Turbofan case for controlling blade deflection

a technology of blade deflection and turbine case, which is applied in the direction of efficient propulsion technologies, machines/engines, liquid fuel engines, etc., can solve the problems of fan blade deflection, unstable blade deflection, and limited air that is able to bypass the fan through the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

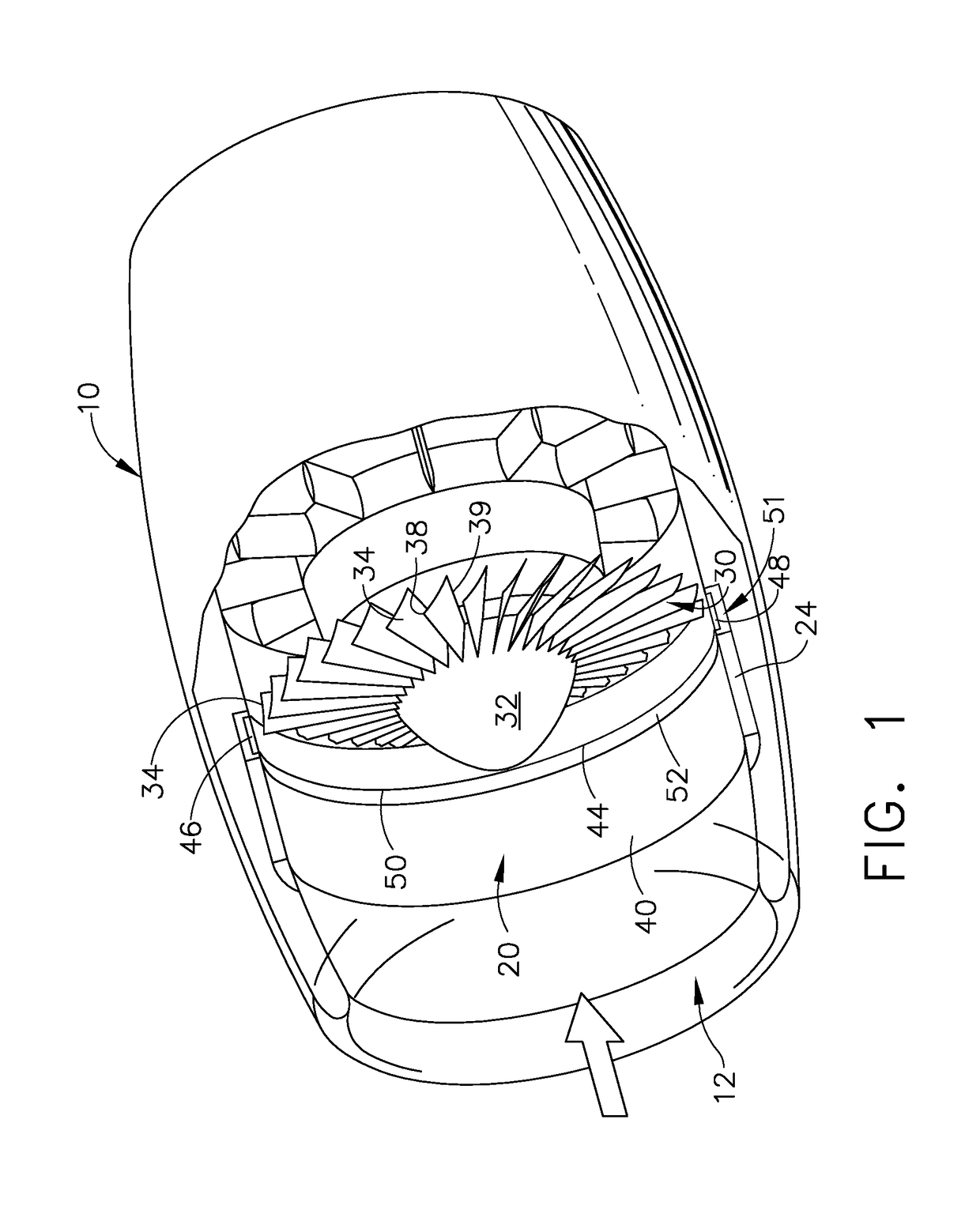

[0012]Referring to the drawings wherein identical reference numerals denote the same elements throughout the various views, FIG. 1 illustrates an abradable fan containment structure 20 for use in turbomachinery, such as a high bypass turbofan engine 10 shown in FIG. 1. The containment structure 20 can be used in other machinery that includes a rotation structure such as pumps, compressors, or turbomachinery. In the configuration shown, the engine 10 includes a rotation structure that is a fan 12 and a fan case 24. The fan 12 includes a plurality of fan blades 30. The fan blades 30 are mounted to a fan disk 32 which is located within the fan section 12 of the engine 10. In the configuration shown, the engine 10 includes a rotating structure that is a fan 12 and a plurality of fan blades 30. The fan blades 30 are mounted to the fan disk 32.

[0013]The fan blades 30 include blade tips 34 that define a circular path that has an outer diameter. The blades 30 are configured such that the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com