Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Umbilical cord tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Umbilical Tape is used to prevent excessive bleeding of the umbilical stump and to help prevent the introduction of navel infections. This product is an alternative to the umbilical clamp. Umbilical Tape is non-sterile and made from spun polyester.

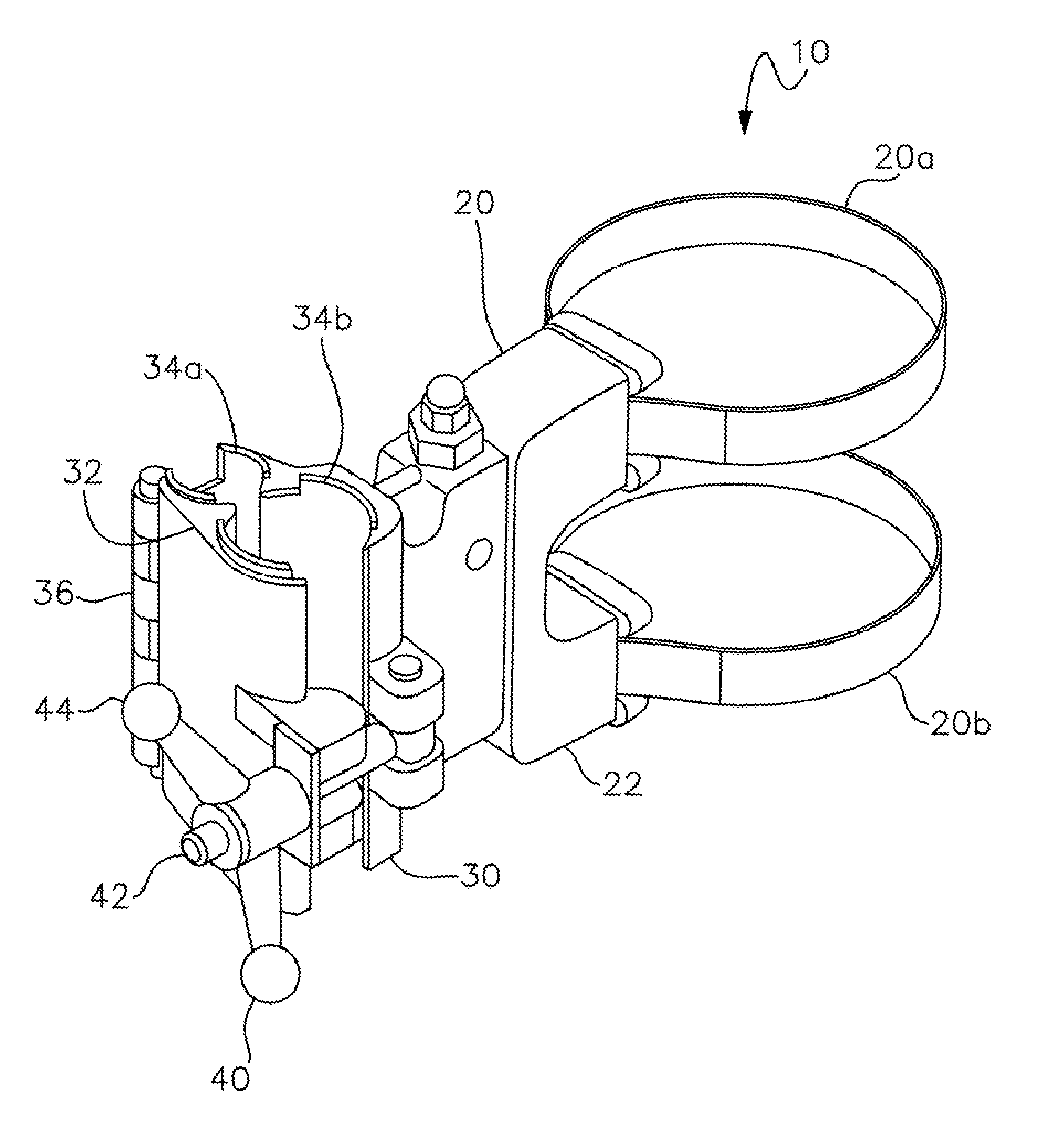

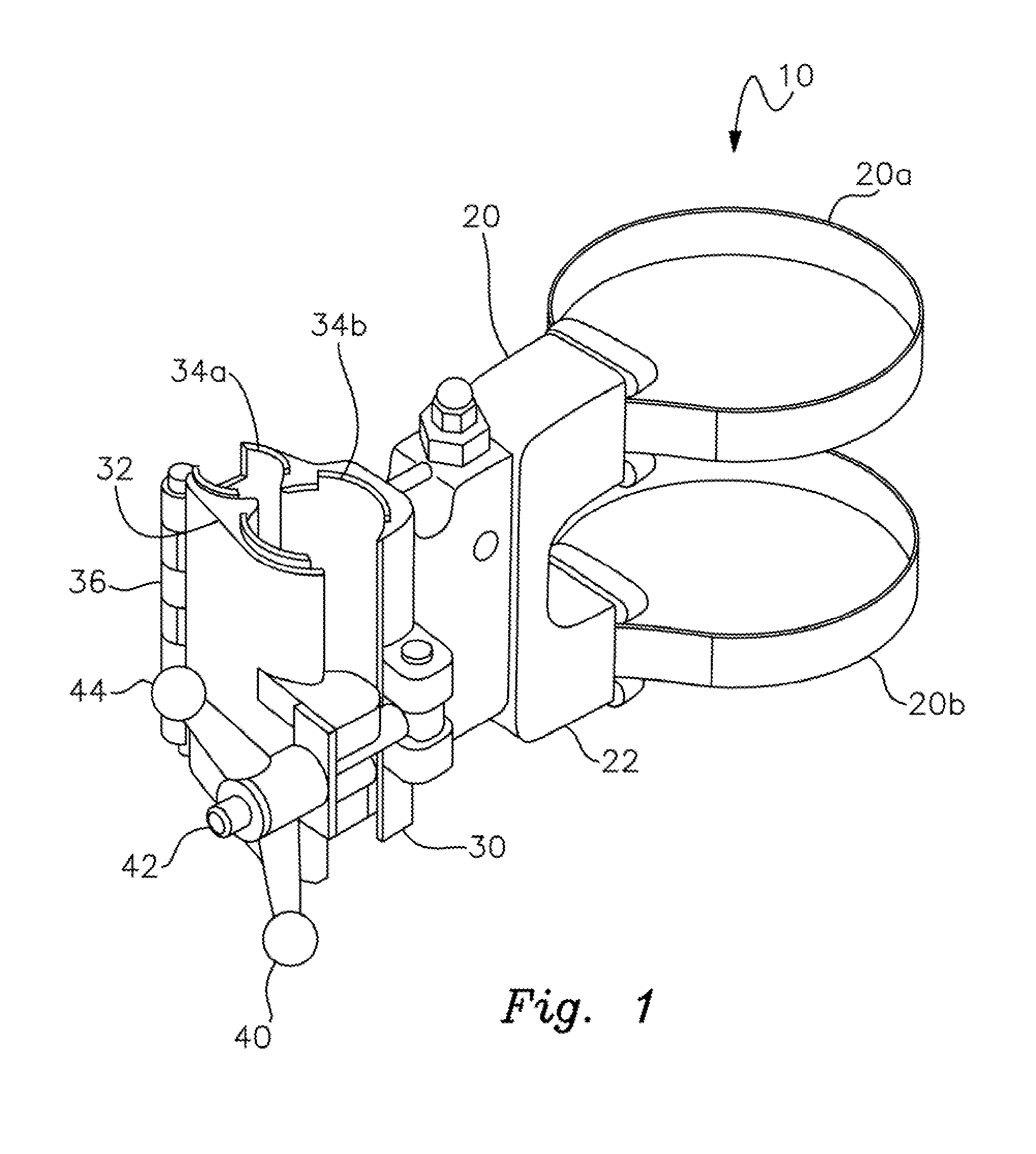

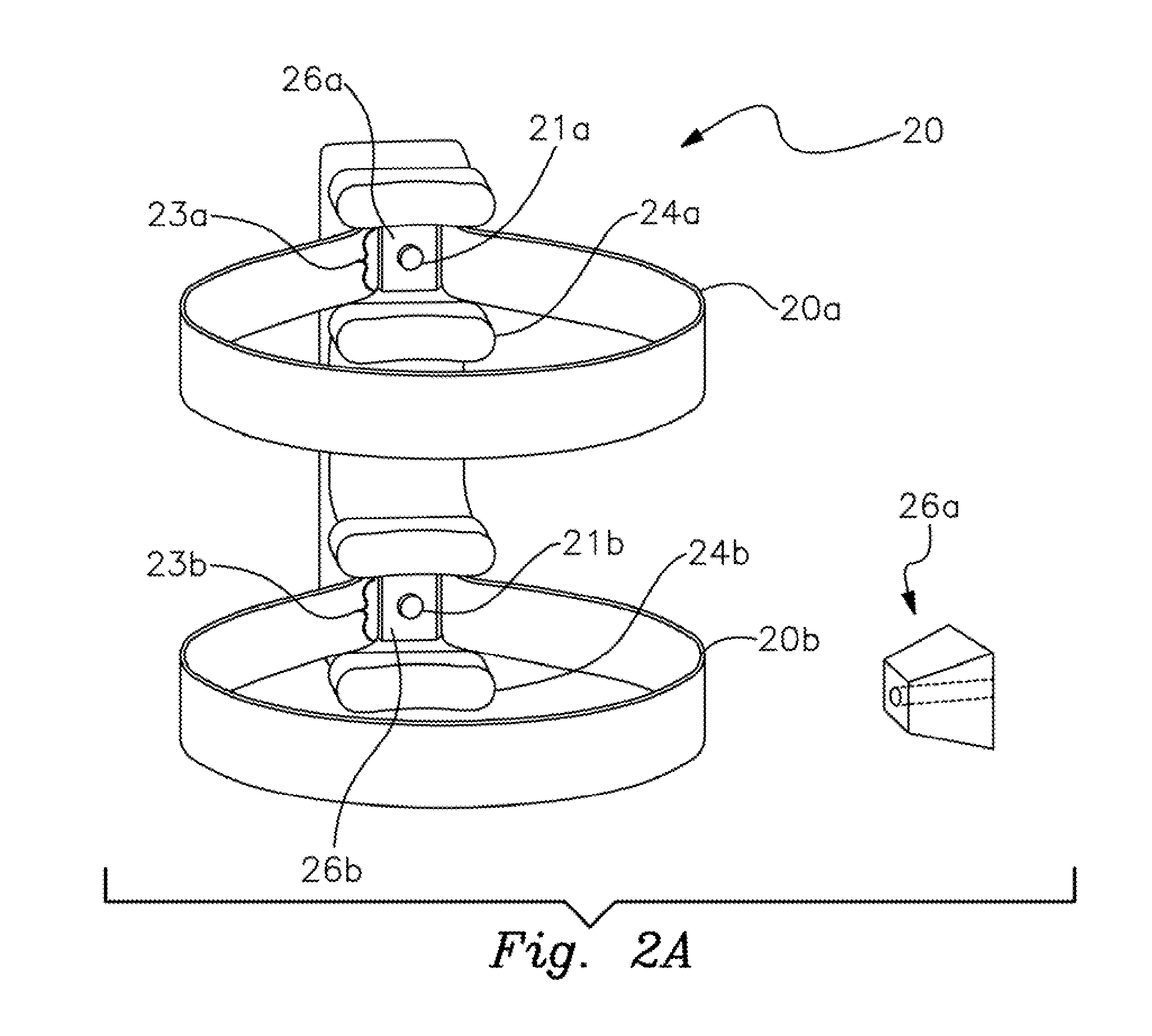

Retrofit Clamp for MUX, Umbilicals and IWOCS

A clamp for placement about a riser having an assembly with a housing for releasably engaging at least one strap, the strap having a first and second end wherein the first and second ends are releasably attached to the housing, a plate on the housing for selectively engaging the first and second ends of the strap; and a support operably connected to the housing for releasably holding MUX, IWOC and other umbilical cables used in subsea applications. The housing may have two straps for engagement to a riser that shorten and lengthen by the turning of a screw through a plate engaged to the straps. The clamp may also have a hinged or fixed circular member for attachment around the riser. The cables are held by a hinged attachment to the housing that forms cylindrical vertical openings upon closure of the hinge.

Owner:THE SUBSEA

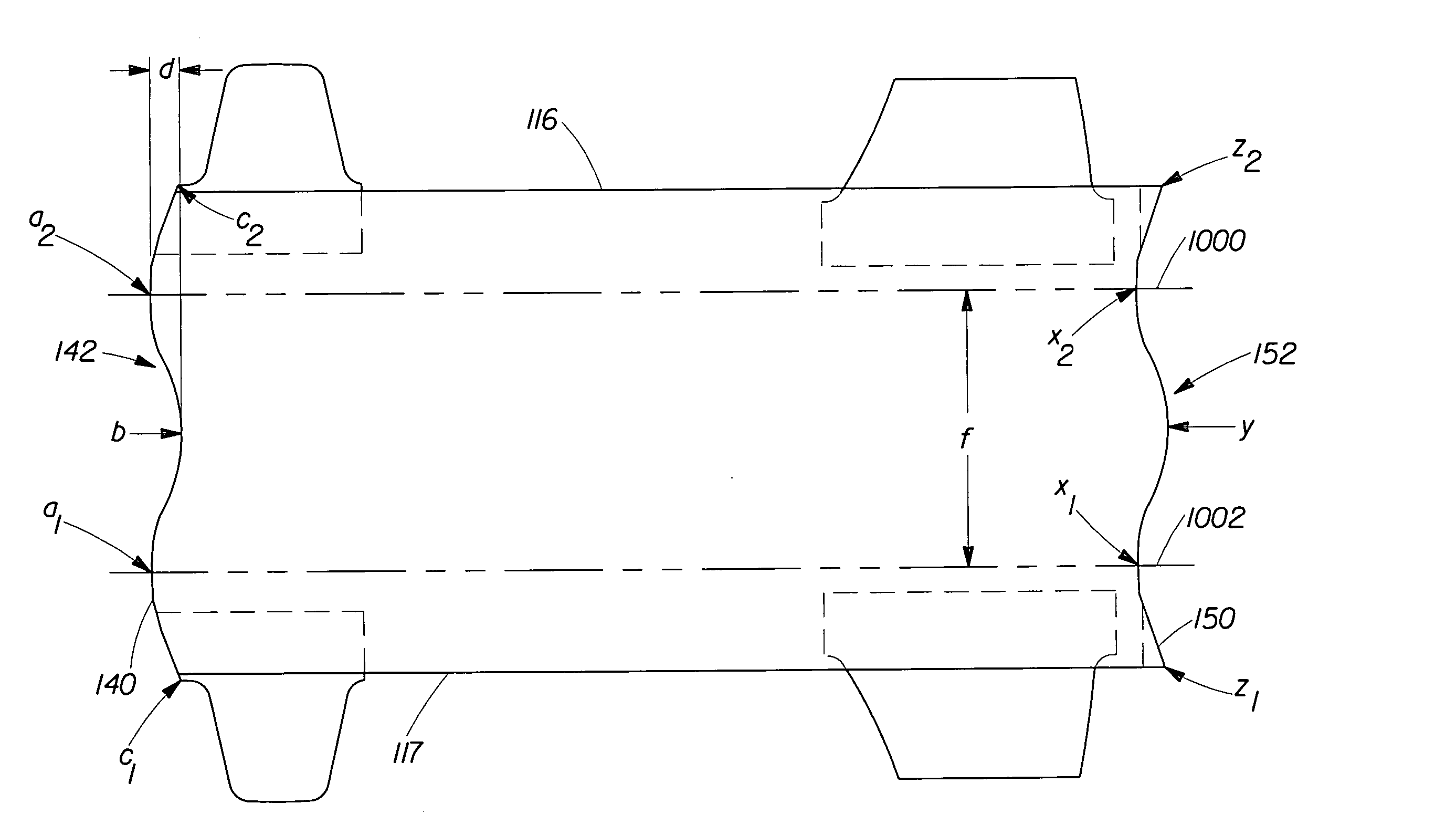

Absorbent article having an umbilical notch cut

A disposable absorbent article having a non-linear notch cut without the presence of a significantly laterally extending resulting piece. The resulting absorbent article having a front end edge and a back end edge which are complementary. The front end edge having at least three tangential points (a1, a2, b). Tangential point b is longitudinally inboard of a1 and a2. The back end edge having at least three tangential points (x1, x2, y), wherein y is longitudinally outboard of x1 and x2. The absorbent article being longitudinally folded about a first fold line. The first fold line may be drawn between points a2 and x2. The absorbent article being longitudinally folded about a second fold line, said second fold line may be drawn between points a1 and x1.

Owner:THE PROCTER & GAMBLE COMPANY

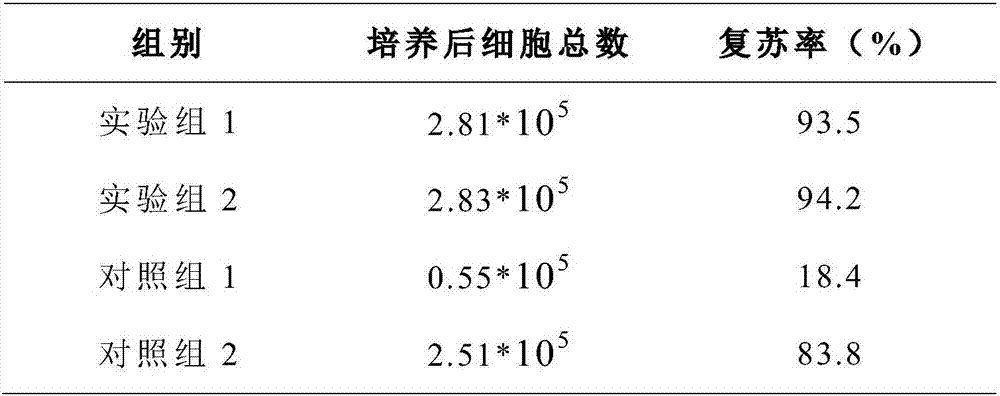

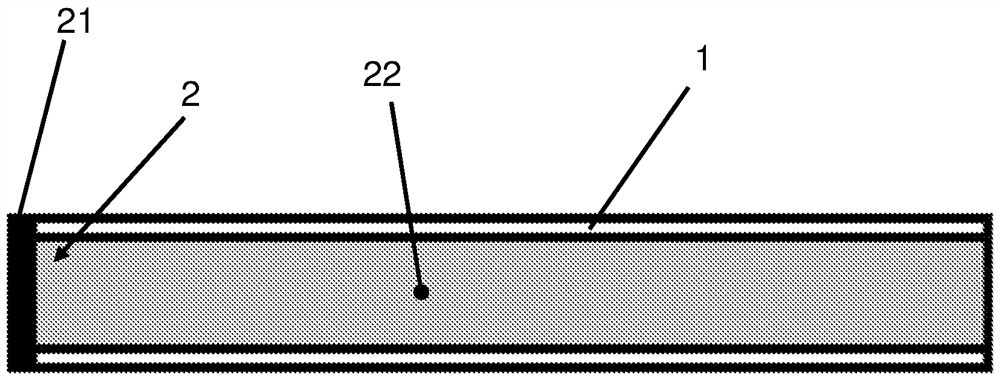

Umbilical cord tissue freeze preservation and unfreezing method

InactiveCN107467014AReduced probability of impaired apoptosisImprove survival rateDead animal preservationSkeletal/connective tissue cellsCell adhesionUmbilical cord tissue

The invention provides an umbilical cord tissue freeze preservation and unfreezing method. According to the umbilical cord tissue freeze preservation and unfreezing method, cell aggregate freeze preservation is adopted instead of single cell freeze preservation, so that cell damage apoptosis rate is reduced, and survival rate is increased; cell adhesion molecules are added to promote bonding of cells, reduce the amount of single cells, and increase cell survival rate; ultrasonic treatment is adopted so as to ensure full penetration of a refrigeration protective solution and an unfreezing protective solution into intercellular spaces, solutions are dispersed into small liquid drops, and the permeability is improved; a cell activity inhibitor is adopted for reversible inhibition of physiological activities in cells, and improving of freeze preservation effect without influencing cell activity. The umbilical cord tissue freeze preservation and unfreezing method is capable of reducing physical and chemical damages on cells in freezing and unfreezing process, and increasing cell survival rate and unfreezing rate, so it is convenient for subsequent using.

