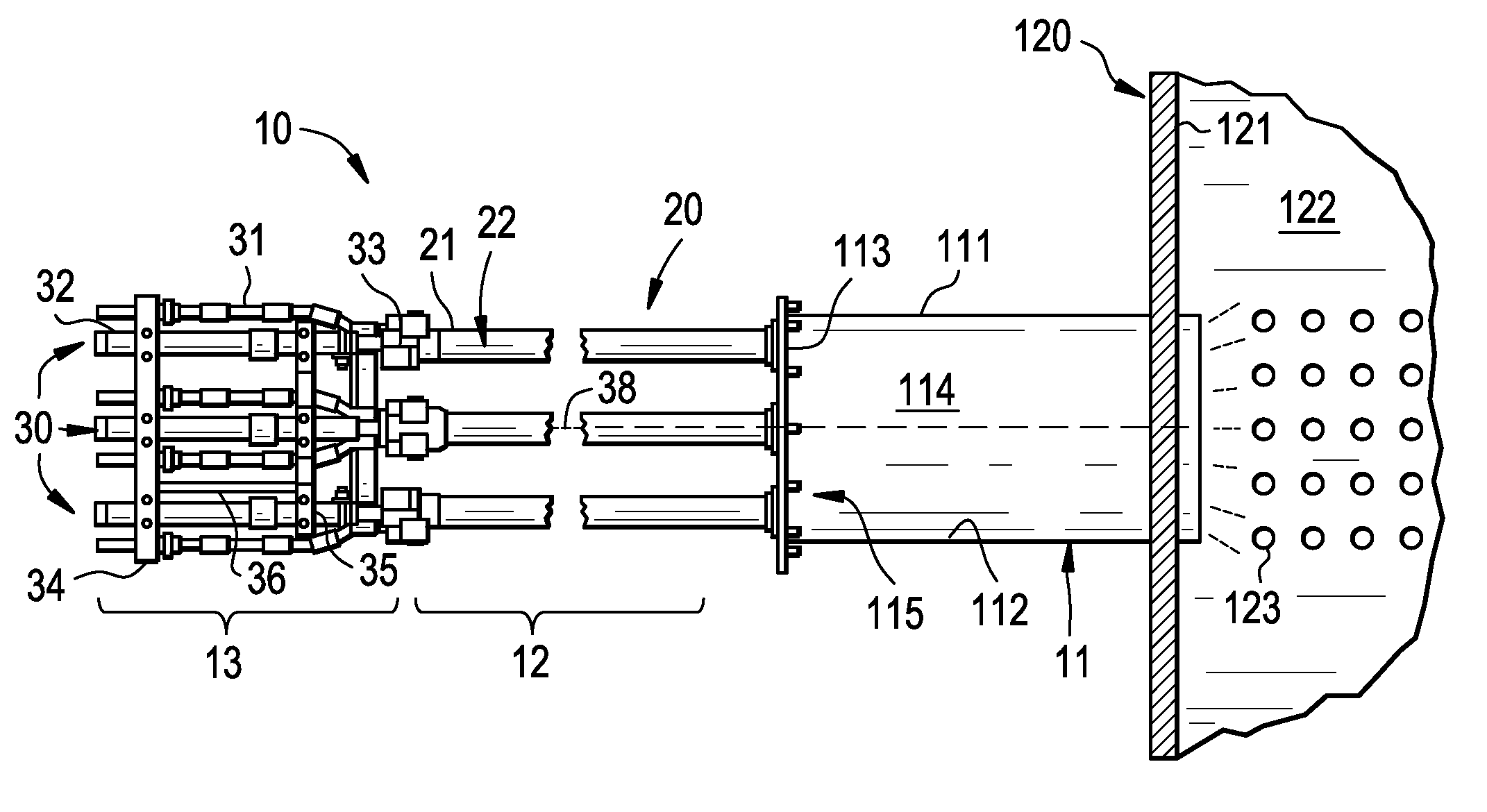

Methods and apparatus are provided for cleaning a surface within a vessel. A fuel / oxidizer charge is provided within a combustion conduit. An initial deflagration commenced in a first portion of the charge produces a final detonation at least in another portion of the charge to expel a shockwave from the conduit which impinges upon the surface. The deflagration-to-detonation transition may be encouraged by mechanical enhancements and / or by making the first charge portion more detonable than the second.

Owner:SHOCKSYST

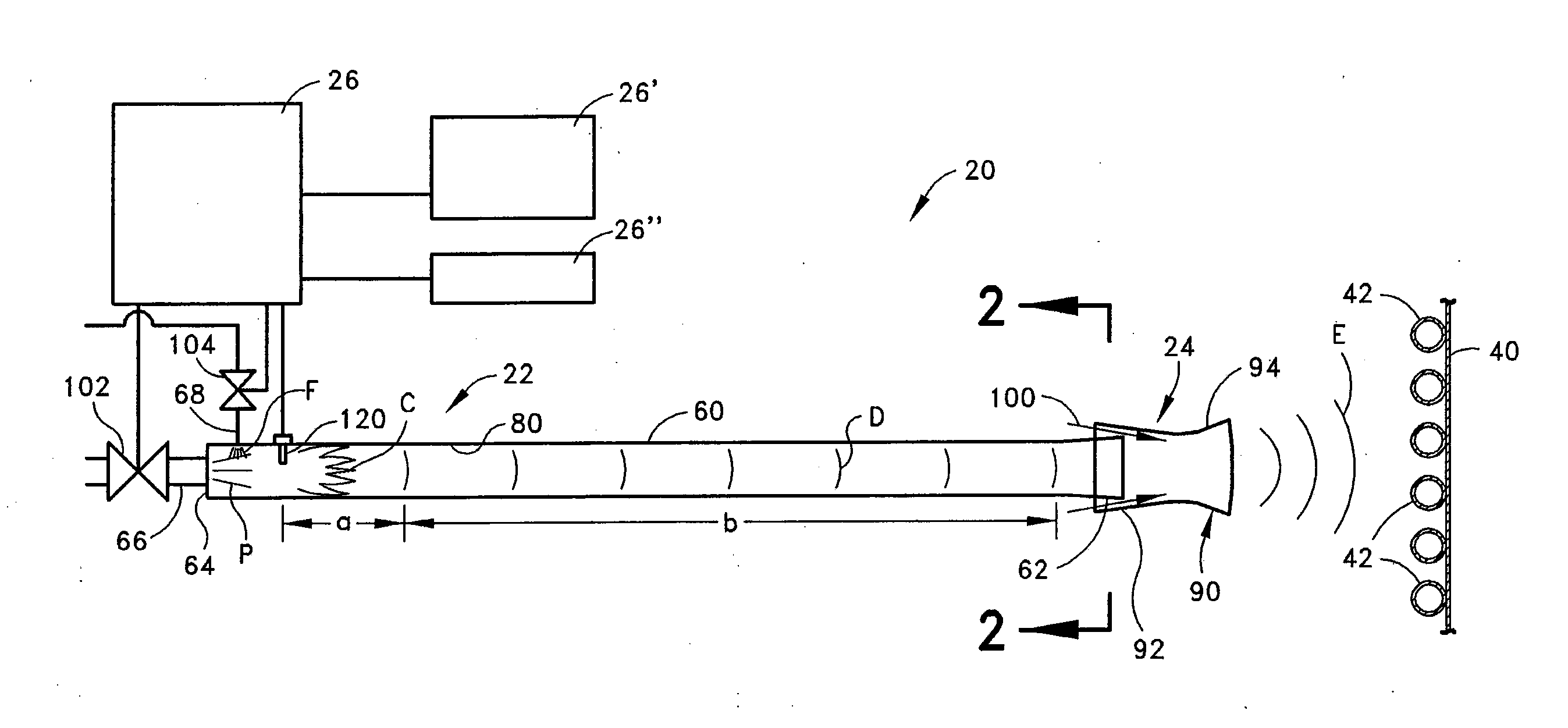

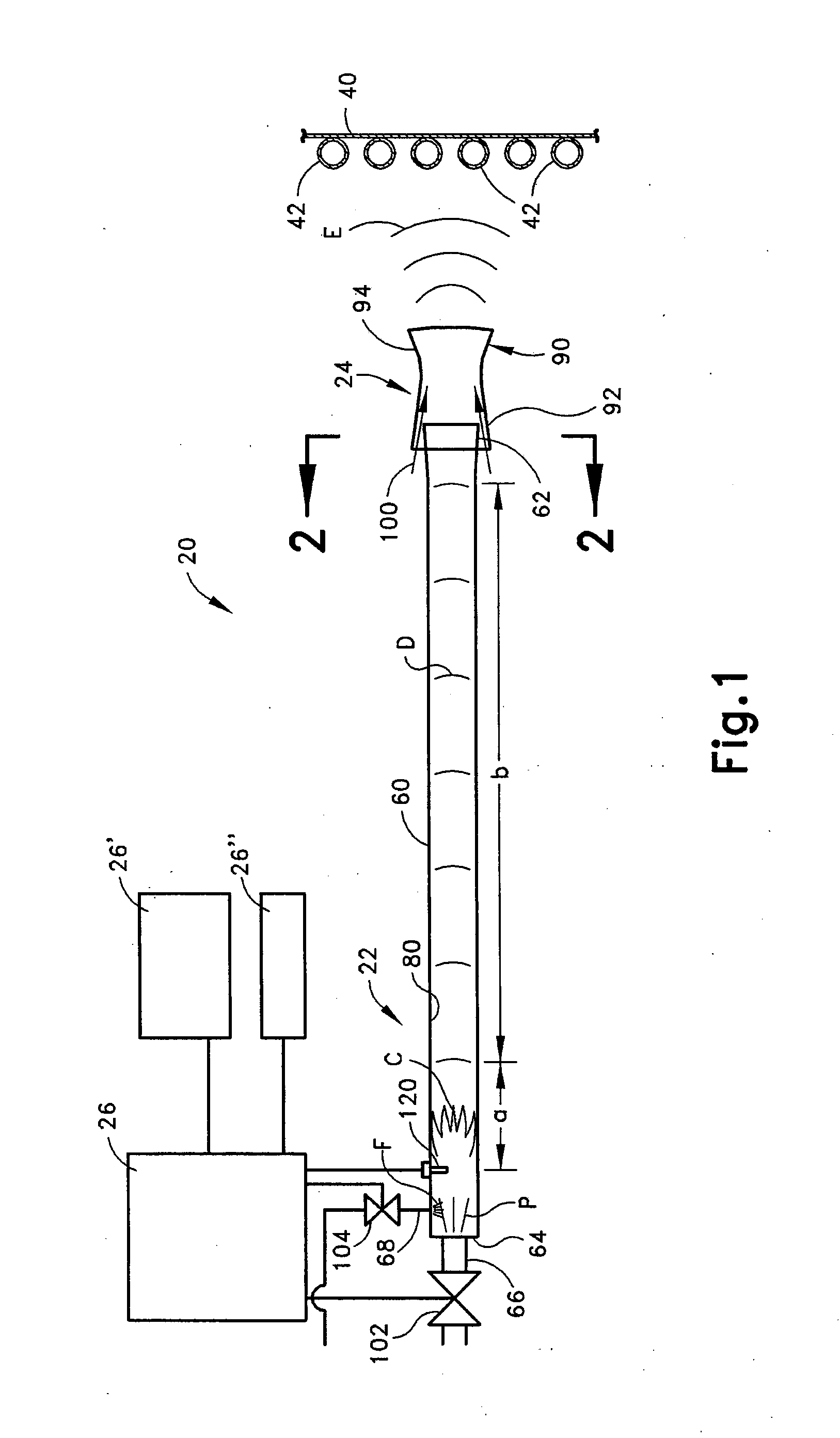

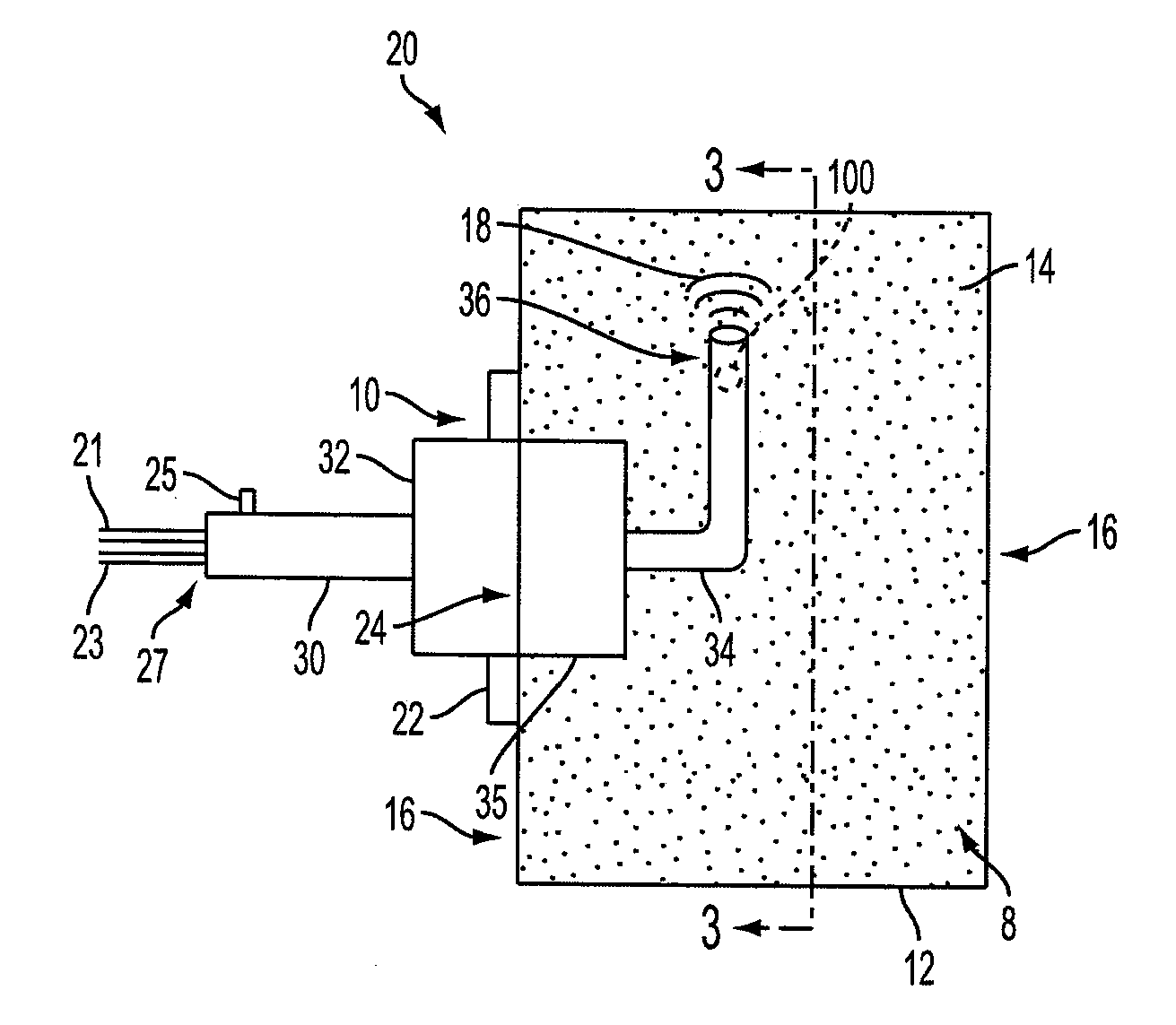

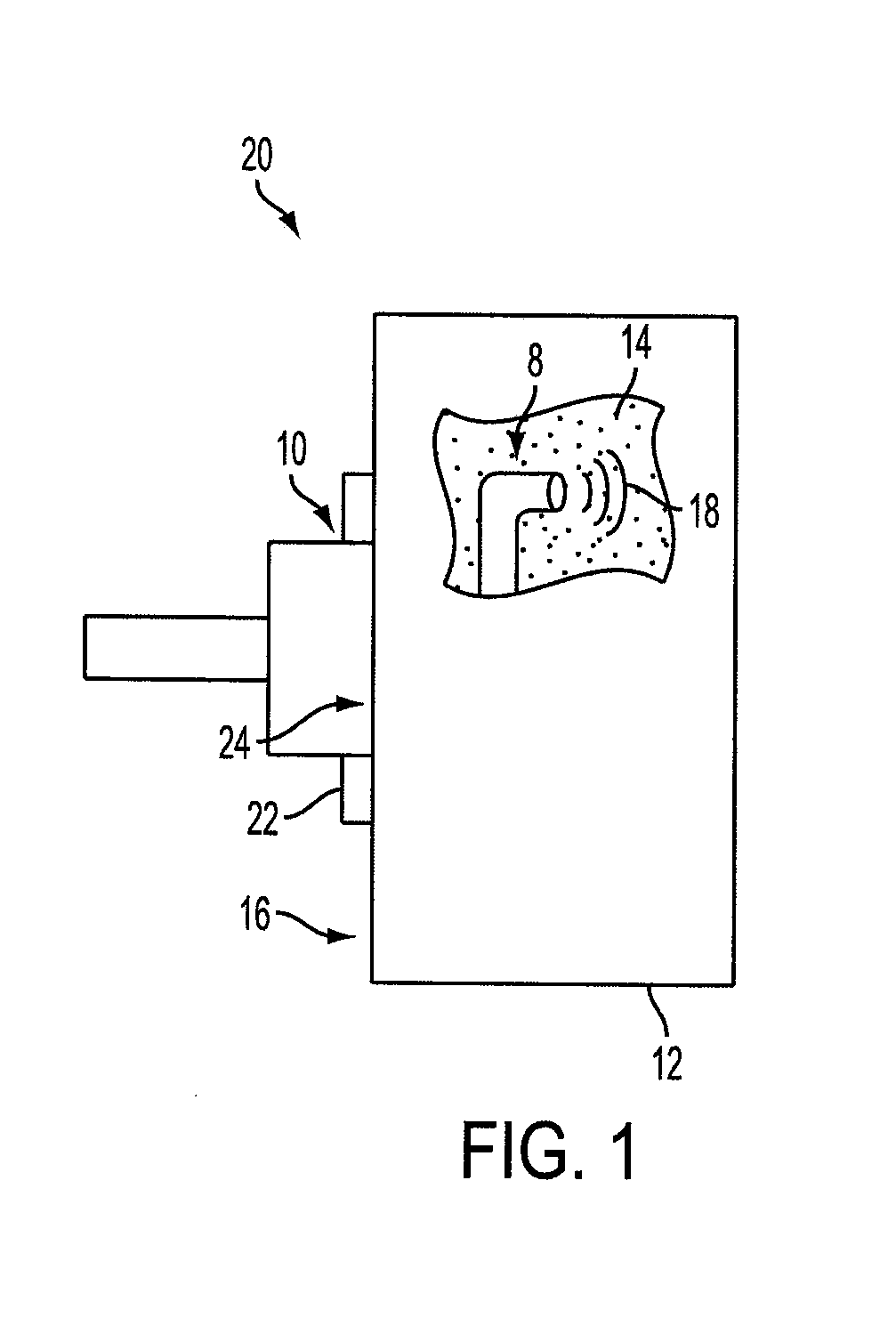

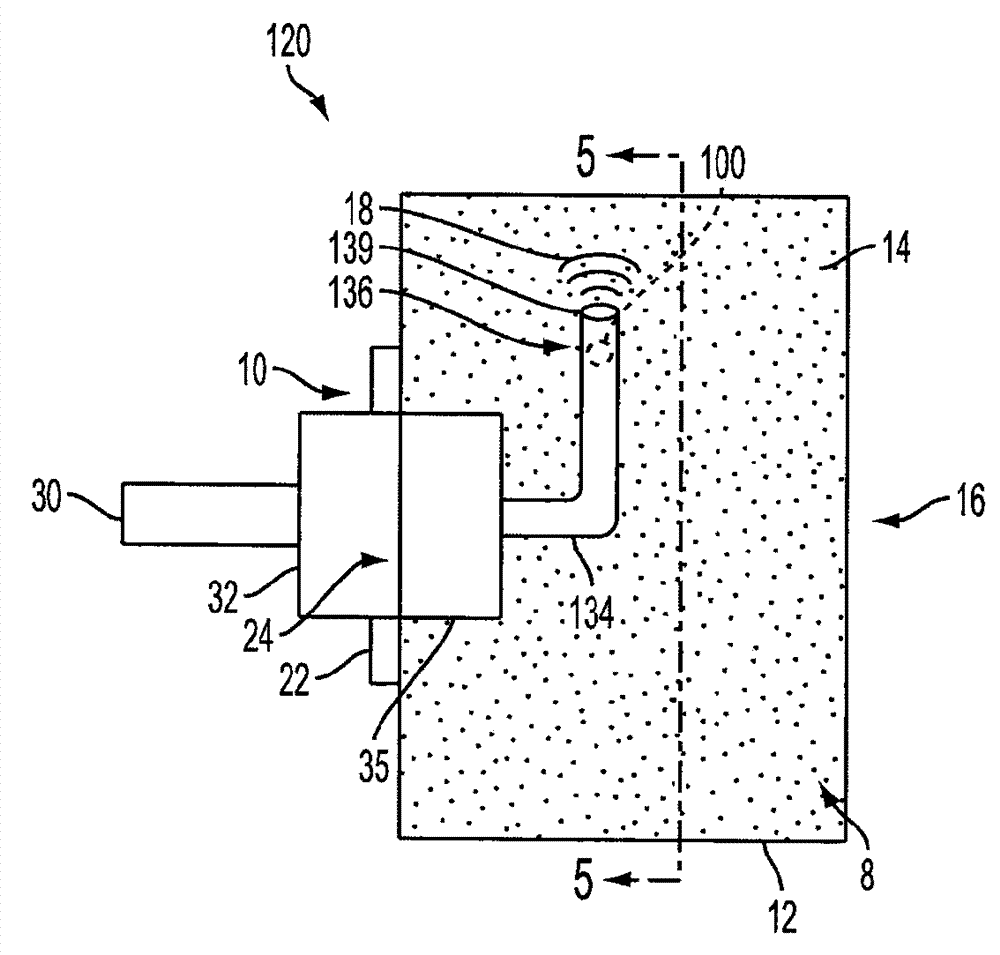

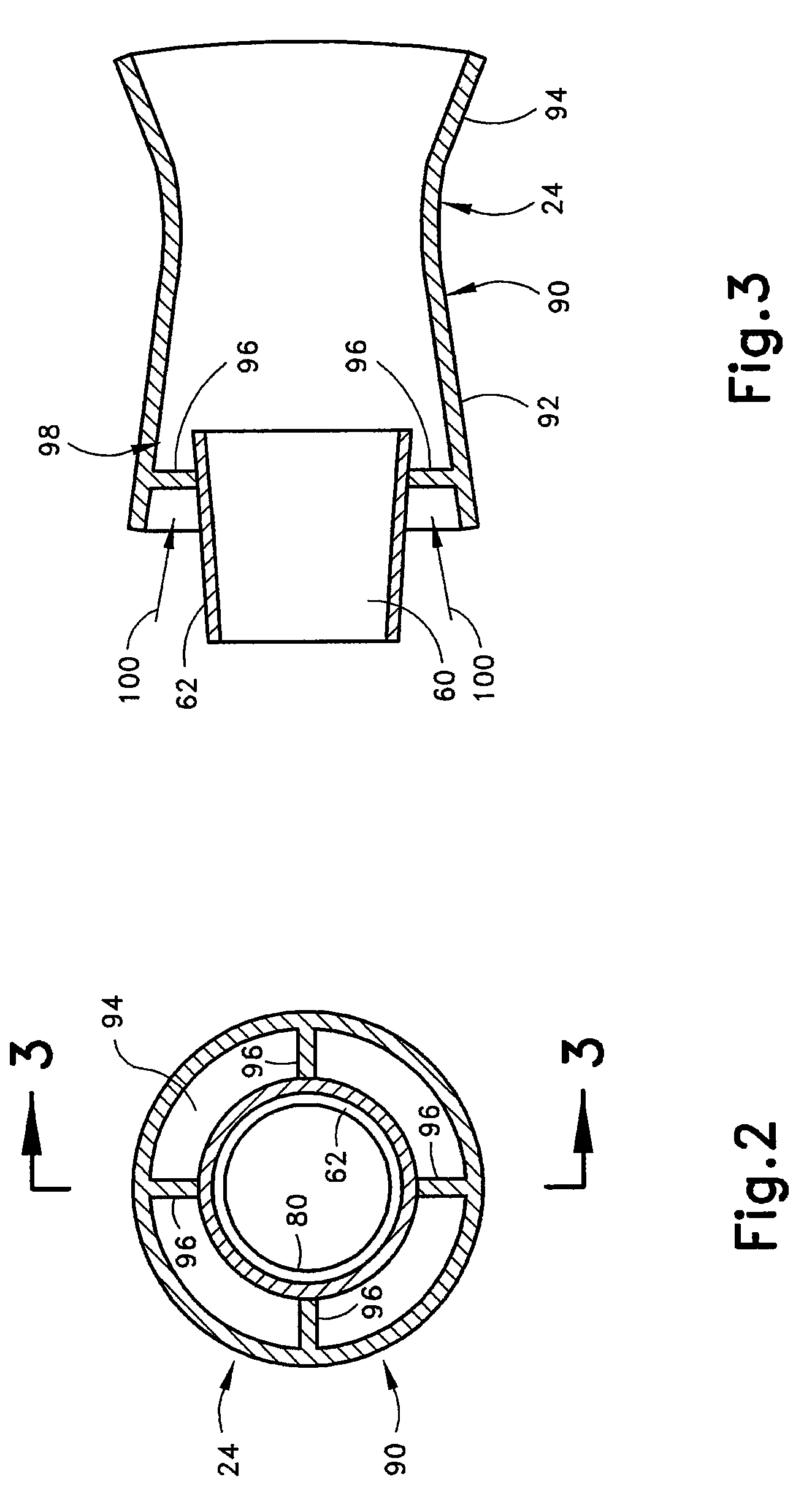

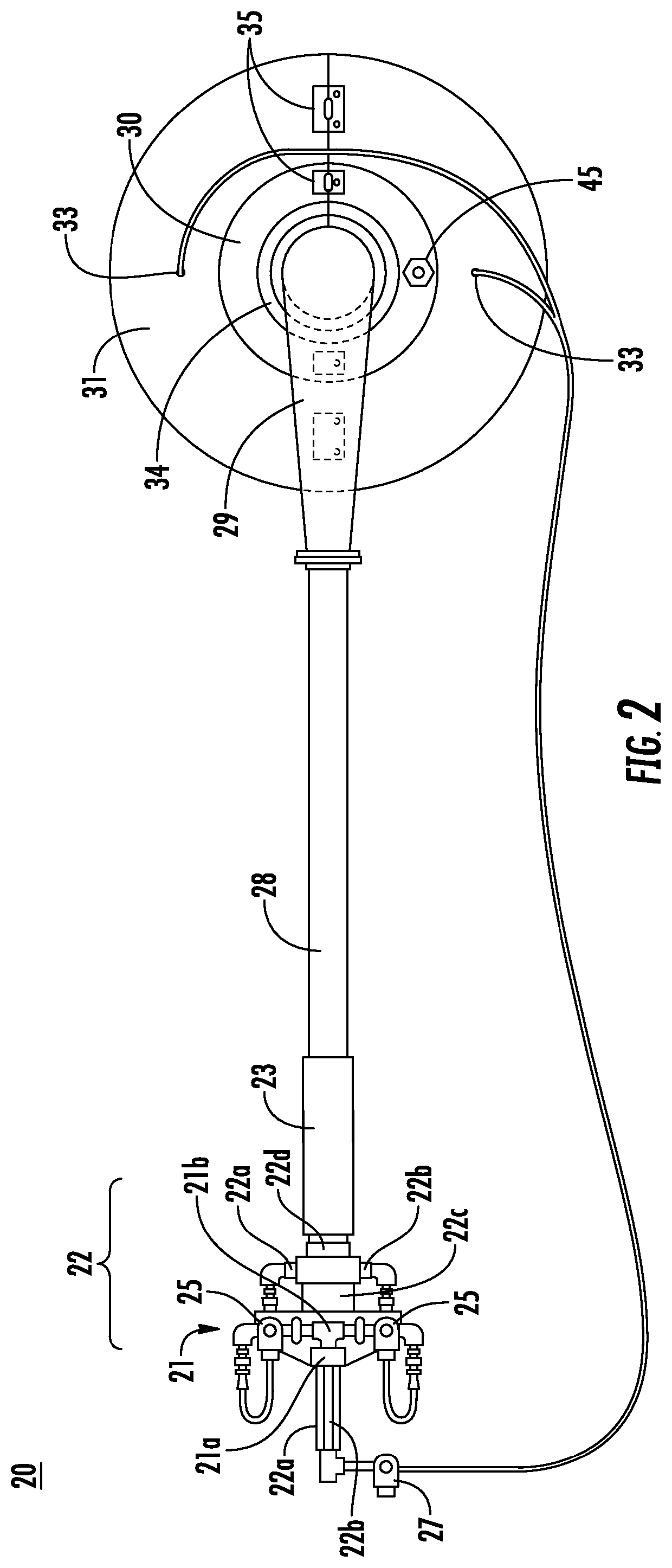

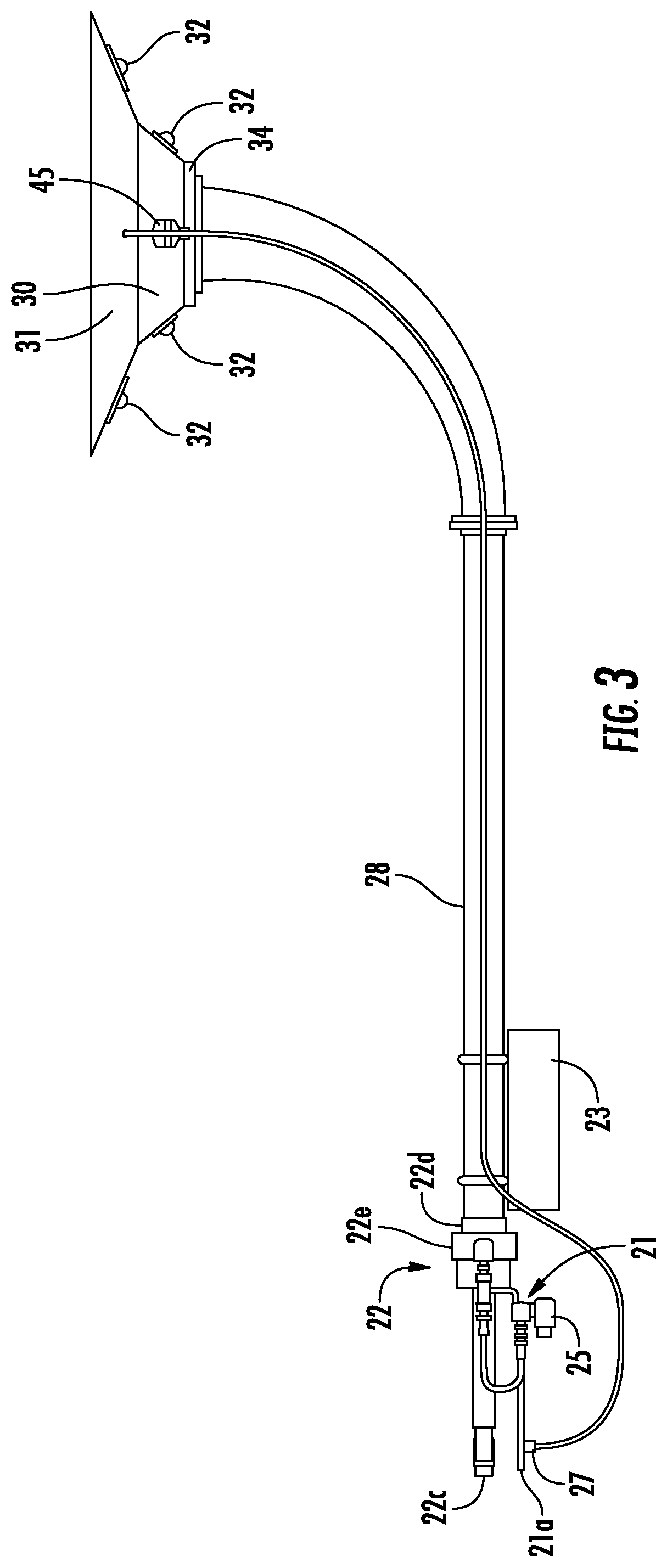

Device to improve effectiveness of pulse detonation cleaning

ActiveUS20110226284A1Increase heightEasy to cleanMechanical cleaningPressure cleaningCombustion chamberDetonation

