Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "PackBot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PackBot is a series of military robots by Endeavor Robotics (previously by iRobot), an international robotics company founded in 2016, created from iRobot, that previously produced military robots since 1990. More than 2000 were used in Iraq and Afghanistan. They were then used again to aid searching through the debris of the World Trade Center after 9/11 in 2001. Another instance of the PackBot technology being implemented was to the damaged Fukushima nuclear plant after the 2011 Tōhoku earthquake and tsunami where they were the first to assess the site. As of November 2014, the U.S. Army is refurbishing 224 iRobot 510 robots. The PackBot technology is also used in collaboration with NASA for their rovers and probes.

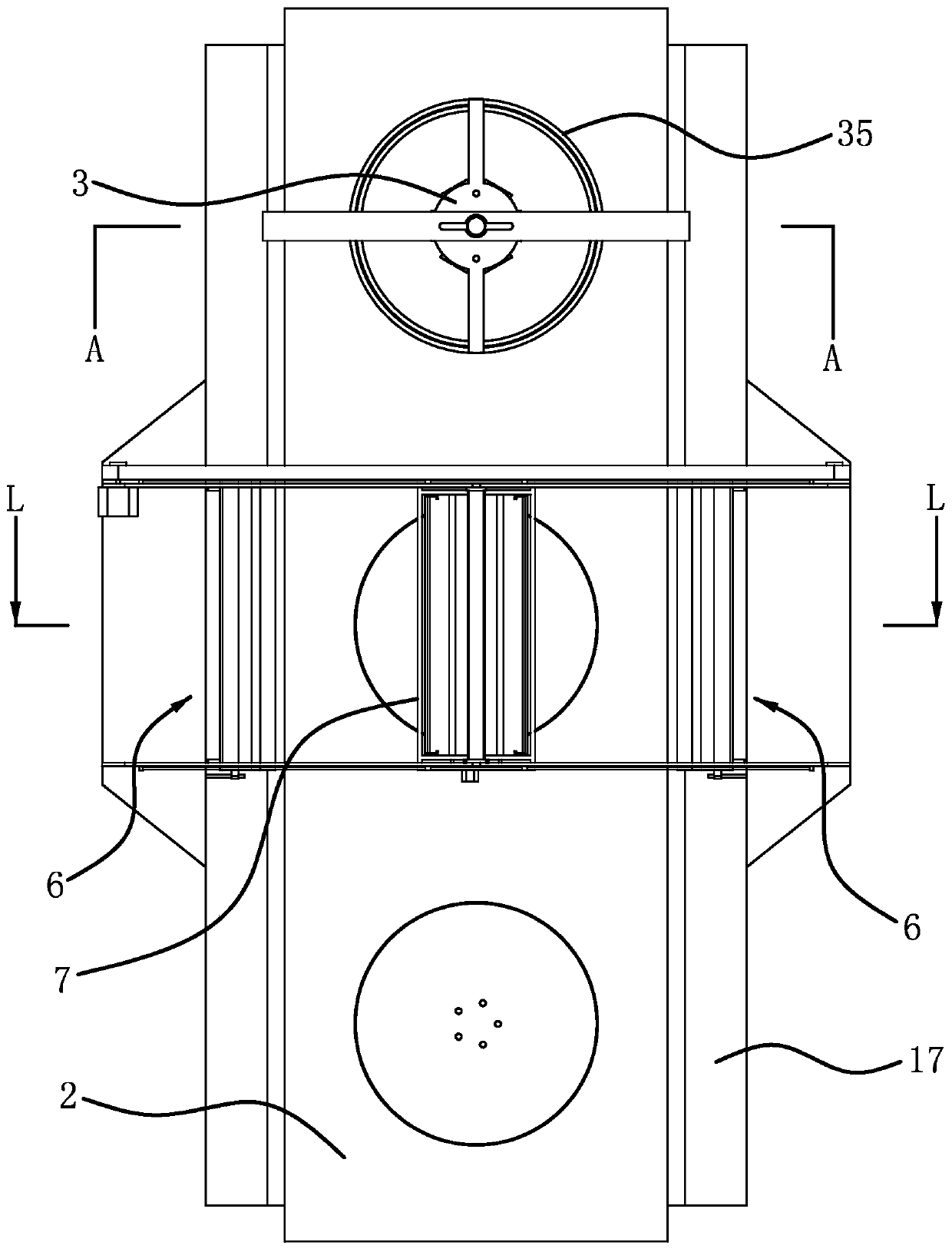

Multiple robot system

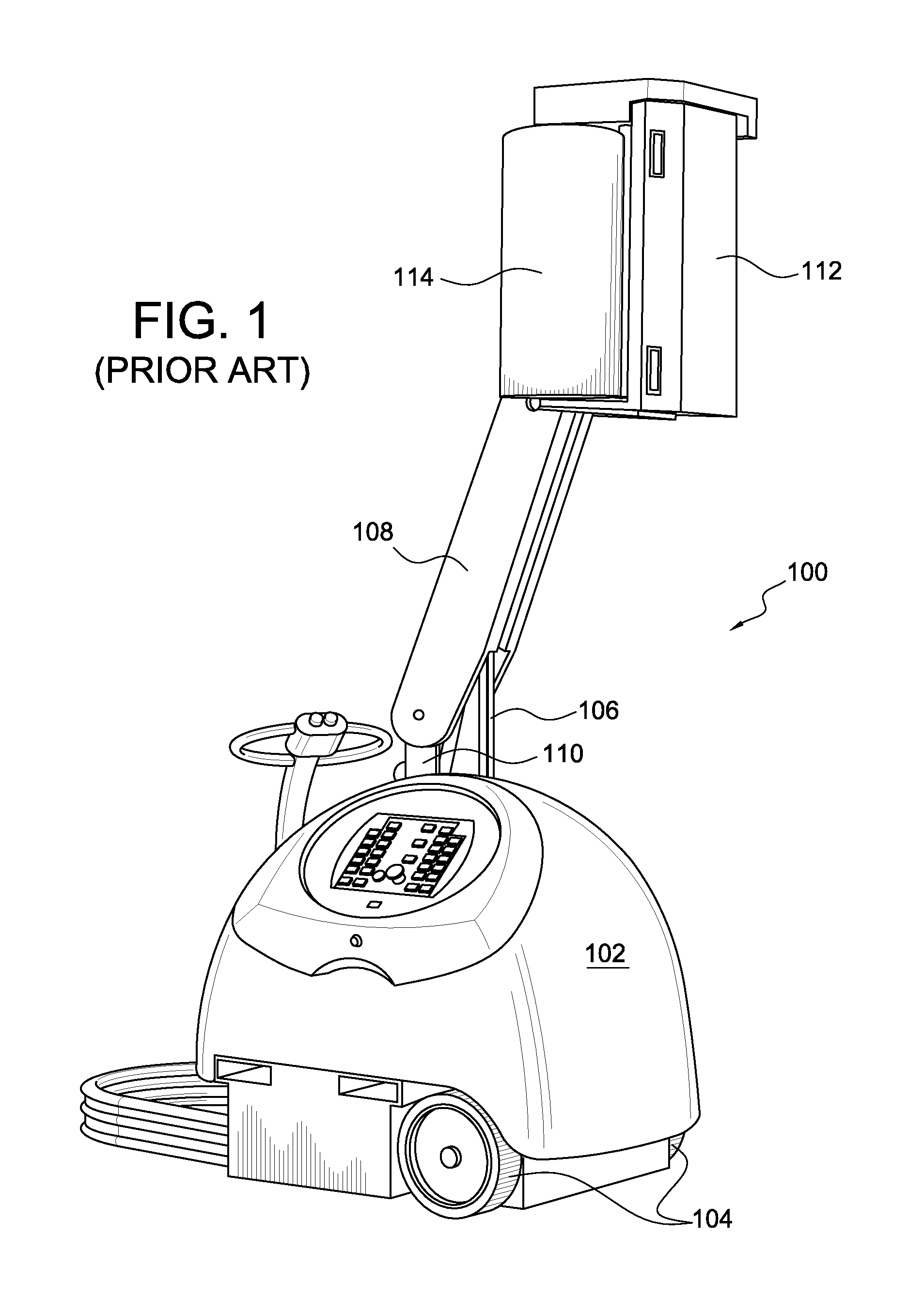

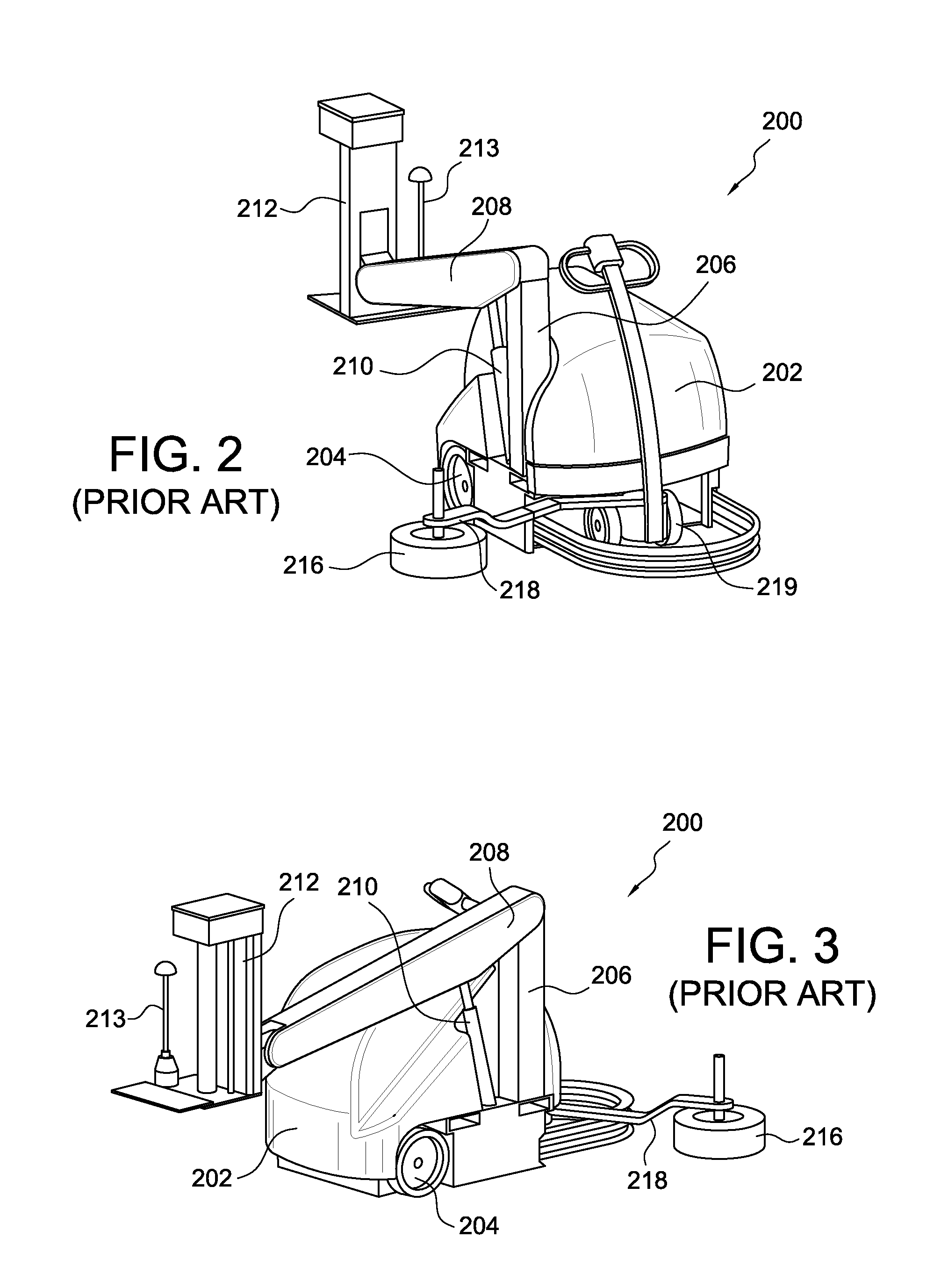

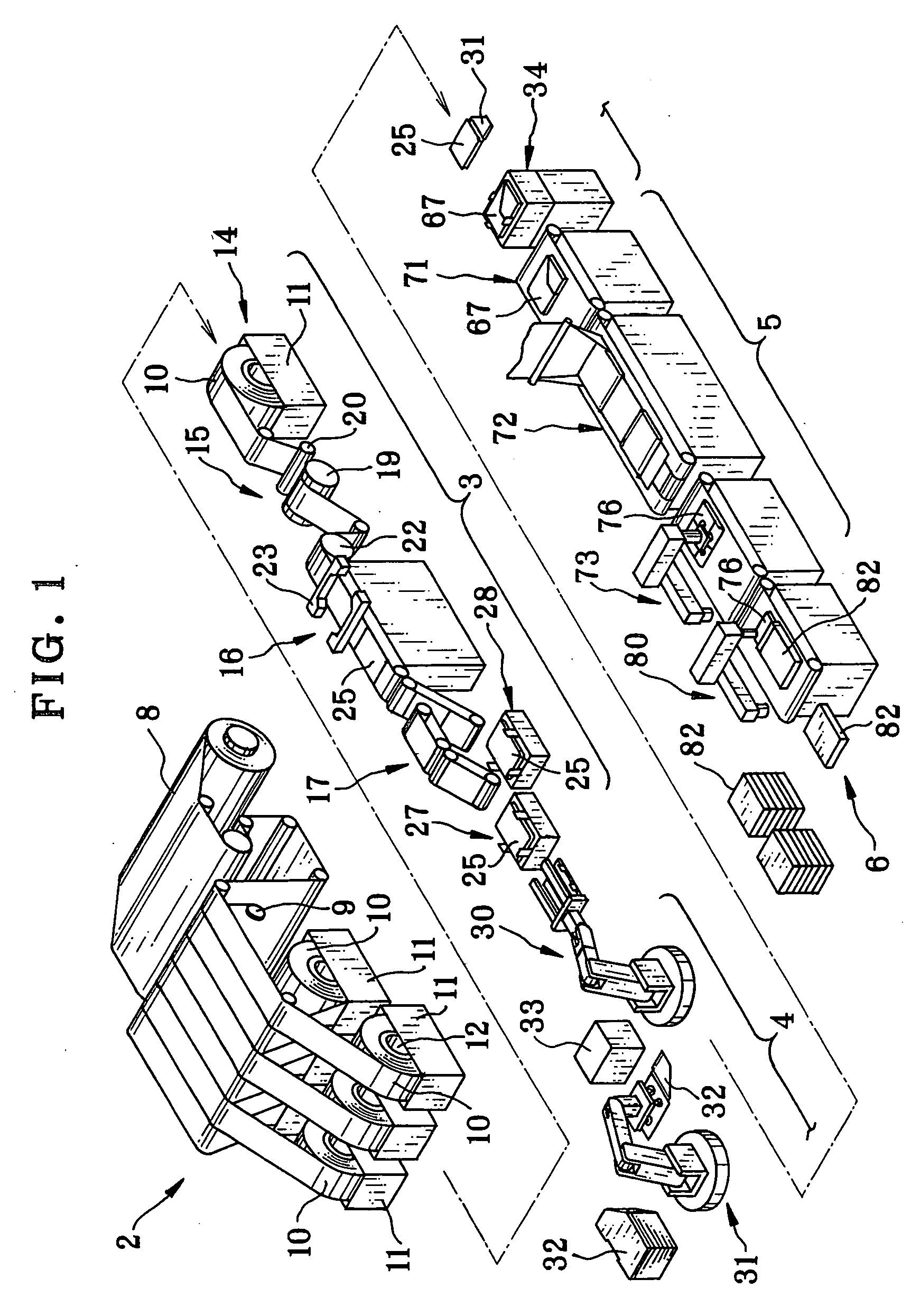

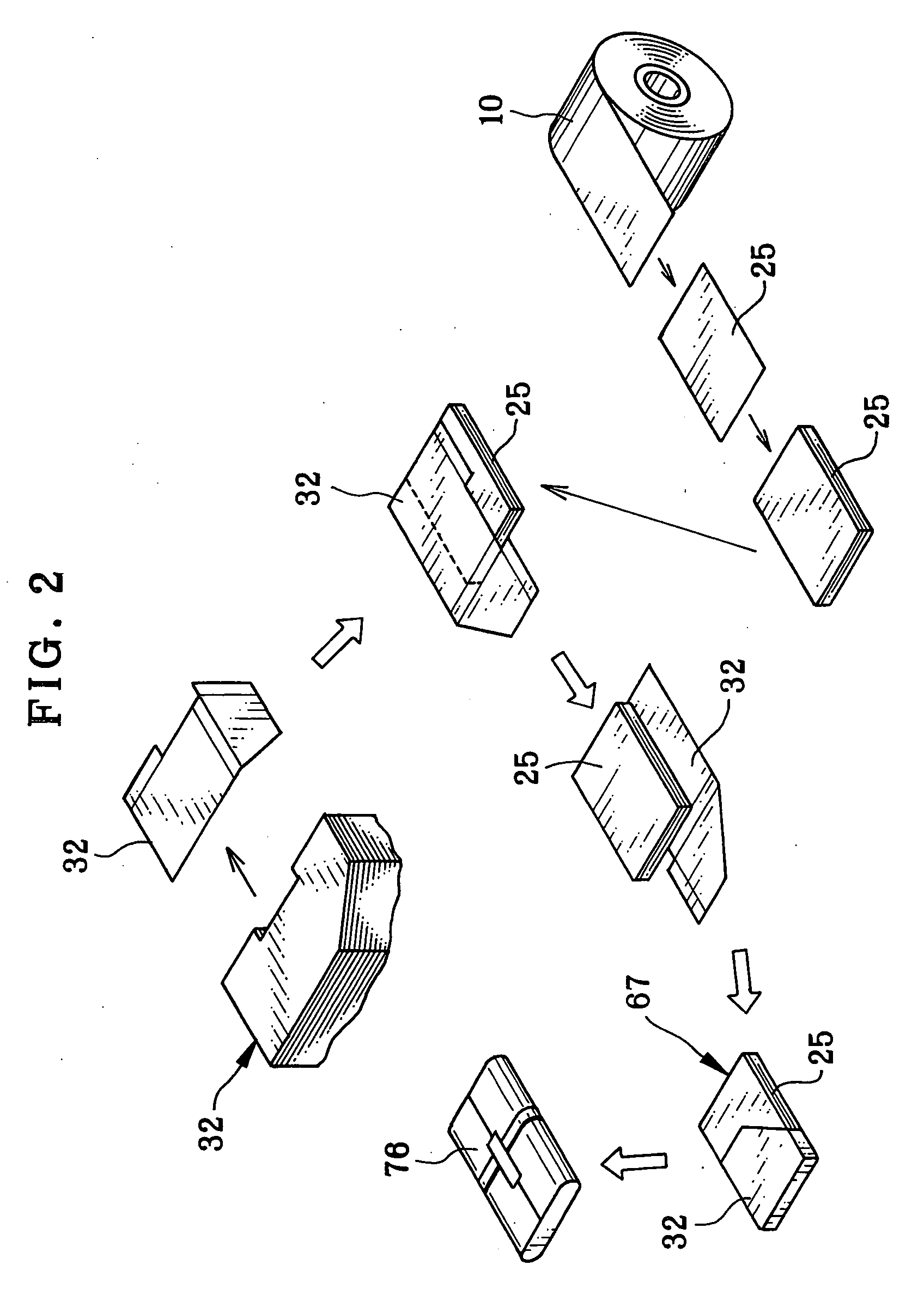

InactiveUS20130061558A1Web rotation wrappingWrapper folding/bending apparatusProgrammable logic controllerMultirobot systems