Owner:北京唐颐惠康生物医学技术有限公司

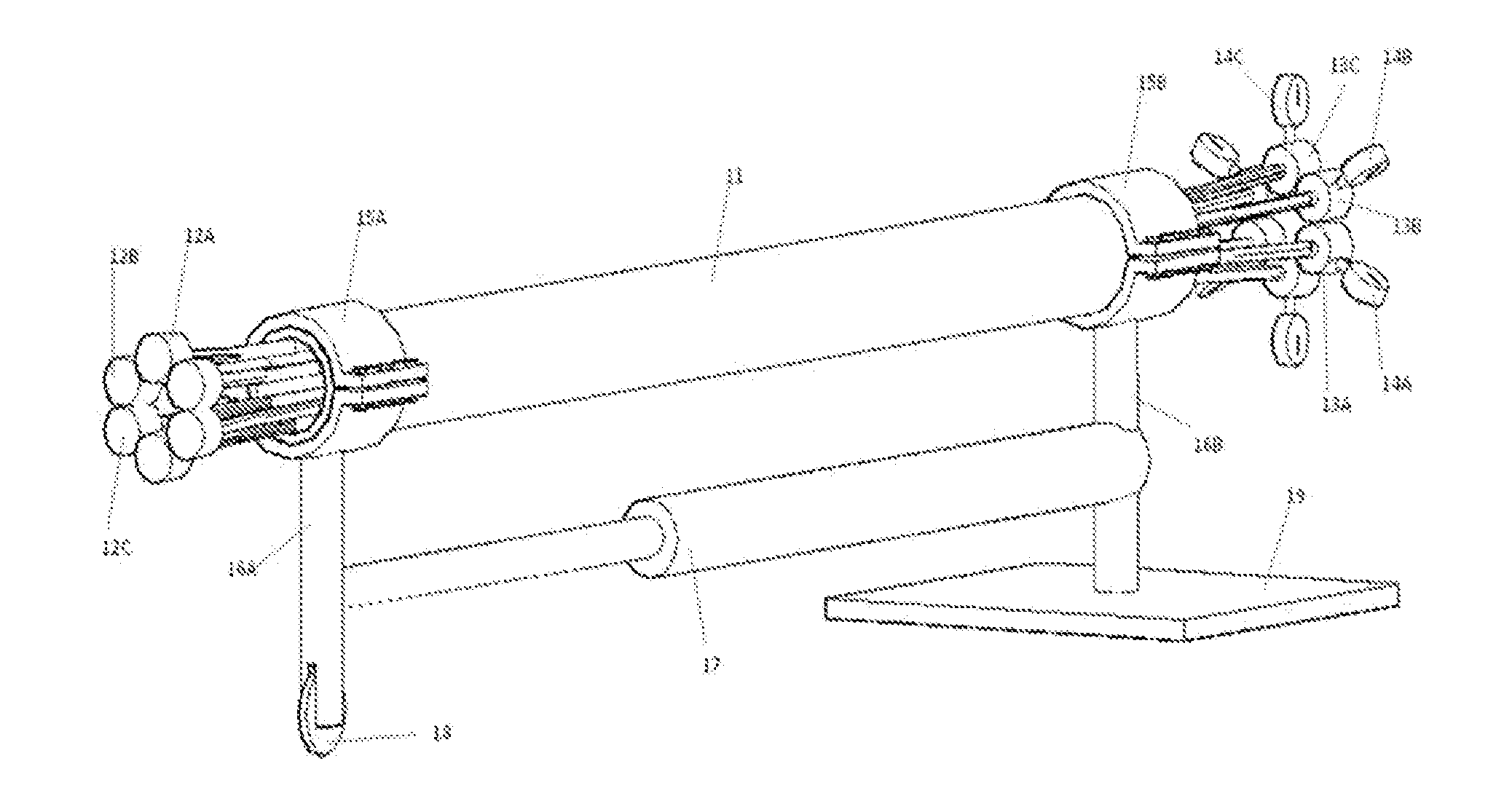

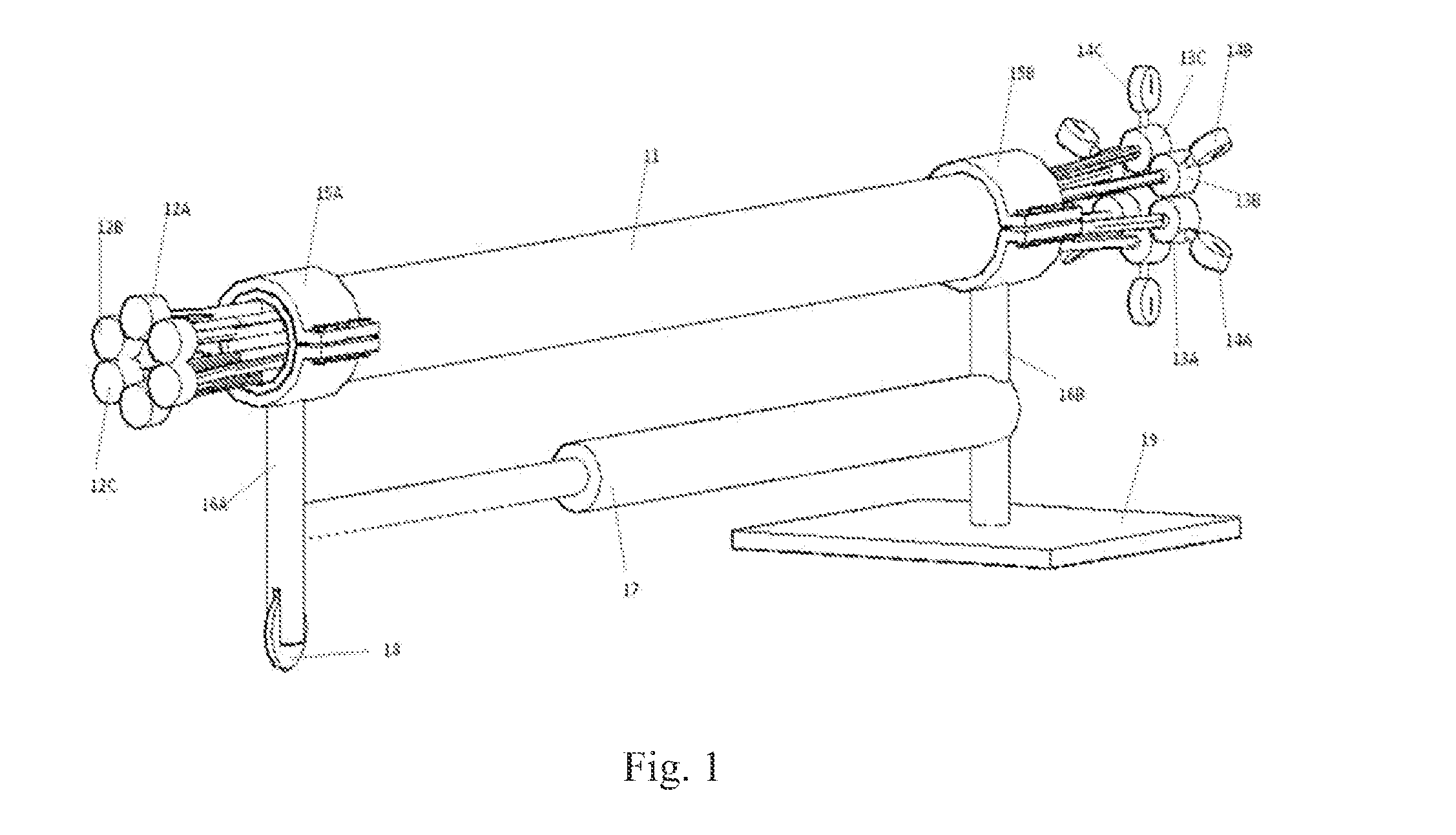

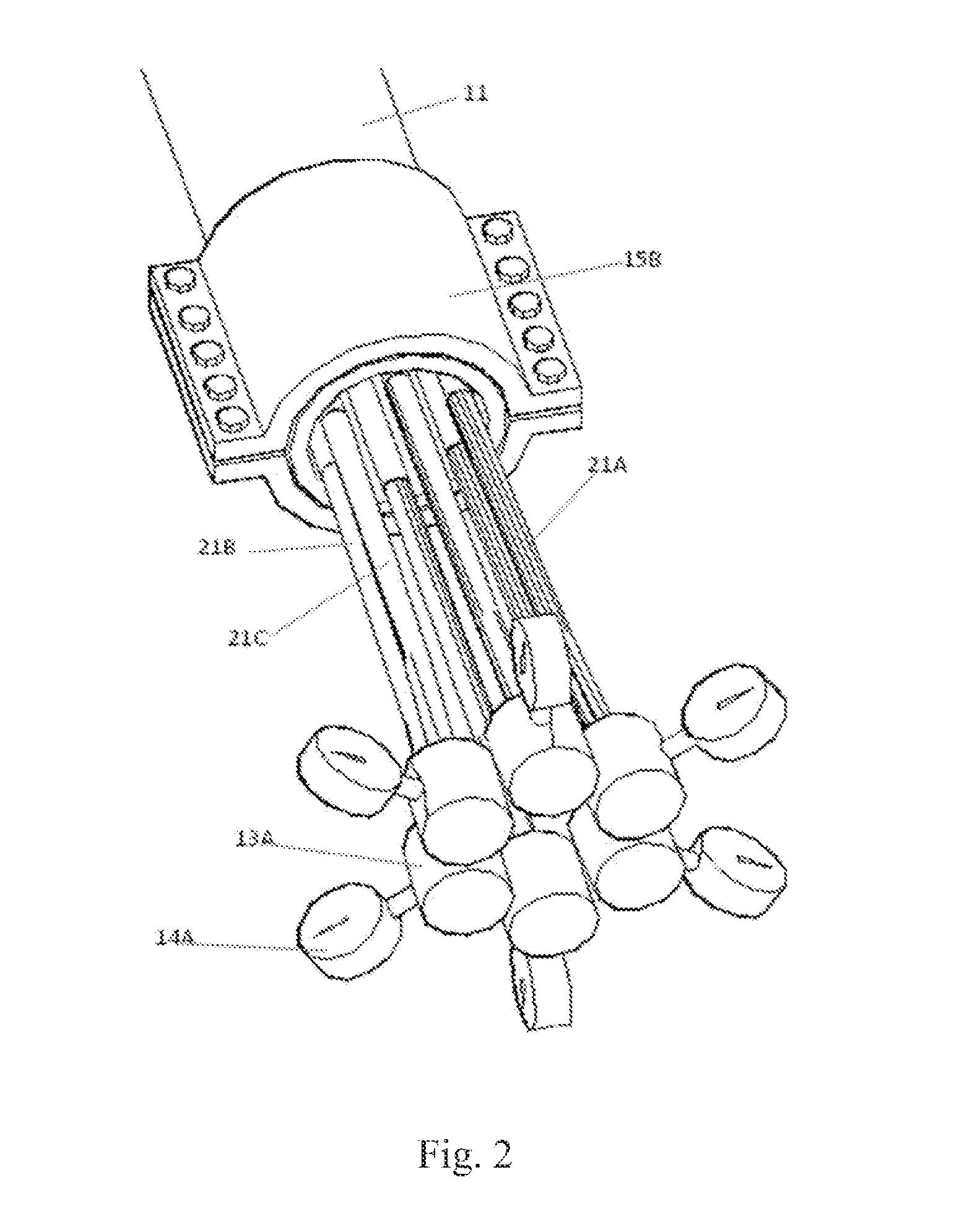

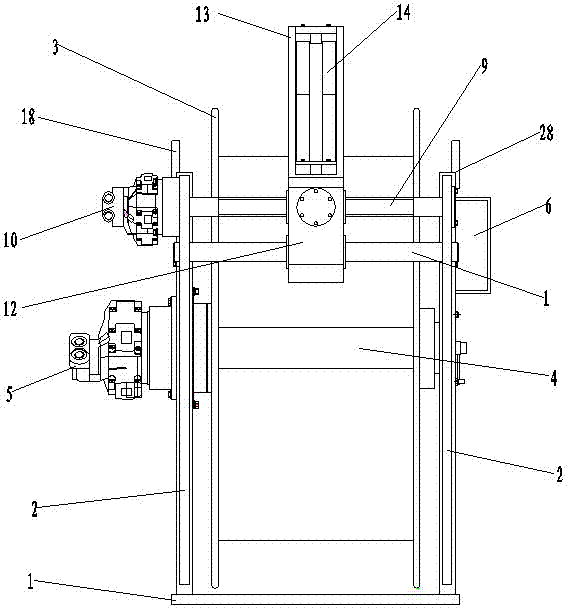

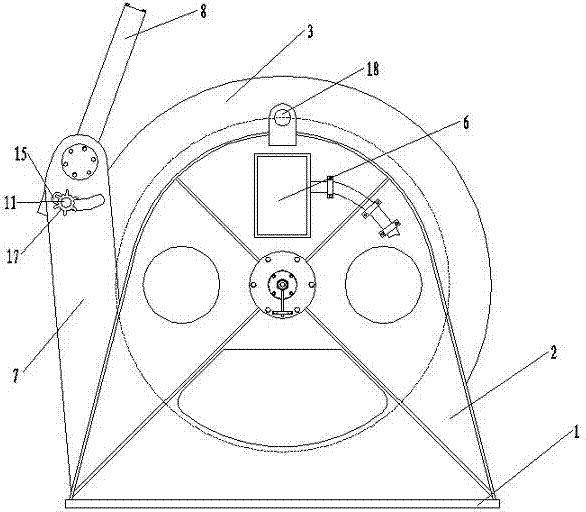

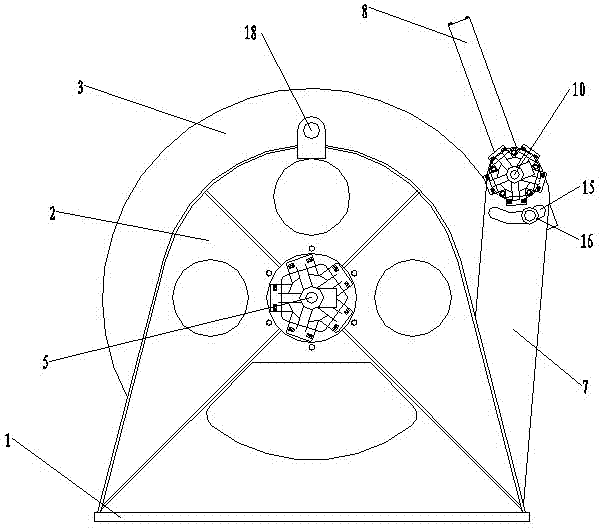

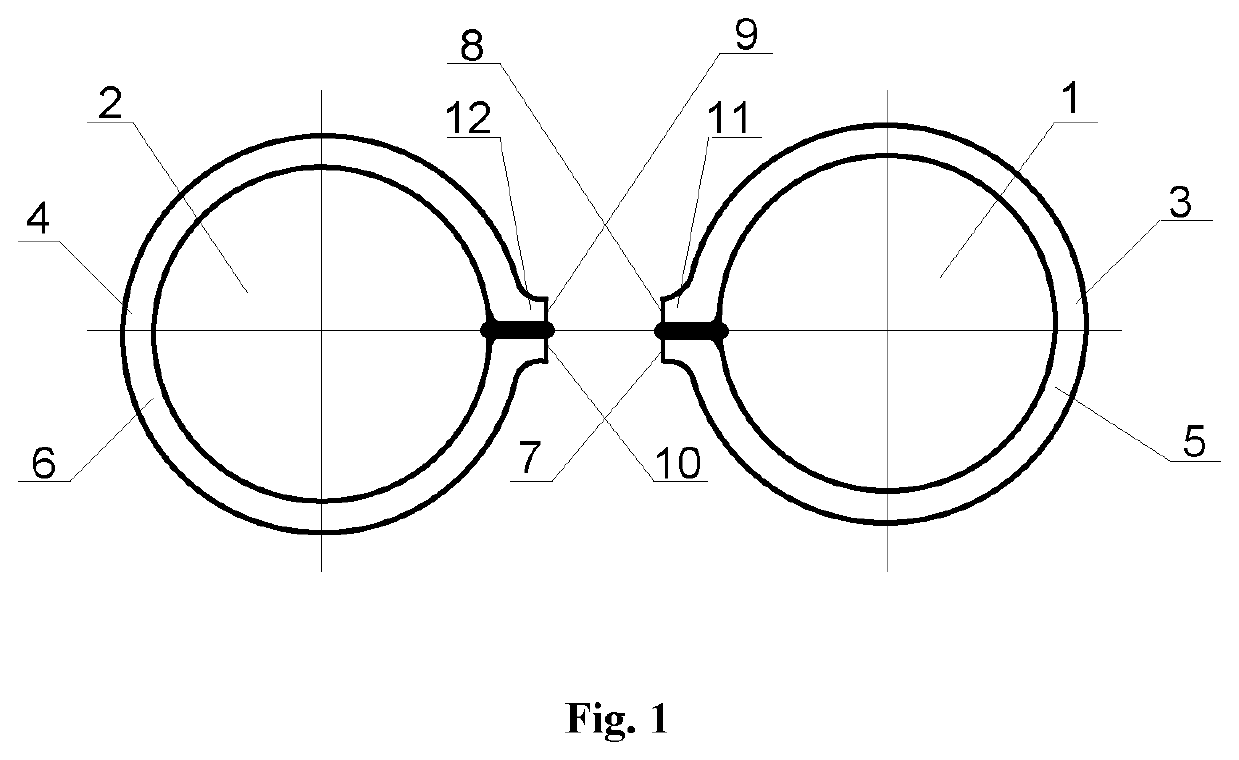

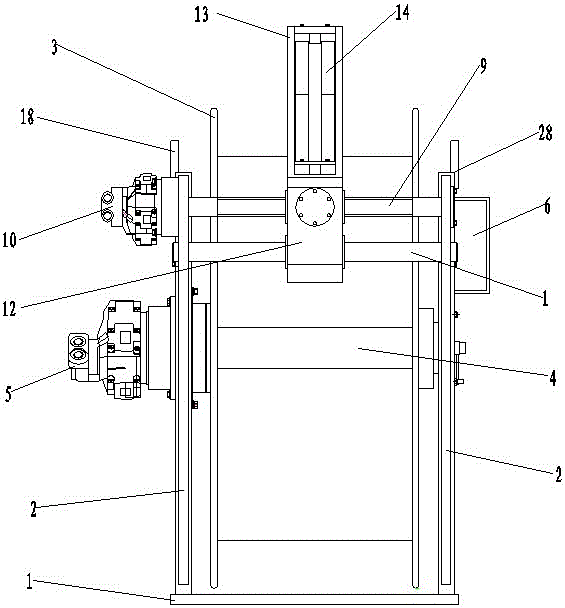

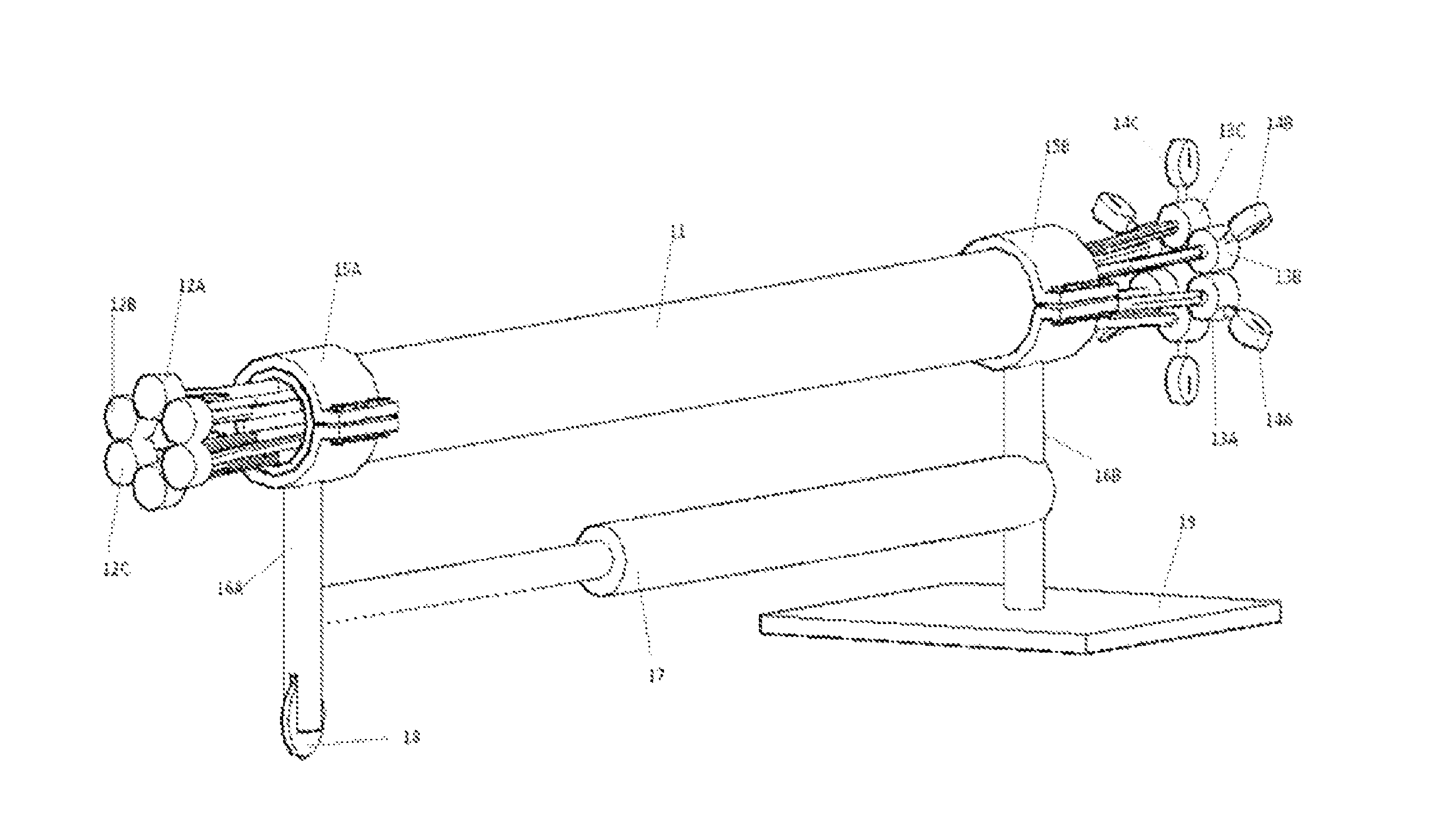

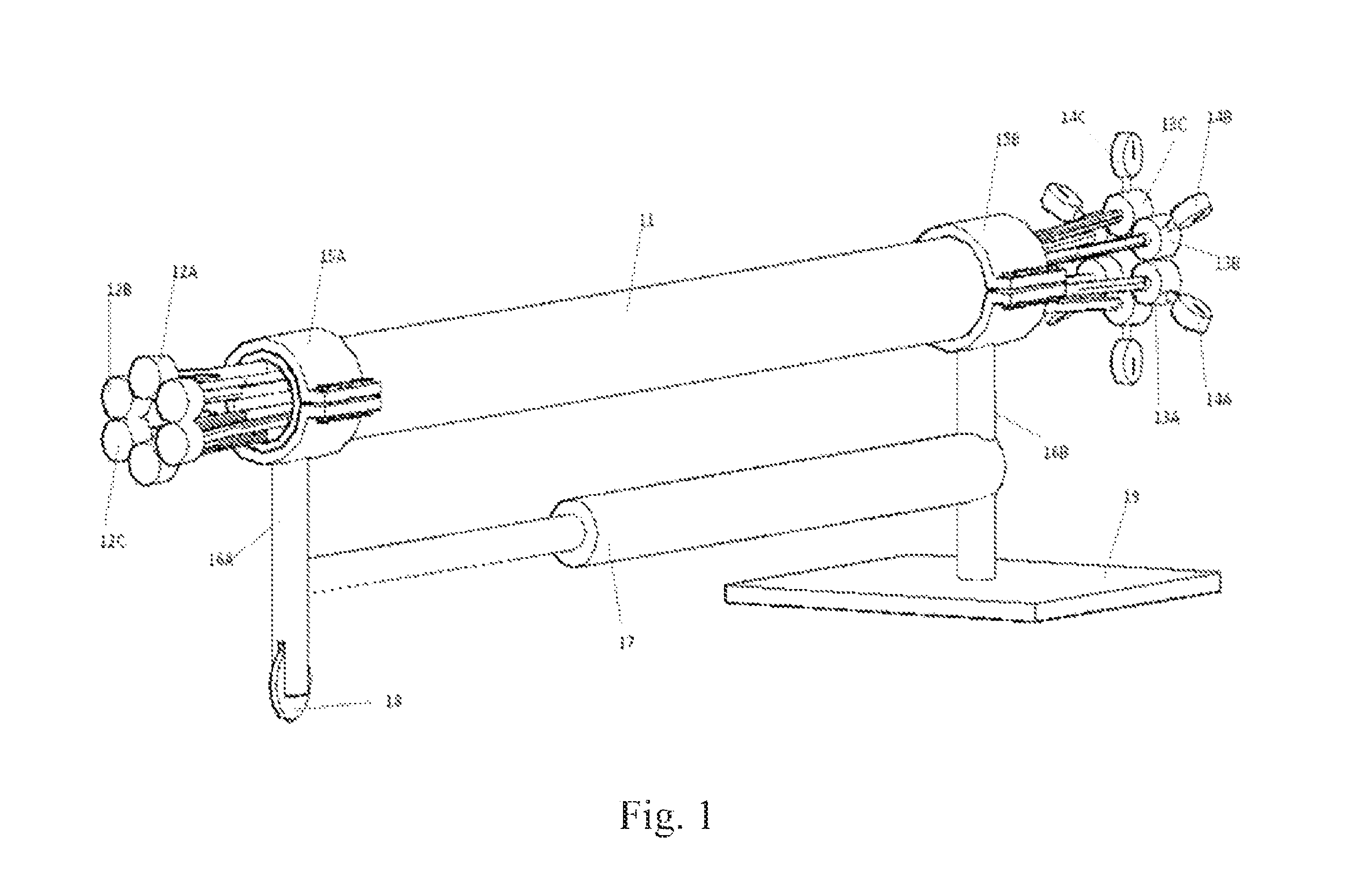

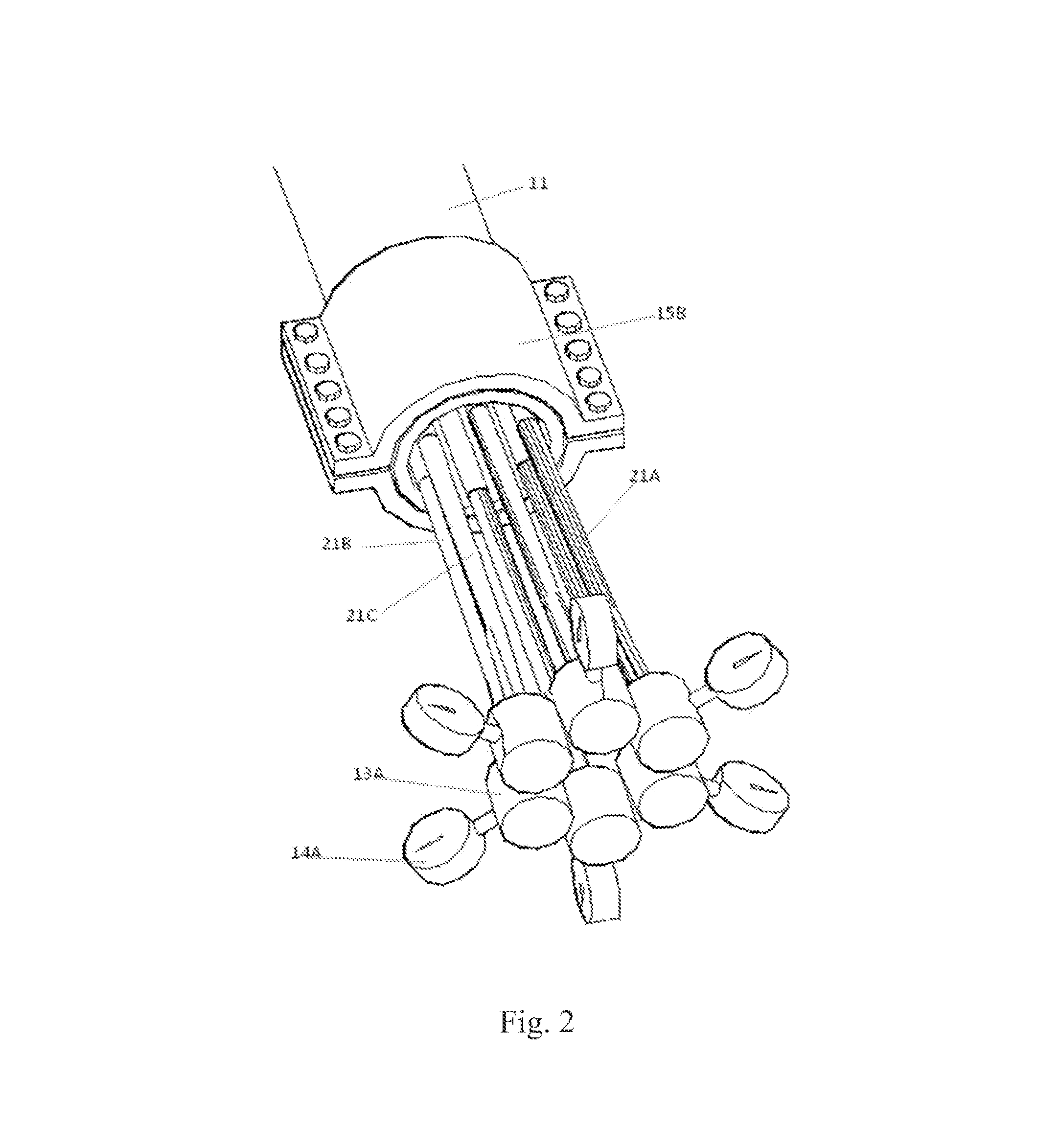

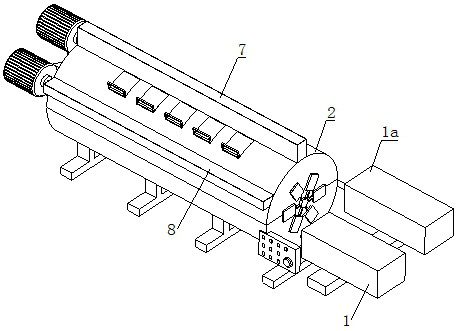

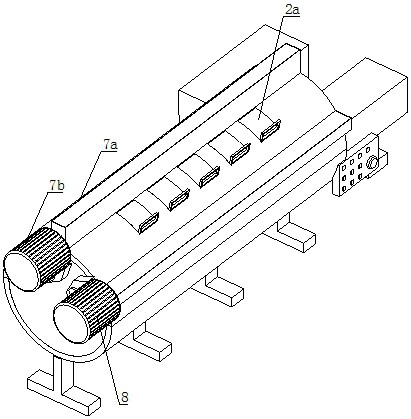

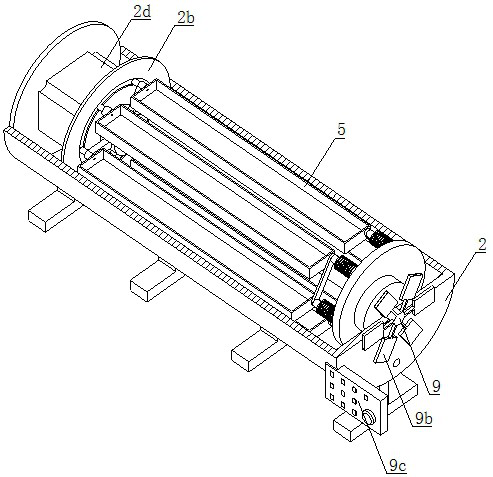

Umbilical buckling testing

Apparatus and methods related to umbilical buckling testing are described. For example, some embodiments may contain two damps, a plurality of test fittings, one or more pressure gages, a hydraulic cylinder, and a testing platform, and may be used for testing the umbilical buckling behavior and capacity of an umbilical testing sample.

Owner:DMAR ENG

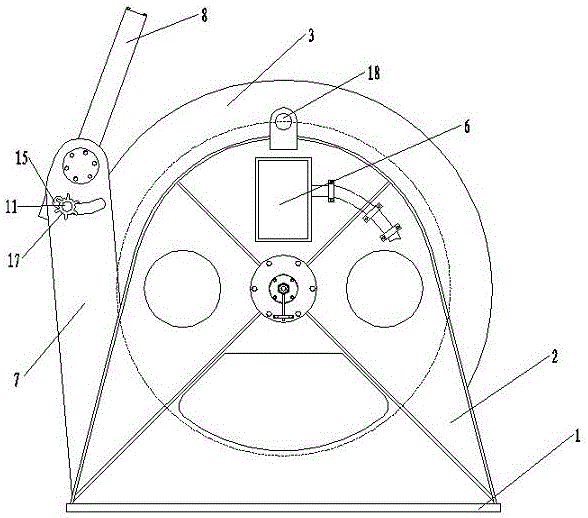

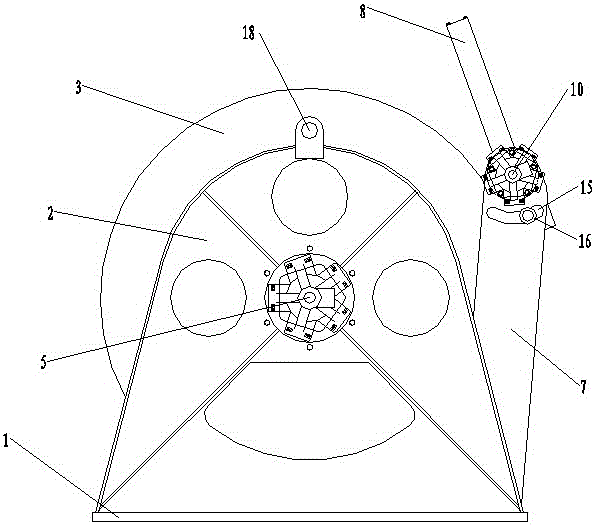

Umbilical winch for underwater robot

The invention discloses an umbilical winch for underwater robot and belongs to the technical field of diving equipment. The umbilical winch comprises a winch support seat and a rotation disk arranged on the winch support seat, a cable arranging mechanism is further arranged on the winch support seat to collect and release umbilical cables, and meanwhile, the cable arranging mechanism can be used for arranging the umbilical cables. The umbilical winch is simple in structure and convenient to use.

