Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about "Analogue computers for non-electric machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

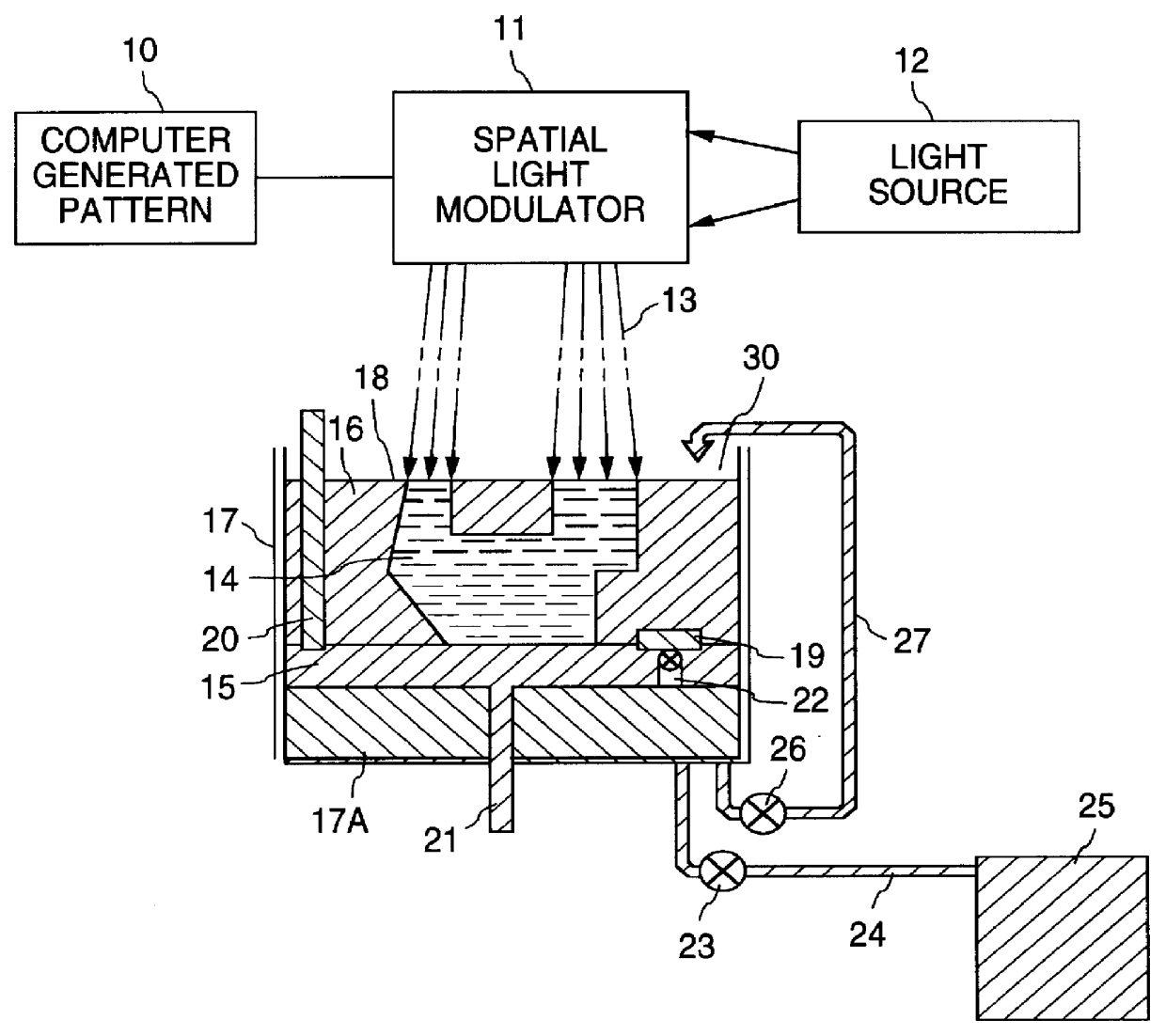

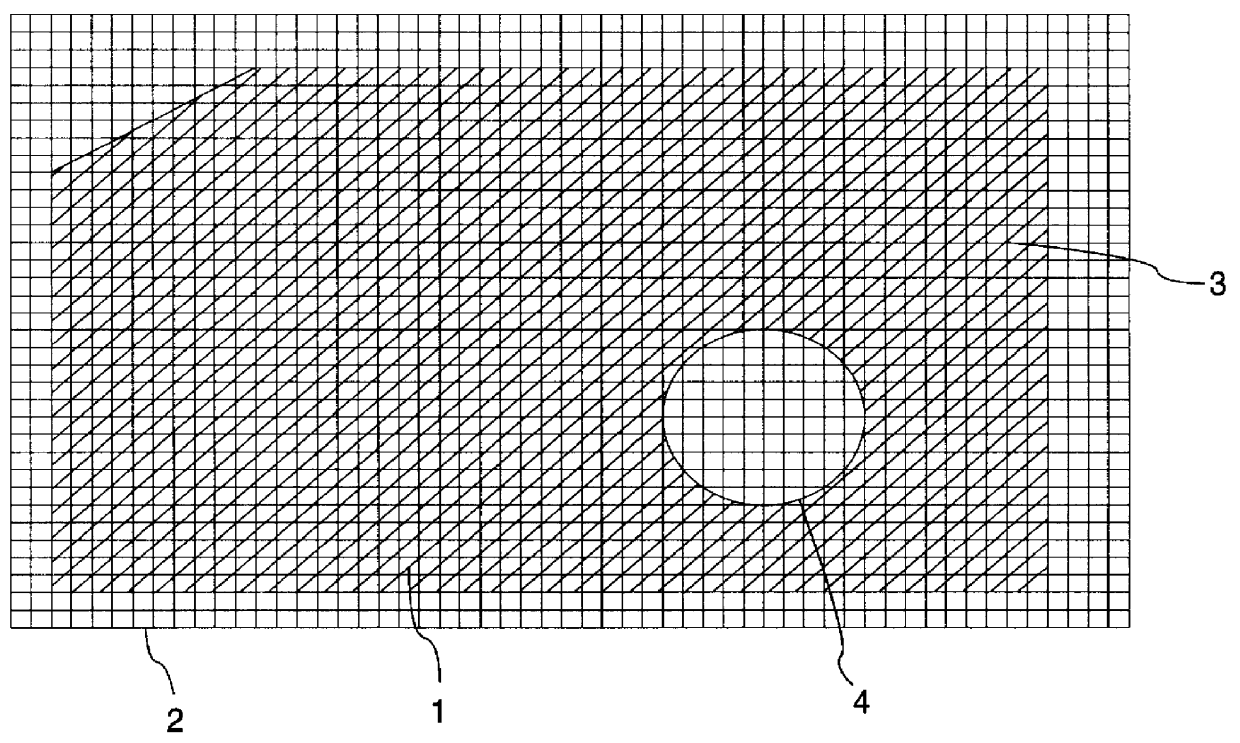

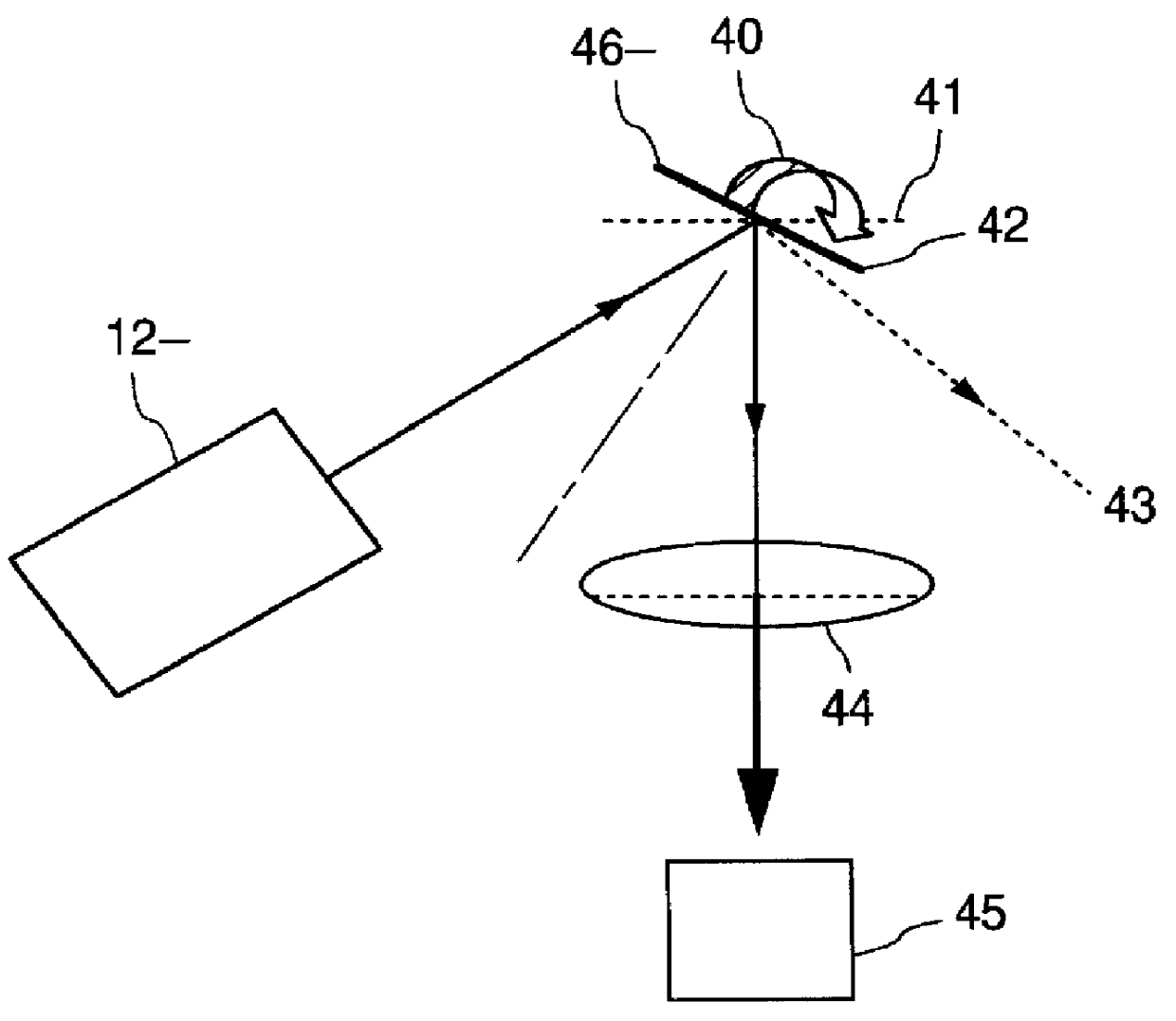

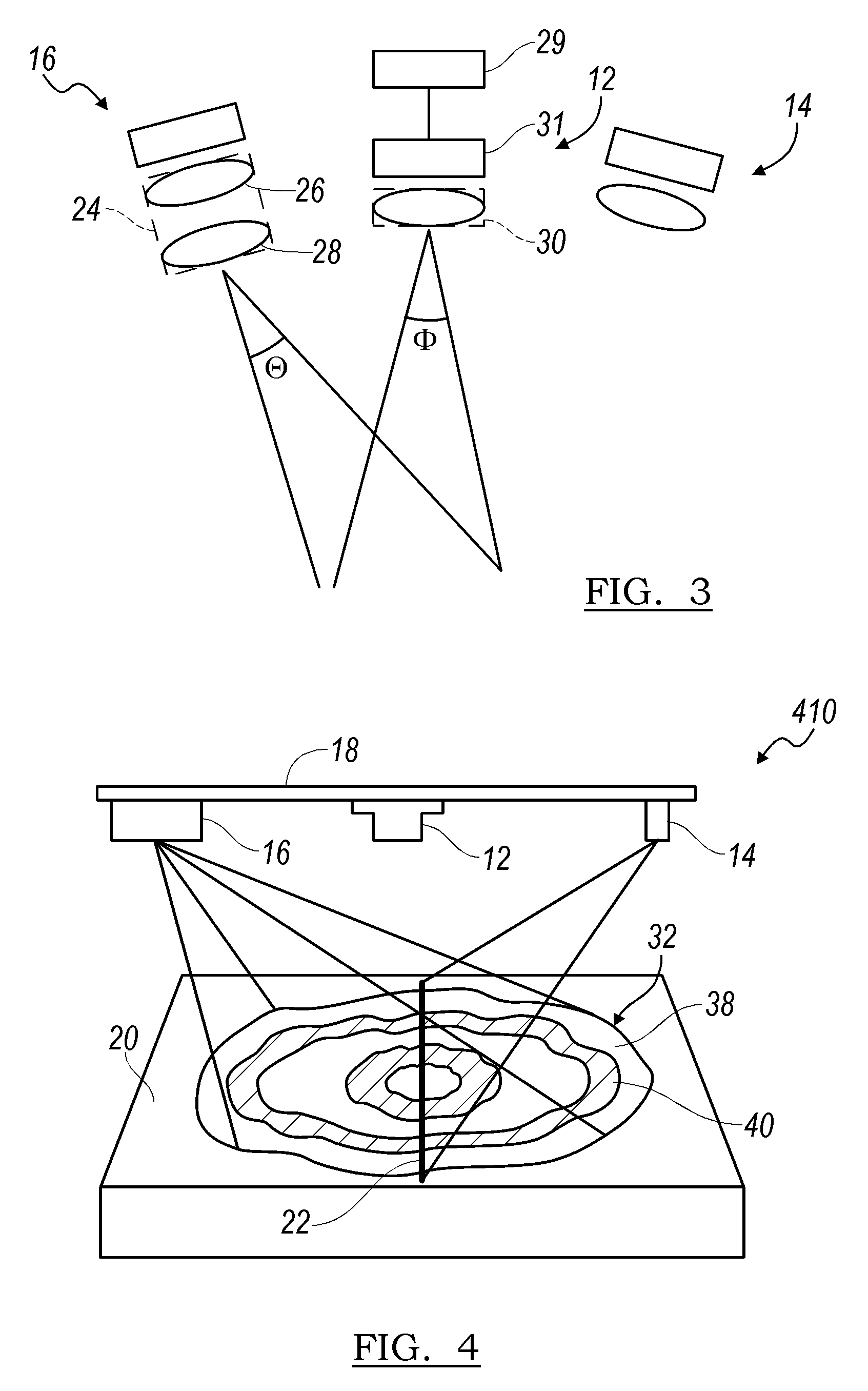

Apparatus and method for production of three-dimensional models by spatial light modulator

InactiveUS6051179AFacilitate cross-linkingHigh mechanical strengthAdditive manufacturing apparatusAnalogue computers for control systemsSpatial light modulatorWide beam

An apparatus and the method of its operation for rapid prototyping of a three-dimensional object which includes a radiant energy source of a wide beam of radiant energy of suitable intensity and wavelength for curing a layer of photo-curable resin contained in an open vat, a spatial light modulator (SLM) having an array of pixel elements which are individually digitally controllable by a computer, for modulating the radiant energy beam projected from the radiant energy source on a pixel by pixel basis, to form a series of time sequential images of the cross-sectional laminae of the object, an optical system for focusing each image formed by the SLM, one at a time, onto successive layers of photo-curable resin for predetermined exposure times to thereby form stacked laminae of cured resin, each lamina of cured resin being in the shape of a different one of the cross-sectional laminae, and a piston support for lowering each lamina of cured resin after it is formed by the SLM and for depositing a layer of resin corresponding to the thickness of one cross sectional lamina of the three-dimensional object before the step of projecting a new image by the SLM. The SLM, the piston support for lowering, and the optical system operate repeatedly and sequentially until a complete copy of the object is thereby produced.

Owner:GLOBAL FILTRATION SYST

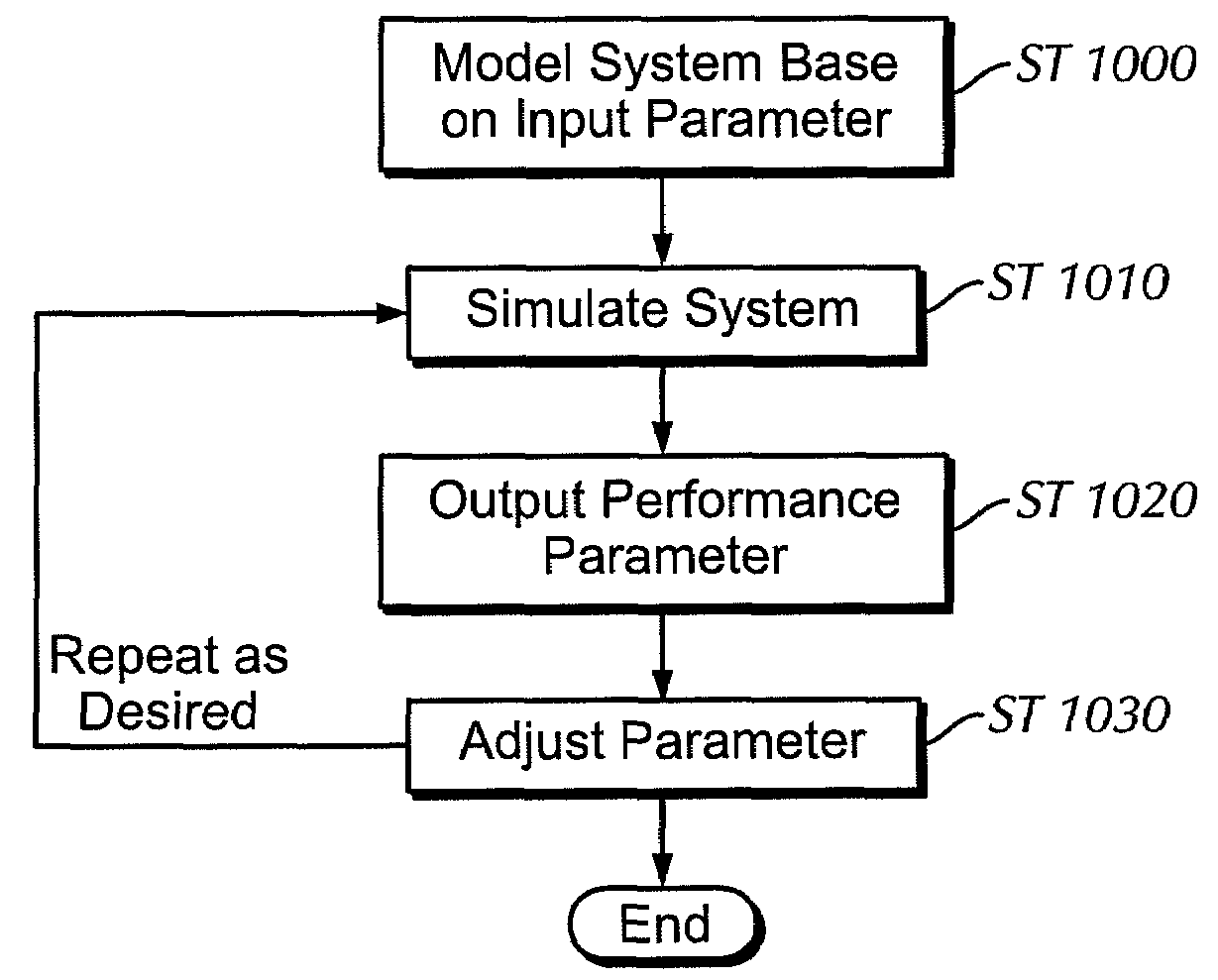

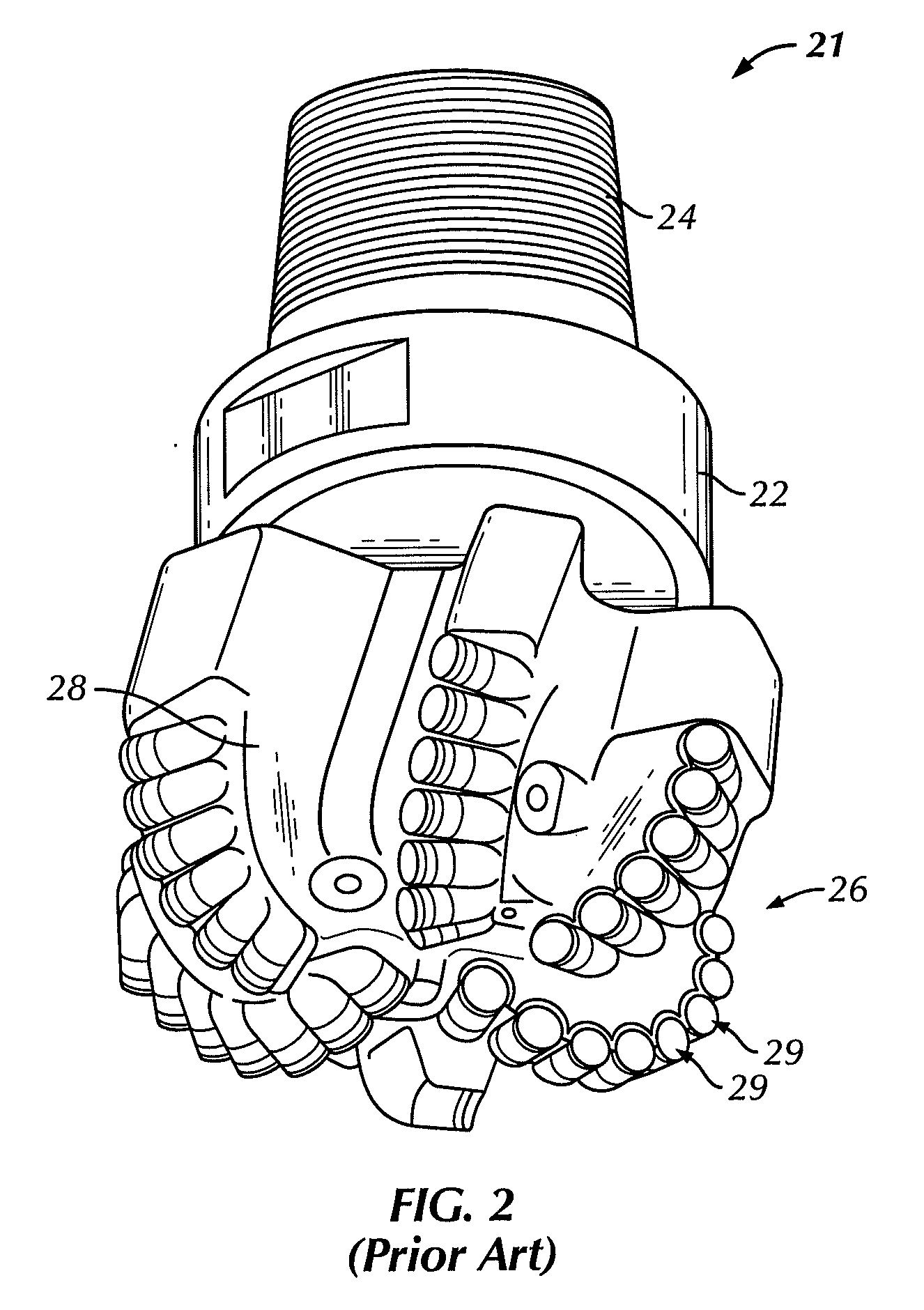

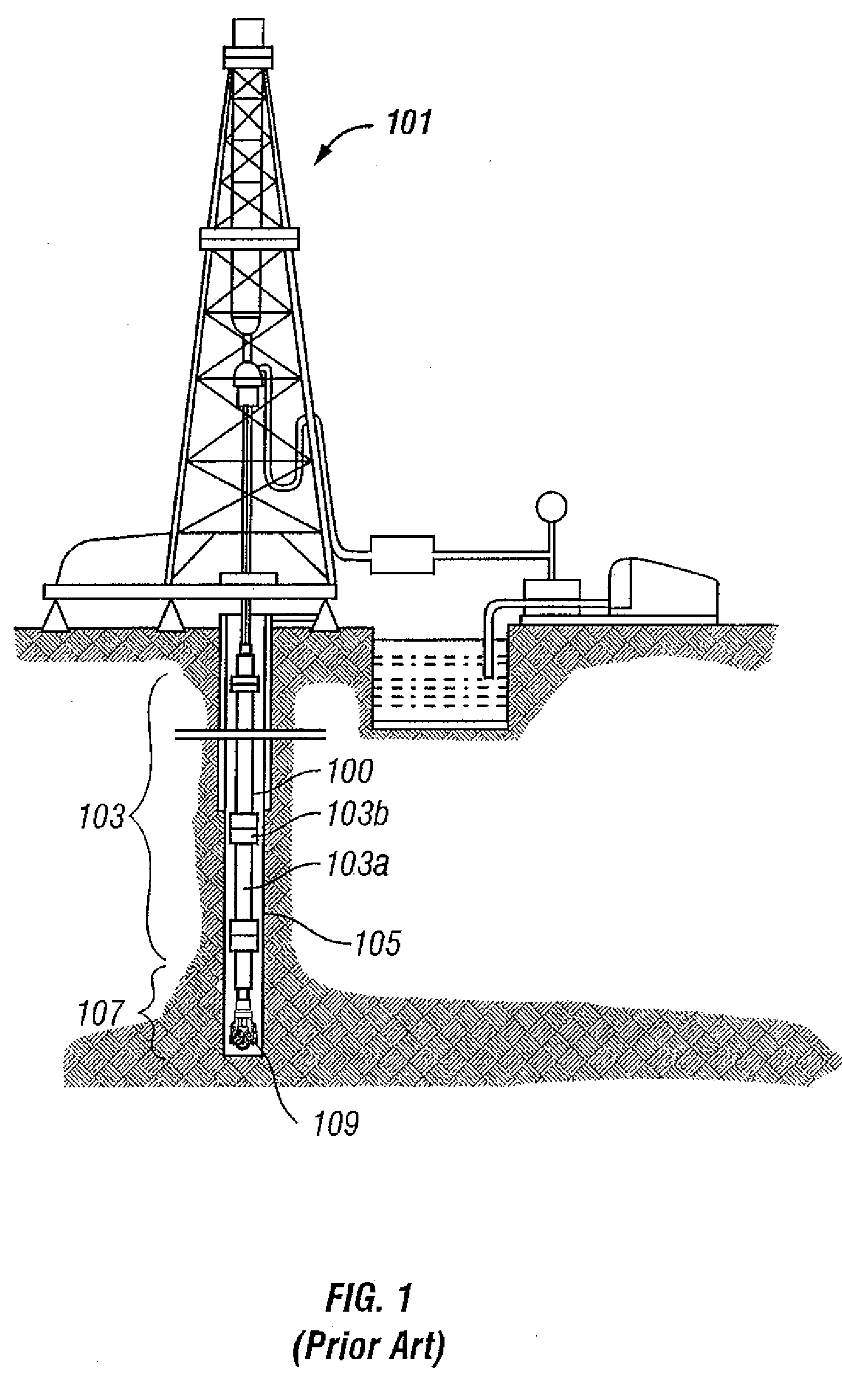

Methods for designing secondary cutting structures for a bottom hole assembly

InactiveUS20090055135A1Improve the situationImprove cutting performanceGeometric CADSurveyStructure basedBottom hole assembly

A method for designing a secondary cutting structure for use in a bottom hole assembly, the method including defining initial design parameters for the secondary cutting structure and analyzing forces acting on the secondary cutting structure. Additionally, the method includes modifying at least one design element of the secondary cutting structure and simulating an effect of the modifying on both the secondary cutting structure and a primary cutting structure to determine if an improved condition is met. Also, a method for designing a drilling tool assembly, the method including defining initial drilling tool assembly design parameters including a primary cutting structure and a secondary cutting structure, and simulating a dynamic response of the drilling tool assembly. Additionally, the method includes adjusting at least one design element of the secondary cutting structure based on the dynamic response of the drilling tool assembly, determining if the adjusted design element improved a condition of the drilling, and repeating the simulating and adjusting until the condition is optimized.