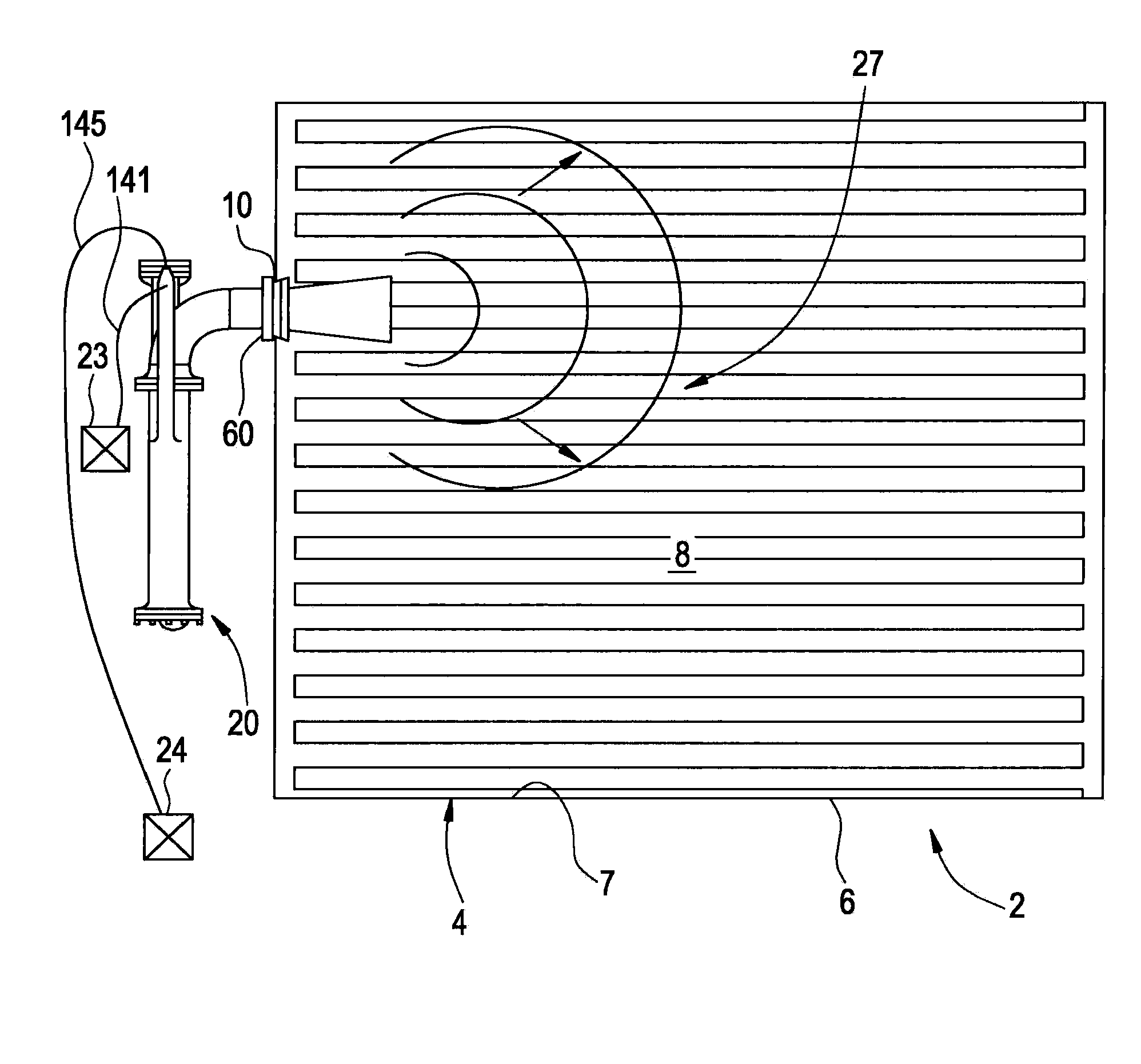

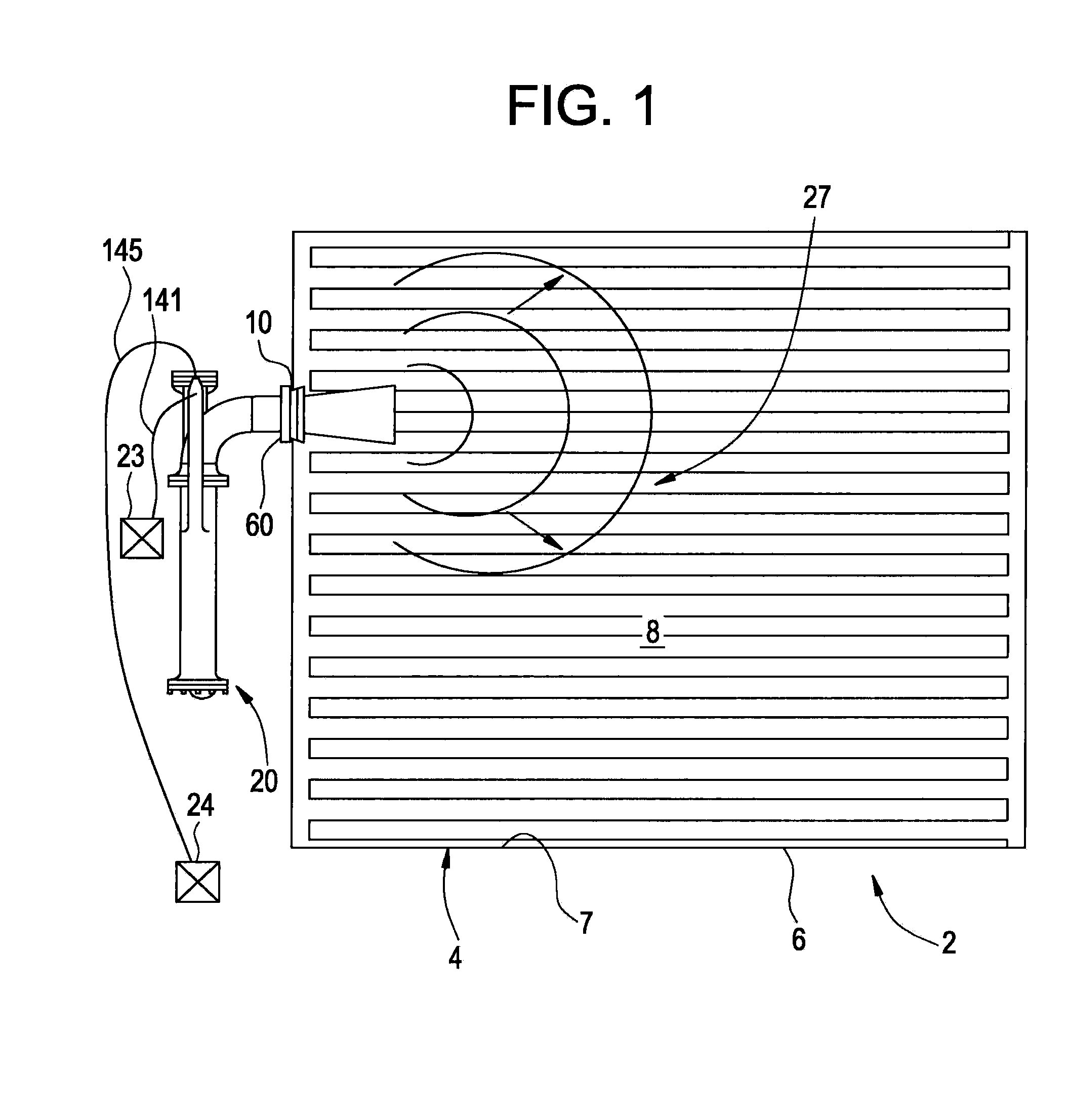

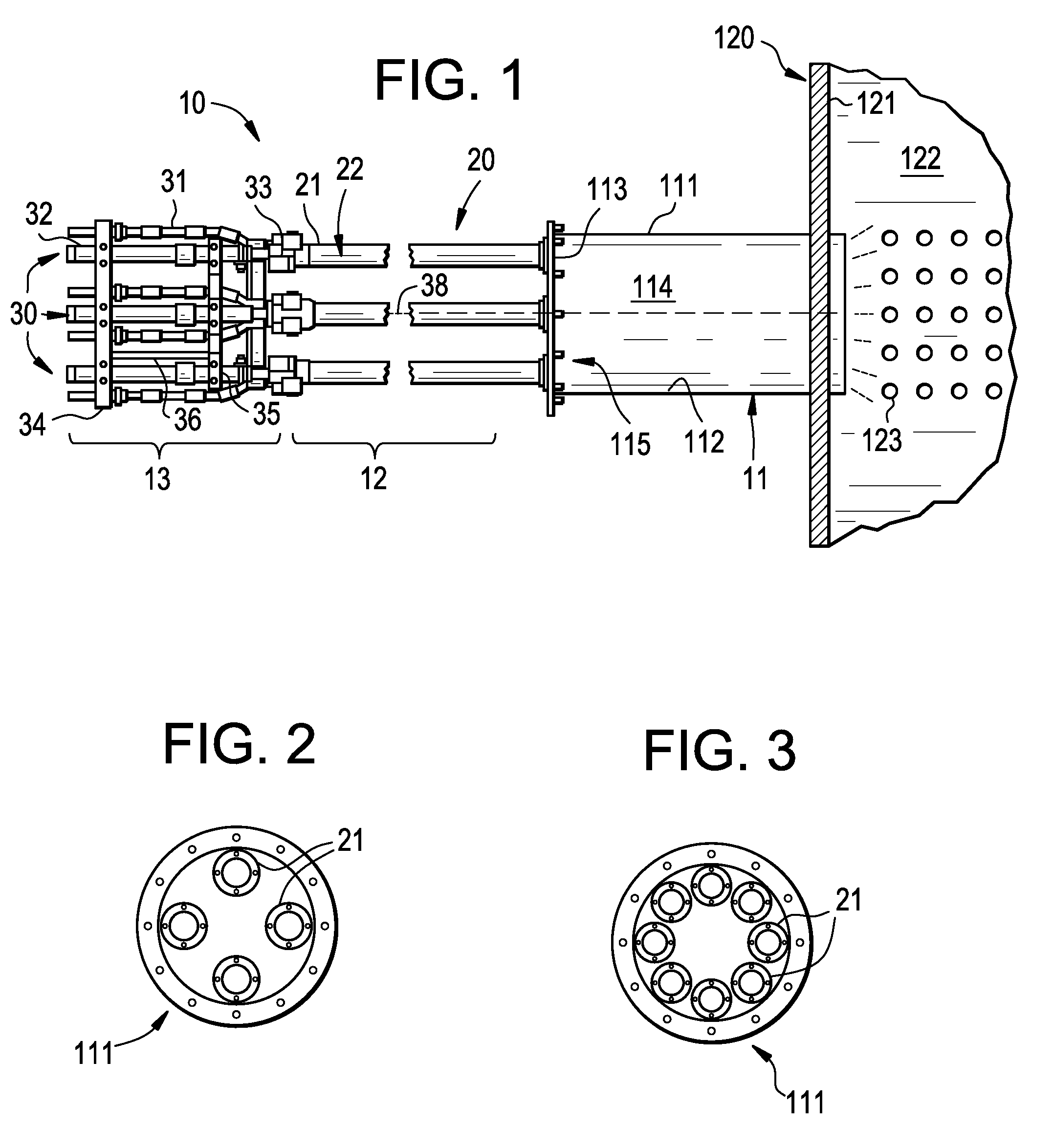

A system and associated method for removing accumulated debris from a surface of a vessel. The system includes an impulse cleaning device defining a combustion chamber in which combustible fuel and air are mixed and ignited to produce combustion that is directed at the surface to be cleaned within the vessel, and an eductor assembly surrounding a downstream end of the chamber for inducting surrounding atmosphere into the combustion to widen the area being cleaned.

Owner:BARRETO INVESTMENT GRP INC

Detonative cleaning apparatus

InactiveUS20050112516A1Pulsating combustionHollow article cleaningCombustionDeflagration to detonation transition

Methods and apparatus are provided for cleaning a surface within a vessel. A fuel / oxidizer charge is provided within a combustion conduit. An initial deflagration commenced in a first portion of the charge produces a final detonation at least in another portion of the charge to expel a shockwave from the conduit which impinges upon the surface. The deflagration-to-detonation transition may be encouraged by mechanical enhancements and / or by making the first charge portion more detonable than the second.

Owner:SHOCKSYST

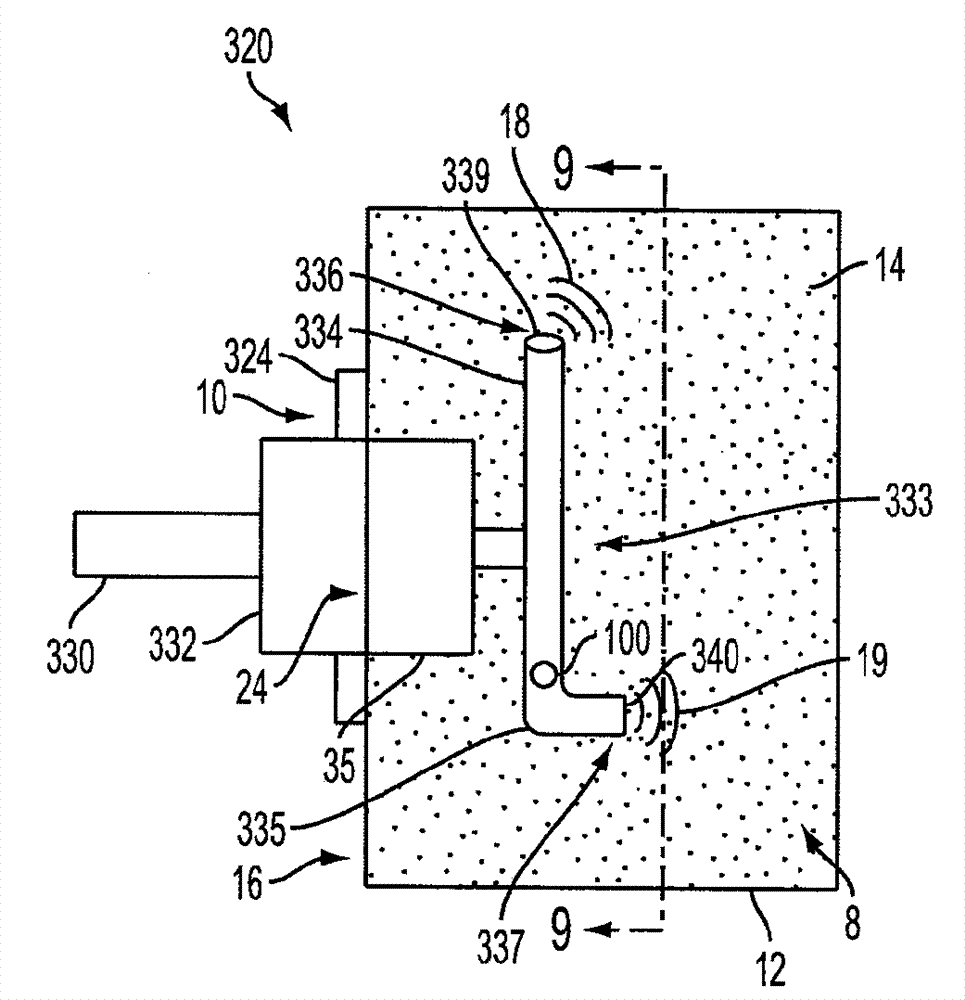

Detonation Combustor Cleaning Device and Method of Cleaning a Vessel with a Detonation Combustor Cleaning Device

A detonation combustor cleaning device includes at least one combustion chamber having combustion flow path and including a deflection member. An ignition device is operatively connected to the at least one combustion chamber is selectively activated to ignite a combustible fuel within the at least one combustion chamber to produce a shockwave that moves in a first direction along the combustion flow path, impacts the deflection member, reverses direction and passes into a vessel to dislodge particles clinging to inner surfaces thereof.

Owner:BARRETO INVESTMENT GRP INC

Soot blower access apparatus

An apparatus for providing detonative cleaning through a vessel wall has a first conduit extending through the wall. A first valve has an open condition permitting communication through the first conduit and a closed condition. A second conduit has an insertion portion dimensioned to be received within a receiving portion of the first conduit. A second valve has an open condition permitting communication through the second conduit and a closed condition.

Owner:SHOCKSYST

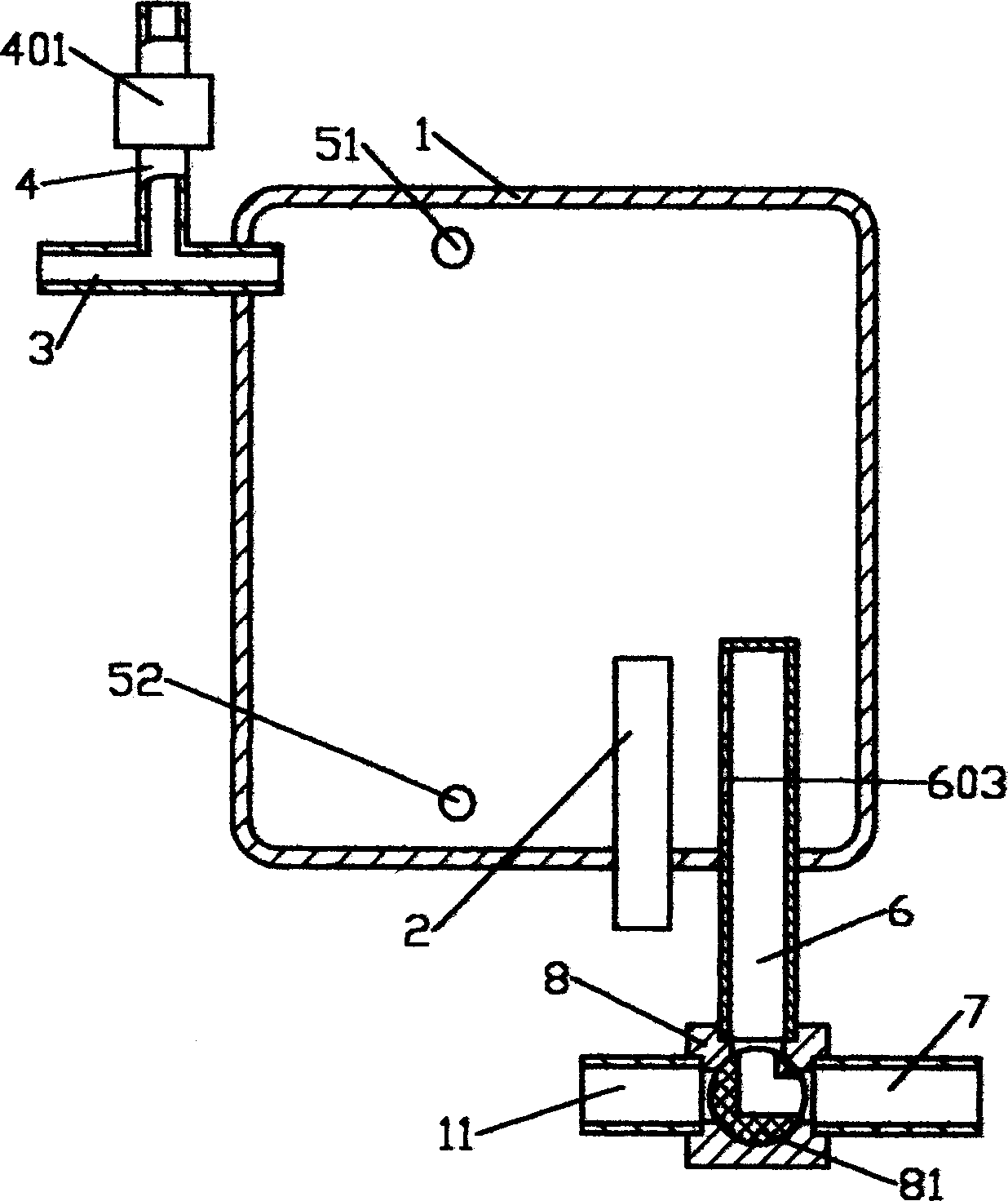

Automatic scale cleaning method for electric heating tube in electric water heater

InactiveCN1458491AExtended service lifeGuaranteed heat exchange efficiencyDistortion cleaningCombustion cleaningInlet valveEngineering

The automatic descaling method for electric heating tube in electric water heater features that descaling condition is set in the controller, and when the condition is fulfilled the controller completes the following steps: draining water from the electric water heater to expose the electric heating tube in air; powering the electric heating tube instantaneously to raise the temperature of the scale on the surface of the electric heating tube; opening the water inlet valve to make cold water shower to the scale; shutting down the power source to make the electric water heater return to ready state after the water level raises to certain value.

Owner:麦广树

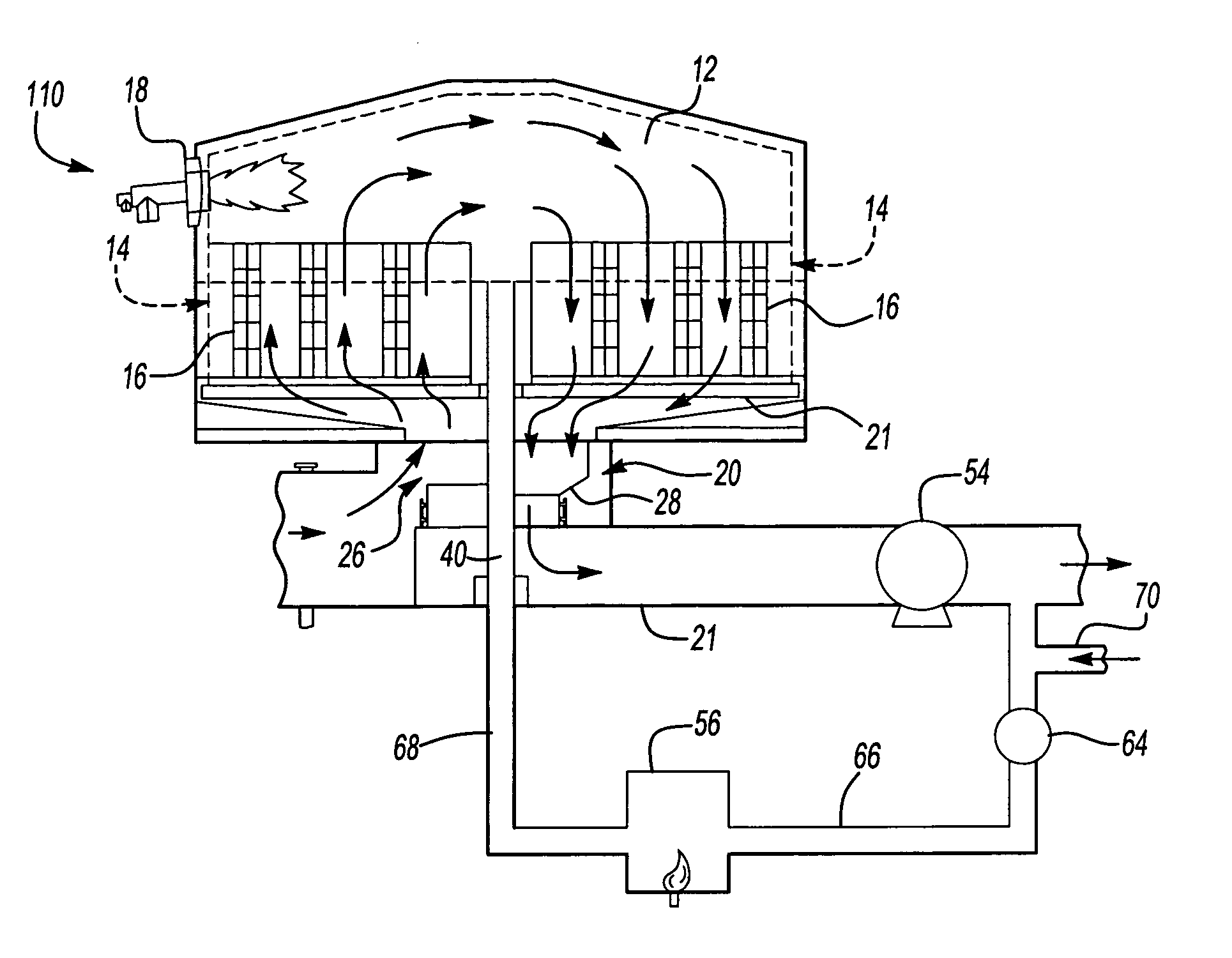

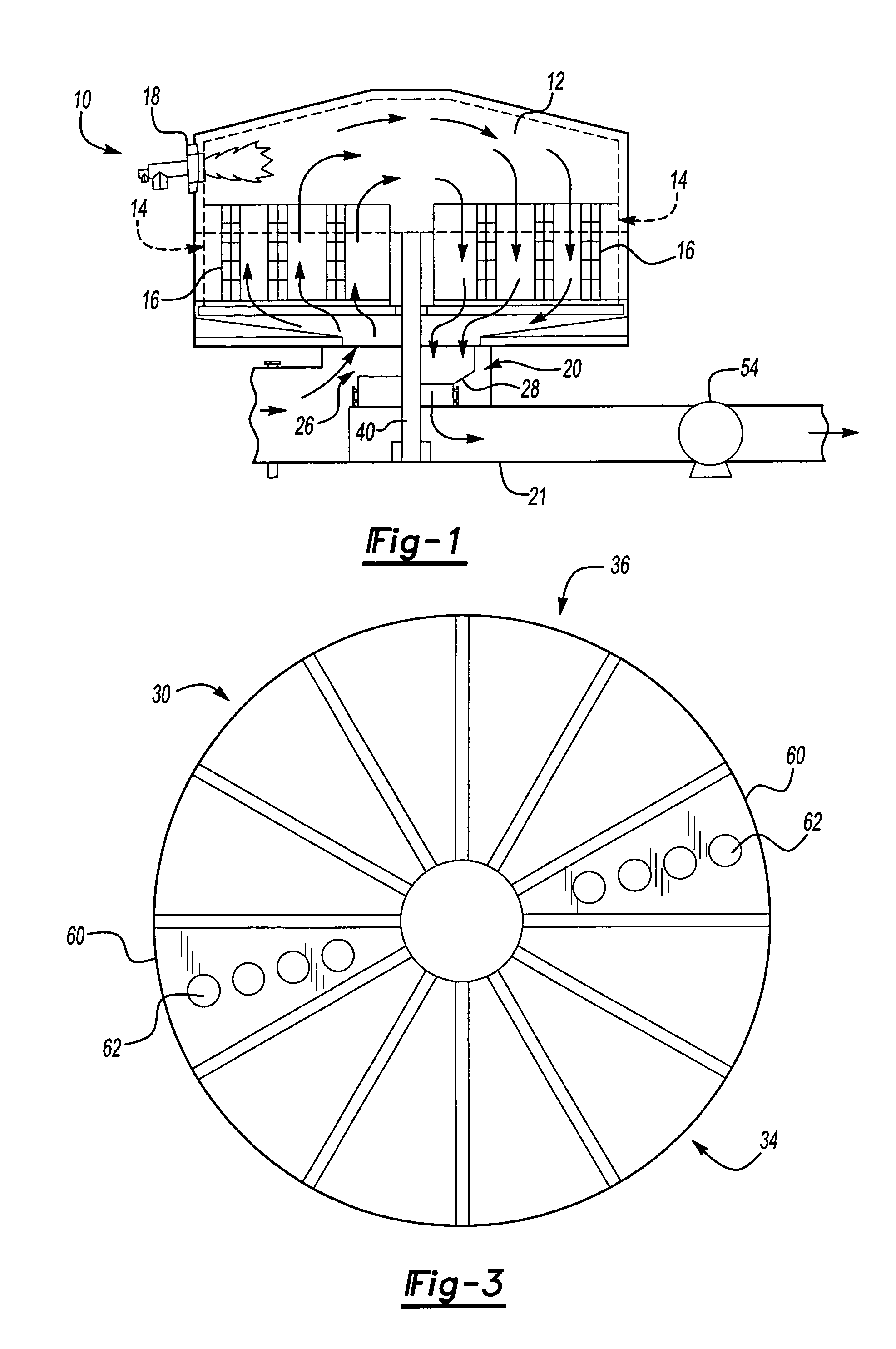

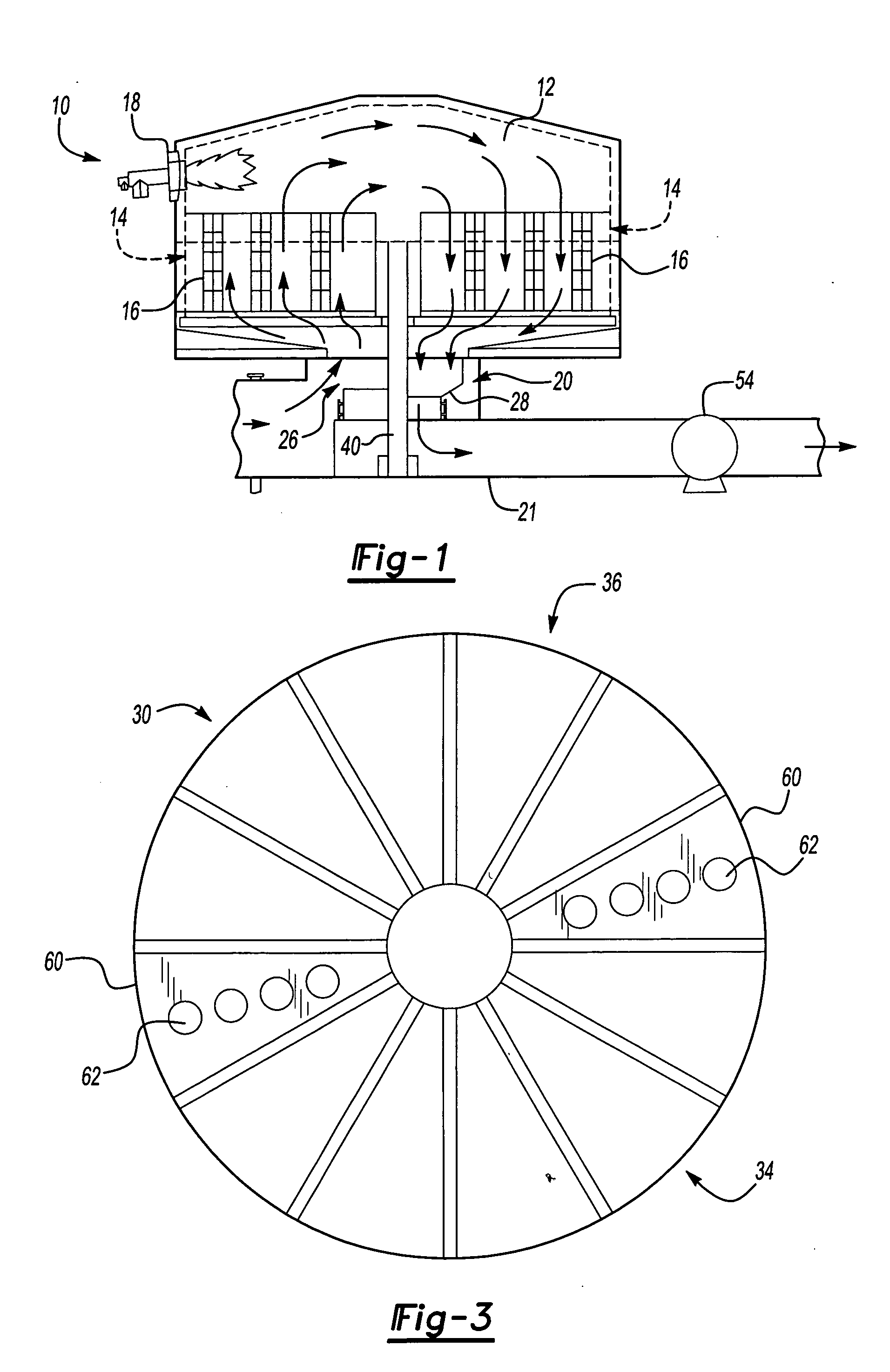

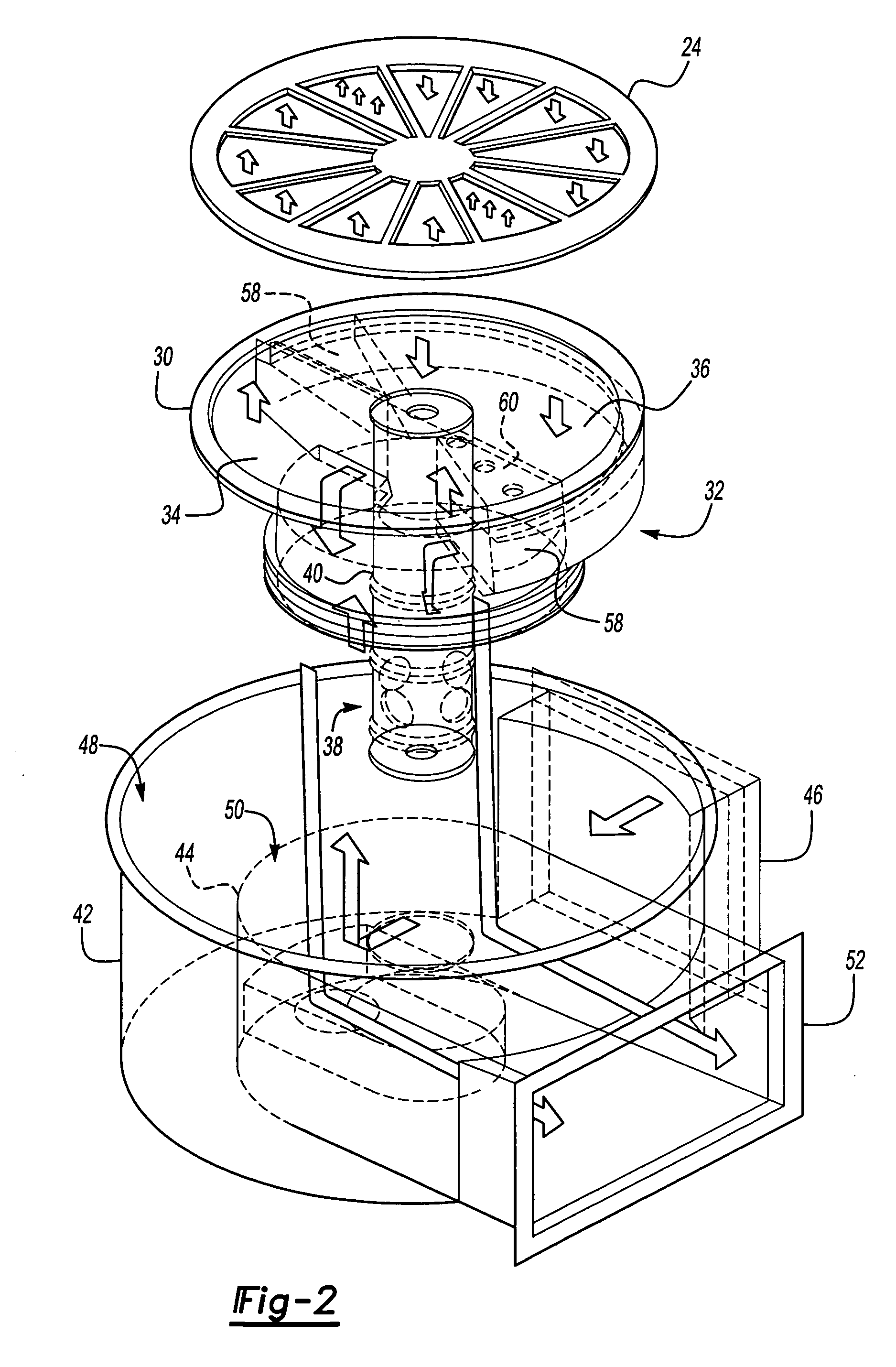

Online bakeout of regenerative oxidizers

ActiveUS6974318B2Improve destruction efficiencyReduce baking timeFuel additivesCombustion cleaningRotary valveEngineering

A method of burning off accumulated contaminants from heat sink media of a regenerative oxidizer having a plurality of segments containing media arranged around a central axis and a rotary valve which includes repeatedly rotating the rotary valve 180 degrees to alternatively direct waste gas through a first plurality of segments, direct the hot gas through a second plurality of segments and purge gas through a third segment to burn off the contaminants, then indexing the rotary valve one segment and repeating the burn-off process of all segments.