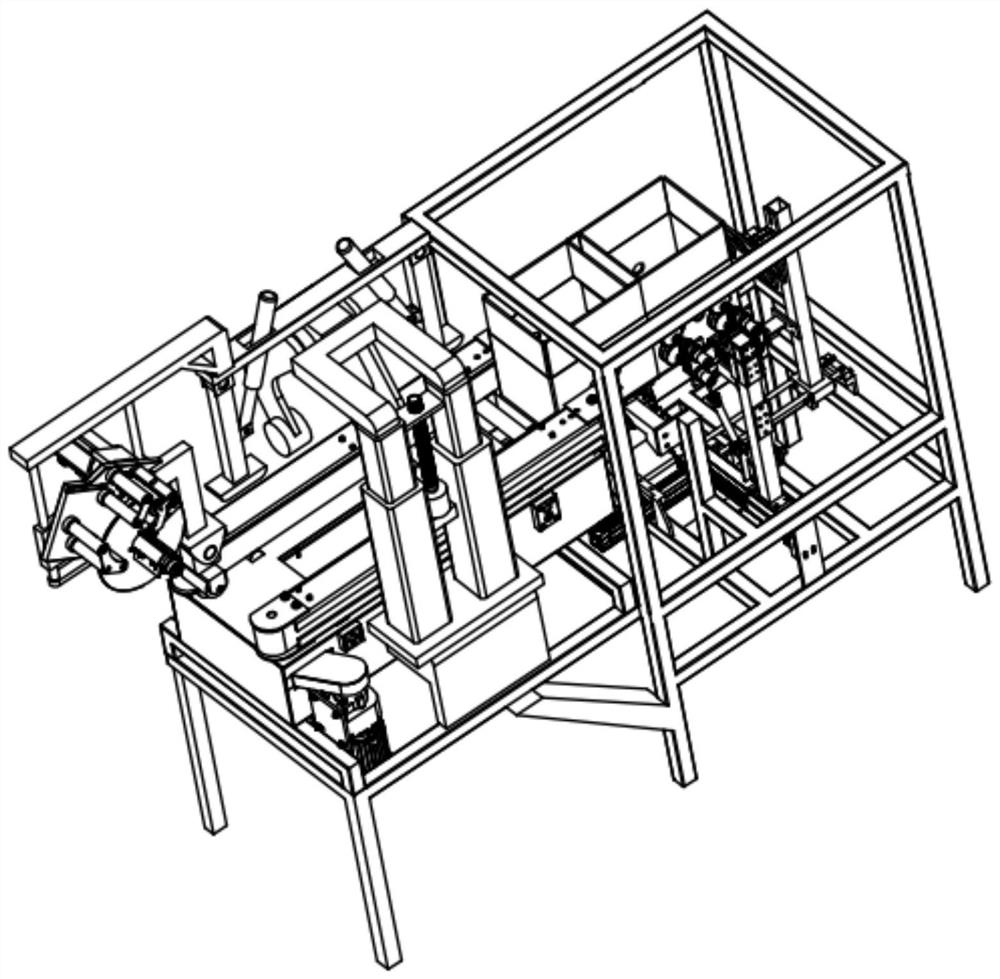

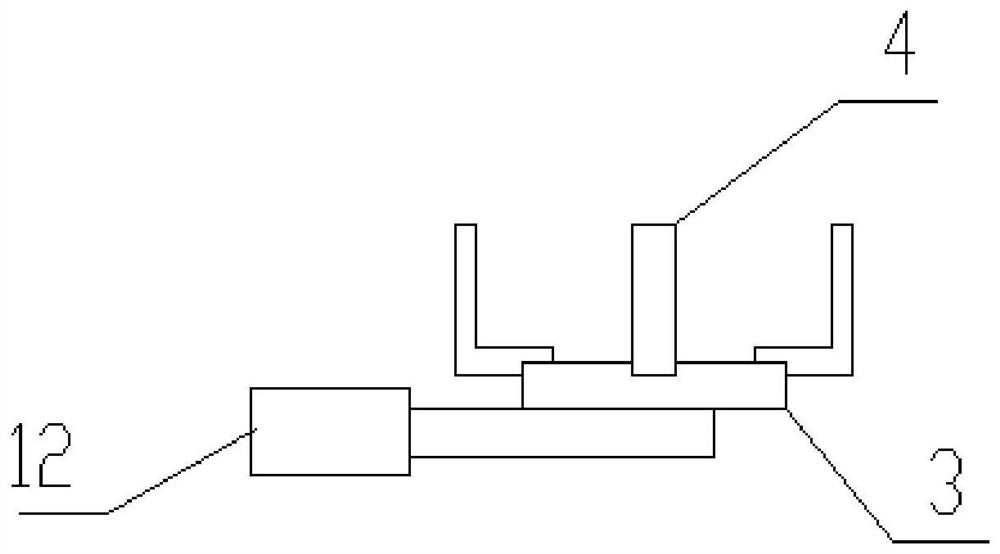

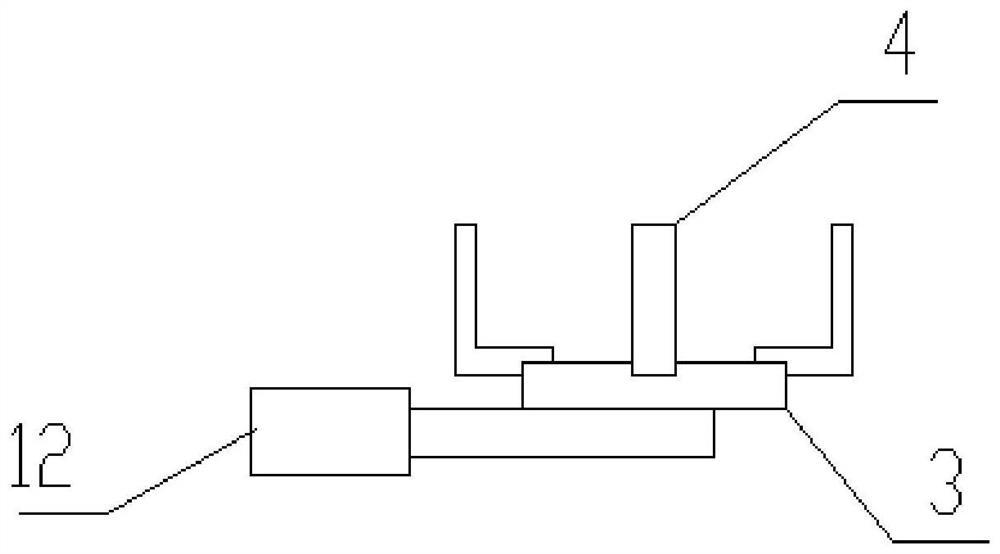

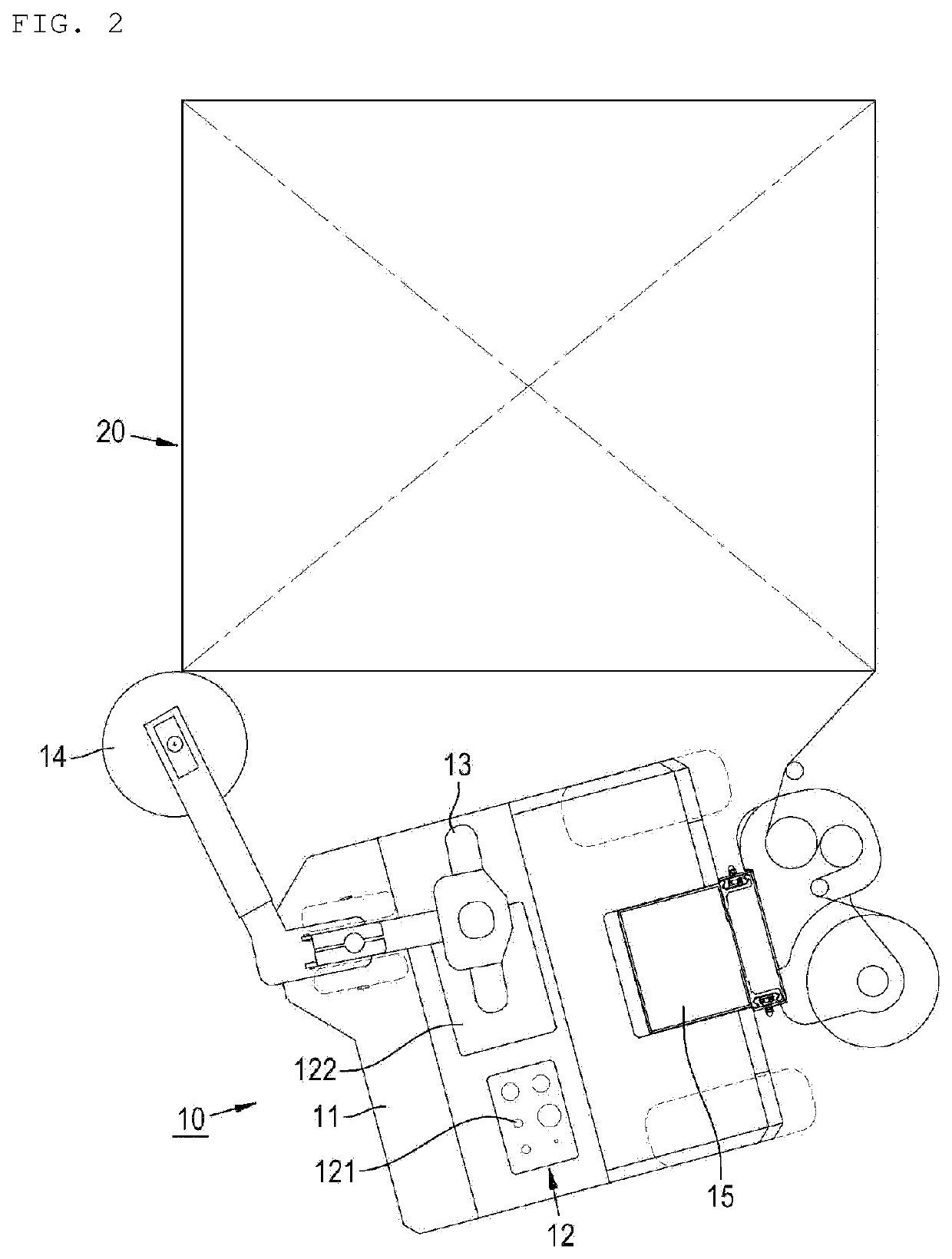

The present invention relates generally to film wrapping or packaging systems, and more particularly to a new and improved robotic film wrapping or packaging system which is not only substantially entirely automatic in its operation except for its initialization or START procedure, but in addition, a single programmable logic controller (PLC) can control the cyclic operations of one or more film wrapping or packaging robots.