Owner:SMITH INT INC

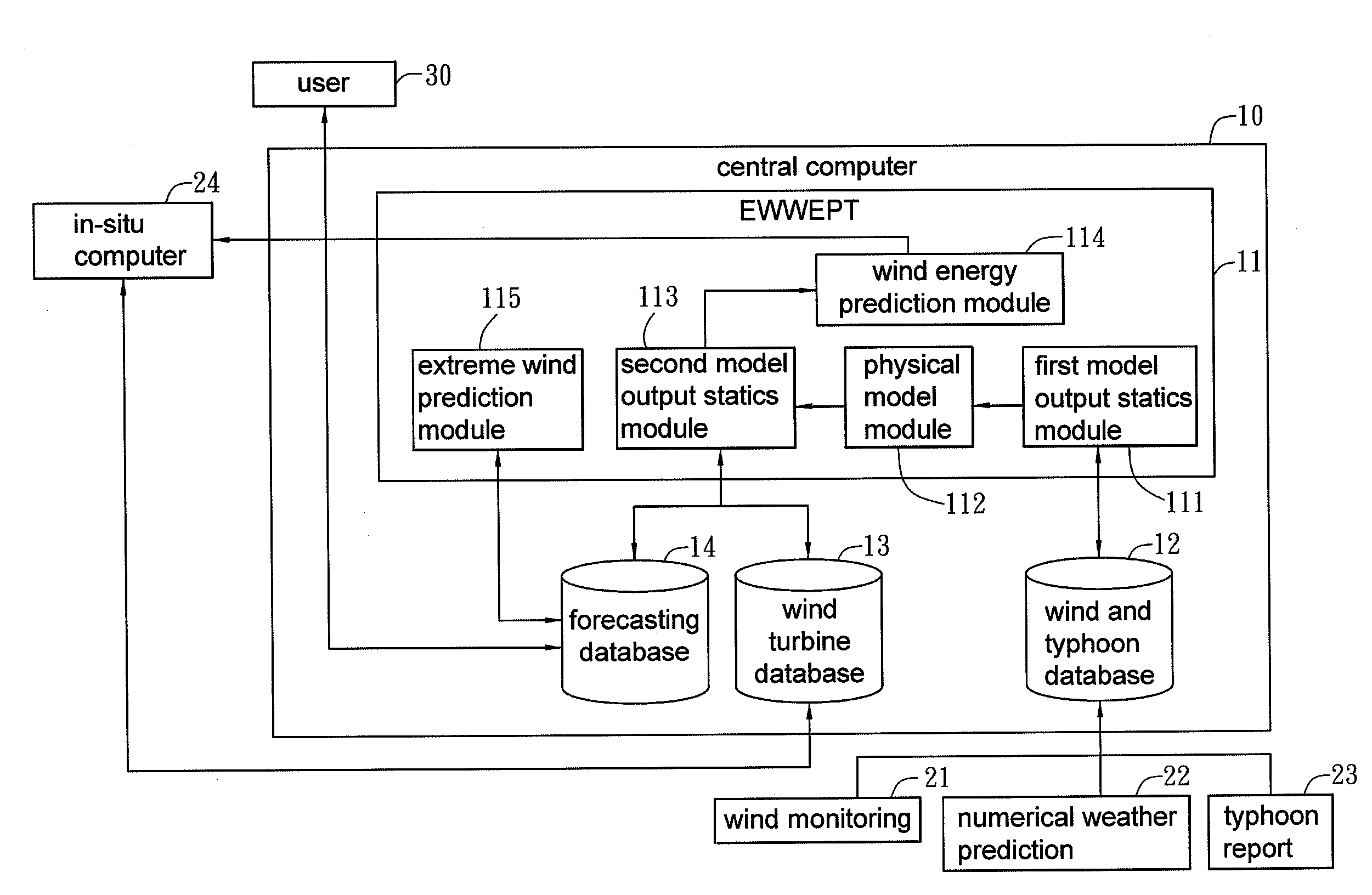

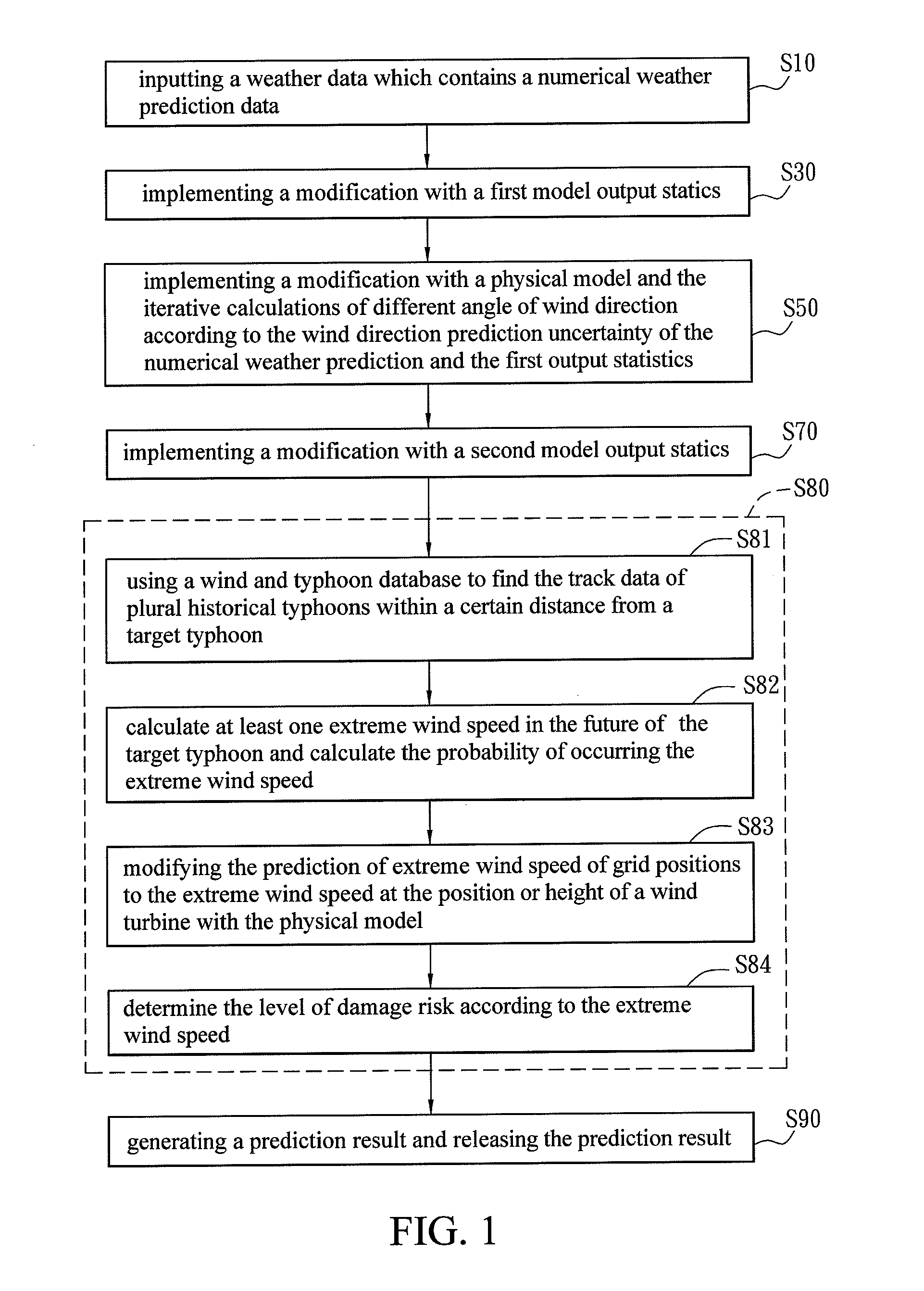

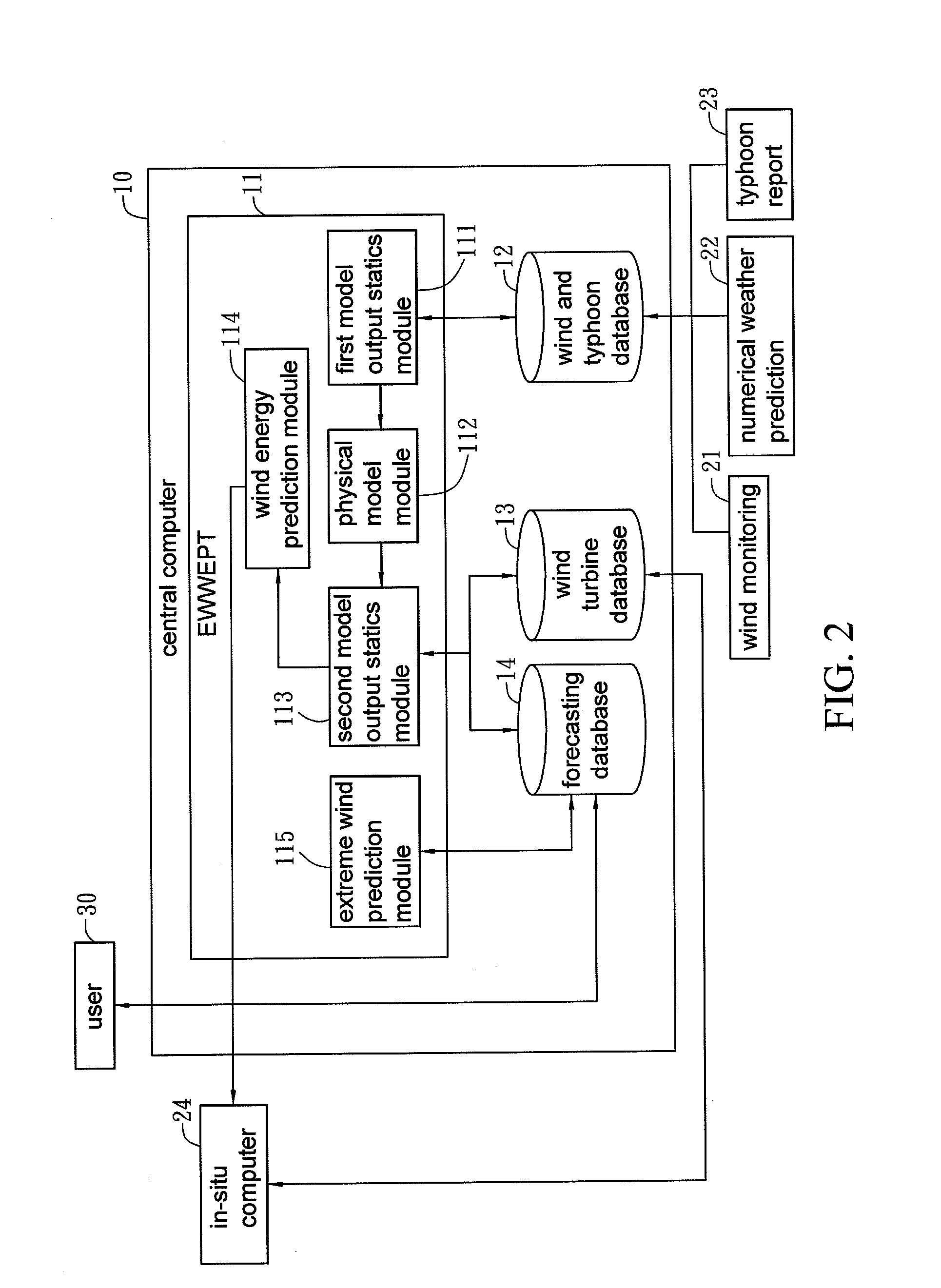

Wind energy forecasting method with extreme wind speed prediction function

InactiveUS20120046917A1Improve efficiencyProcess safetyWeather condition predictionEngine fuctionsNumerical weather predictionPhysical model

A wind energy forecasting method with extreme wind speed prediction function cooperated with a central computer, comprising the steps of: inputting a weather data which contains a numerical weather prediction data; implementing a modification with a first model output statistics; implementing a modification with a physical model in accordance with the output of the first model output statistics that can iteratively calculate the results by varying the angles of wind direction; implementing a modification with a second model output statistics; and implementing a prediction of extreme wind speed caused by typhoon, which comprises the following sub-steps of: using a wind and typhoon database to find track data of plural historical typhoons within a certain distance from a target typhoon; using an extreme wind and wind energy prediction tool to calculate at least one extreme wind speed in the future of the target typhoon and calculate the probability of occurring the extreme wind speed; and modifying the extreme wind speed with the physical model to the extreme wind speed at the position or height of a wind turbine.

Owner:INST NUCLEAR ENERGY RES ROCAEC

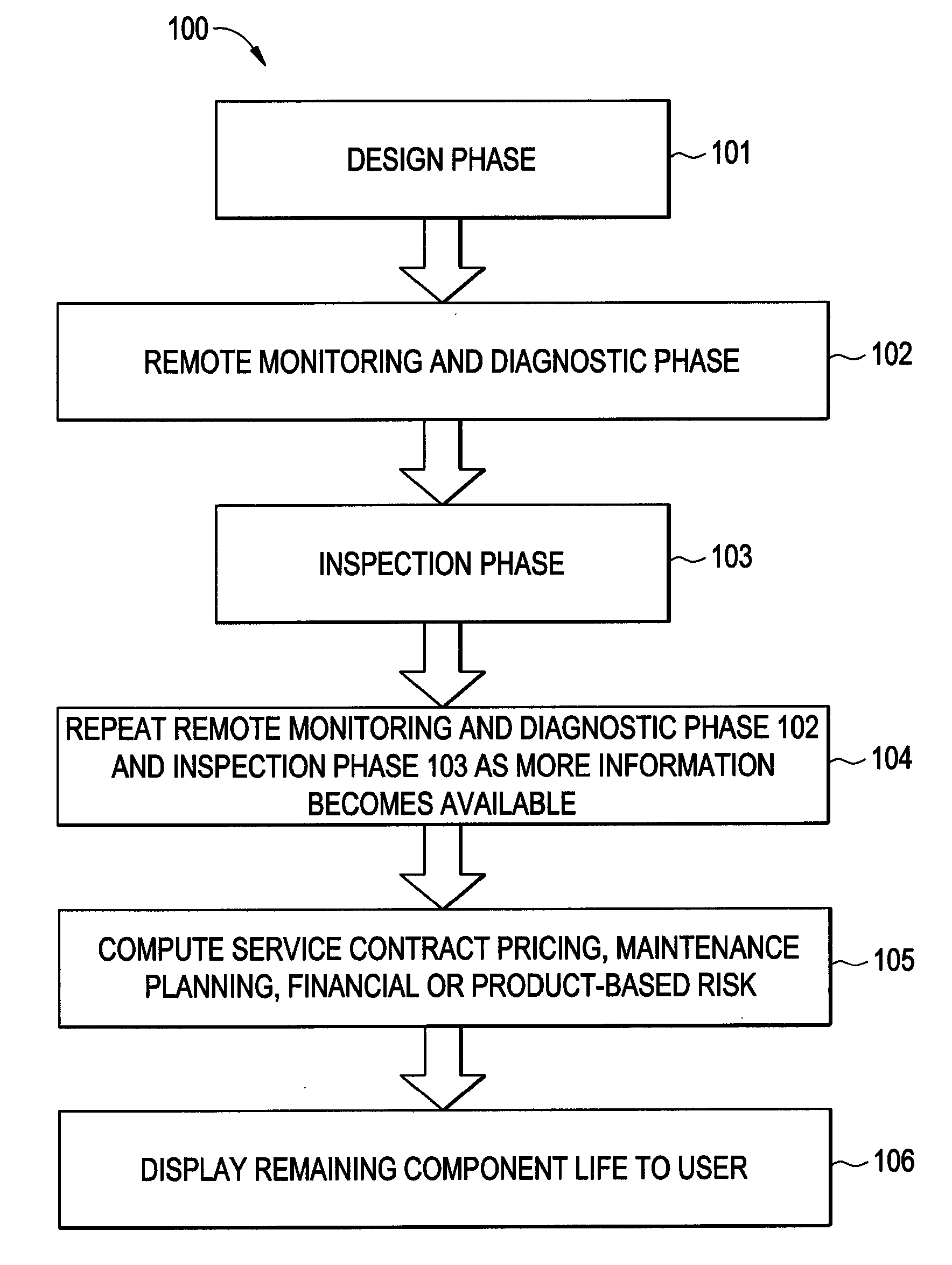

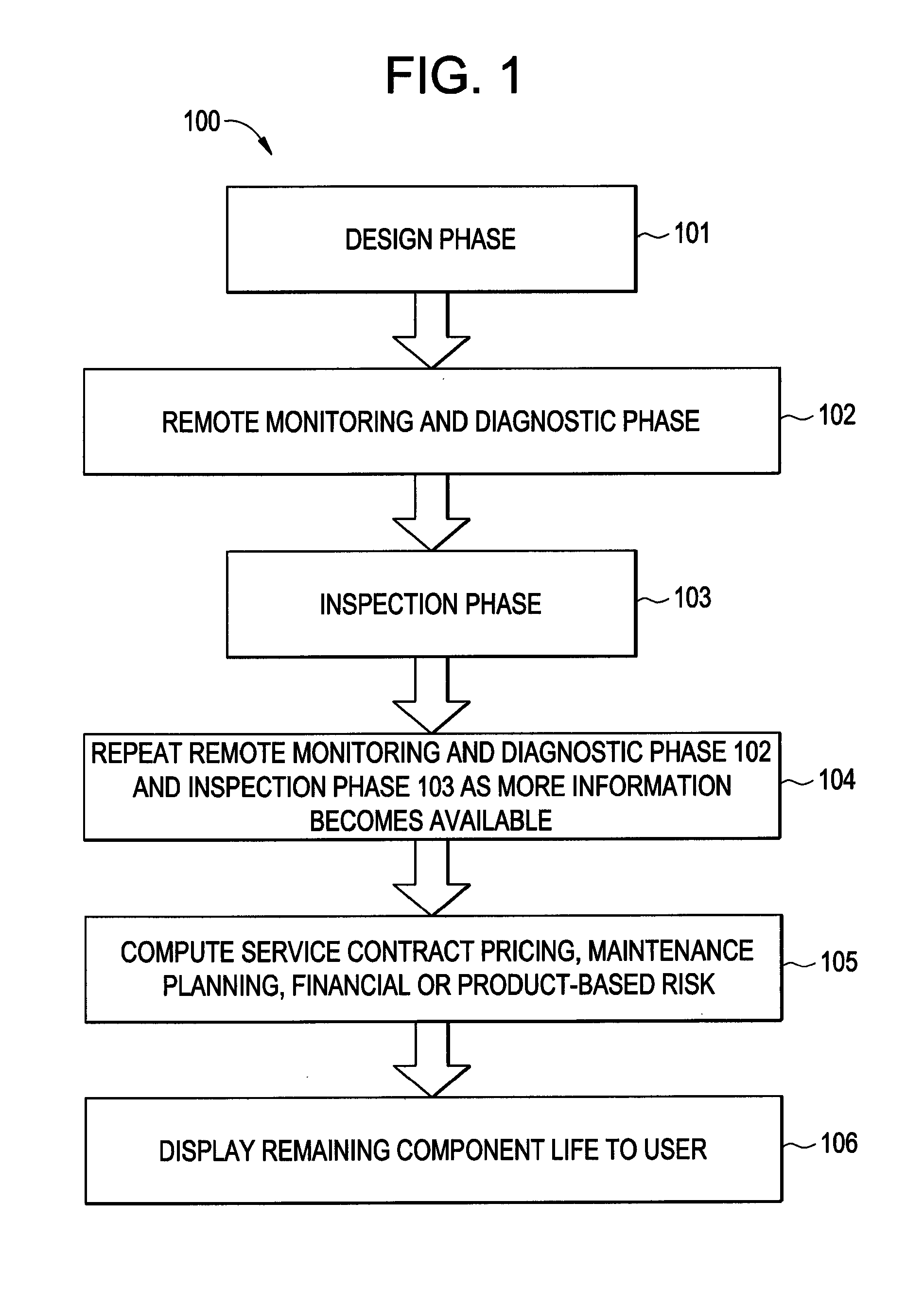

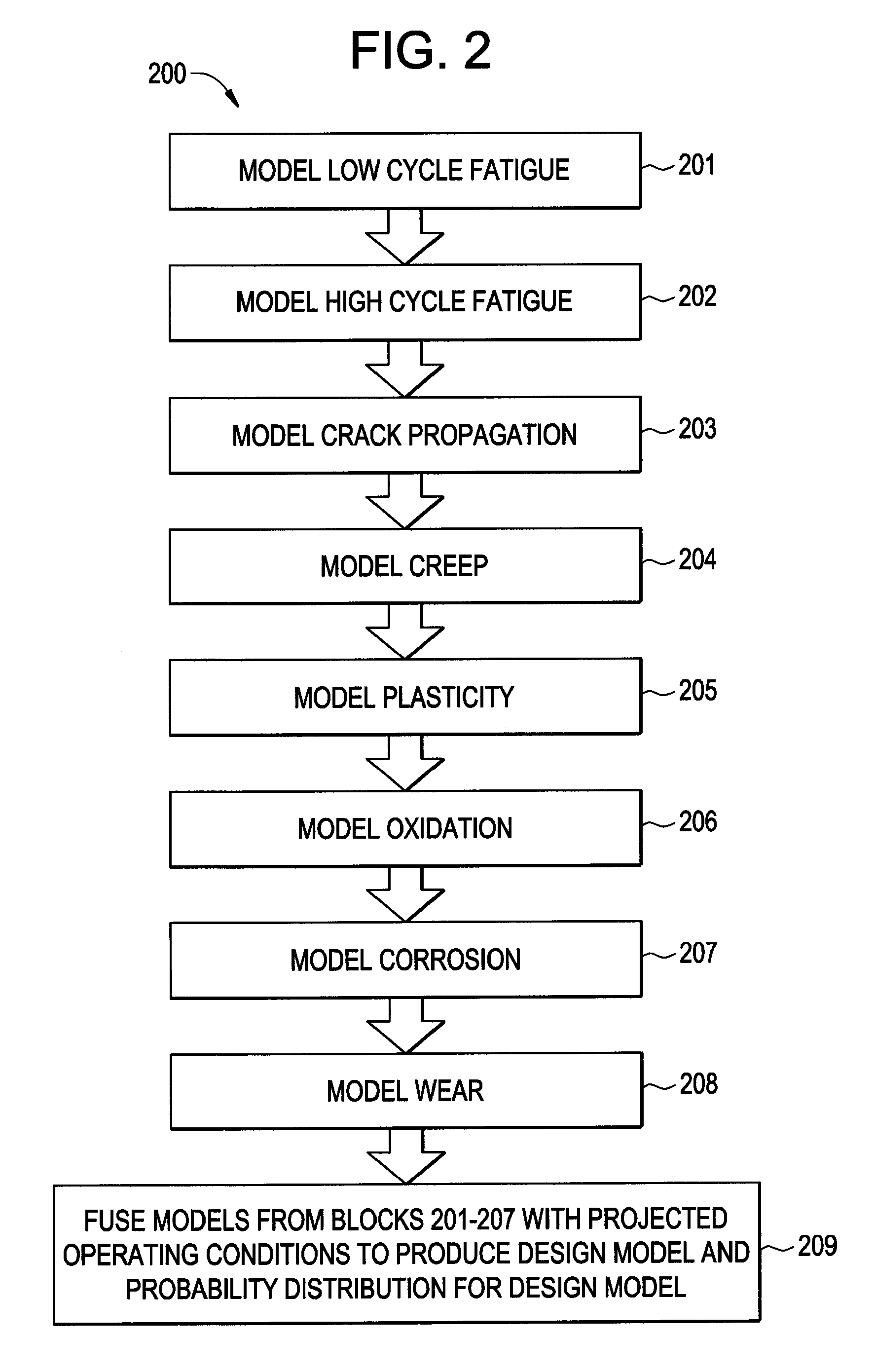

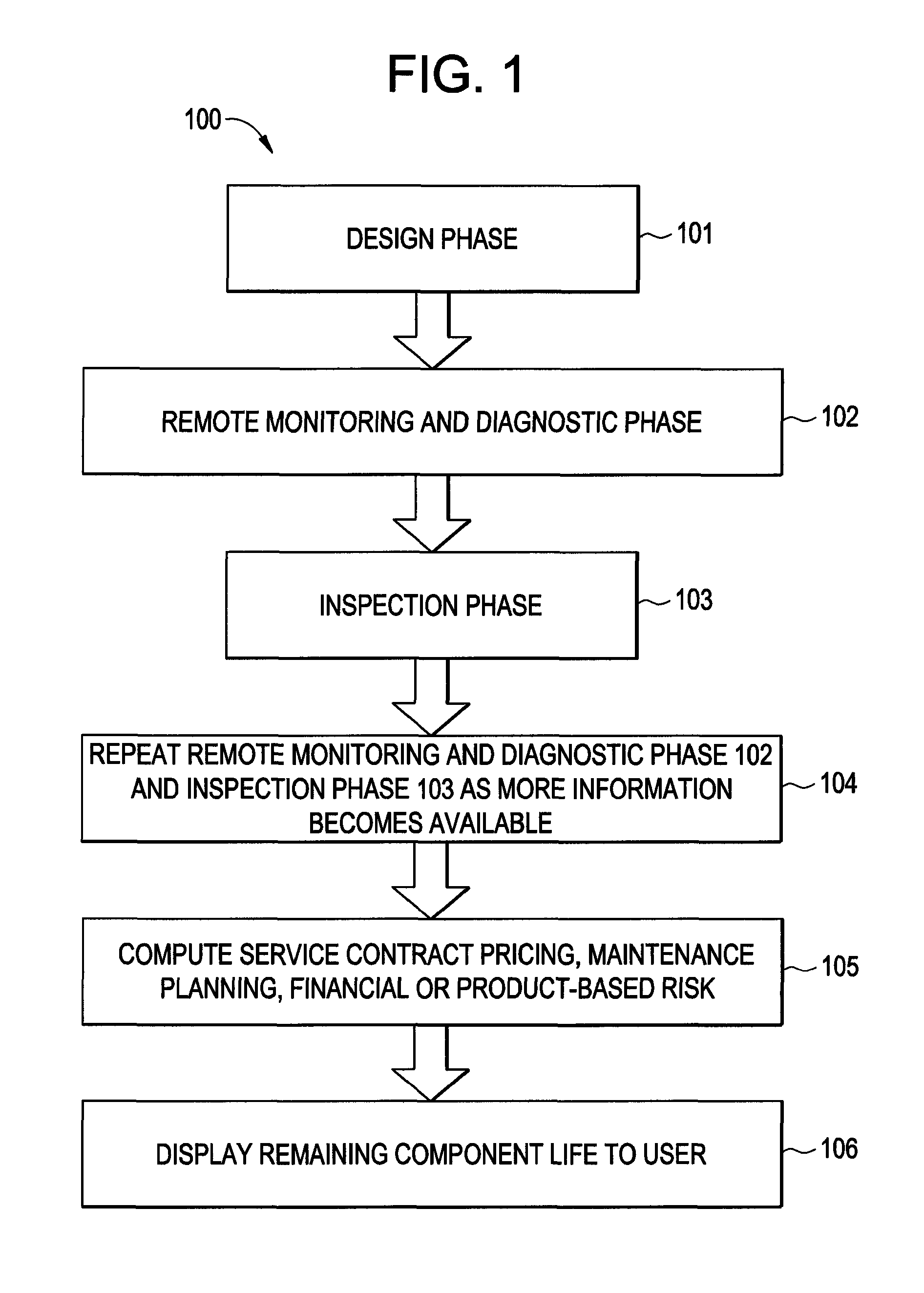

Physics-Based Lifespan Modeling

ActiveUS20100153080A1Testing/monitoring control systemsAnalogue computers for non-electric machinesAutomotive engineeringPhysics based

An embodiment of a method for lifespan modeling for a turbine engine component includes determining a design-phase model of the lifespan of an turbine engine component; fusing the design-phase model with sensor data collected during operation of the turbine engine component to produce an updated model of the lifespan of the turbine engine component; and fusing the updated model with data collected during an inspection of the turbine engine component to produce an overall model of the lifespan of the turbine engine component. Systems for lifespan modeling for a turbine engine component are also provided.