Owner:DURR SYST INC

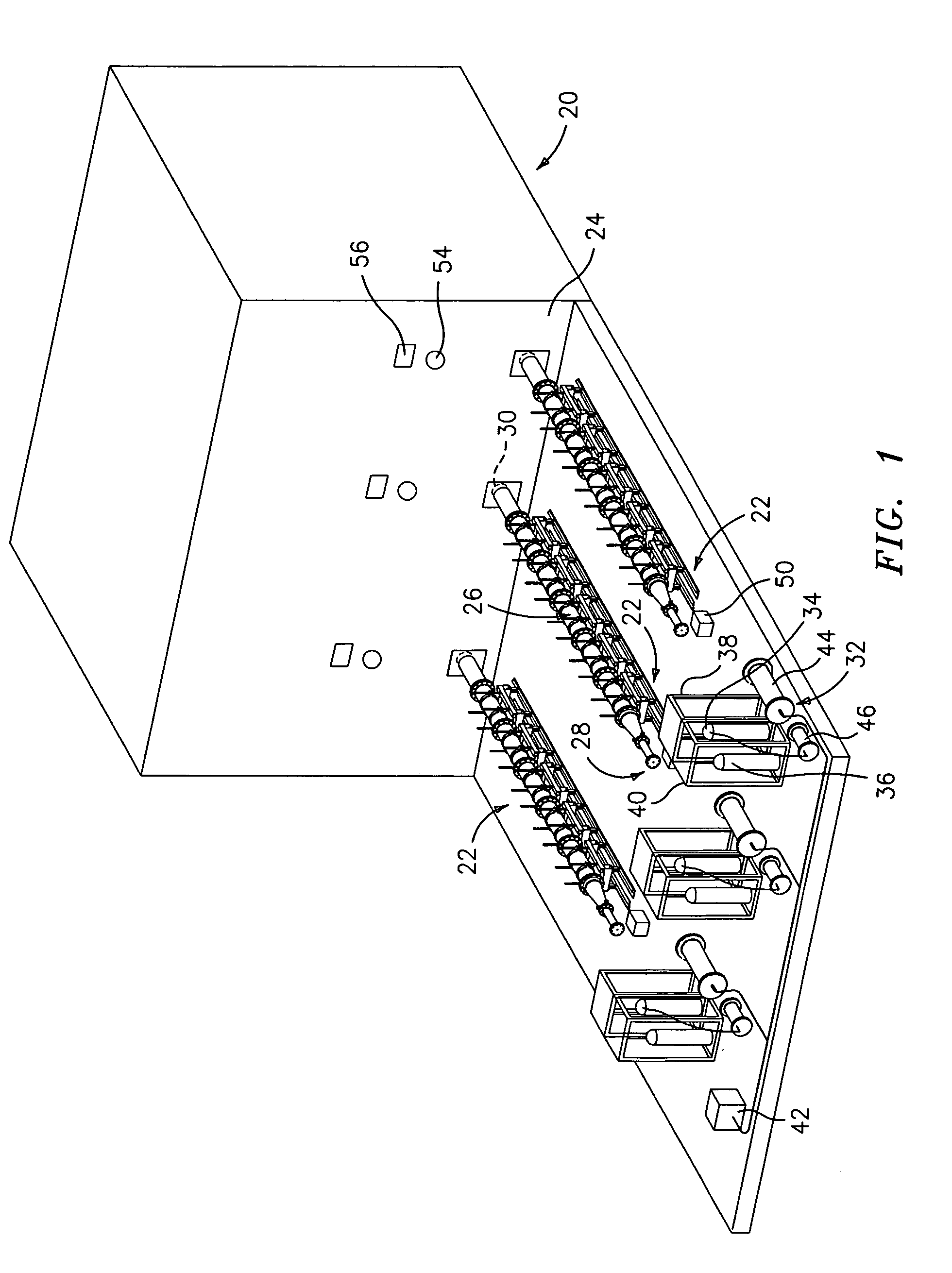

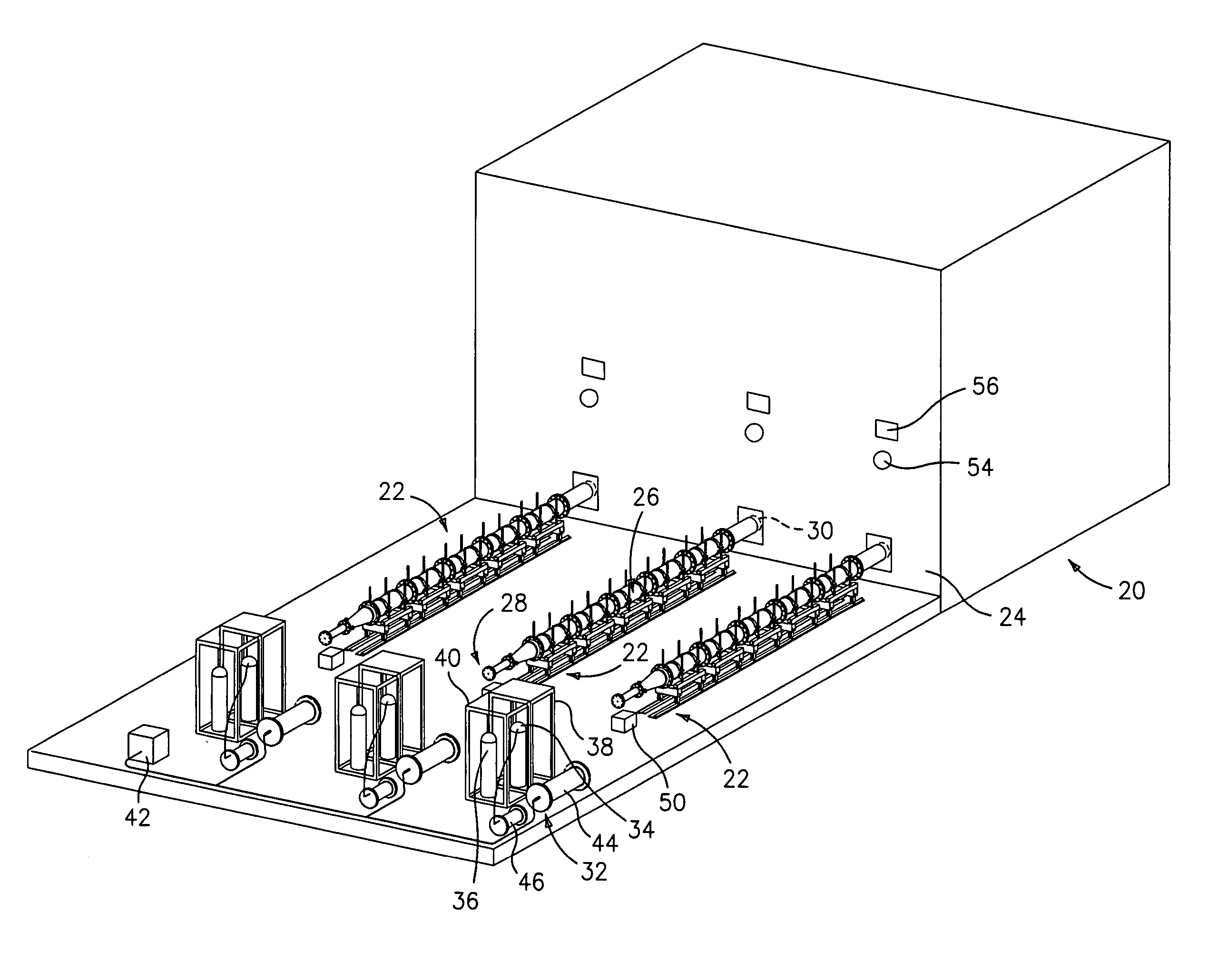

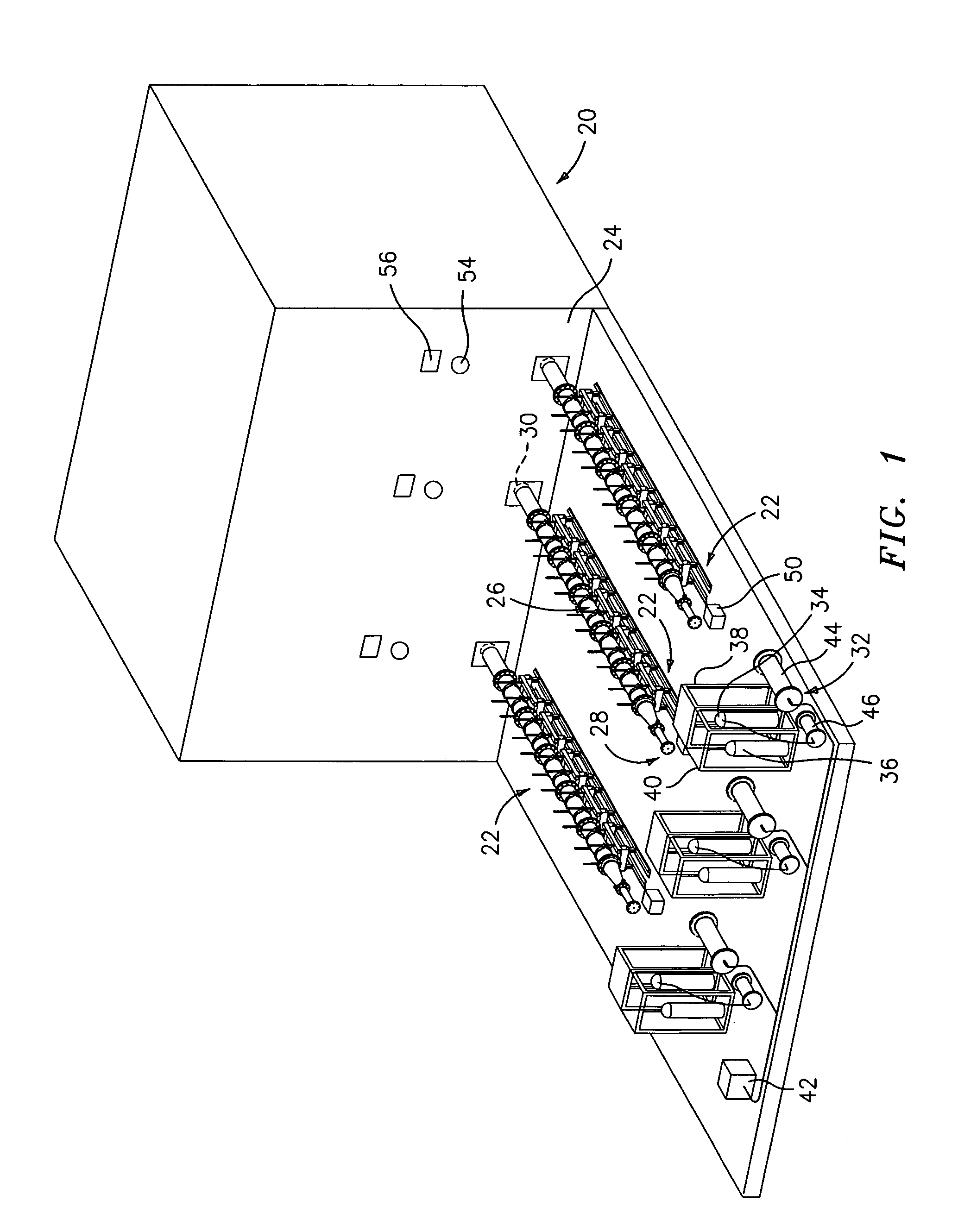

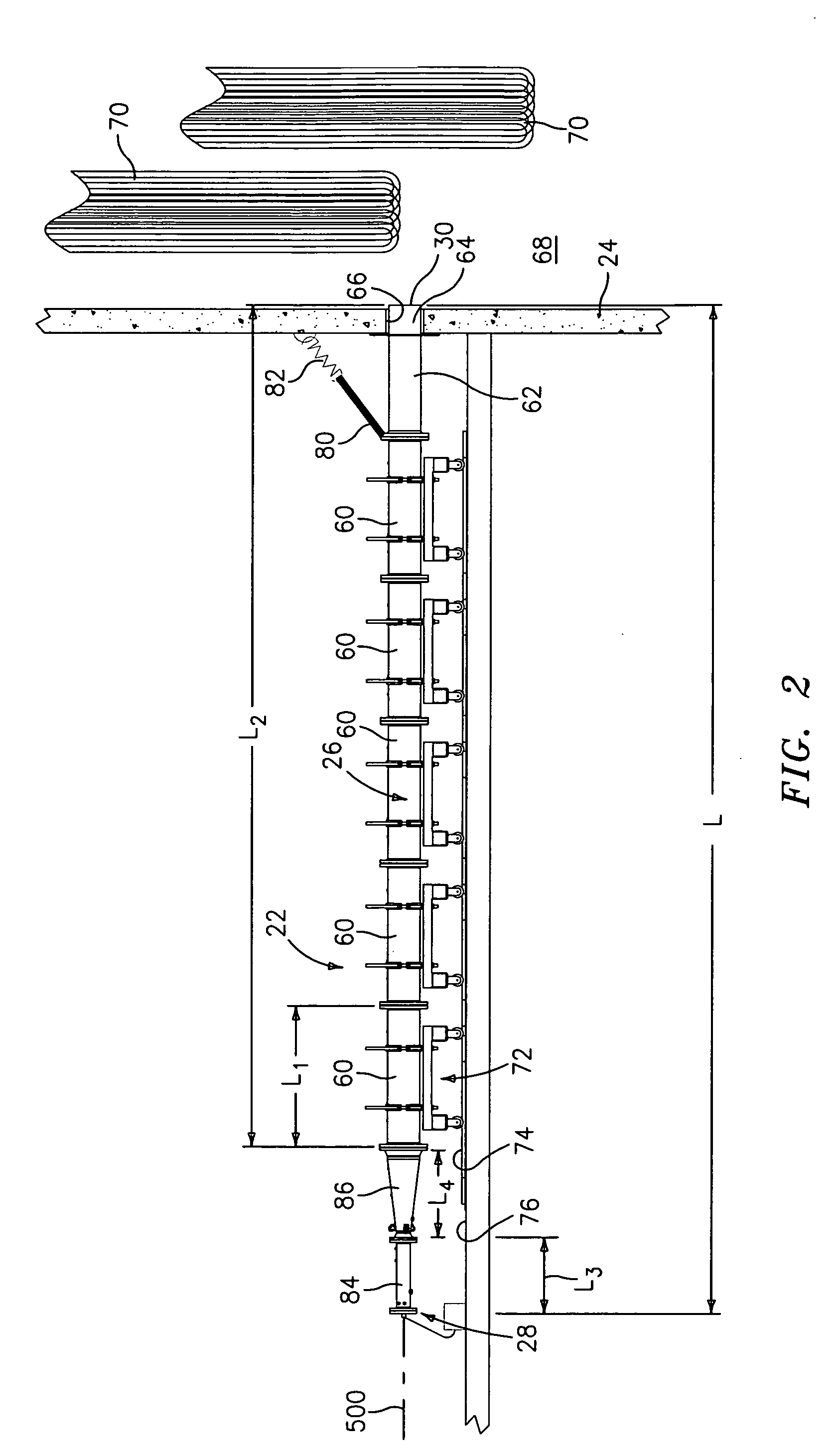

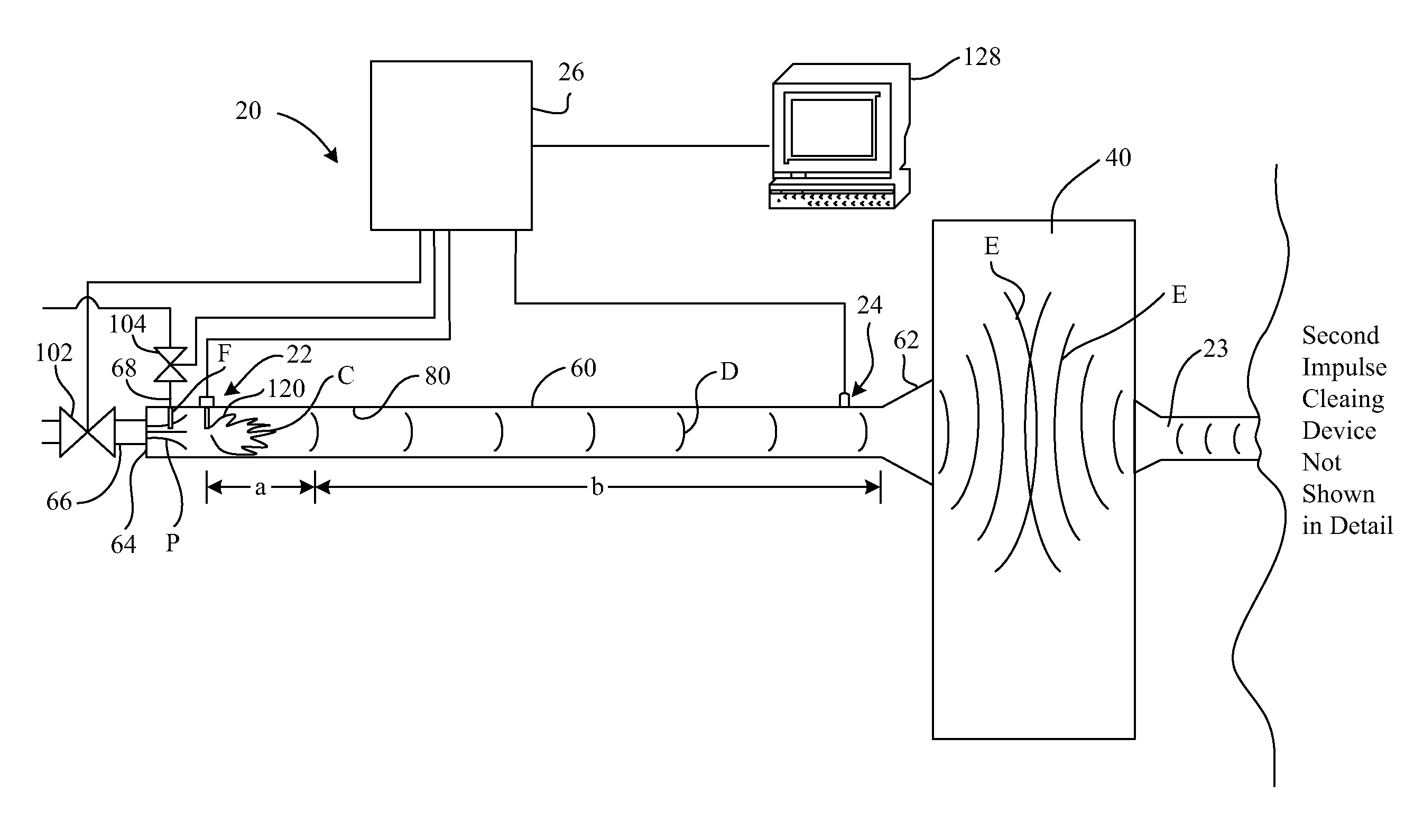

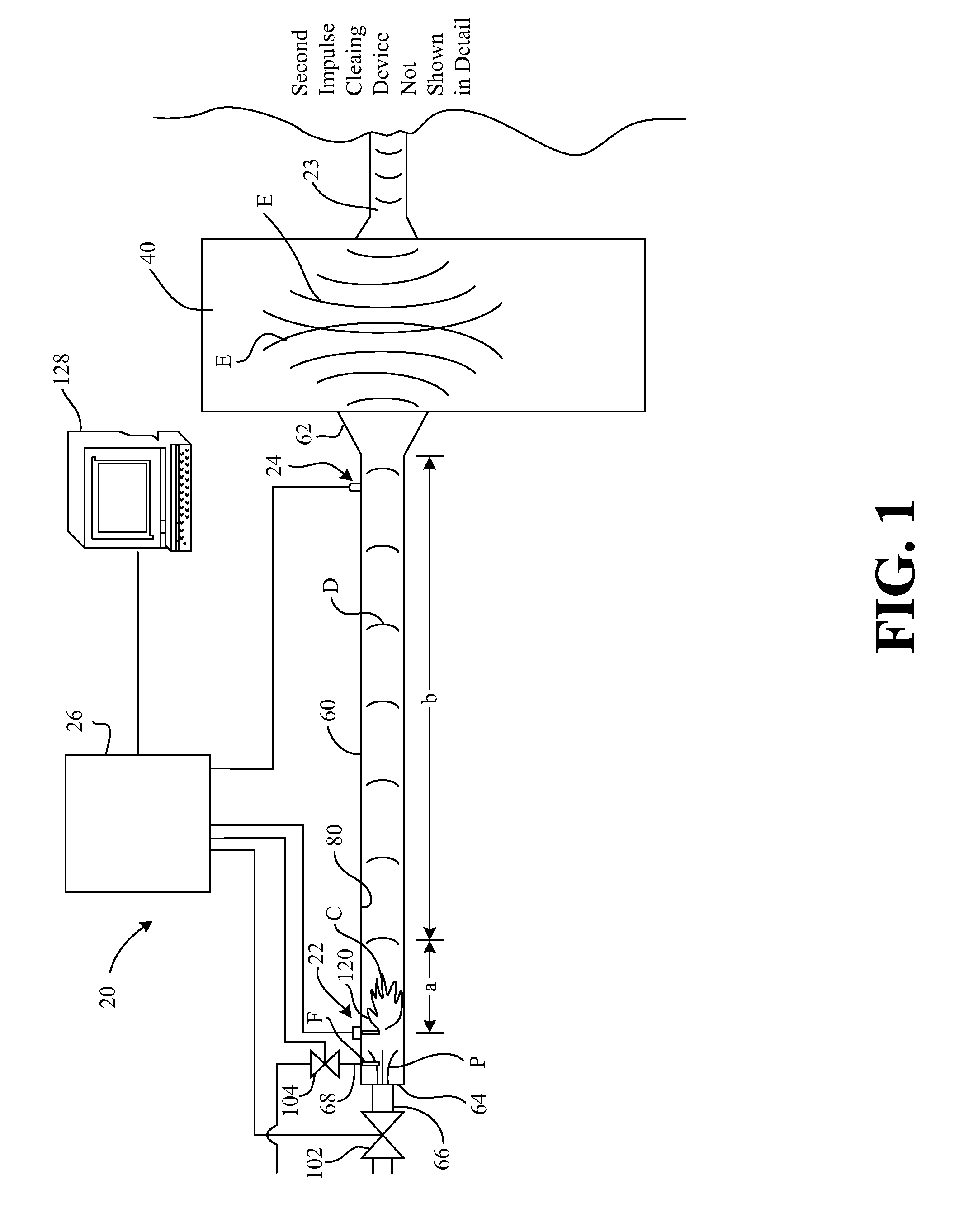

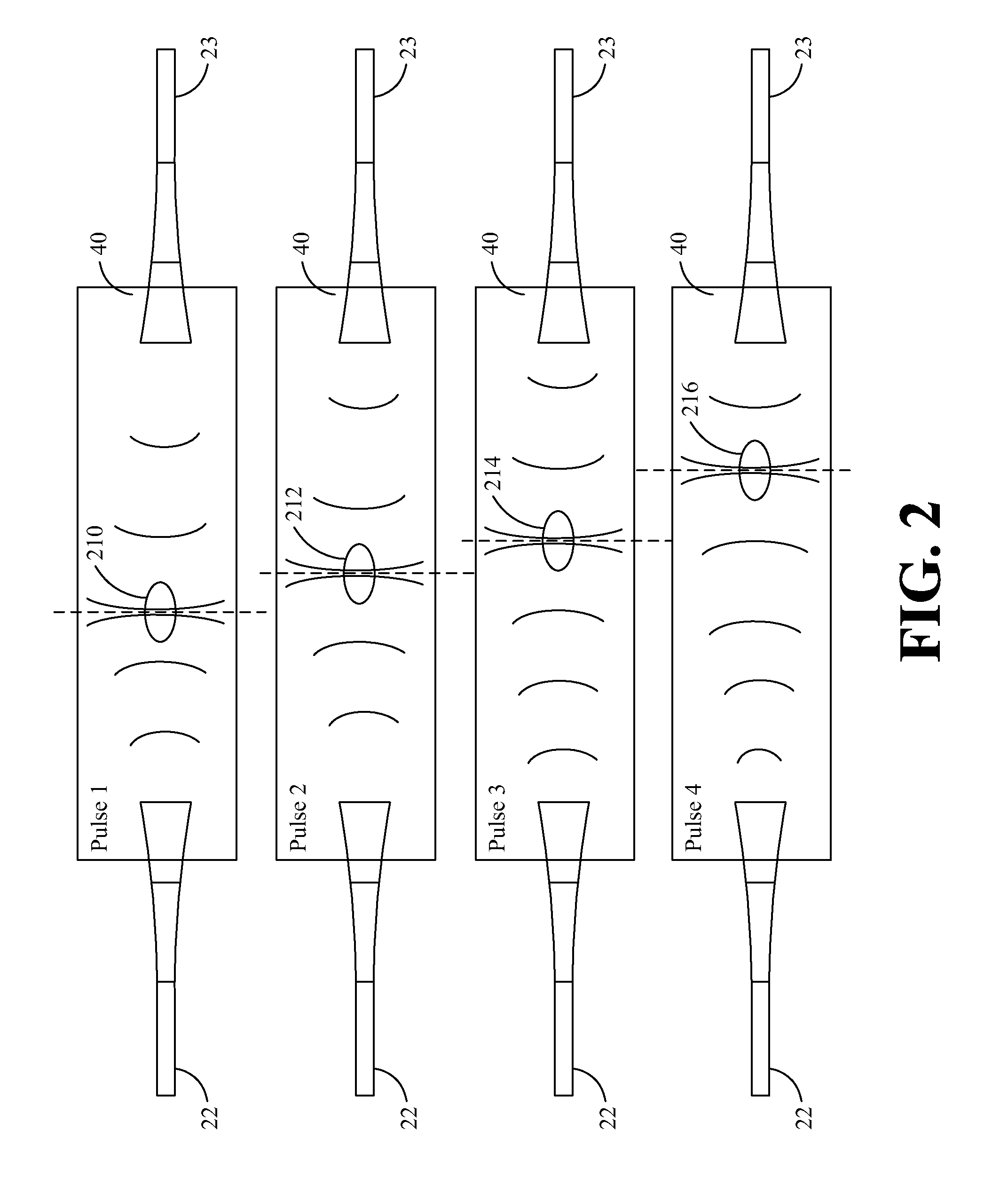

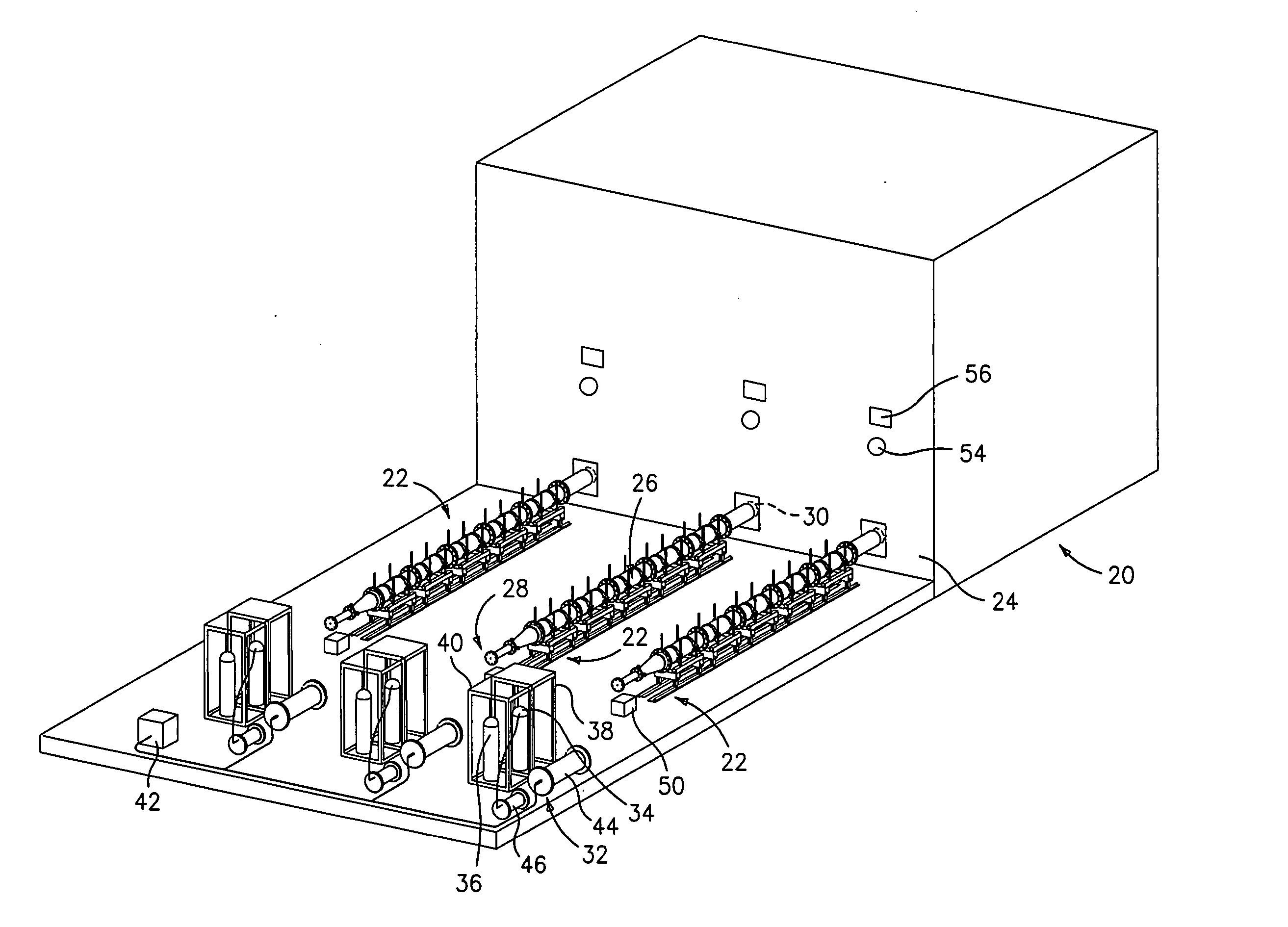

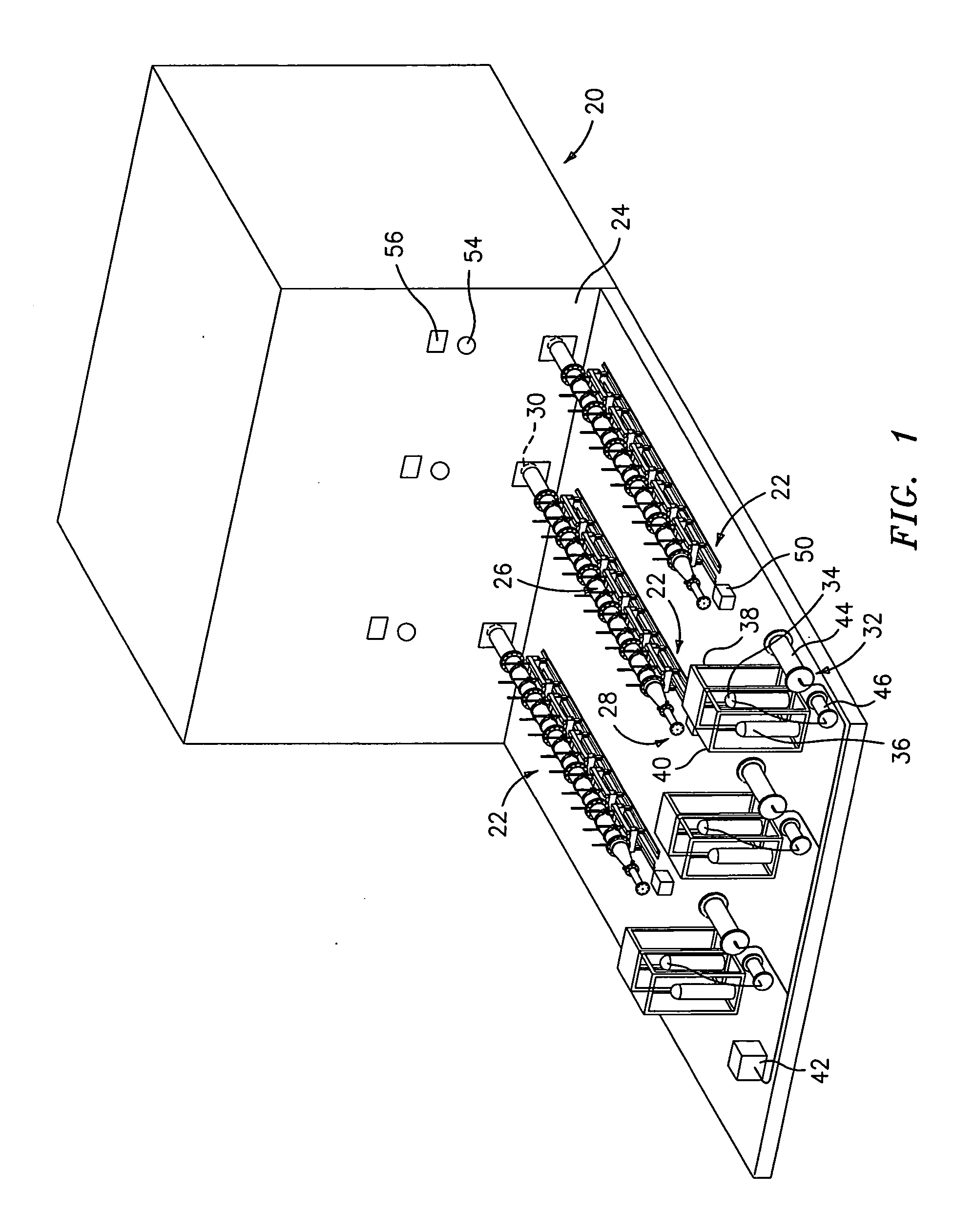

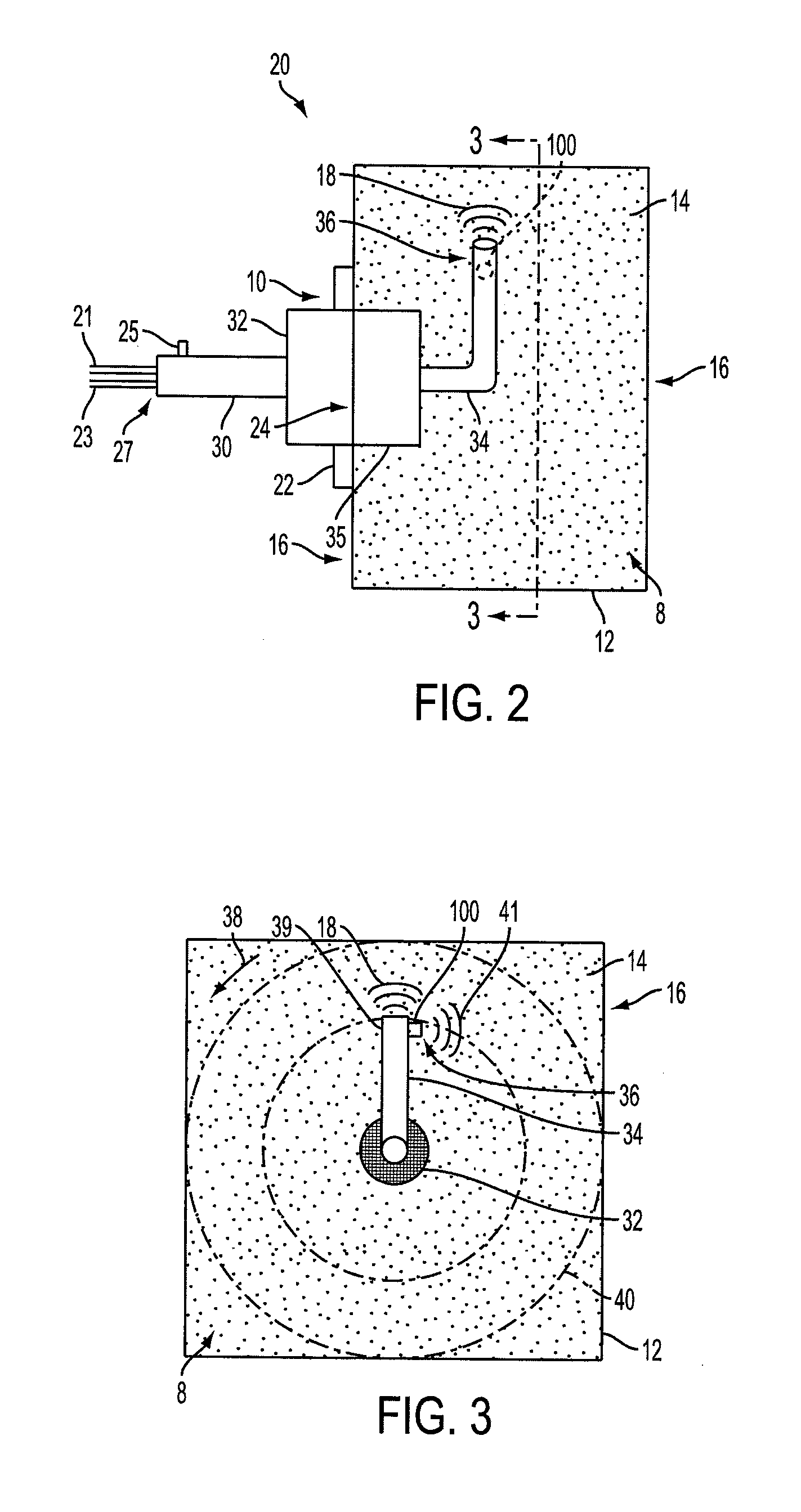

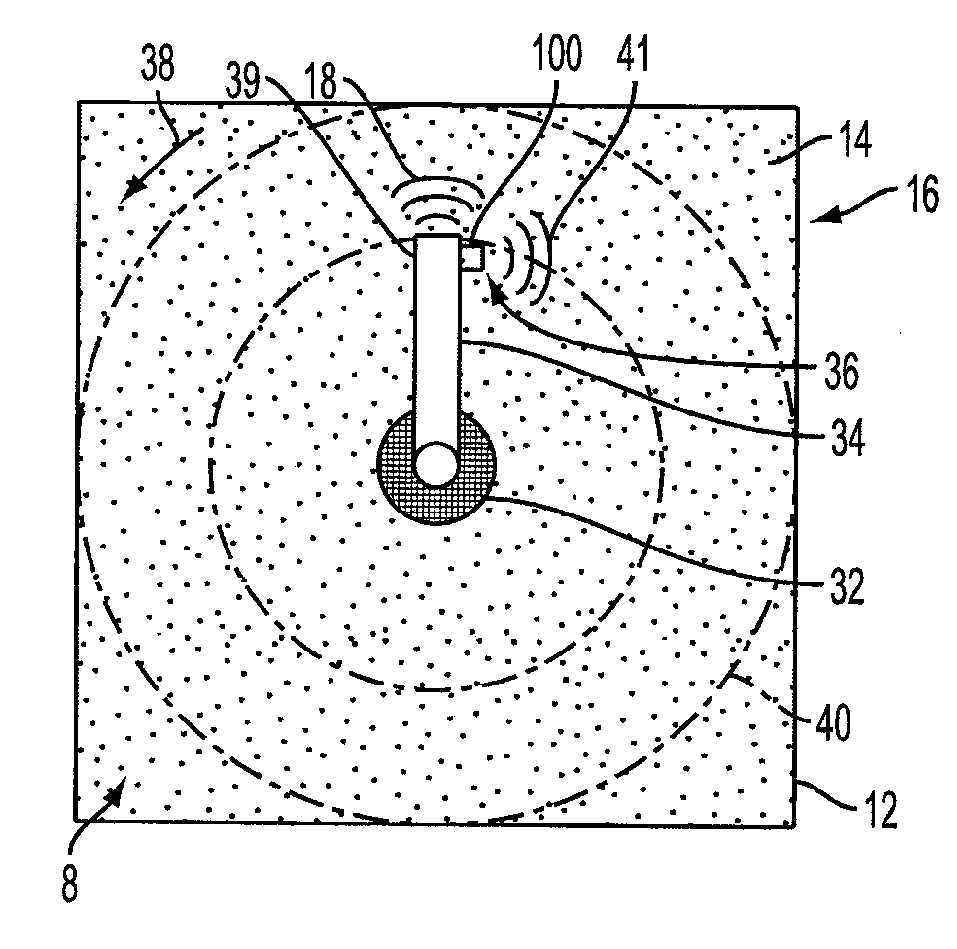

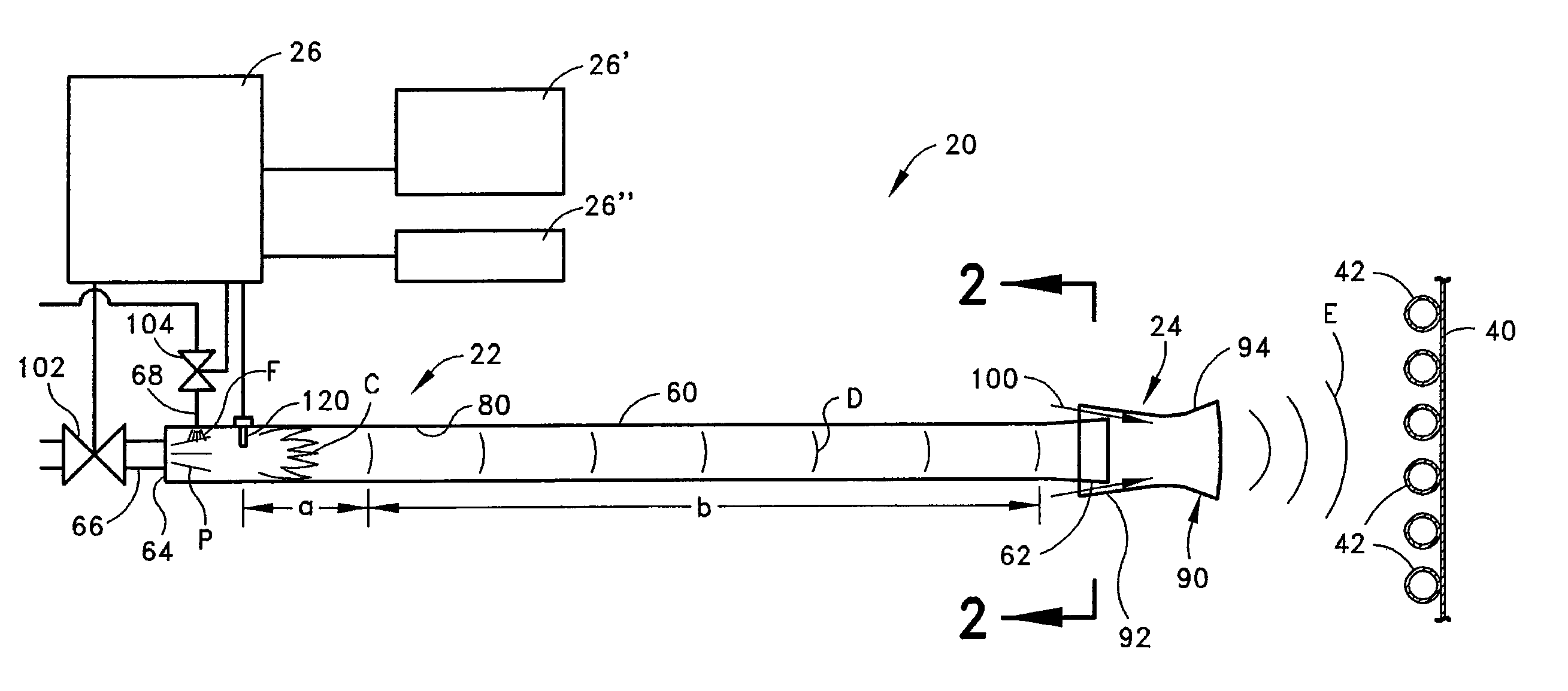

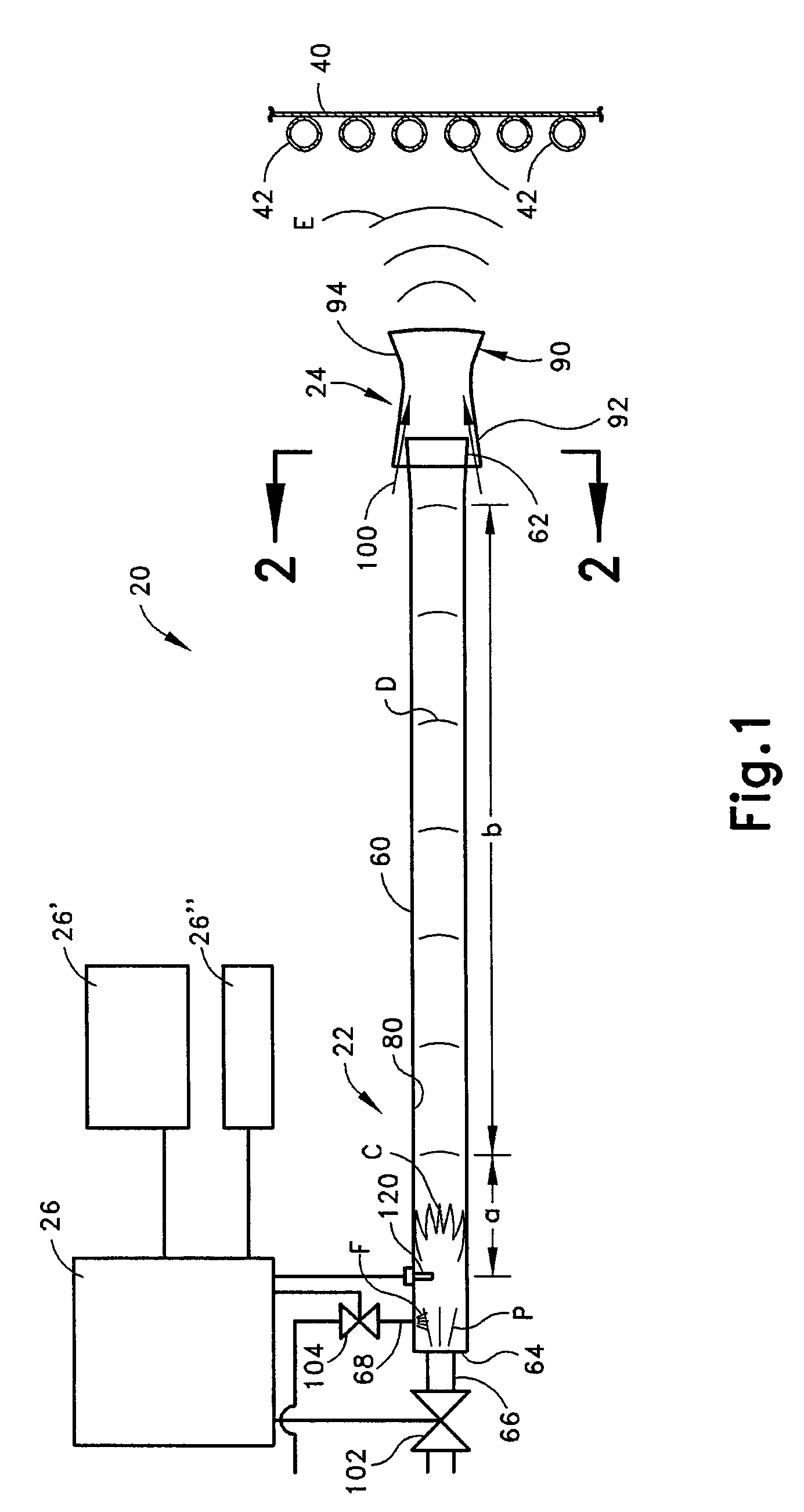

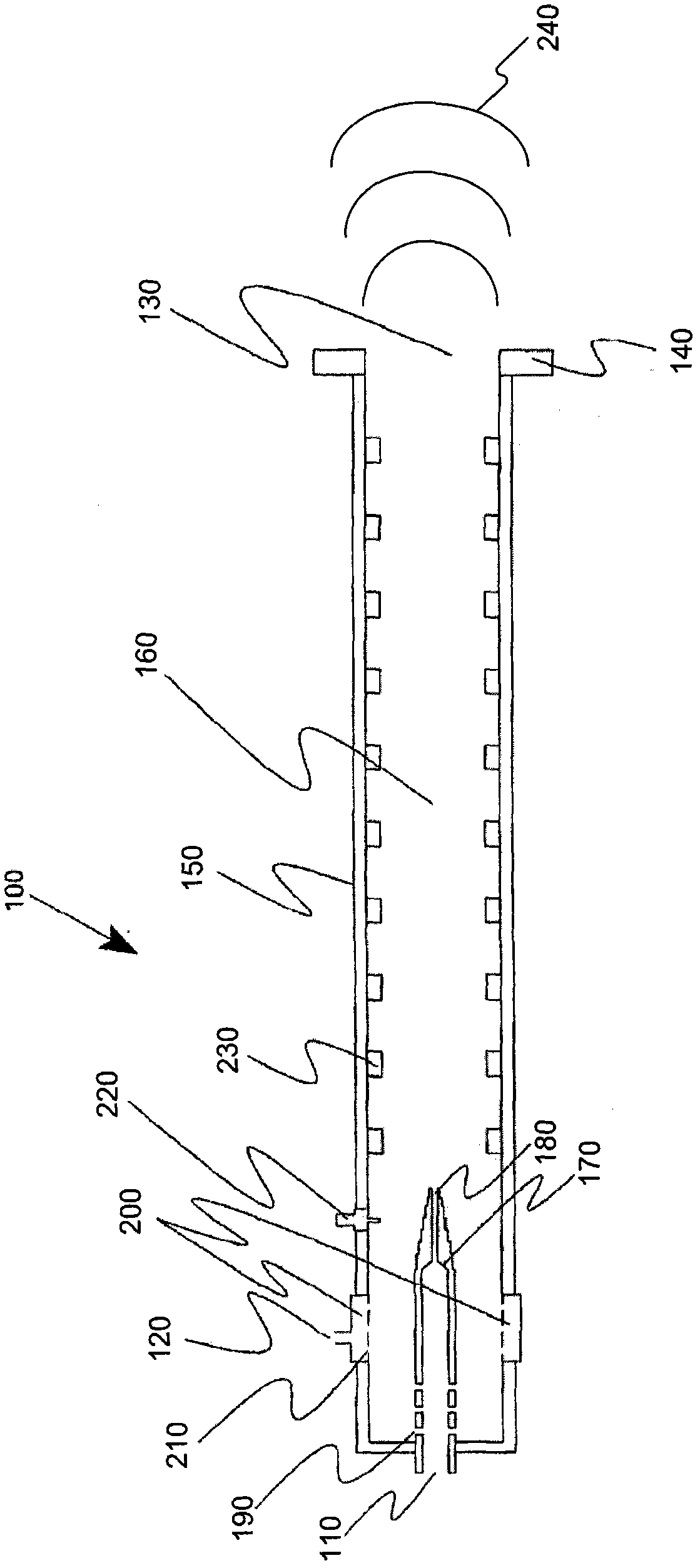

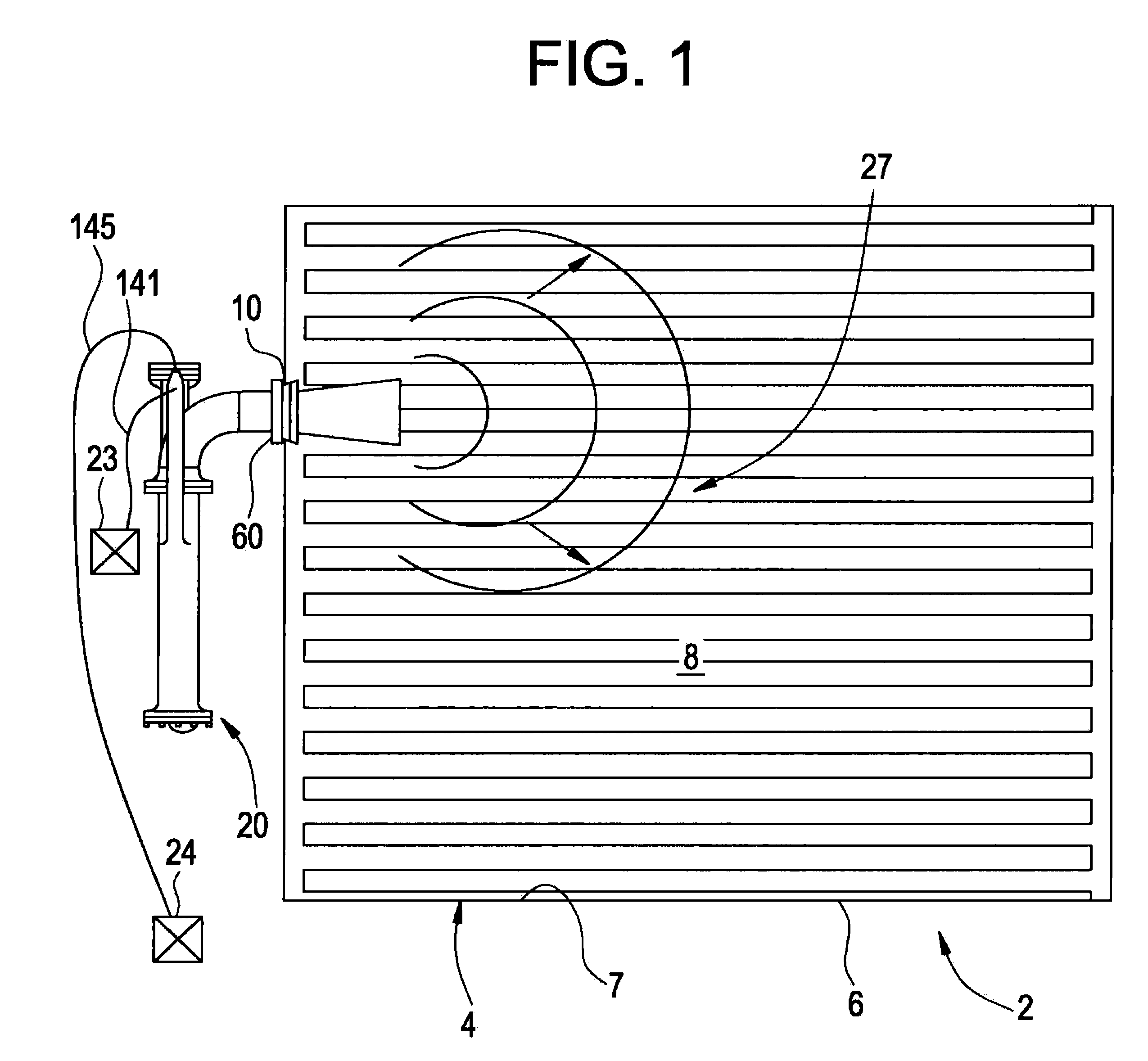

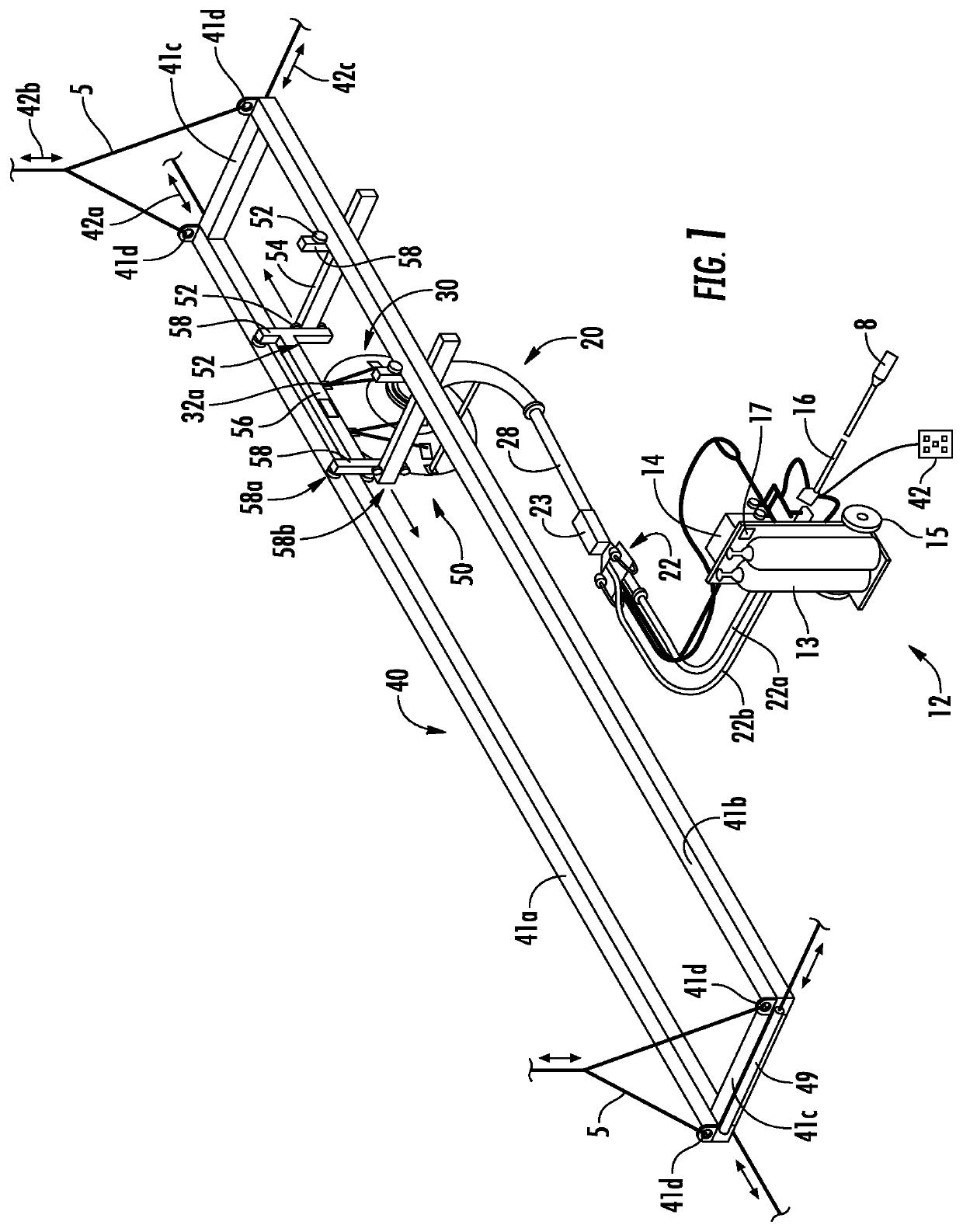

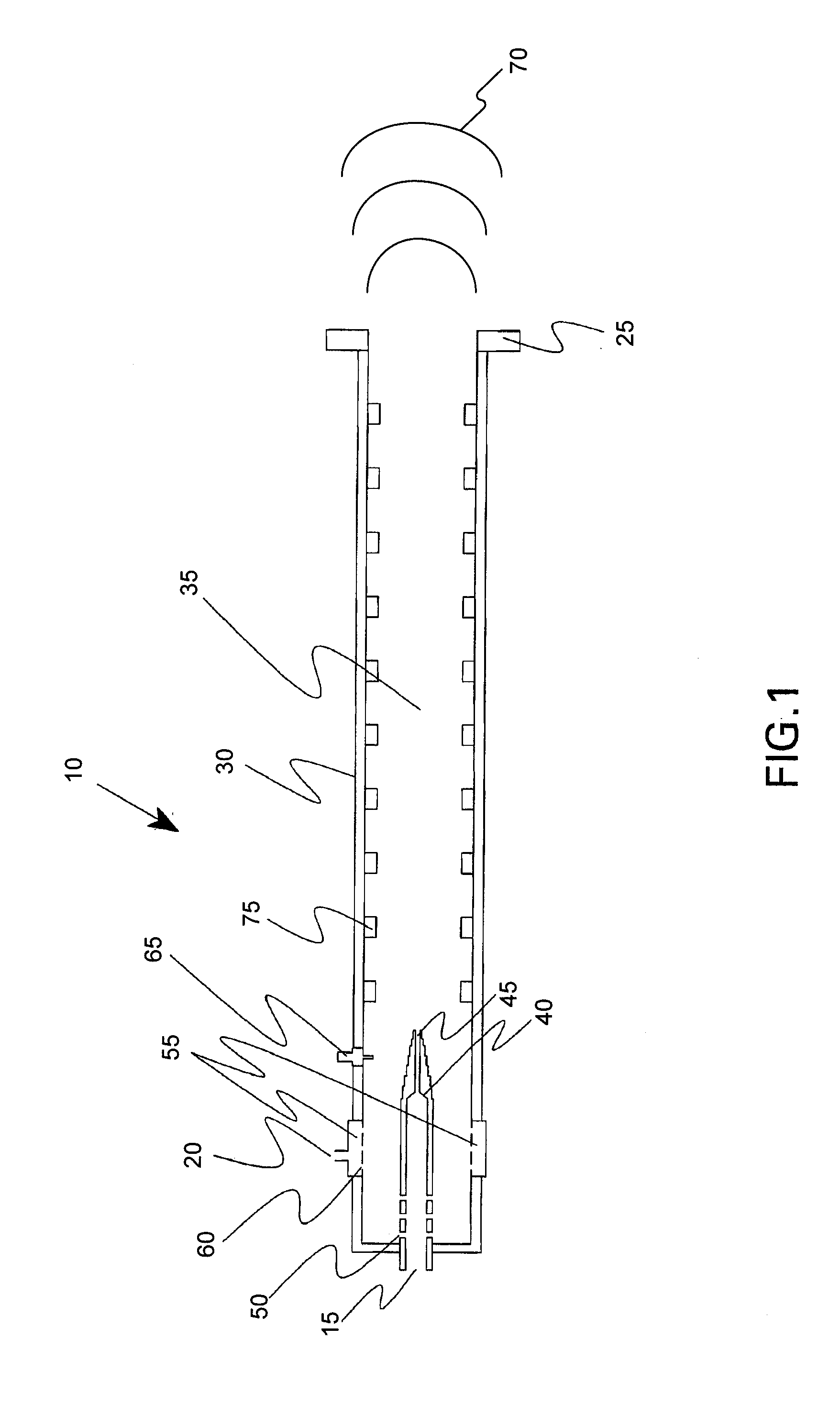

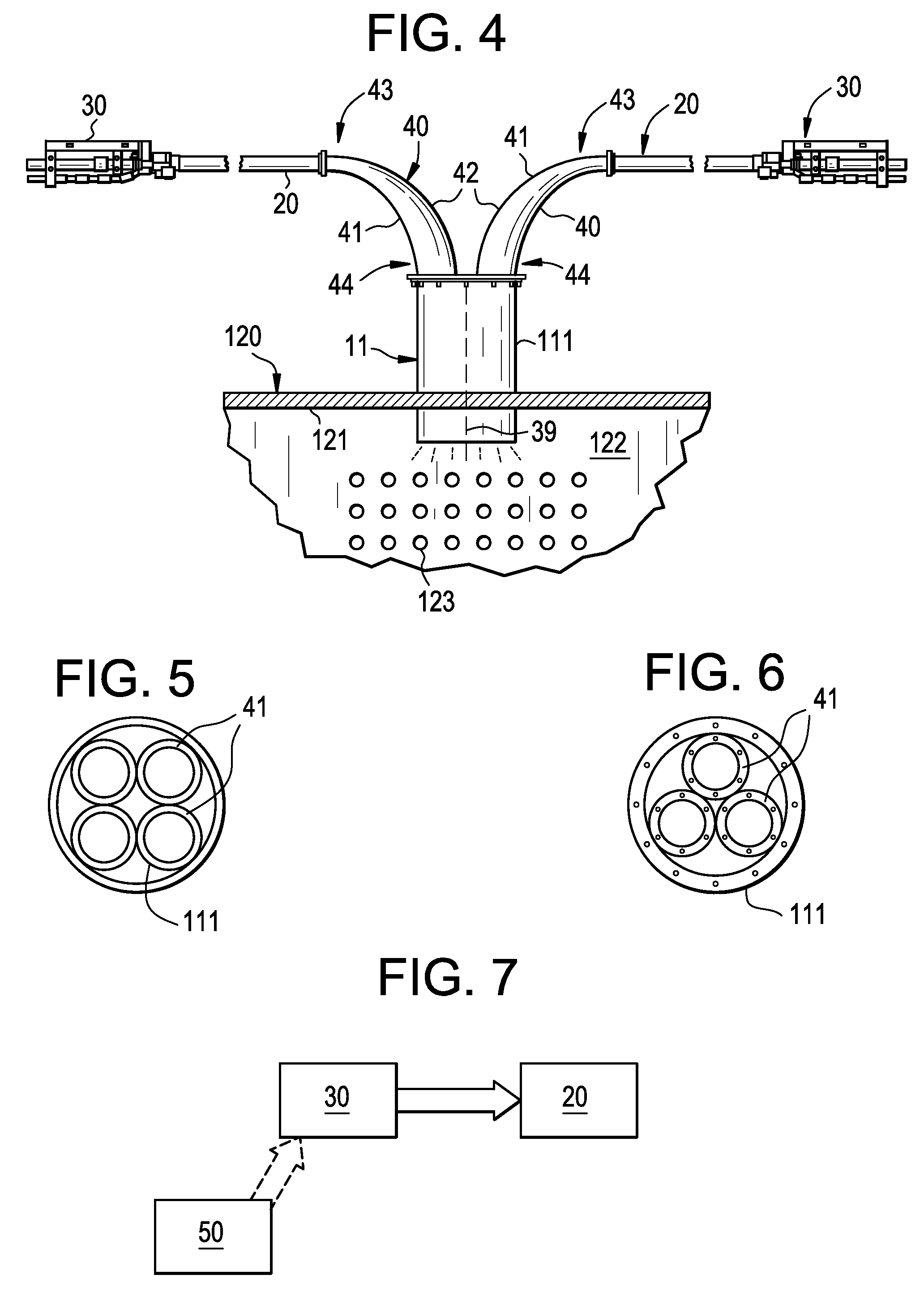

Systems and Methods for Phasing Multiple Impulse Cleaning Devices

Embodiments provide systems and methods for removing debris from a surface. A system can include a first impulse cleaning device and a second impulse cleaning device, each impulse cleaning device generating shock waves directed to a surface to be cleaned, wherein the first impulse cleaning device and the second impulse cleaning device are oriented such that the respective shock waves intersect at or proximate the surface. The system can further include a controller in operable communication with the first impulse cleaning device and the second impulse cleaning device, wherein the controller is configured to selectively cause phased operation of the first impulse cleaning device and the second impulse cleaning device such that the phased operation selectively controls the location of the intersection of the respective shock waves.