Owner:SIGNODE IND GRP

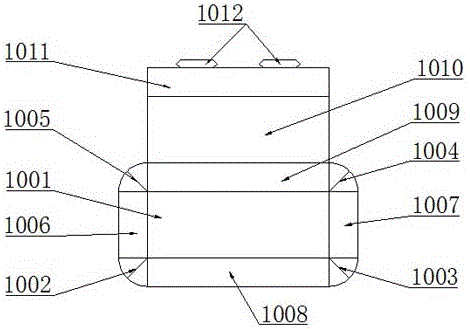

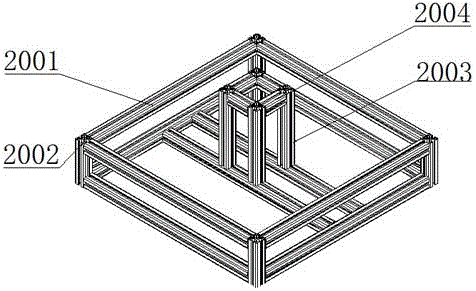

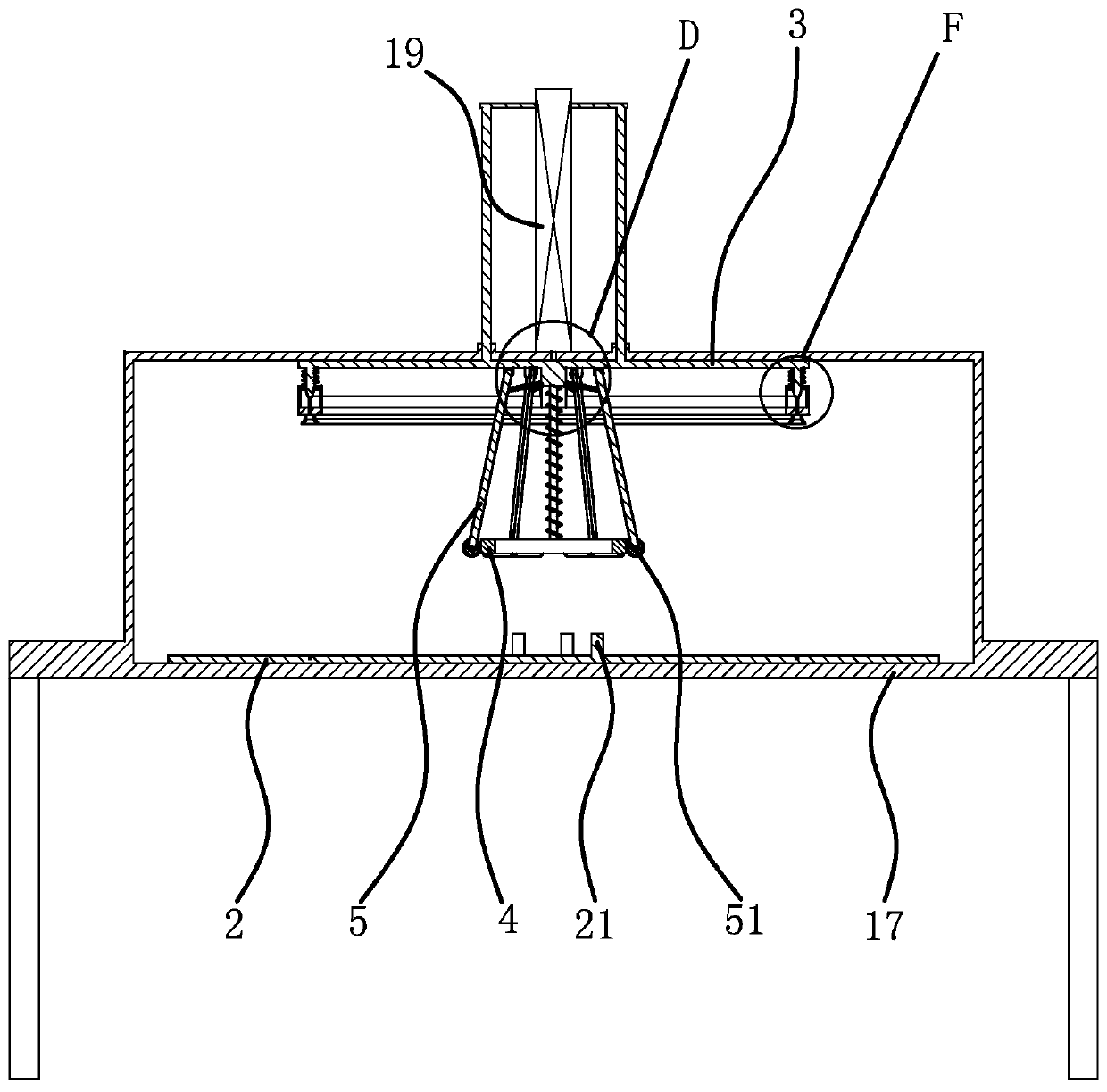

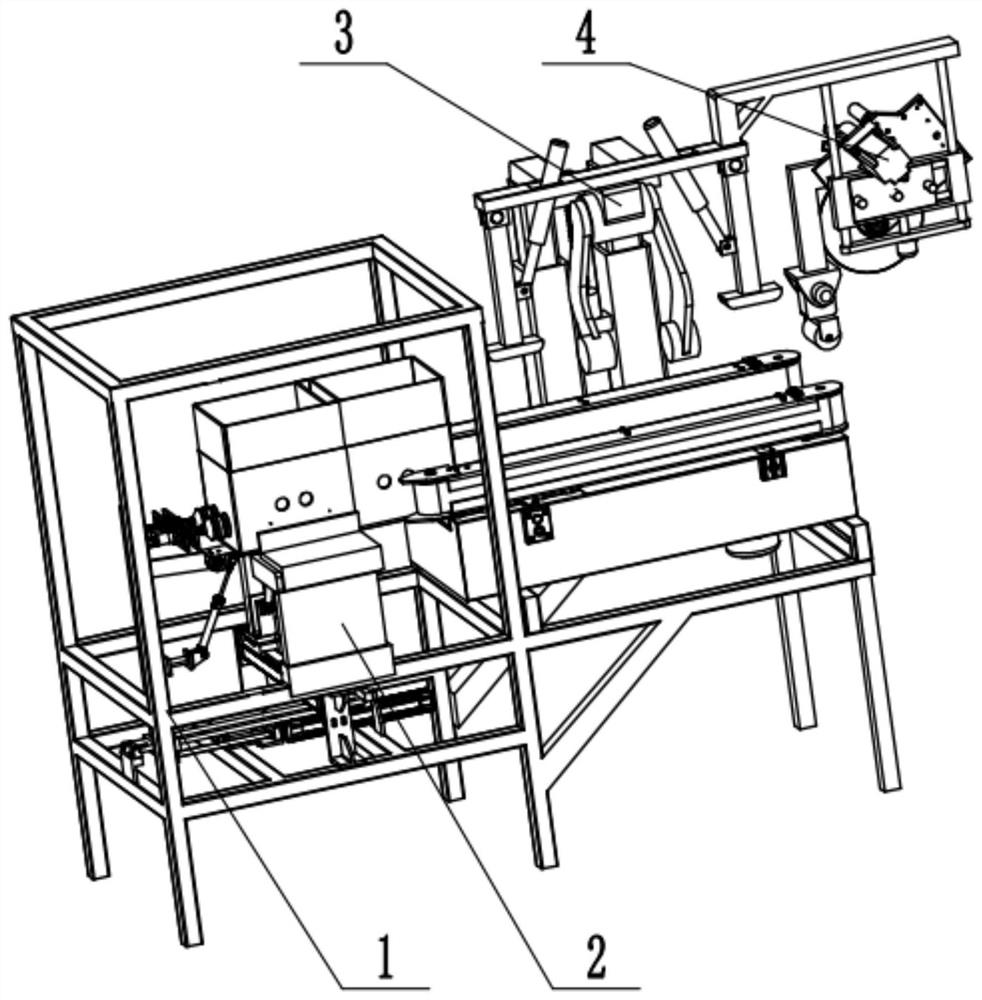

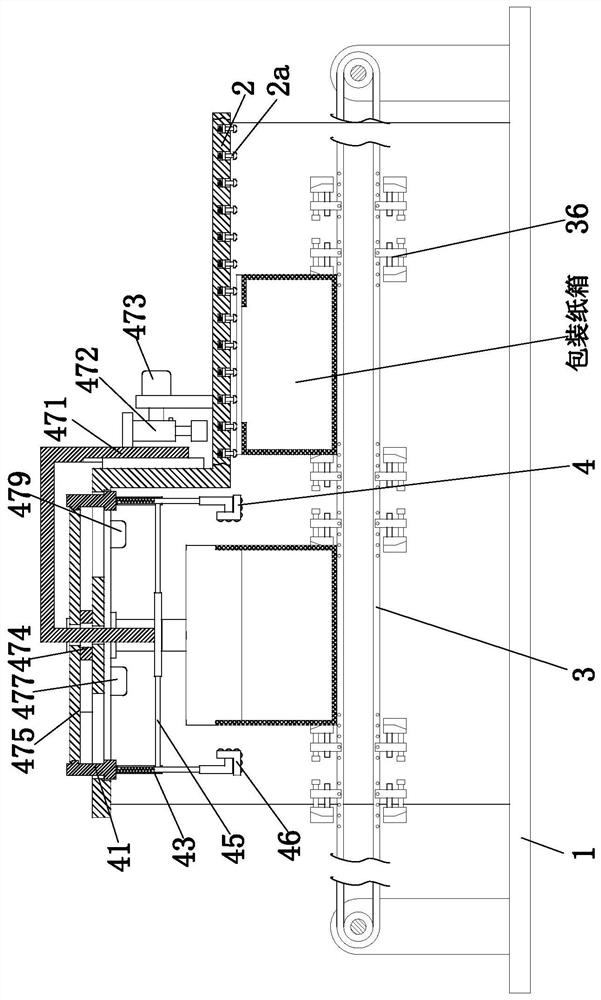

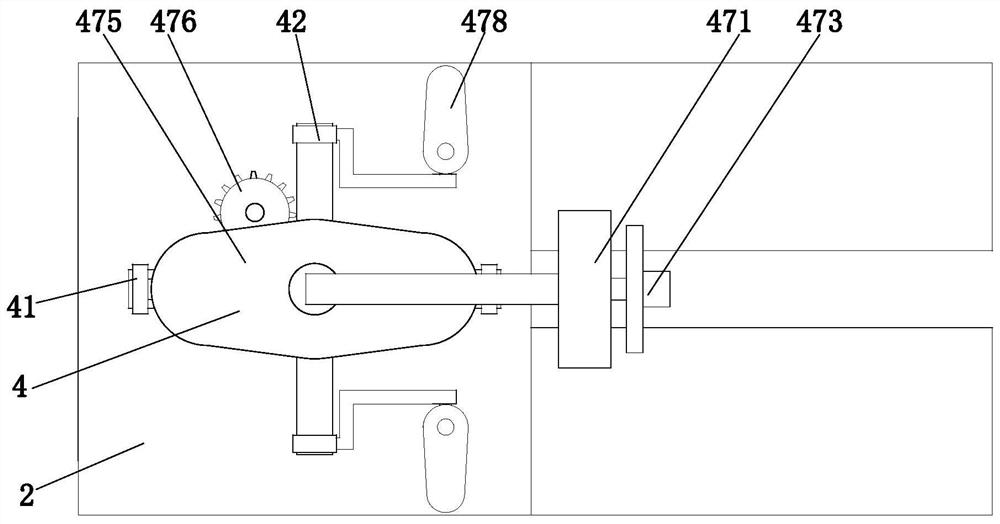

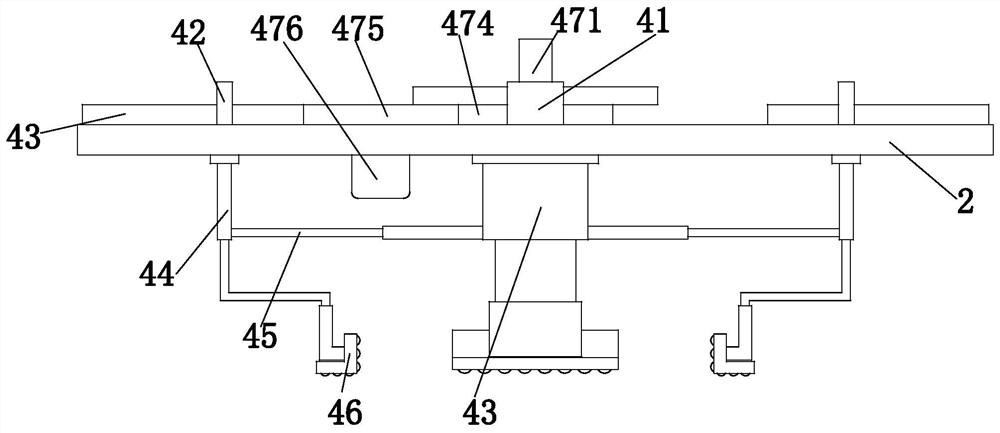

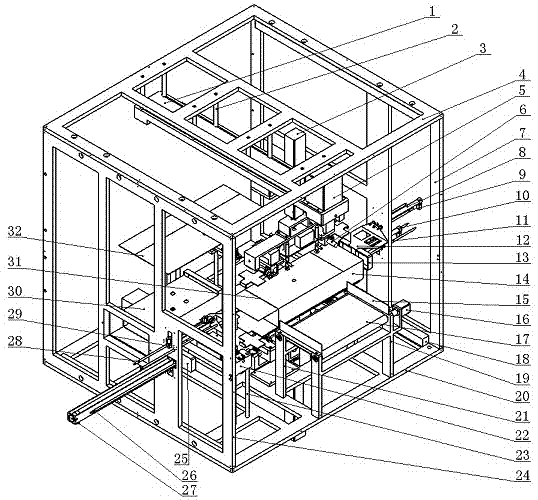

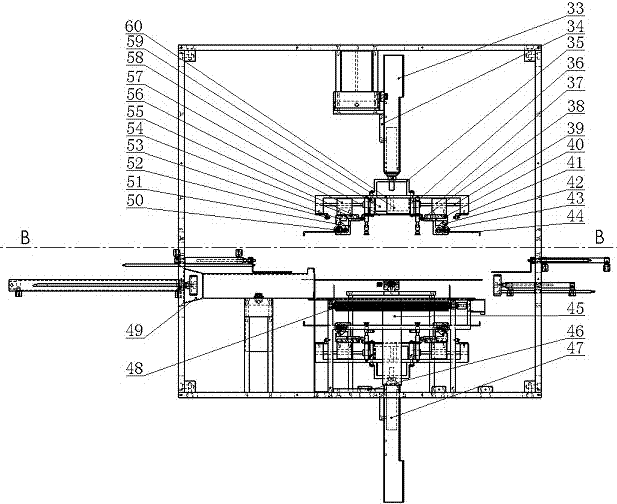

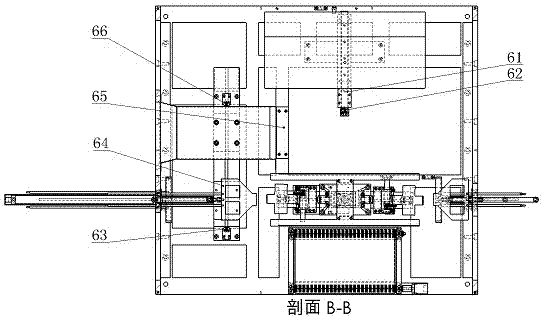

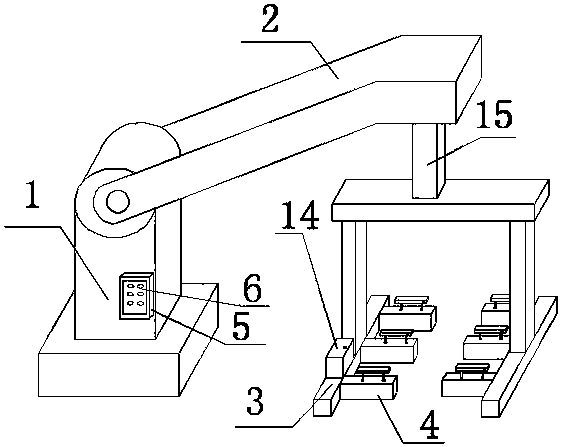

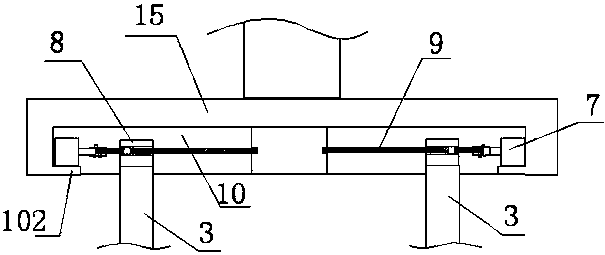

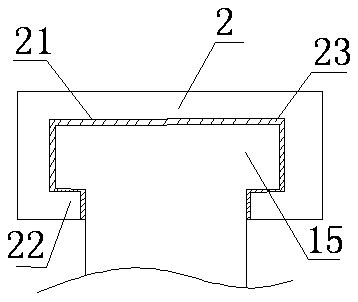

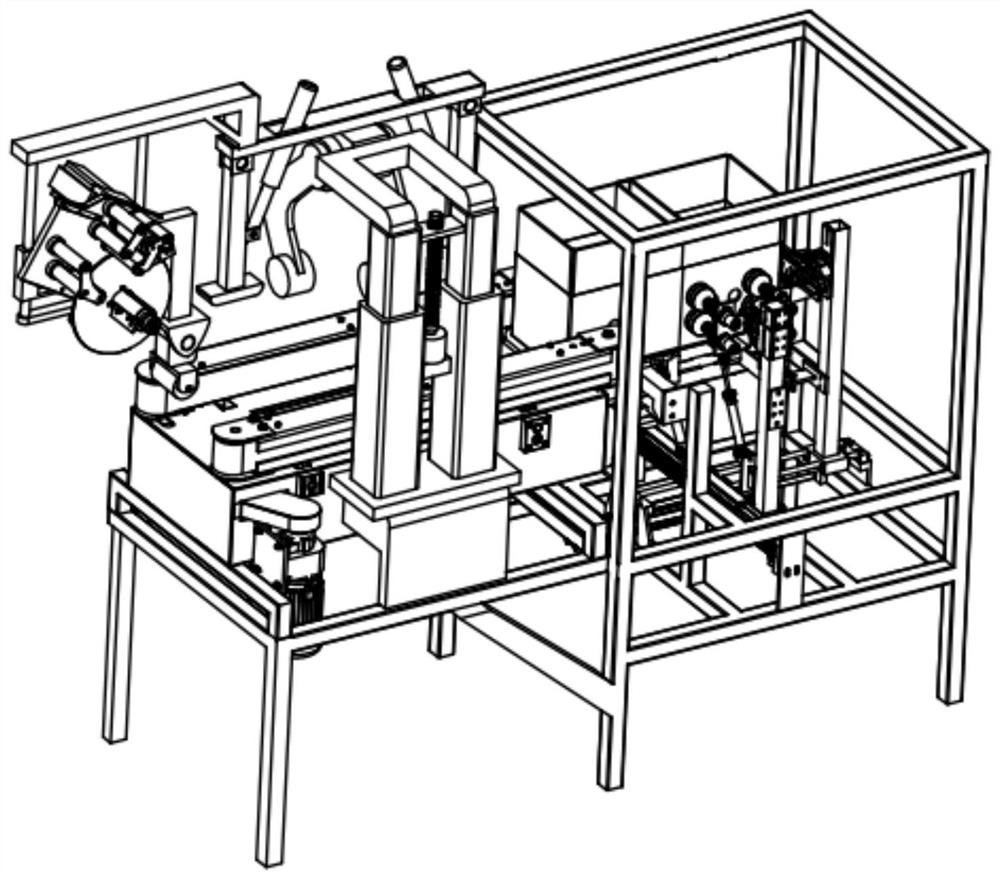

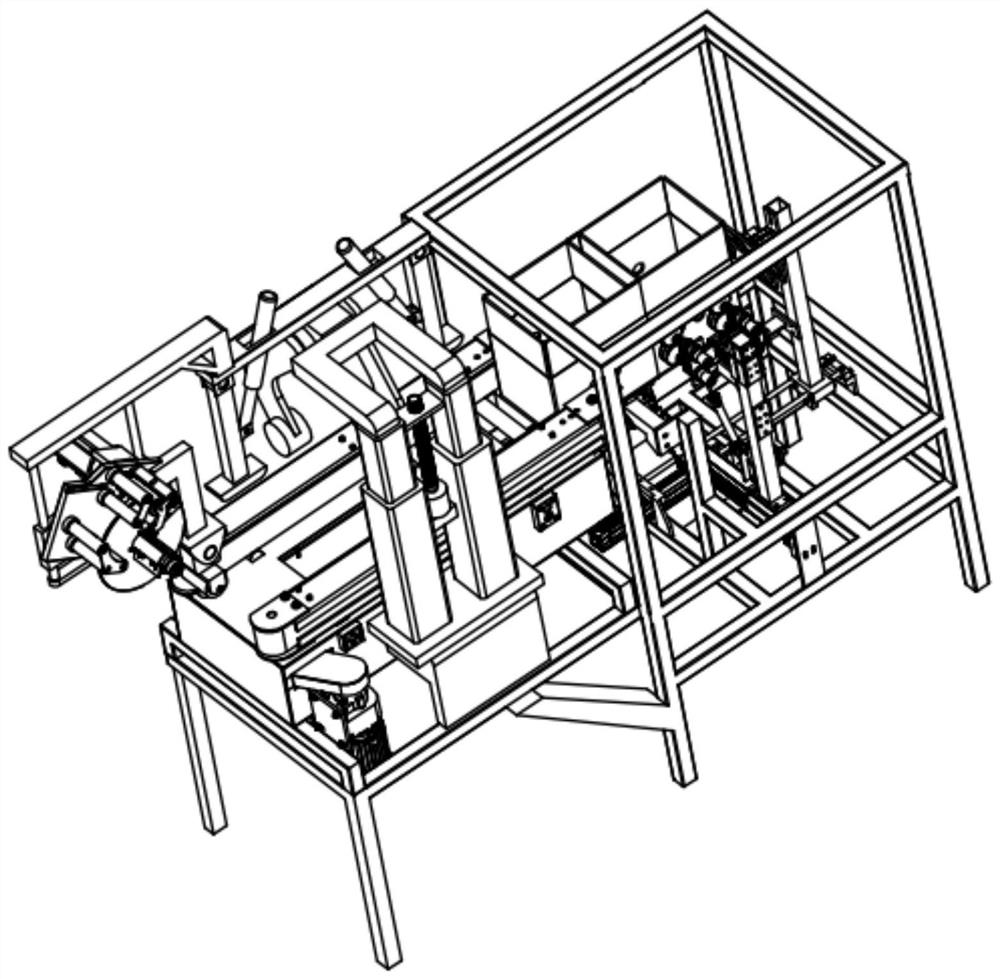

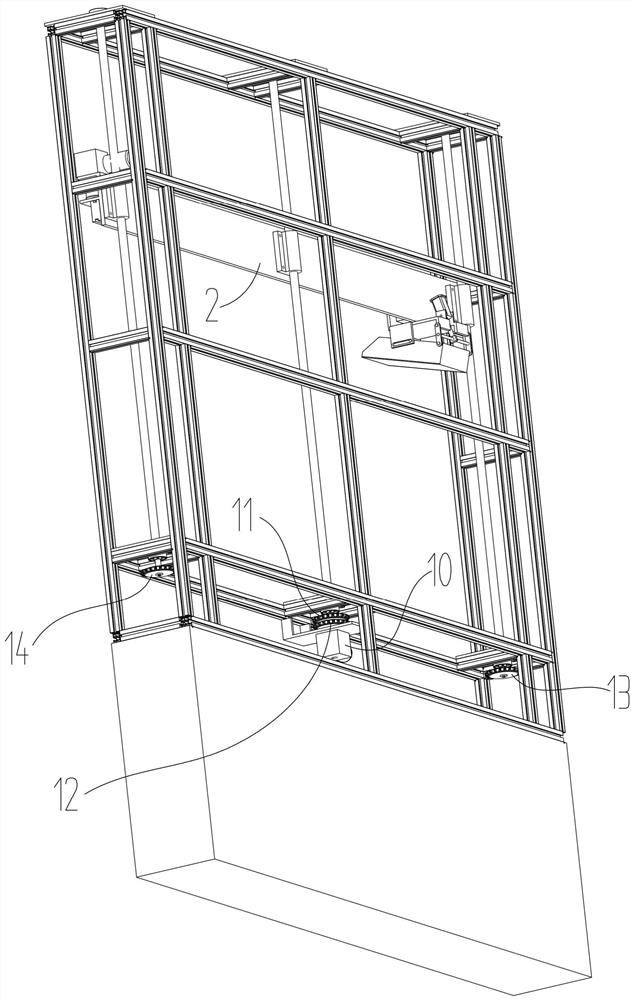

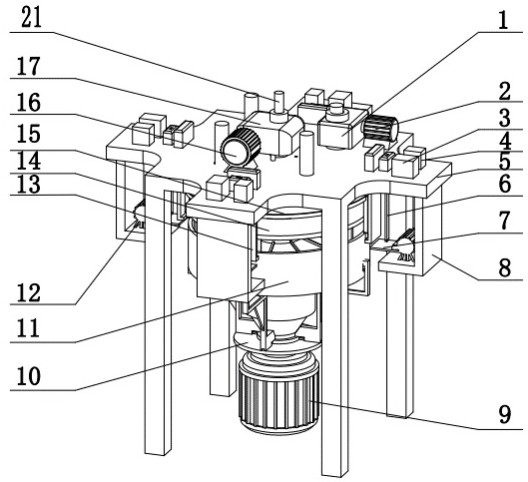

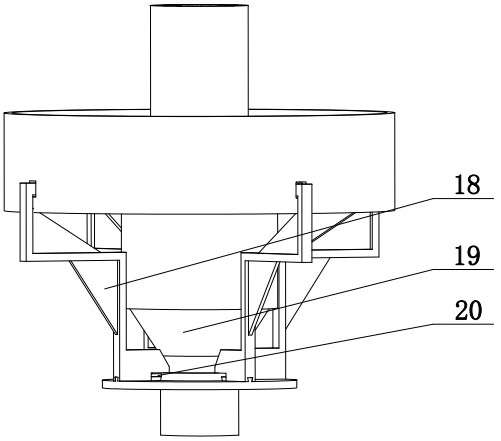

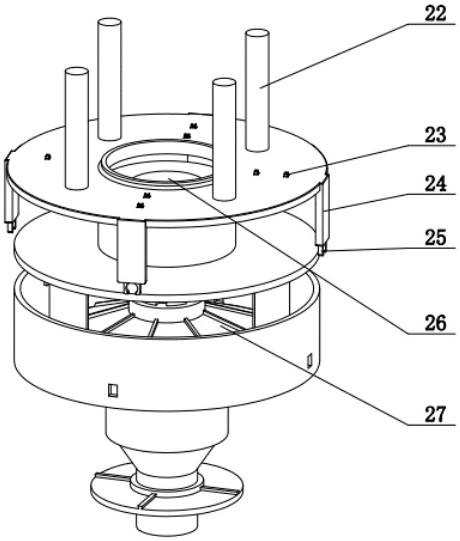

Carton inserting tongue packaging robot capable of being adaptive to trays with various specifications