Owner:GENERAL ELECTRIC CO

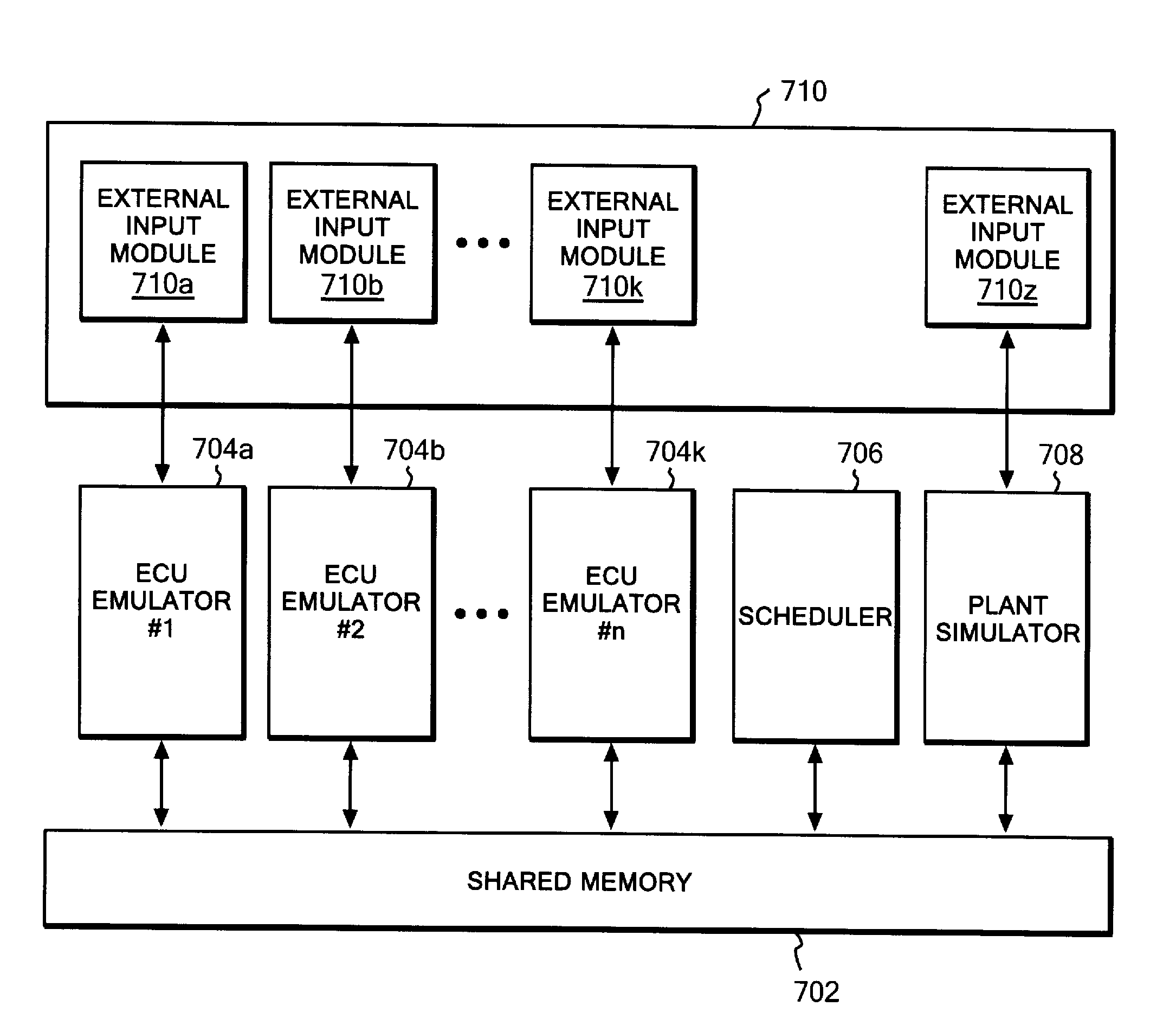

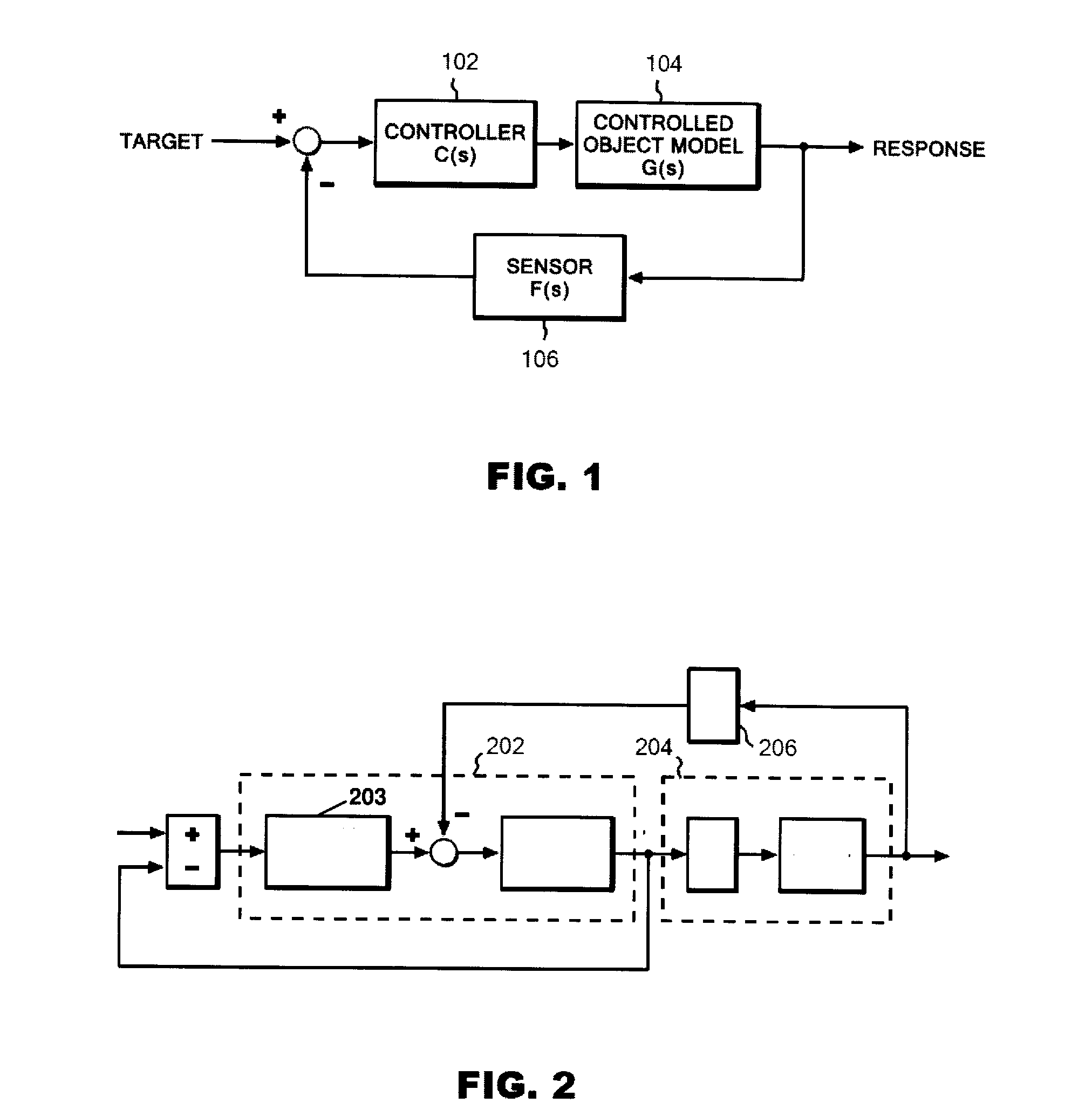

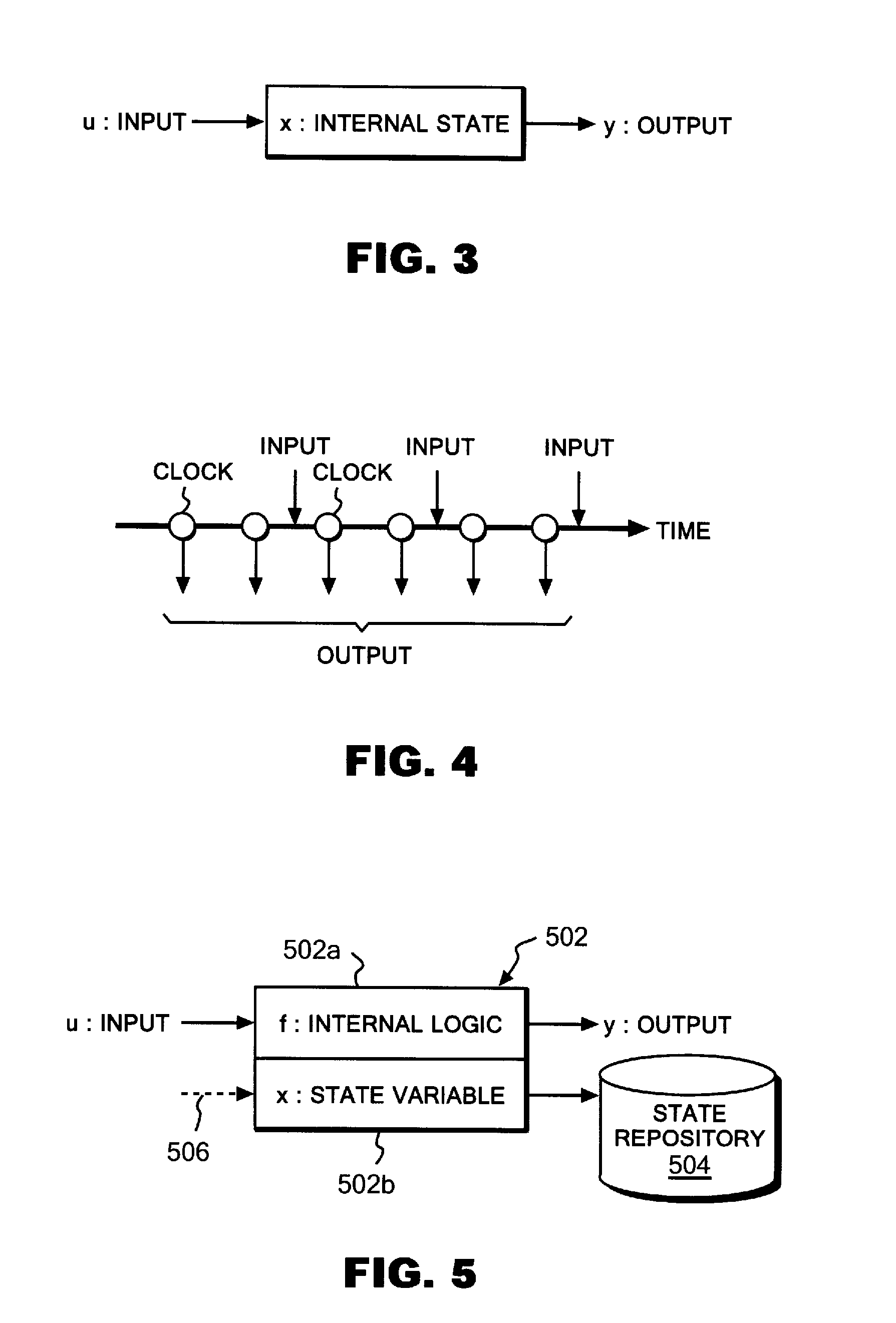

Control unit simulation method, system, and program

A method, system, and computer readable article of manufacture for simulating a mechanism system controlled by a plurality of electronic control units operating at different clock rates. The simulation system includes a mechanism system simulator; a plurality of electronic control unit emulators for electronically emulating the respective plurality of electronic control units, each thereby receiving an input signal with a time and giving an output signal with a time; and a scheduler for receiving and storing the output signals with the times from the plurality of electronic control unit emulators, and for providing, in response to a change in the output signal coming from the electronic control unit emulator and having a relatively late time, the output signal with a time preceding the relatively late time to the mechanism system simulator.

Owner:IBM CORP

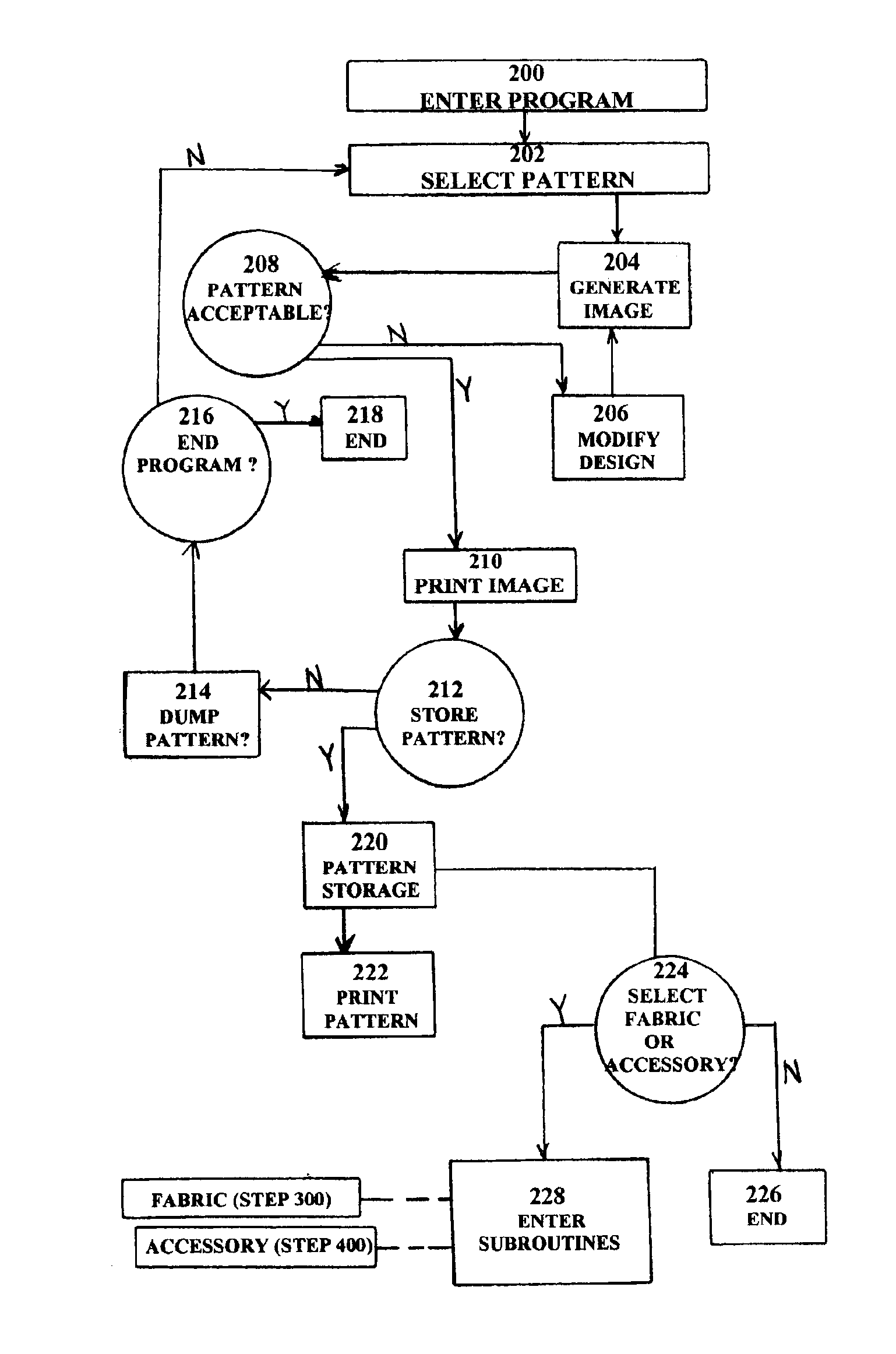

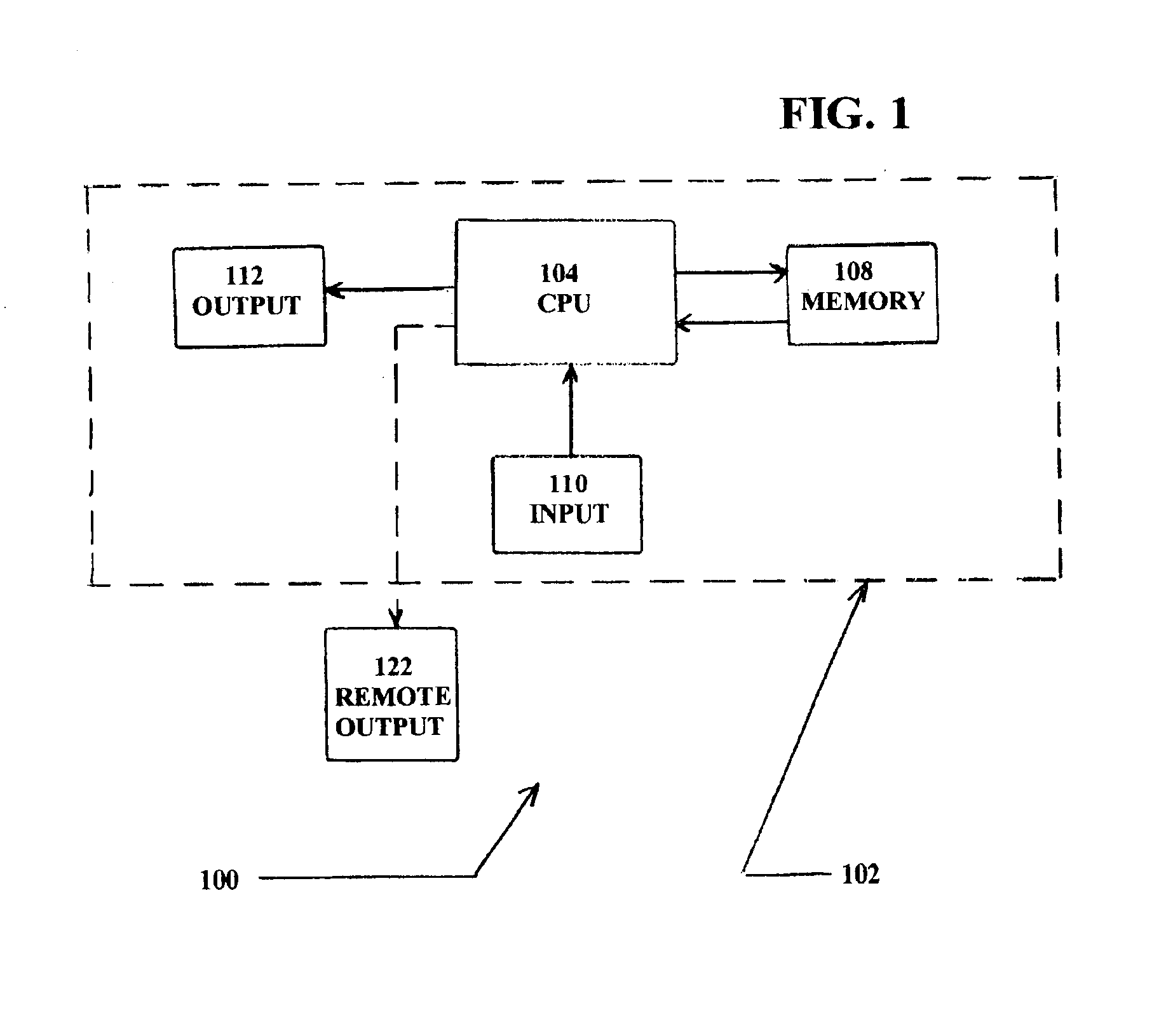

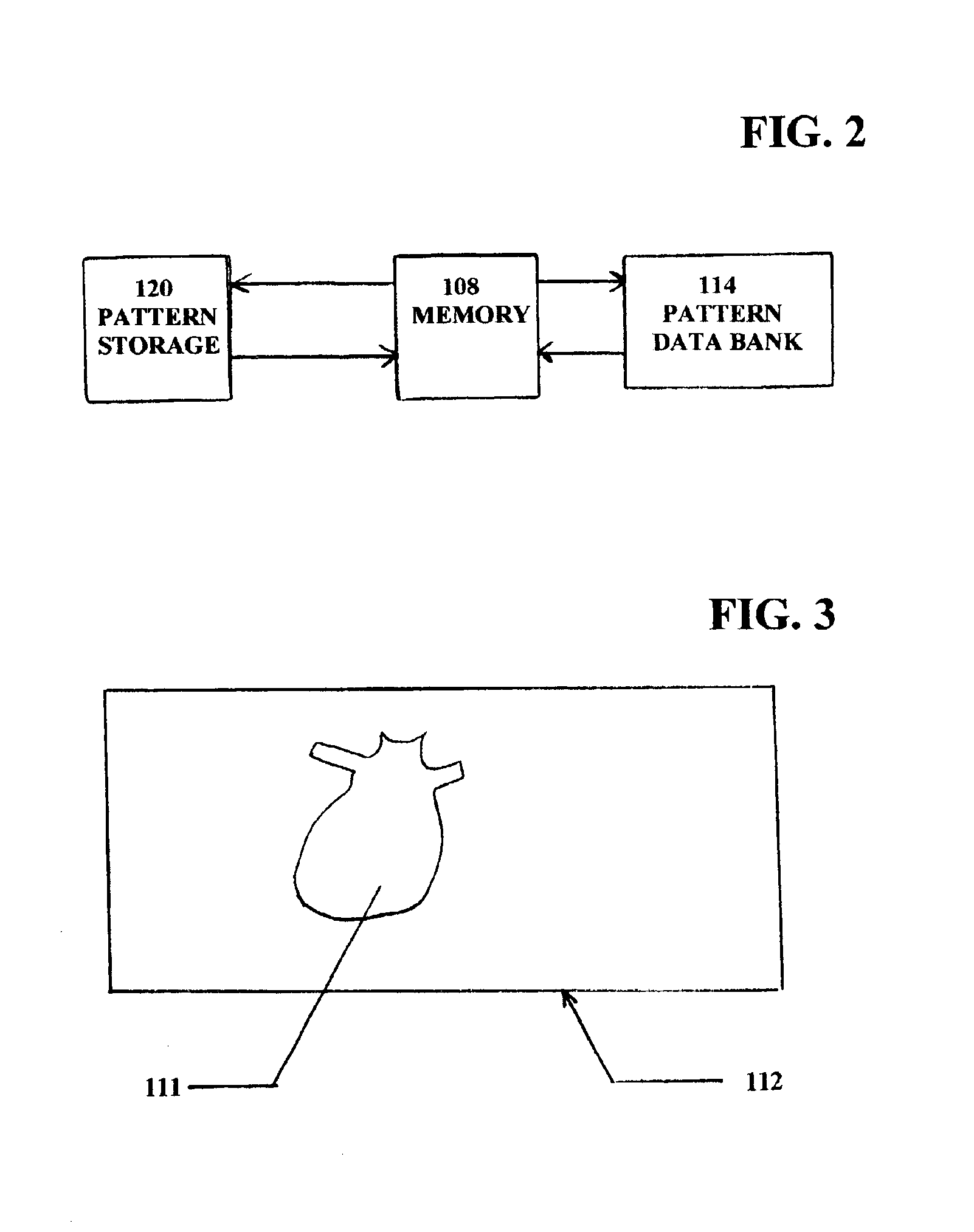

Method and apparatus for producing a sewing pattern

InactiveUS6859679B1Programme-controlled sewing machinesAnalogue computers for control systemsEngineering

Owner:SMITH ALEXANDRA K +1

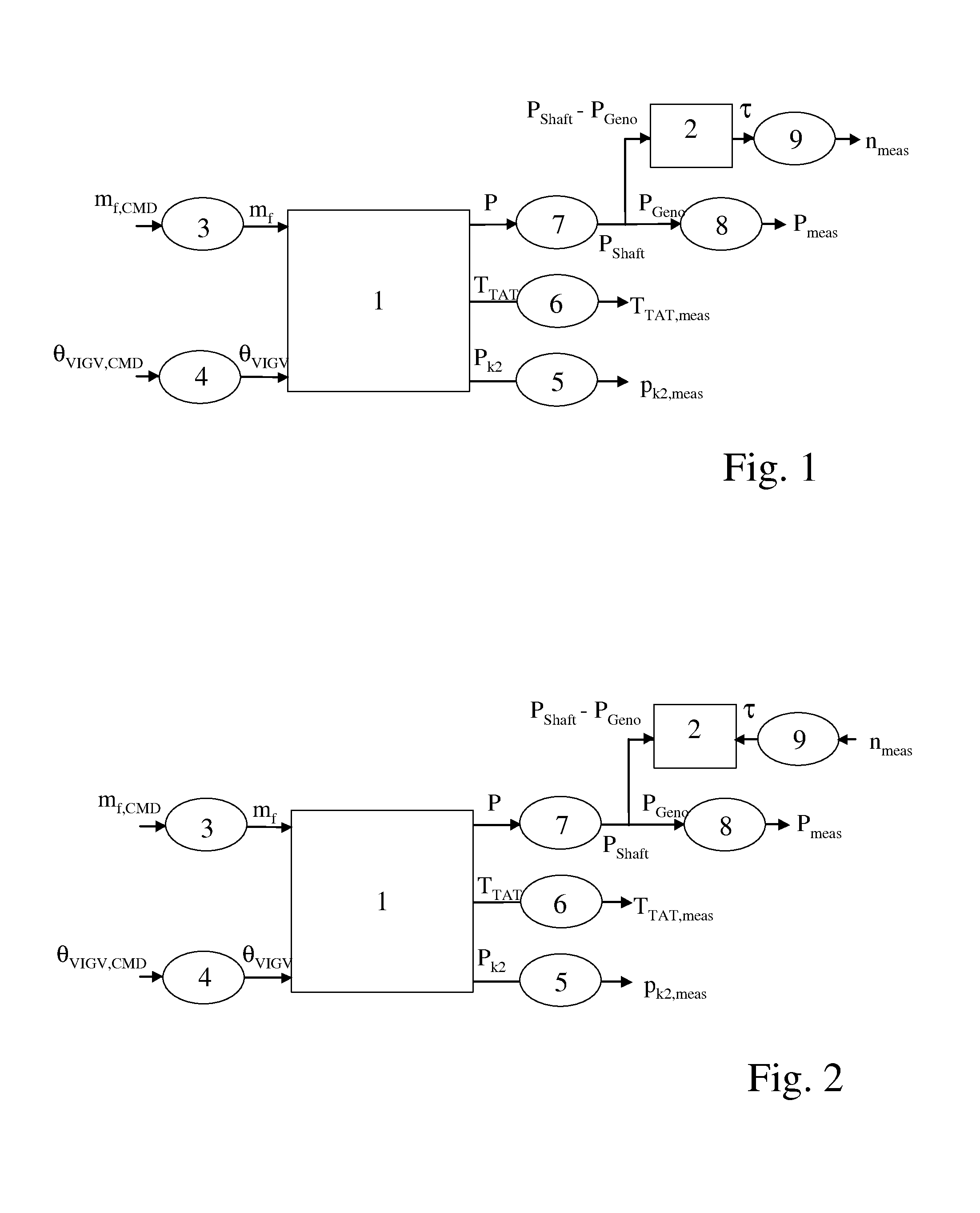

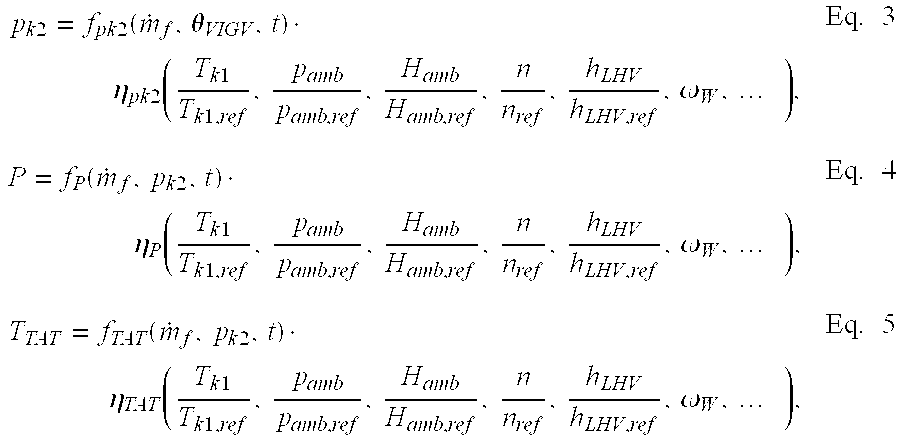

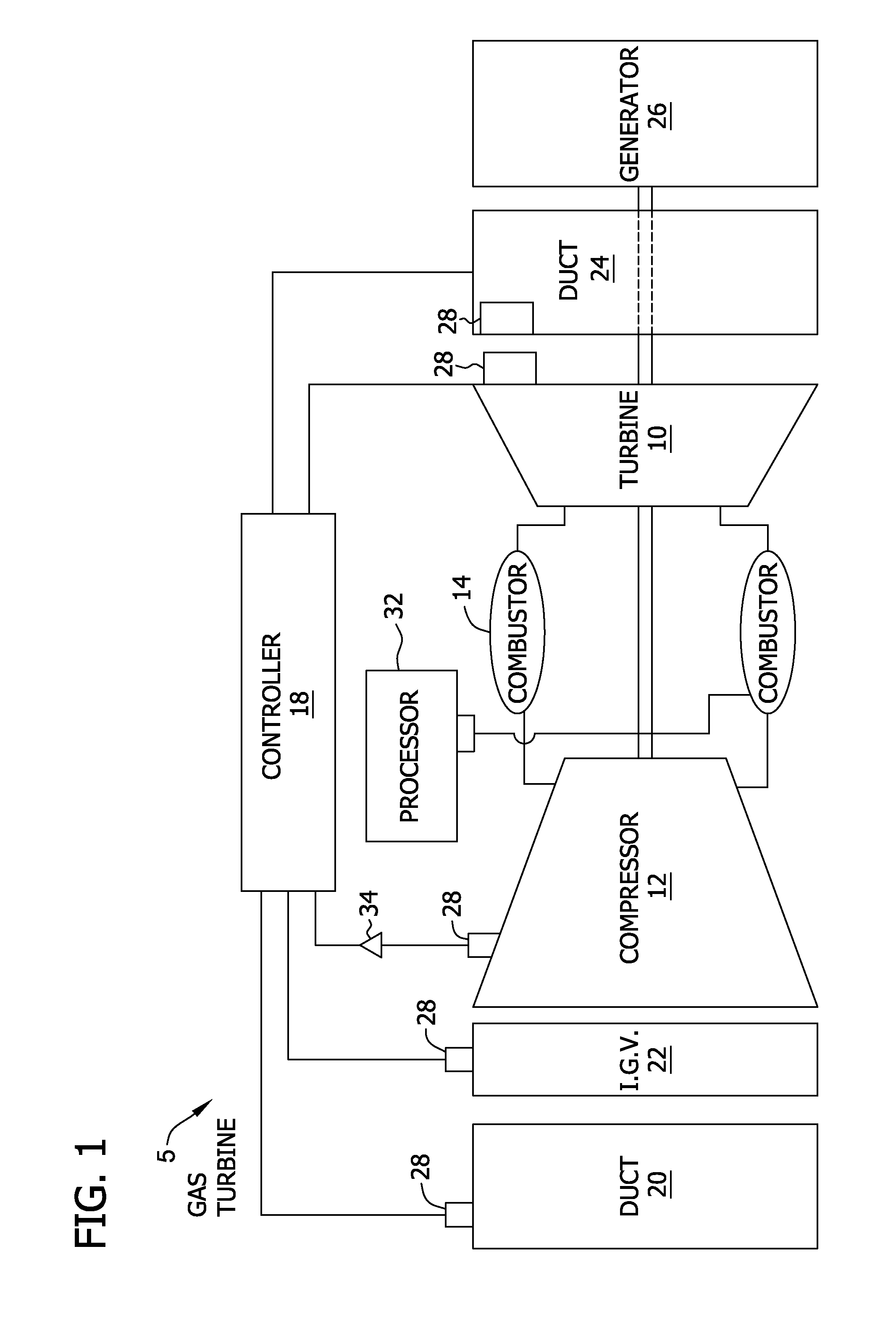

Gas turbine model and a method for the modeling of a gas turbine

InactiveUS20110224959A1Improve accuracyNumerically efficientSimulator controlAnalogue computers for non-electric machinesEngineeringActuator

Numerical gas turbine models permit transient modeling with high precision and at the same time numerically efficient processes for modeling a gas turbine. A gas turbine model includes a plurality of sub models. These sub models are either purely dynamic or static, which allows significant simplifications in the numerical solution of the overall model. System parts, which simulate the effects of volumes, metal masses, of actuators, and of measuring systems are regarded as dynamic. The remaining system parts are regarded as static over a time characteristic.