Owner:上海打捞局芜湖潜水装备厂有限公司

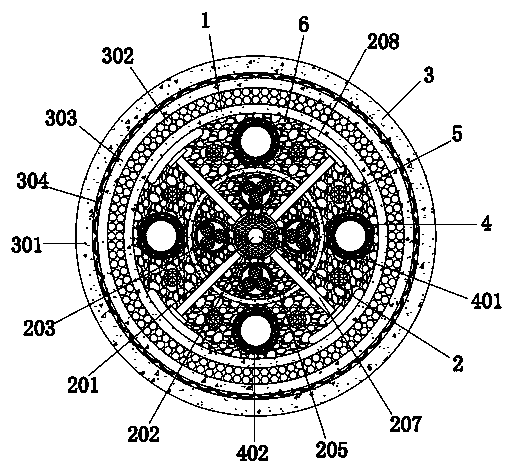

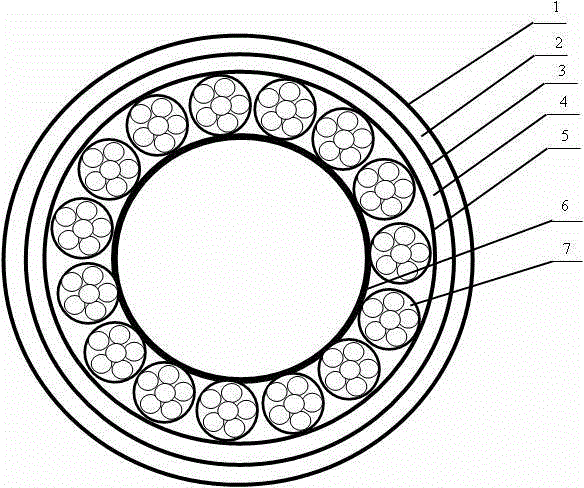

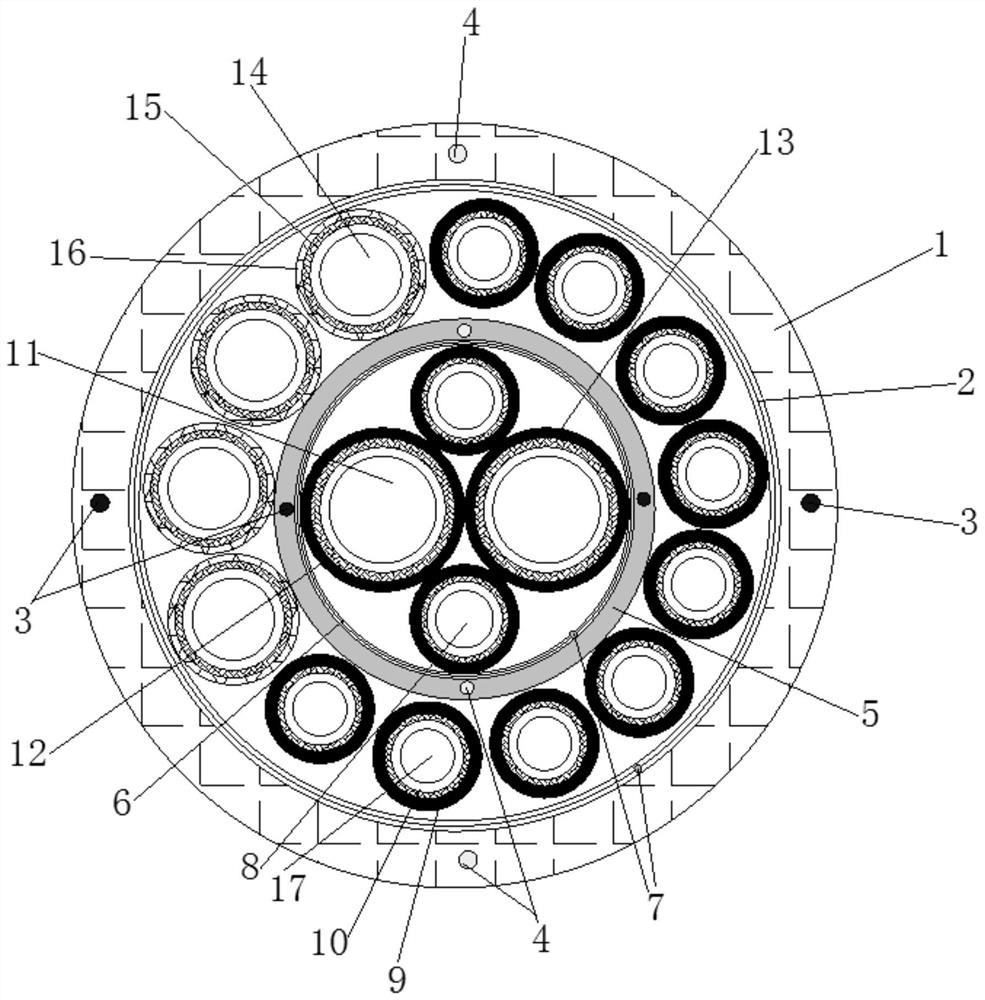

Umbilical cable

InactiveCN108335793AReduce static loadHigh strengthSubmarine cablesInsulated conductorsFiber-reinforced compositeUmbilical cord tape

The invention provides an umbilical cable. The umbilical cable comprises a core, an inner protecting layer which is arranged at the outside of the core, and an armor layer which is arranged at the outside of the inner protecting layer, wherein the armor layer comprises a plurality of armor wires; and each armor wire comprises a base body which is manufactured through a fiber reinforced composite material. The umbilical cable has the characteristics of being low in specific gravity, and high in intensity; and the umbilical cable meets the requirement on deep underwater production work by beingcompared with an existing metal wire armor umbilical cable.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD +1

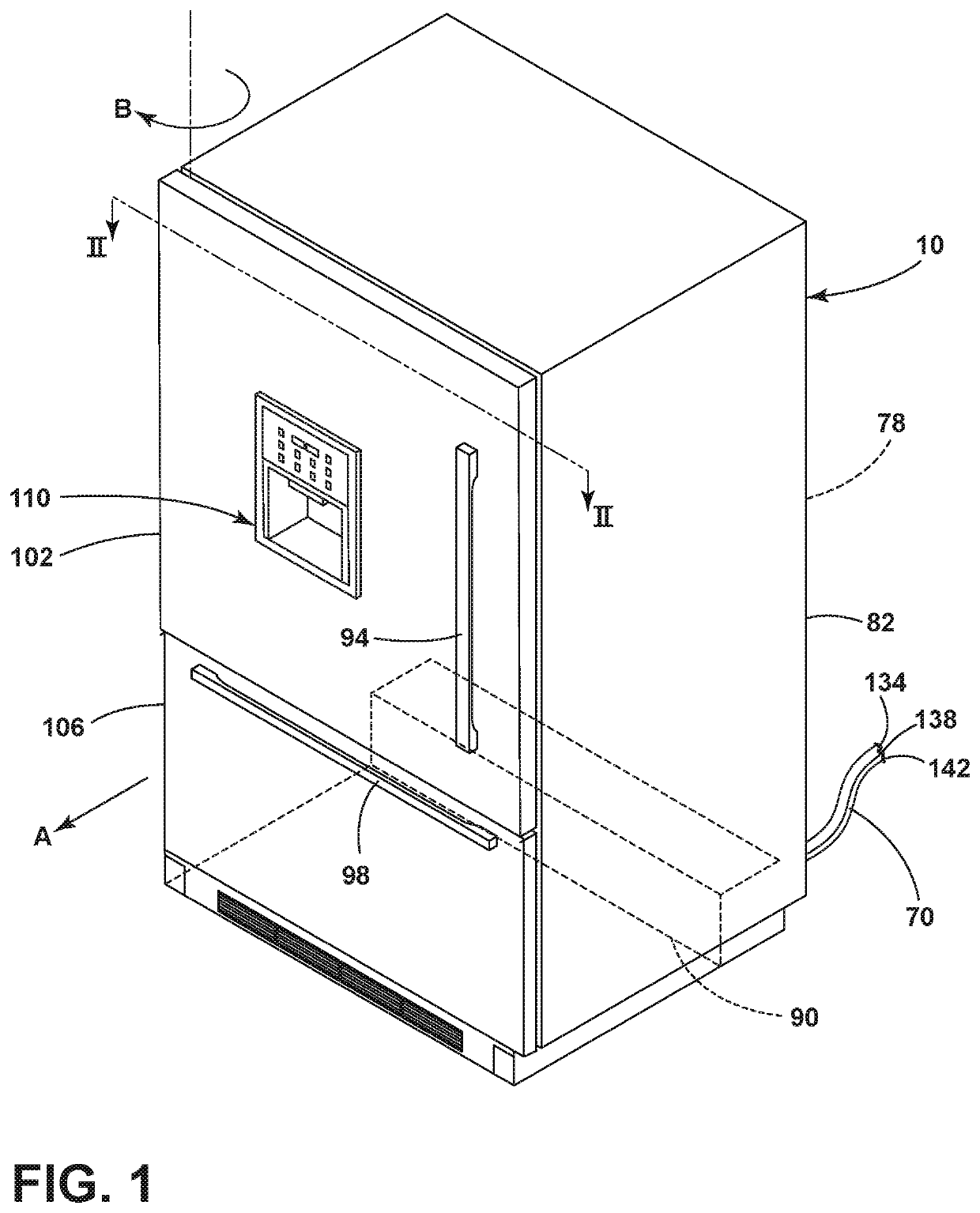

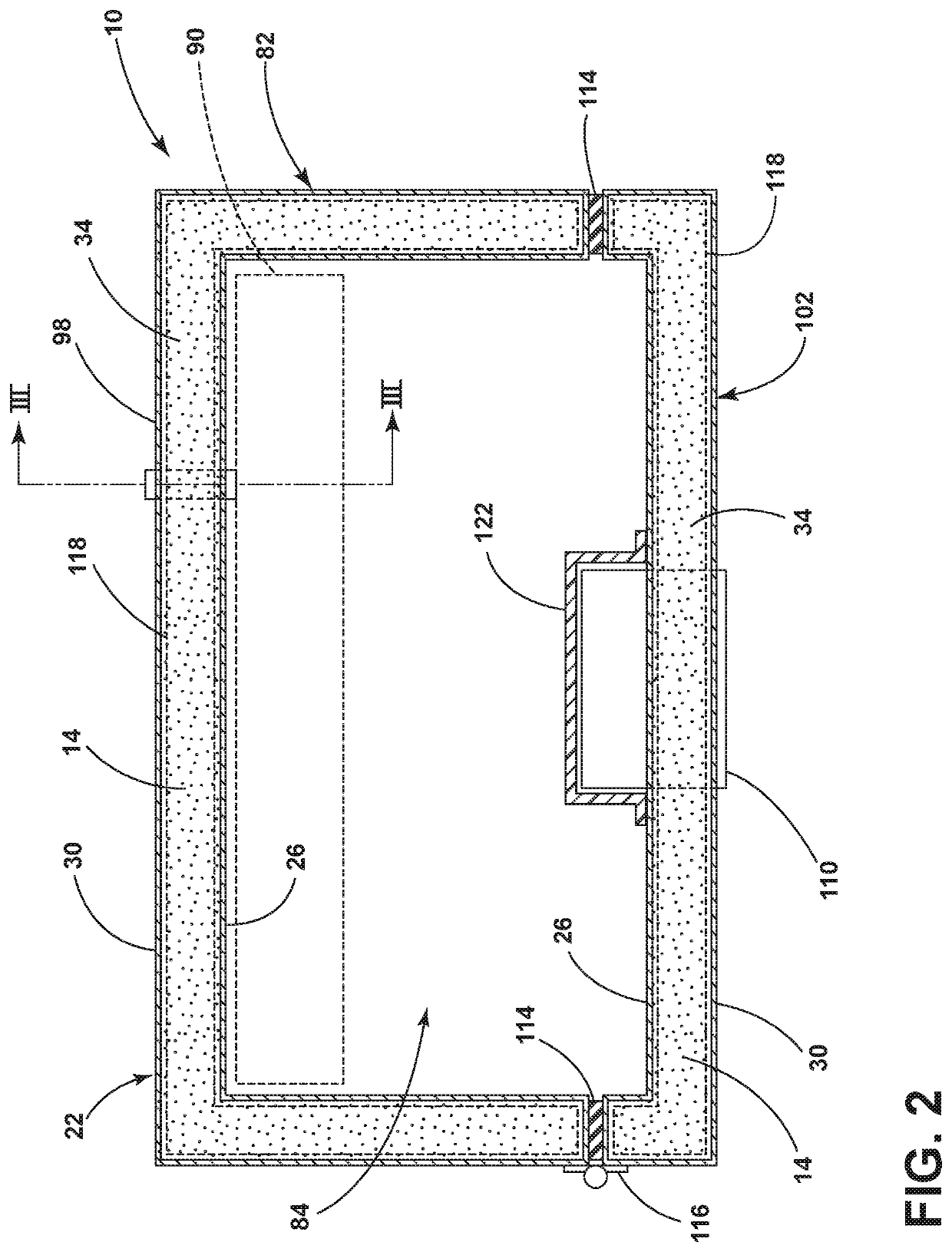

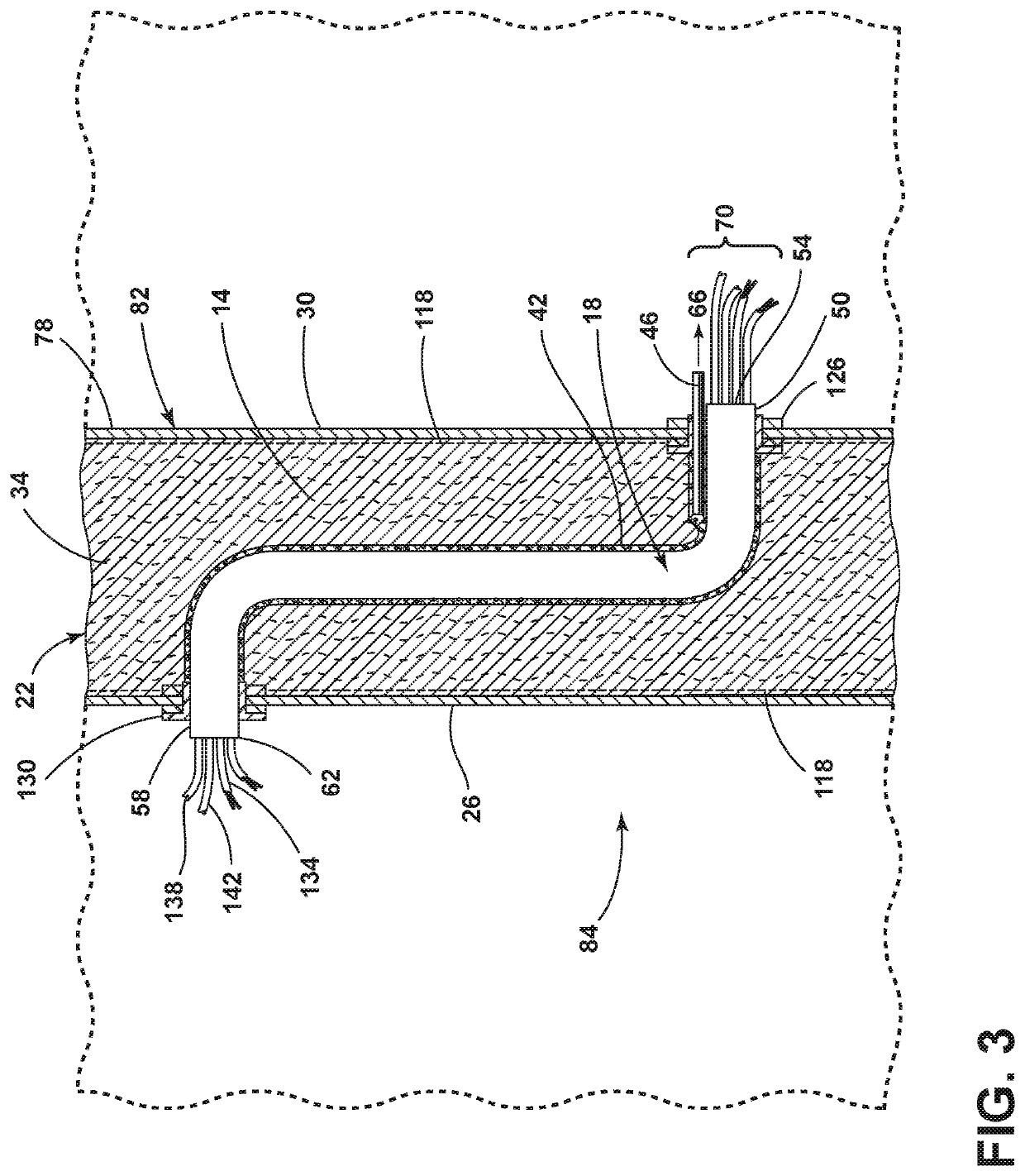

Method for ensuring reliable core material fill around the pass throughs in a vacuum insulated structure