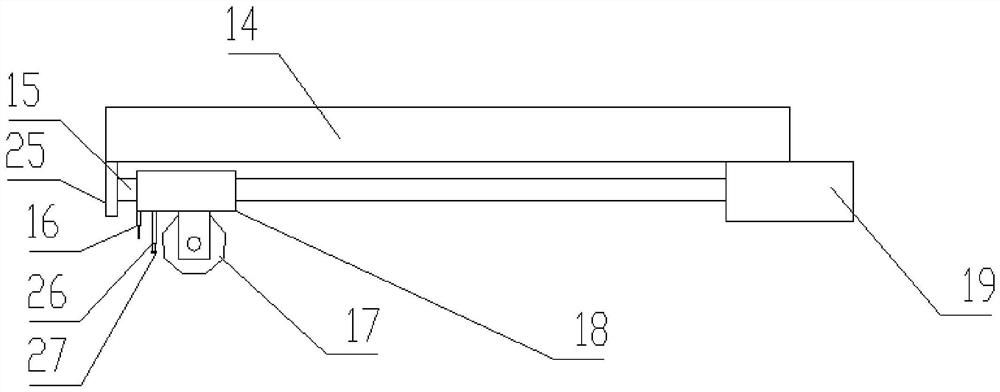

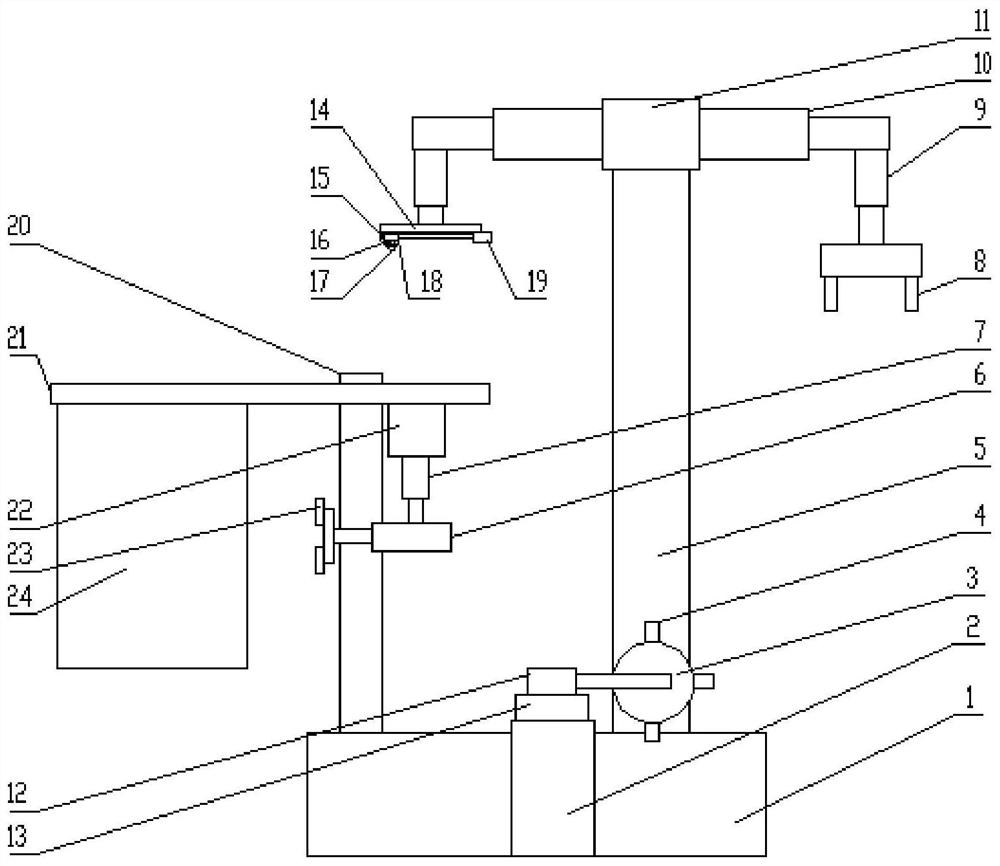

The invention provides a carton inserting tongue packaging robot capable of being adaptive to trays with various specifications and relates to carton packaging machinery, aiming at solving the technical problems that an existing tray type carton packaging machine has a relatively large size and the carton packaging machine is lack of commonality. According to the carton inserting tongue packaging robot, a packaging adaptive adjusting device is connected with a base supporting device; a carton side edge body plate packaging device is fixed on a sliding block of the packaging adaptive adjusting device; a carton inserting tongue guiding device and a carton cover plate folding device are fixedly connected onto a front-side air cylinder connecting plate and a rear-side air cylinder connecting plate of the carton side edge body plate packaging device; a carton lacing folding device is fixed on a carton side edge body plate folding device through a U-shaped connecting plate; a carton fixing device is fixedly connected onto the base supporting device; a grasping mechanical arm device is fixedly connected onto the base supporting device. A control system is composed of a pneumatic control system and a motor control system. The carton inserting tongue packaging robot provided by the invention can be adaptive to cartons with different specifications; folding and closing package of tray type cartons is finished; one carton inserting tongue packaging robot has a plurality of functions.