Owner:GENERAL ELECTRIC TECH GMBH

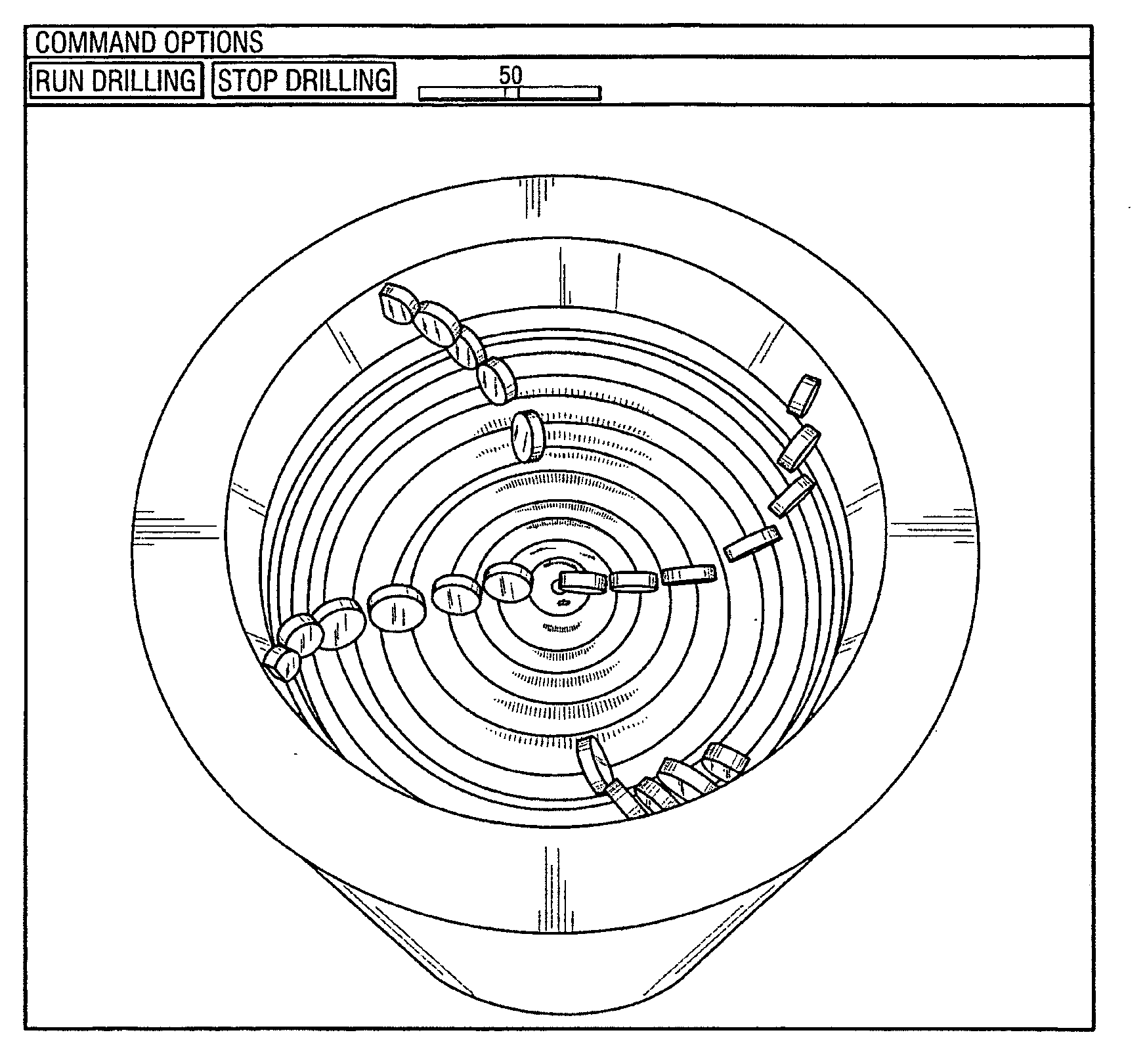

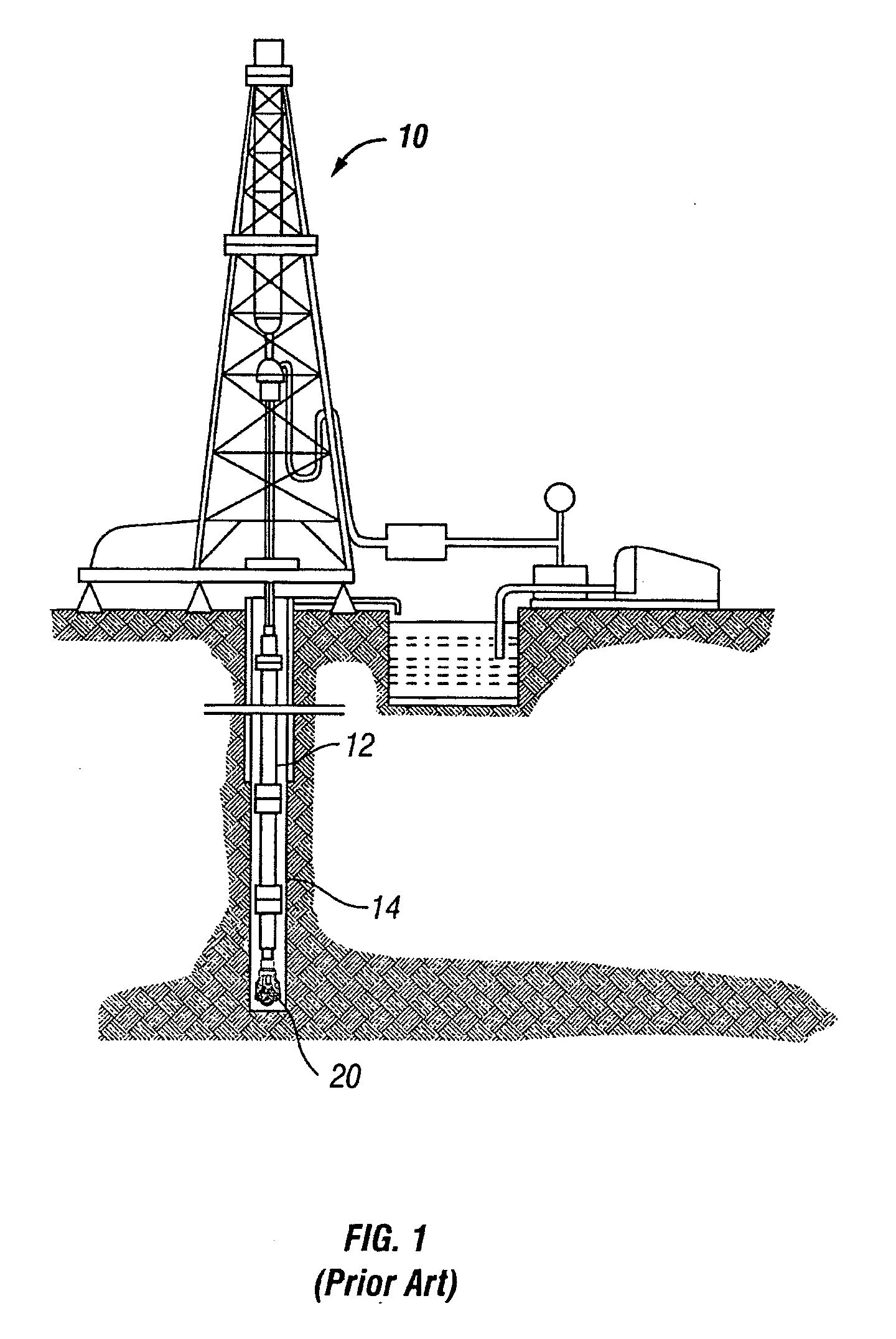

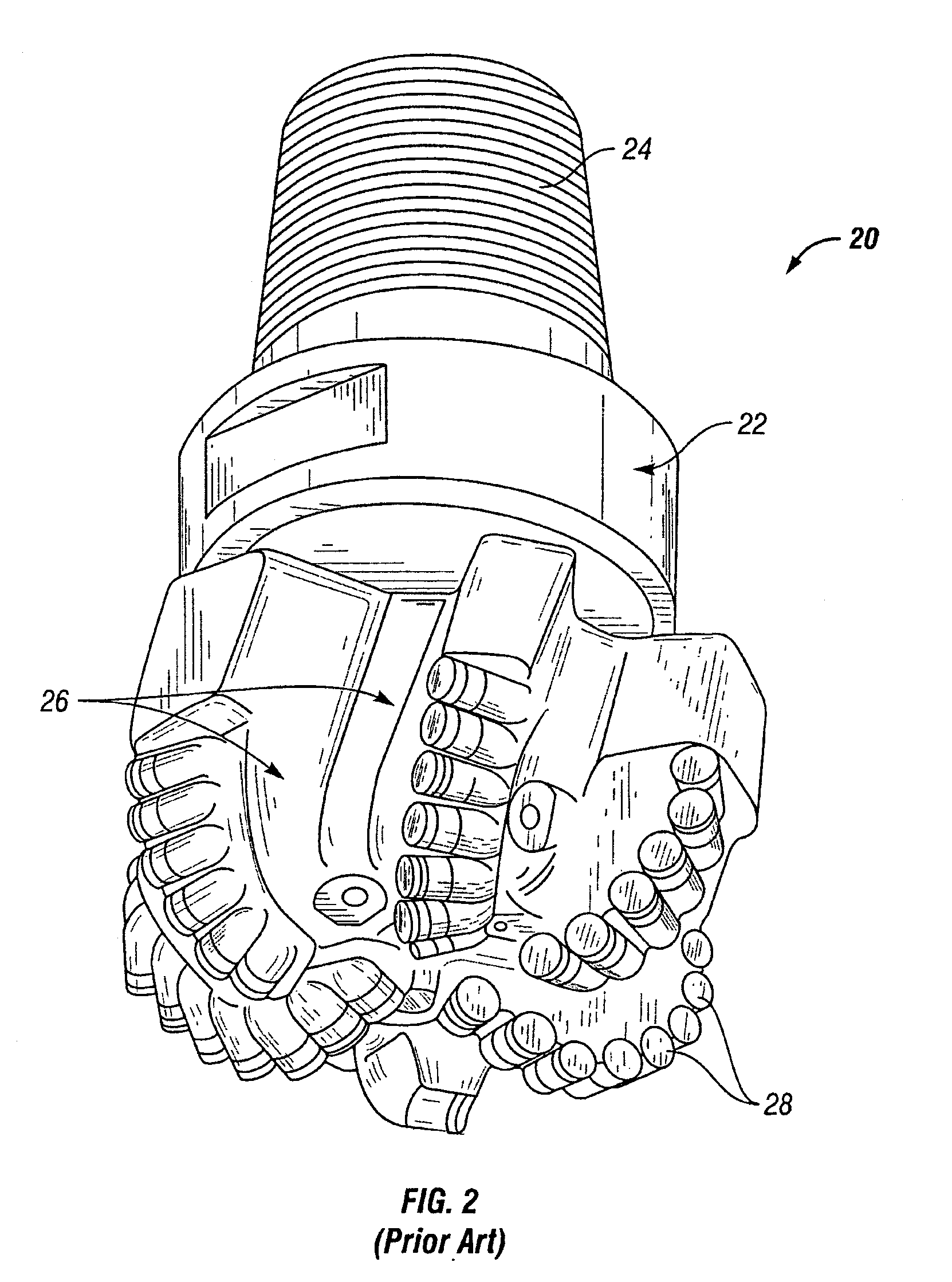

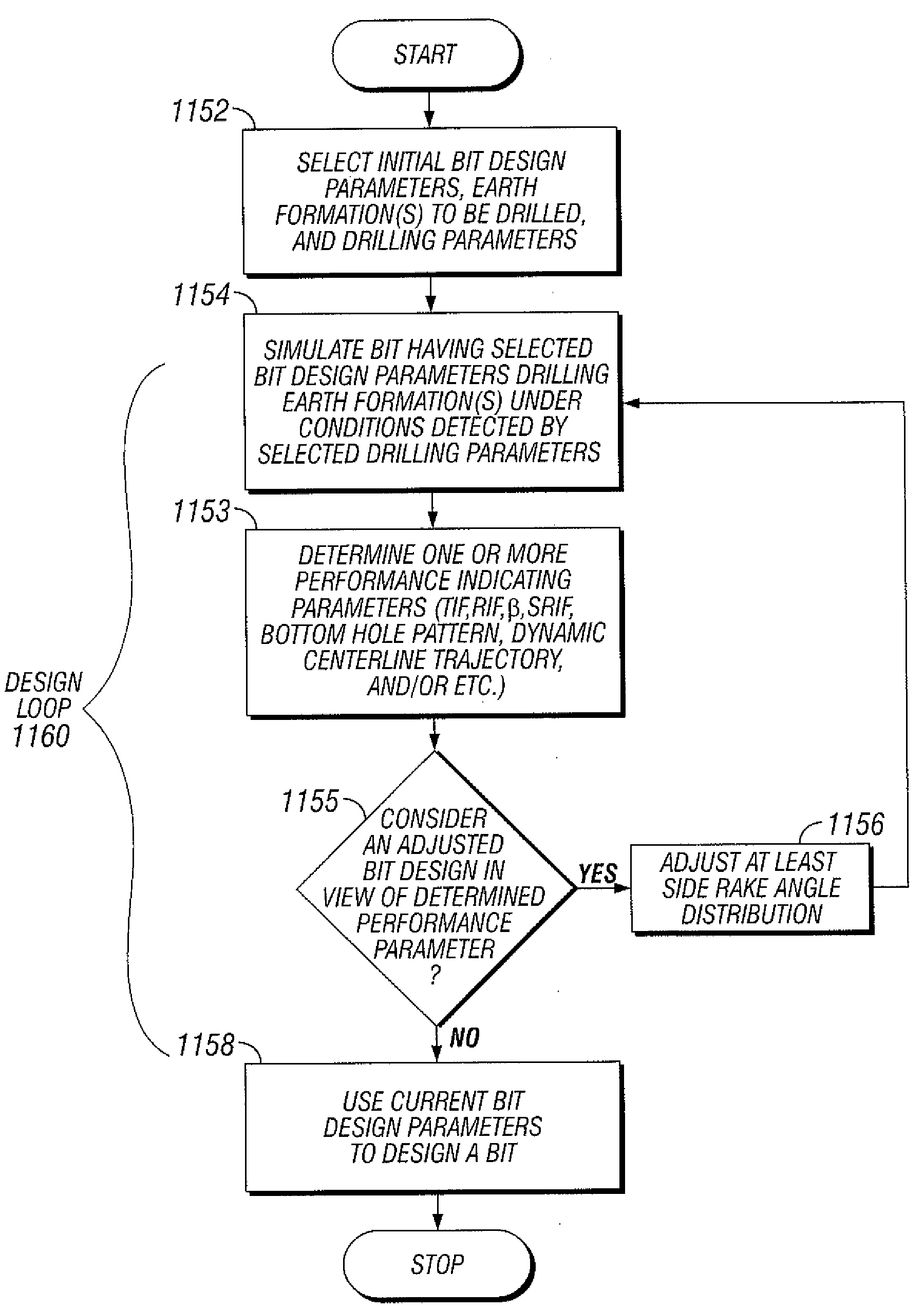

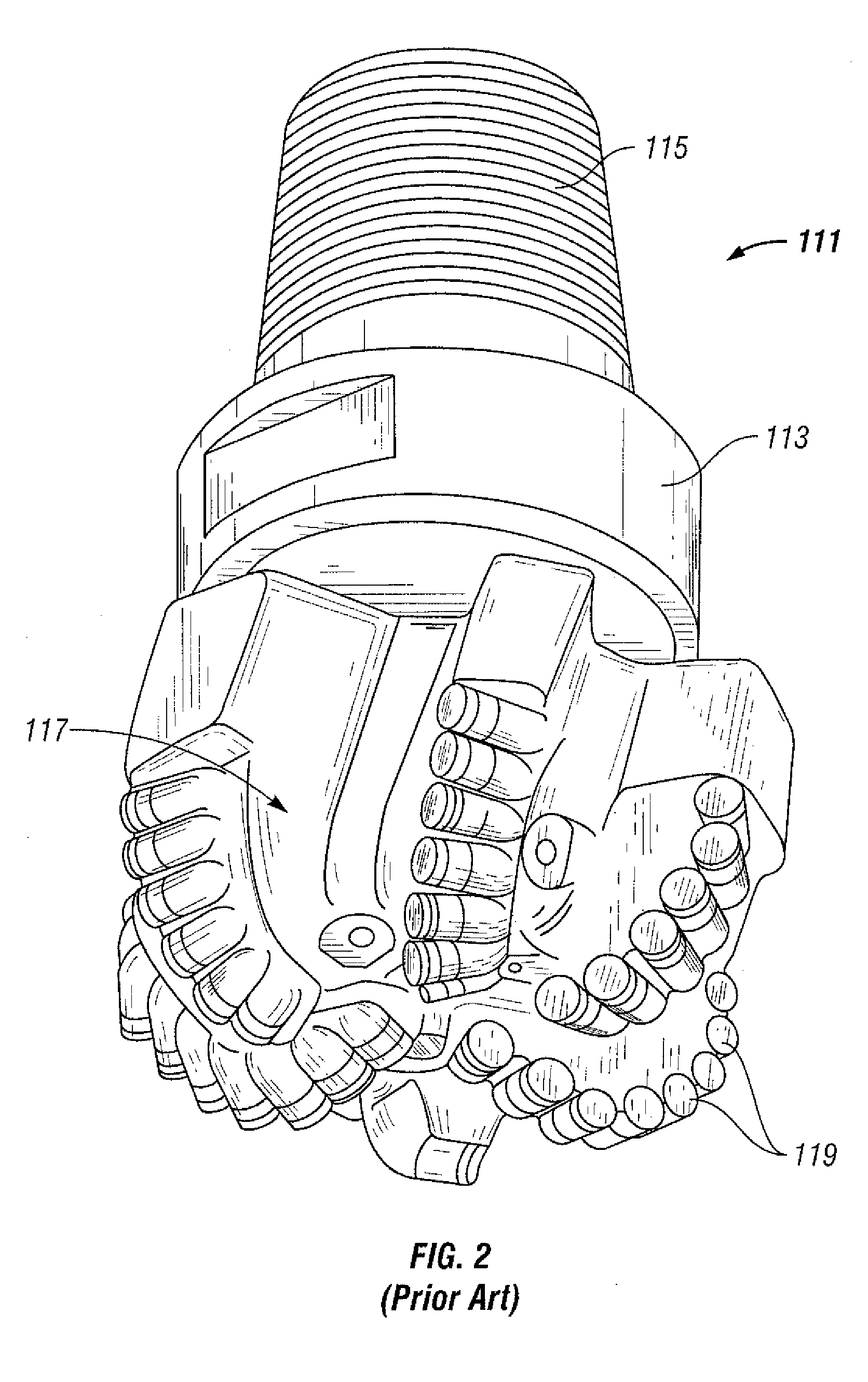

Methods for modeling, displaying, designing, and optimizing fixed cutter bits

ActiveUS20100211362A1Electric/magnetic detection for well-loggingEarth drilling toolsEngineeringDesign methods

In one aspect, the invention provides a method for modeling the performance of a fixed cutter bit drilling an earth formation. In one embodiment, the method includes selecting a drill bit and an earth formation to be represented as drilled, simulating the bit drilling the earth formation, displaying the simulating, and adjusting at least one parameter affecting the performance. The method of design is used to make a fixed cutter drill bit. In another embodiment the method includes numerically rotating the bit, calculating bit interaction with the earth formation during the rotating, and determining the forces on the cutters during the rotation based on the calculated interaction with earth formation and empirical data.

Owner:SMITH INT INC

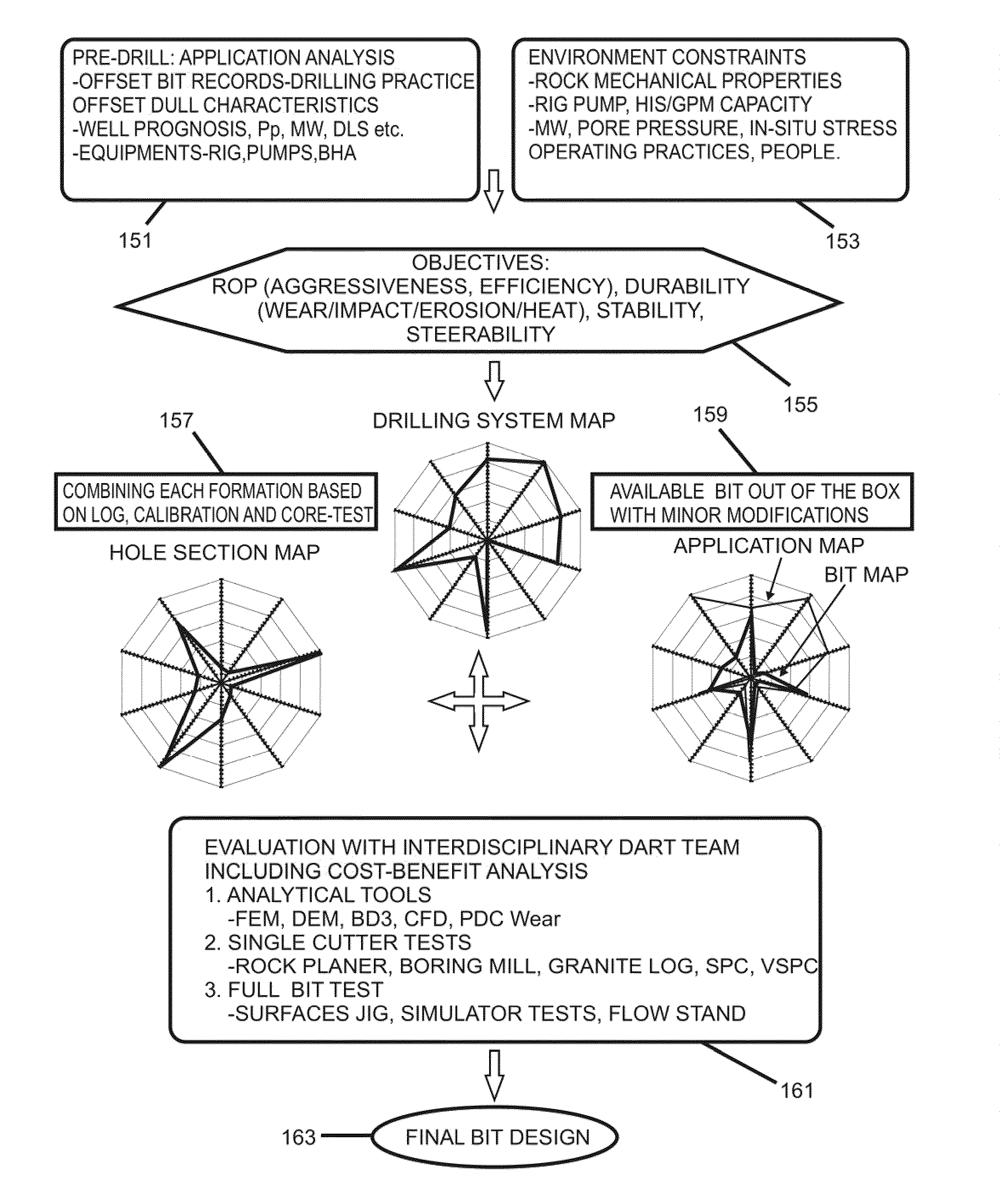

System, program product, and related methods for bit design optimization and selection

ActiveUS20100030527A1Easy to compareOptimize critical drilling bit performance characteristicDrill bitsAnalogue computers for non-electric machinesEngineeringSelection system

Systems, program product, and methods are provided which include analyzing the drillability of a subterranean formation and a database of performance characteristics for drilling bits to facilitate bit design optimization and selection for that formation. Using component subterranean formation data, computer models can be generated for the drillability of a target section in terms of physical, mechanical, and micro-structural properties, and for postulated suitable drilling bit performance characteristics based on physical, mechanical, and micro-structural properties of the target section. The drilling bit performance characteristics are then updated by quantifying effects of the drilling system to be employed. Each performance characteristic can be normalized and plotted on its own axis for easy comparison. Next, a candidate drilling bit design is selected from a library of computer models of drilling bit characteristics for a suite of drilling bit designs. An optimization of the drilling bit design may be also performed.