Owner:WHIRLPOOL CORP

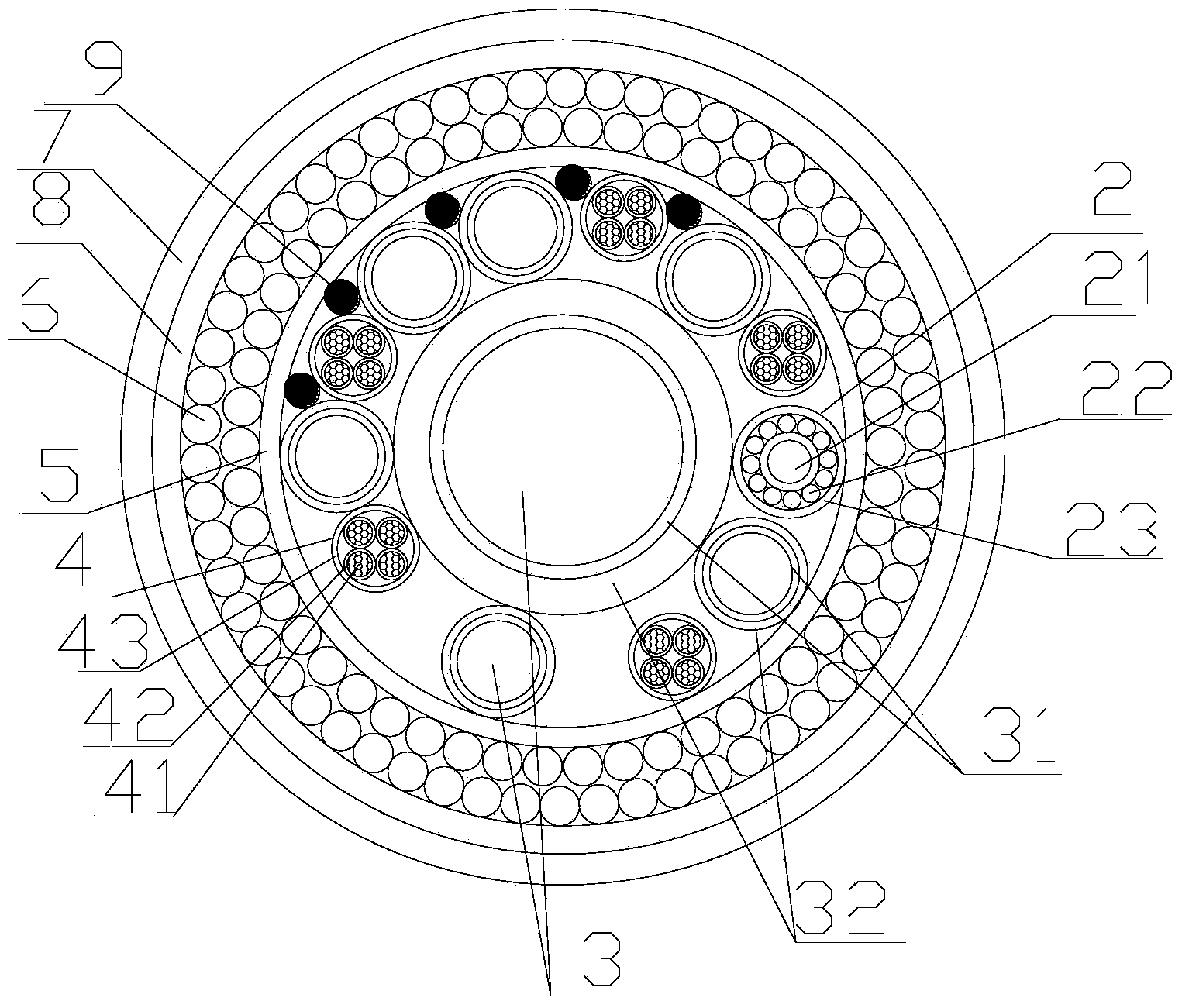

Umbilical cable system

ActiveCN111354509ALess prone to internal transmission interruptionsEasy to useClimate change adaptationSubmarine cablesFiberStructural engineering

The invention discloses an umbilical cable system which comprises a cylinder, a cable core is arranged in the cylinder, the cable core comprises a steel core, a rubber cylinder, a cable, first fiber filling paste, an insulating sleeve, a first arc-shaped plate, a supporting plate and a second arc-shaped plate, the steel core is located in the center of the interior of the cylinder, and the rubbercylinder is arranged on an outer wall of the steel core. According to the umbilical cable, the cylinder is matched with the cable core; the first fiber filling paste and the supporting plate are arranged in the cylinder; the cylinder can be effectively supported; when an outer side of the cylinder is impacted and extruded by external force; through the transmission of the second arc-shaped plate,the supporting plate and the first arc-shaped plate, external acting force is transmitted to the rubber cylinder, the rubber cylinder can be compressed to a certain degree, then stress on the outer side of the cylinder can be buffered, the cable in the cylinder has high compression resistance, the situation that the transmission effect in the umbilical cable is interrupted is not likely to happen,and the long-term stable use of the umbilical cable is facilitated.

Owner:征予(浙江)新能源科技发展有限公司

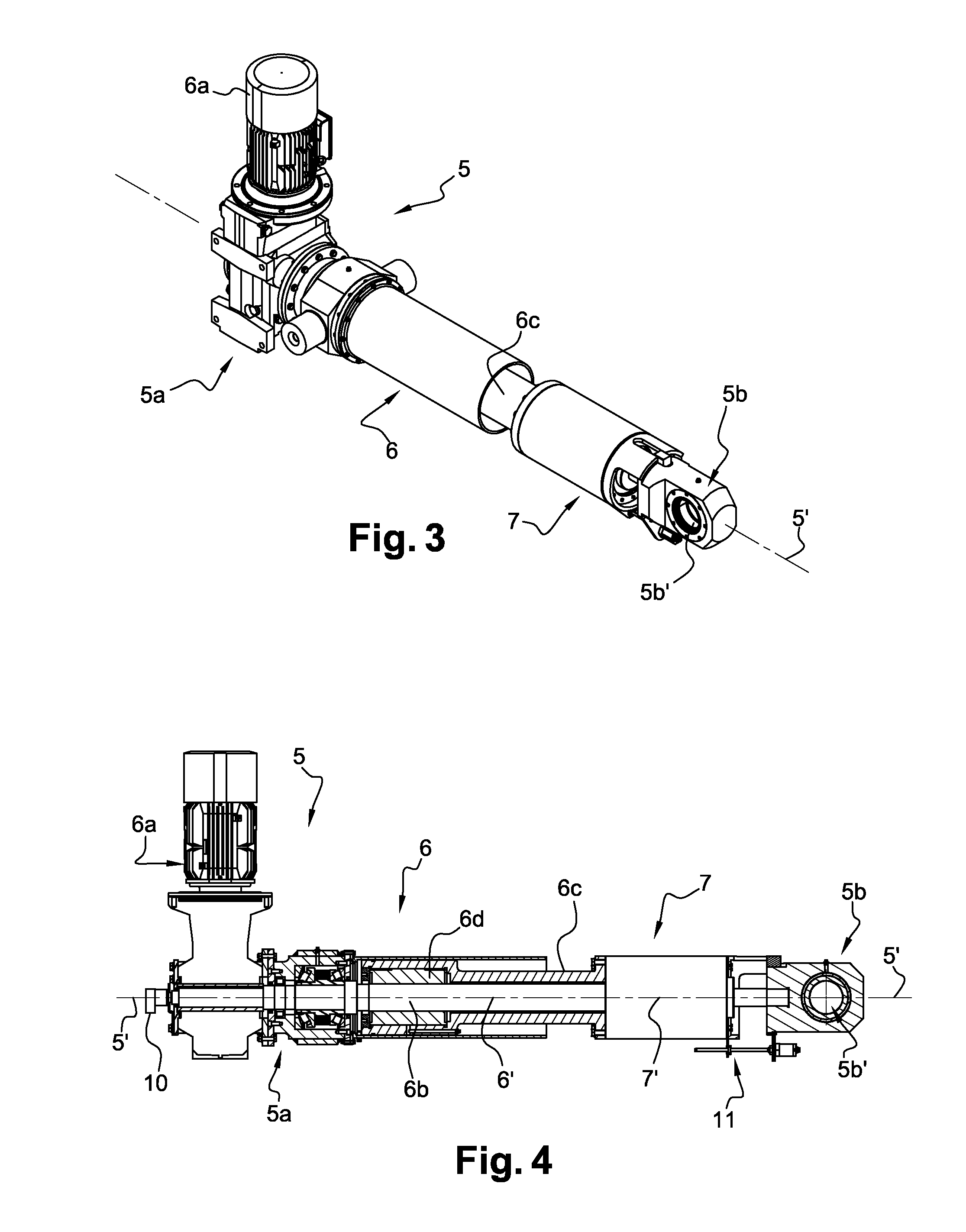

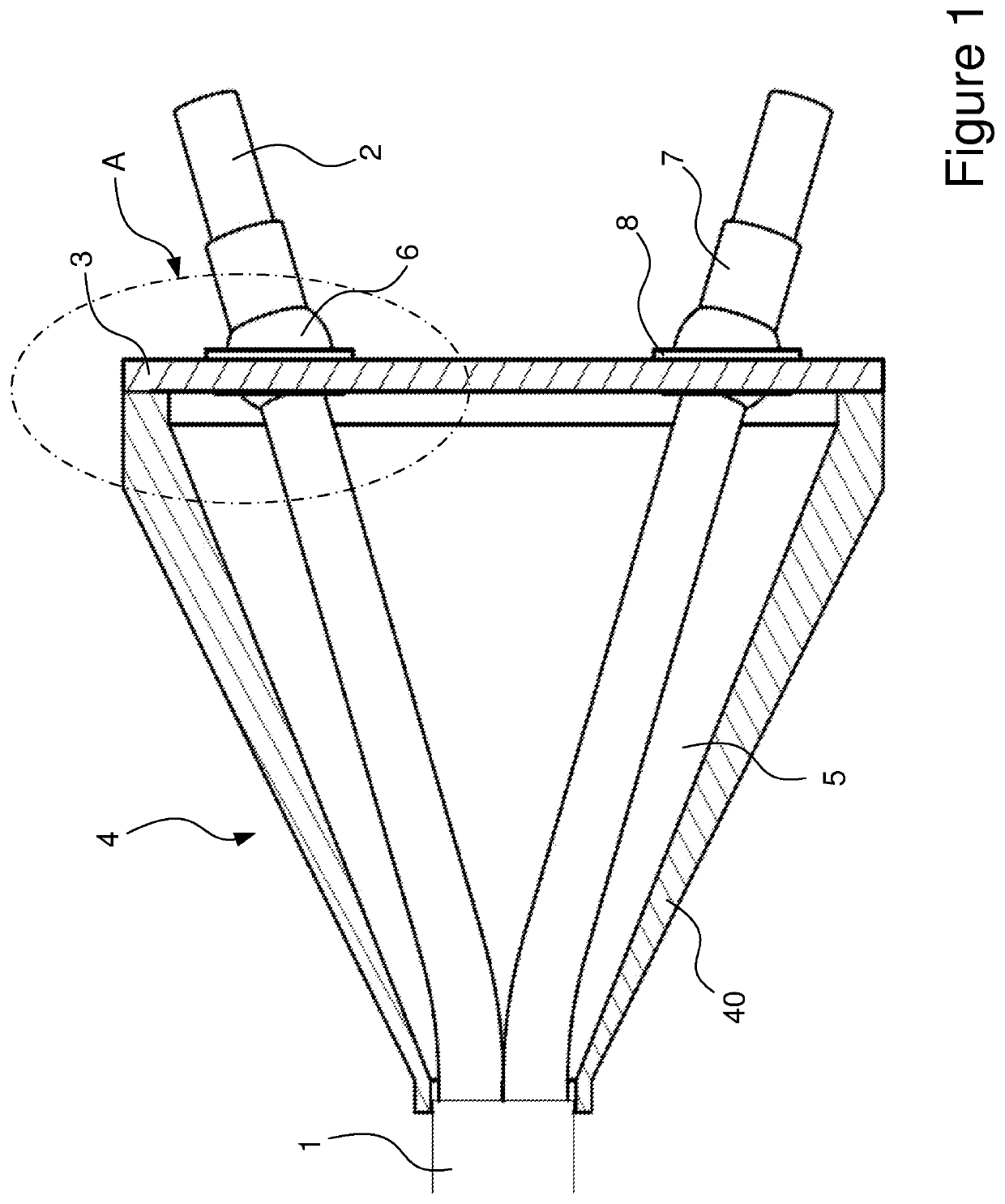

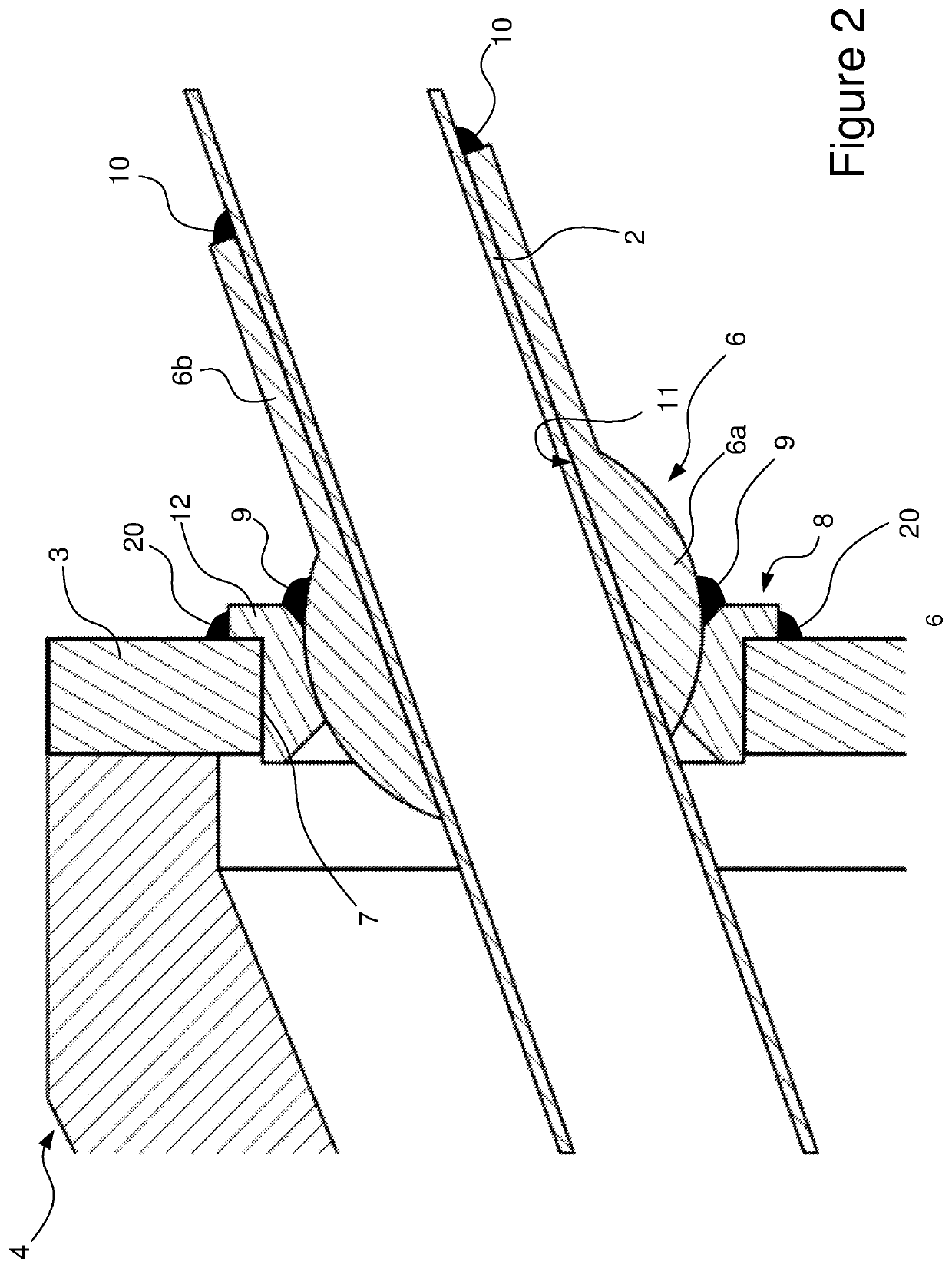

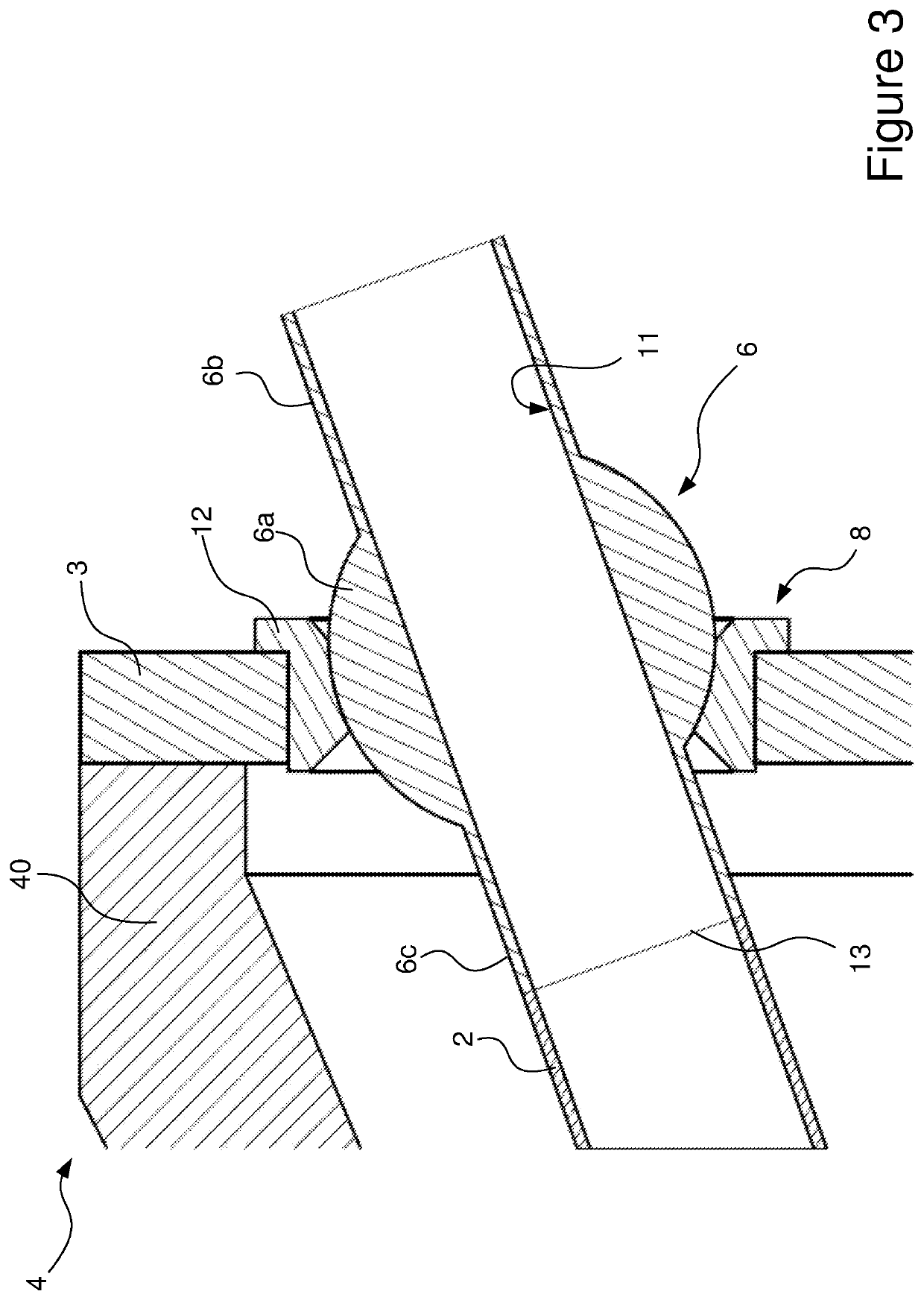

Tensioner for the controlled clamping and moving of an elongated body, in particular for an installation for laying pipelines, umbilicals or cables