Owner:ZHONGBEI UNIV

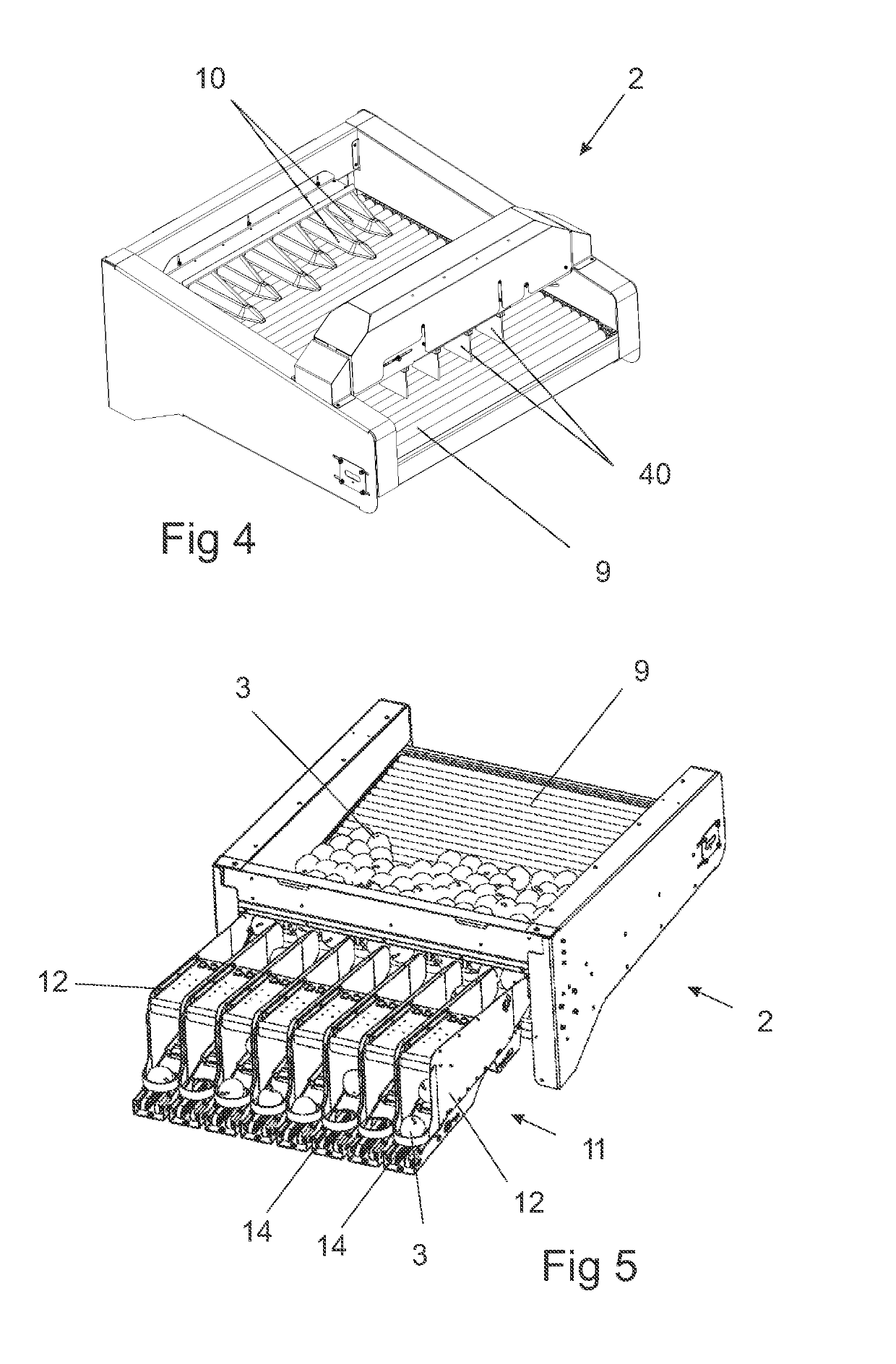

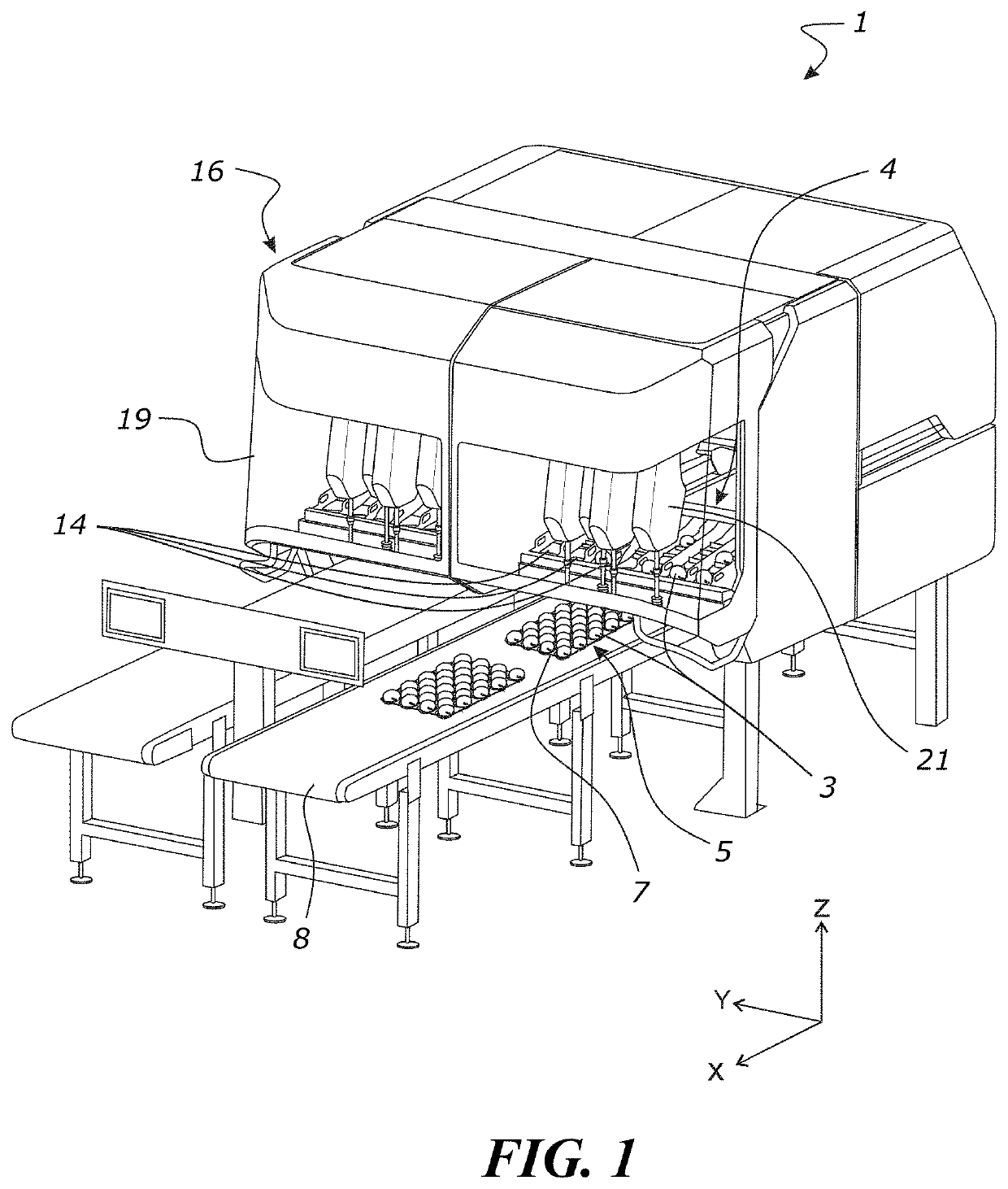

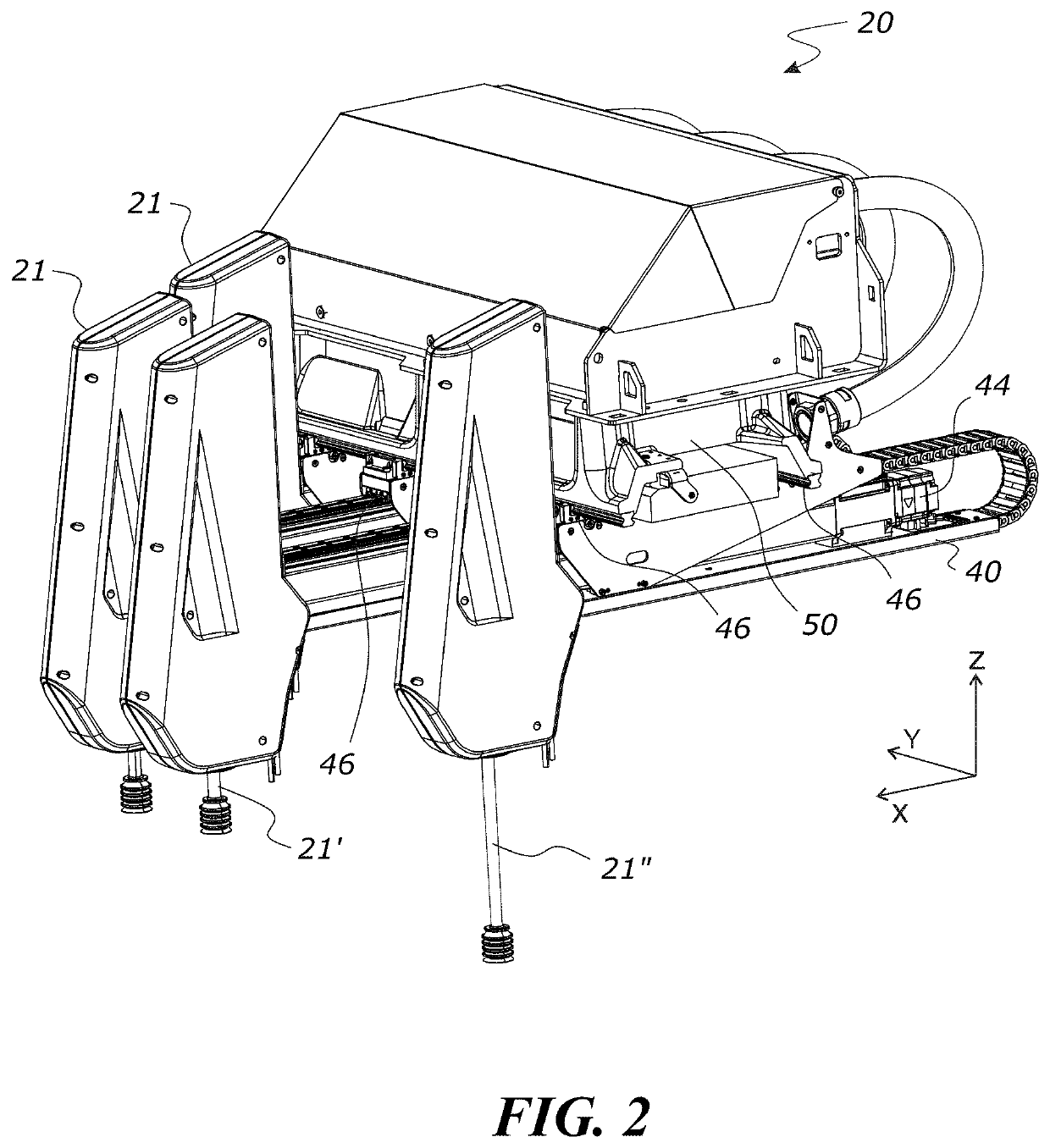

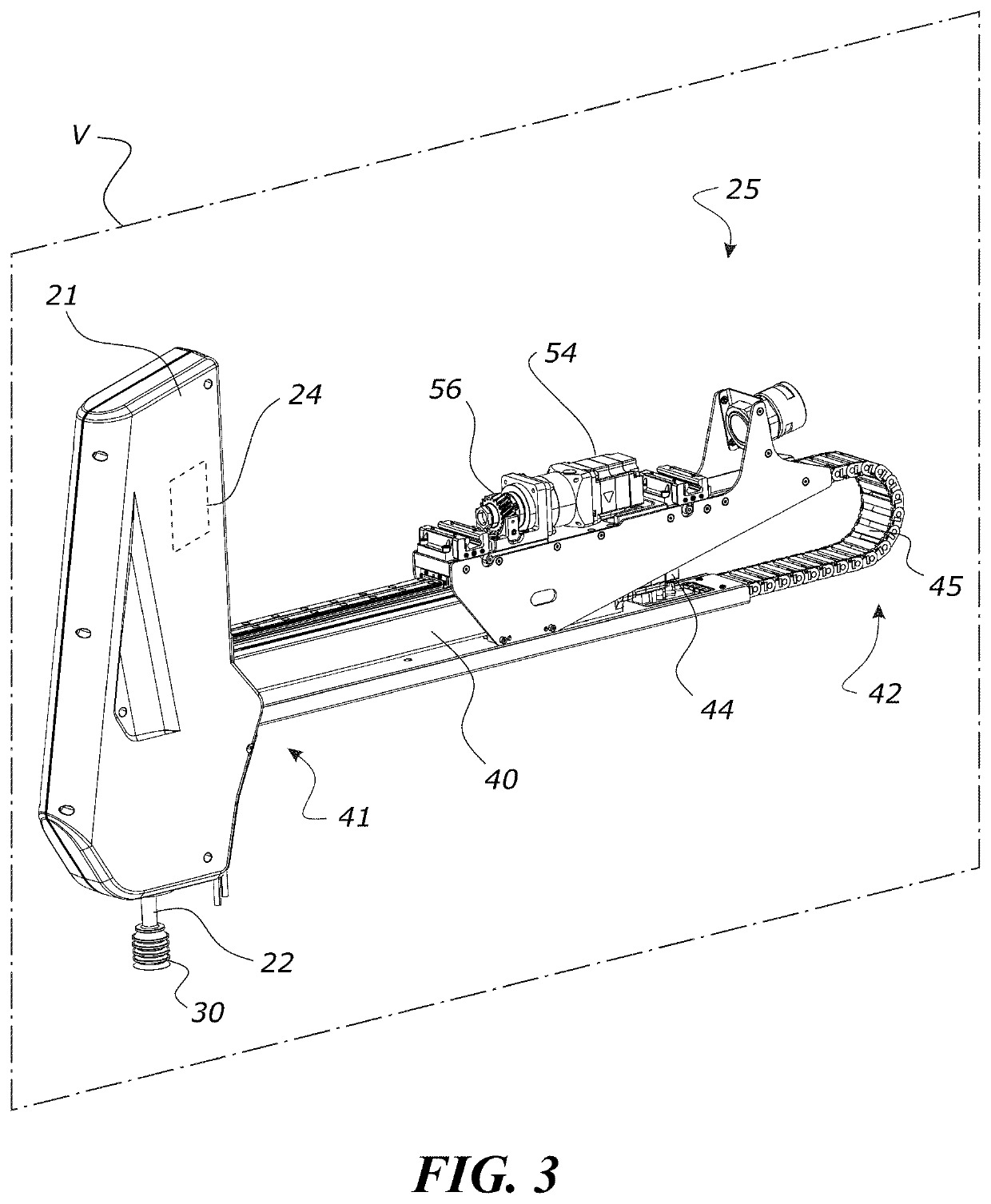

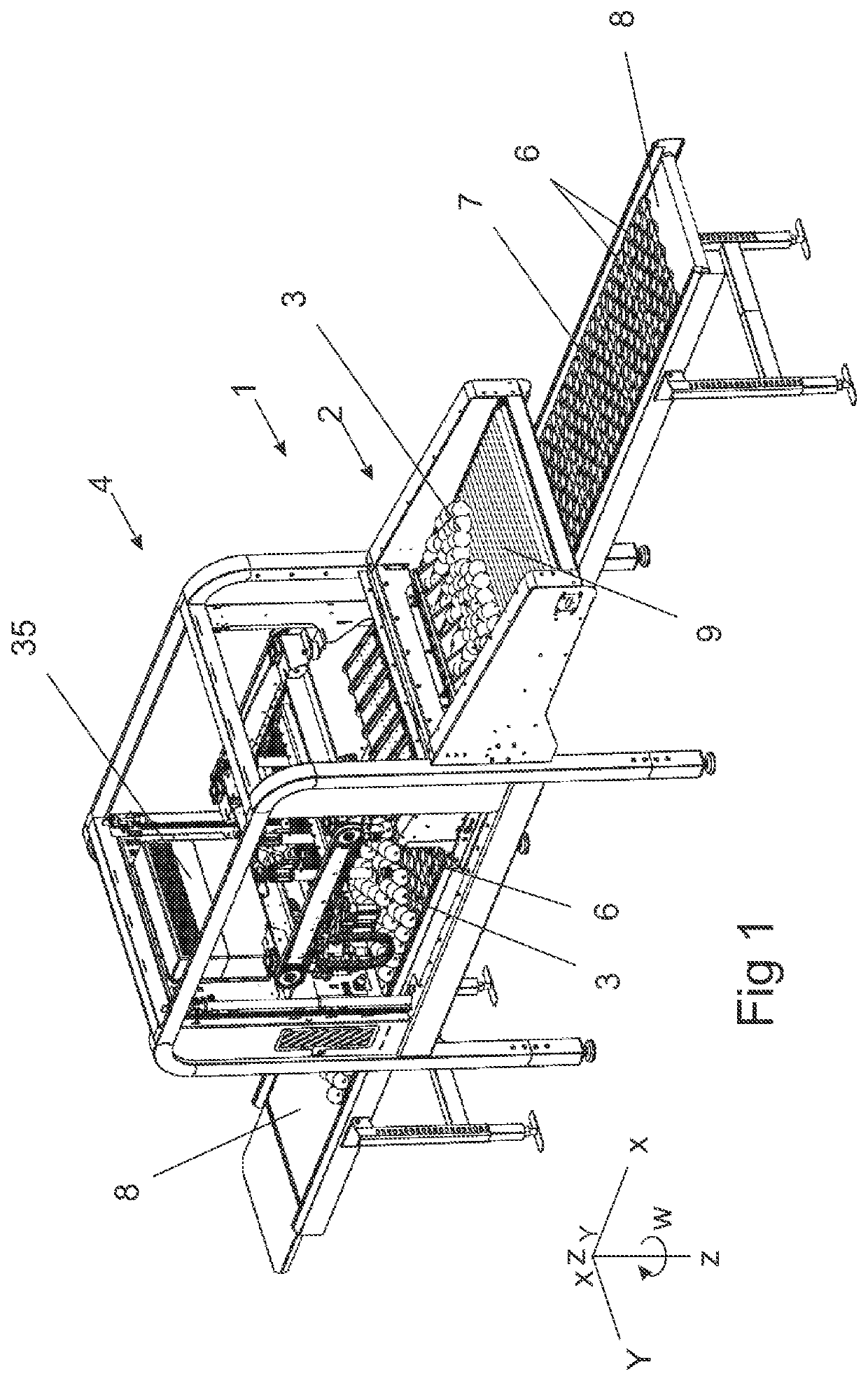

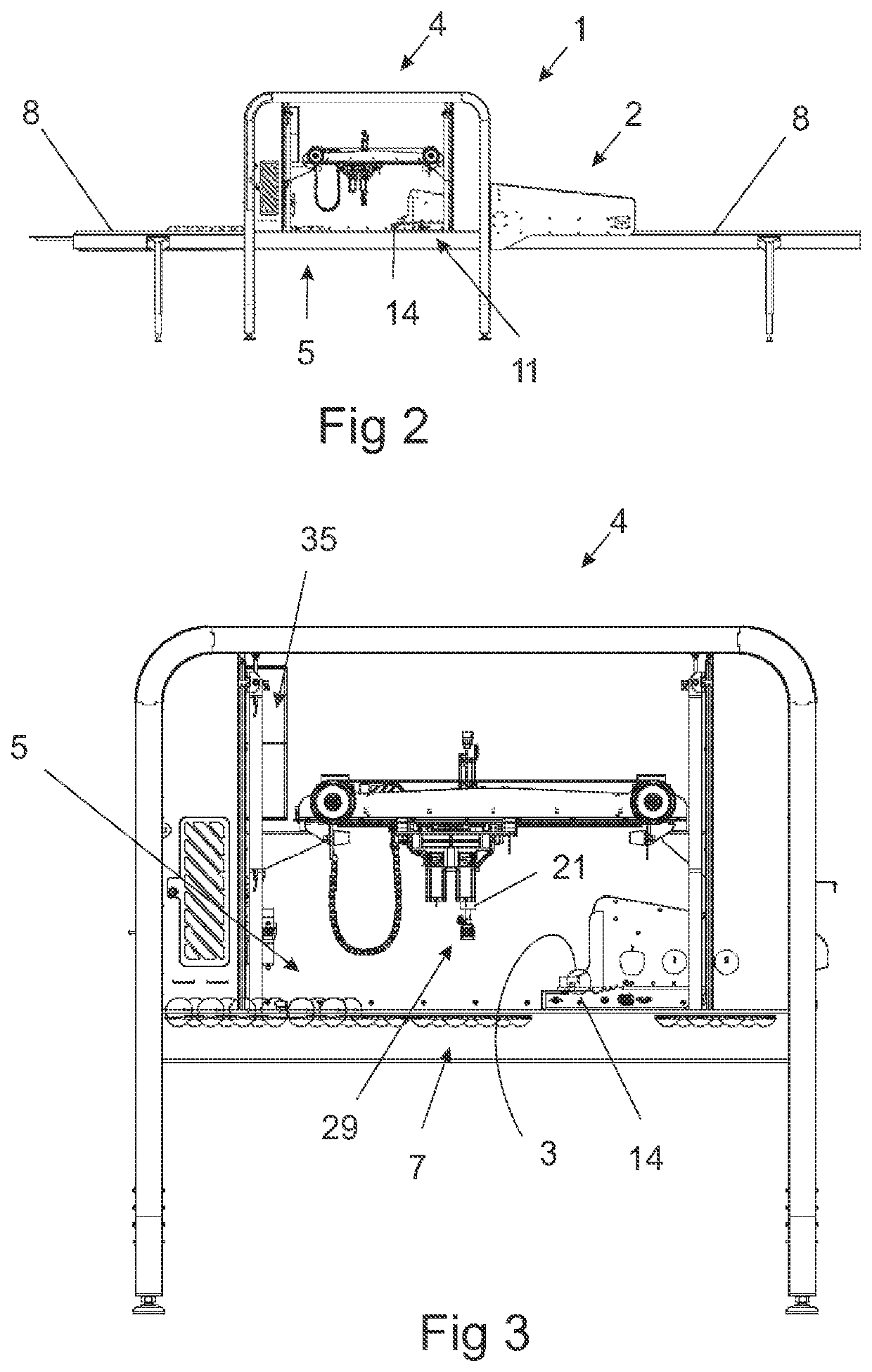

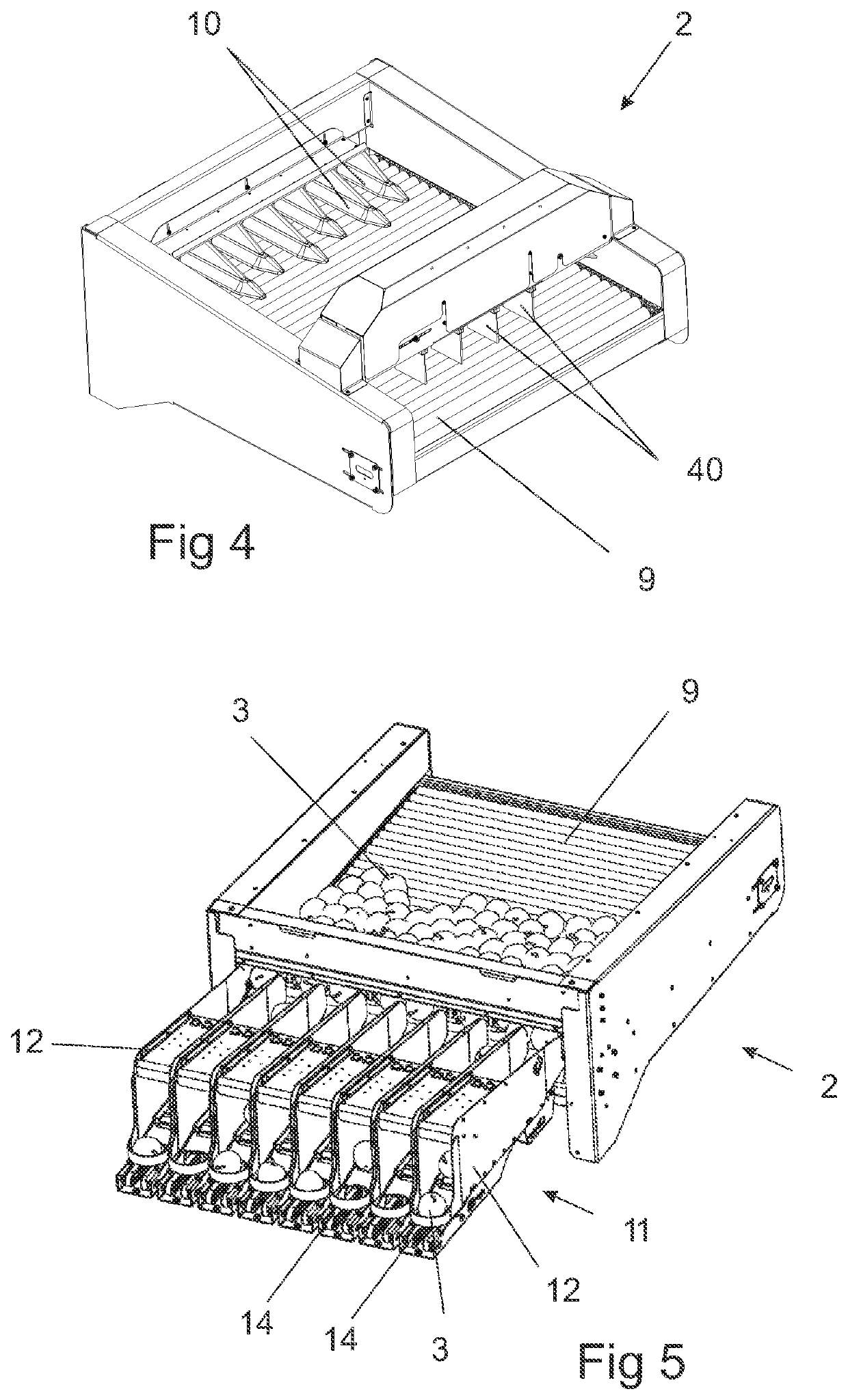

Packing robot

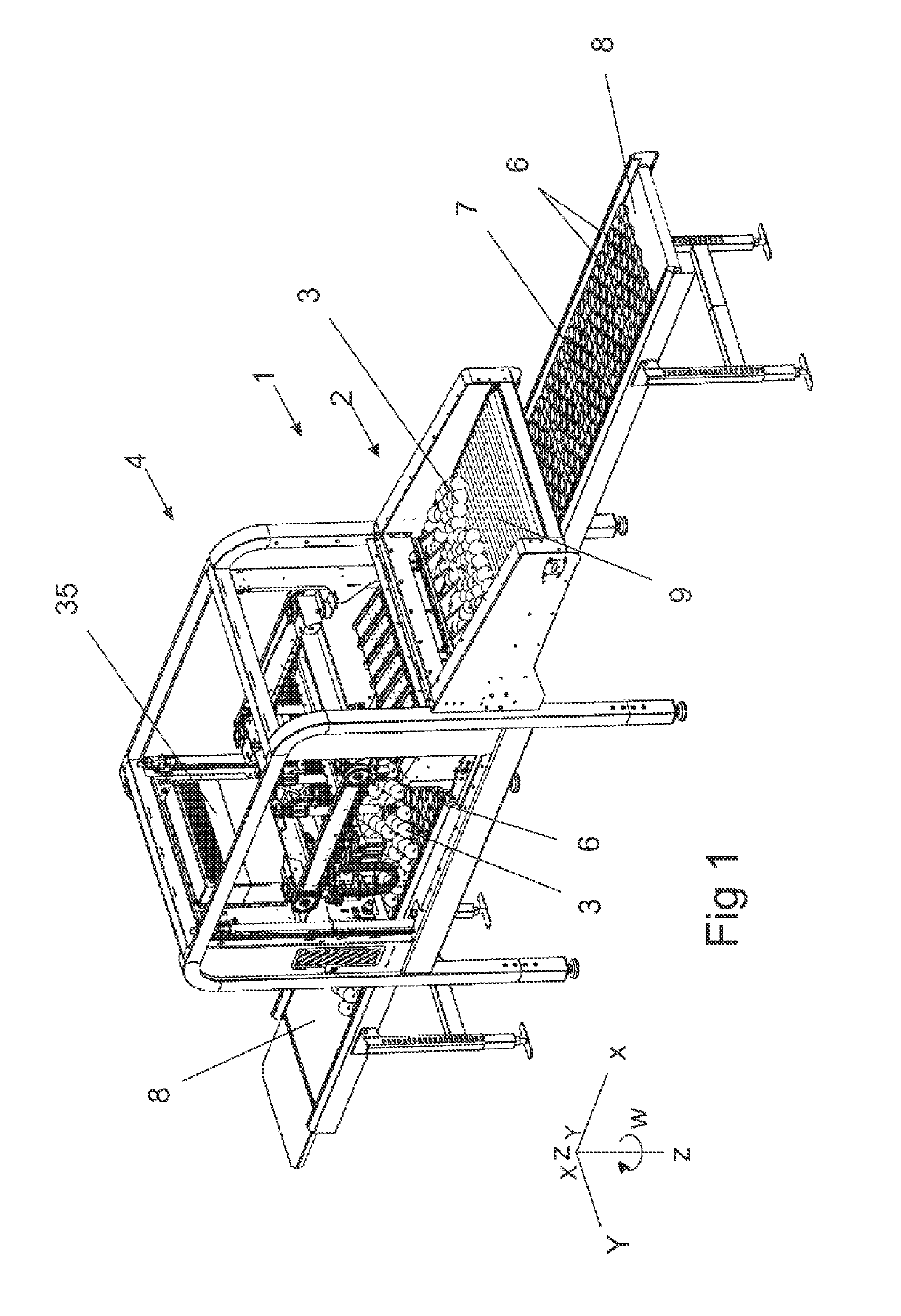

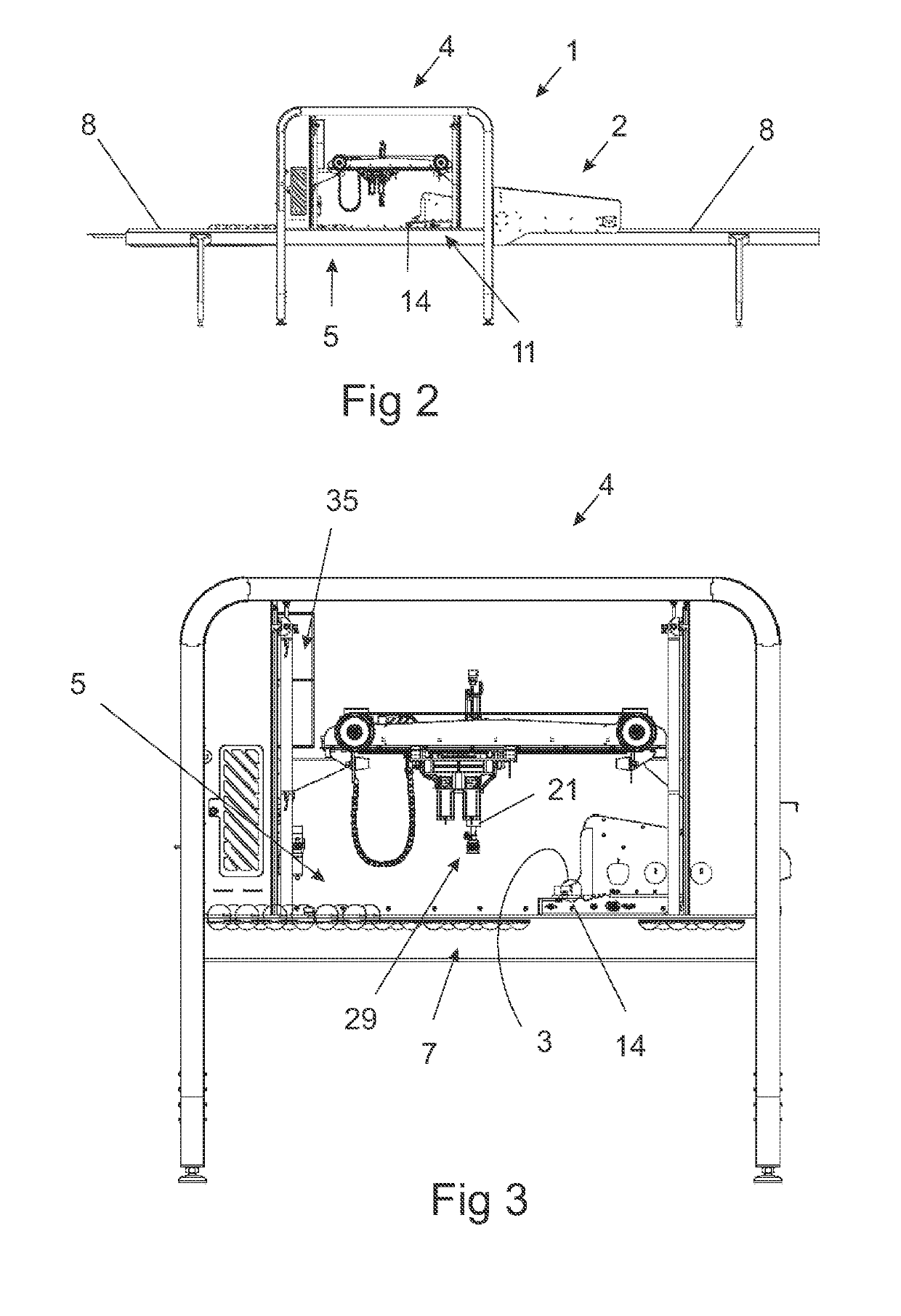

ActiveUS20190143542A1Minimize timeProgramme-controlled manipulatorGripping headsCommon railEngineering

A produce packing robot is provided comprising a plurality of heads for picking up items of produce from a plurality of pick-up locations, and moving the items of produce and dropping them off at a plurality of drop-off locations. The plurality of heads move together in a first direction on a common rail. The robot may also comprise a range imaging camera and controller for sensing the location of the drop-off points dynamically.

Owner:ROBOTICS PLUS LTD

Wheel hub cover packaging robot

The invention provides a wheel hub cover packaging robot, belongs to the technical field of mechanical equipment, and solves the problem that an existing wheel hub cover coating quality and efficiencyare relatively low. The wheel hub cover packaging robot comprises a rack and a conveyor belt. A film loading mechanism is arranged at the front end of the conveyor belt on the rack, a lifting plate is arranged above the back end of the conveyor belt on the rack, an inner pressure ring is connected to the lifting plate, a plurality of swing rods are arranged circumferentially on the outer side ofthe inner pressure ring, the upper ends of the swing rods incline inward radially and are hinged to the lifting plate, the lower ends of the swing rods are rotatably connected to push rollers, reset