Owner:BAKER HUGHES INC

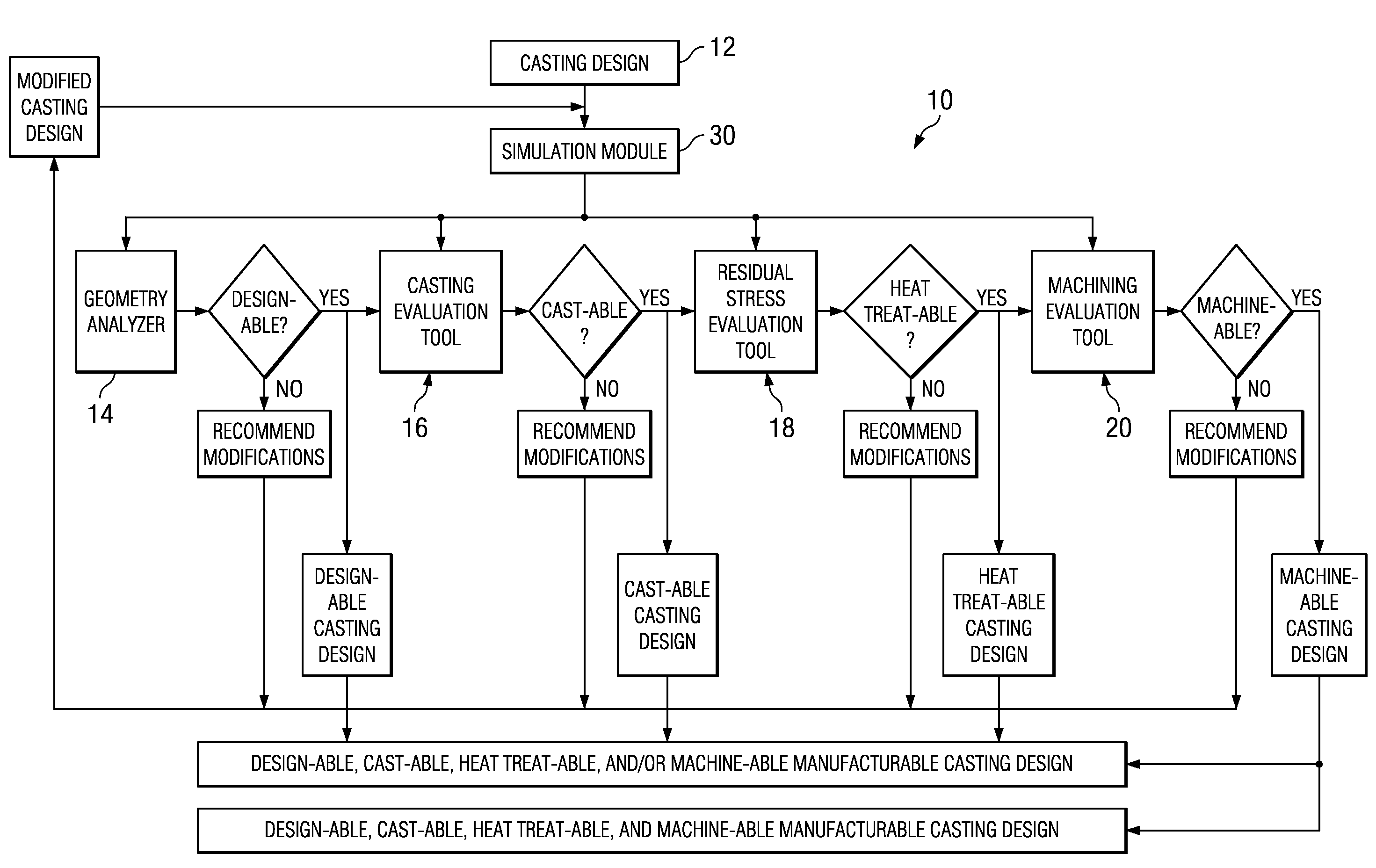

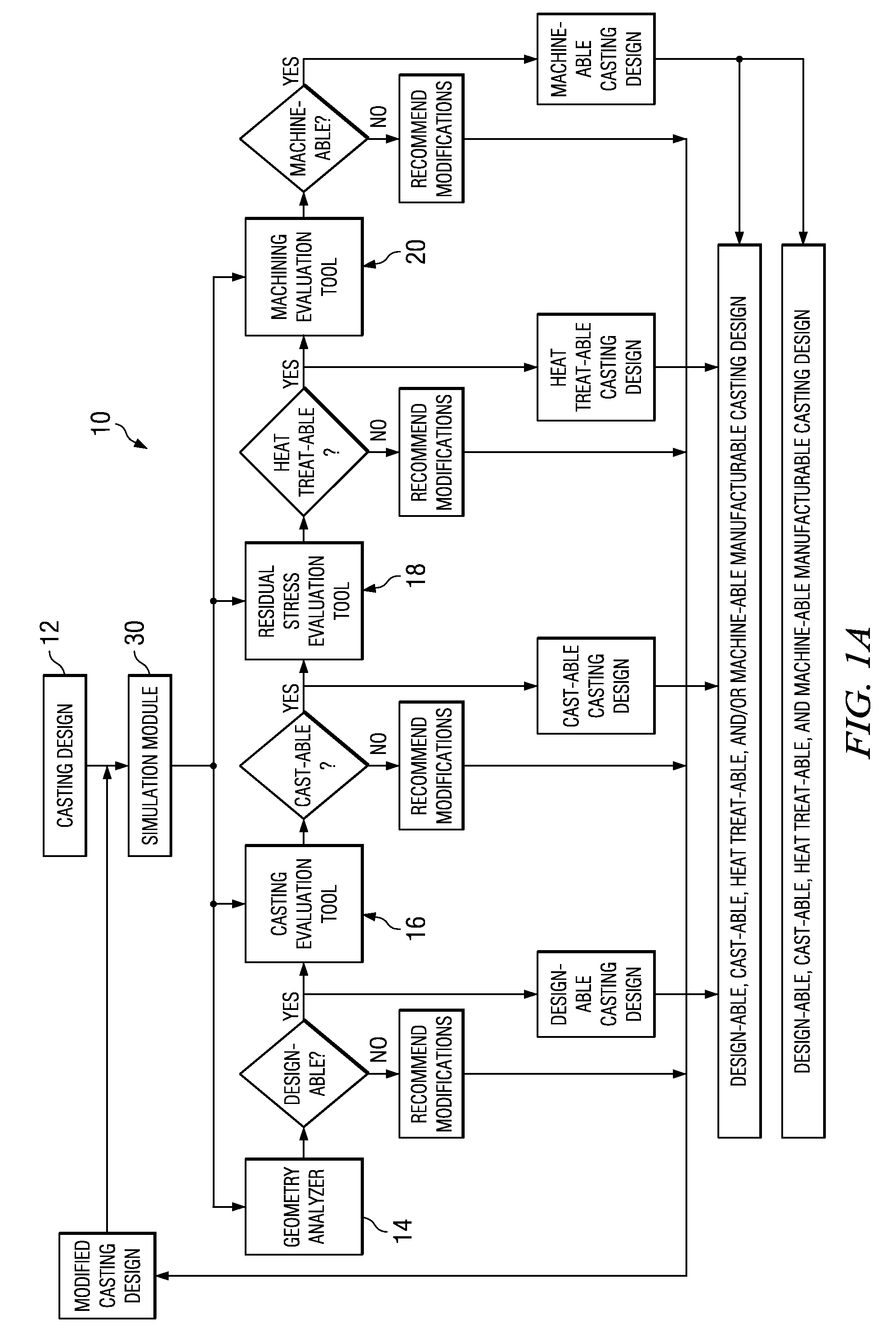

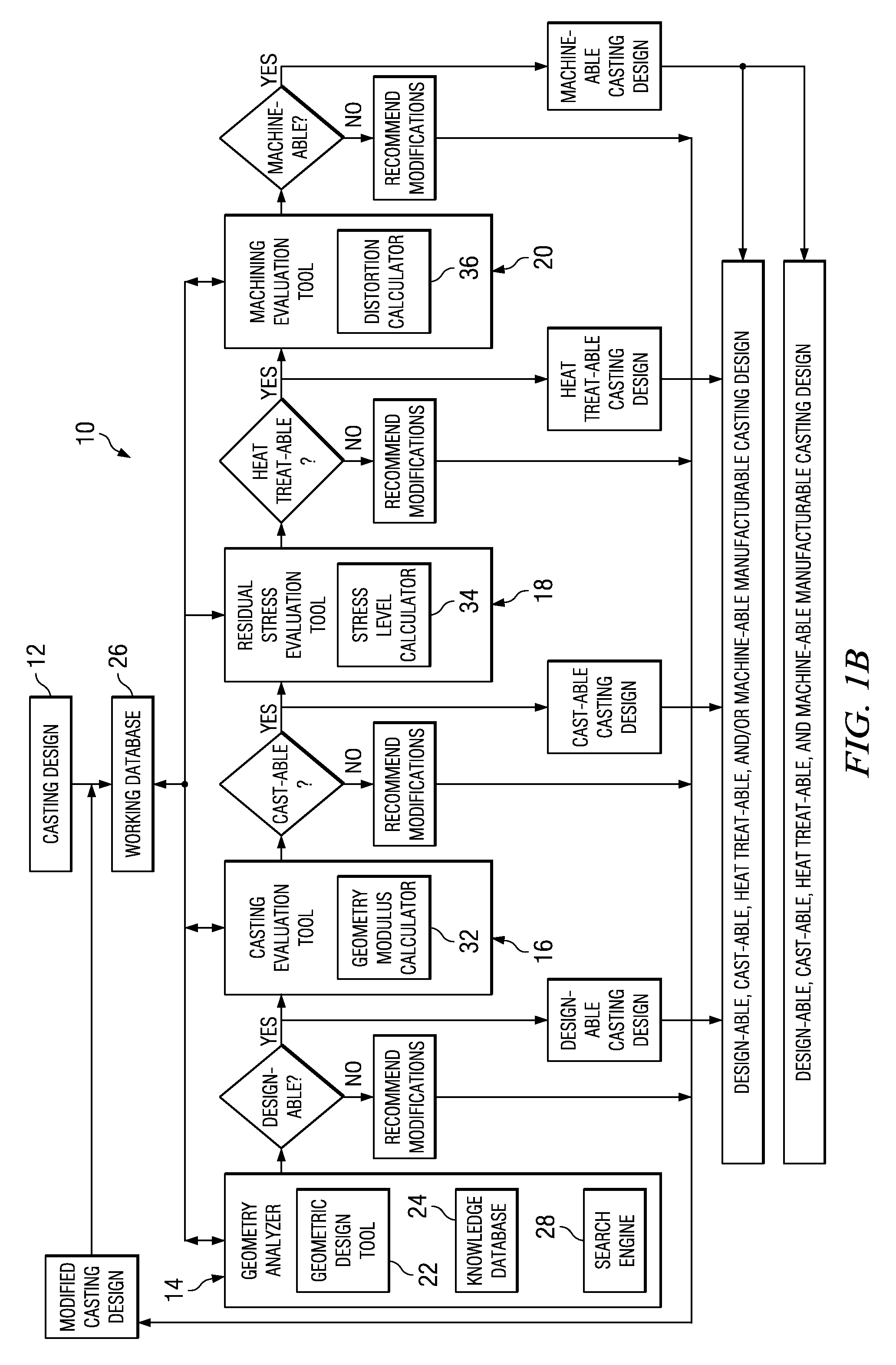

System for evaluating manufacturability of a casting design

ActiveUS20100185312A1Digital data processing detailsAnalogue computers for non-electric machinesGeometric designHeat treated

A system for evaluating a manufacturability of a casting design. The system includes at least one of a geometry analyzer, a casting evaluation tool, a residual stress evaluation tool, and a machining evaluation tool. The geometry analyzer analyzes a geometric design of the casting design to determine its geometric design-ability, the casting evaluation tool evaluates the casting design to determine its cast-ability, the residual stress evaluation tool evaluates the casting design to determine its heat treat-ability, and the machining evaluation tool evaluates the casting design to determine a machine-ability of the casting design. If the casting design is determined as not geometrically design-able, not cast-able, not heat treat-able, or not machine-able by the geometry analyzer, the casting evaluation tool, the residual stress evaluation tool, or the machining evaluation tool, respectively, then modifications to the casting design are recommended to optimize the casting design for manufacturing.

Owner:GM GLOBAL TECH OPERATIONS LLC

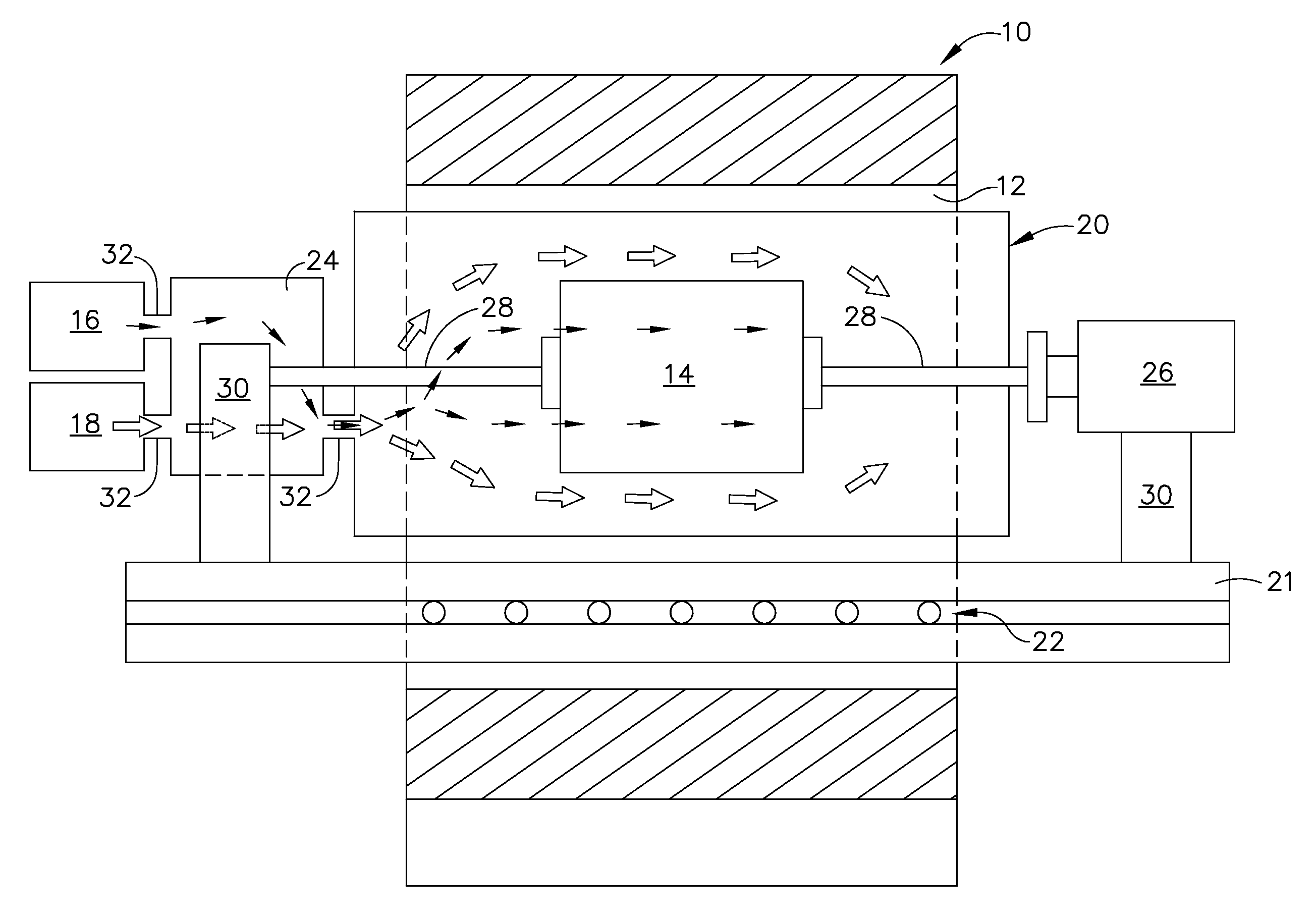

Turbocharger fleet management system

ActiveUS20100023369A1Well formedAnalogue computers for vehiclesCombustion enginesFleet managementTurbocharger

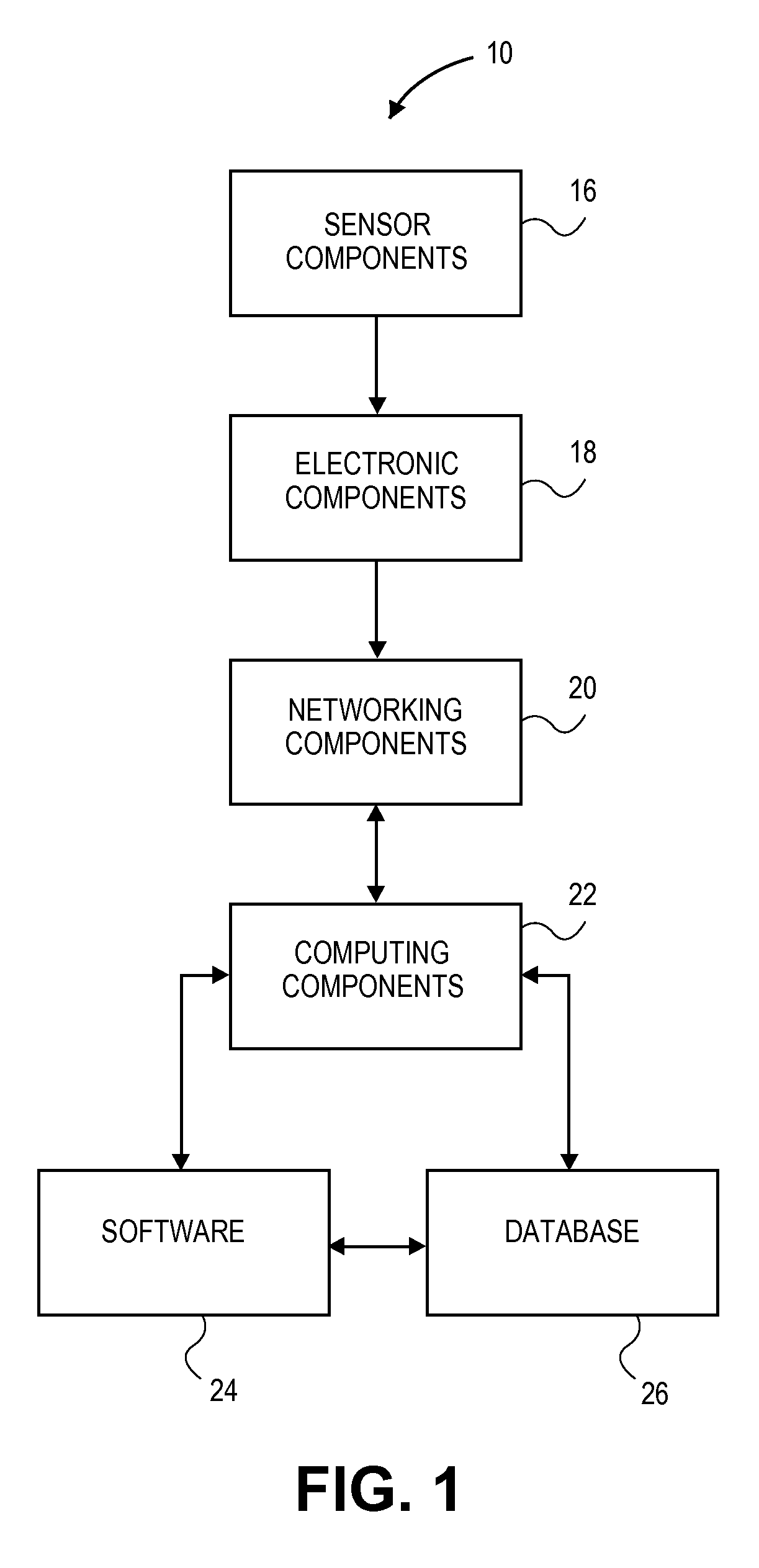

A system of monitoring the performance characteristics of a turbocharged engine and forecasting a performance parameter based on measured data include sensor components for measuring various performance parameters such as pressures and temperatures. The measured data may be received by electronic components that forward the data through networking components to computing components. The data may be stored in a database. Methods for forecasting turbocharger performance and indicating turbocharger malfunctions include retrieving measured data, performing calculations to correct at least a portion of the measured data, retrieving input from a user, performing regression analysis to determine a forecasting model used to forecast future values, and determining a time when the future values reach a user-specified level.

Owner:SCAVENGETECH I

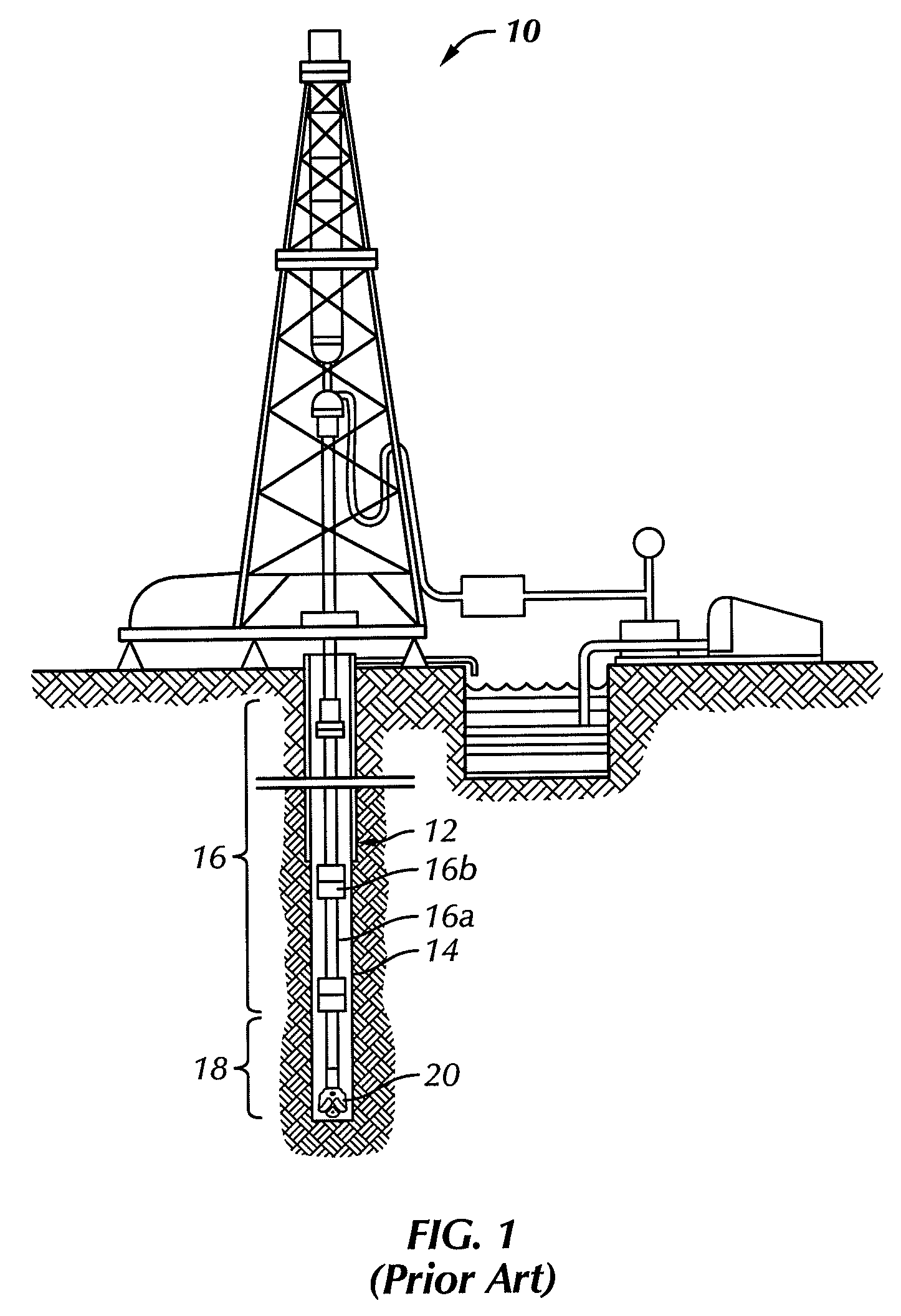

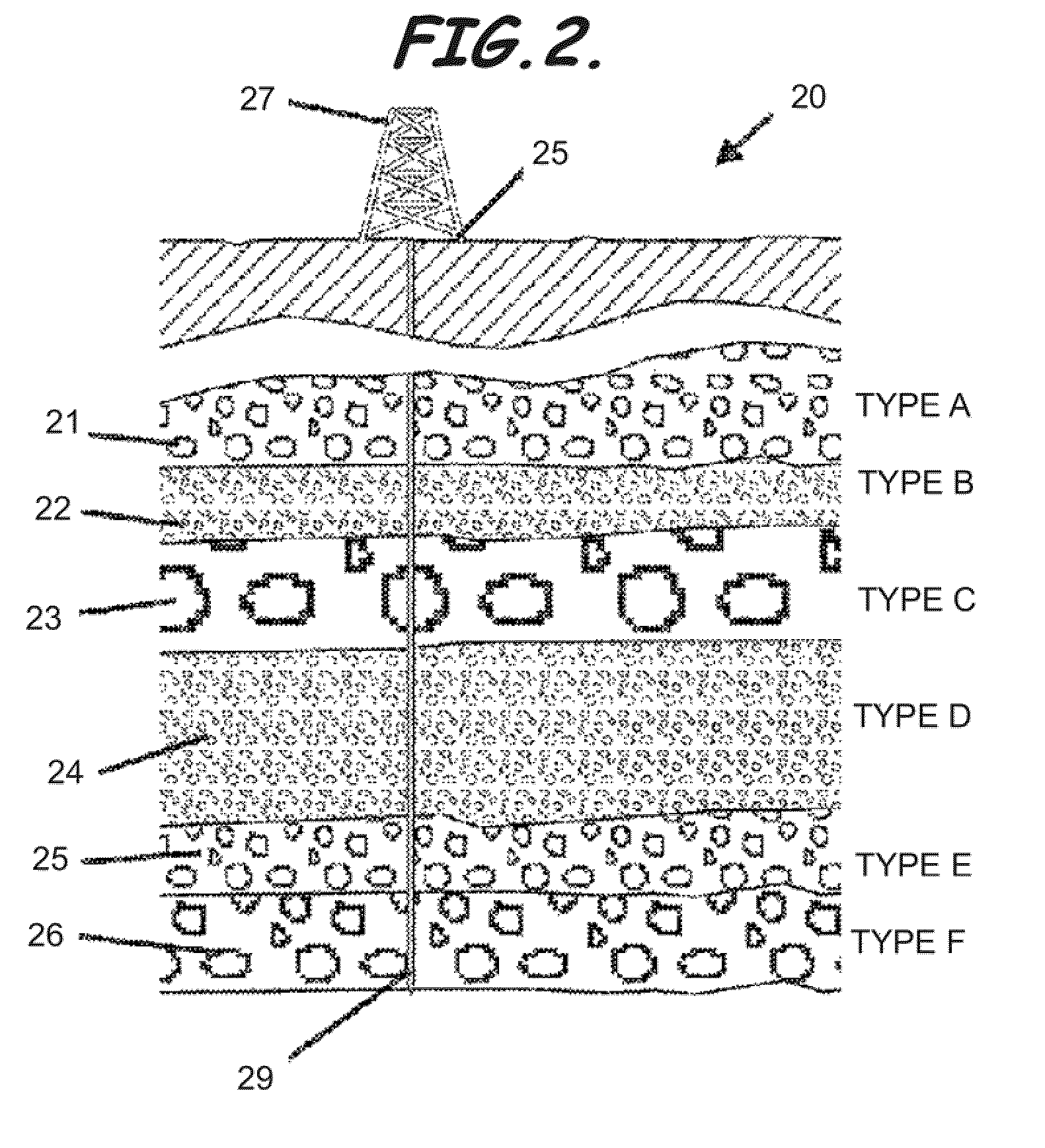

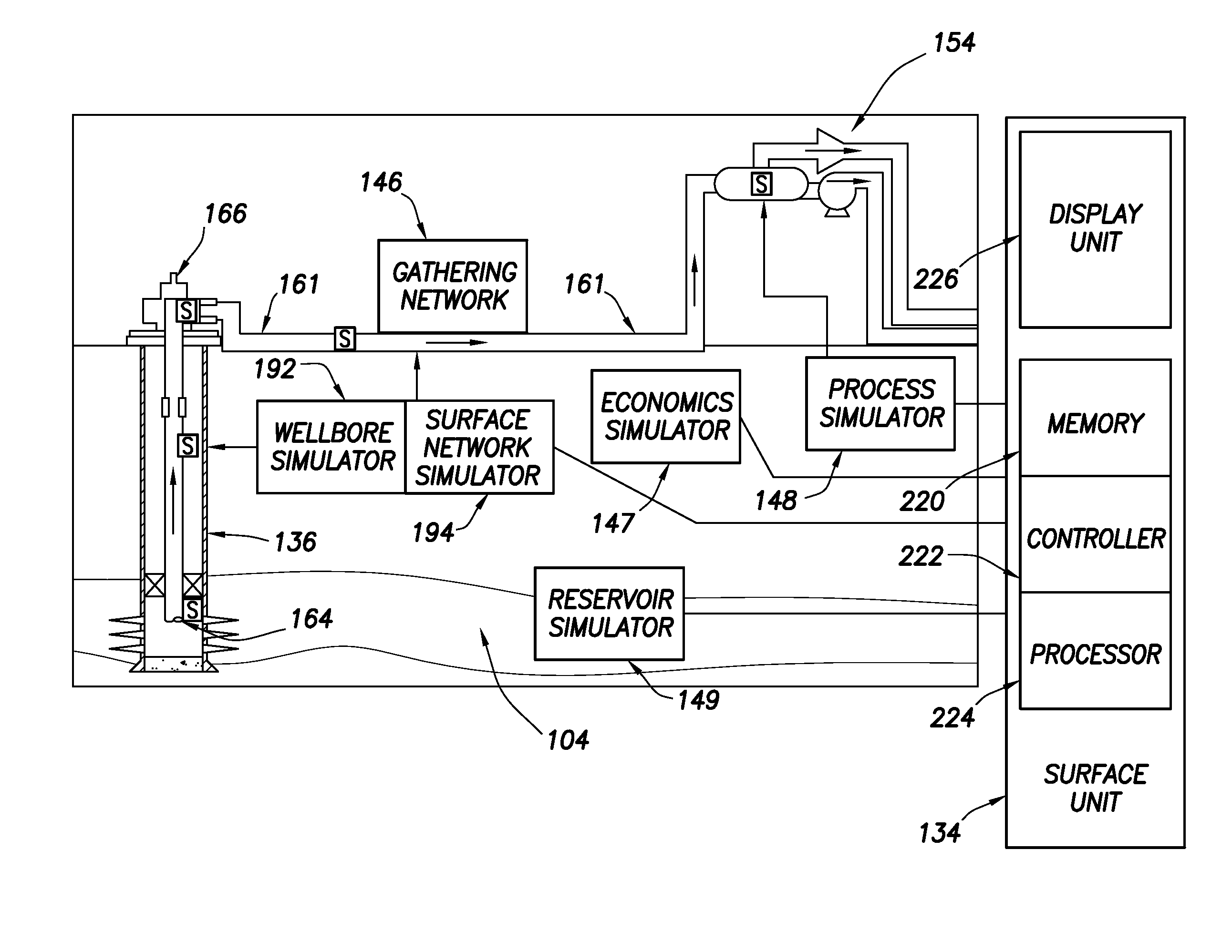

System and method for oilfield production operations

InactiveUS20080262802A1Electric/magnetic detection for well-loggingFluid removalParallel computingControl parameters

The invention relates to a method of performing production operations. The method includes identifying a plurality of simulators from a group consisting of a wellsite simulator for modeling at least a portion of the wellsite of the oilfield and a non-wellsite simulator for modeling at least a portion of a non-wellsite portion of the oilfield, defining a first strategy template comprising a first condition defined based on a first variable of the plurality of simulators and a first action defined based on a control parameter of the plurality of simulators, wherein execution of the first action during simulation is determined based on the first condition in view of a logical relationship, developing a first strategy for managing the plurality of simulators during simulation, wherein the first strategy is developed using the first strategy template, and selectively simulating the operations of the oilfield using the plurality of simulators based on the first strategy.