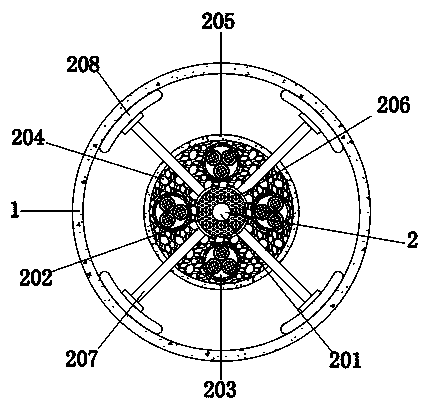

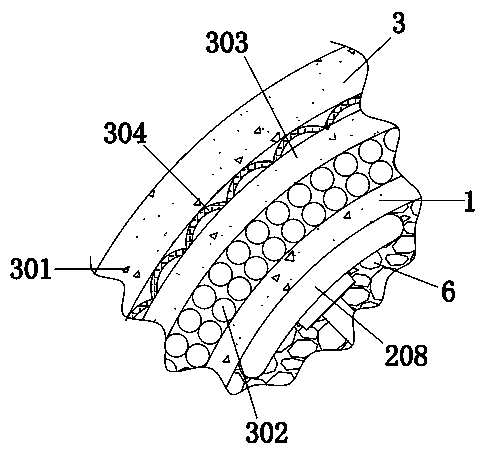

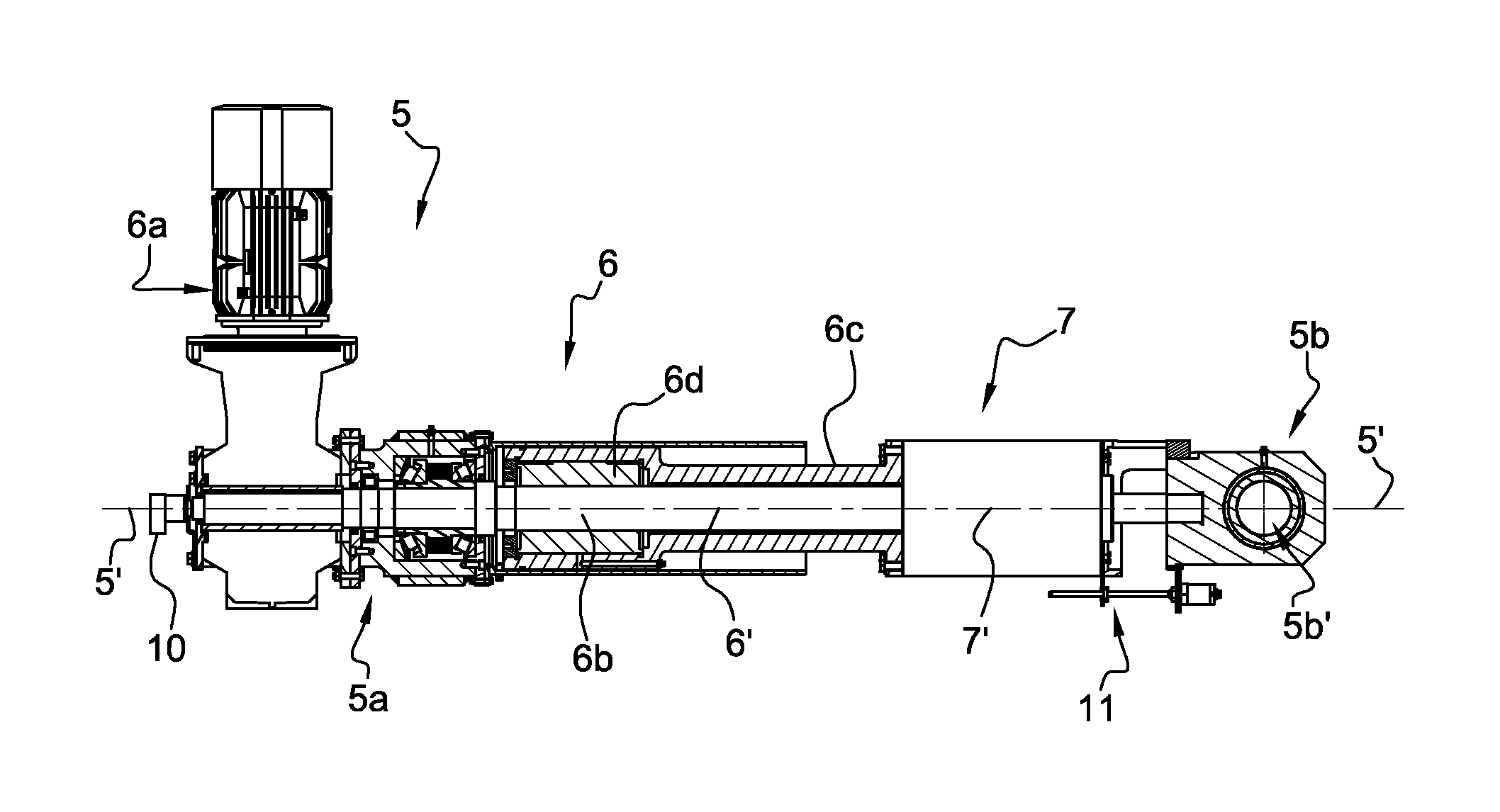

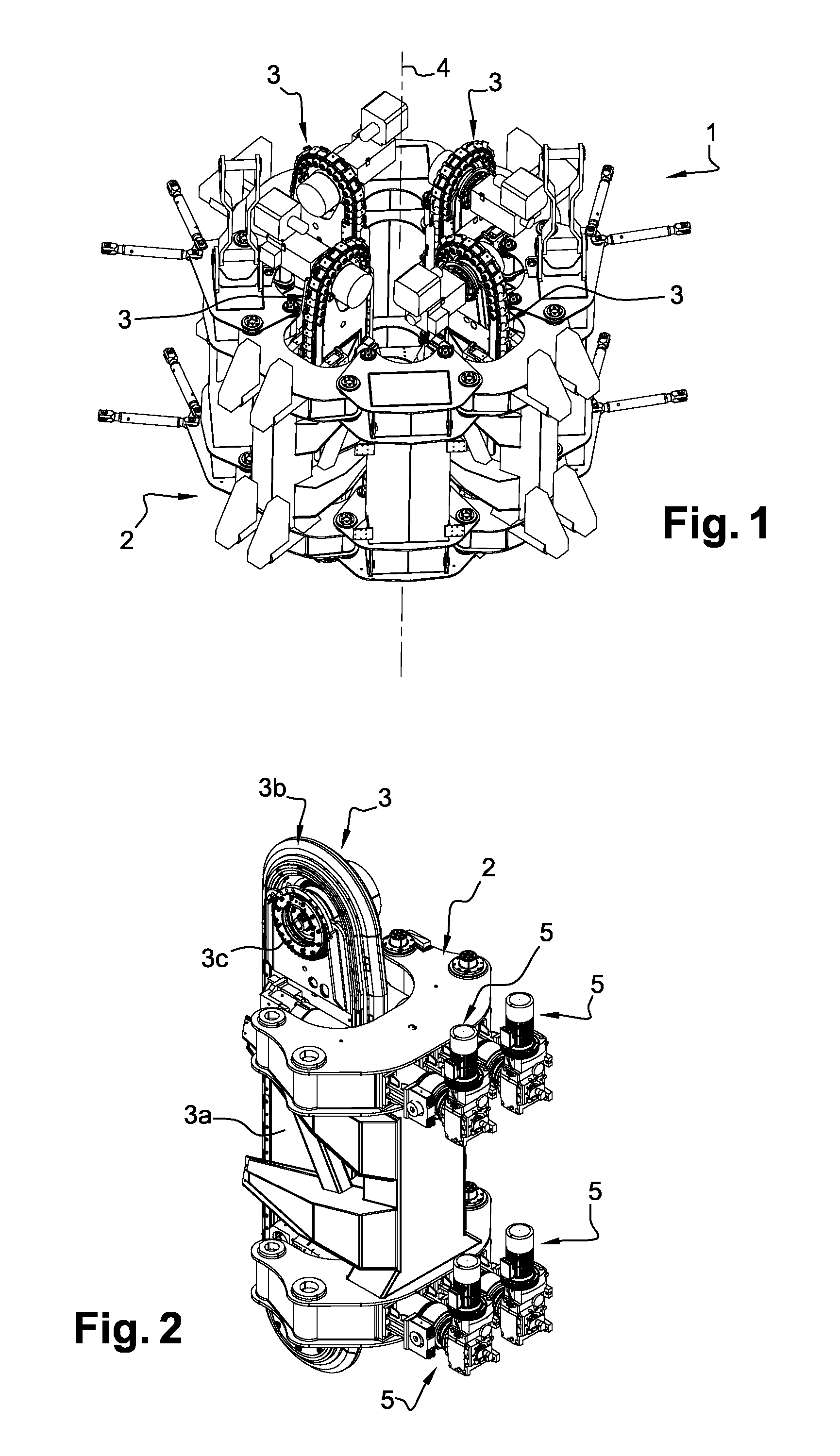

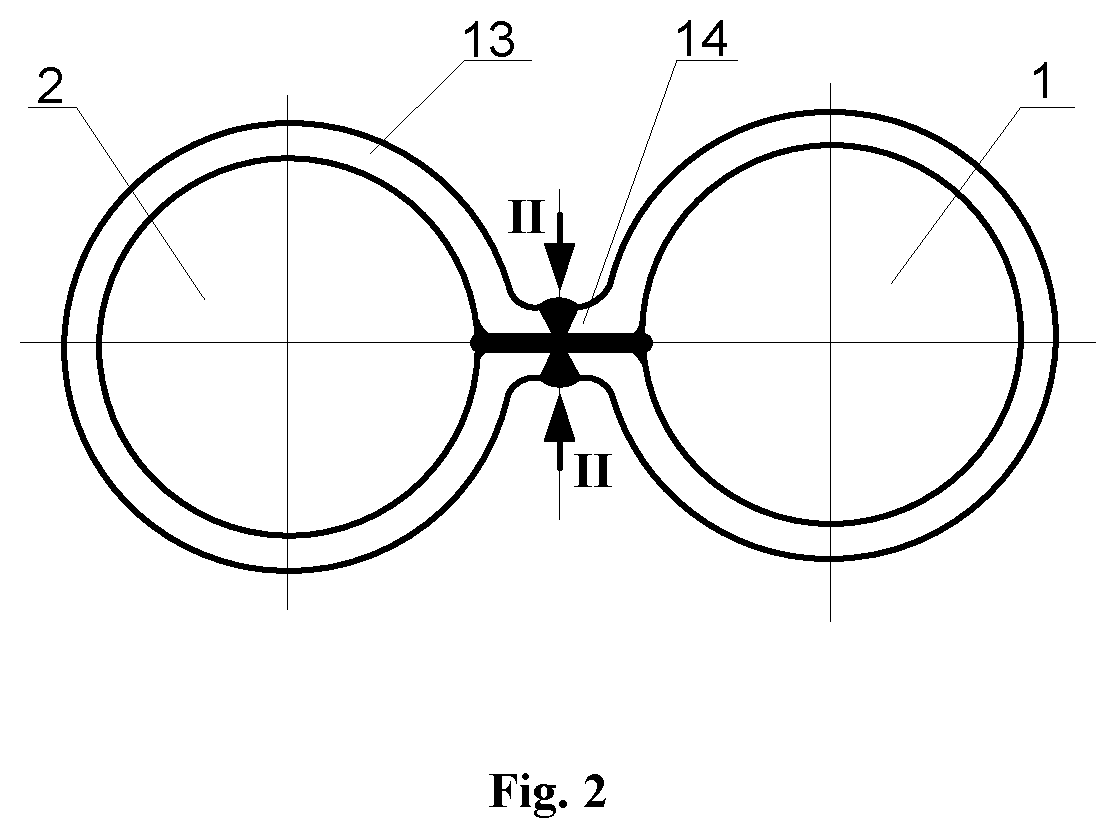

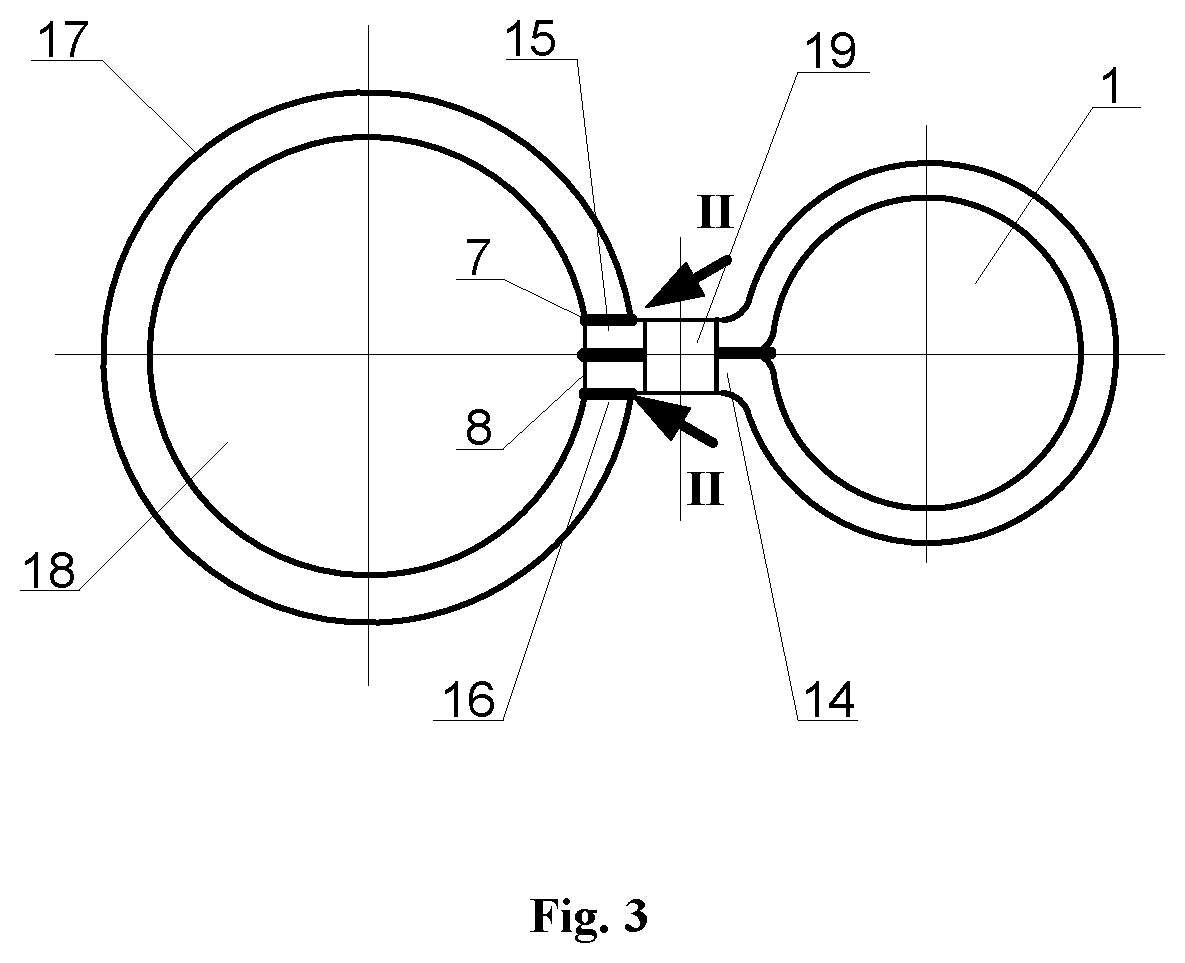

ActiveUS20150115091A1Easy to operateImprove carrying capacityPipe laying and repairFilament handlingAxis of symmetryBraced frame

A tensioner for the controlled clamping and moving of an elongated body (A), in particular for an installation for laying pipelines, umbilicals or cables, includes a frame carrying at least two guiding boxes (3) that are arranged about an axis of symmetry (4), for clamping a segment of the elongated body (A). The guiding boxes (3) according to the invention are mounted mobile on their support frame through operating elements (5) including: (i) at least one linear actuator (5) including an operating cylinder extended by spring element, which operating cylinder and which spring element each have a longitudinal extension axis, the extension axes being oriented coaxially, or at least approximately coaxially, relative to each other, so as to form together the extension axis of the linear actuator; and (ii) programmable elements for controlling the operating cylinder in extension.

Owner:REEL

Umbilical cable

InactiveCN105590670AIncreased load-bearing capacityWith integrated functionSubmarine cablesFlexible pipesUmbilical cord tapeCommunication problem

The invention relates to an umbilical cable. The umbilical cable comprises an outer sheath, an air tube, a self-adhesive tape and an inner sheath; a reinforcing layer is arranged between the outer sheath and the inner sheath; the self-adhesive tape is arranged at the inner side of the inner sheath; a waterproof tape is arranged between the self-adhesive tape and the inner sheath; the air tube is arranged at the center in the umbilical cable; and a cable core is arranged between the air tube and the self-adhesive tape. By applying the umbilical cable in the invention, the communication problem of deepwater detection equipment is effectively solved, the cable core of the umbilical cable in the invention is connected with one end of the detection equipment, conventional communication can be carried out, a power source is provided for the detection equipment, and therefore, production efficiency is greatly improved, and the market prospect of the umbilical cable is wide.

Owner:王帅

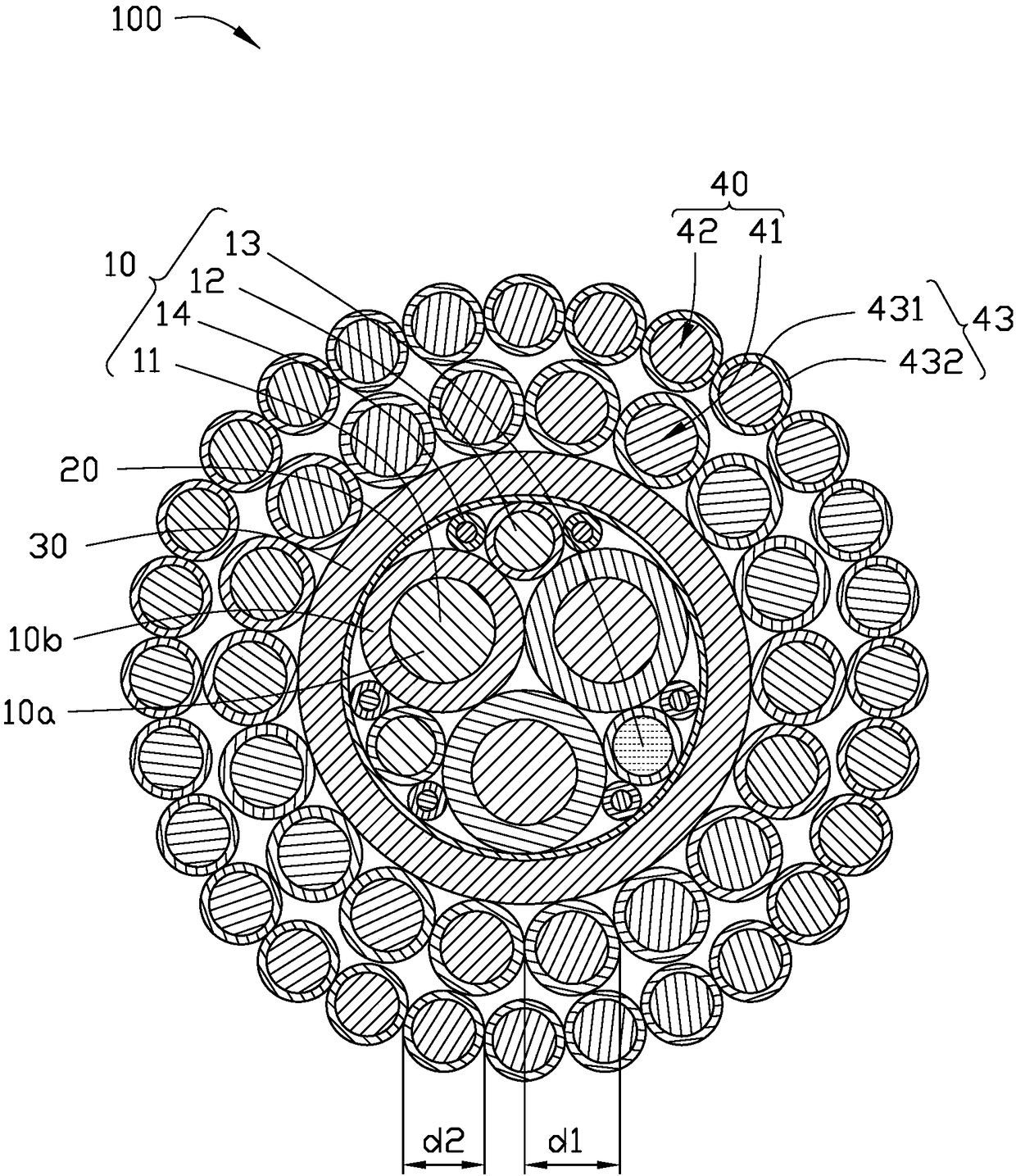

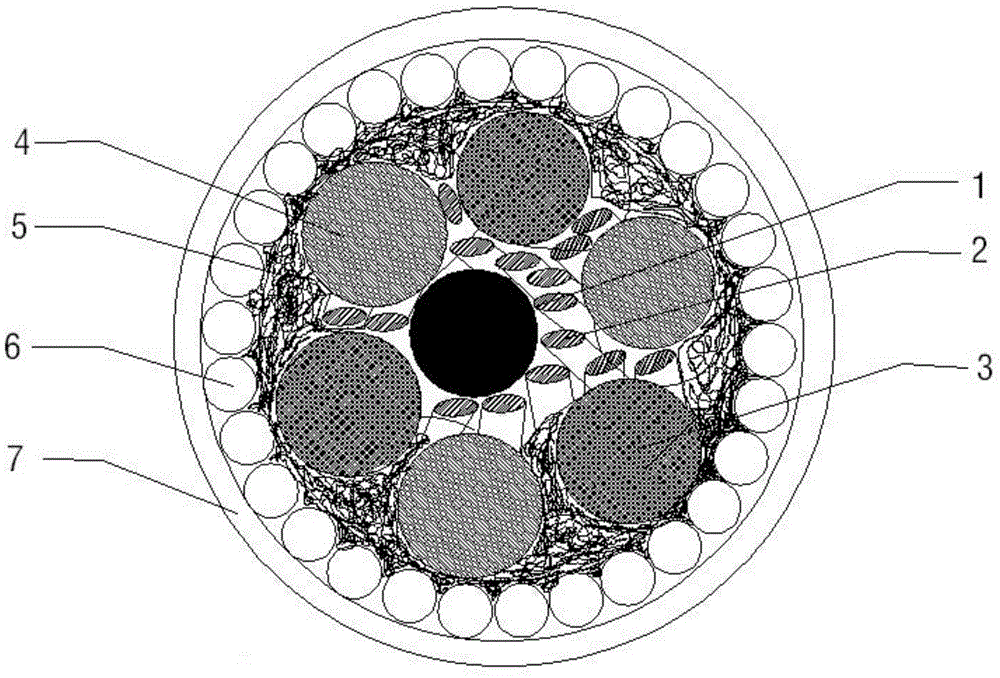

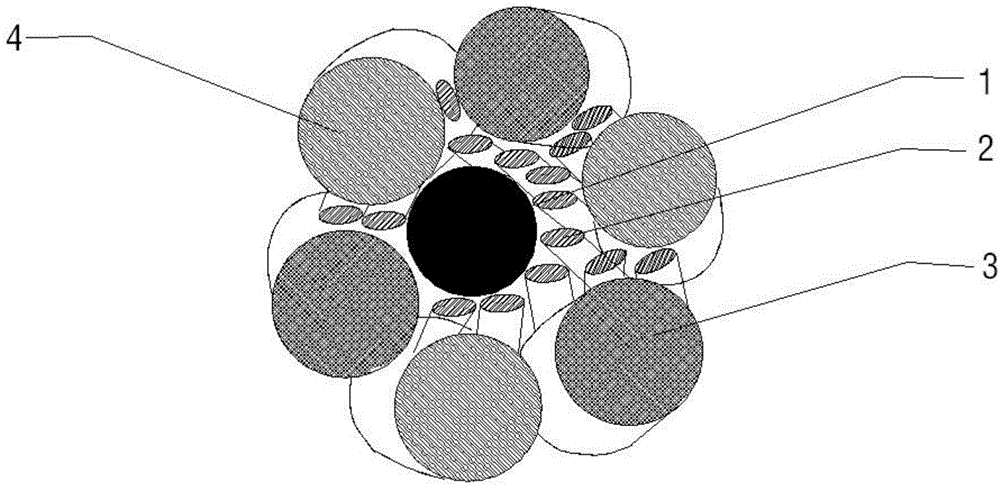

Umbilical cable

InactiveCN104103346AReduce weightImprove ultimate carrying capacityInsulated cablesInsulated conductorsFiberEngineering

The invention relates to the technical field of cable manufacture, in particular to an umbilical cable. The umbilical cable is composed of a reinforcement cable, an optical fiber, an electric cable, a straight fiber, a functional fiber, a reinforcement layer and an insulation protection layer, wherein the reinforcement cable is a cable processed through hot stretching. The umbilical cable is stable in product structure, high in stretching resistance, high in bending resistance and deformation resistance, and high in extrusion resistance, and effectively protects the optical fiber and the electric cable by adding the reinforcement cable. Furthermore, ultimate bearing capacity of the umbilical cable is greatly improved, the application range of the umbilical cable is broadened, defects in the prior art and commercially available products are effectively remedied, and market requirements are met.

Owner:QINGDAO HUAKAI OCEAN SCI & TECH

Umbilical cable

InactiveCN103646715AProvides water resistanceProvide corrosivePlastic/resin/waxes insulatorsSubmarine cablesElectrical conductorEngineering

The invention discloses an umbilical cable comprising an optical unit assembly, liquid transmission assemblies and power line cores. The optical unit assembly includes an optical fiber, optical unit reinforcing steel wires and an optical unit sheath, wherein the optical unit reinforcing steel wires and the optical unit sheath sequentially coat the optical fiber. Each power line core includes conductors coated with insulating layers, and the insulating conductors are stranded and then coated with a sheath. The optical unit assembly, the liquid transmission assemblies and the power line cores are stranded and then sequentially coated with a cable core sheath, two armor layers and an outer sheath. The outer layer of the cable is coated with the two armor layers and the outer sheath, which improves the water resistance and corrosion resistance of the cable.

Owner:四川鑫电电缆有限公司

Termination assembly

ActiveUS20200109742A1More transfer of loadLow costRotary bearingsElectrical apparatusMedicineEngineering

The invention relates to an umbilical termination assembly for terminating a cable or umbilical. The termination assembly comprises a plurality of umbilical elements extending from an umbilical and which pass through a bulkhead plate. The seated ball element has a spherical body through which an umbilical element passes. The ball element is seated in a cup member which allows the ball element to rotate through a large range of angles allowing it to be aligned with the umbilical element without the umbilical element needing to be manipulated or forced into position. The umbilical element can then be attached to the ball element which is supported by the cup member on the bulkhead. This allows the axial tension in the umbilical element to be transferred to the bulkhead.