tension springs are connected between the swing rods and the lifting plate, a slicer is also fixedly connected to the lifting plate, and when the lower ends of the swing rods swing outward to unfold, the slicer can lean against the conveyor belt, and an outer pressure ring is circumferentially connected to the slicer. The wheel hub cover packaging robot can adhere and coat the wheel hub cover by aprotecting film, so that the coating quality and efficiency are improved.

Owner:徐州朗华机械有限公司

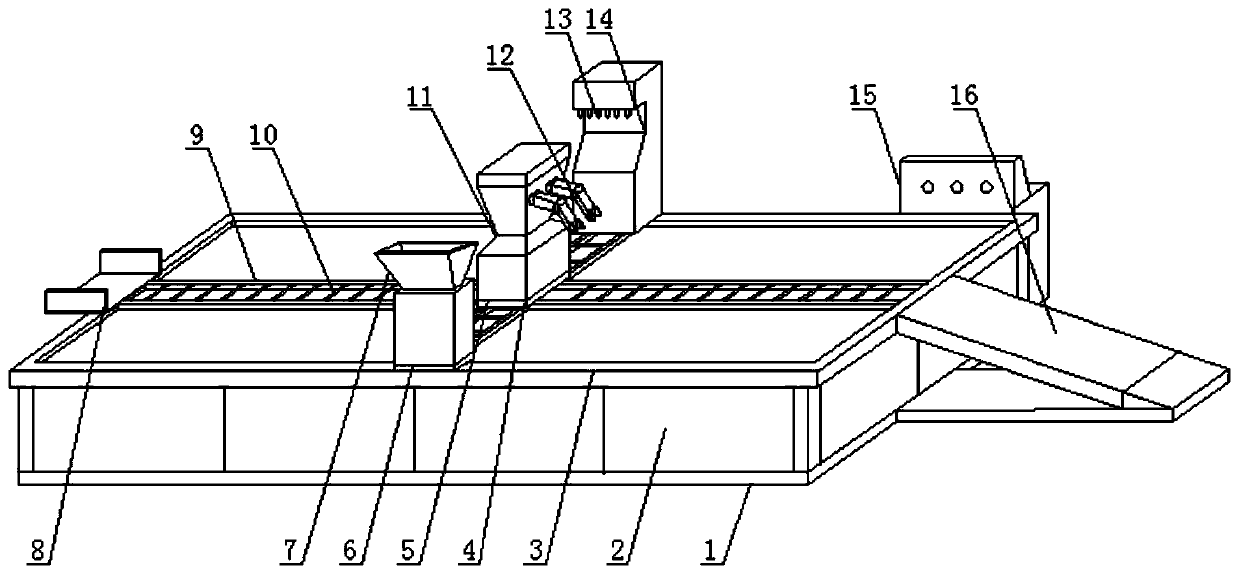

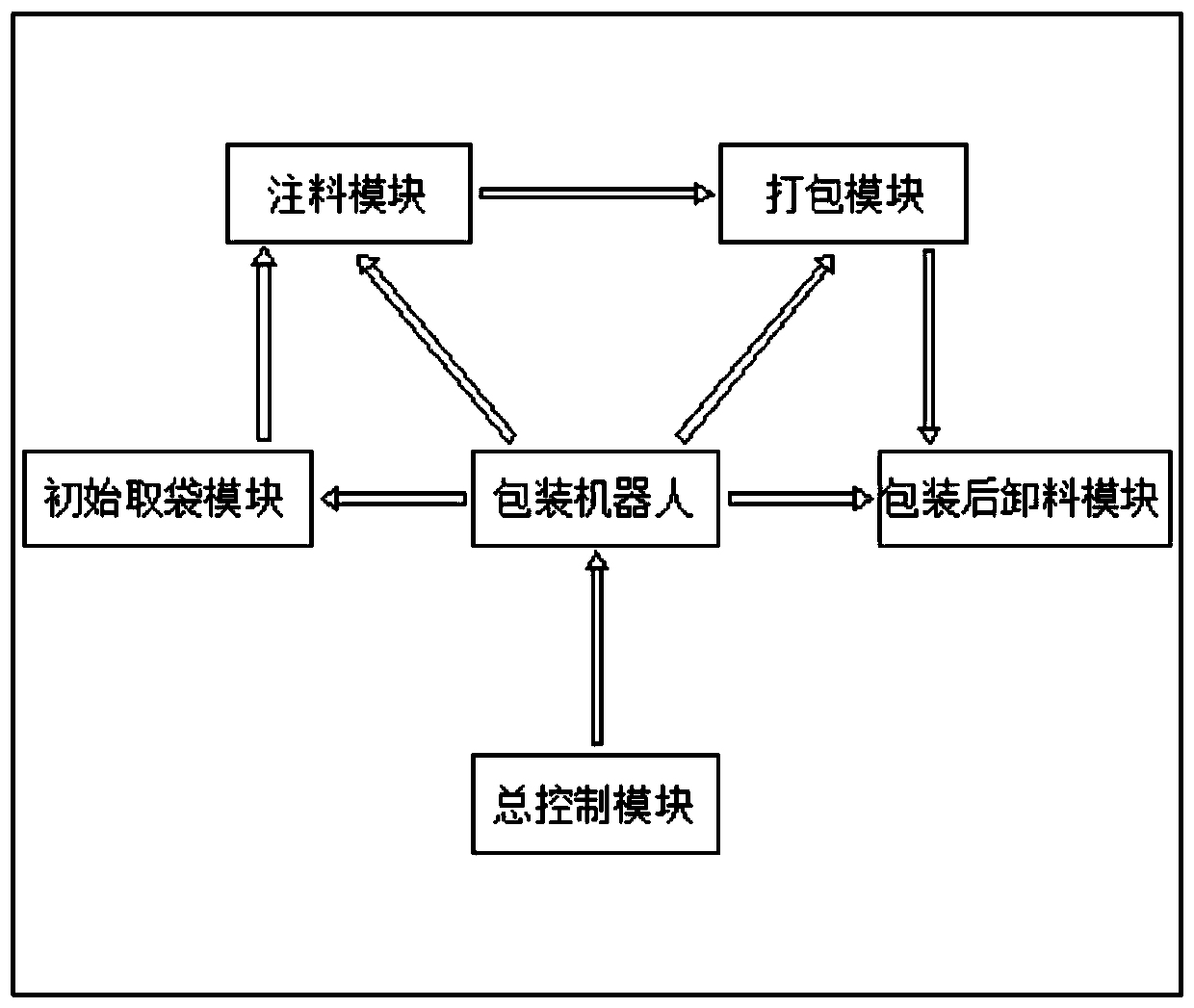

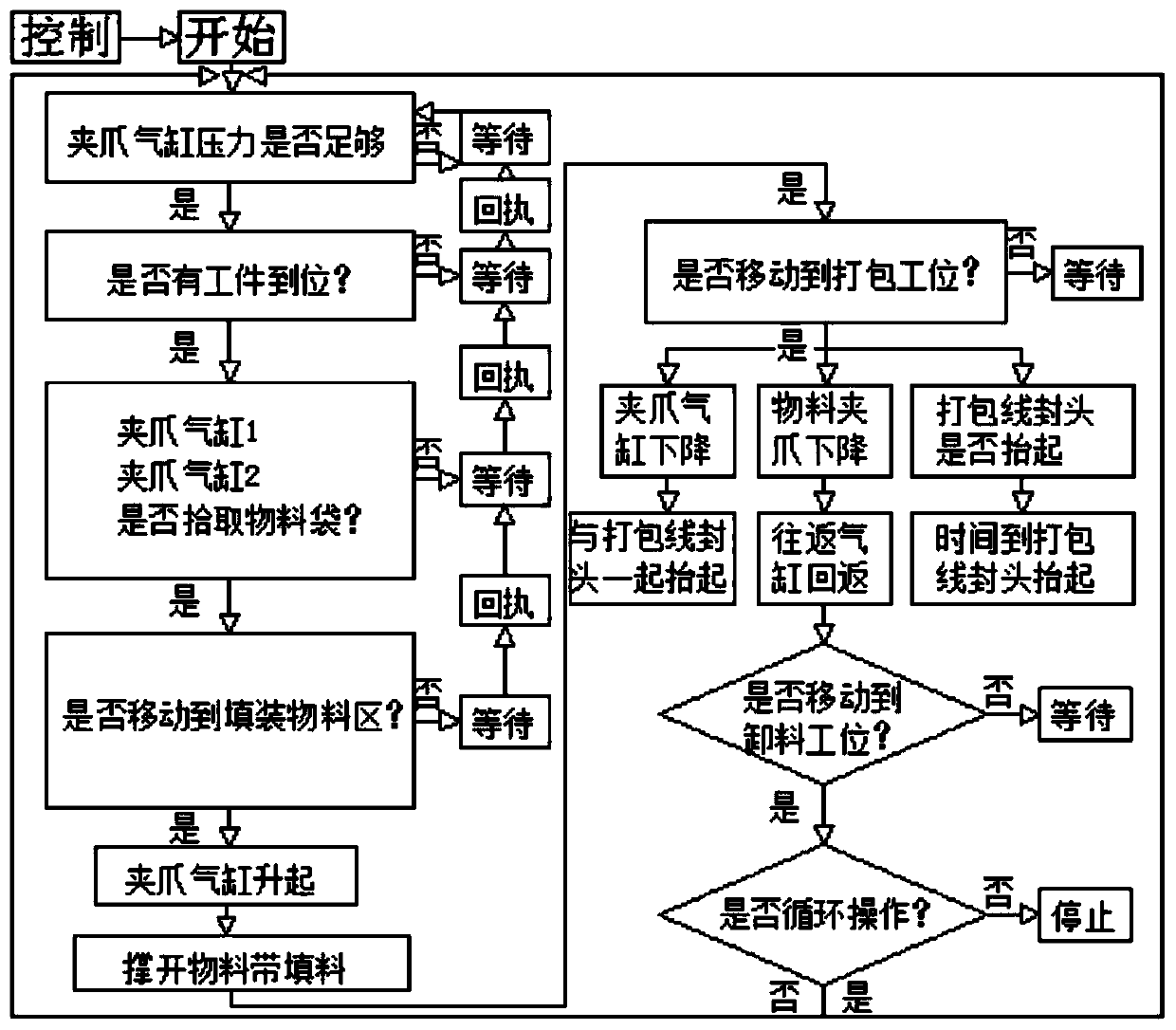

Robot type intelligent flexible packaging machine

The invention discloses a robot type intelligent flexible packaging machine. The machine comprises a placing base and a working platform; the working platform is mounted at the upper end of the mounting base; and the working platform and the placing base are fixedly connected through welding. According to the robot type intelligent flexible packaging machine of the invention, the guarantee mode ofa traditional intelligent flexible packaging machine is changed. The novel packaging robot is used for carrying out the working procedures of material taking, material injecting, packaging and discharging. Different from a traditional stiff intelligent flexible packaging mode, a mode adopting the packaging robot to perform packaging makes a whole packaging process more flexible and an operation stroke shorter. In this way, compared with the traditional intelligent flexible packaging machine, the robot type intelligent flexible packaging machine has higher packaging efficiency and a lower error rate, and can rapidly complete a whole packaging process only by installing a set track through two material clamping jaws.