Owner:SCHLUMBERGER TECH CORP

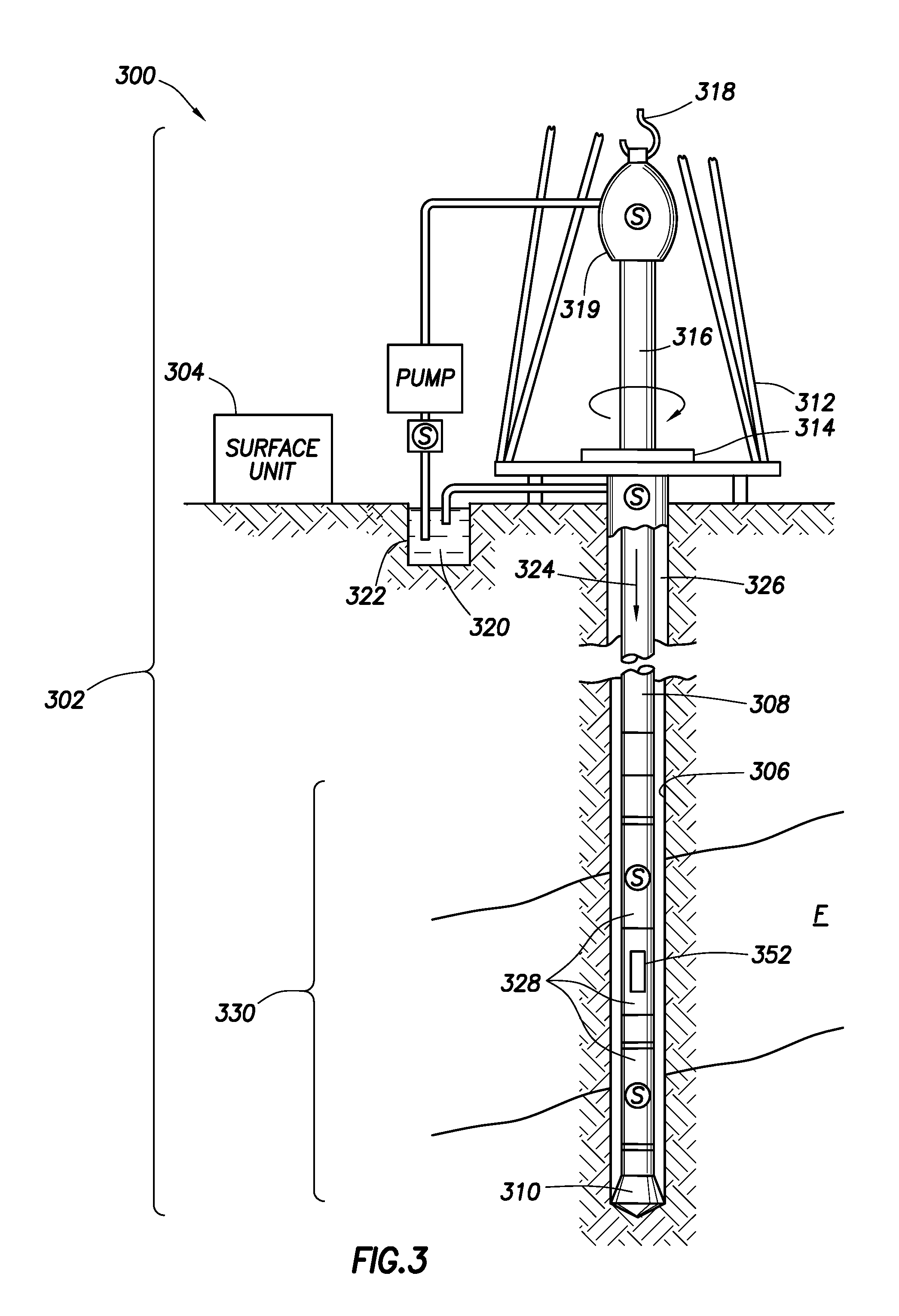

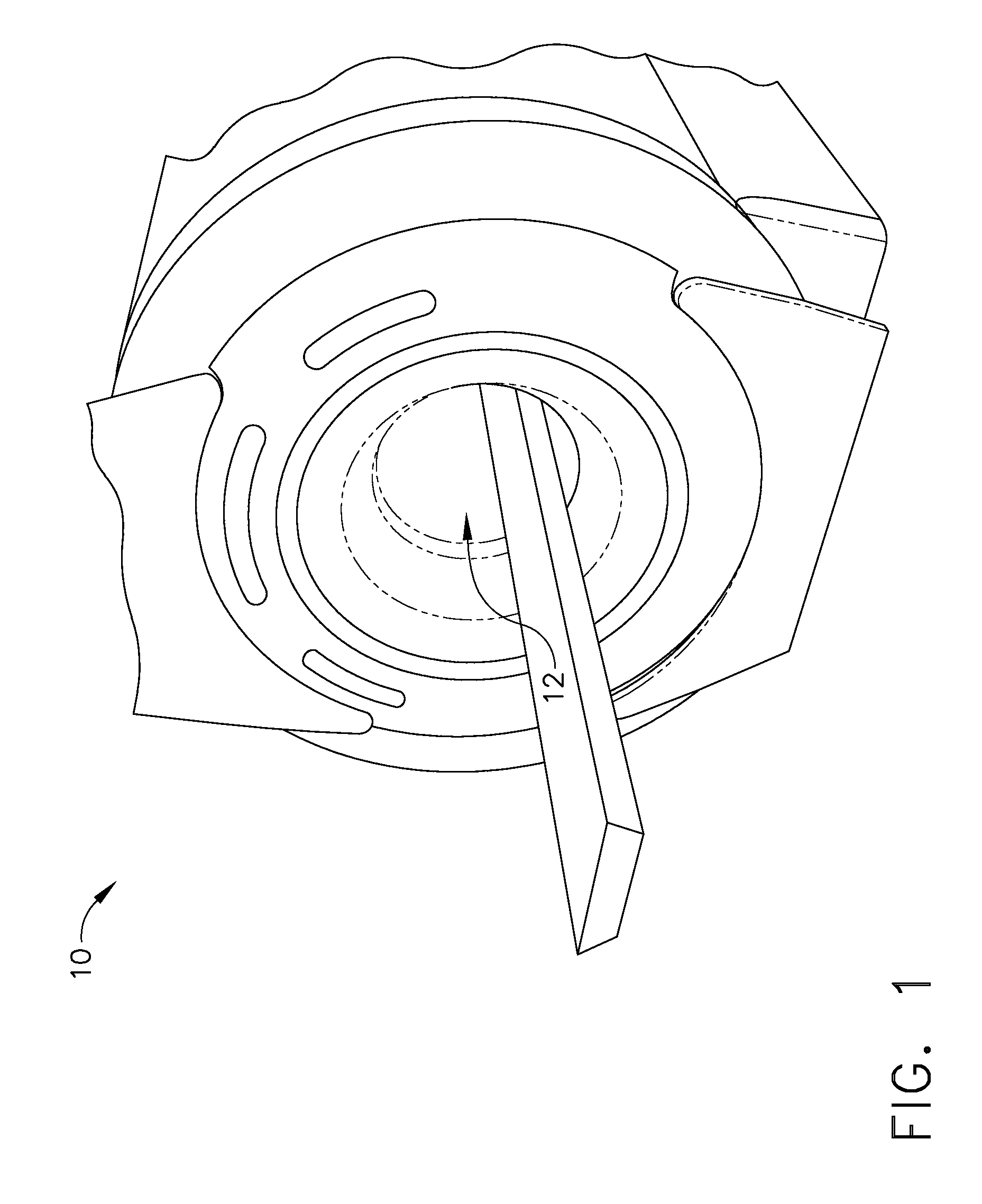

Pdc drill bit using optimized side rake angle

ActiveUS20090030658A1Improve performancePerformance can be improved and optimizedDrill bitsAnalogue computers for non-electric machinesRake anglePetroleum engineering

A fixed cutter drill bit and a method for designing a fixed cutter drill bit includes simulating the fixed cutter drill bit drilling in an earth formation. A performance characteristic of the simulated fixed cutter drill bit is determined. A side rake angle distribution of the cutters is adjusted at least along a cone region of a blade of the fixed cutter drill bit to change the performance characteristic of the fixed cutter drill bit.

Owner:SMITH INT INC

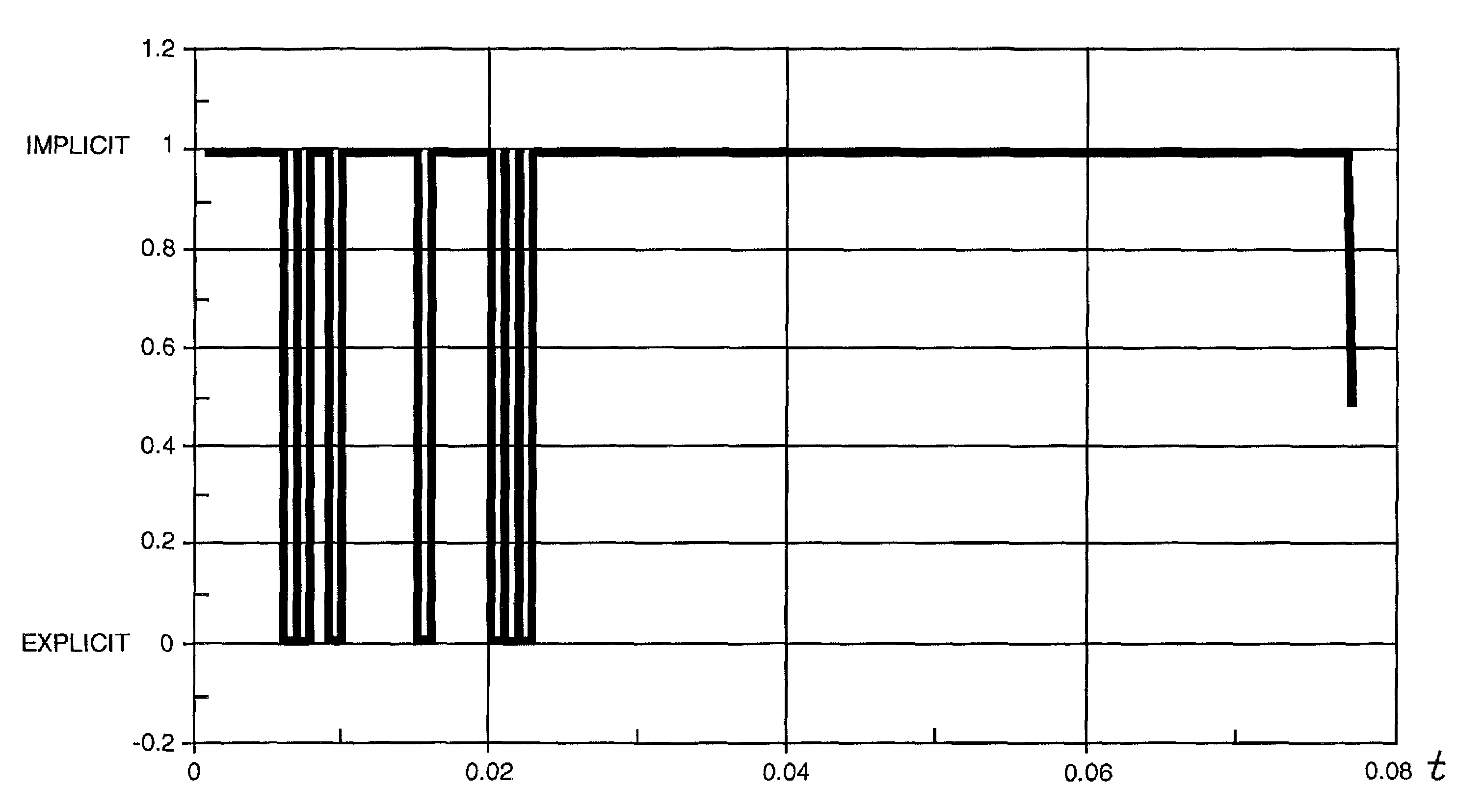

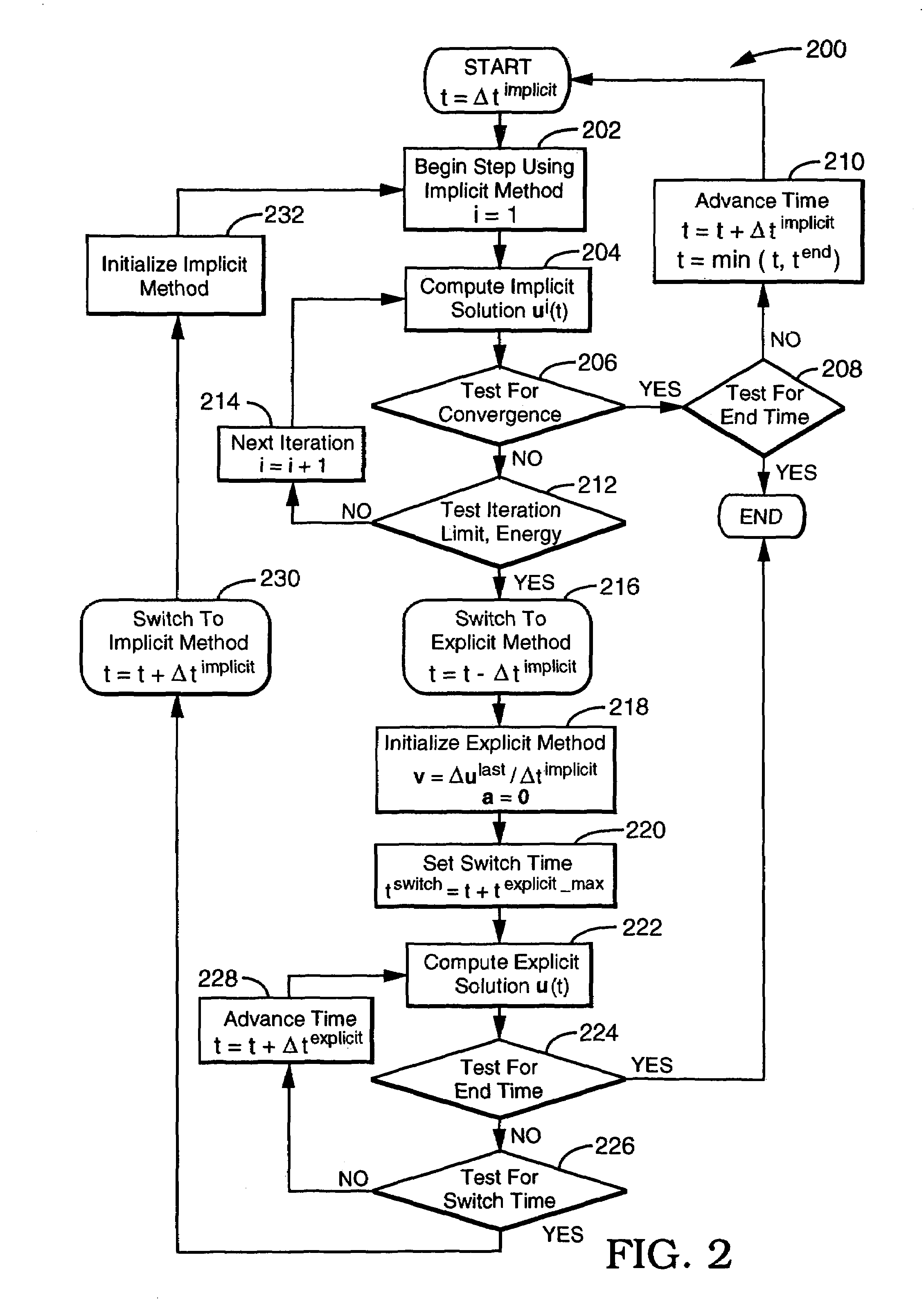

Implicit-explicit switching for finite element analysis

InactiveUS7286972B2Overcome disadvantagesAnalogue computers for non-electric machinesComputation using non-denominational number representationElement analysisFinite element analyse

A method for performing a finite element simulation. The method includes switching between an implicit method and an explicit method during the finite element simulation. By switching between the implicit and explicit methods during a simulation, an accurate solution can be obtained quickly and reliably.

Owner:ANSYS

Methods for optimizing parameters of gas turbine engine components

ActiveUS20080281562A1Analogue computers for vehiclesAdditive manufacturing apparatusTurbineGas turbines

Methods for optimizing at least one operating parameter of an engine component using an experimentally measured 3D flow field involving providing a magnetic resonance imaging machine, providing a model of an engine component, placing the model into the magnetic resonance imaging machine with a fluid flow source for applying an external fluid flow, applying the external fluid flow to the model, collecting data related to the external fluid flow about the model, and optimizing at least one operating parameter of the component using the data.

Owner:GENERAL ELECTRIC CO

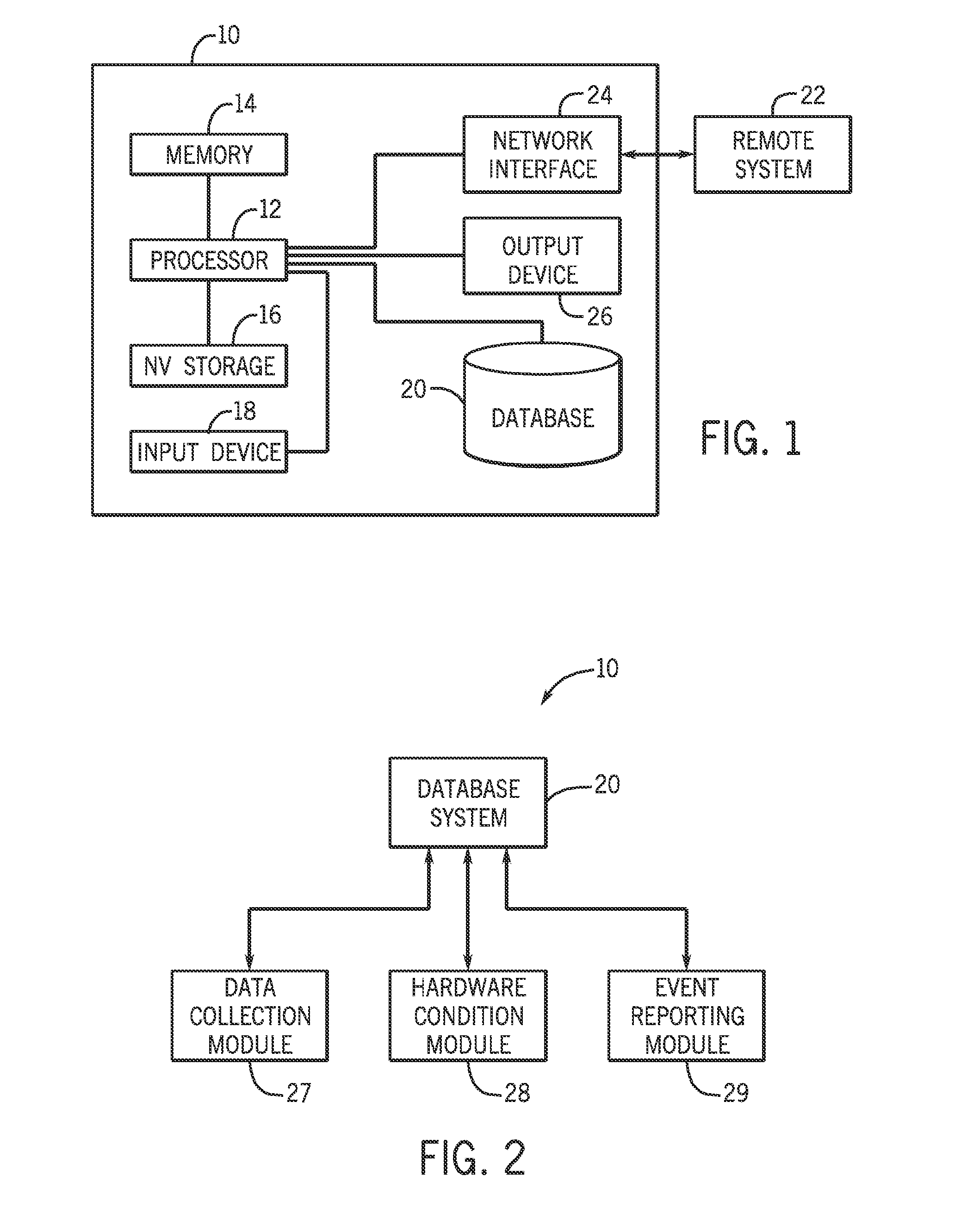

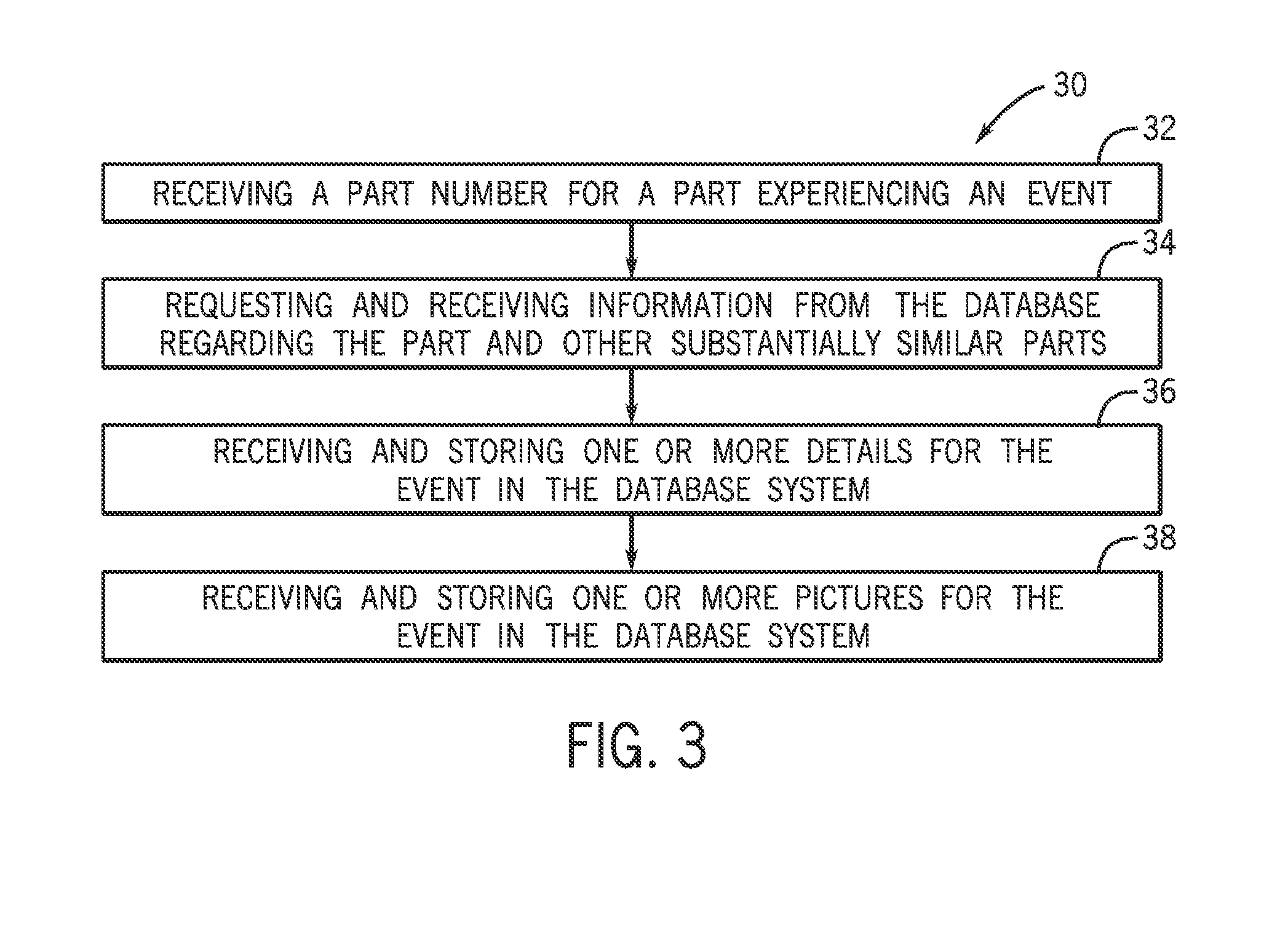

Systems and methods for managing mechanical systems and components

A system includes an interface configured to receive one or more images from an inspection of a component of a mechanical system. Each of the one or more images includes corresponding annotations that at least define one or more dimensions of the component or damages observed in the component. The system also includes a processor configured to construct a degradation model for the component based, at least in part, on the one or more images and their corresponding annotations received by the interface. The processor is further configured to determine one or more maintenance recommendations for the component based, at least in part, on the degradation model constructed for the component.

Owner:GENERAL ELECTRIC CO

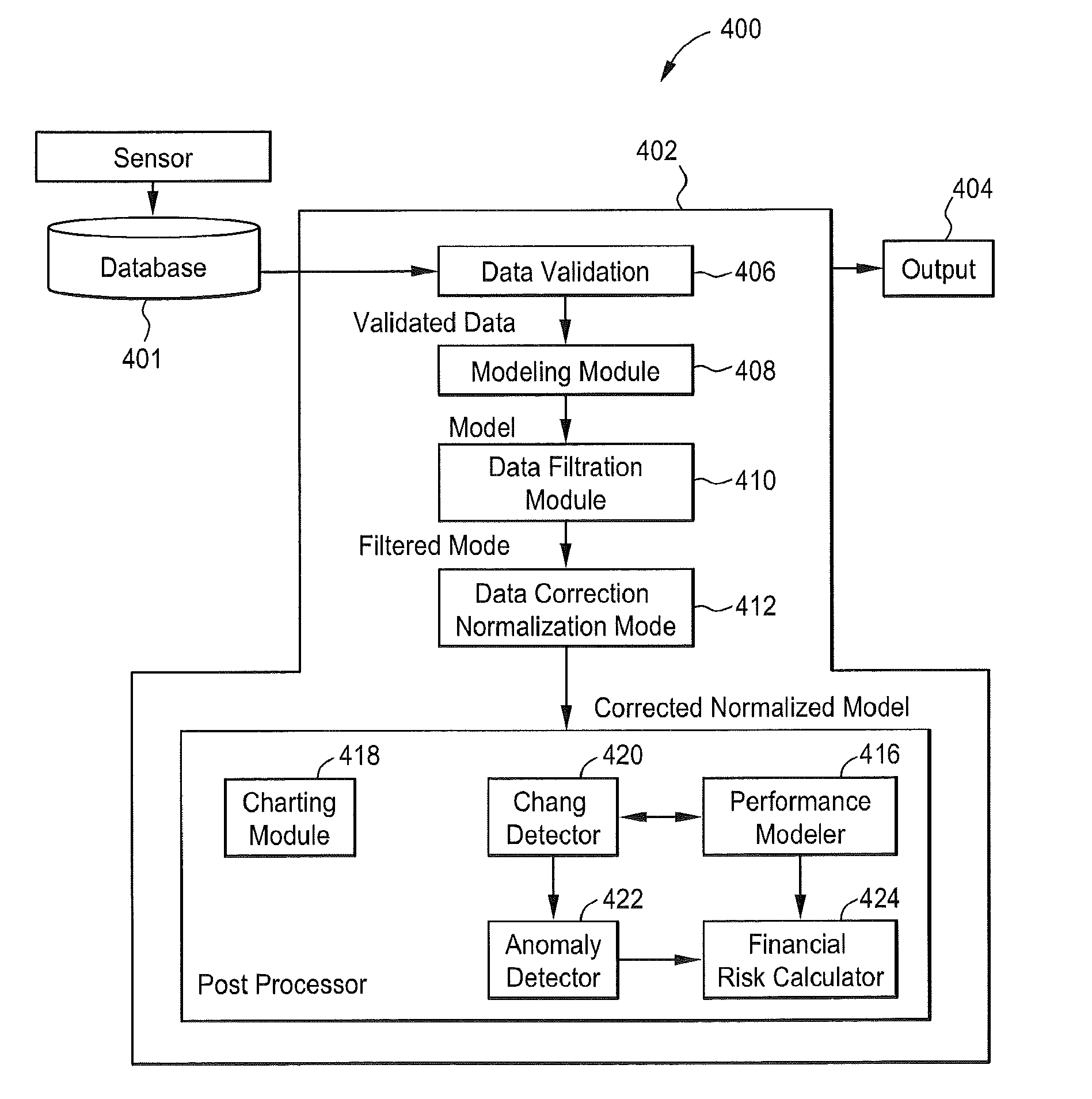

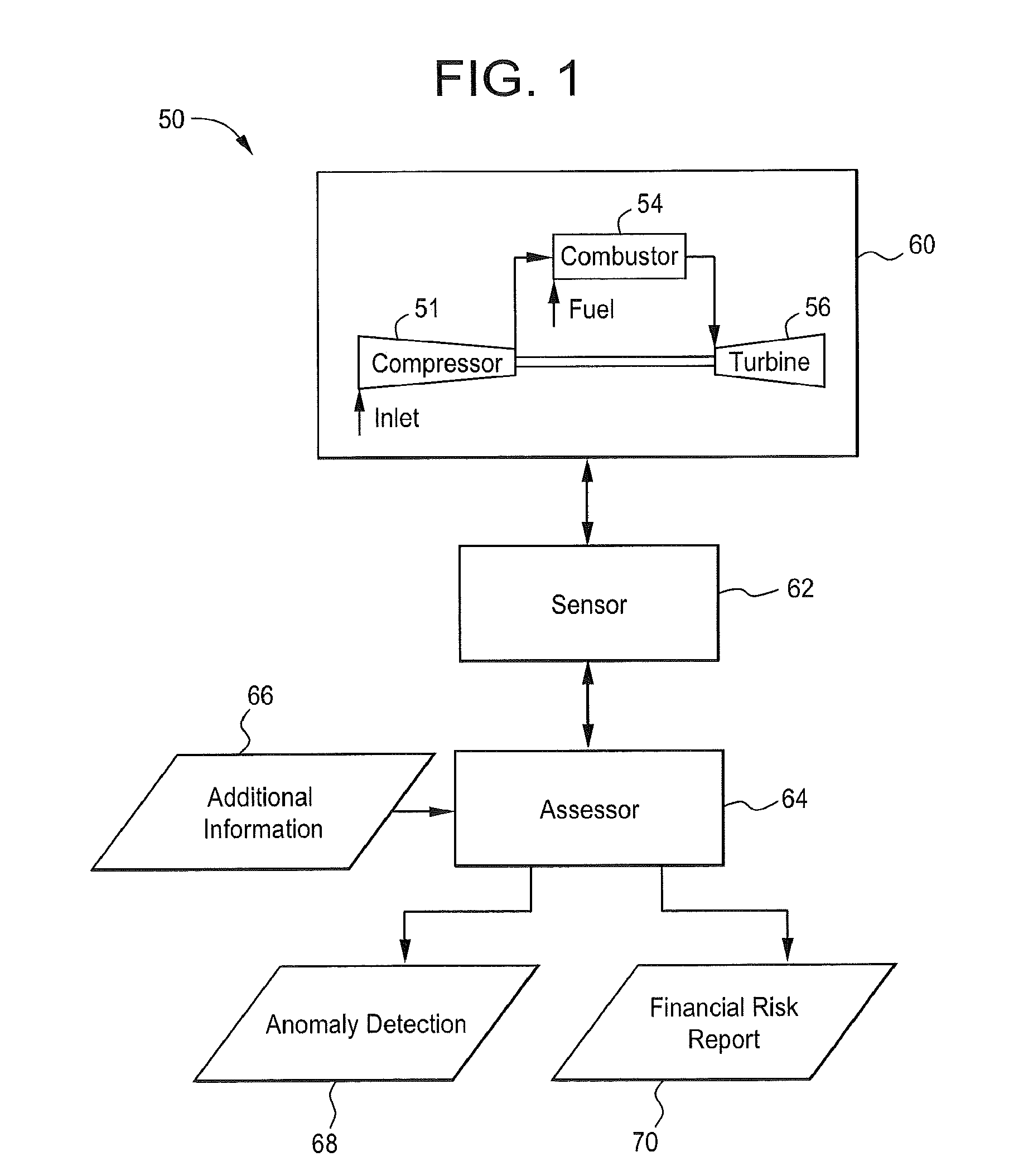

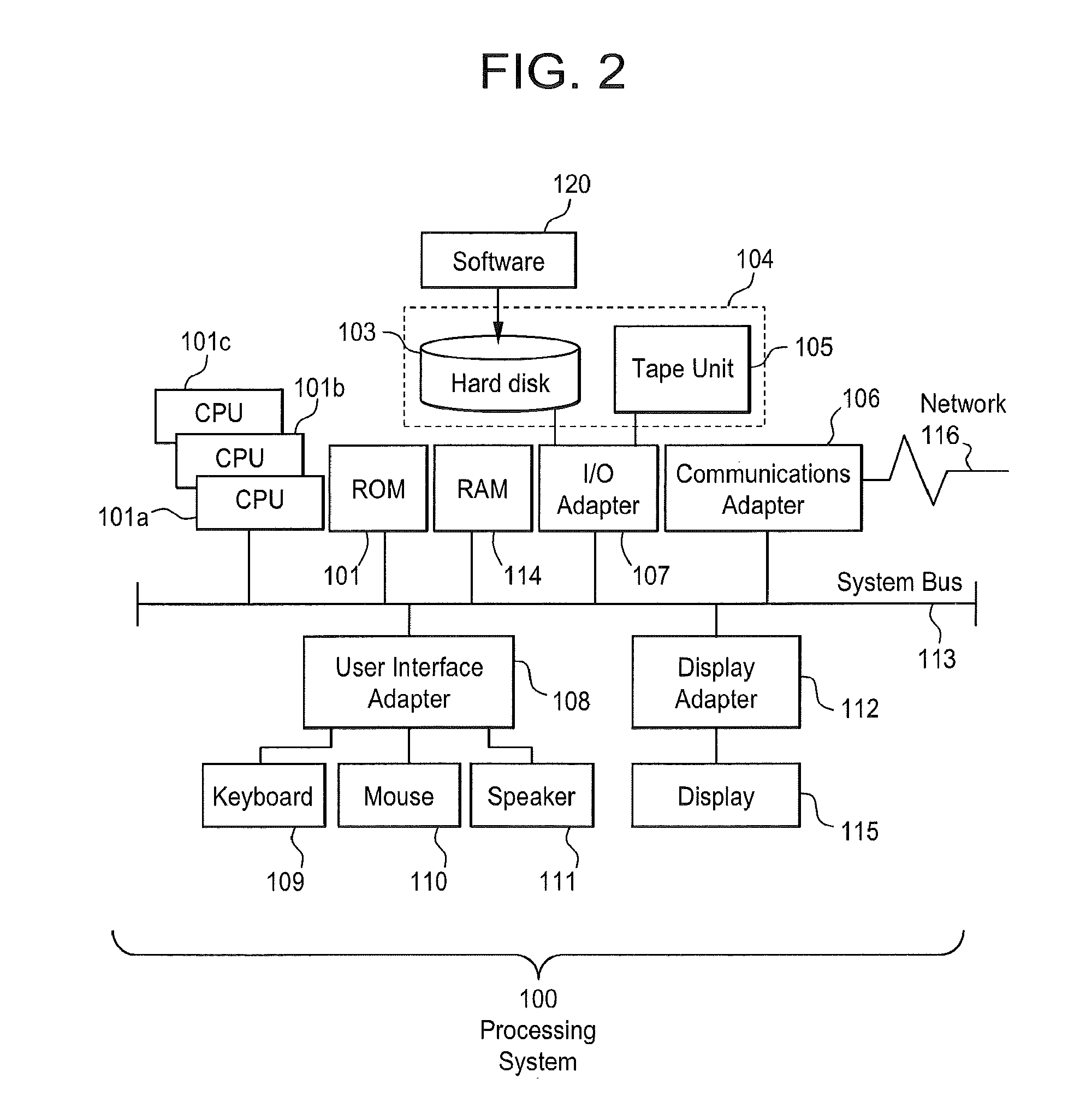

Turbine operation degradation determination system and method

A system for creating a financial risk model for at least one turbine includes a database storing operational characteristics of one or more turbines and a processing module coupled to the database that receives information from the database and creates the financial risk determination. The processing module includes a performance degradation modeler that receives performance data and creates a model there from and a financial risk calculator coupled to the performance modeler that determines financial exposure to a contract based on the model received from the performance modeler.