Owner:JDR CABLE SYST

Intelligent umbilical cable for offshore oil and gas transmission and processing technology thereof

PendingCN113192669AReal-time monitoring of the operating environmentReal-time monitoring pressure valueInsulated cablesInsulated conductorsPolyesterOffshore oil and gas

The invention discloses an intelligent umbilical cable for offshore oil and gas transmission and a processing technology thereof, the umbilical cable comprises a first sheath layer, a first polyester wrapping layer and a central tube unit, and the central tube unit comprises a second sheath layer, a second polyester wrapping layer and a central stranded tube. The first sheath layer, the first polyester wrapping layer, the second sheath layer and the second polyester wrapping layer are provided with optical fiber sensors, a first conveying pipe and a second conveying pipe are circumferentially arranged between the first polyester wrapping layer and the second sheath layer, and the center stranded pipe is formed by stranding a third conveying pipe and a fourth conveying pipe. The outer diameter of the third conveying pipe is larger than that of the first conveying pipe, that of the second conveying pipe and that of the fourth conveying pipe. Nitrogen and seabed oil extraction control liquid are conveyed to an underwater oil well, the operating environment of the umbilical cable is monitored in real time by arranging the optical fiber temperature sensor, the optical fiber pressure sensor and the optical fiber humidity sensor, it is guaranteed that required media are conveyed to the underwater oil well under the safe condition, and the umbilical cable is resistant to corrosion, high in strength, long in service life and easy to replace.

Owner:FAR EAST CABLE +2

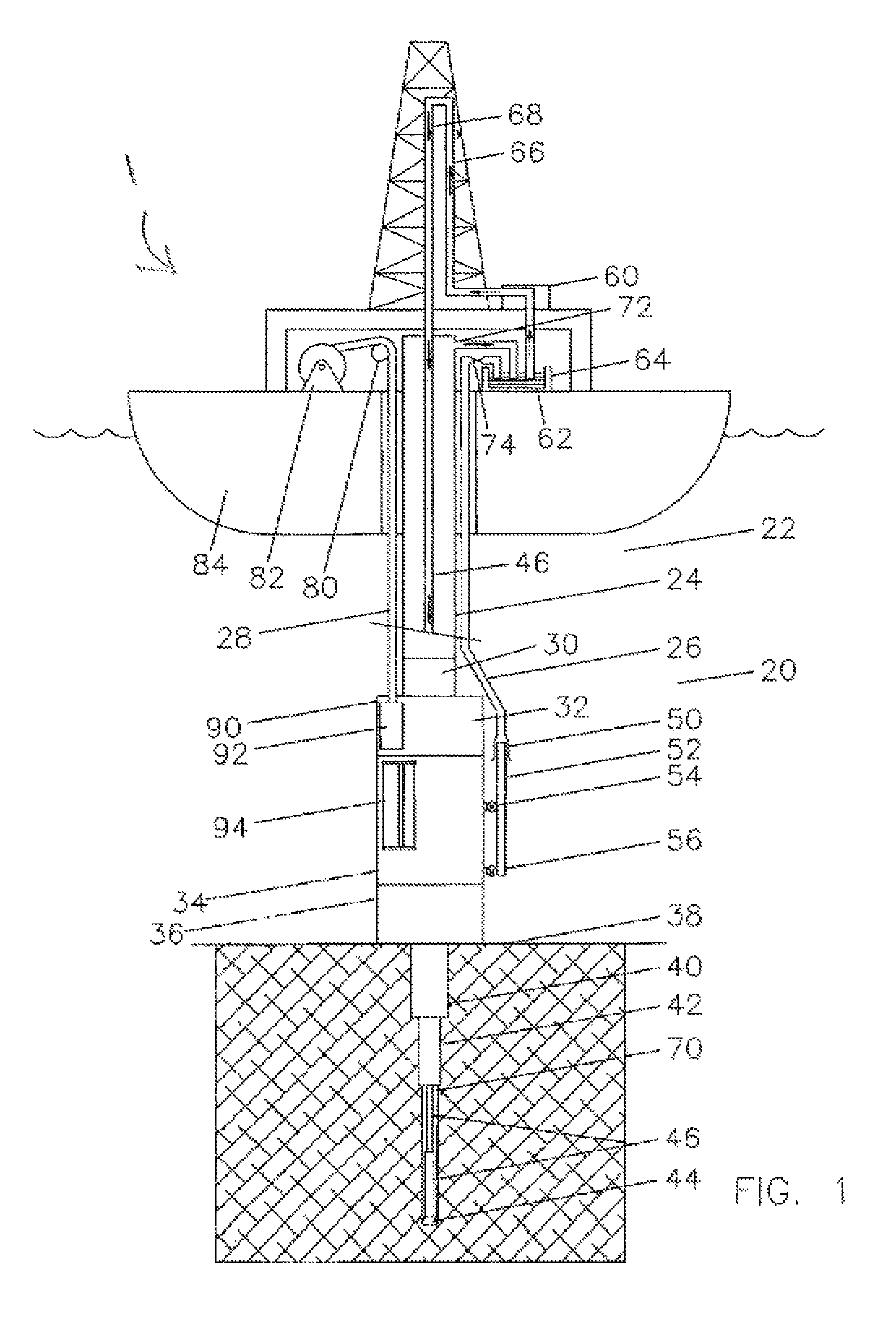

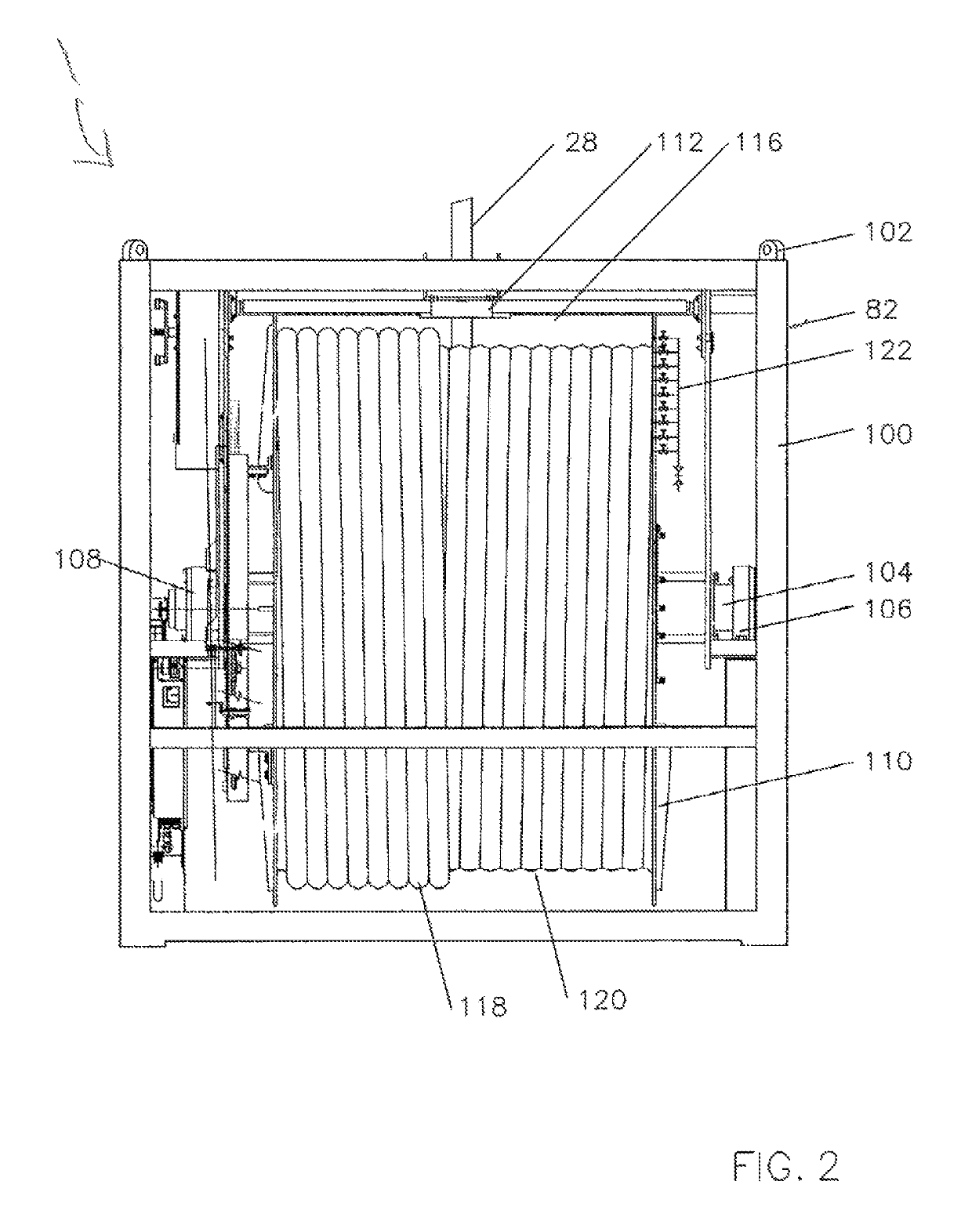

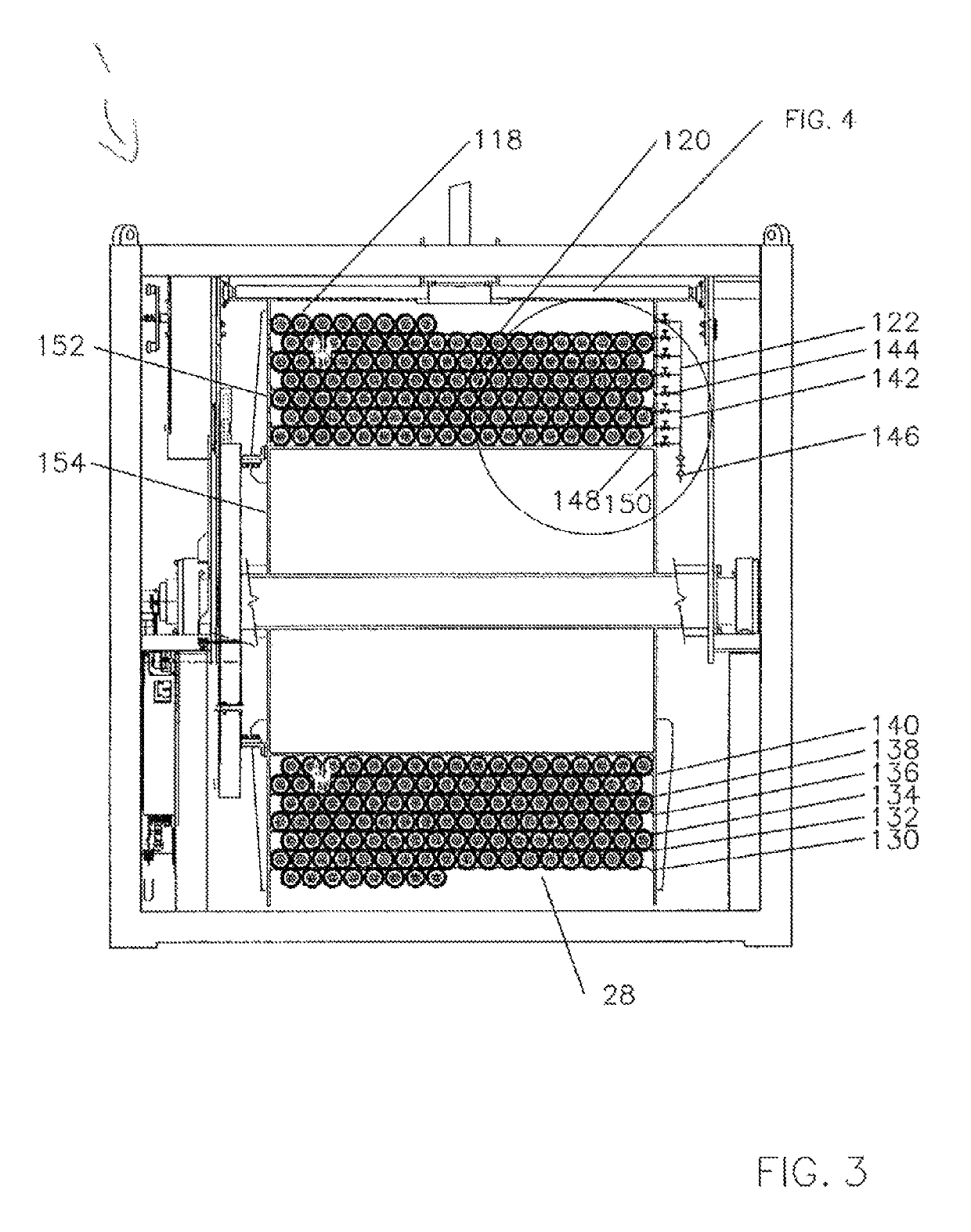

Reel cooling method

ActiveUS10304591B1Without mess and corrosivenessCool evenlyDrilling rodsFilament handlingUmbilical cord tapeMultiple layer

A method of cooling an offshore reel with multiple layers of umbilical with heat generating electrical current flowing through internal wires by supplying a coolant through a wrap between the layers of the umbilical.

Owner:REEL POWER LICENSING

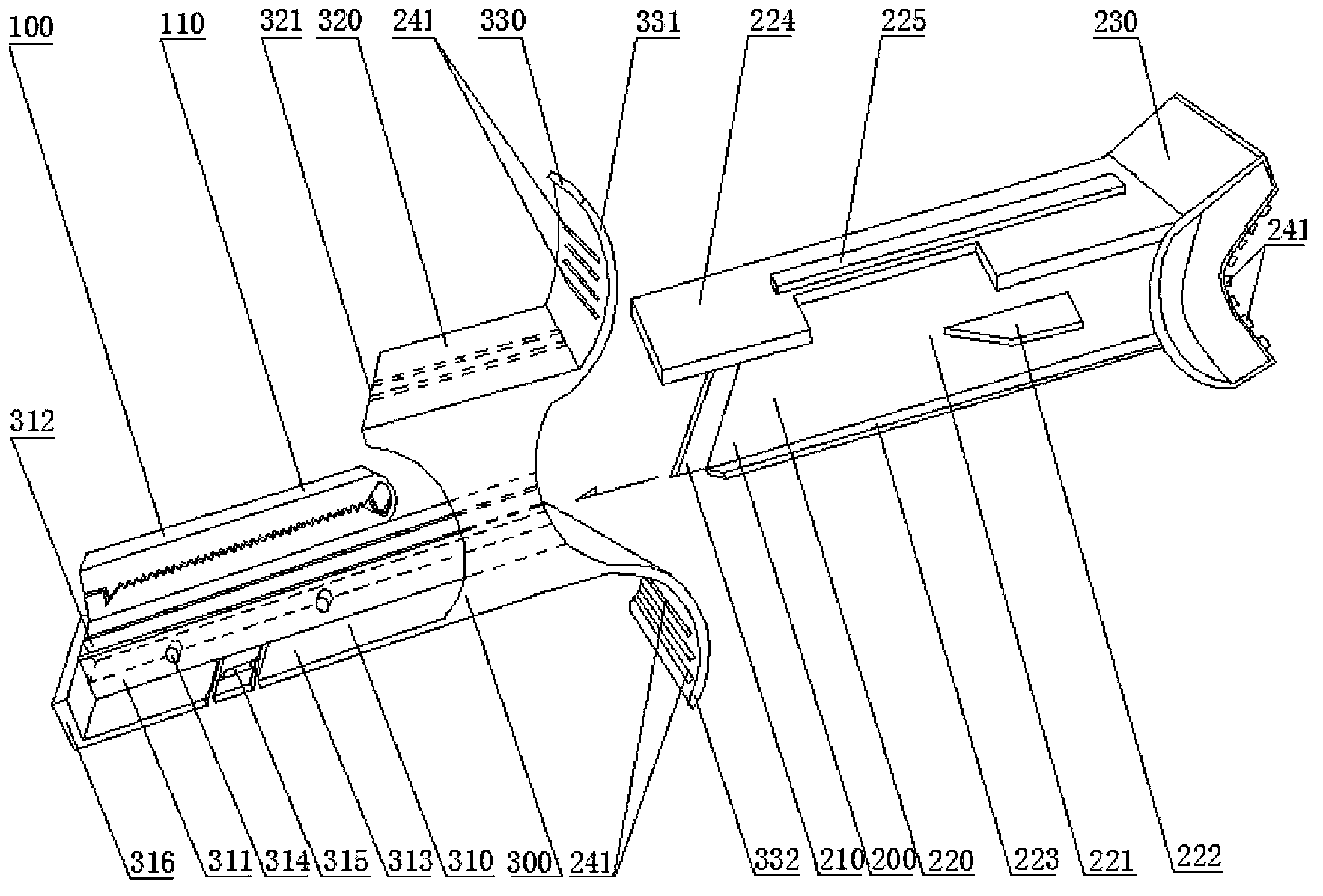

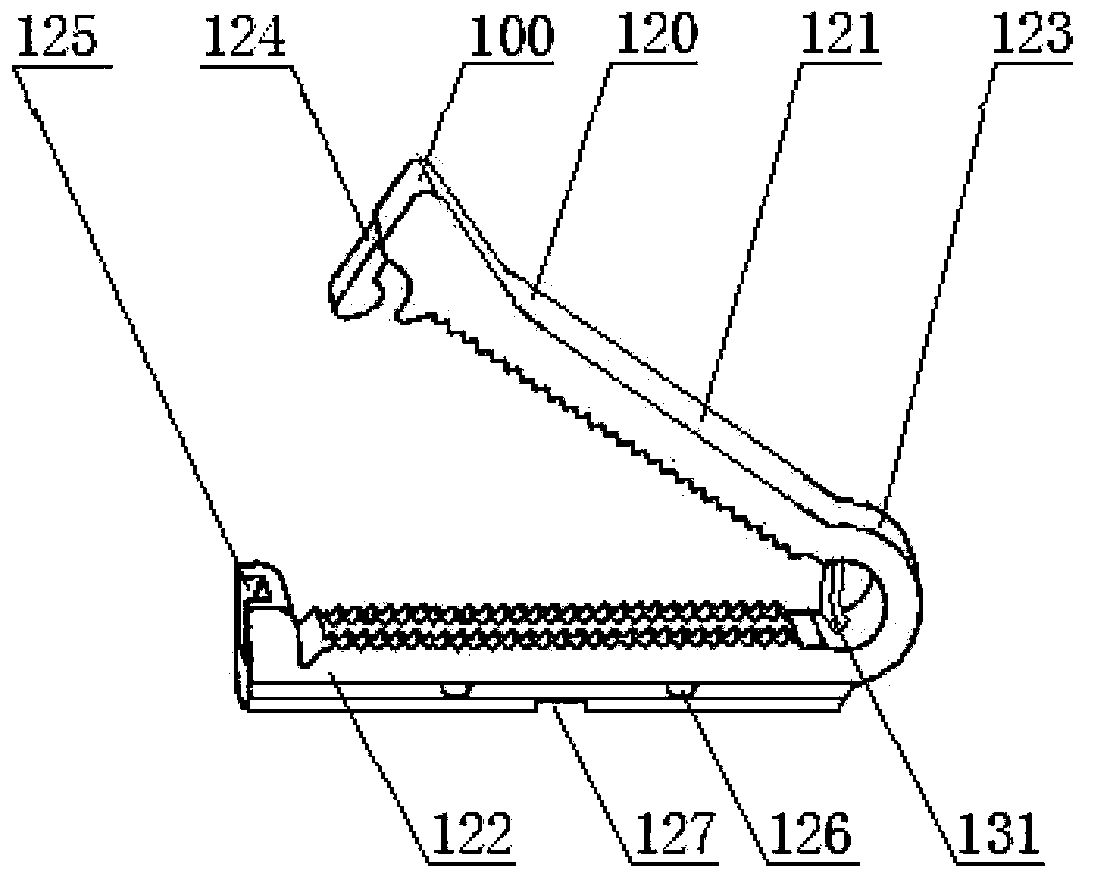

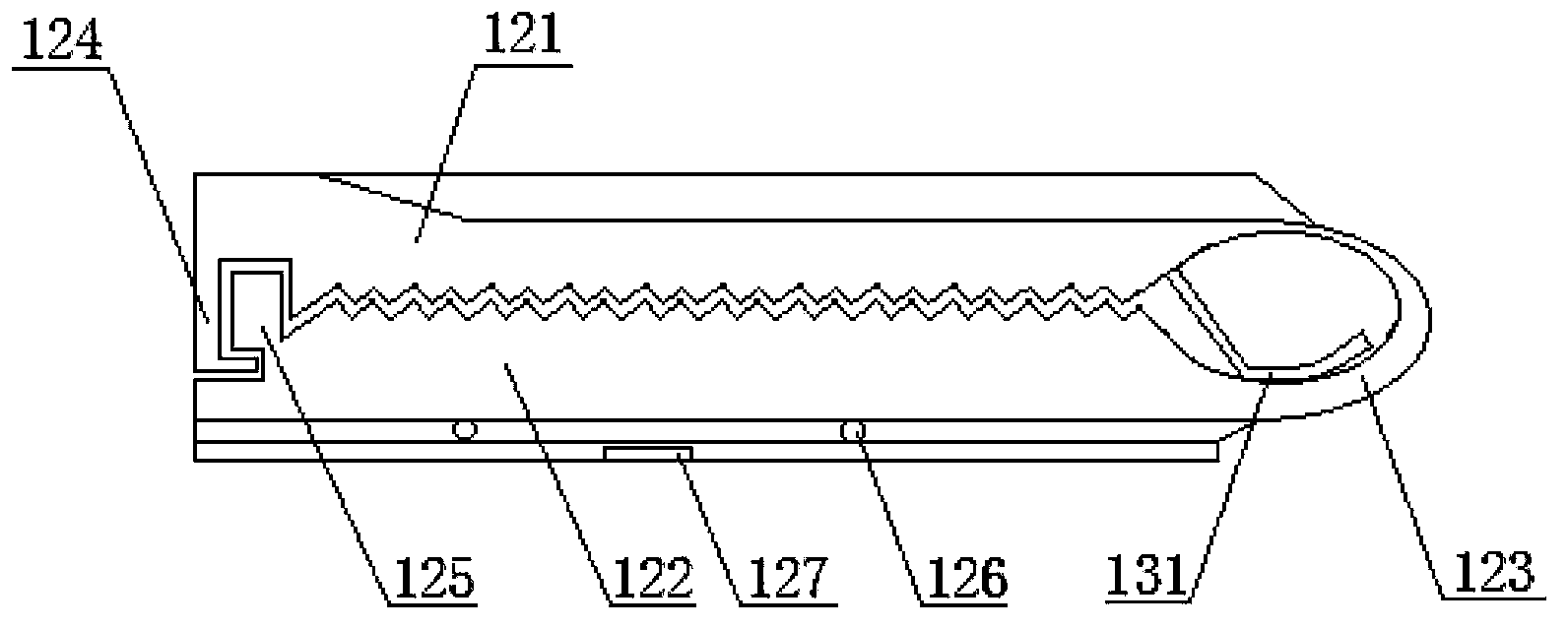

Umbilical cord clamping and cutting device and use method for same

InactiveCN104138288ANot easy to slip offReduce the possibility of scatter and lossIncision instrumentsWound clampsFeeding forceUmbilical cord clamping