Owner:合肥浩普智能装备科技有限公司

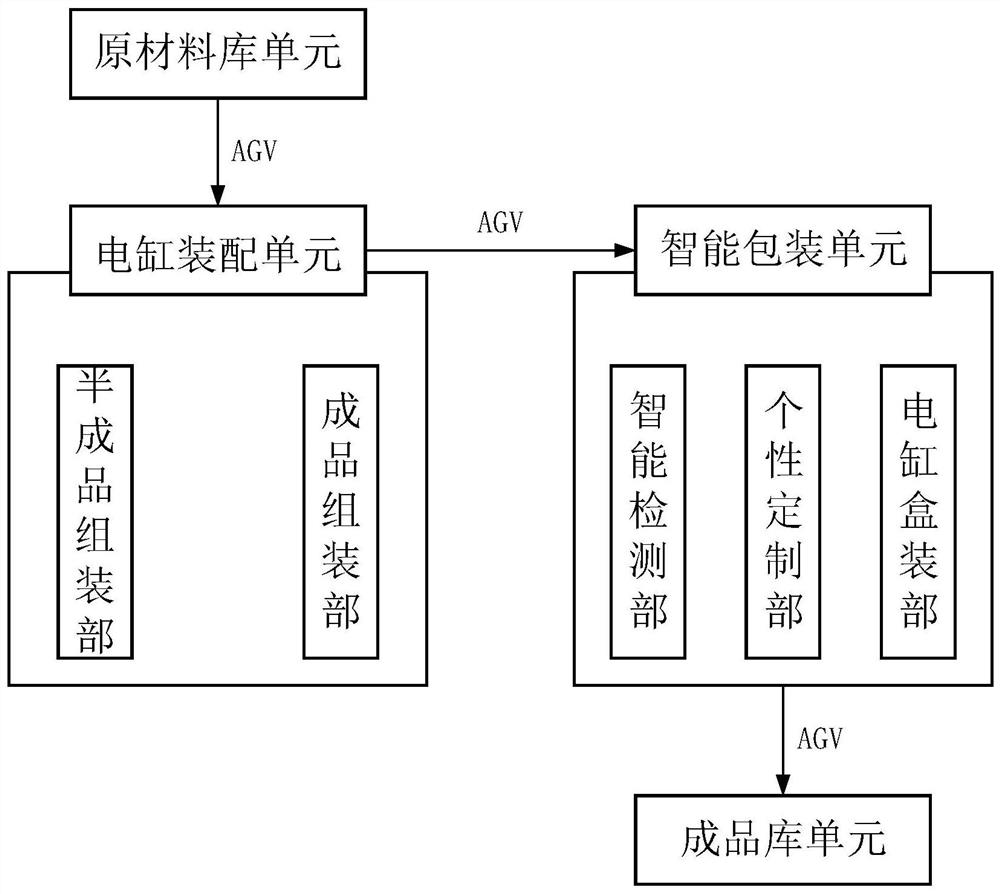

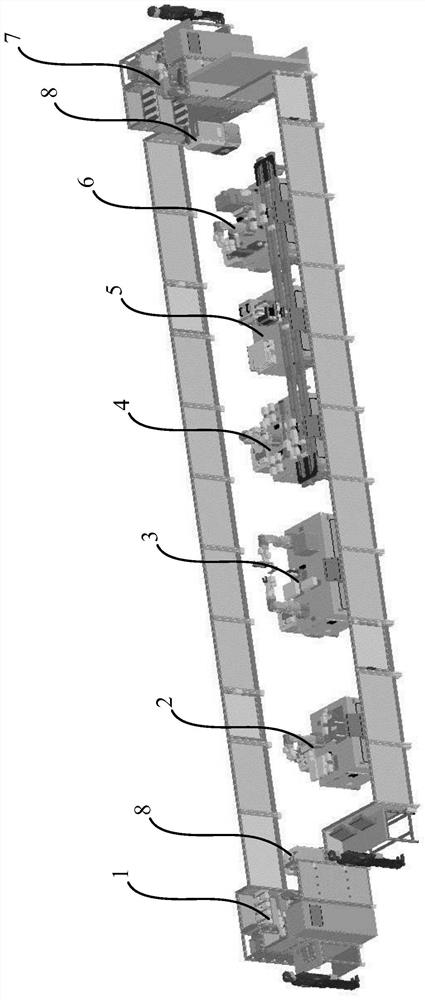

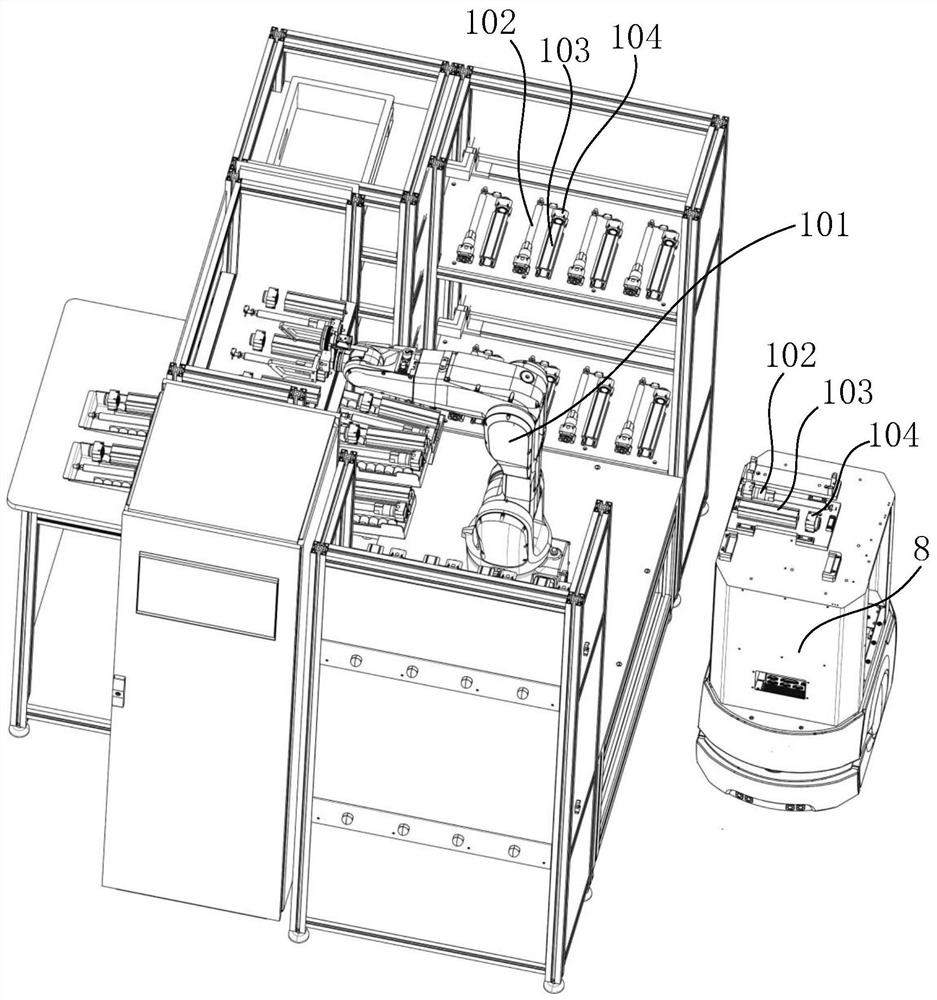

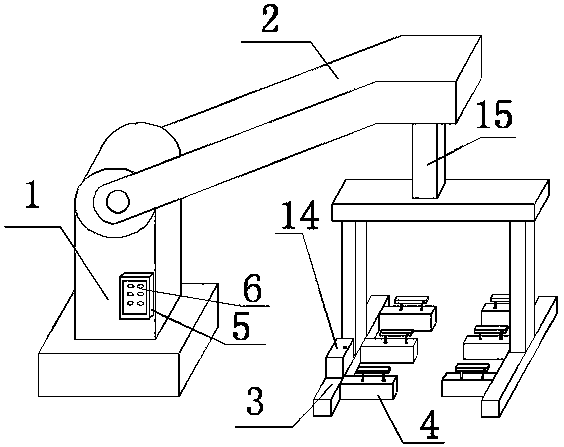

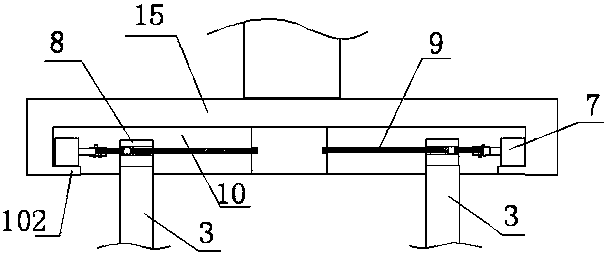

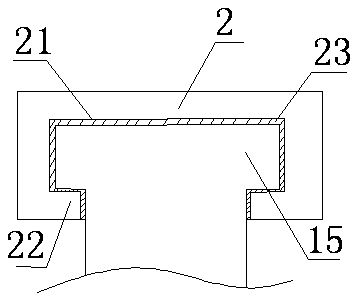

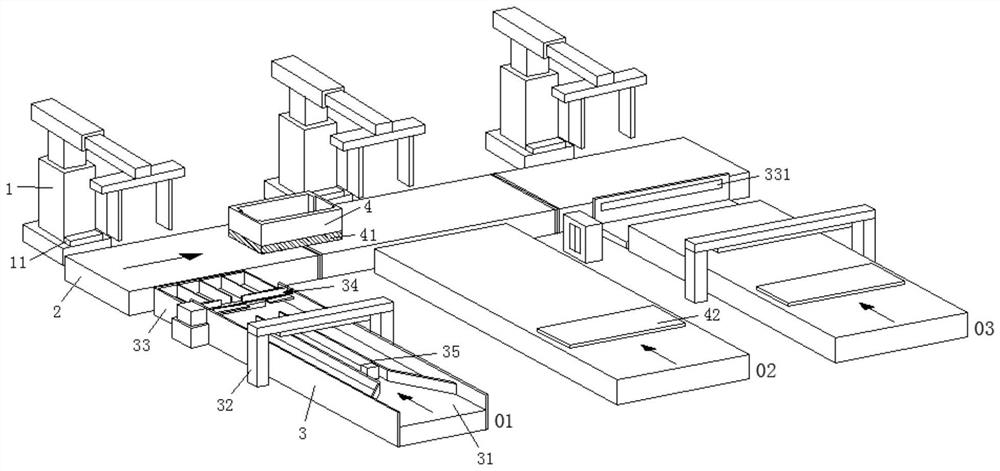

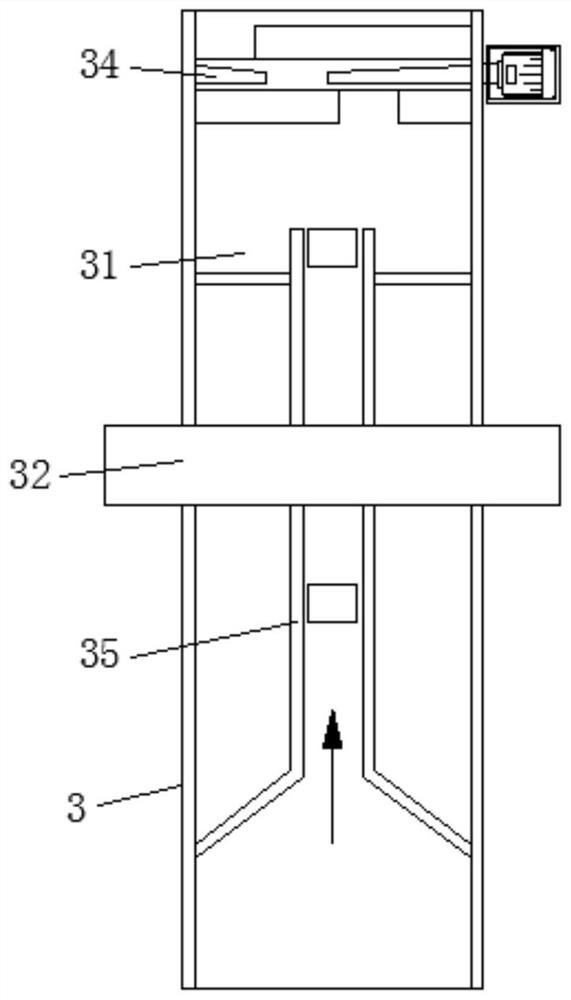

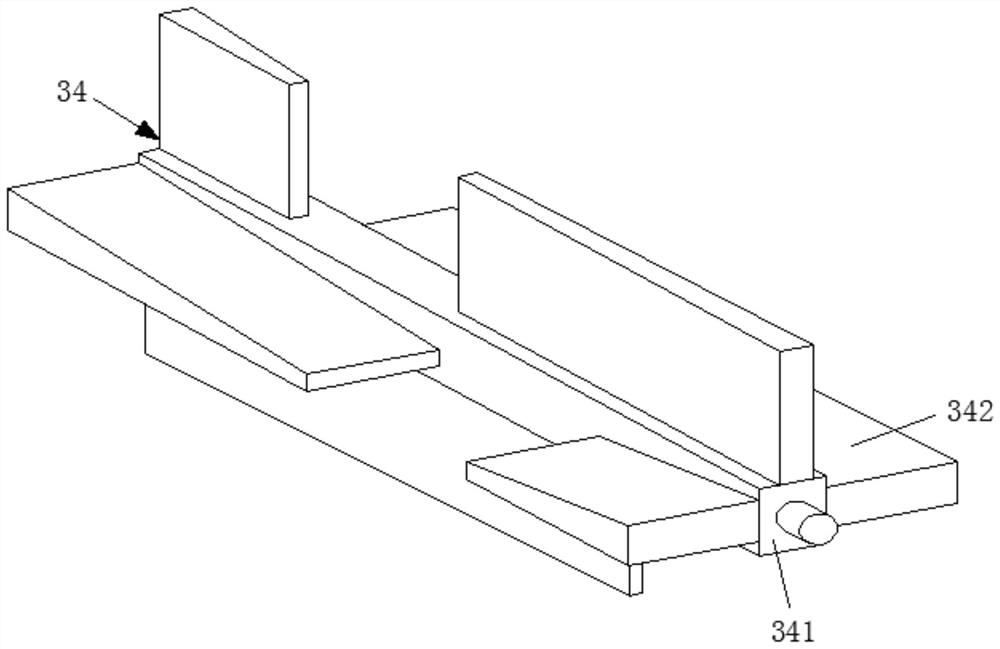

Intelligent manufacturing production line for electric cylinders

ActiveCN113084502ARealize automatic feeding processRealize coordinated controlPackaging automatic controlMetal working apparatusAssembly cellsAssembly line

The invention provides an intelligent manufacturing production line for electric cylinders. The intelligent manufacturing production line comprises an electric cylinder assembling unit. The electric cylinder assembling unit comprises: a semi-finished product assembling robot, configured to abutting and connecting electric cylinder components according to assembling positions; a finished product assembling robot, configured to fixedly connecting the abutted and connected electric cylinder components through screws to form finished electric cylinders; and an intelligent packaging unit capable of receiving the finished electric cylinders, wherein the intelligent packaging unit comprises a packaging robot used for loading the finished electric cylinders into packaging boxes to complete packaging to form boxed electric cylinders. Quicker and more stable mass production of the electric cylinders is realized; the workload of workers is effectively reduced, a traditional manual production mode is replaced with an industrial assembly line production mode, and intelligent production of the electric cylinders is achieved; the electric cylinder production efficiency is greatly improved, and the electric cylinder yield is further improved; and the stability of the production quality of the electric cylinders is guaranteed, meanwhile, the yield of electric cylinder production is also improved, and the manufacturing cost is reduced.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE

Automatic packaging robot

InactiveCN111792072ARealize transportationHeight adjustableWrapper twisting/gatheringPackaging machinesElectric machineryEngineering

The invention discloses an automatic packaging robot. The automatic packaging robot comprises a supporting and conveying mechanism, a carton conveying mechanism, a carton folding mechanism and a carton sealing mechanism; the carton conveying mechanism is used for pushing the cartons which are not opened; an electric push rod stretches out and draws back to drive a push plate to move, and thereforeconveying of the boxes is achieved; and a lead screw motor drives a rotating lead screw to drive a bottom movable rod to move up and down, so that the height of a connecting rod is adjusted; and a fixing frame is fixedly mounted at the end of a piston rod of the bottom movable rod. The lead screw motor drives the rotating lead screw to drive the bottom movable rod to move up and down, so that theheight of the connecting rod is adjusted, firstly, a steering engine drives a round block to press down the short covers of the cartons, then an air cylinder drives a swing rod to press down the longcovers of the cartons, and therefore the effect of automatic carton folding is achieved; the carton sealing mechanism is fixedly mounted at the upper end of the carton folding mechanism, and the folded carton covers are sealed by glue through the carton sealing mechanism.