Owner:GENERAL ELECTRIC CO

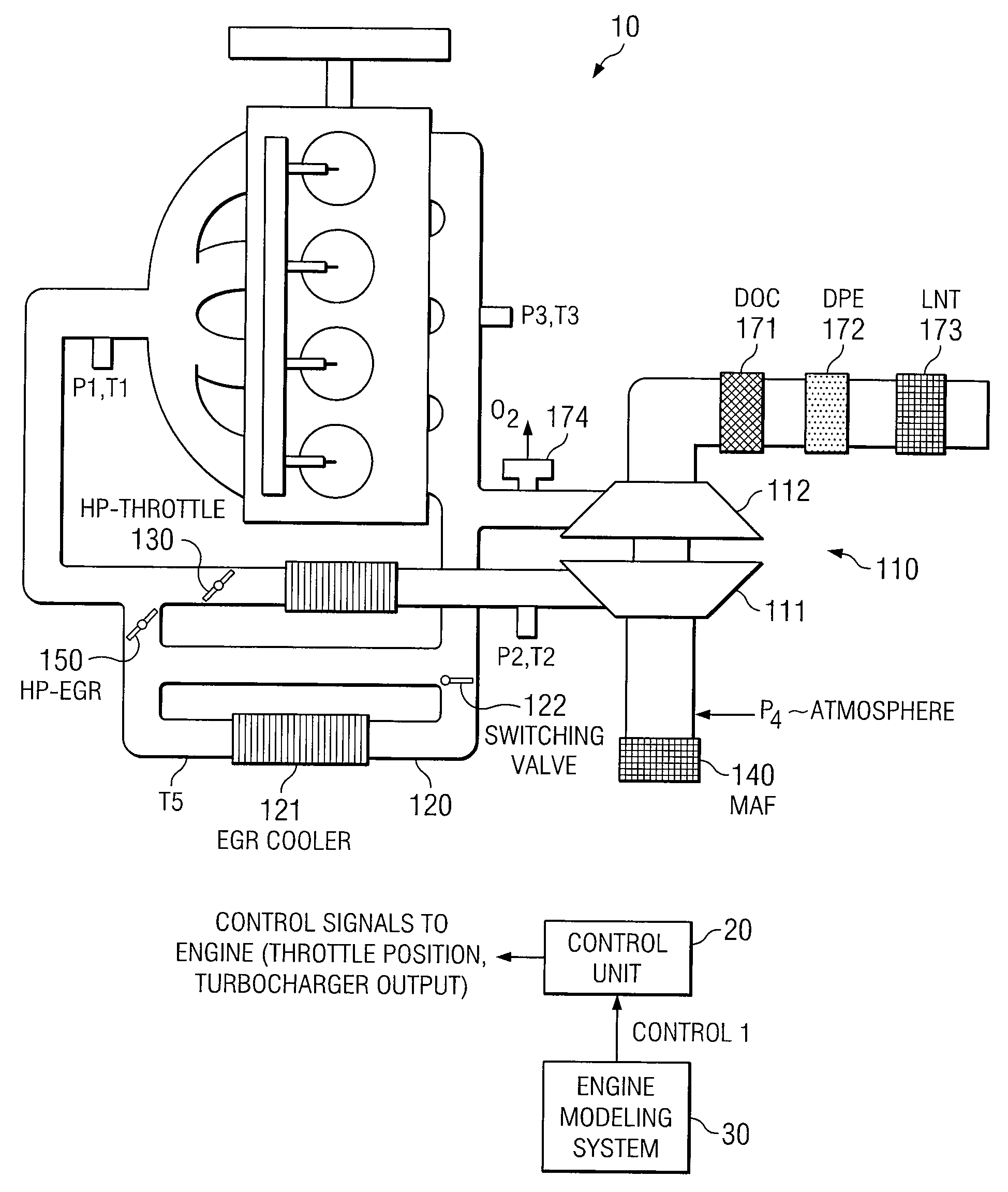

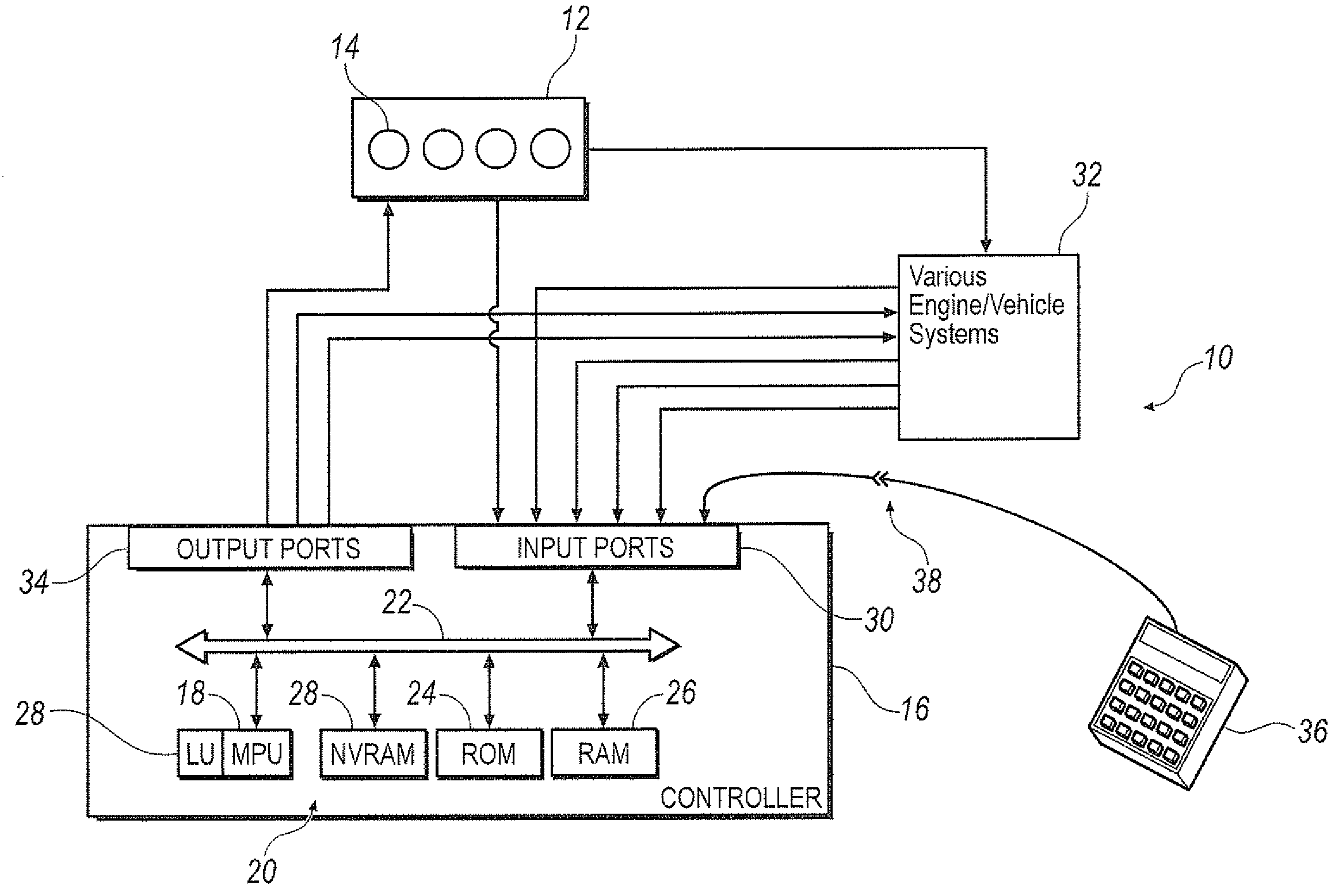

Dynamic modeling of an internal combustion engine operating with multiple combustion modes

A method of modeling a diesel engine that is capable of multiple combustion modes and equipped with a turbocharger and EGR loop. The model comprises a set of equations, each equation representing one of the following as a time derivative: pressure at the intake manifold, pressure between the turbine and an intake manifold throttle, pressure at the exhaust manifold, the compressor power, and the fresh air fraction (the ratio of fresh air to EGR). The model is used to determine what engine conditions (such as throttle positions and turbocharger output) will result in desired pressures and fresh air fraction.

Owner:SOUTHWEST RES INST

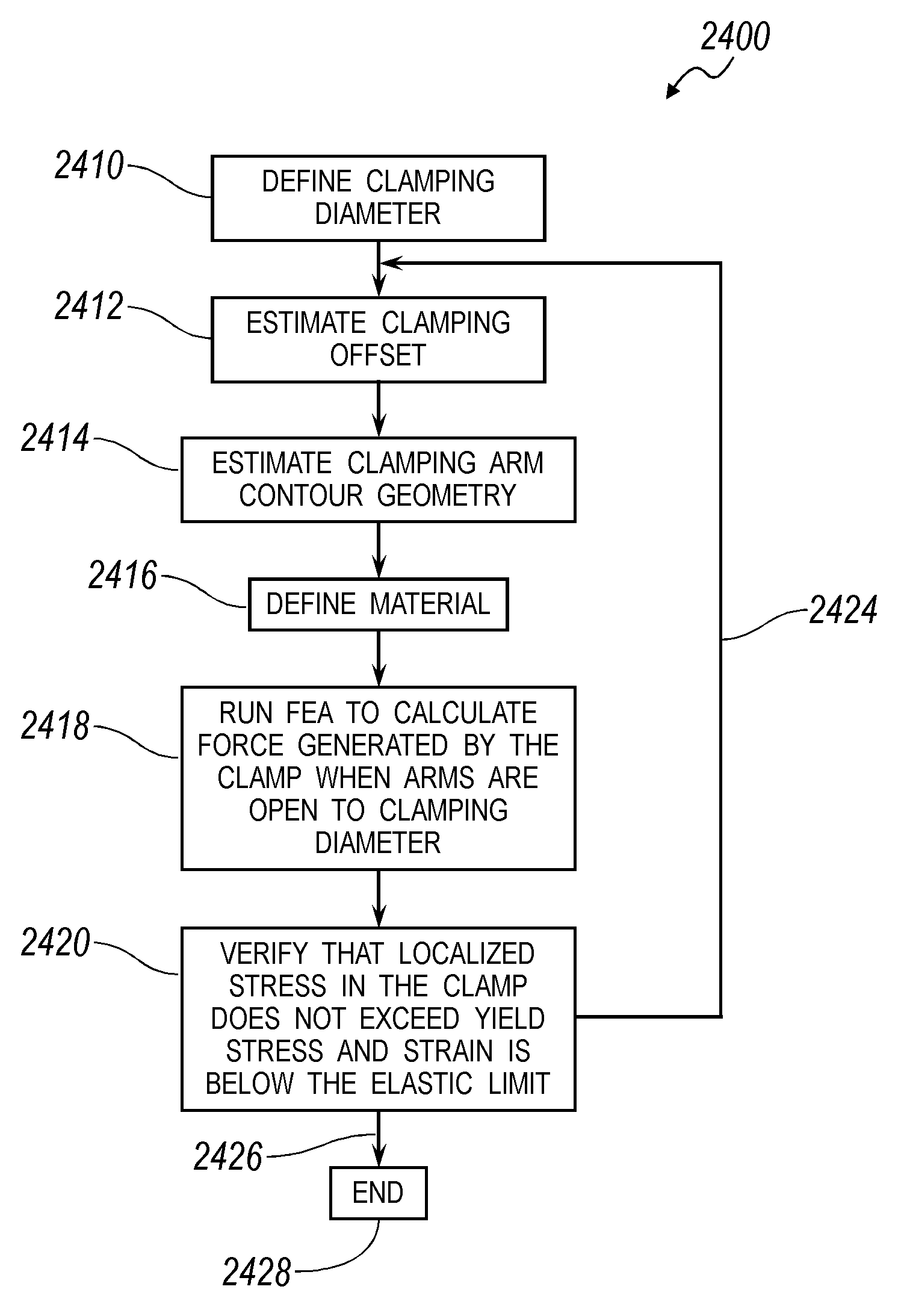

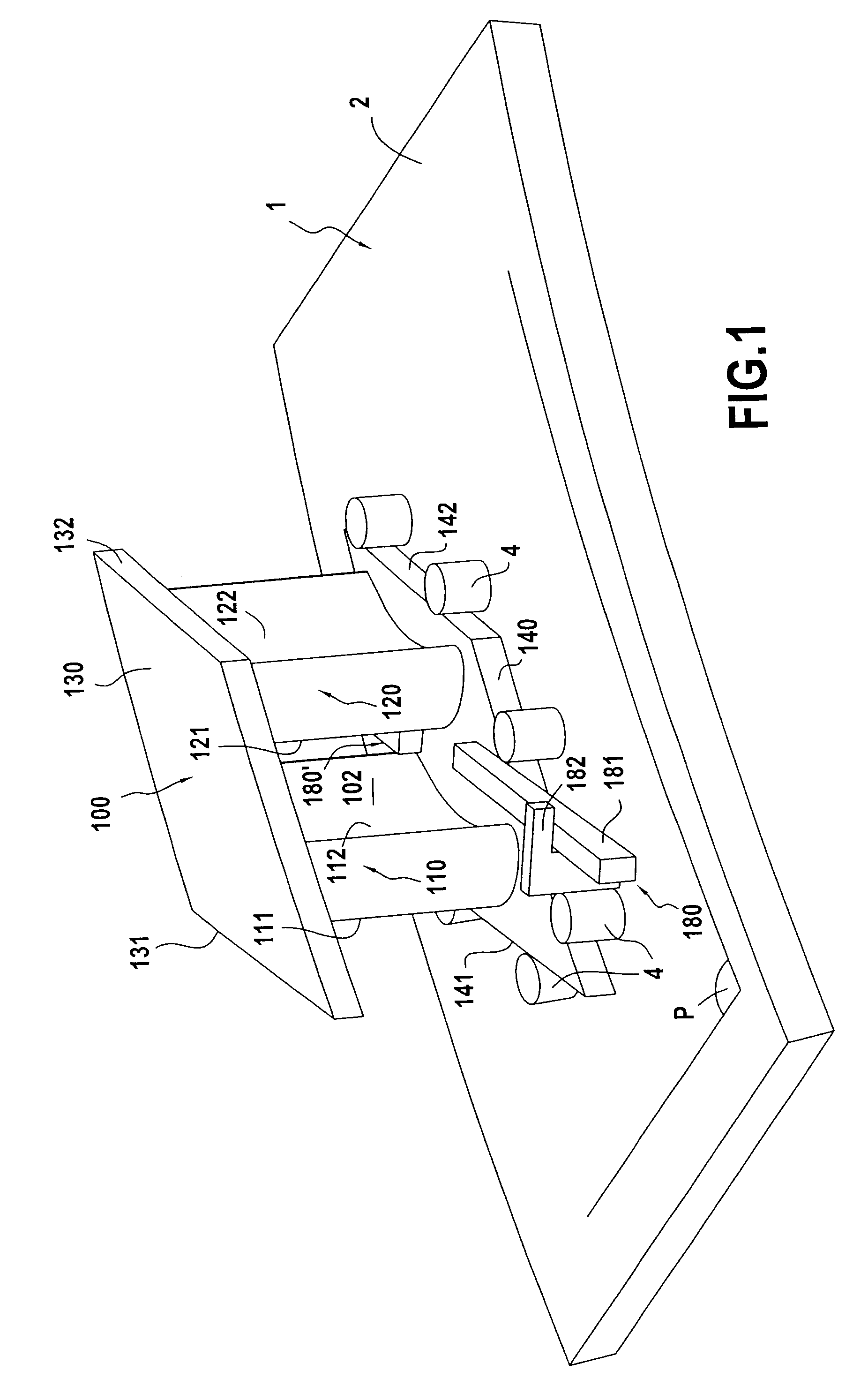

Sensor system and reverse clamping mechanism

A sensor system and a reverse clamp is provided. The reverse clamp may include a back portion, a first arm, and a second arm. The first and second arm extending from the back portion to form an opening configured to receive a cylindrical arm.

Owner:PERCEPTRON

Method, computer, and recording medium storing a program for computing engine design variables

InactiveUS20090222245A1Optimizing degree of change (smoothness)Electrical controlAnalogue computers for non-electric machinesLower limitValue set

For a plurality of combinations of a plurality of operating states included in an operating range of an engine and for a plurality of combinations of a plurality of objective variables, a system, which calculates design variables, includes a calculating device for obtaining global optimal solutions of the design variables that minimize or maximize a sum of the plurality of objective variables, which respectively correspond to the plurality of combinations of the plurality of operating states; a receiving device for receiving designation of an upper limit or a lower limit of the plurality of objective variables; and a searching device for searching for global optimal solutions that result in the smoothest change in the design variables when changing the operating states in a range of the received upper limit to the received lower limit of the objective variables, with one of the global optimal solutions as an initial value set.

Owner:ONO SOKKI CO LTD +1

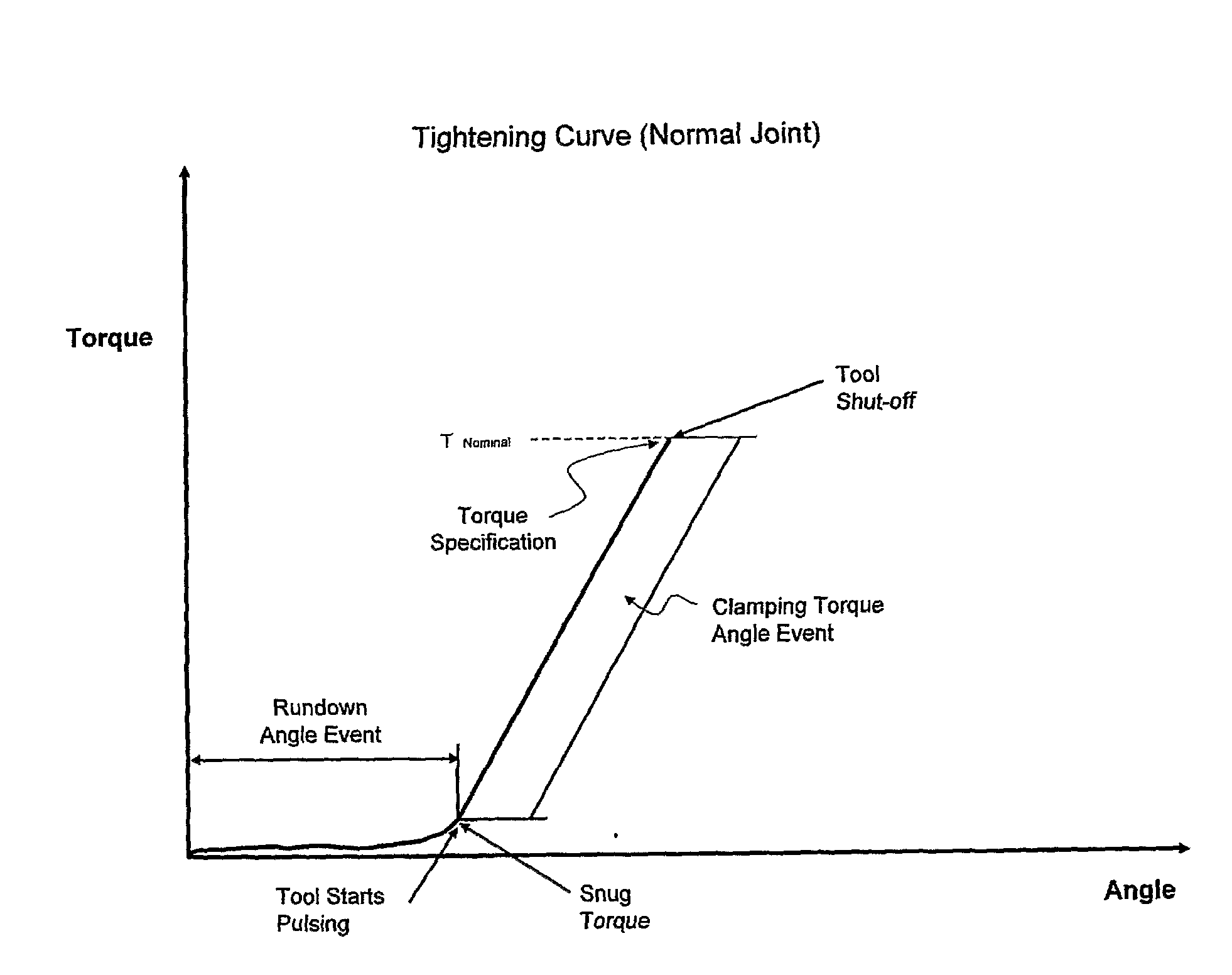

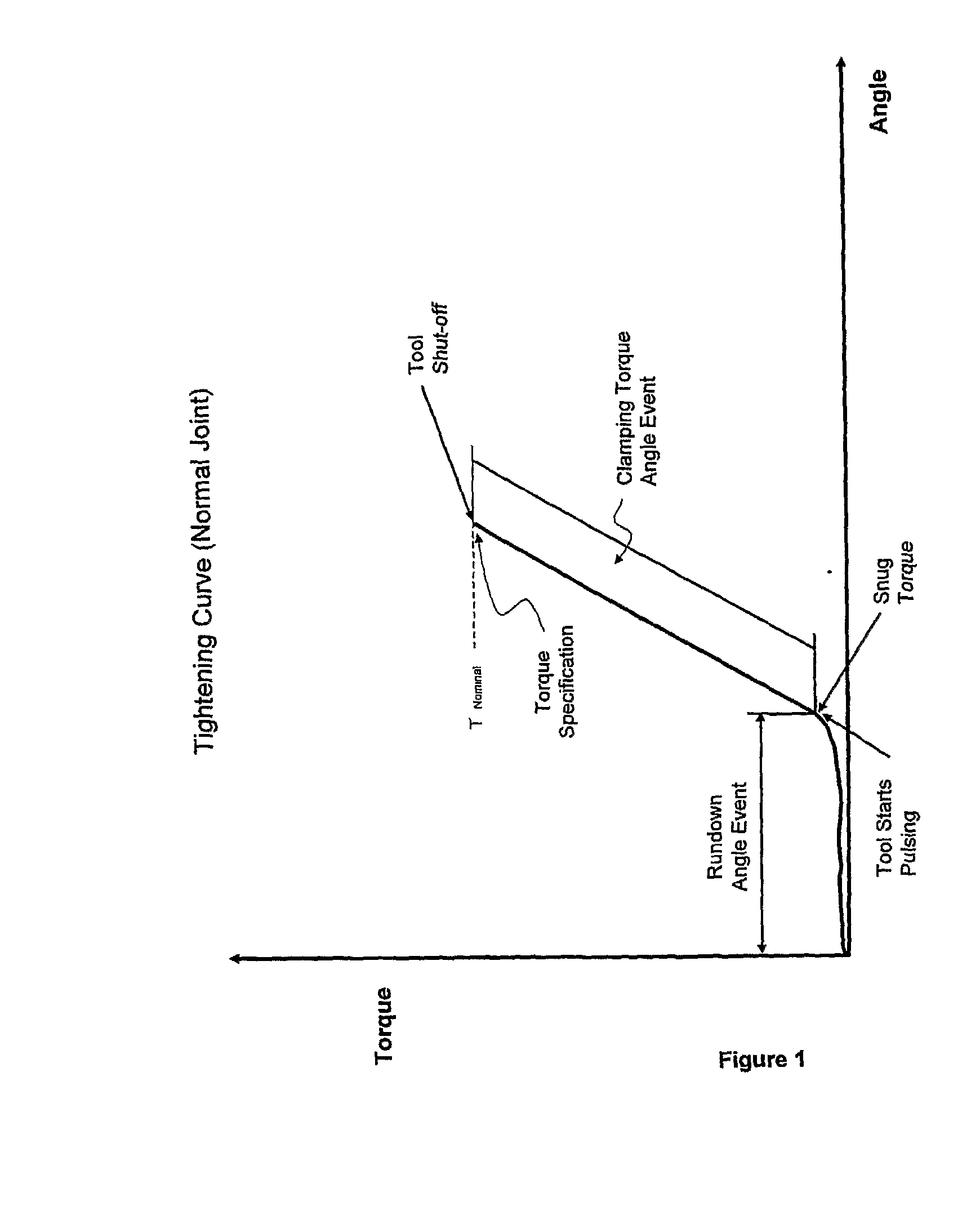

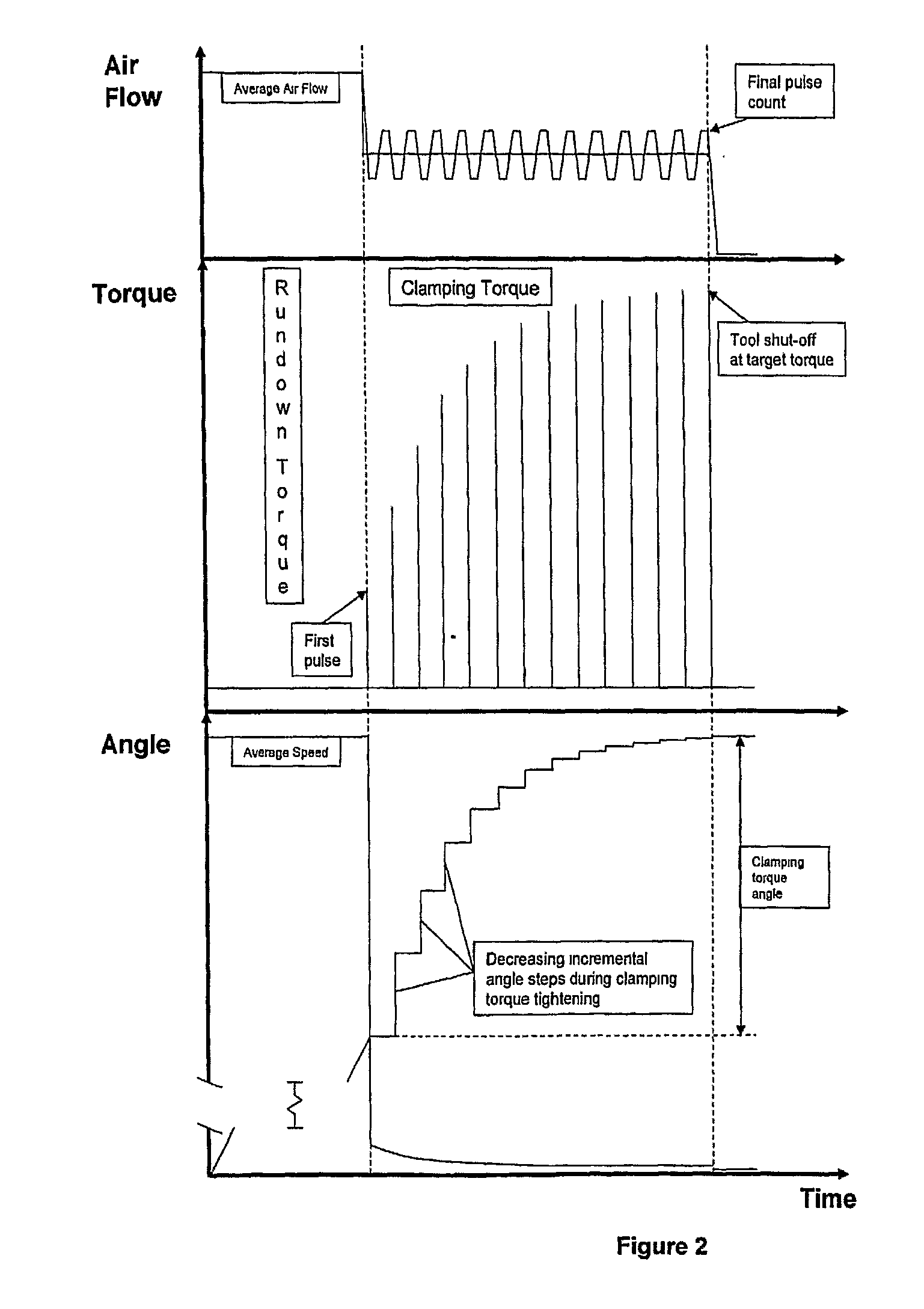

Electro-Hydraulic Timed Angle Controlled Joint Simulation Torque Calibration, Certification and Analysis Device

InactiveUS20090265135A1Overcomes shortcomingIncrease pressureForce measurementNuclear monitoringElectro hydraulicPower tool

A joint simulator is provided having a housing with a chamber, a piston, slidable within the chamber, and a shaft rotatable within the housing, the shaft having (i) an end configured to engage a power tool to be tested, and (ii) a threaded end engaged with the piston, whereby rotating the shaft causes the piston to slide within the chamber Hydraulic fluid fills a section of the chamber formed by a side of the piston and the housing, and computer software controlled pressure and relief valves are actuated to regulate the flow of hydraulic fluid in the chamber, to achieve target pressures. The pressure of the hydraulic fluid creates resistance to rotation of the shaft, thereby increasing the torque relative to the angular increase on the shaft and / or relative to time. The joint simulator is provided with means to determine the angular displacement and torque applied to the shaft;

Owner:HETZEL ADRIAN H

Methods and systems for performing diagnostics regarding underlying root causes in turbine engines

ActiveUS20090150131A1Easy to identifyConducive to diversificationTesting/monitoring control systemsAnalogue computers for non-electric machinesEngineeringRoot cause

A method for performing diagnostics for an engine comprises the steps of identifying an engine component as potentially being related to operational data of an engine, calculating a deviation from a thermodynamic model, and comparing the deviation with root cause deviation measures. The deviation relates the engine component to an adjustment to the thermodynamic model with respect to a variable of the thermodynamic model, based at least in part on the operational data. Each root cause deviation measure relates one of a plurality of potential root causes to the thermodynamic model with respect to the variable of the thermodynamic model.