Owner:BHA ALTAIR

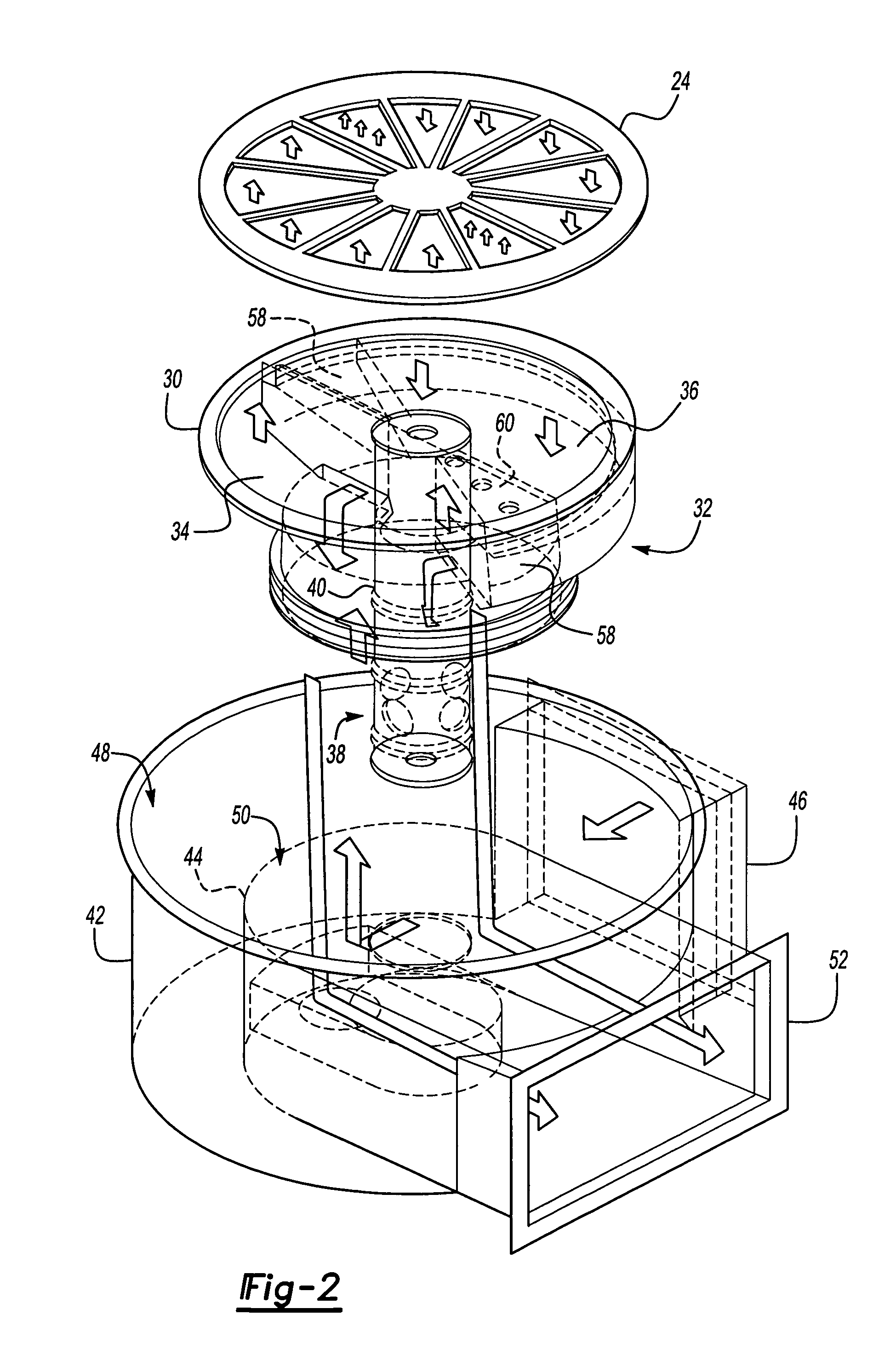

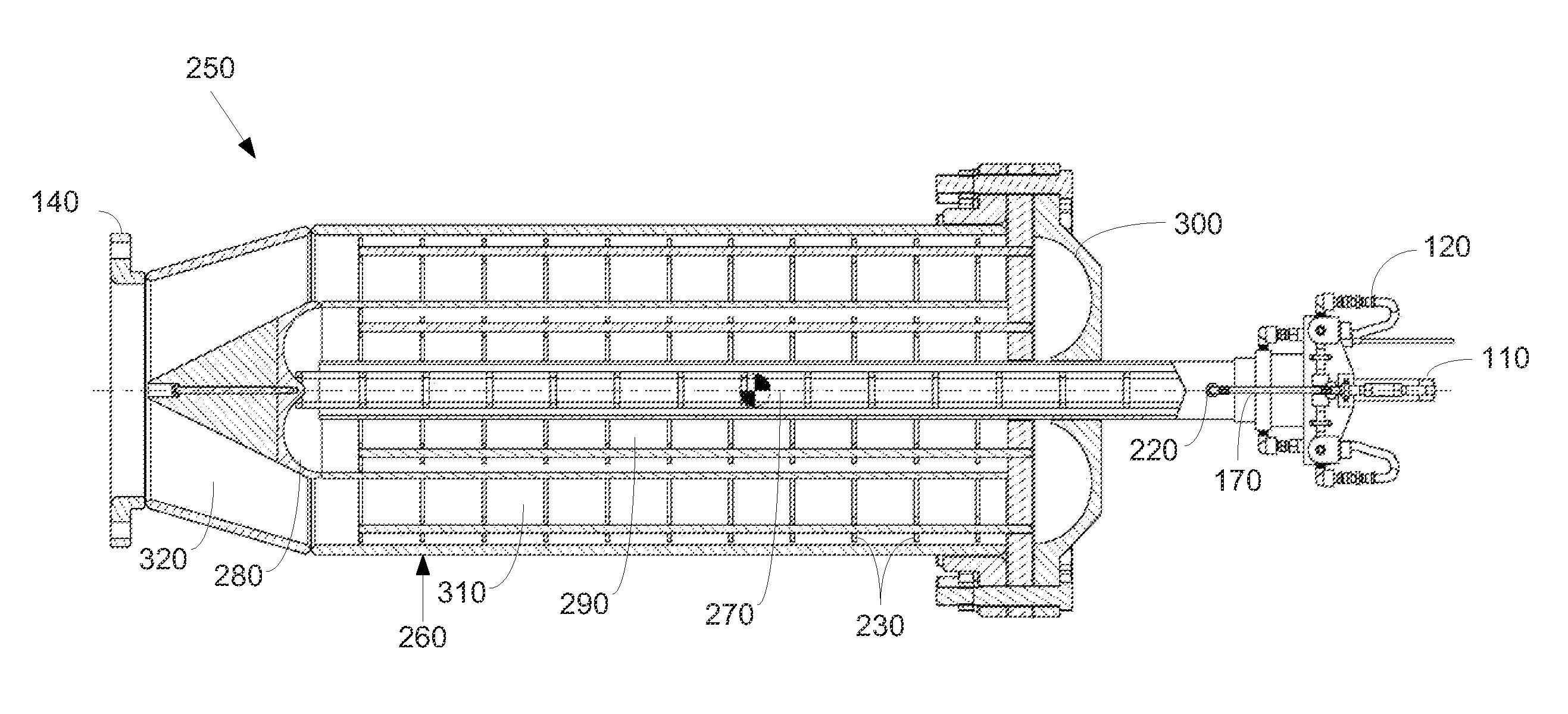

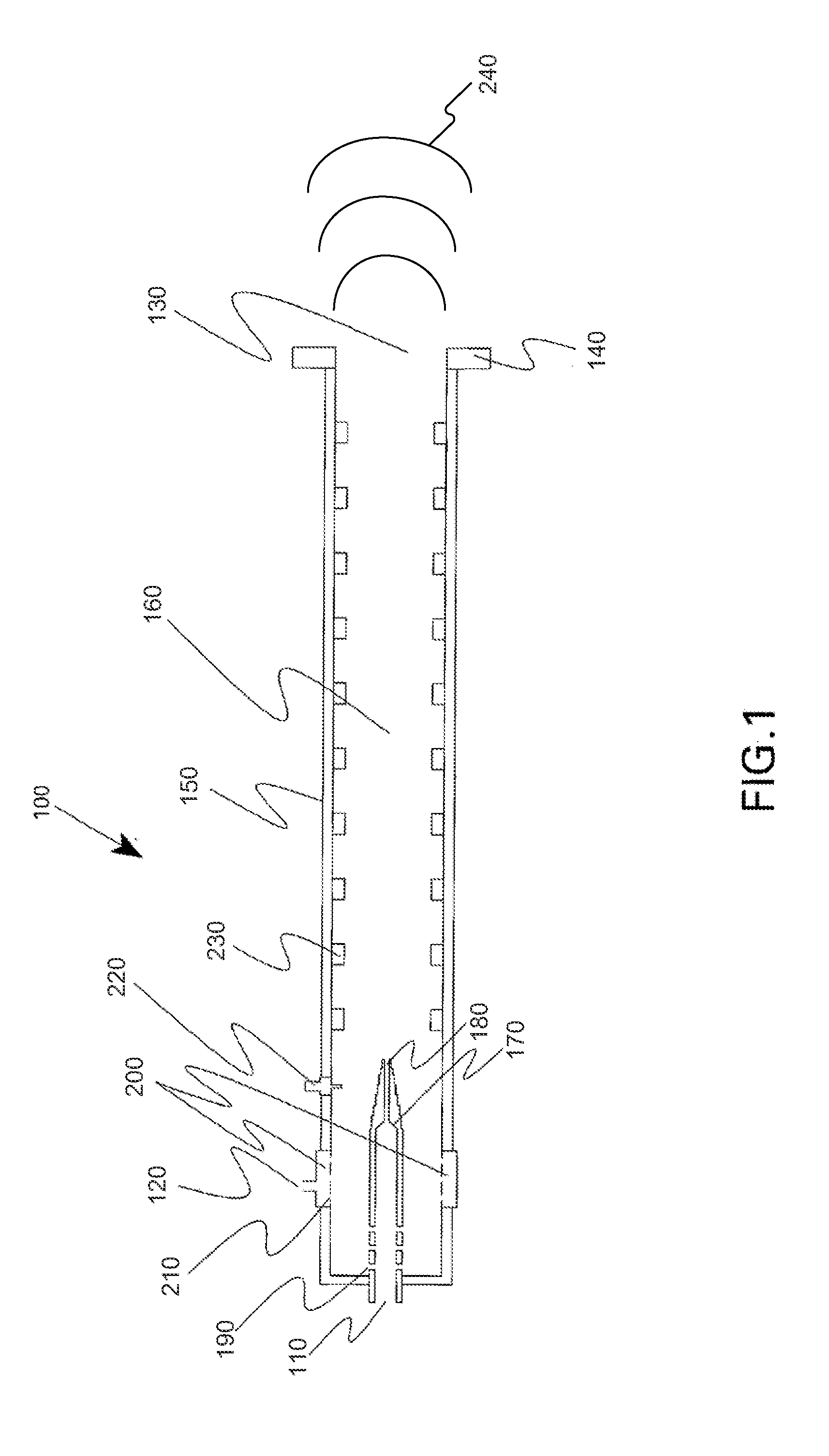

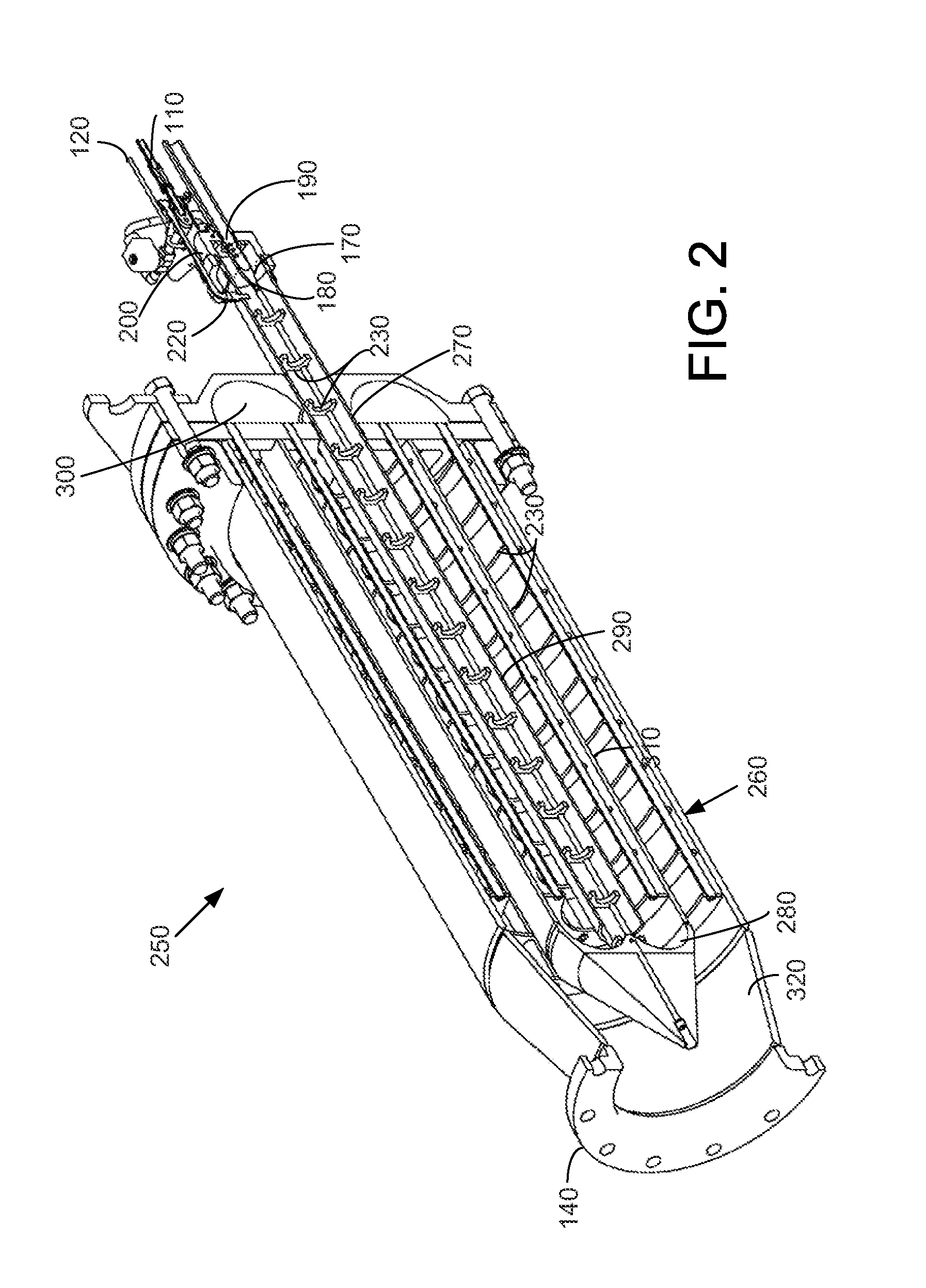

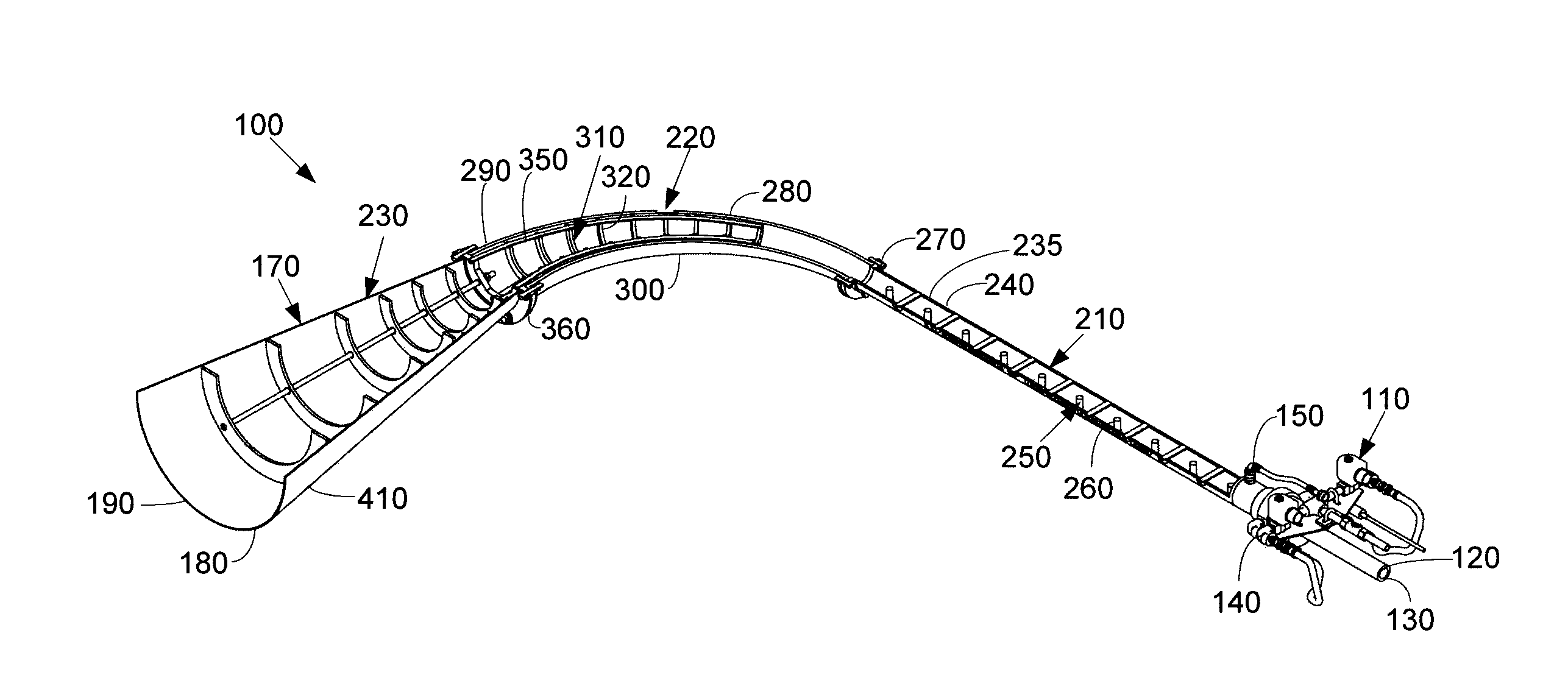

Pulsed Detonation Cleaning Device with Multiple Folded Flow Paths

The present application provides a pulsed detonation cleaning device. The pulsed detonation cleaning device may include an air inlet, a fuel inlet, an ignition device in communication with the air inlet and the fuel inlet for creating detonation waves, a number of folded flow paths in communication with the ignition device, and a number of flow turning devices positioned about the folded flow paths such that the detonation waves reverse direction a number of times.

Owner:BHA ALTAIR

Online bakeout of regenerative oxidizers

ActiveUS20050227189A1Reduce baking timeIncrease temperatureCombustion cleaningFuel additivesRotary valveEngineering

A method of burning off accumulated contaminants from heat sink media of a regenerative oxidizer having a plurality of segments containing media arranged around a central axis and a rotary valve which includes repeatedly rotating the rotary valve 180 degrees to alternatively direct waste gas through a first plurality of segments, direct the hot gas through a second plurality of segments and purge gas through a third segment to burn off the contaminants, then indexing the rotary valve one segment and repeating the burn-off process of all segments.

Owner:DURR SYST INC

Detonative cleaning apparatus

InactiveUS20060185623A1Hollow article cleaningBoiler cleaning apparatusCombustionDeflagration to detonation transition

Methods and apparatus are provided for cleaning a surface within a vessel. A fuel / oxidizer charge is provided within a combustion conduit. An initial deflagration commenced in a first portion of the charge produces a final detonation at least in another portion of the charge to expel a shockwave from the conduit which impinges upon the surface. The deflagration-to-detonation transition may be encouraged by mechanical enhancements and / or by making the first charge portion more detonable than the second.

Owner:AARNIO MICHAEL J +2

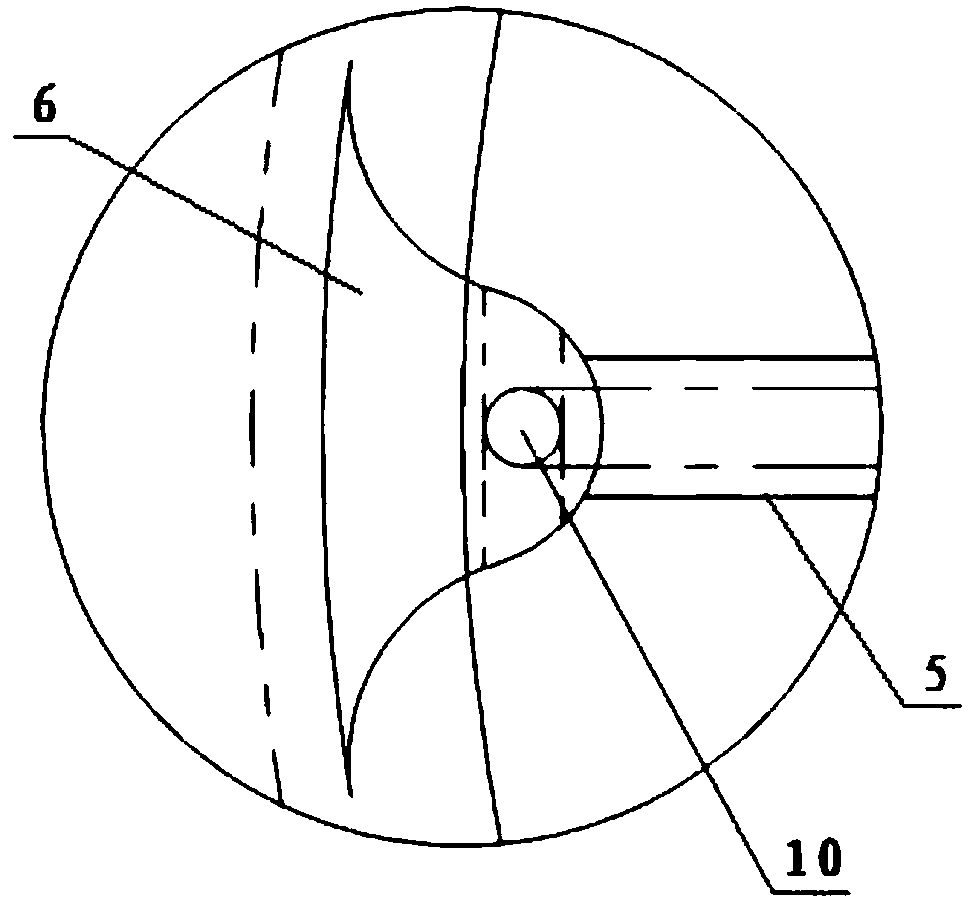

Self driven rotating pulse detonation cleaning system

InactiveUS20130056034A1Increase cleaning coveragePulsating combustionHollow article cleaningShock waveDetonation

A pulse detonation device can provide one or more shock waves to an operating device. The pulse detonation device includes a pulse detonation chamber providing one or more shock waves, at least one pulse detonation outlet extending into the operating device and in operative association with the pulse detonation chamber, and a rotary union. The rotary union rotatably attaches the pulse detonation chamber to the at least one pulse detonation outlet, wherein the at least one pulse detonation outlet can move with respect to the pulse detonation chamber. The at least one pulse detonation outlet is rotatable within the operating device and can deliver the one or more shock waves to a plurality of locations within the operating device.