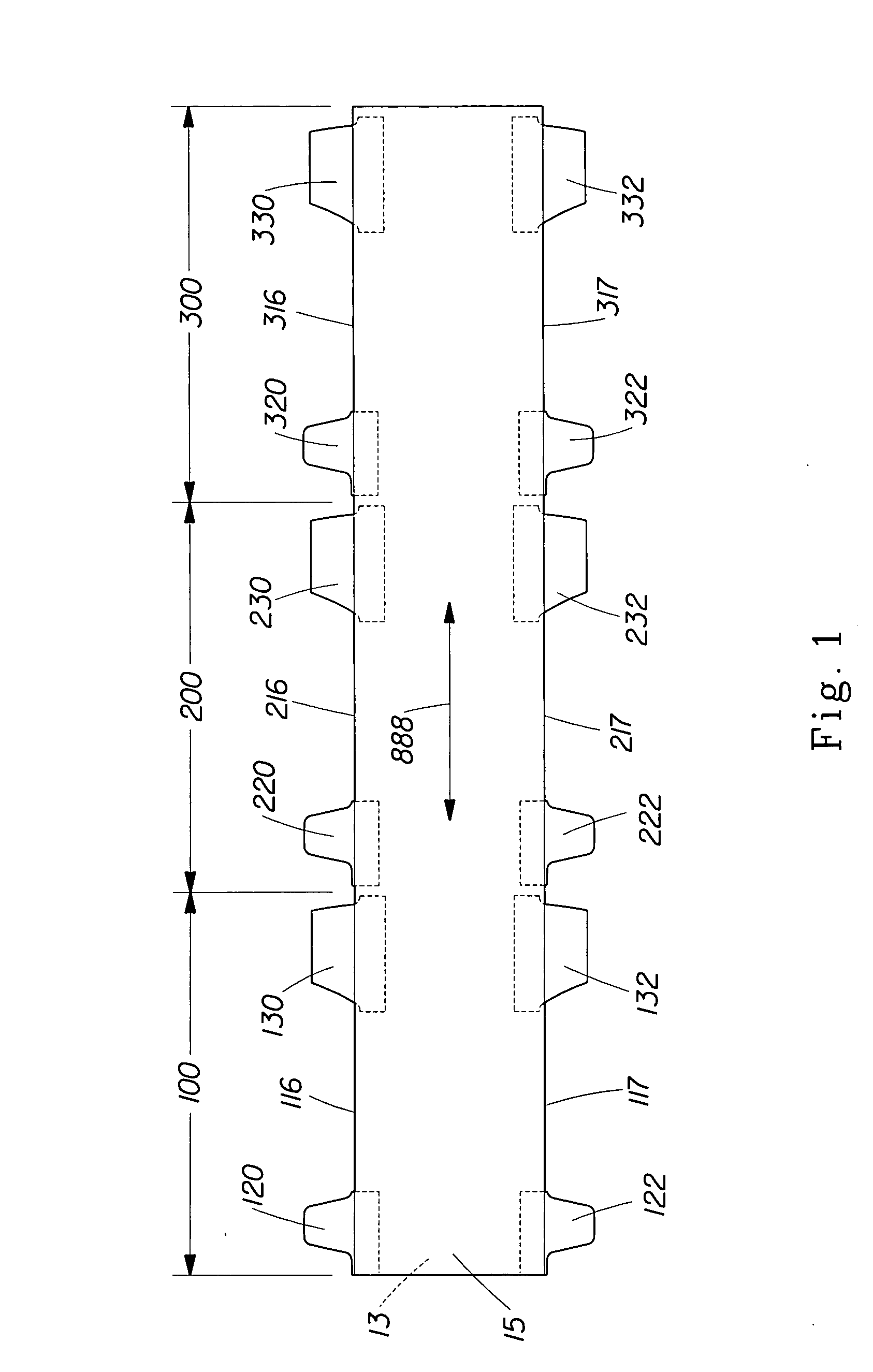

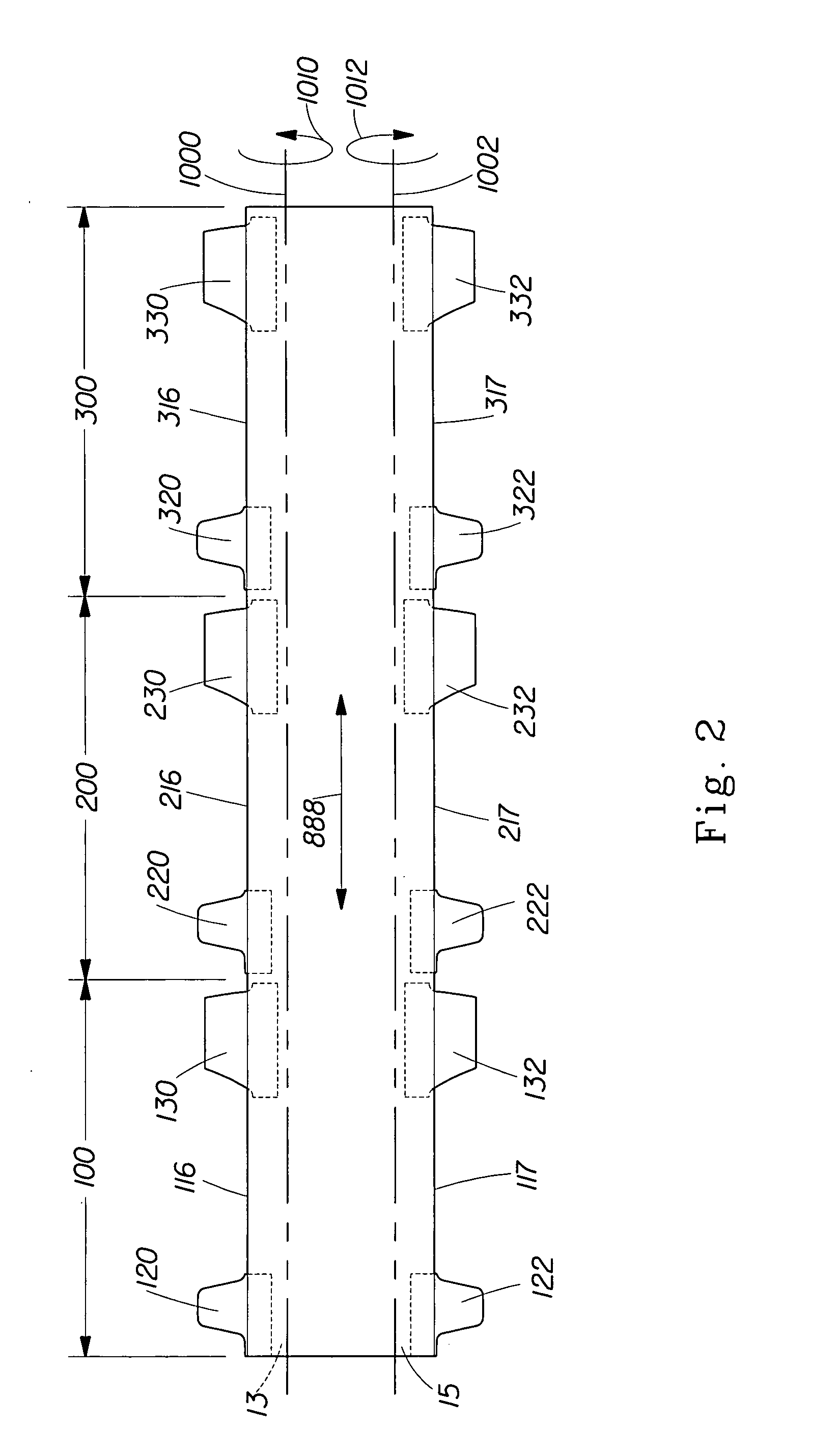

The invention relates to an umbilical cord clamping and cutting device. The umbilical cord clamping and cutting device comprises a clamping device 100, a cutting component 200 and a knife rest component 300, wherein the clamping device 100 comprises a fixed clamp 110 and a movable clamp 120; the cutting component 200 comprises a knife bit 210, a knife back extension plate 220 and a feeding force-holding portion 230; the knife back extension plate 220 comprises a knife back extension plate body 221, a fin-shaped bulged push plate 222 and a feeding guide plate 223; the knife rest component 300 comprises a knife rest plate 310, a knife guide rest 320 and a knife rest force-holding portion 330; the knife rest plate 310 comprises a fixed clamp connection portion, a movable clamp connection portion and a feeding guide groove structure. The invention further relates to a use method for the umbilical cord clamping and cutting device above. The use method comprises the steps of selecting a type, disinfecting, assembling, cutting and the like. The umbilical cord clamping component disclosed by the invention is not liable to separate off and slide off, and capable of reducing the possibility of scattering and loss thereof during packaging and transport processes.

Owner:SHANGHAI ALIFUN MEDICAL TECH CO LTD

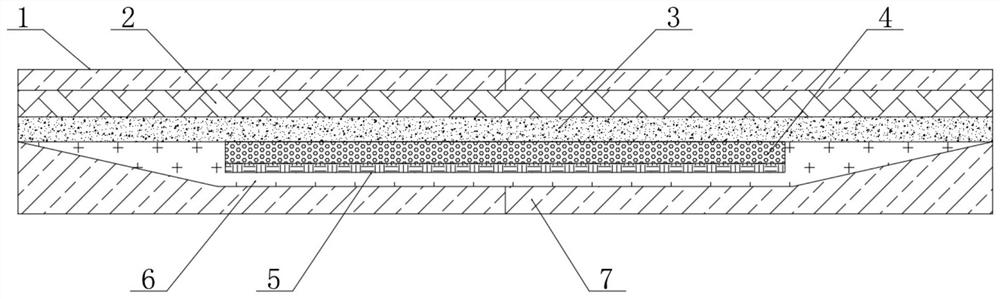

Manufacturing method of silica gel navel-protecting patch

InactiveCN113384400ASimple preparation processEasy to useBreast bandagesPlastersSilicone GelsWound healing

The invention relates to the technical field of navel-protecting patches, and particularly relates to a manufacturing method of a silica gel navel-protecting patch. A backing layer is bonded to the lower surface of centrifugal paper I; the lower surface of the backing layer is coated with a silica gel layer; an absorption pad is bonded to the lower surface of the silica gel layer; a PE film is bonded to the lower surface of the absorption pad; an anti-sticking layer is bonded to the lower surface of the PE film; centrifugal paper II is bonded to the lower surface of the anti-sticking layer; and easy-to-tear openings are formed in the middle sections of the centrifugal paper II and the centrifugal paper I. The silica gel navel-protecting patch is simple in preparation process, can effectively avoid bacterium breeding, prevent wound infection and increase the wound healing speed, is waterproof, breathable, free of pain during stripping, convenient to carry and use and capable of inhibiting scar hyperplasia and avoiding the problem that sweat causes inflammation to the umbilical cord of an infant.

Owner:江苏弘生生物工程有限公司

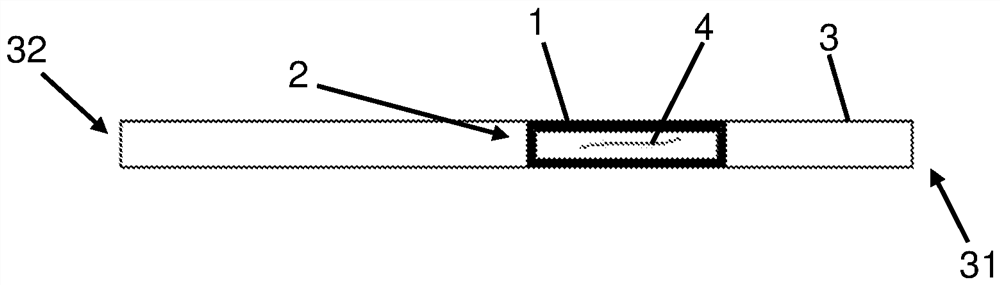

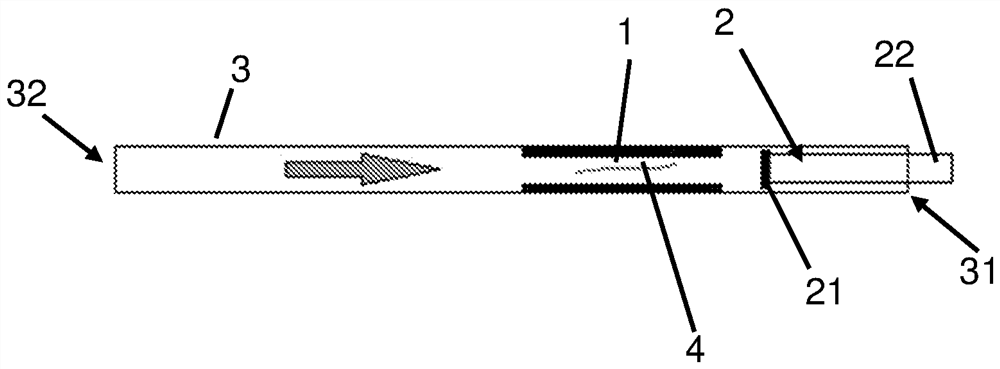

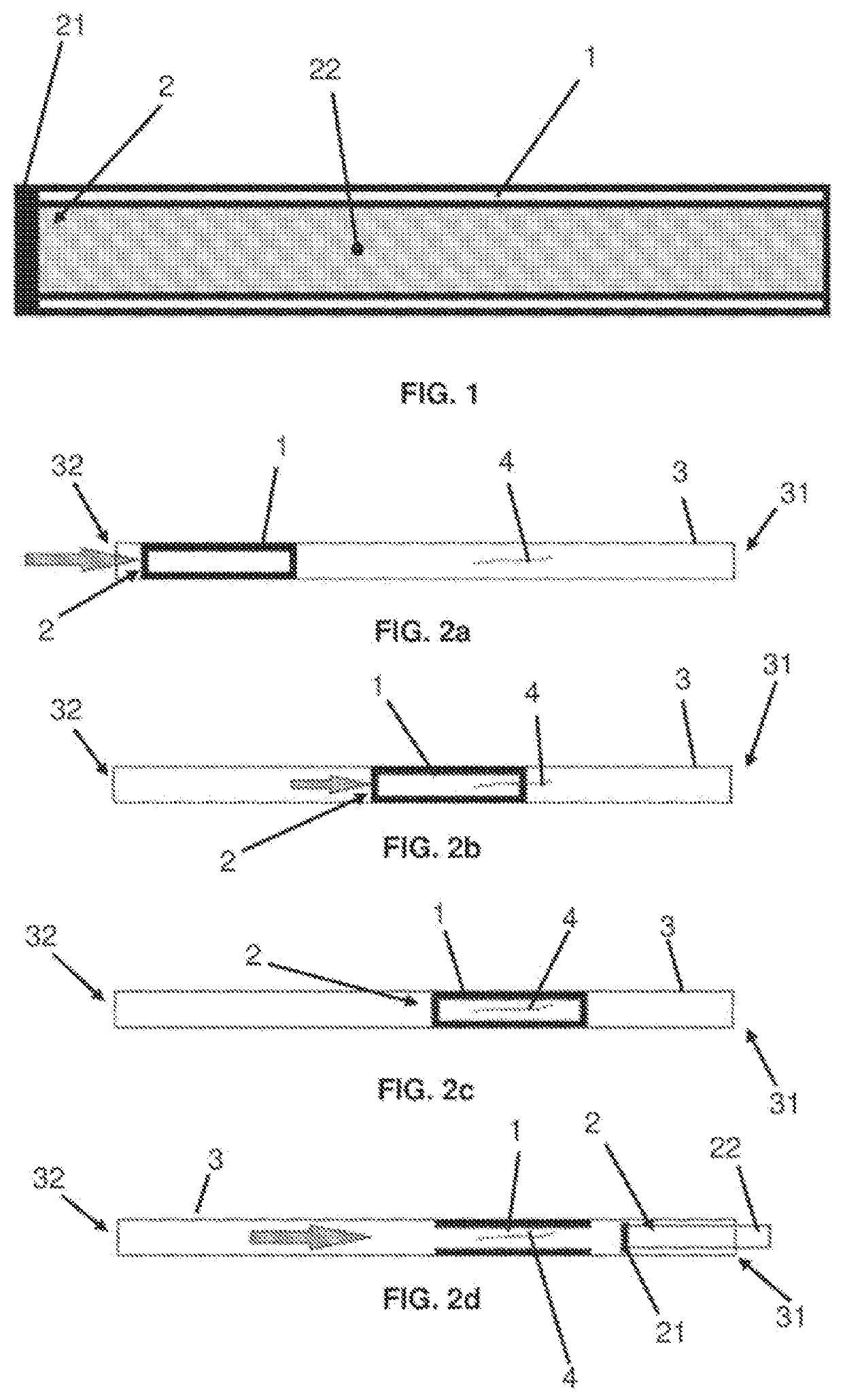

Device and method for repairing a hose of umbilicals

The present invention relates to a device for repairing hoses of umbilicals. In this context, the present invention provides a device, for repairing a hose (3) of umbilicals, comprising a tubular repair body (1) and a fusible element (2) suitable for obstructing the passage of a fluid through the inside of the repair body (1), wherein the repair body (1) comprises an outside diameter that coincides with the inside diameter of the hose (3) to be repaired. In addition, the invention further provides a method for repairing a hose (3) of an umbilical comprising the steps of: blocking a first end (31) of a hose (3) of an umbilical; inserting a device for repairing a hose (3) of umbilicals into a second end (32) of the hose (3); injecting a polymer sealant at the second end (32) of the hose (3); using upstream pressure to move the repair device as far as the region of the leak, until the repair body (1) completely covers the opening / leak site (4); flushing the polymer sealant between the internal wall of the hose (3) and the external wall of the device as far as the opening / leak site (4) in the hose (3); solidifying the polymer sealant, thereby immobilizing the tubular repair body (1) inside the hose (3); releasing the first end (31) of the hose (3) of an umbilical; and flushing the fusible element (2) through the inside of the hose (3).

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Long flexible tubing element (variants)

The invention relates to long-dimensional flexible tubes (coiled tubing). There are several variants of the proposed basic pairs of an umbilical coiled tubing and include means of their production with multi-stage sequential shaping process of one or multiple strips at an estimated geometry, and where isolated channels, partitions and flanges are formed during this process. If required, longitudinal butts of an additional shaped longitude strips can be welded to them to form additional hydraulic channels of the umbilical coiled tubing which can be reeled up to a drum. Other types of service channels (electric, fiber-optic, capillary etc.) or standard coiled tubing can be placed inside or outside channels in the form of a service channels tape. Flanges located beyond the outside dimensions of an umbilical coiled tubing may have a wave-type of form. Connecting partitions may have holes intended for fingers of injector, for elevator, for service channels tape. Flanges and partition holes are weight-carrying members of umbilical coiled tubing. Welding seams, flanges, centers of a closed channels and partitions are located, mainly, on the middle line of an umbilical coiled tubing's cross-section. The umbilical coiled tubing makes it possible to significantly increase possibilities of coiled tubing units in technological operations as well as in artificial lift methods due to its multi-channel design and, consequently, multifunctionality.

Owner:UCT TECH LLC RU RU

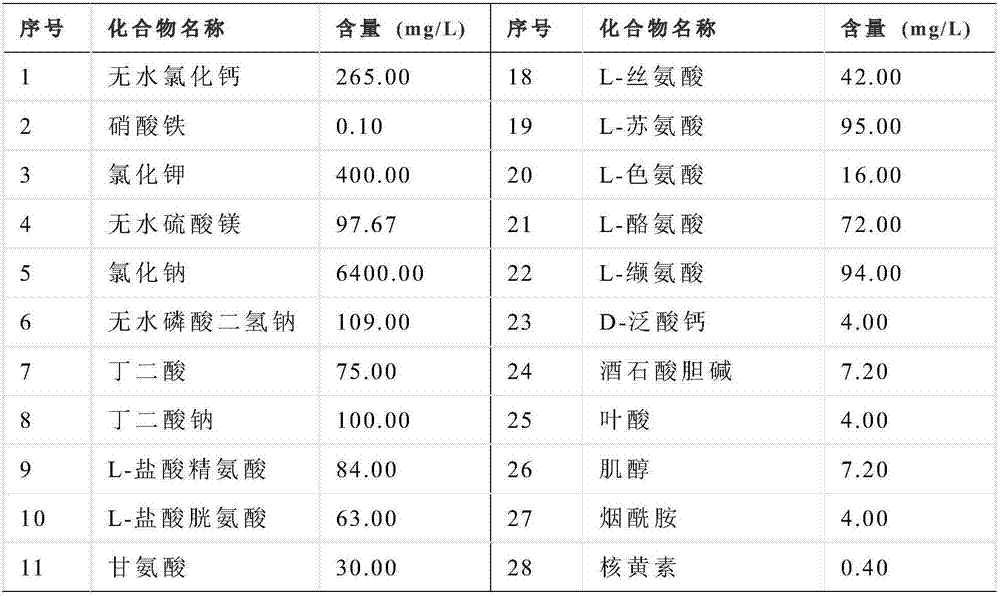

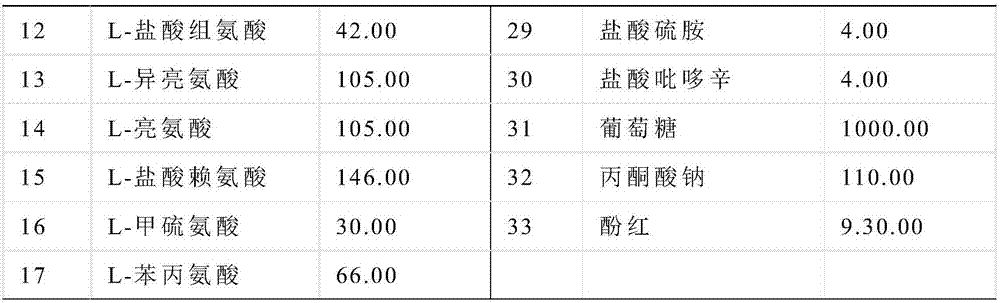

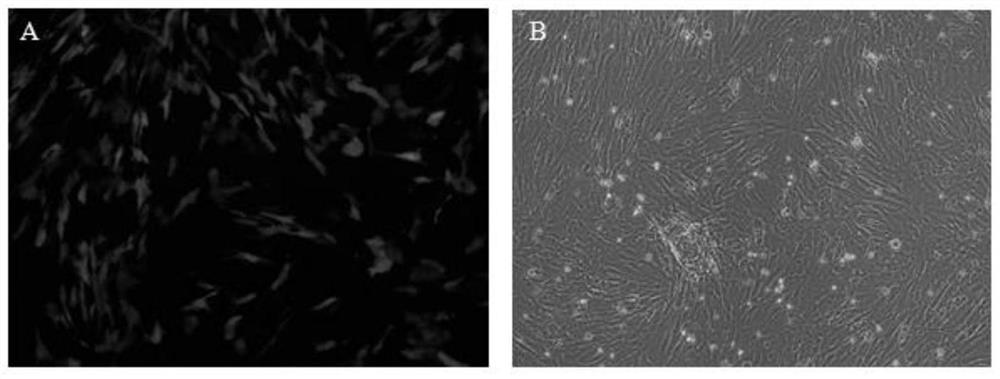

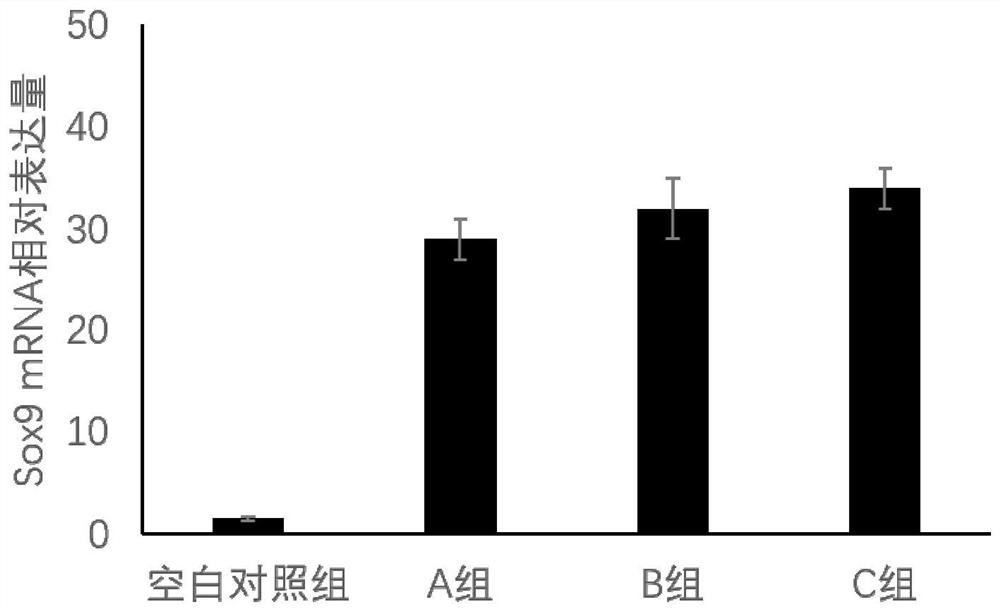

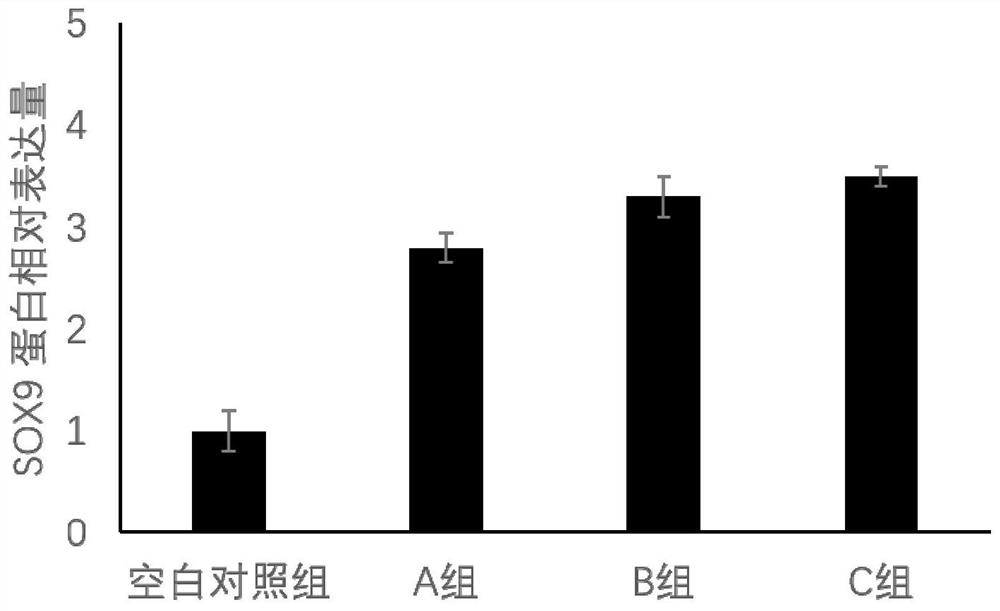

Three-dimensional culture method of umbilical cord mesenchymal stem cells

ActiveCN111139220BCell dissociation methodsSkeletal/connective tissue cellsMesenchymal stem cellUmbilical cord tape

The invention relates to a three-dimensional culture method of umbilical cord mesenchymal stem cells. The three-dimensional culture method of umbilical cord mesenchymal stem cells comprises the following steps: seeding umbilical cord mesenchymal stem cells in a cell culture device, and then rotating and culturing the umbilical cord mesenchymal stem cells at a horizontal rotation speed of 20 rpm to 40 rpm, wherein the cell culture device The inner surface of the bottom is curved, and the inner surface of the bottom is treated with anti-cell attachment. The above three-dimensional culture method of umbilical cord mesenchymal stem cells can increase the yield of exosomes secreted by umbilical cord mesenchymal stem cells.