Owner:HONEYWELL INT INC

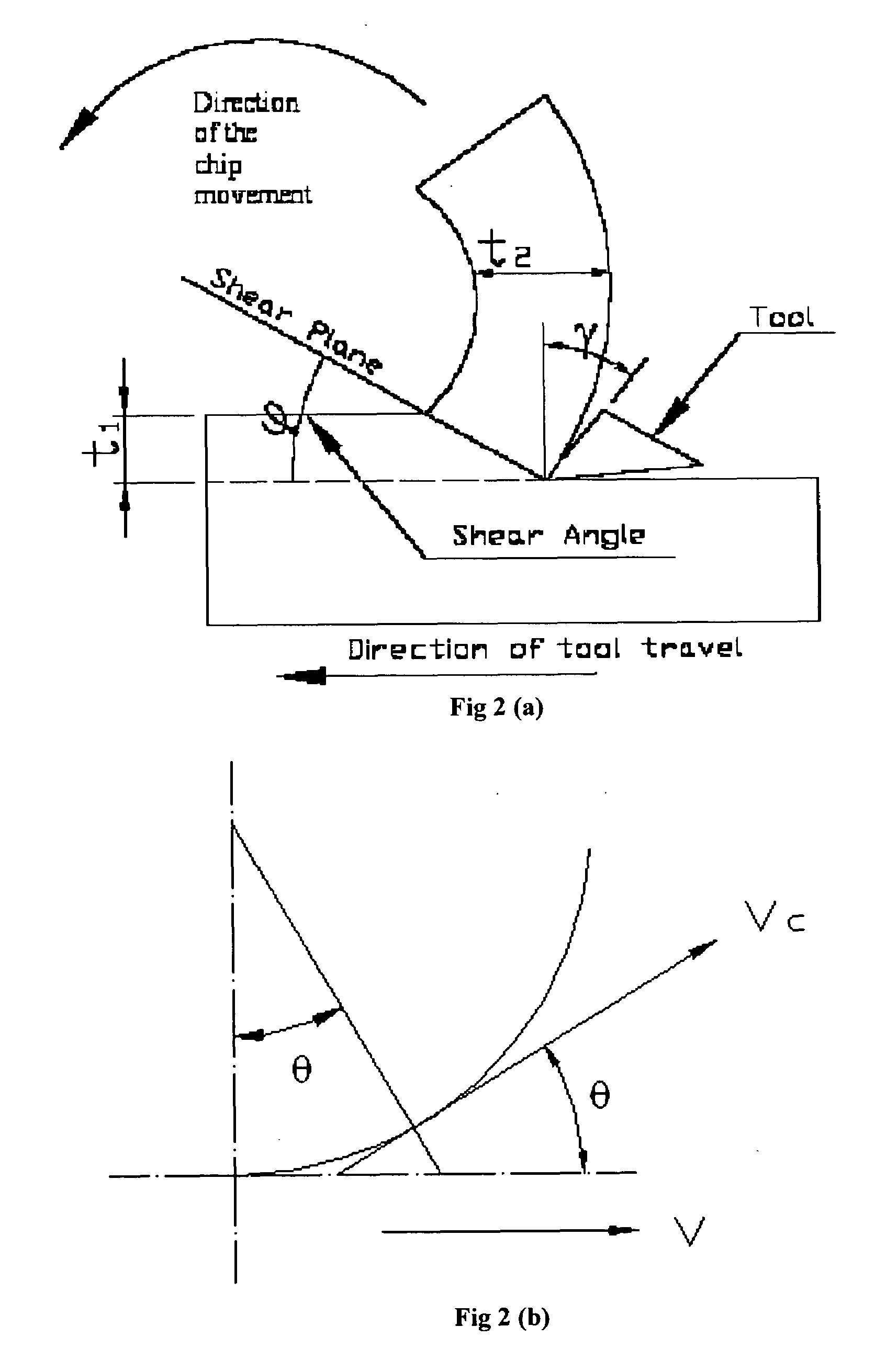

Virtual manufacturing of transmission elements

A software structure which when adapted in an apparatus is capable of virtual manufacturing of transmission elements for example gear means with chip formation, the software structure comprising a start module for loading the source file in a main editor-file that contains the computer program, an input module for providing input parameters that are essential for the configuration of a product and a cutting tool, a product design module for evolving the parameters for the manufacturing of the product; and a virtual manufacturing module having at least three sub-modules one each for tool generation, visualisation of machining operation, and disassembly of the product from the machine bed.

Owner:IONSENSE +1

Method of measuring flow sections of a turbomachine nozzle sector by digitizing

InactiveUS20090164185A1Possible to displayImprove performanceMeasurement devicesEngine manufactureAbutmentNumerical models

A method of measuring flow sections of a turbomachine nozzle sector relative to two reference vanes, wherein:a) a three-dimensional numerical model of the sector is produced by digitizing;b) numerical models are provided for the two reference vanes;c) the reference vanes are reset at the ends of the numerical model of the sector in their assembly relative positions in the nozzle; andd) the flow sections of the sector are determined from sections of the numerical models of the sector and of the reference vanes;the nozzle sector having contact surfaces, and being positioned relative to adjacent nozzle sectors by putting said contact surfaces into abutment, the numerical models of the sector and of the reference vanes including models of the contact surfaces involved in putting them into their assembly relative position, and step c) being performed by putting the contact surfaces into correspondence.

Owner:SNECMA SERVICES

Methods and systems for gas turbine modeling using adaptive kalman filter

ActiveUS20130054031A1Easy to adjustSampled-variable control systemsComputer controlKaiman filterProcess engineering

A system and method for modeling a gas turbine assembly include a plurality of sensors configured to measure a plurality of operating parameters of a turbine assembly. The system further includes a model configured to compare the plurality of operating parameters with a plurality of predicted parameters to determine difference values. A Kalman filter of system is configured to evaluate the difference values to facilitate adjusting the model. The Kalman filter is further configured to accommodate for a missing operating parameter of the plurality of operating parameters to facilitate tuning the model.

Owner:GENERAL ELECTRIC CO

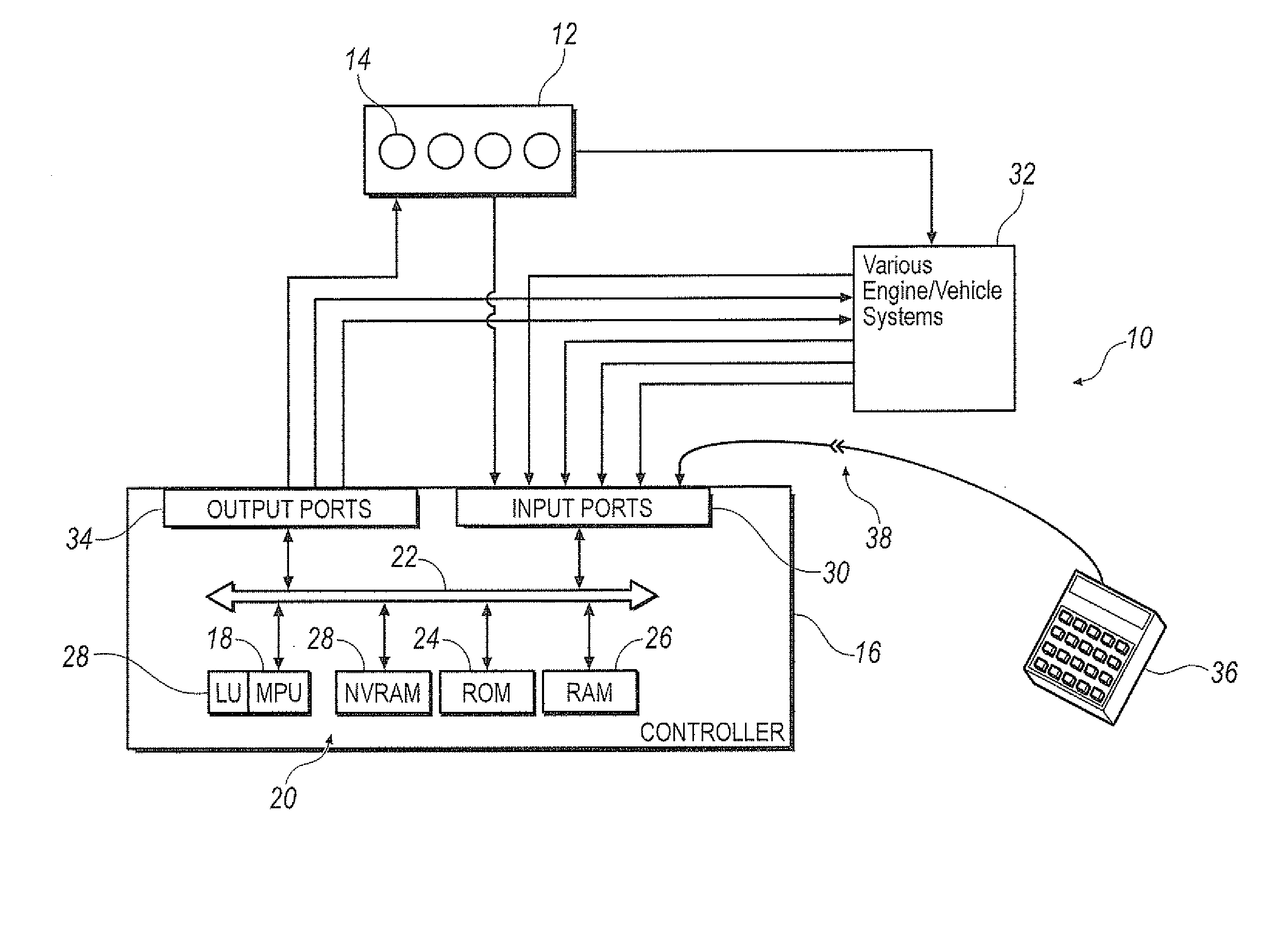

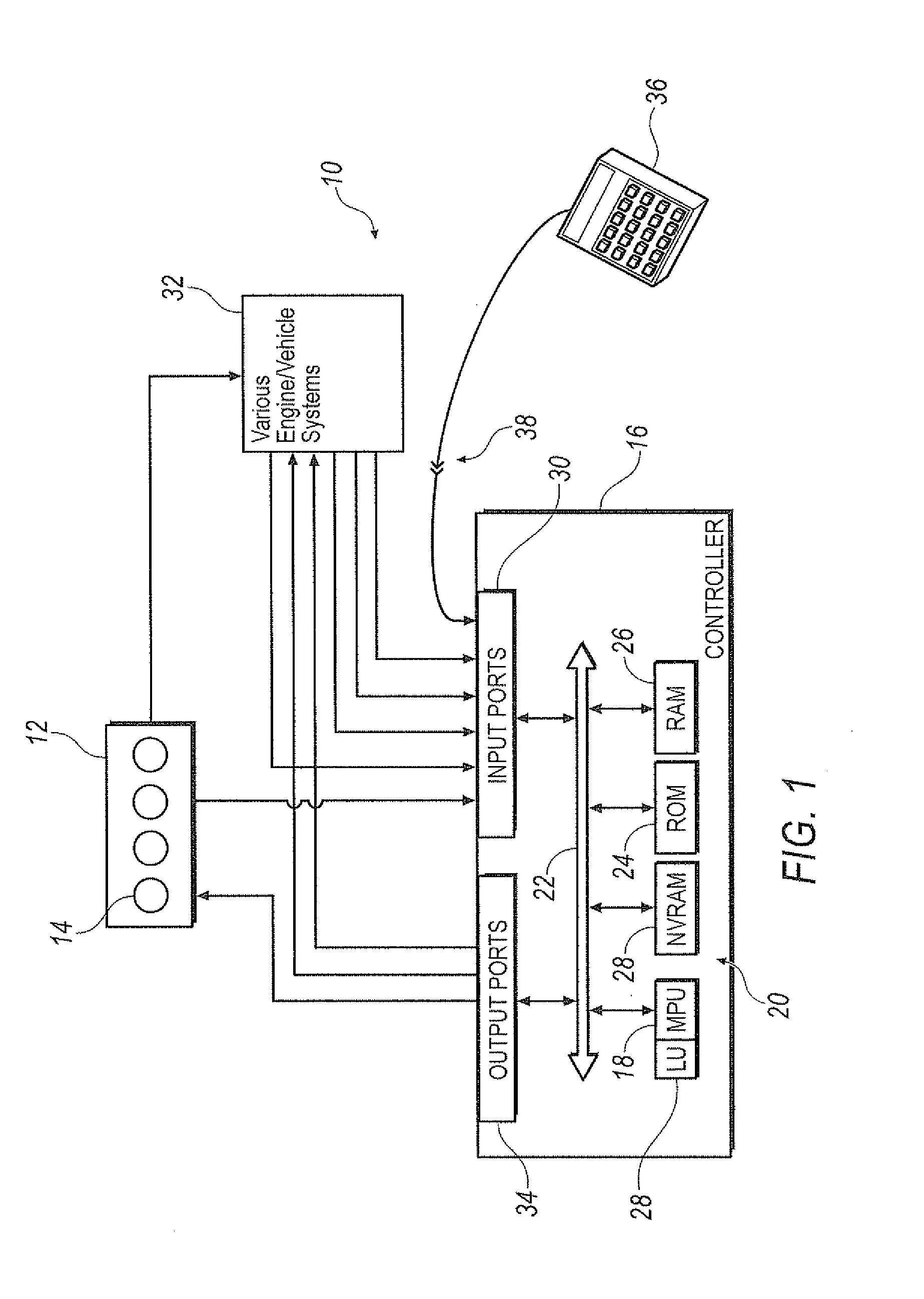

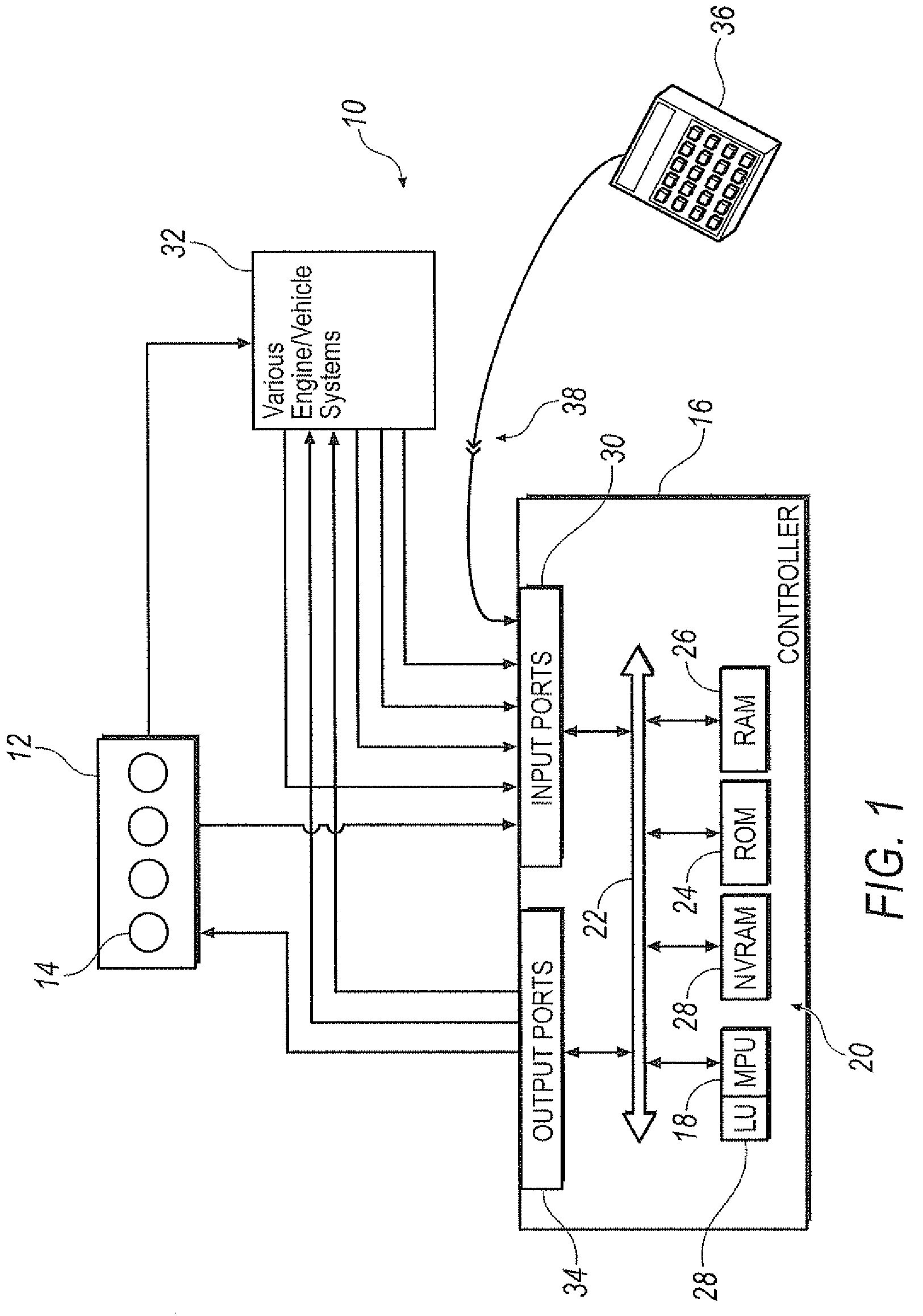

Monitoring unit state chart and a debounce logic

InactiveUS20080162025A1Shorten speedAnalogue computers for vehiclesRegistering/indicating working of vehiclesInternal combustion engineReliability engineering

A method of logging faults in an electronic controlled internal combustion engine that passes any fault readings through a debounce logic to determine whether the fault indication is real.

Owner:DETROIT DIESEL CORP

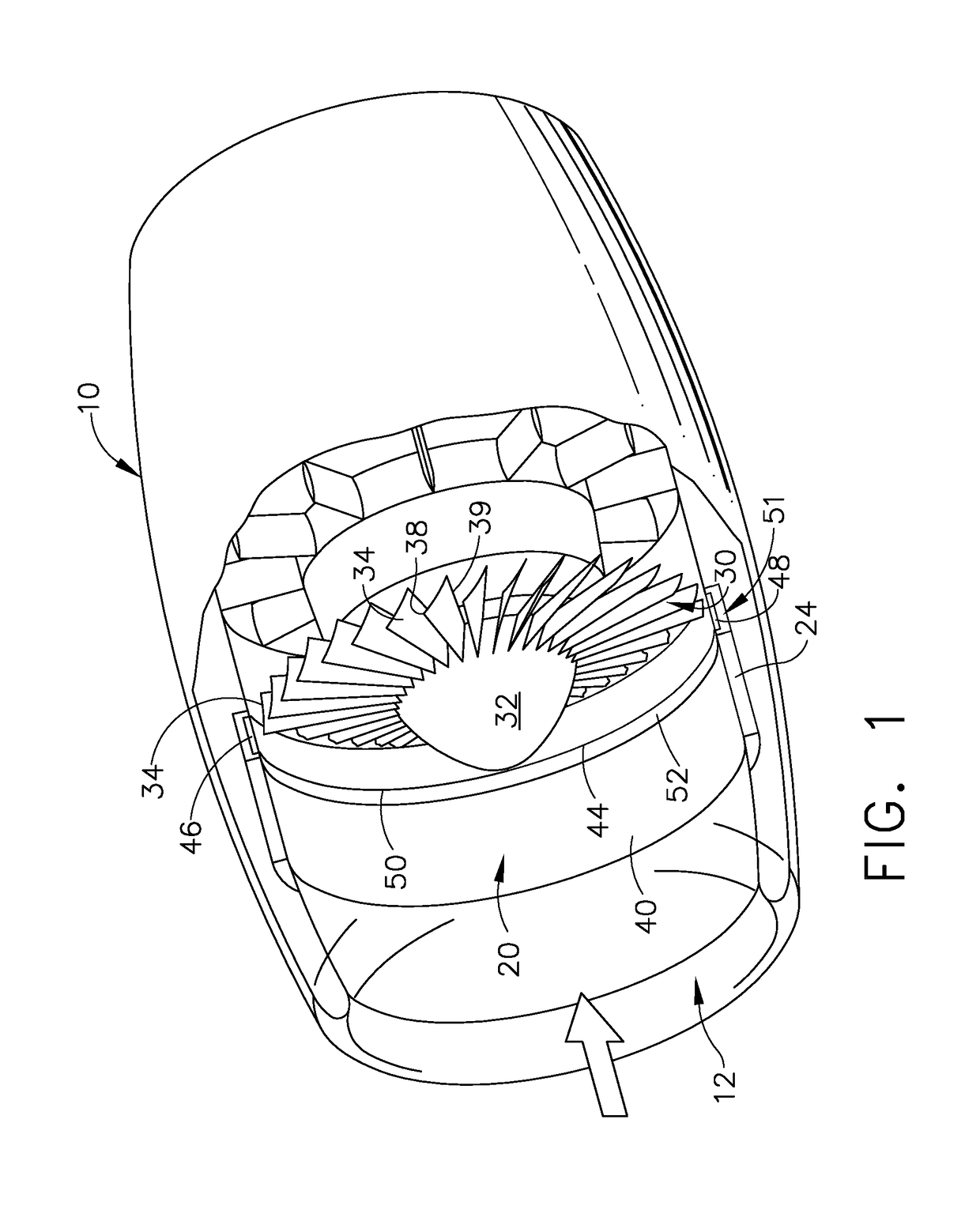

Turbofan case for controlling blade deflection

Owner:GENERAL ELECTRIC CO

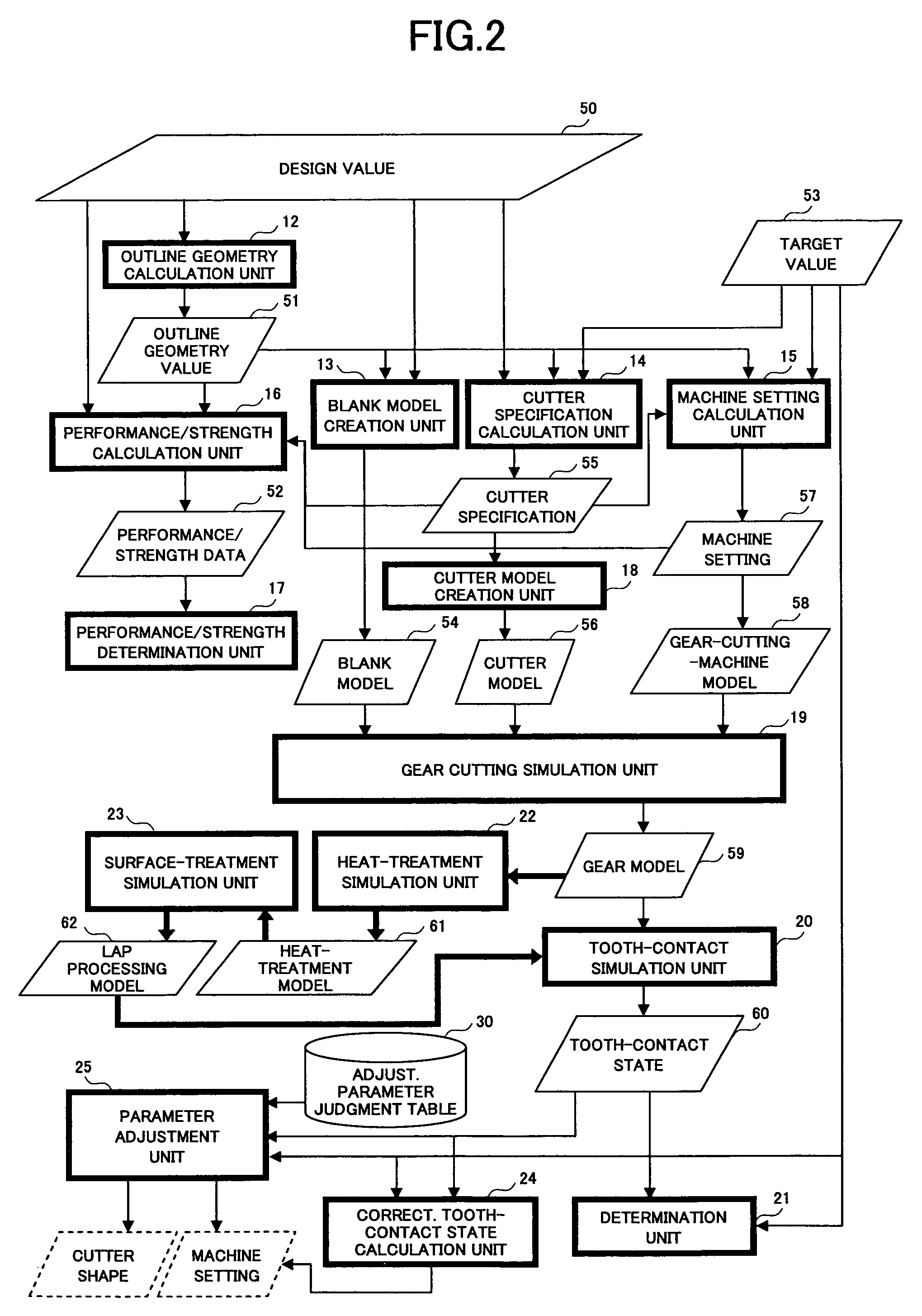

Gear cutting simulation method, gear cutting simulation program, and gear cutting simulation device

In a gear cutting simulation method and device, a gear-cutting-machine model which specifies relative positions between a blank model and a cutter model is created. A gear model is created as a result of simulation of gear cutting which is performed with the blank model and the cutter model arranged in the gear-cutting-machine model.

Owner:SUMITOMO HEAVY IND LTD

Physics-based lifespan modeling

ActiveUS9477224B2Electric testing/monitoringAnalogue computers for non-electric machinesPhysics basedDesign phase

An embodiment of a method for lifespan modeling for a turbine engine component includes determining a design-phase model of the lifespan of an turbine engine component; fusing the design-phase model with sensor data collected during operation of the turbine engine component to produce an updated model of the lifespan of the turbine engine component; and fusing the updated model with data collected during an inspection of the turbine engine component to produce an overall model of the lifespan of the turbine engine component. Systems for lifespan modeling for a turbine engine component are also provided.

Owner:GENERAL ELECTRIC CO

Monitoring unit state chart and a debounce logic

InactiveUS7693649B2Shorten speedAnalogue computers for vehiclesRegistering/indicating working of vehiclesInternal combustion engineMonitor unit

A method of logging faults in an electronic controlled internal combustion engine that passes any fault readings through a debounce logic to determine whether the fault indication is real.

Owner:DETROIT DIESEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com