Owner:BHA ALTAIR

Self driven rotating pulse detonation cleaning system

Owner:BHA ALTAIR

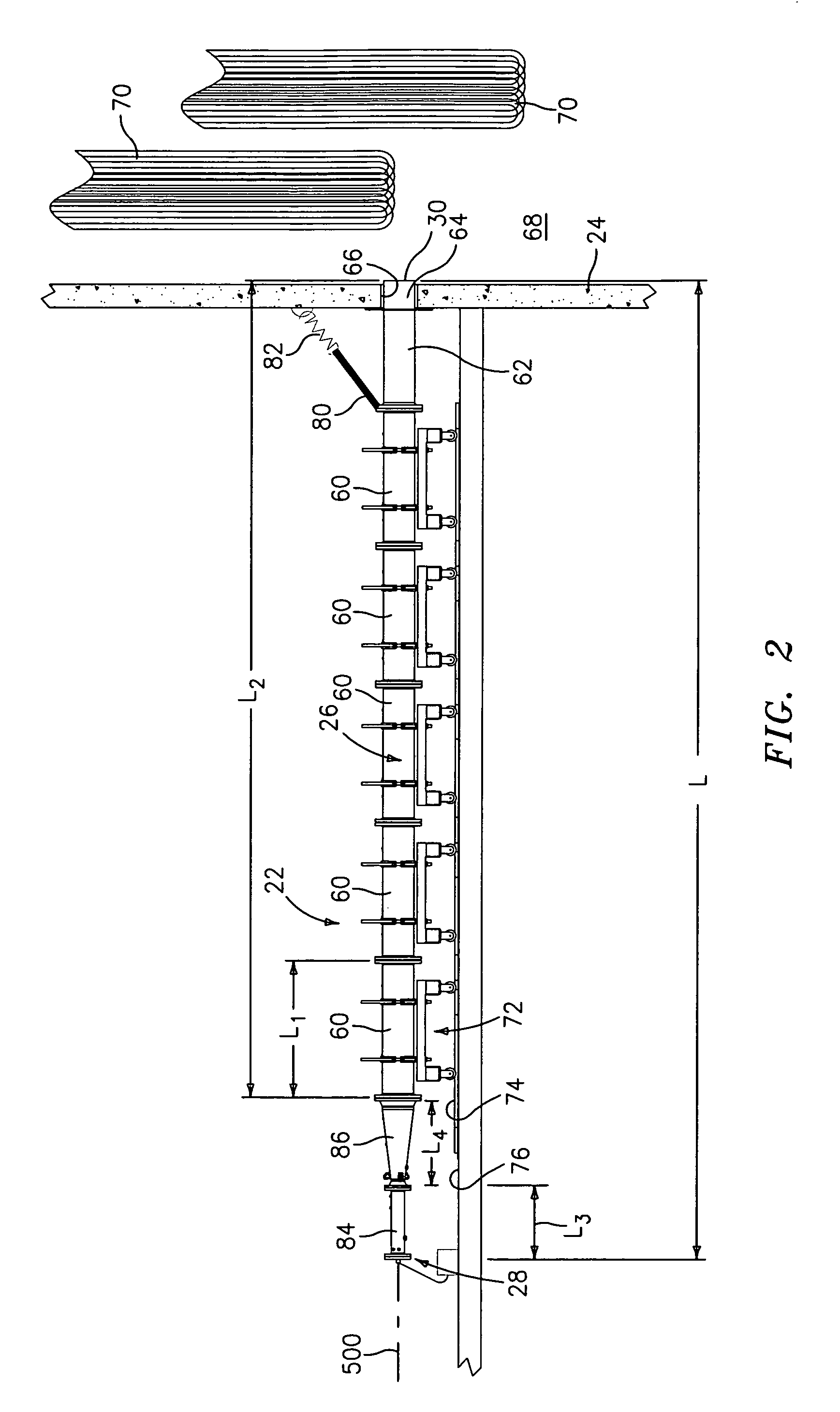

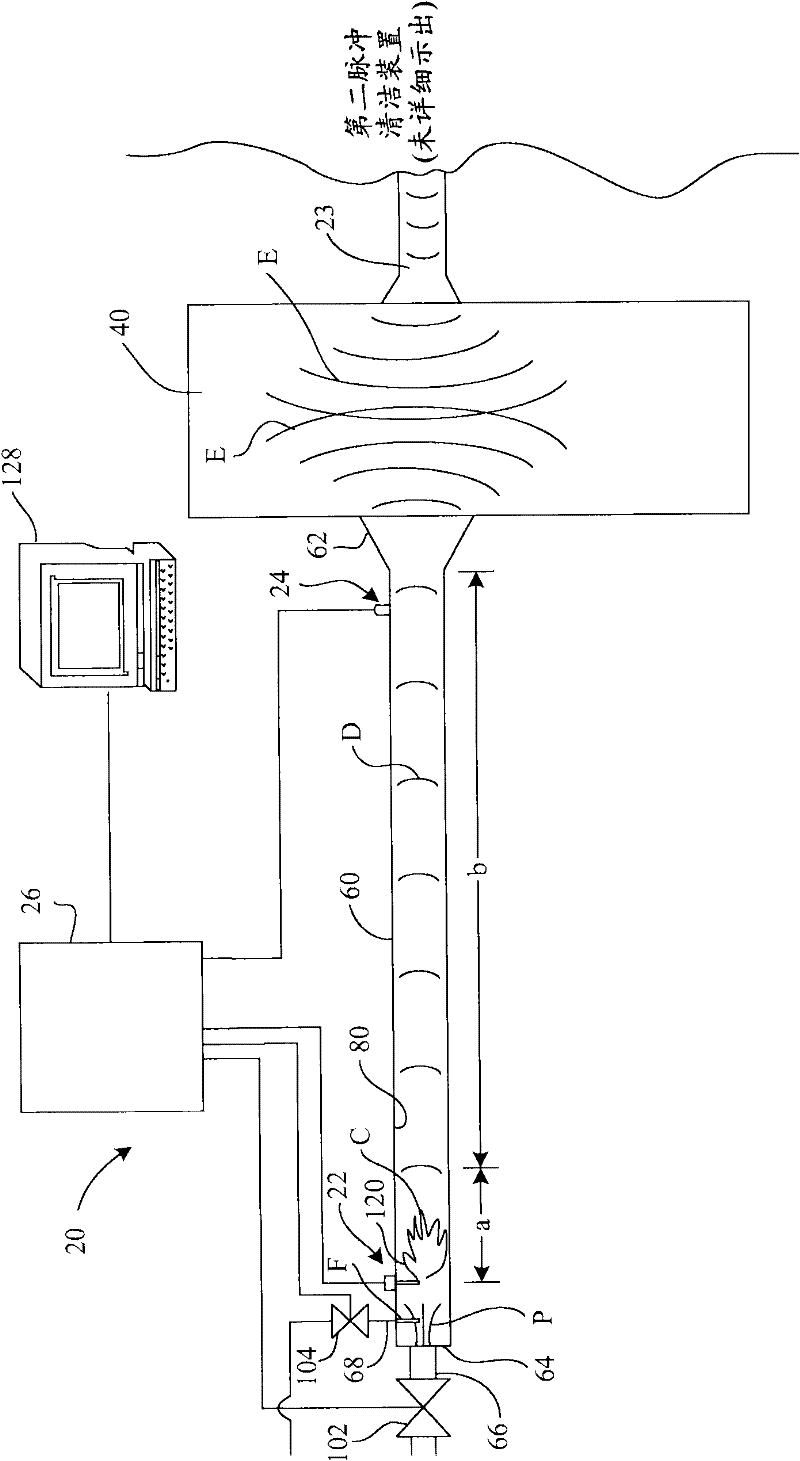

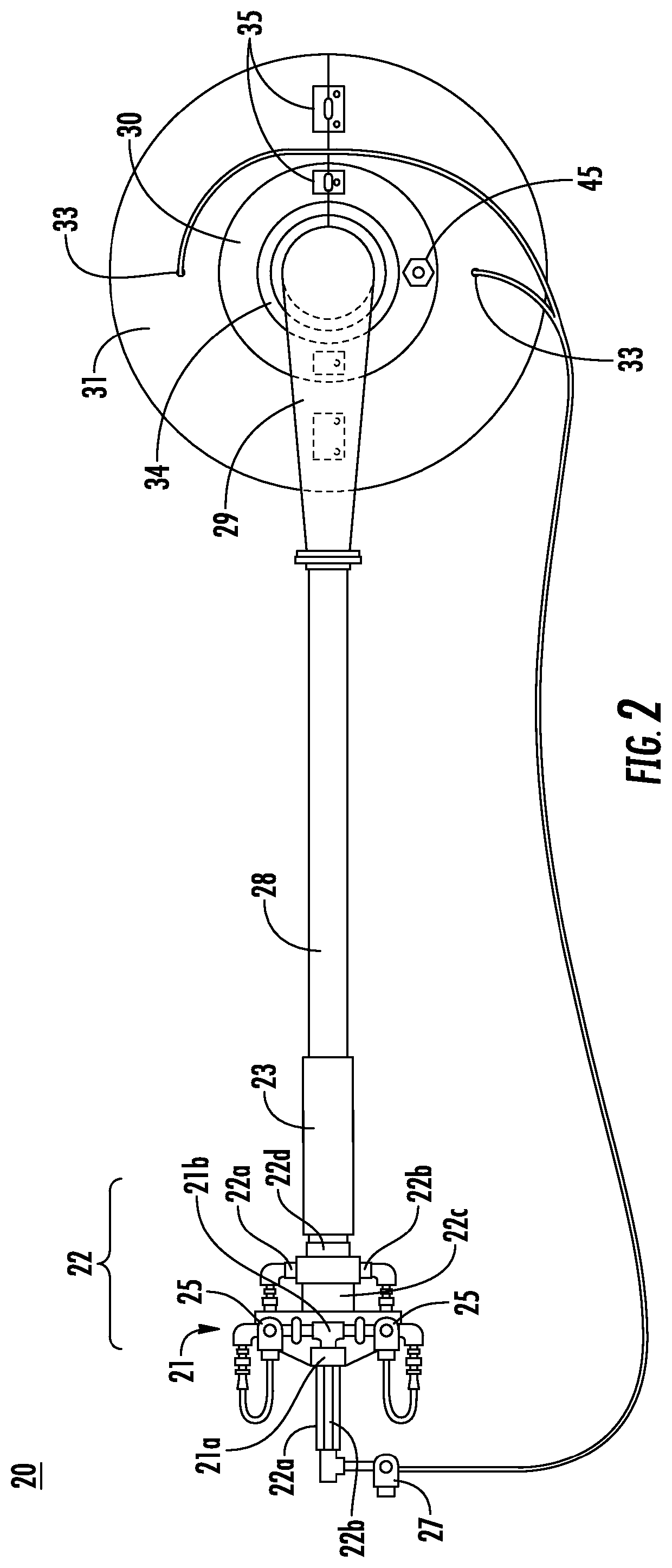

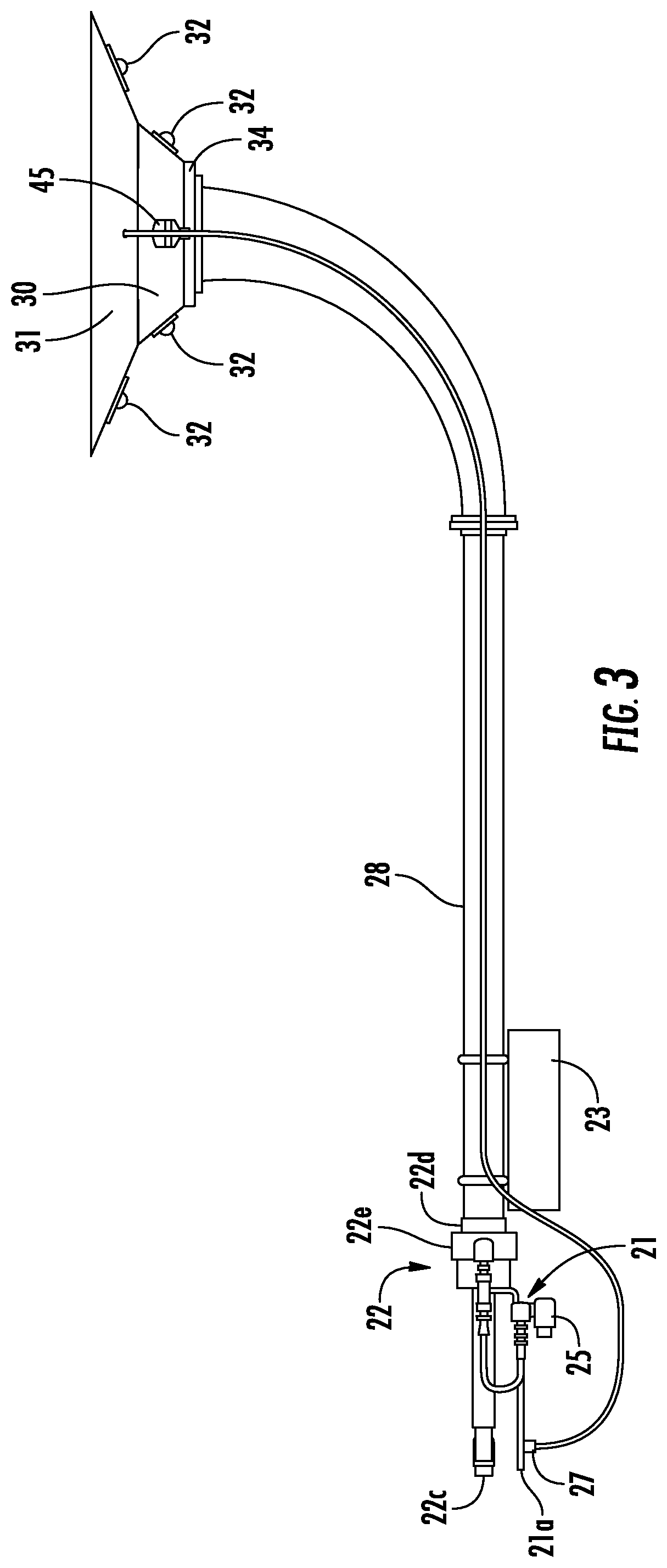

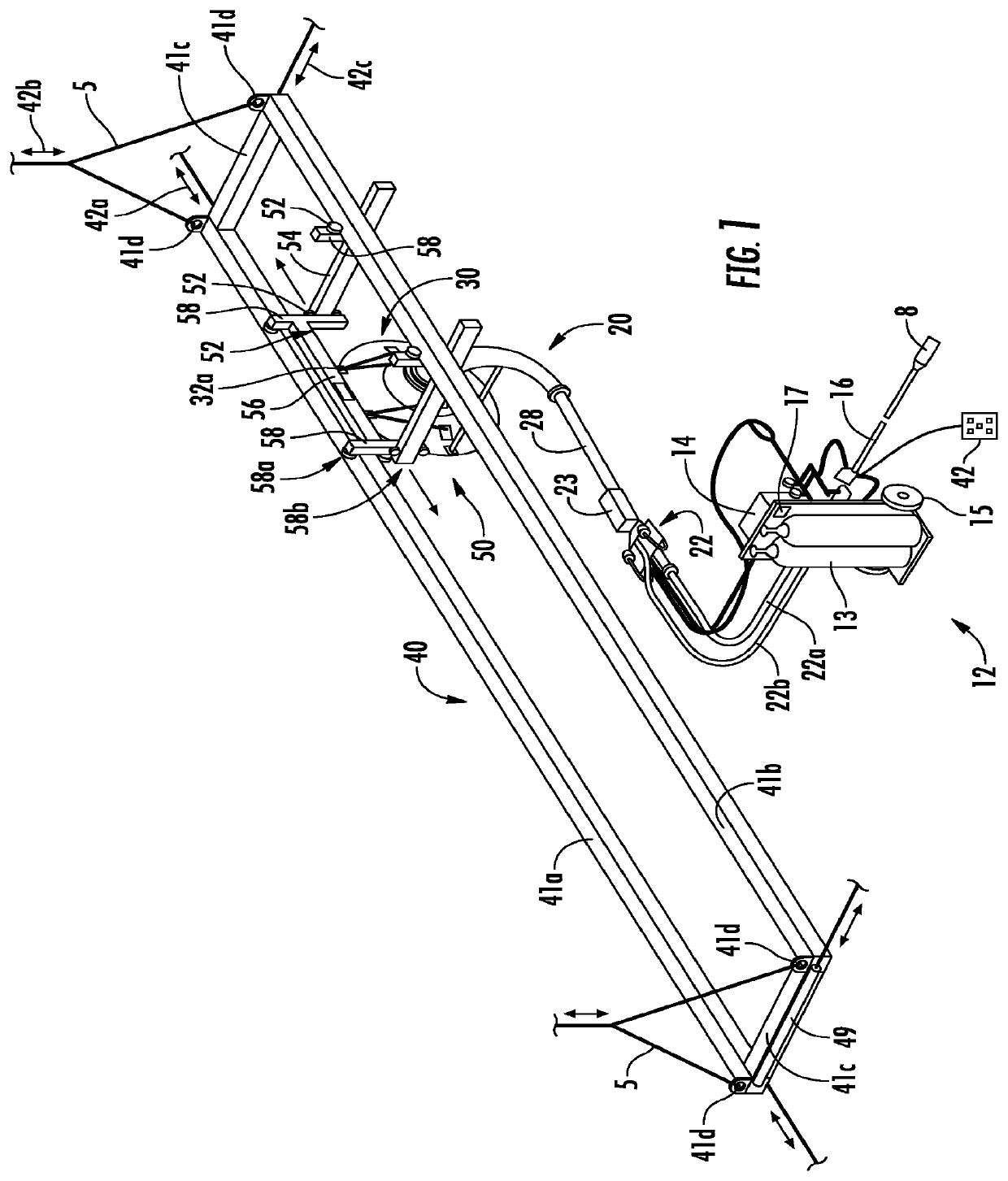

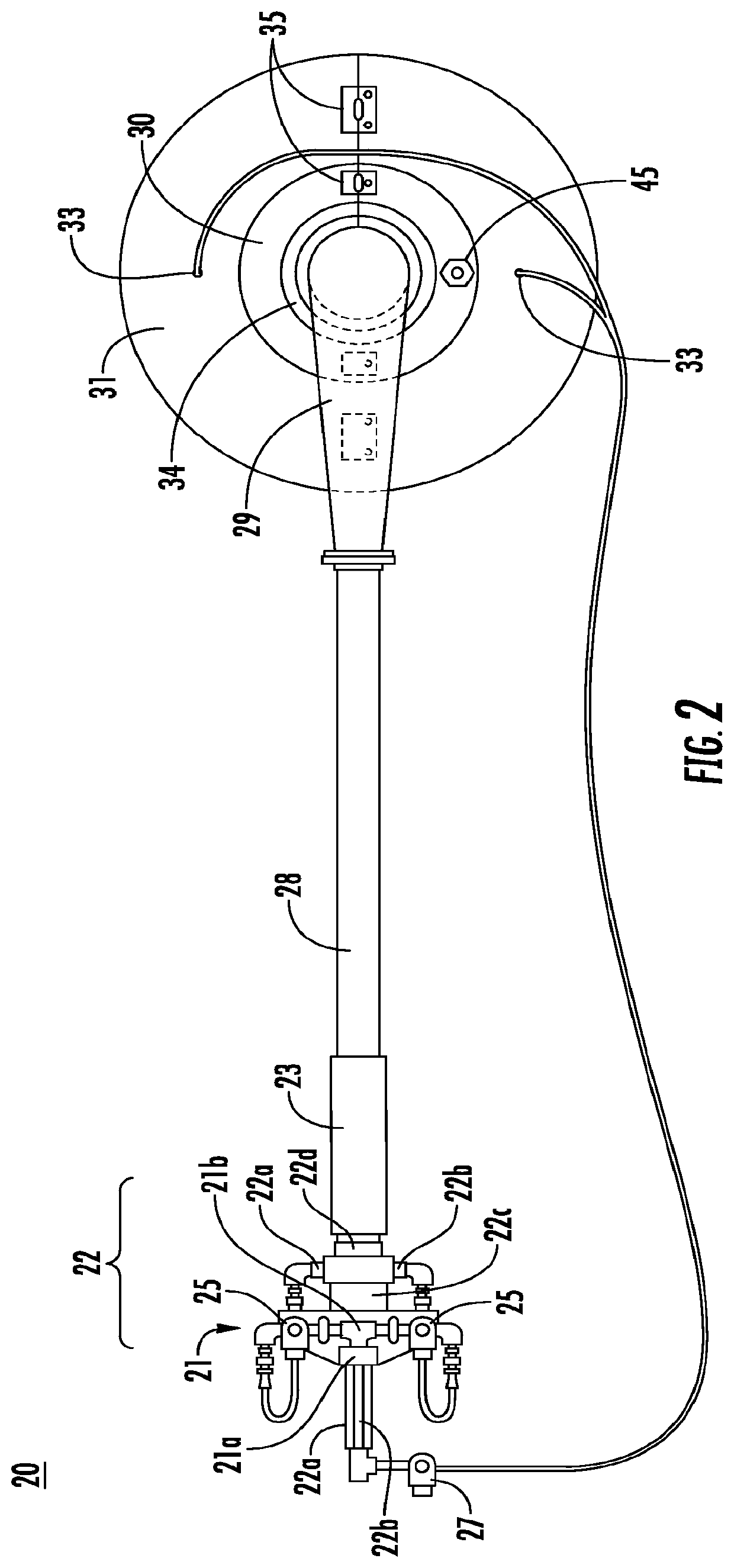

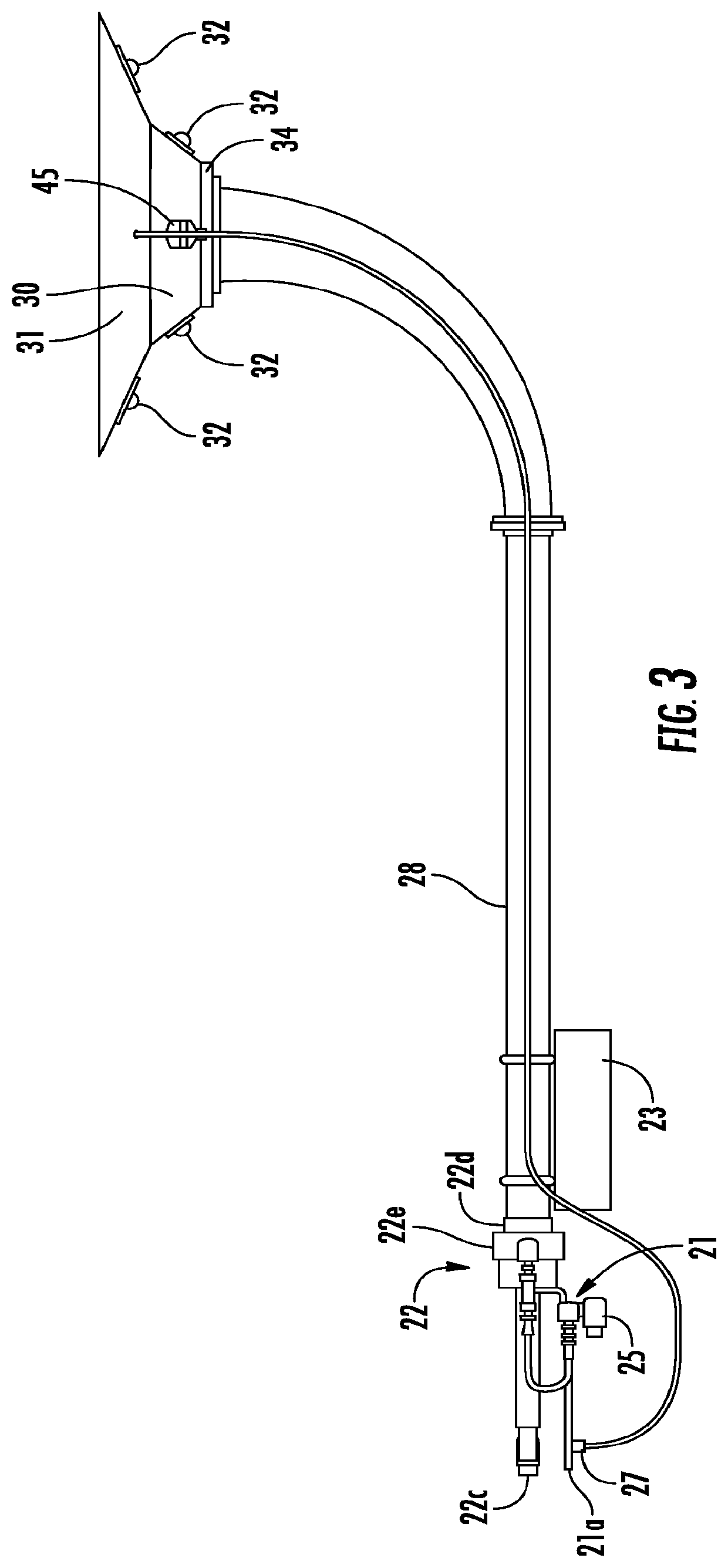

Systems and methods for phasing multiple impulse cleaning devices

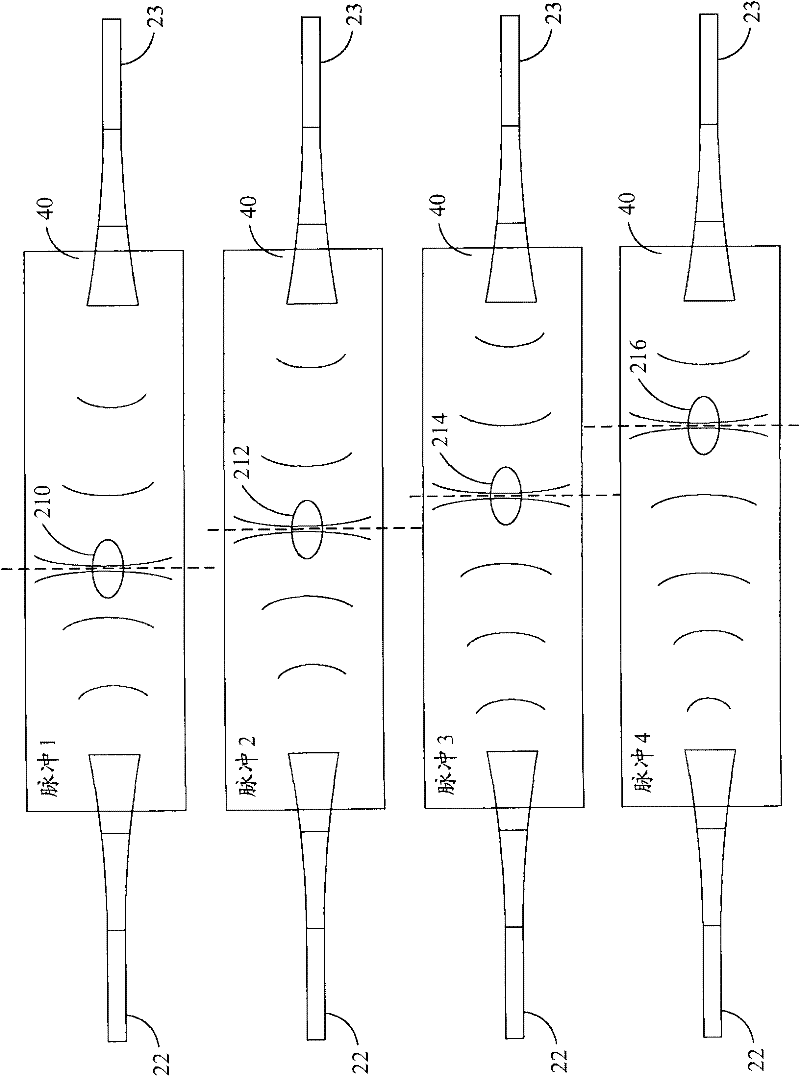

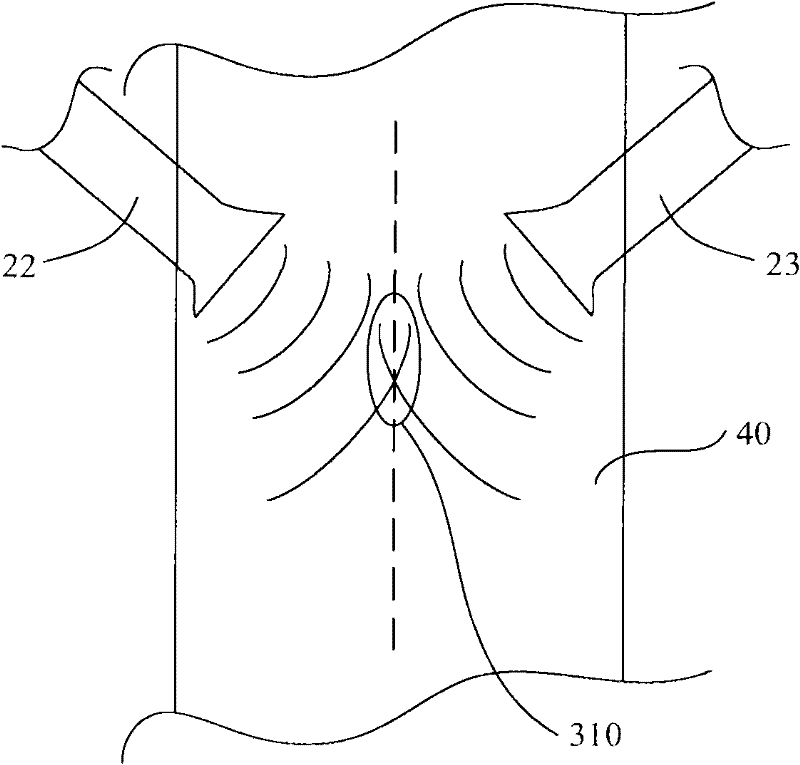

Embodiments provide systems 20 and methods 500 for removing debris from a surface. A system 20 can include a first impulse cleaning device 22 and a second impulse cleaning device 23, each impulse cleaning device generating shock waves directed to a surface to be cleaned, wherein the first impulse cleaning device and the second impulse cleaning device are oriented such that the respective shock waves intersect 210 at or proximate the surface. The system can further include a controller 26 in operable communication with the first impulse cleaning device 22 and the second impulse cleaning device 23, wherein the controller 26 is configured to selectively cause phased operation of the first impulse cleaning device 22 and the second impulse cleaning device 23 such that the phased operation selectively controls the location of the intersection 210 of the respective shock waves.

Owner:GENERAL ELECTRIC CO

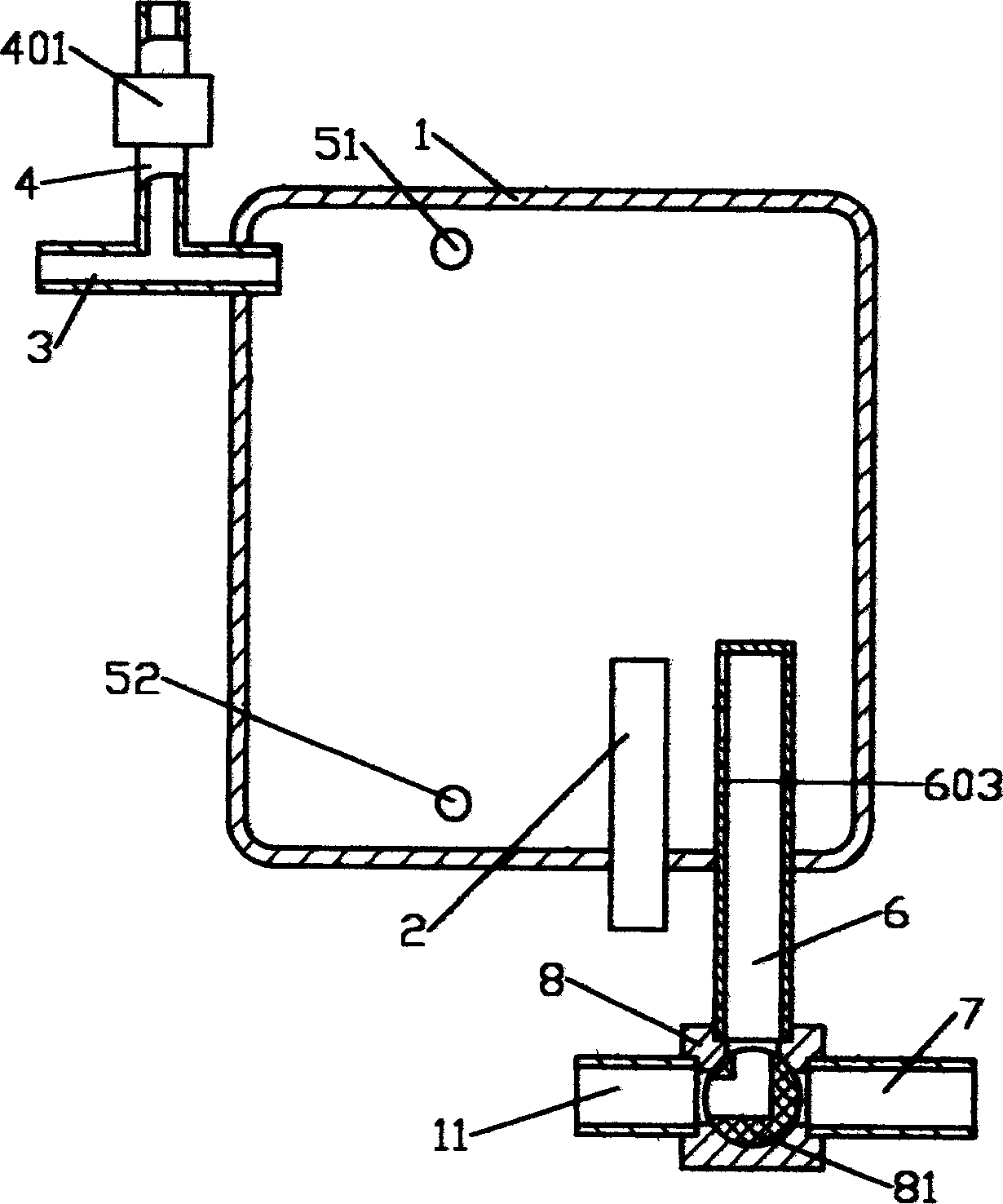

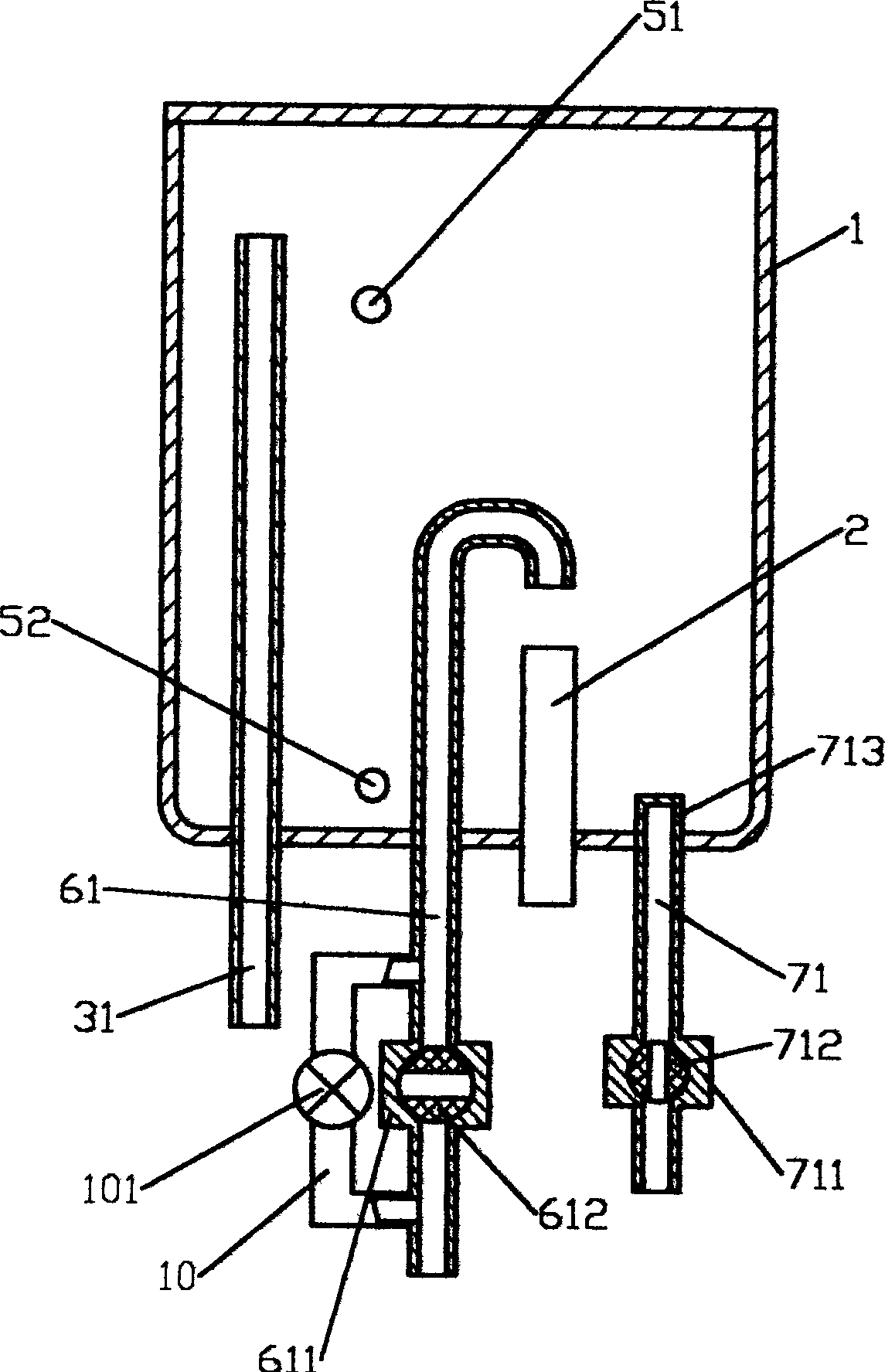

Automatic cleaning coke oven raw coke oven gas waste heat recovery heat exchange tube tar and carbon deposition device

PendingCN108489328ATo achieve the purpose of maximizing recyclingContinuously workingCombustion cleaningFlush cleaningPlate heat exchangerReciprocating motion

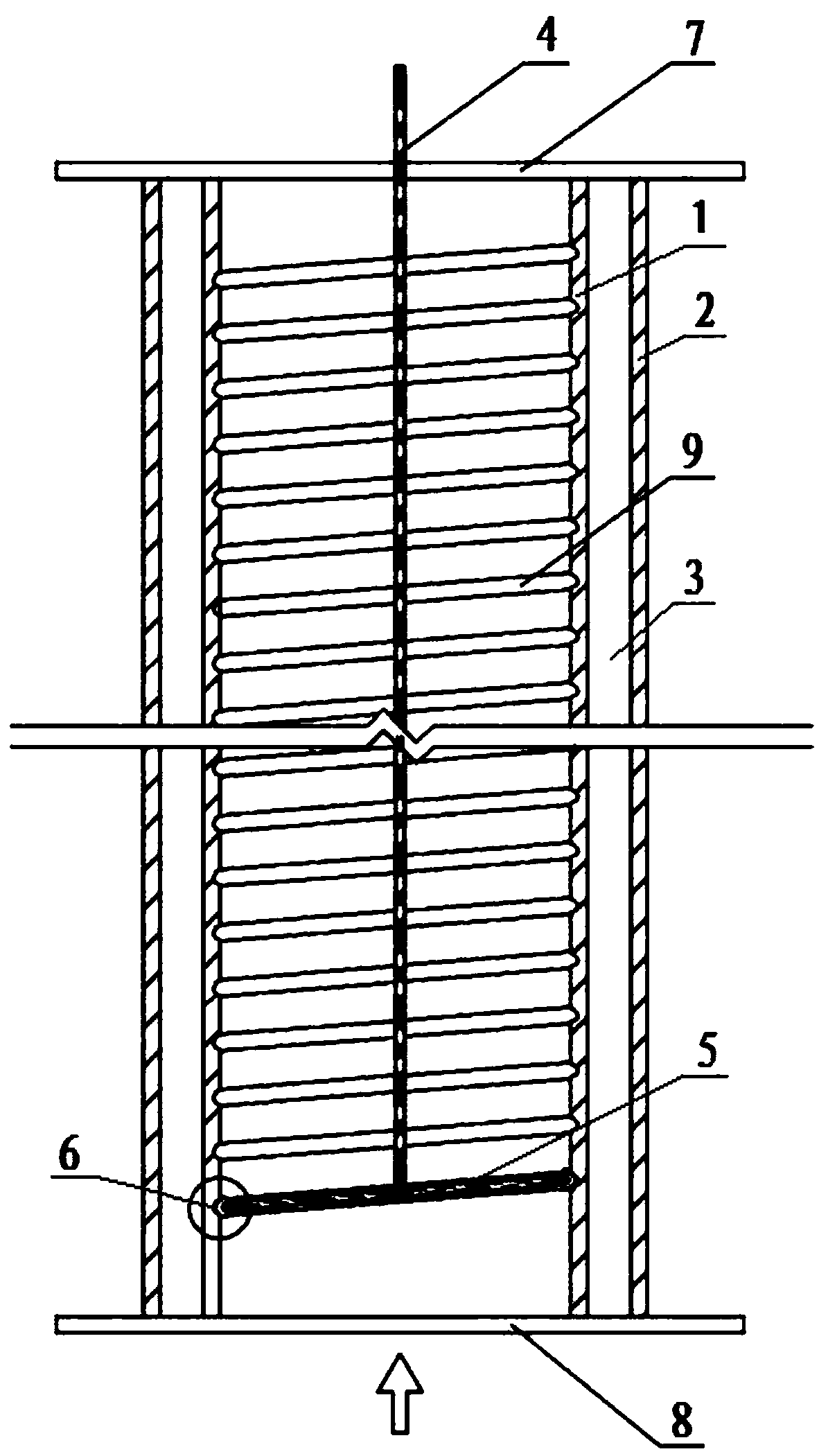

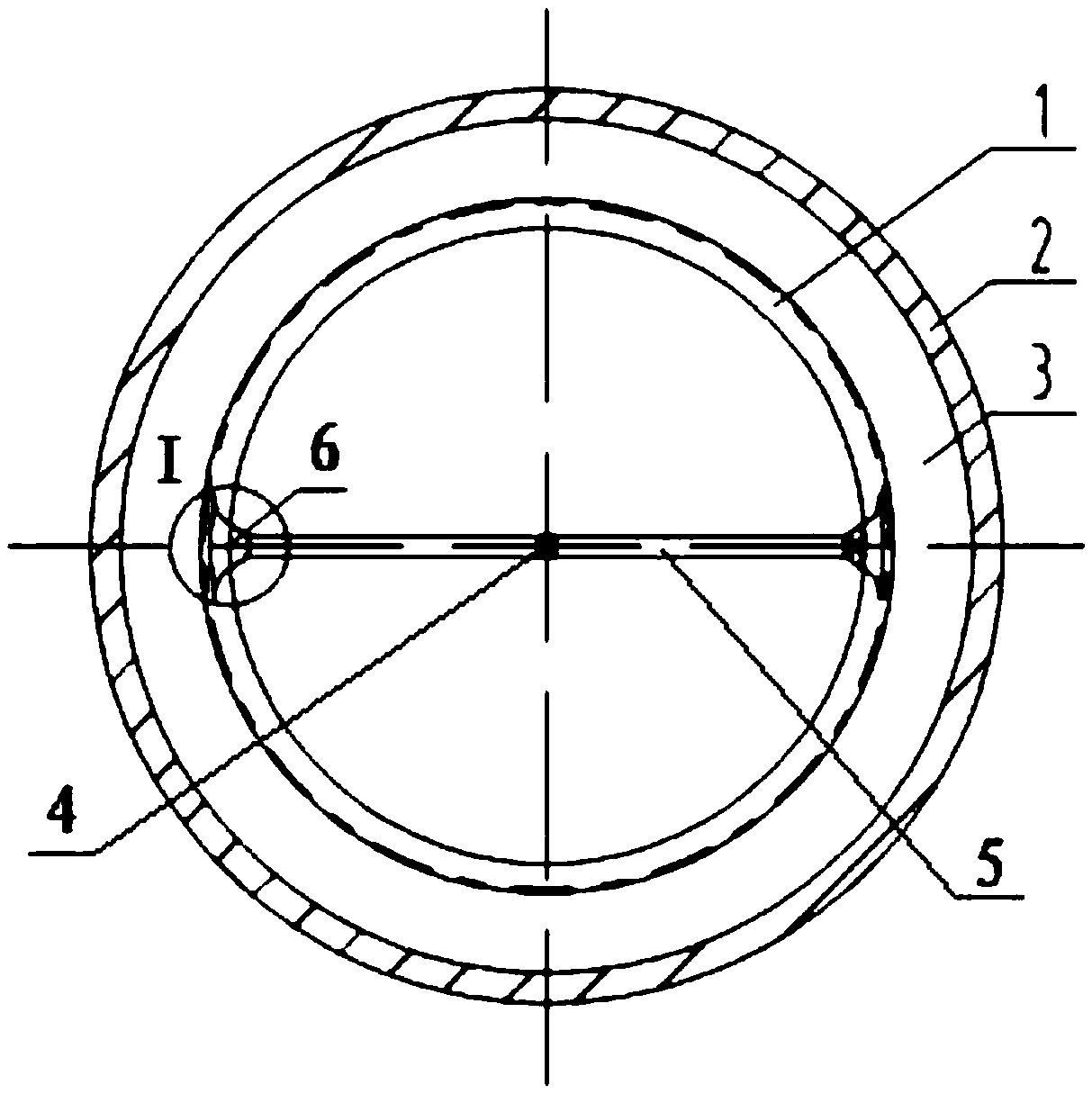

The invention discloses an automatic cleaning coke oven raw coke oven gas waste heat recovery heat exchange tube tar and carbon deposition device. According to the technical characteristics, the innerwall of a heat exchange pipe is of a thread type groove structure, a rotating rod is installed on a center line of the heat exchange pipe, the upper end of the rotating rod extends out of an upper end cover of the heat exchange pipe to be connected with a driving device outside a shell, an ash removing head clamping rod is connected to the lower end of the rotating rod, and ash removing heads areinstalled at the two ends of the ash removing head clamping rod and are in clearance fit with a thread type groove in the inner wall of the heat exchange pipe; and the ash removing head clamping rodand the ash removing heads are driven by the rotating rod to do spiral rotation reciprocating motion along the thread type groove in the inner wall of the heat exchange pipe, the ash removing heads inrotation motion remove tar and deposition carbon attached to the inner wall of the heat exchange pipe, and meanwhile, disturbance is applied to raw coke oven gas. The device solves the problem that heat exchange efficiency reduction caused by tar congealing and carbon deposition on the inner wall of a rising pipe, raw coke oven gas waste heat can be recovered to the largest degree, and it can beguaranteed that the heat exchanger continuously and normally works under the complex working conditions.

Owner:HUNAN UNIV OF SCI & TECH

Device to improve effectiveness of pulse detonation cleaning

A system and associated method for removing accumulated debris from a surface of a vessel. The system includes an impulse cleaning device defining a combustion chamber in which combustible fuel and air are mixed and ignited to produce combustion that is directed at the surface to be cleaned within the vessel, and an eductor assembly surrounding a downstream end of the chamber for inducting surrounding atmosphere into the combustion to widen the area being cleaned.

Owner:BARRETO INVESTMENT GRP INC

Pulse detonation cleaning unit with multiple folded flow paths

Owner:PARKER HANNIFIN CORP

Press probe

Pressure probe methods and apparatus are disclosed. An exemplary probe includes a body having an outer surface with a forwardly converging nose. A passageway extends between the first port in the body and the pressure sensor. The support member holds the body in the operative position. A cooling fluid circuit extends at least partially through the support member and the body. Pressure probes can be used in combination with detonation cleaning equipment.

Owner:UNITED TECH CORP

Detonation combustor cleaning device and method of cleaning a vessel with a detonation combustor cleaning device

A detonation combustor cleaning device includes at least one combustion chamber having combustion flow path and including a deflection member. An ignition device is operatively connected to the at least one combustion chamber is selectively activated to ignite a combustible fuel within the at least one combustion chamber to produce a shockwave that moves in a first direction along the combustion flow path, impacts the deflection member, reverses direction and passes into a vessel to dislodge particles clinging to inner surfaces thereof.

