Umbilical cable

An umbilical cable and cable technology, which is applied in the field of rope manufacturing, can solve the problems of unstable umbilical cable structure, poor tensile performance and poor anti-extrusion performance, and achieve high tensile and anti-extrusion performance. , the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

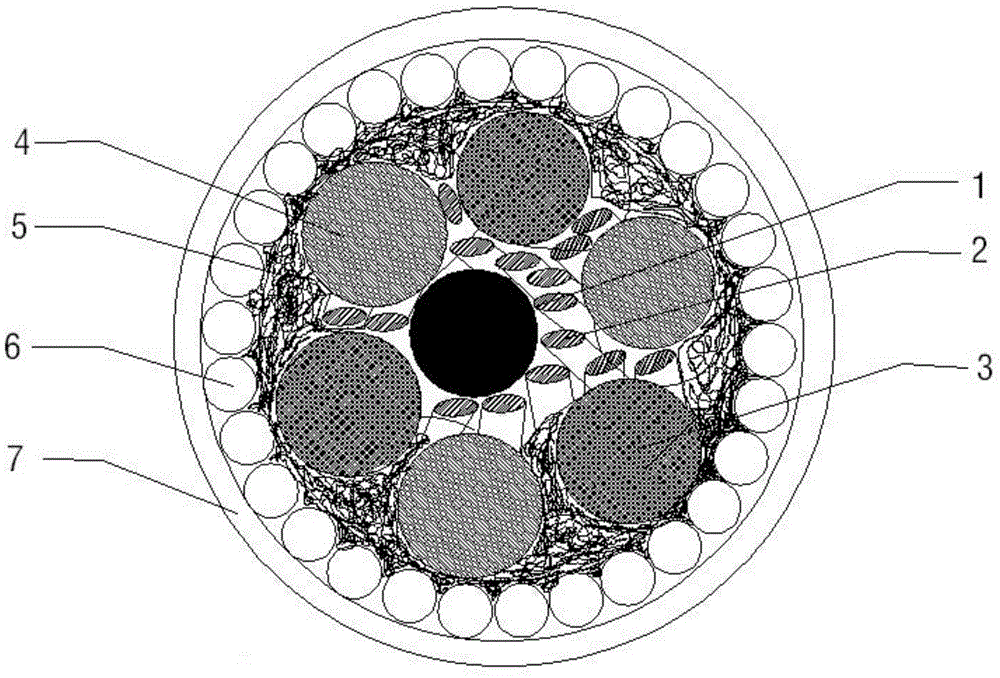

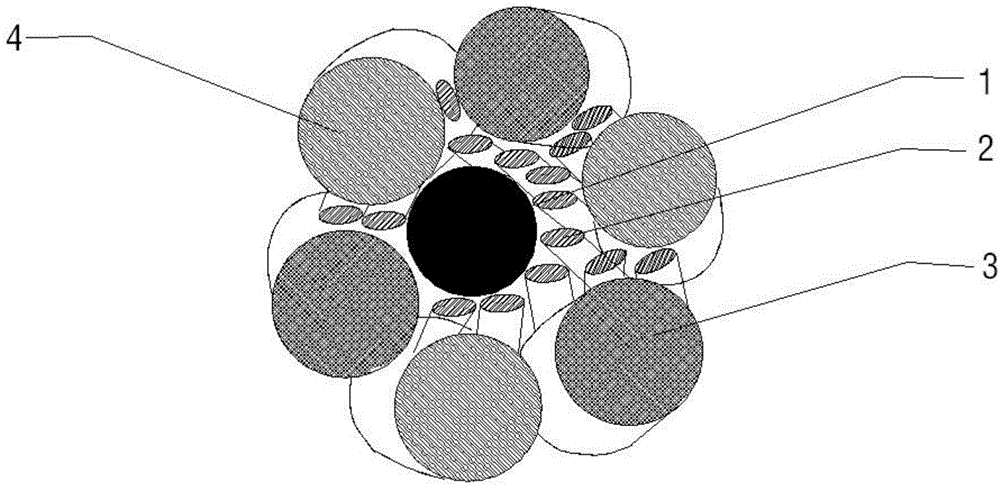

[0017] An umbilical cable embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0018] The present invention adopts the fiber cable that has been heat-drawn to be placed in the middle of the umbilical cable as the reinforcing cable 1; the straight fiber 2 is placed in parallel around the optical fiber 3 and the cable 4, effectively reducing the weight of the umbilical cable and reducing the stress on the umbilical cable. The force of the optical fiber 3 and the cable 4; the optical fiber 3 and the cable 4 are twisted into a convoluted structure as a whole, and the extension space formed by the convoluted structure can effectively improve the tensile performance; a layer of strengthening layer 6 is arranged outside the convoluted structure, The reinforcing layer 6 adopts strong fibers, which can effectively improve the axial rigidity; the gap between the convoluted structure and the reinforcing layer 6 is filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com