Owner:深圳市旷逸生物科技有限公司

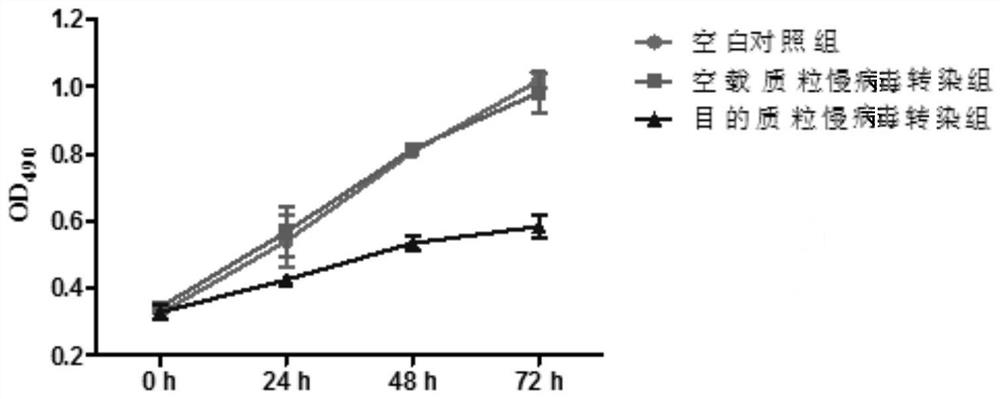

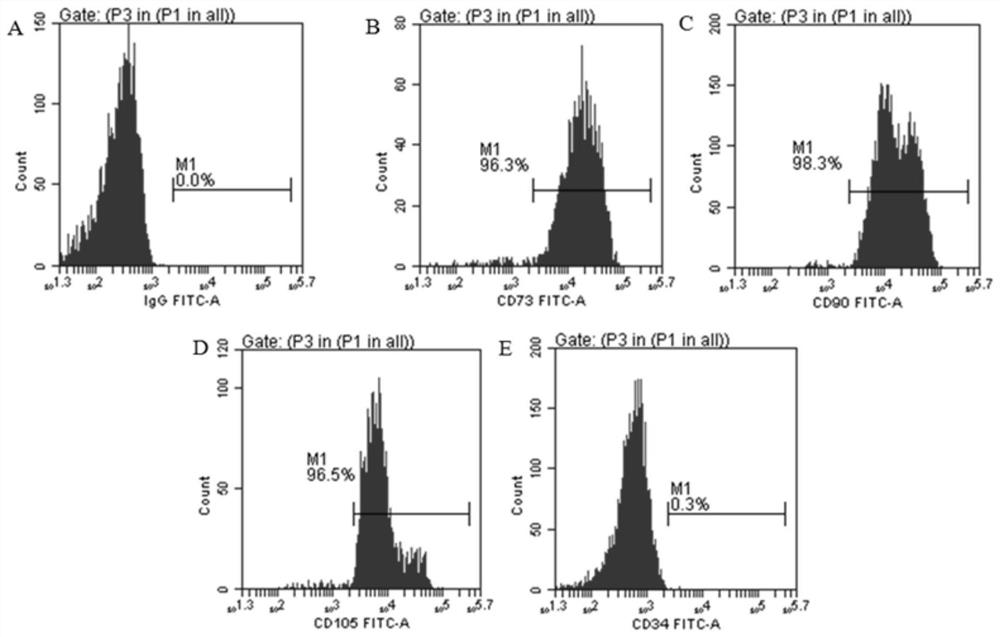

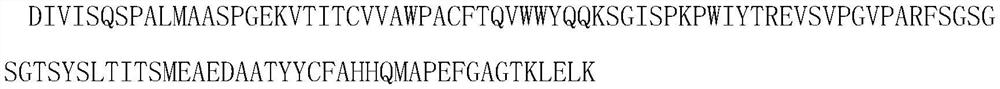

Umbilical cord mesenchymal stem cells silenced by mir338 gene and its preparation method and application

ActiveCN109609554BProliferate fastGood treatment effectNervous disorderGenetically modified cellsInjury brainTherapeutic effect

The invention discloses a mir338 gene silenced umbilical cord mesenchymal stem cell, a preparation method and application thereof. The preparation method comprises the following steps: S1. Inserting the target gene into the lentiviral system vector to construct the LentiCRISPR v2-mir338 recombinant plasmid; S2. Co-transfecting the host cell with the LentiCRISPR v2-mir338 recombinant plasmid obtained in S1 and the packaging plasmid to prepare Lentiviral particles; S3. The lentiviral particles obtained in S2 are transfected into HUMSCs to obtain genetically engineered HUMSCs. After HUMSCs silenced the expression of mir338 gene, the cell proliferation speed was accelerated, and the injection of HUMSCs into brain-injured minipigs had a good therapeutic effect on brain injury.

Owner:SOUTHERN MEDICAL UNIVERSITY

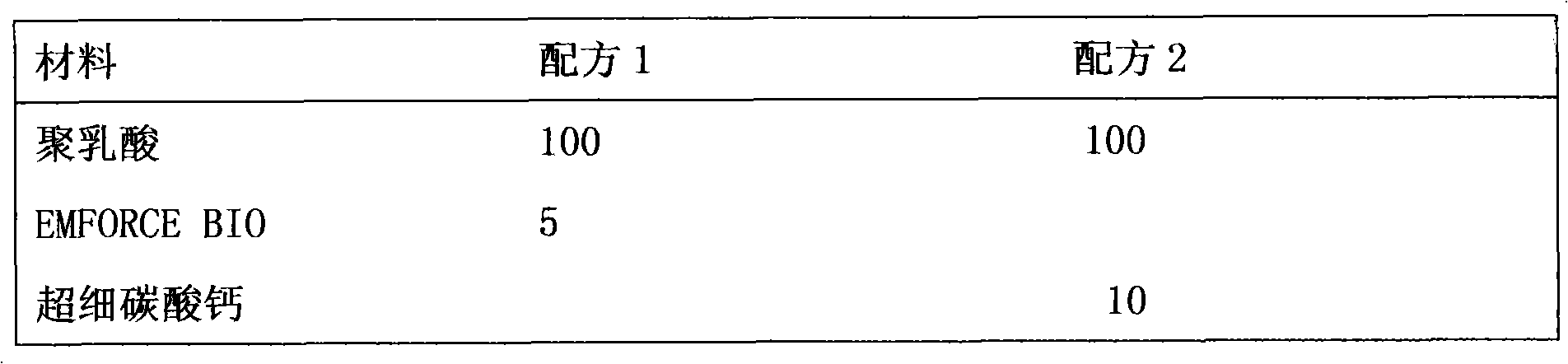

Degradable material used for disposable umbilical cord clamp and preparation method

InactiveCN102727941ALower injection temperatureReduce power consumptionSurgeryEnvironmental resistanceHuman health

The invention provides a degradable material used for a disposable umbilical cord clamp and a preparation method. The disposable umbilical cord clamp is prepared from a degradable high polymer main material and a reinforcing agent. An injection molding process adopted in the invention comprises that: a feed inlet is at a temperature of 150-165DEG C, a compression section is at a temperature of 155-165DEG C, a metering section is at a temperature of 160-170DEG C, and a nozzle is at a temperature of 165-175DEG C; a mold is at a temperature of 20-45DEG C; the injection pressure is 70Mpa at the first level, 80Mpa at the second level, and 55Mpa at the third level; the injection molding period is 41sec; the pressure-holding time is 0sec; and the screw rotation speed is 180 rpm / min. The obtained degradable disposable umbilical cord clamp has all performances in full compliance with the requirements of clinical use, needs no burning after use and is completely biodegradable in the natural environment by landfill, thus reaching the purposes of low carbon, energy saving, environmental protection and human health protection.

Owner:SHANGHAI LINJING MEDICAL EQUIP

Umbilical winch for underwater robot

The invention discloses an umbilical winch for underwater robot and belongs to the technical field of diving equipment. The umbilical winch comprises a winch support seat and a rotation disk arranged on the winch support seat, a cable arranging mechanism is further arranged on the winch support seat to collect and release umbilical cables, and meanwhile, the cable arranging mechanism can be used for arranging the umbilical cables. The umbilical winch is simple in structure and convenient to use.

Owner:上海打捞局芜湖潜水装备厂有限公司

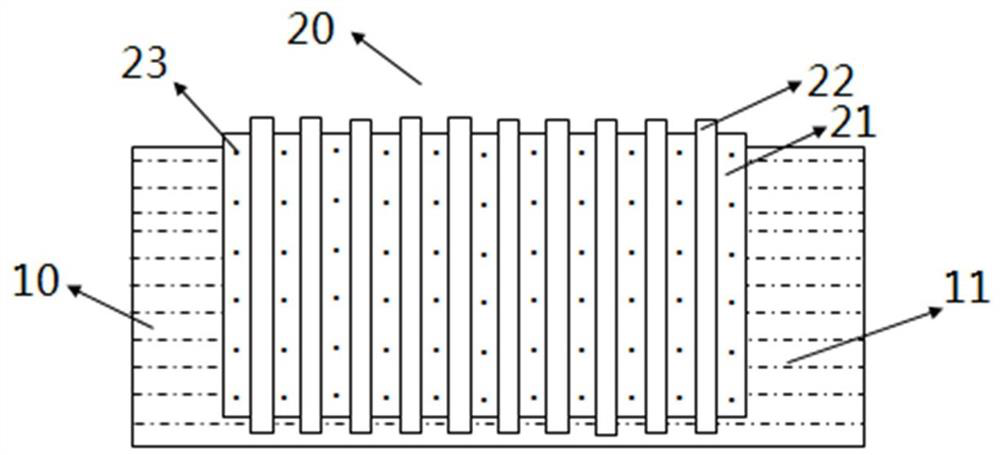

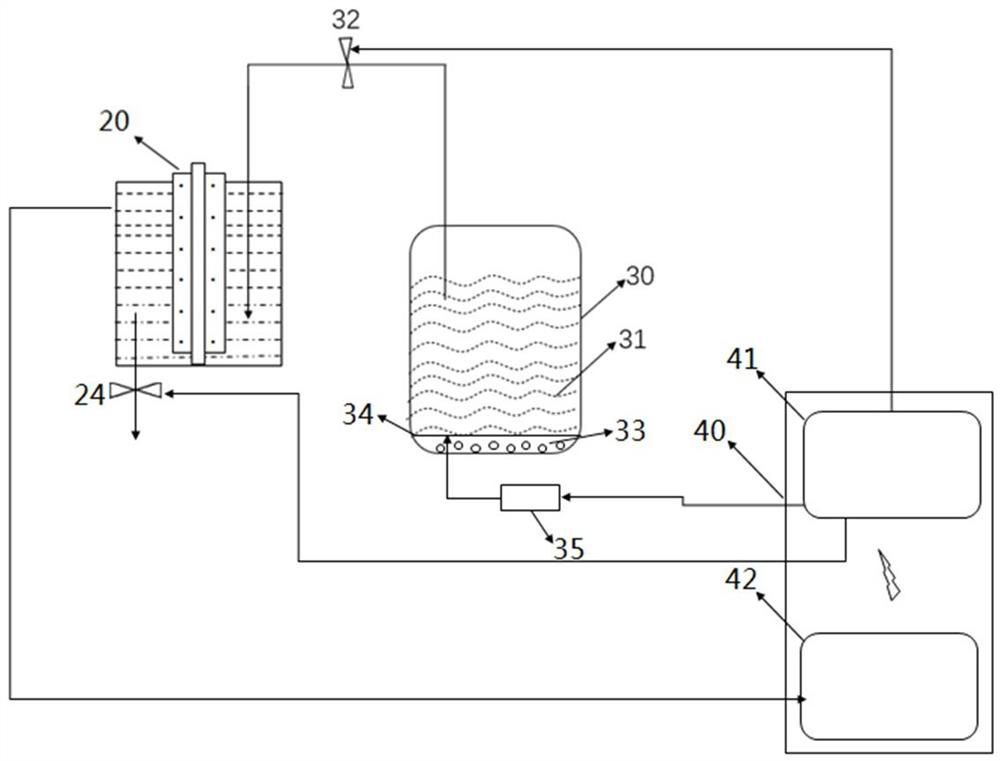

Bioreactor system for long-term and large-scale expansion of human umbilical cord mesenchymal stem cells

ActiveCN113736658BBioreactor/fermenter combinationsBiological substance pretreatmentsFiberCulture fluid

The present invention proposes a biological reaction system for long-term and large-scale expansion of human umbilical cord mesenchymal stem cells, including: a culture module formed by a plurality of nanofiber tubes and a substrate; the substrate has a three-dimensional network formed by a plurality of fiber support cloths Innumerable small holes are formed on the substrate composed of multiple fiber support cloths; the bioreactor has an input pipe at the upper end, which is connected to the culture fluid storage, and is used to receive the culture fluid input from the culture fluid storage according to the controlled flow rate and flow rate. There is an output pipe at the lower end of the bioreactor, which periodically discharges the internal culture liquid through a valve; the bioreactor contains a porous carrier for absorbing the culture liquid; the culture liquid storage is used for storing the culture liquid, An oxygen containment space is provided at the bottom thereof; a control system including an electronic logic module and a remote computing device, the electronic logic module being wirelessly communicatively coupled to the remote computing device.

Owner:北京国卫生物科技有限公司

Umbilical buckling testing

Owner:DMAR ENG

Device and method for repairing a hose of umbilicals

The present invention relates to devices for repairing hoses of umbilicals. In this context, the present invention provides a device for repairing a hose (3) of an umbilical, comprising a tubular repair body (1) and a fusible element (2) adapted to obstruct the passage of fluid through the inside of the repair body (1), wherein the repair body (1) comprises an outside diameter that matches the internal diameter of the hose (3) to be repaired. In addition, the invention further provides a method for repairing a hose (3) of an umbilical comprising the steps of: blocking a first end (31) of a hose (3) of an umbilical; inserting a device for repairing a hose (3) of an umbilical into a second end (32) of the hose (3); injecting a polymer sealant into the second end (32) of the hose (3); using upstream pressure to move the repair device as far as the region of the leak, until the repair body (1) completely covers the opening / leak site (4); flushing the polymer sealant between the internal wall of the hose (3) and the external wall of the device as far as the opening / leak site (4) in the house (3); solidifying the polymer sealant, thereby attaching the tubular repair body (1) inside the hose (3); releasing the first end (31) of the hose (3) of the umbilical; and flushing the fusible element (2) through the inside of the hose (3).

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Stem cell therapeutic agent for treating lower limb ischemic disease and use thereof

ActiveCN111012801BCell dissociation methodsInorganic non-active ingredientsDiseaseMesenchymal stem cell

The present invention relates to a stem cell therapeutic agent for treating lower extremity ischemic diseases and its use. One aspect relates to the use of a cell therapy composition in the preparation of a medicament for treating lower extremity ischemic diseases, the cell therapy composition comprising: umbilical cord mesenchymal stem cells, sodium chloride, and water. Another aspect relates to a cell therapy composition comprising the following components: umbilical cord mesenchymal stem cells, sodium chloride, and water. The preparation method of the cell therapy composition is as follows: adding materials such as sodium chloride into water to dissolve, optionally sterilizing the solution to obtain a matrix of the preparation; suspending the pre-prepared mesenchymal stem cells in the matrix, Pack and get it. The method of the present invention exhibits excellent technical effects as described in the specification. For example, the composition obtained by the present invention exhibits excellent cell resuscitation performance during cell resuscitation, and the viability of cells undergoing resuscitation process and the survival stability of cells after resuscitation are significantly higher than those of the present invention. There are technical solutions.

Owner:BOYALIFE

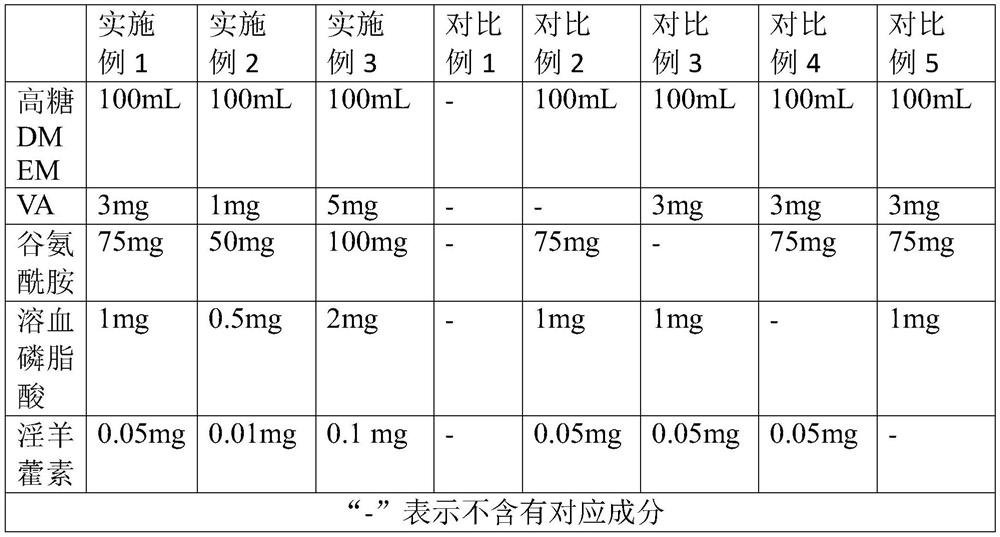

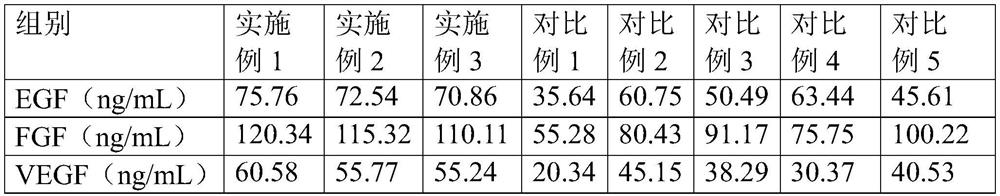

Composition capable of inducing stem cells to secrete cytokines and its application

ActiveCN109852654BReduce the amount of solutionAvoid social and ethical controversiesSkeletal/connective tissue cellsFermentationLysophosphatidic acidCytokine

The invention relates to a composition capable of inducing stem cells to secrete cytokines and its application. The composition comprises: 1mg-5mg vitamin A, 50mg-100mg glutamine, 0.5mg-2mg lysophosphatidic acid, 0.01mg-0.1mg icariin. The composition is added to the induction medium formed in high-sugar DMEM, and the induction medium can stimulate the umbilical cord mesenchymal stem cells to secrete cytokines. In particular, in the process of induction culture, combined with appropriate mechanical stretching and physical stimulation, the amount of cytokines secreted by umbilical cord mesenchymal stem cells can be further enhanced. In addition, the present invention uses umbilical cord mesenchymal stem cells to avoid social and ethical disputes, with faster proliferation and low immune rejection.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

A kind of stem cell cryopreservation medium

ActiveCN113331177BImprove bindingGood ability to bind Caspase proteinDead animal preservationImmunoglobulinsAntiendomysial antibodiesMedicine

The invention relates to a stem cell cryopreservation liquid, which comprises a Caspase monoclonal antibody, and the monoclonal antibody has better ability of binding Caspase protein. By adding corresponding antibodies to the cryopreservation solution, the survival rate of cells after cryopreservation can be effectively improved, which is beneficial to the preservation and application of umbilical cord mesenchymal stem cells, and has good application value.

Owner:样美生物科技(北京)有限公司

A storage rack for umbilical cord mesenchymal stem cells

ActiveCN109169635BMonitor temperature in real timeDoes not affect accessDead animal preservationMesenchymal stem cellElectric machinery

The present invention relates to the field of stem cell storage, in particular to a storage shelf for umbilical cord mesenchymal stem cells, including a liquid nitrogen tank and an air storage tank. The storage shelf includes a cylindrical carrier with a hollow structure, a guide assembly installed in the carrier, and The stepper motor used to drive the guide assembly to rotate around the axis of the carrier; the liquid nitrogen tank communicates with the carrier body through the first air pipe; the gas storage tank communicates with the carrier body through the second air pipe; at least six The storage plate frame for storing stem cells; when the stepping motor drives the guide assembly to rotate, each storage plate frame is always in a horizontal posture; a pressure detector and a temperature sensor are installed in the carrier body, and the present invention can store a large number of stem cells. It does not affect the taking of the staff, and the stem cells can be easily isolated during the taking, so that it is not affected by the external temperature, which greatly facilitates the operation of the staff.

Owner:安徽细胞之星生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com