Owner:BARRETO INVESTMENT GRP INC

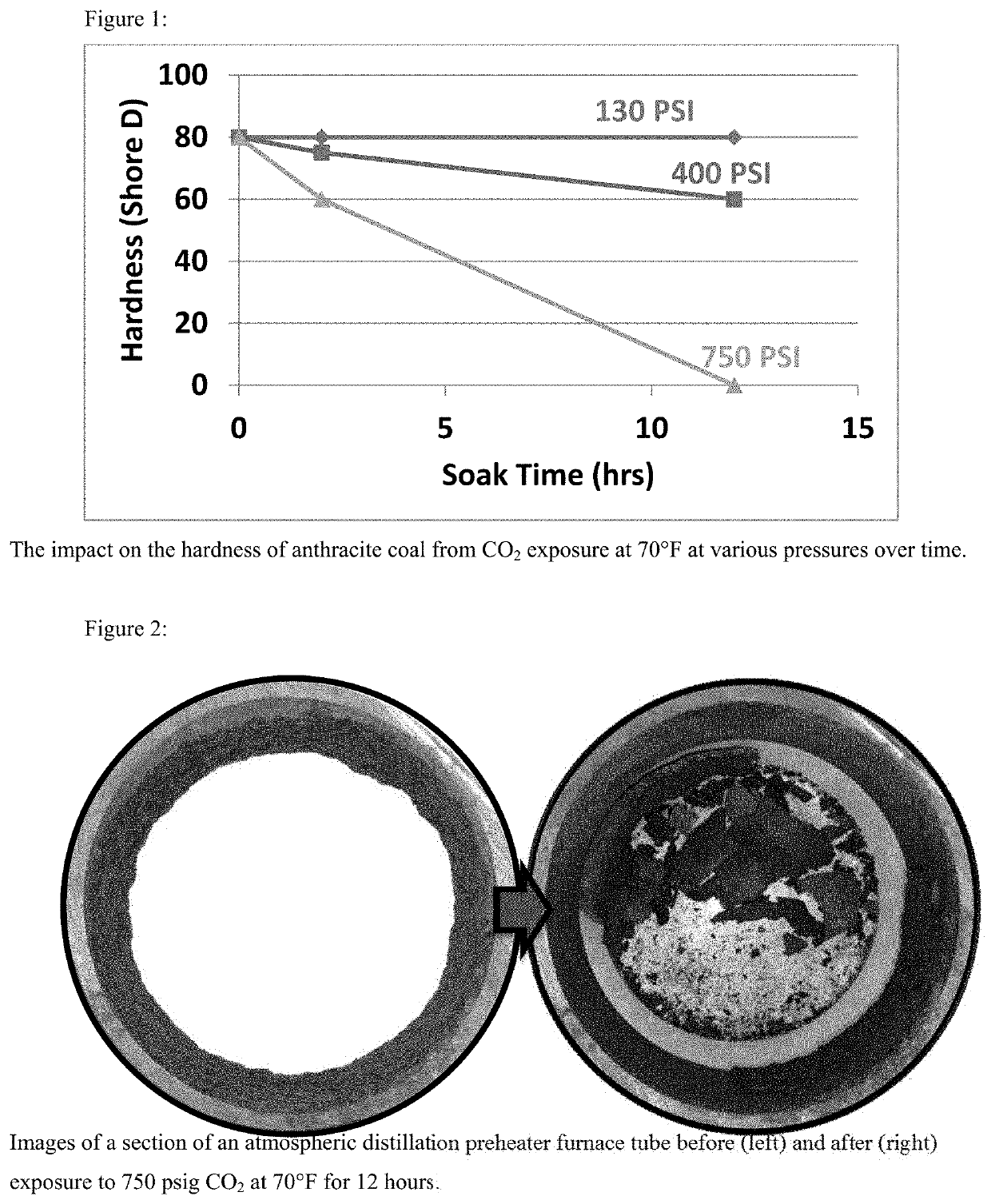

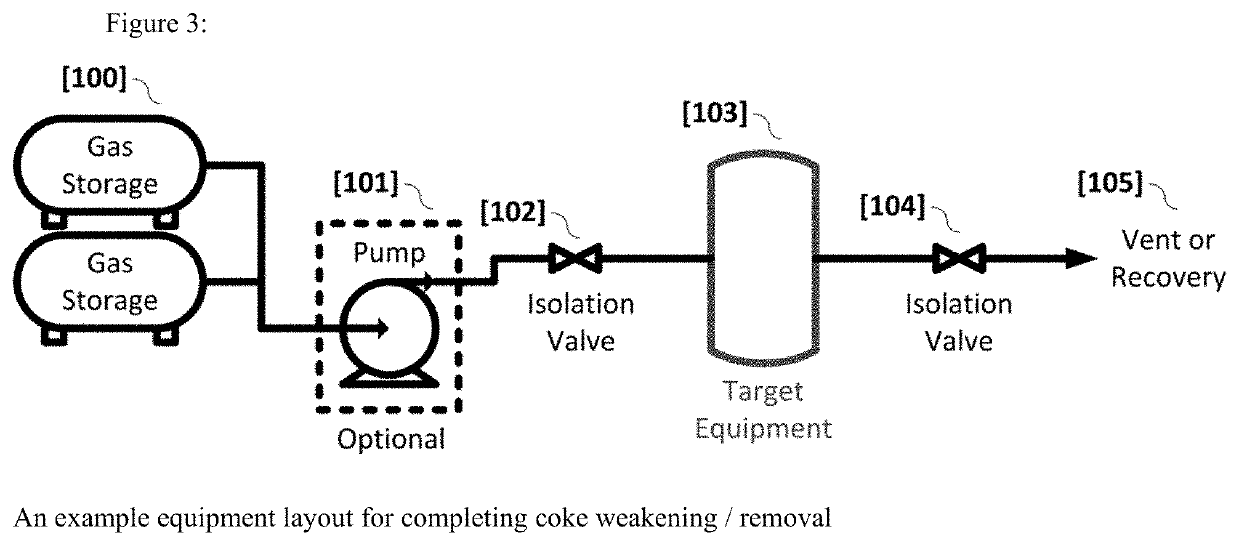

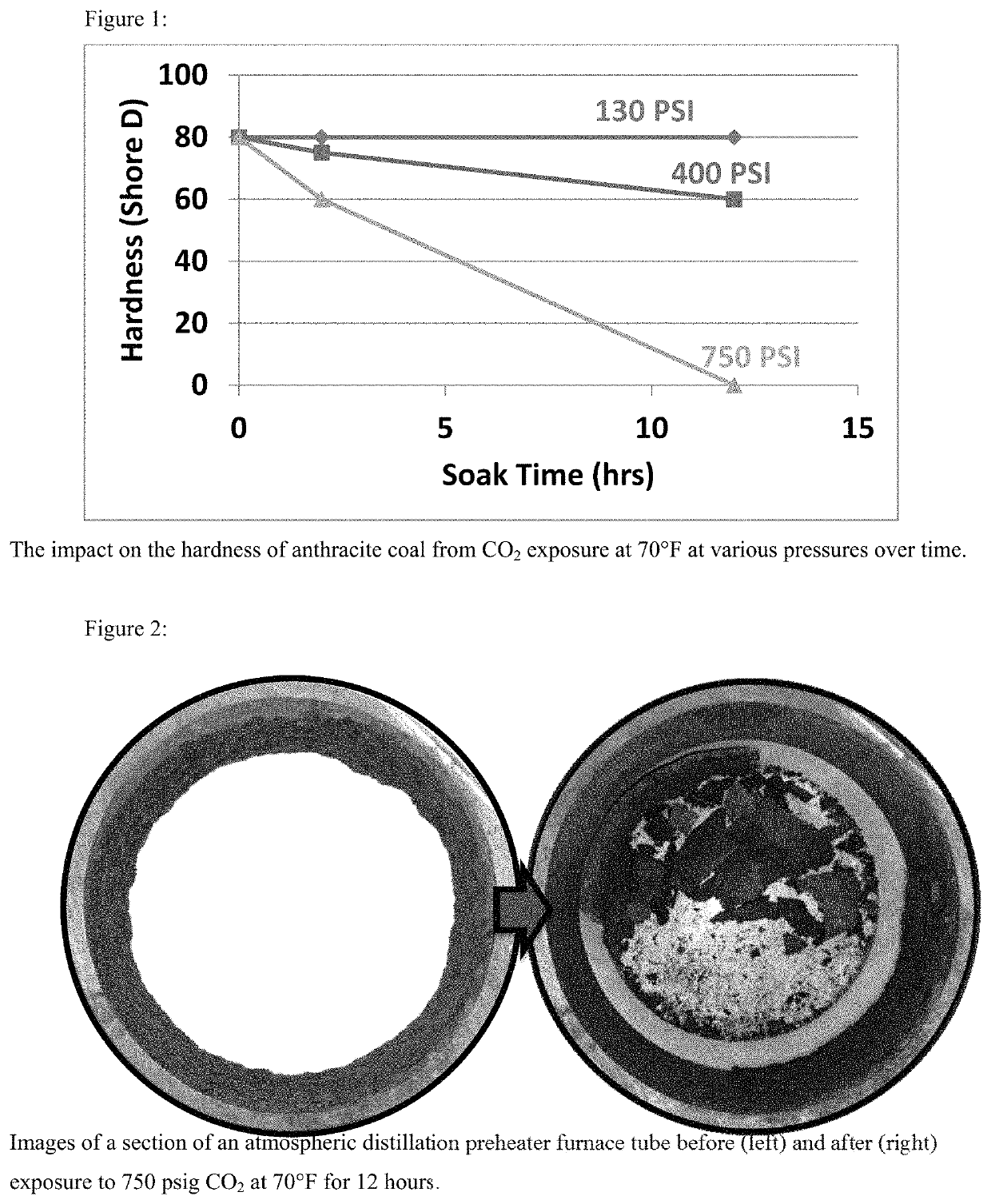

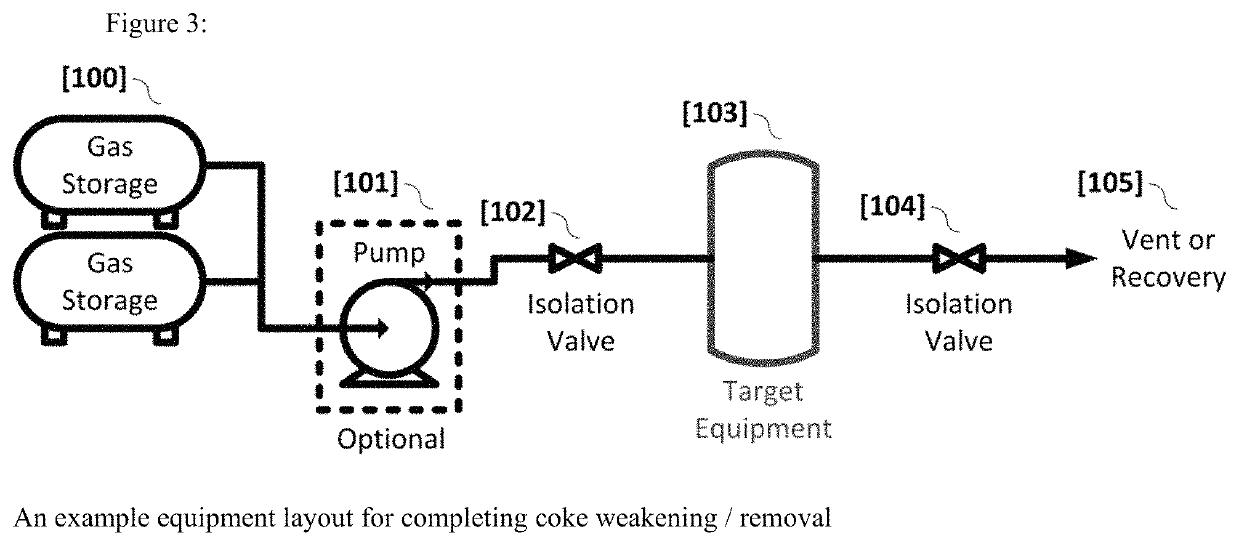

Method for weakening and removing coke and carbonaceous deposits

ActiveUS20190366395A1Thermal non-catalytic crackingHollow article cleaningHydrocotyle bowlesioidesSediment

The present invention concerns a method of weakening and removal of coke or carbonaceous material which deposits as a result of thermal cracking of hydrocarbons on the inner walls of coils, piping, tubing, and in general, hydrocarbon processing equipment.

Owner:PRAXAIR TECH INC

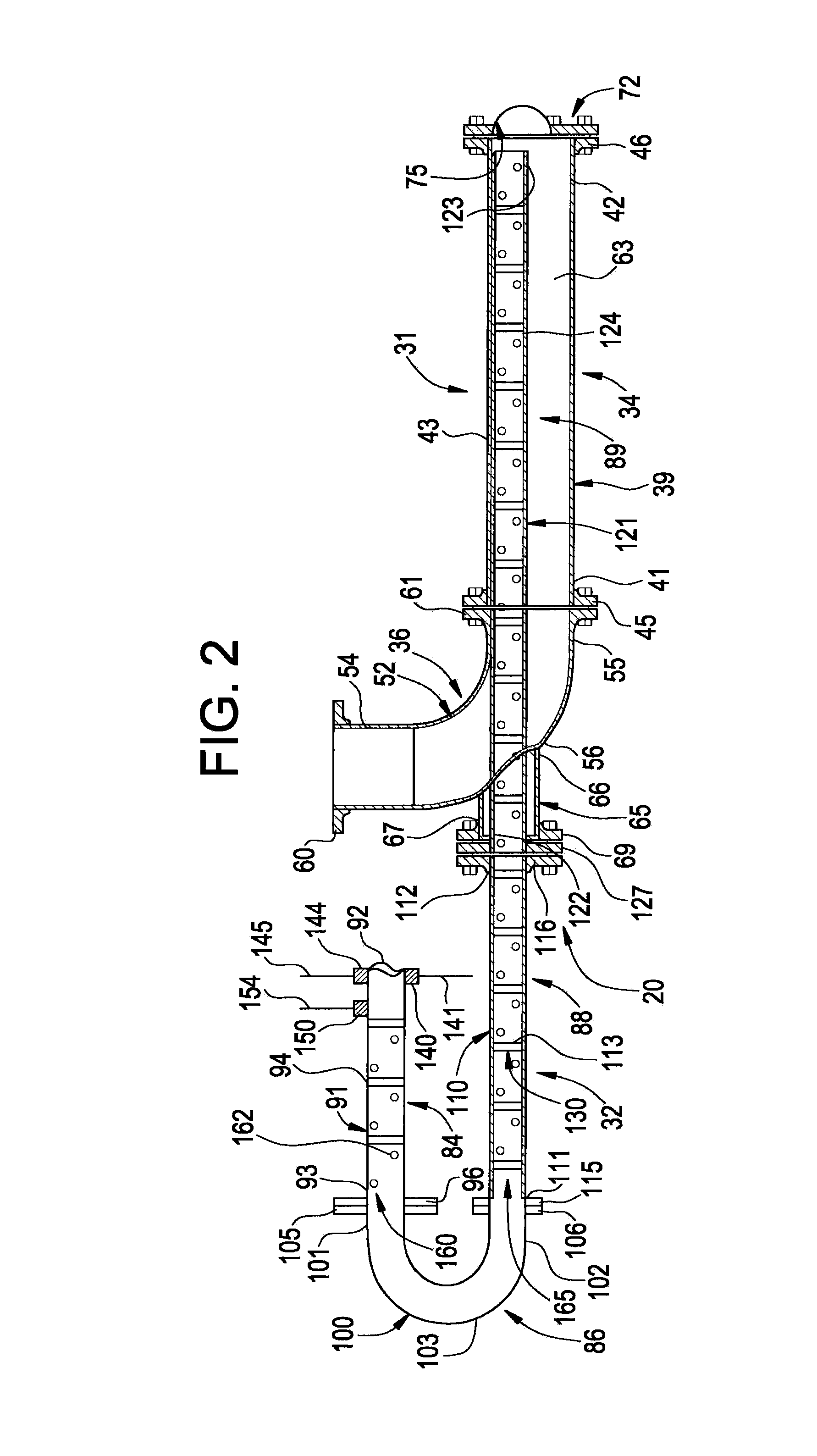

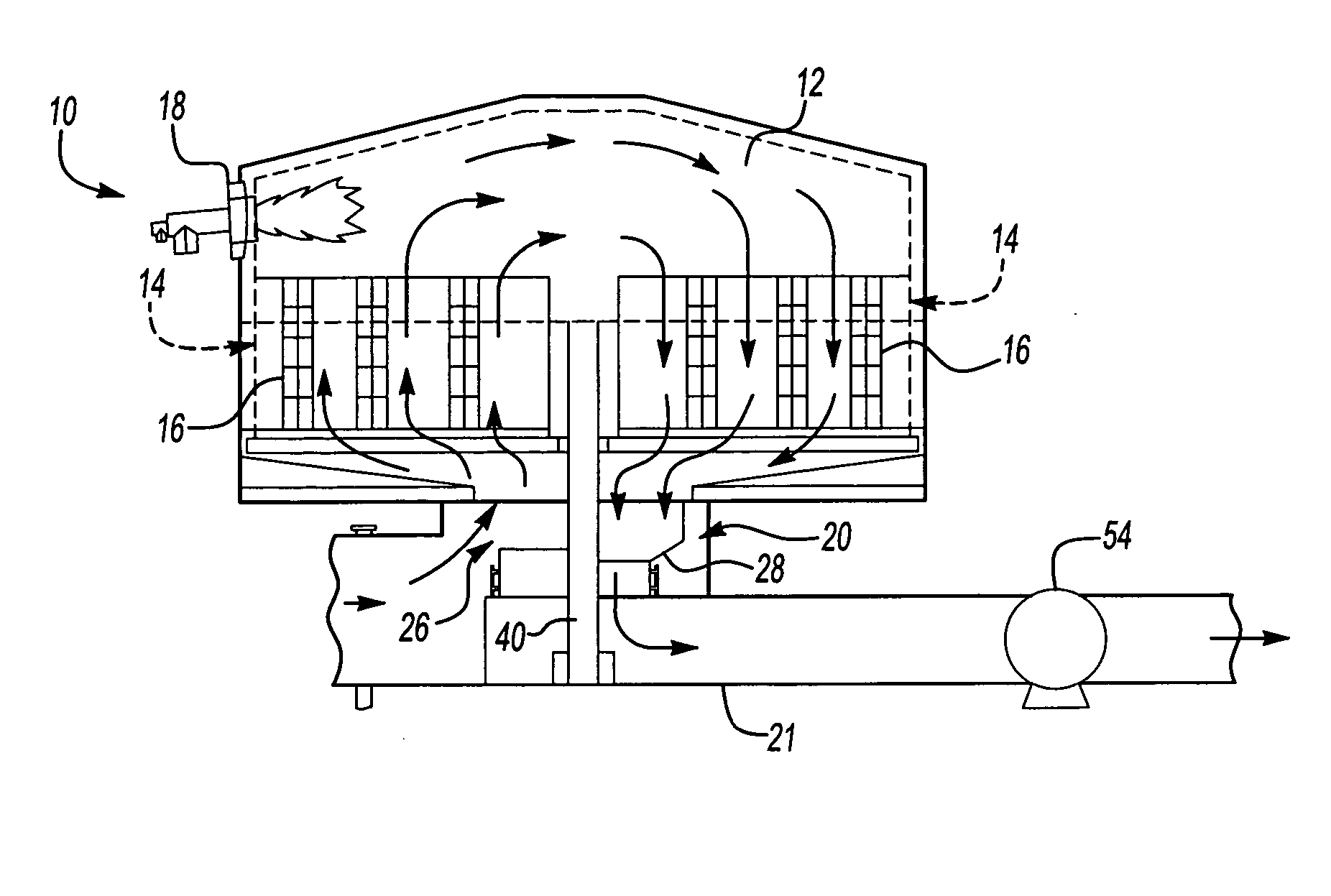

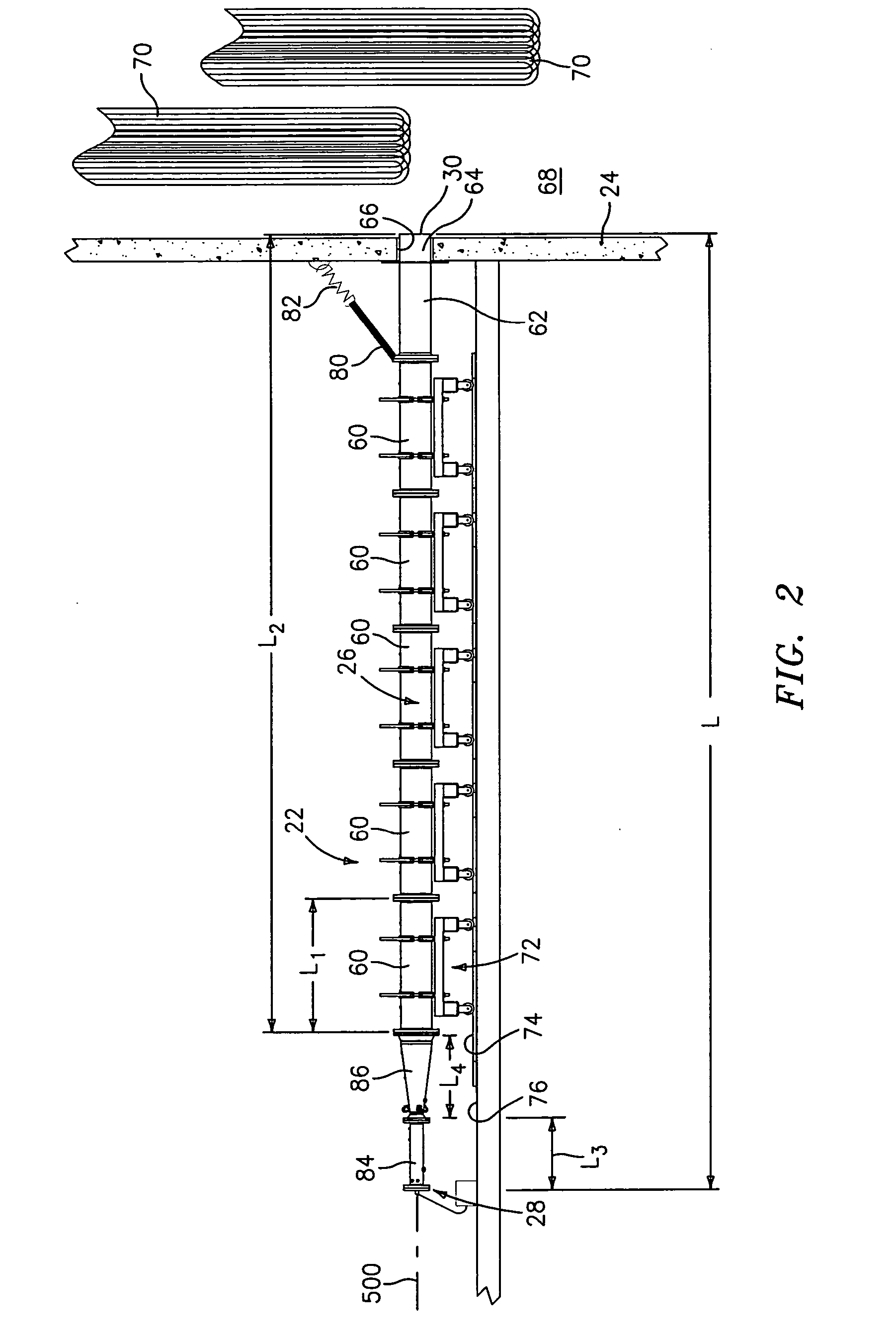

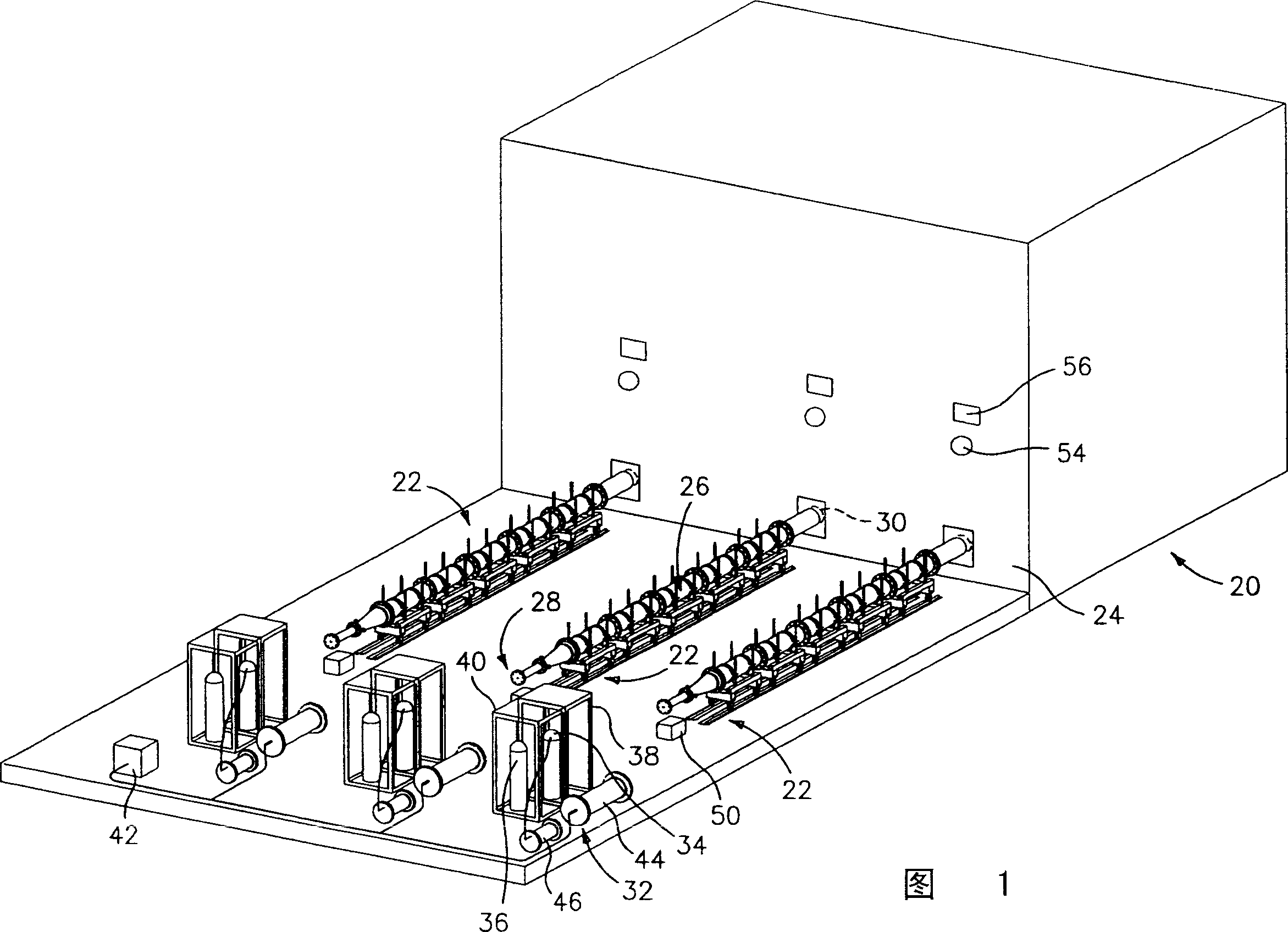

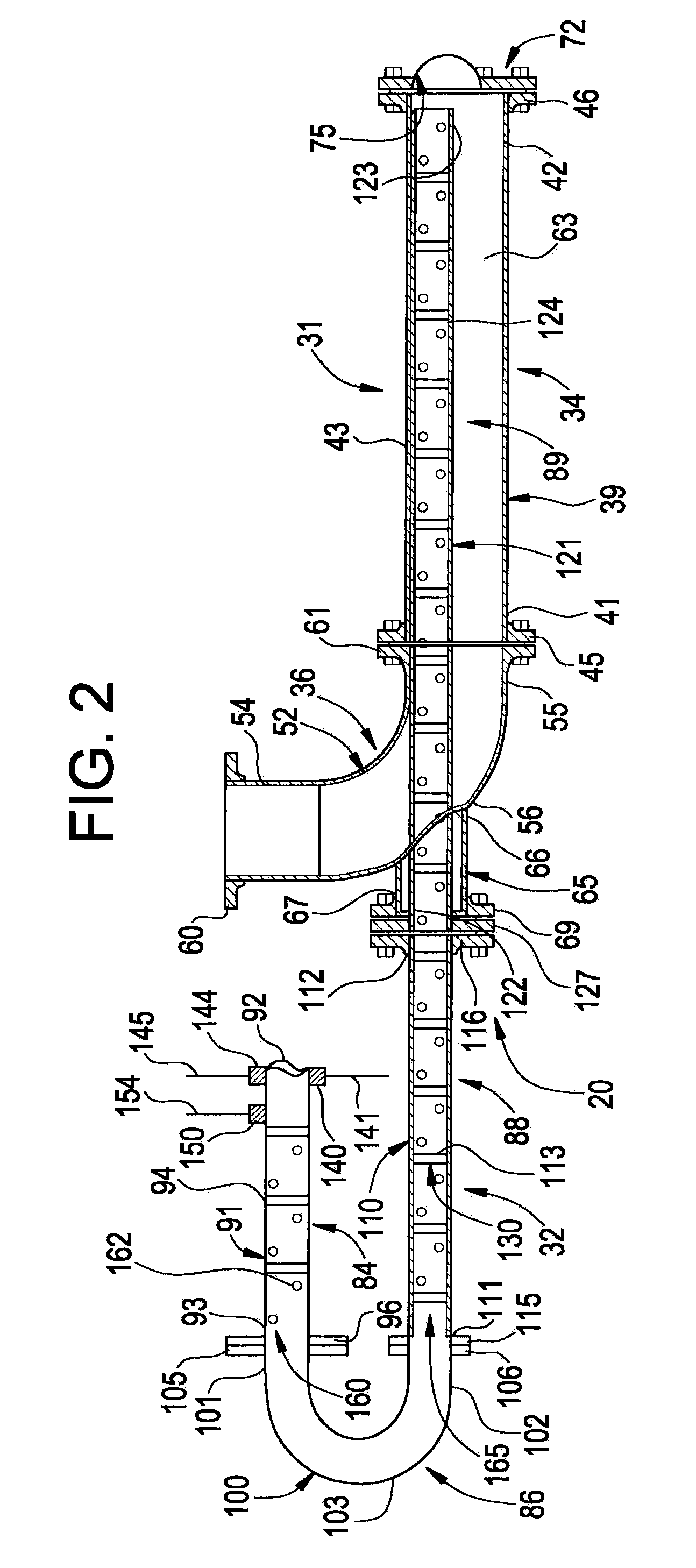

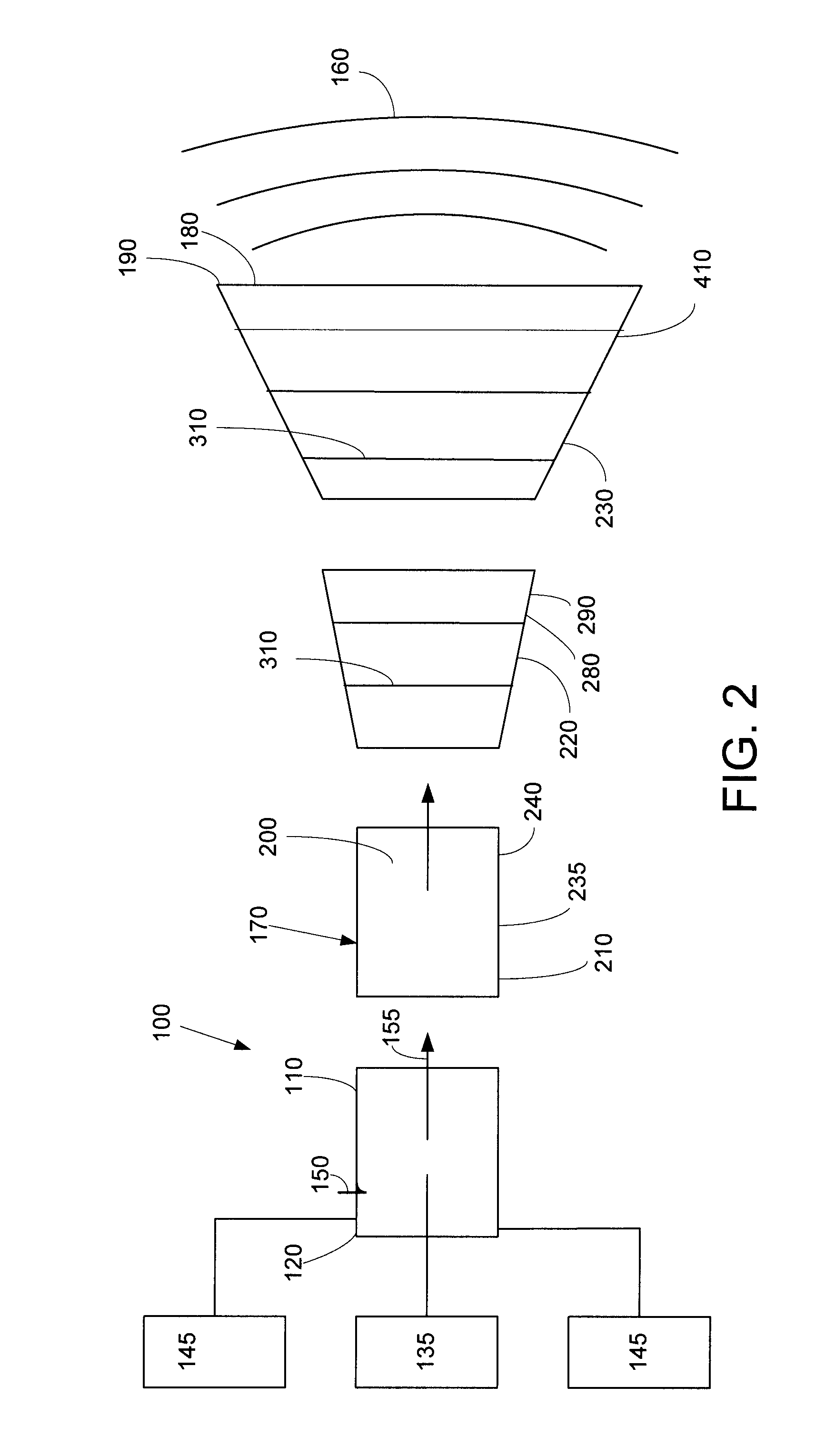

Combustion cleaning system and method

The present invention provides an improved system and method for cleaning a plurality of semi-permeable heat exchange surfaces using an impulse wave which is transmitted by a distribution network and moved around the heat exchange surfaces by a navigational network.

Owner:BARRETO VINCENT P

Method for weakening and removing coke and carbonaceous deposits

The present invention concerns a method of weakening and removal of coke or carbonaceous material which deposits as a result of thermal cracking of hydrocarbons on the inner walls of coils, piping, tubing, and in general, hydrocarbon processing equipment.

Owner:PRAXAIR TECH INC

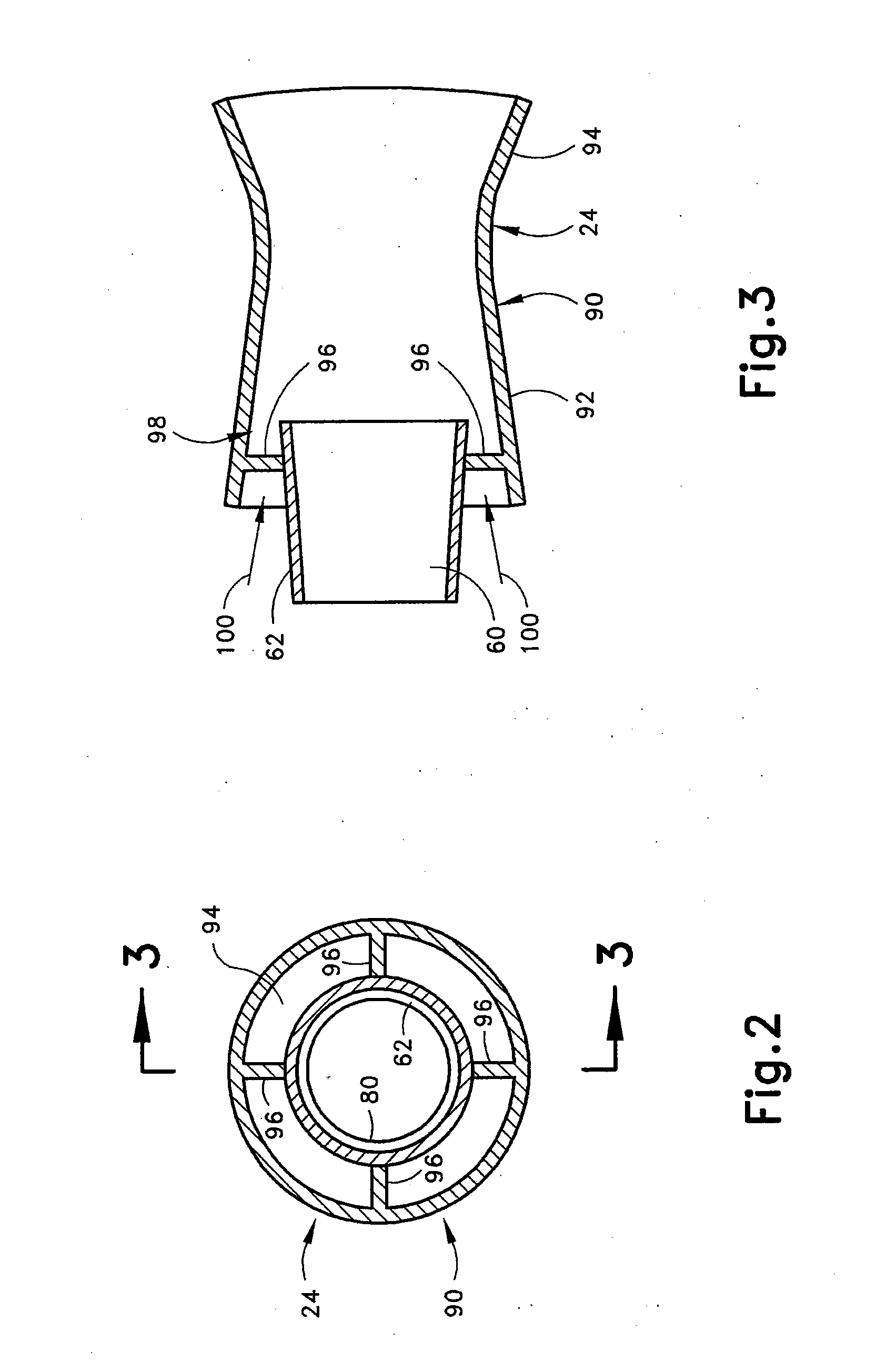

Pulse Detonation Combustor Cleaning Device with Divergent Obstacles

The present application provides a pulse detonation combustor cleaning device. The pulse detonation combustor cleaning device may include a combustion section and one or more combustion tube sections downstream of the combustion section. The combustion tube sections may a divergent shape and a number of divergent obstacles therein.

Owner:BHA ALTAIR

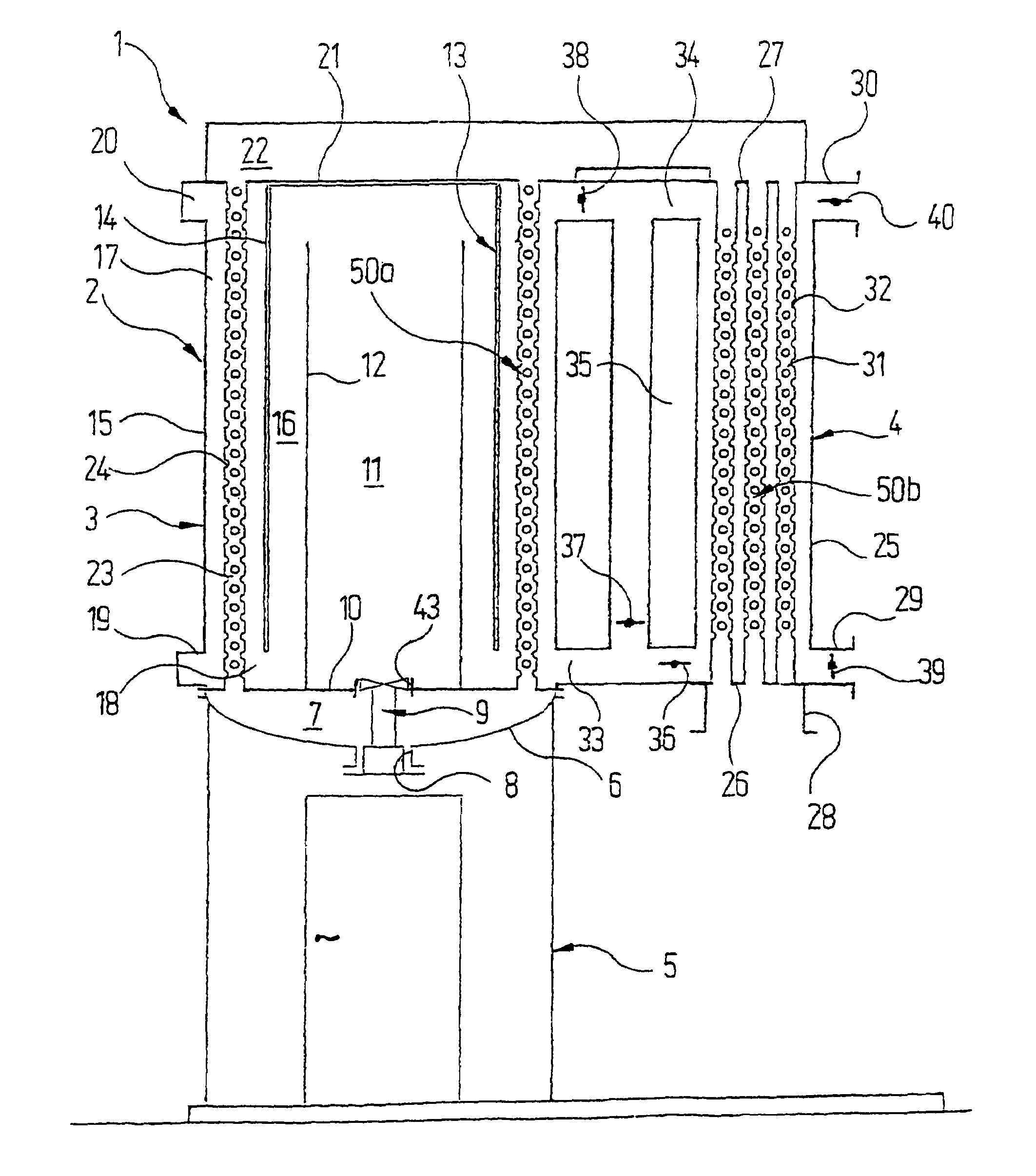

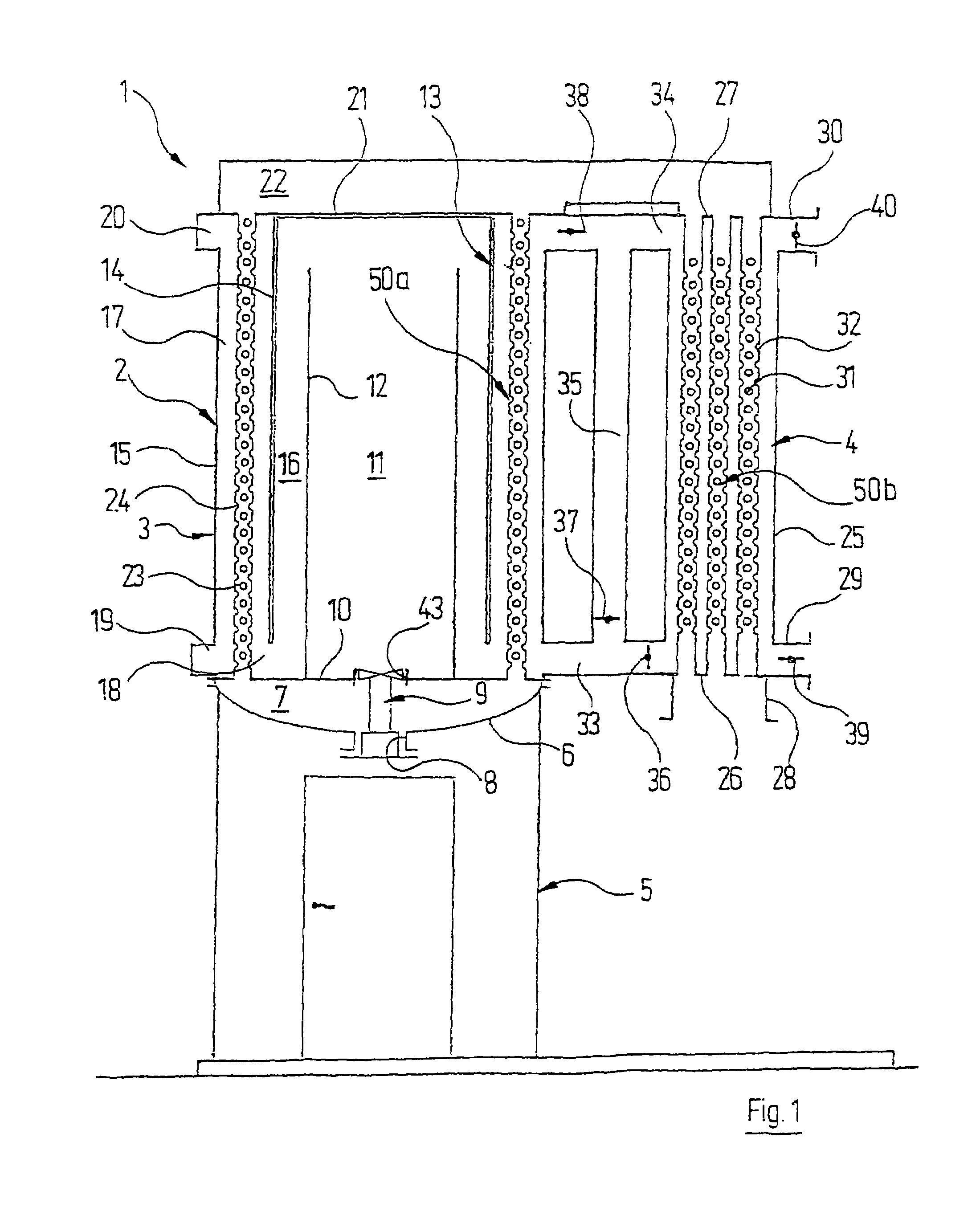

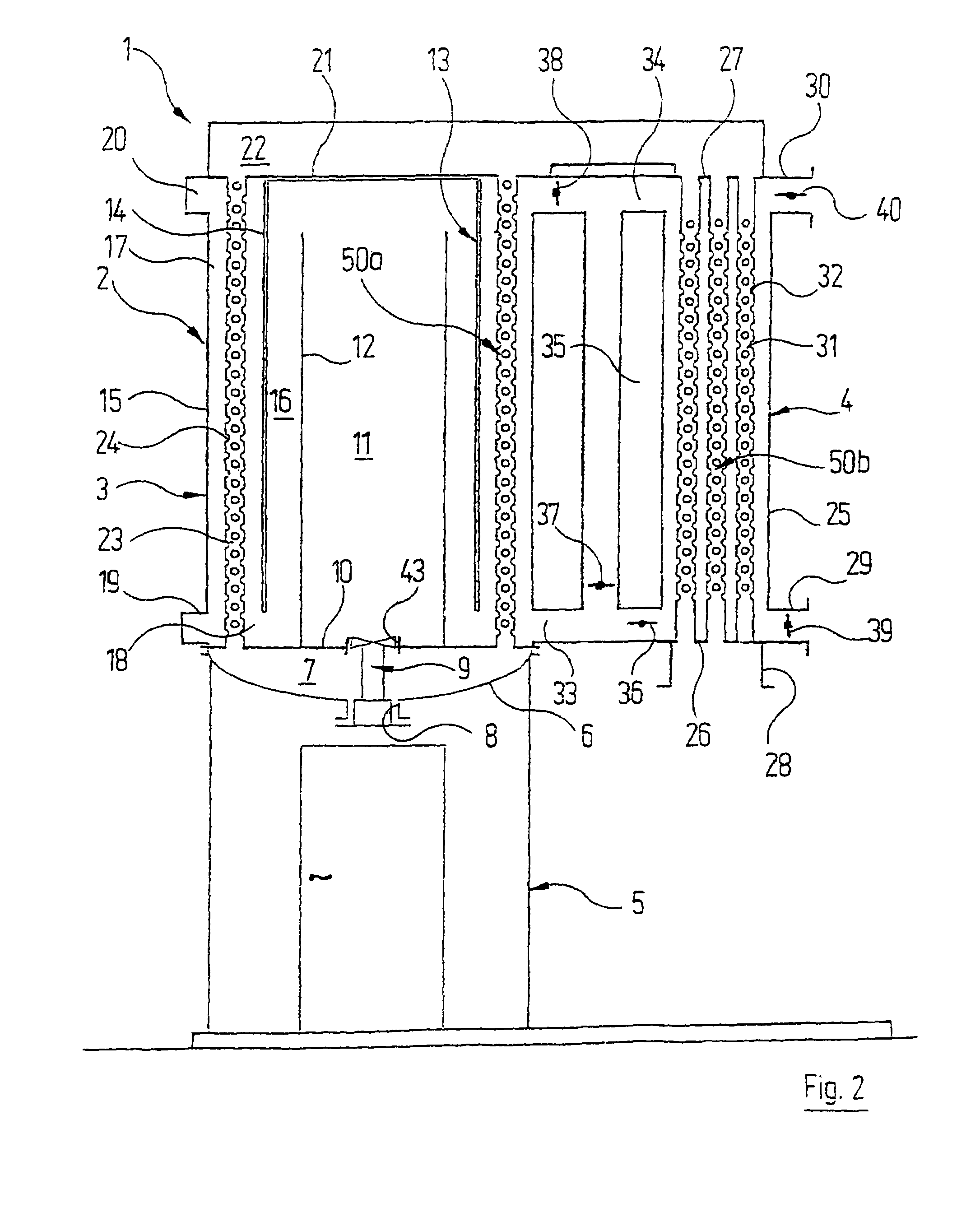

Thermal postcombustion device and method for operating the same

InactiveUS8316922B2Short timeAdhesive residueSolid fuel combustionCombustion cleaningCombustion chamberEngineering

A thermal postcombustion device includes, in a conventional manner per se, a housing, having an inlet for the exhaust air that is to be purified and an outlet for clean air. A combustion chamber is located inside the housing, and inside this combustion chamber, a heating device generates a temperature at which the pollutants carried by the exhaust air burn. In order to reduce the energy requirement, a heat exchanger is provided over which the exhaust air coming from the inlet is guided to the combustion chamber, and the clean air coming from the combustion chamber is guided to the outlet. In order to also be able to process exhaust air, which is loaded with adherent residues, for example, pitch vapors, a device is provided with which, during a purification mode, at least a portion of the clean air can be optionally fed past a section of the heat exchanger located closer to the combustion chamber and into another section of the heat exchanger located further from the combustion chamber. Deposits, which have formed in the vicinity of the cold end of the heat exchanger, can be removed in this manner, particularly oxidized.

Owner:EISENMANN AG

Combustion cleaning system and method

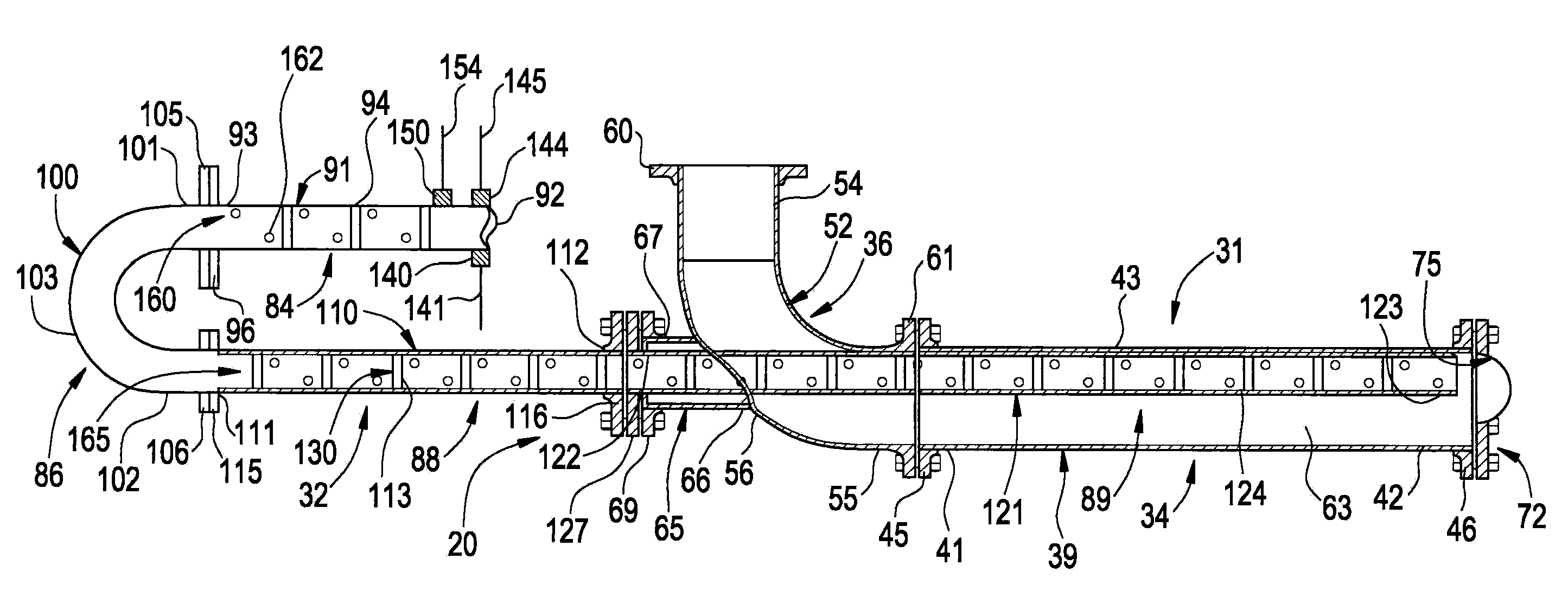

The present invention provides an improved system and method for cleaning a plurality of semi-permeable heat exchange surfaces using an impulse wave which is transmitted by a distribution network and moved around the heat exchange surfaces by a navigational network.

Owner:BARRETO VINCENT P +2

Acrylonitrile device reaction gas cooler quick-cleaning method

ActiveCN107796261AIncrease temperatureIncrease single receiptCombustion cleaningFlush cleaningNitrogenGas cooler

The invention relates to an acrylonitrile device reaction gas cooler quick-cleaning method, which belongs to the technical field of acrylonitrile production, and is characterized by comprising the cleaning steps of removing propylene feeding of a reactor, stopping a heat removing water pump of the reactor, burning ammonia gas for 27min to 33min, rising the temperature of the reactor to 453 DEG C to 458 DEG C through improving the feeding amount of the ammonia gas, maintaining for 55min to 65min, and air purging the reactor so as to replace gas in the reactor; feeding nitrogen into the reactor,wherein the volume of the nitrogen amount entering the reactor under ordinary pressure is 2 to 4 times of the volume of a cooler; starting a water supply pump, independently cooling the cooler connected to the rear part of the reactor, and disassembling a seal head and adding a blind plate for carrying out water pressure cleaning on the cooler after the temperature of the cooler is reduced to theprocessing temperature required for acrylonitrile reaction. According to the cleaning method, the parking time is shortened to be 1 / 4 to 1 / 7 of the original parking time, and the single-pass yield ofacrylonitrile is more than 81 percent after driving.

Owner:CHINA PETROLEUM & CHEM CORP

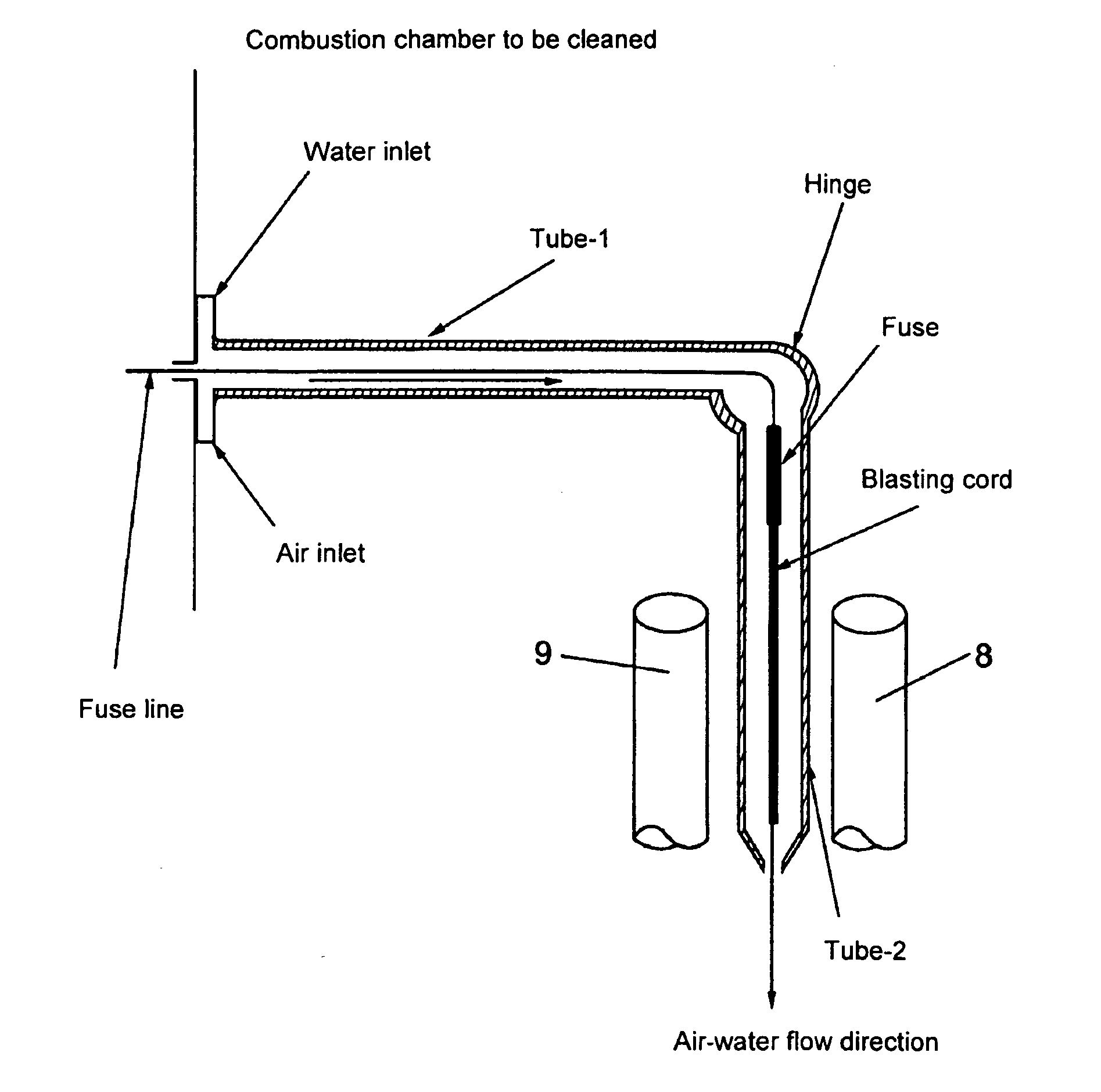

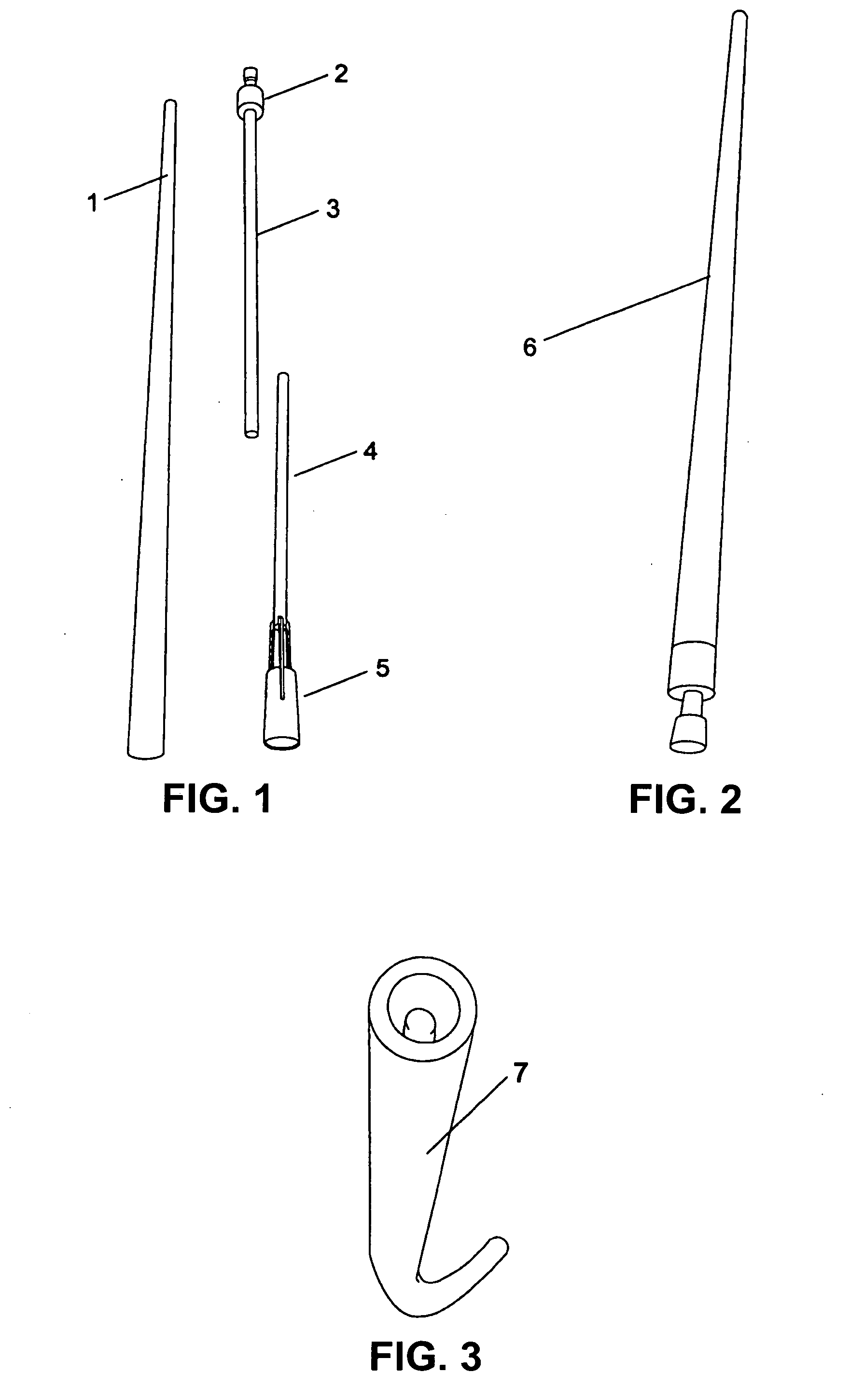

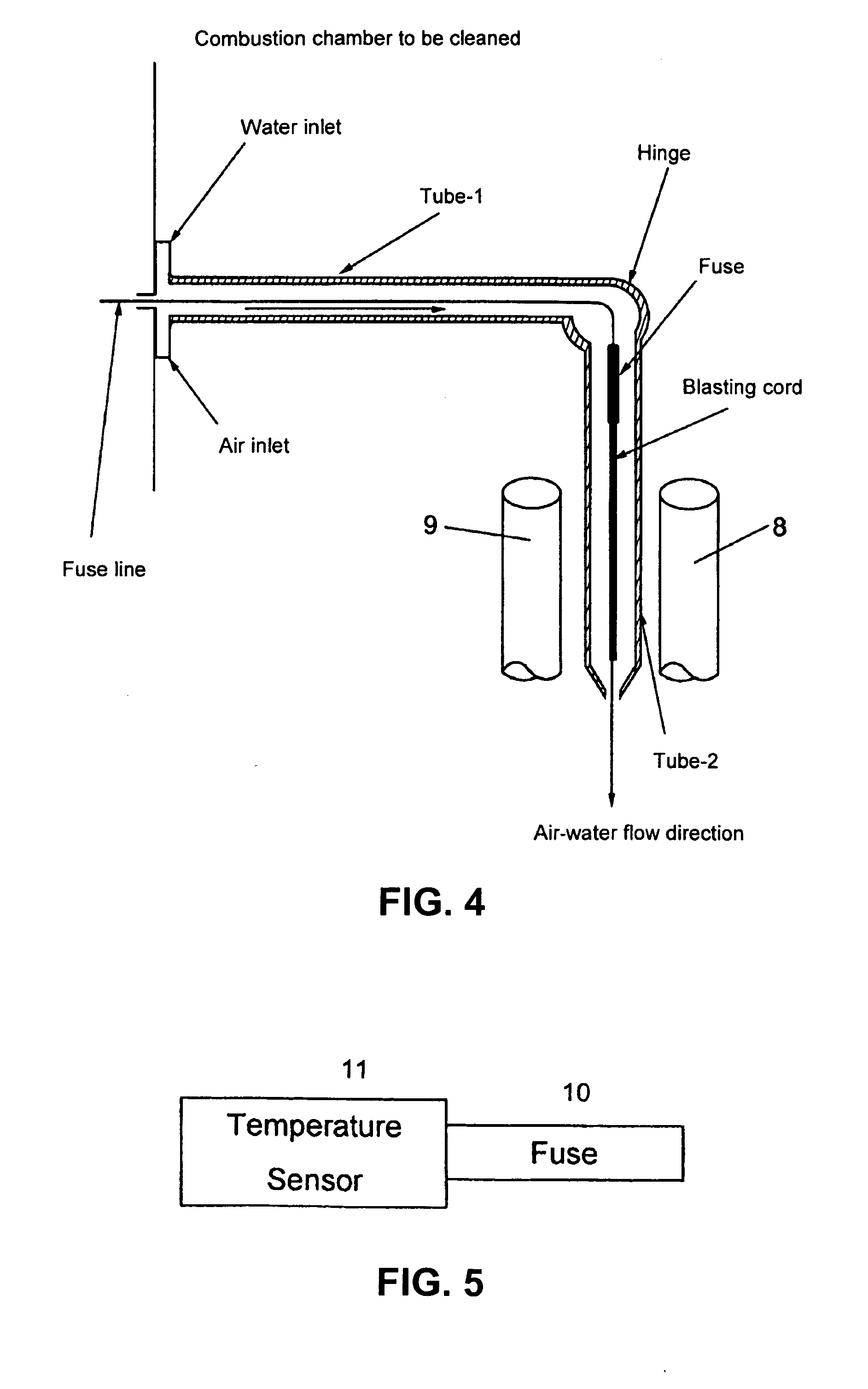

Method of and apparatus for cleaning fouling in heat exchangers, waste-heat boilers and combustion chambers

InactiveUS20110114035A1Remove polluting contaminationConvenient lengthBoiler cleaning apparatusMachines/enginesCombustion chamberCombustible gas

A device for cleaning contamination in heat exchangers, waste-heat boilers, or combustion chambers is provided. In some embodiments, the device comprises a tube, a blasting body, and a combustible gas mixture within the tube. In some embodiments, the tube is destroyed after blasting. In some embodiments, the device further comprises a second tube comprising a blasting cord that is connected to a fuse, wherein the second tube is coupled to the first tube by a hinge.

Owner:STEUR JR FRANS

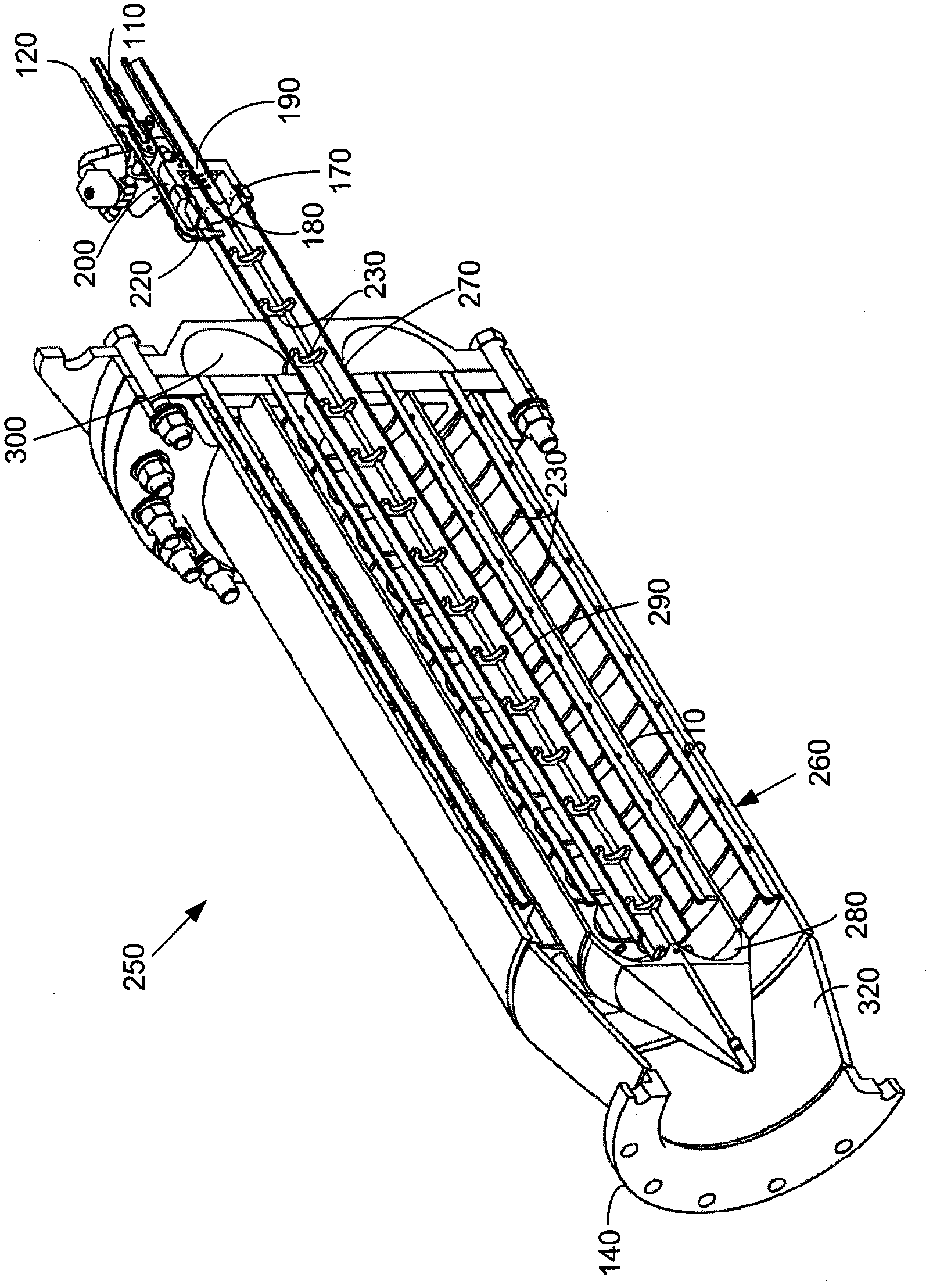

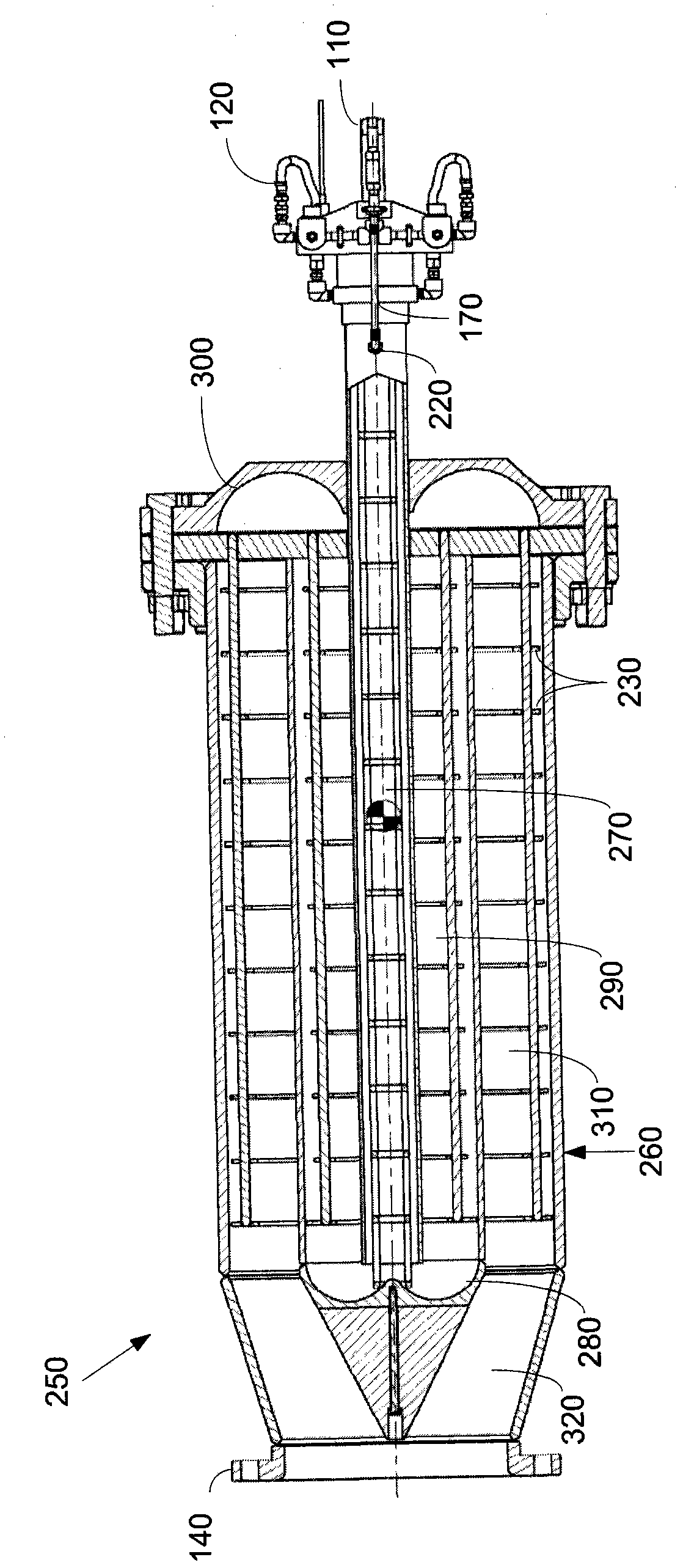

Pulse detonation cleaning system

A pulse detonation cleaning system is provided and includes a common tube, which is fluidly coupled to a vessel, a first array, including a plurality of elongate detonation tubes arrayed about a common axis, each of the plurality of the detonation tubes being disposed upstream from and fluidly coupled to an interior of the common tube and a second array, including a plurality of detonators arrayed about the common axis, each of the plurality of the detonators being disposed upstream from and operably coupled to a corresponding one of the plurality of the detonation tubes such that actuation of each of the plurality of the detonators leads to combustion in the corresponding one of the plurality of the detonation tubes.

Owner:BARRETO INVESTMENT GRP INC

Combustion cleaning system and method

The present invention is directed to an improved mobile combustion cleaning system for removing debris from a plurality of semi-permeable heat exchange surfaces with a moveable distribution network configured for receipt of a combustion mixture from a mobile cart according to a configurable controller the configurable controller generating the impulse wave from the combustion mixture and for moving the moveable distribution network along a plurality of axes in response to a change in pressure.

Owner:BARRETO VINCENT P

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com