Owner:中科未来世界科技(北京)有限公司

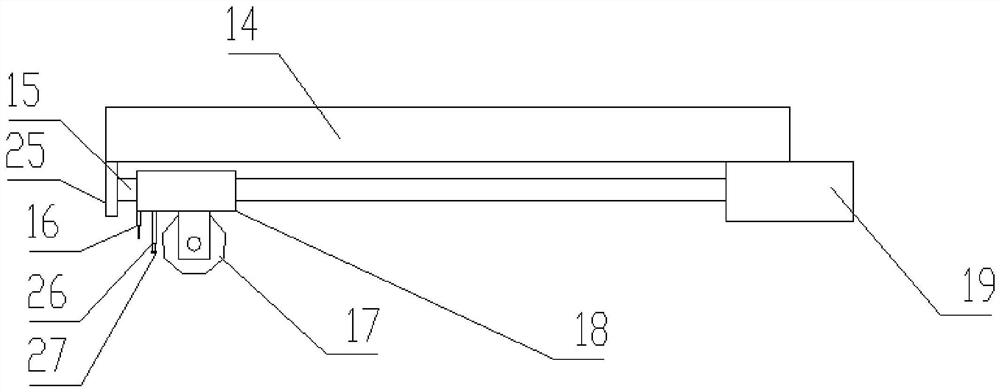

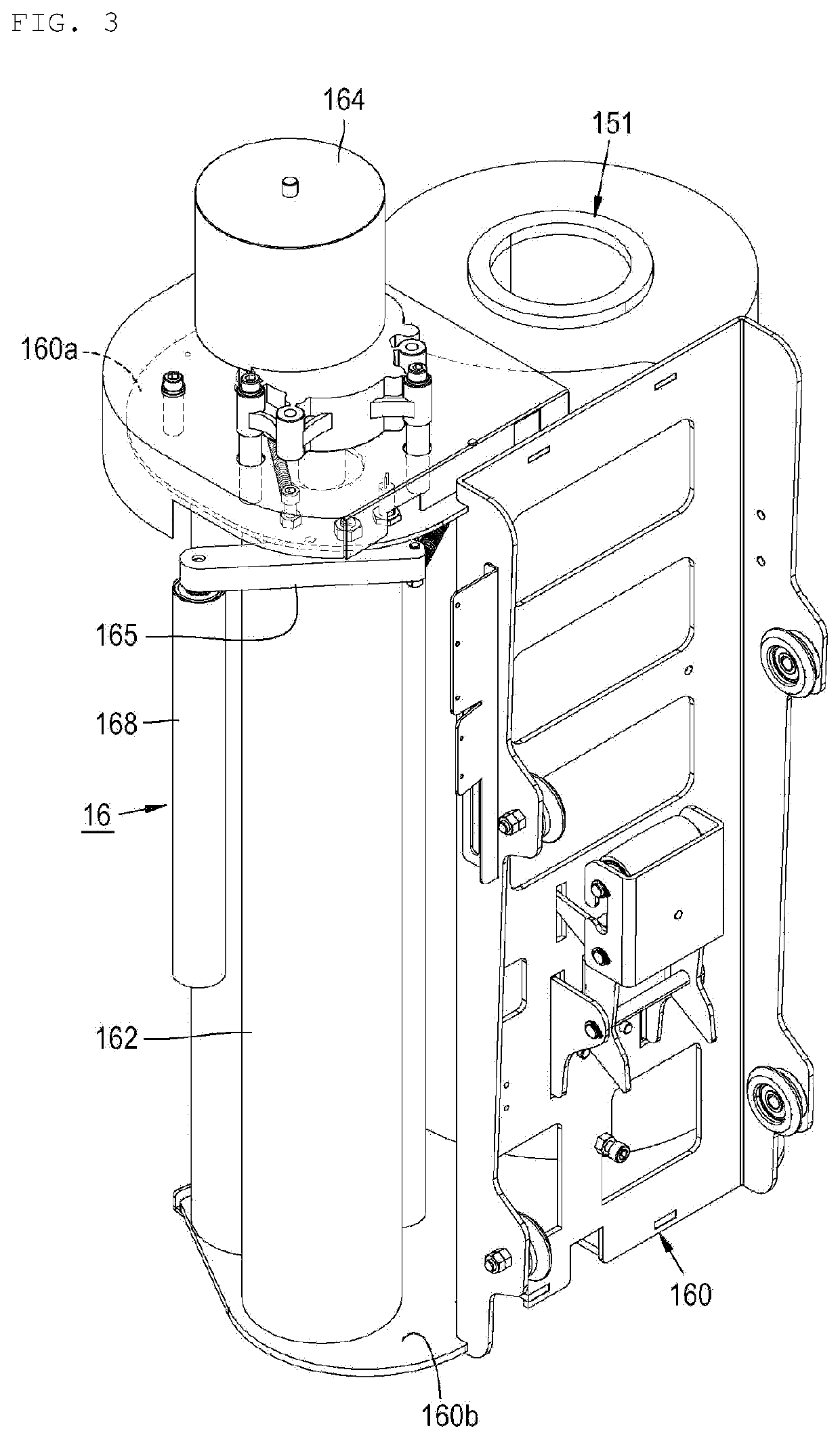

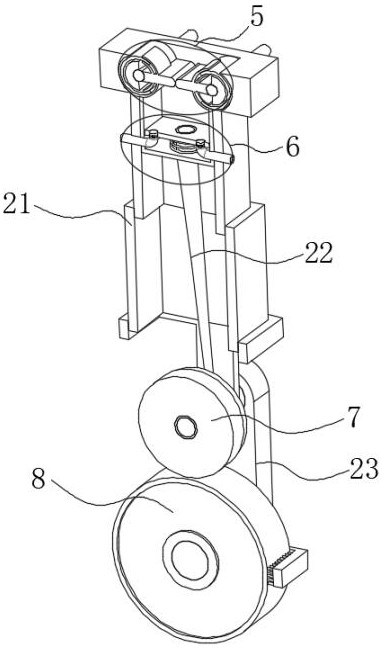

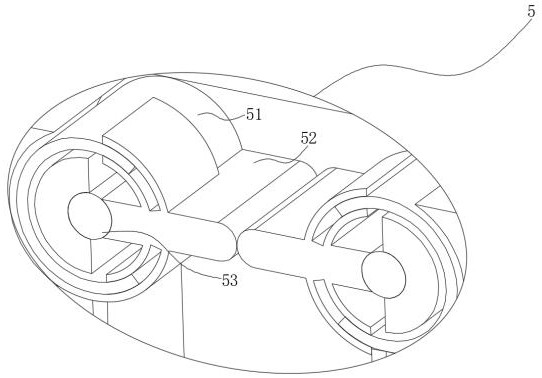

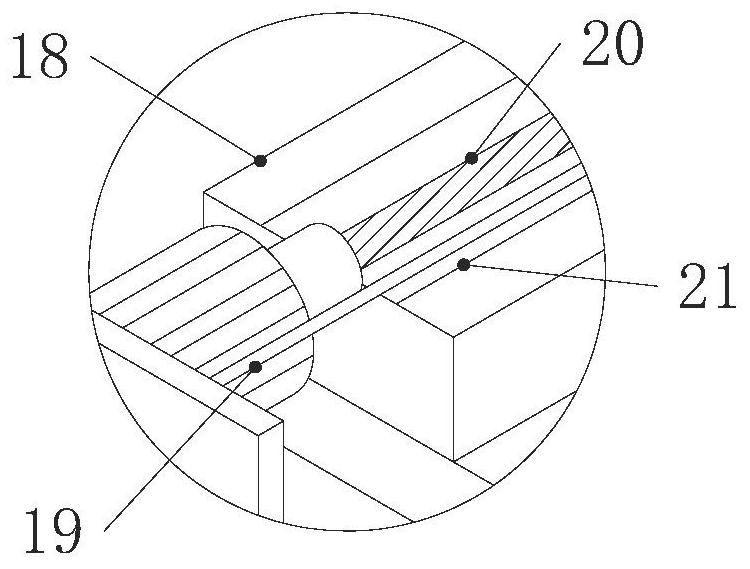

Packaging film fixing device of winding packaging robot

ActiveCN113212826AImprove wrapping efficiencyWeb rotation wrappingArticle deliveryAdhesive beltGear wheel

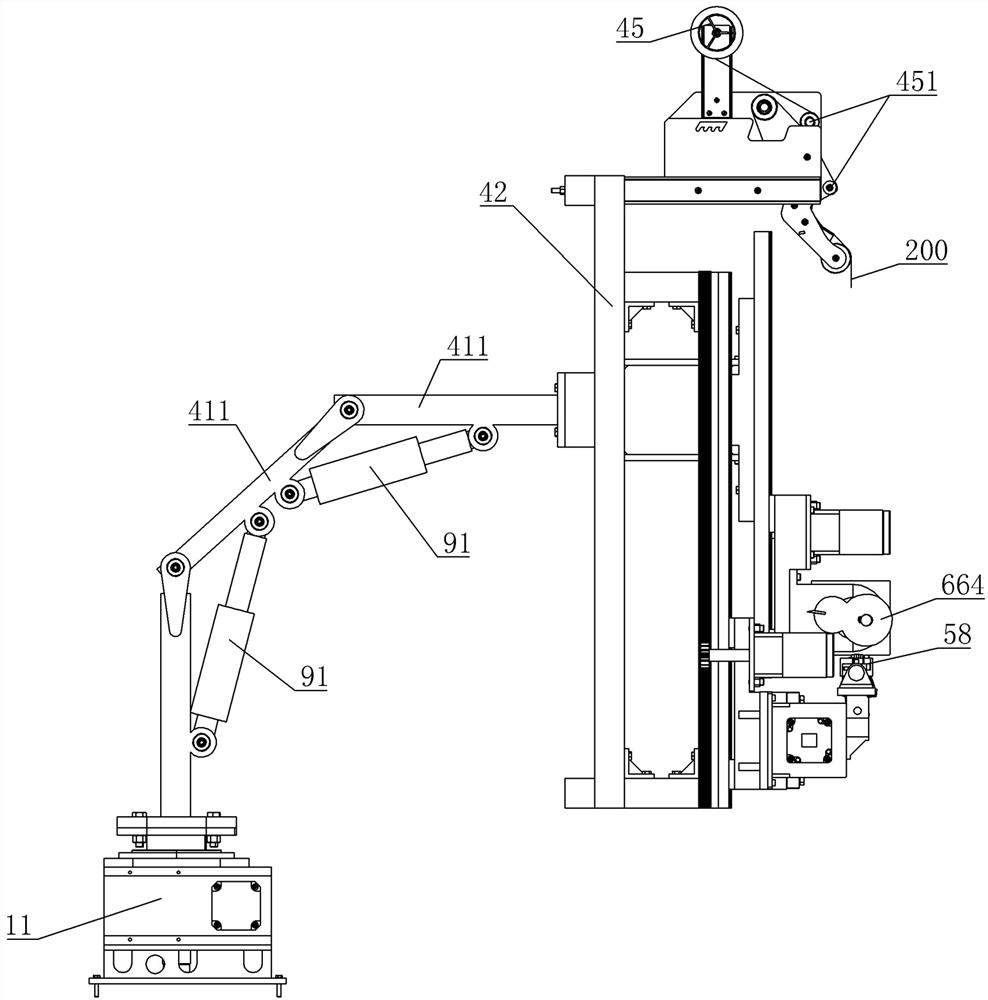

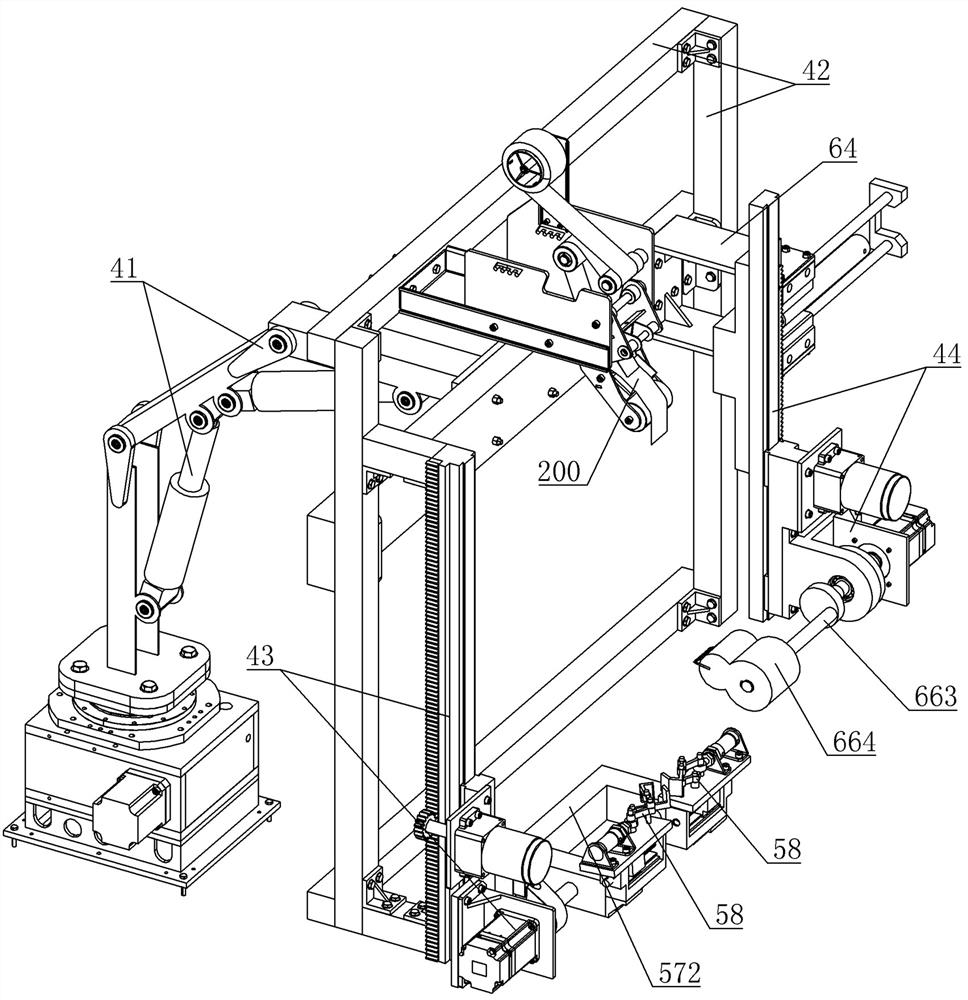

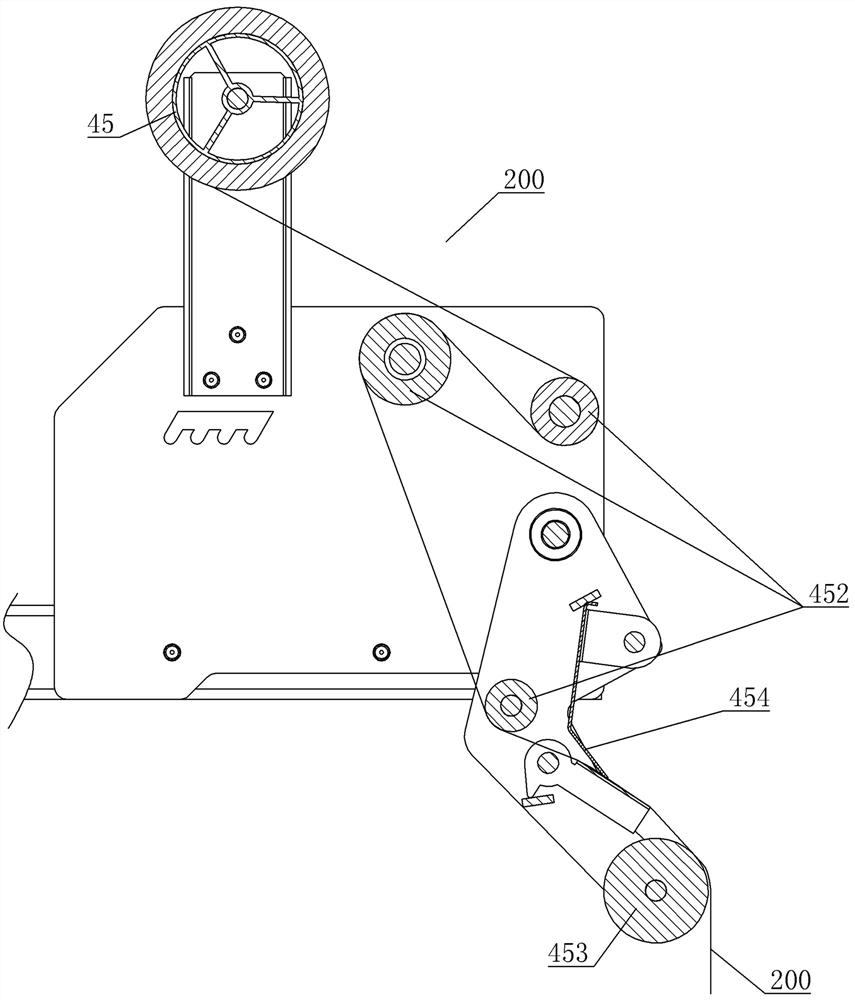

The invention relates to a packaging film fixing device of a winding packaging robot. According to the device, a multi-section arm A, a clamping turnover mechanism and a tape pressing and cutting mechanism which are mounted on a square bracket are used for fixing and cutting a packaging film by an adhesive tape; the clamping turnover mechanism is connected to one side of the square bracket in a sliding mode and driven by a gear rack to vertically slide, two clamping belt assemblies on the clamping turnover mechanism are used for clamping the two sides of the adhesive tape, the clamping turnover mechanism can clamp the adhesive tape and pull the adhesive tape downwards, and after the adhesive tape is pulled out, a turnover shaft is driven by a motor to rotate to eject the pulled-out adhesive tape outwards, and then the adhesive tape is adhered to the packaging film and a to-be-packaged object; an eccentric shaft of the tape pressing and cutting mechanism can drive a cylindrical pressing head to swing outwards so that the adhesive tape can be tightly attached to the packaging film and the to-be-packaged object, and the tape pressing and cutting mechanism can slide up and down so that the whole packaging film can be tightly attached to the to-be-packaged object. Automatic adhesive tape fixing and cutting actions are achieved, traditional manual adhesive tape pasting operation is replaced, and the winding and packaging efficiency of the robot is improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Packaging robot for home decoration plate transportation

The invention discloses a packaging robot for home decoration plate transportation, and relates to the field of home decoration plates. The packaging robot comprises a robot body, an operating arm ismounted on the robot body, two movable driving units are arranged on the bottom side of the operating arm, and the driving units are mechanically connected with a driving motor; two driving units arefixedly connected with the tops of T-shaped conveying rods correspondingly; three containing tables are fixedly mounted on the side, close to each other, of the bottoms of the two T-shaped conveying rods; two supporting rods are fixedly arranged at the tops of the containing tables, and placing plates are fixedly connected to the top of the supporting rods; a pressure sensor is fixedly arranged inthe placing plates; and a control device is electrically connected with the driving motor and the pressure sensor. The packaging robot can be automatically pressed from the side surface, so that theplate does not shake in the transportation process, and the plate can be effectively prevented from falling and damaging or injuring personnel.

Owner:芜湖隆深机器人有限公司

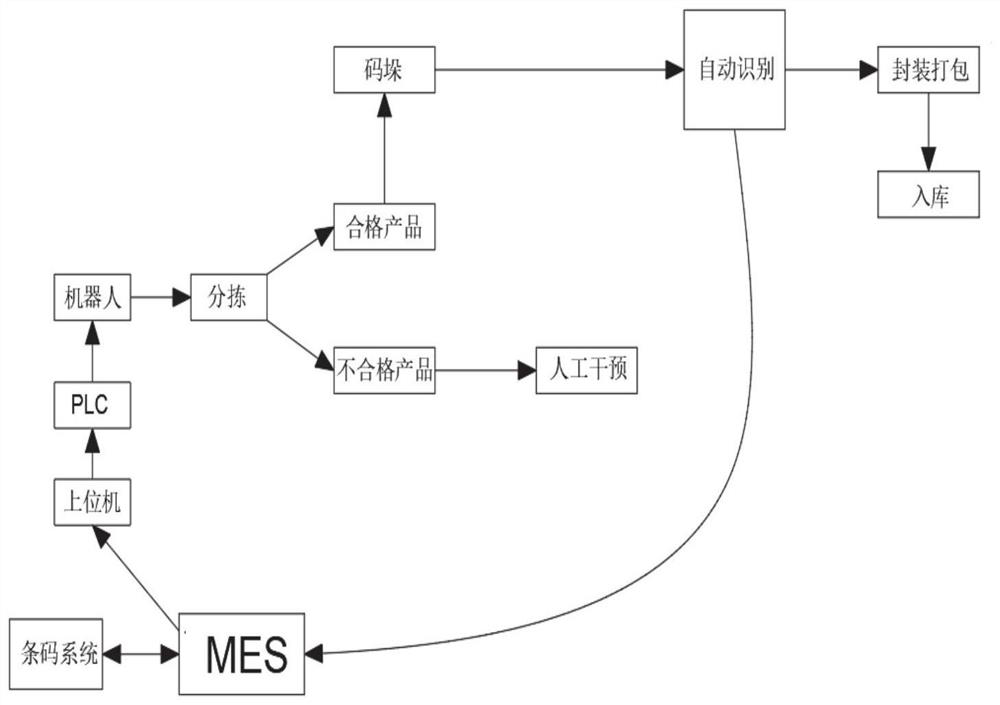

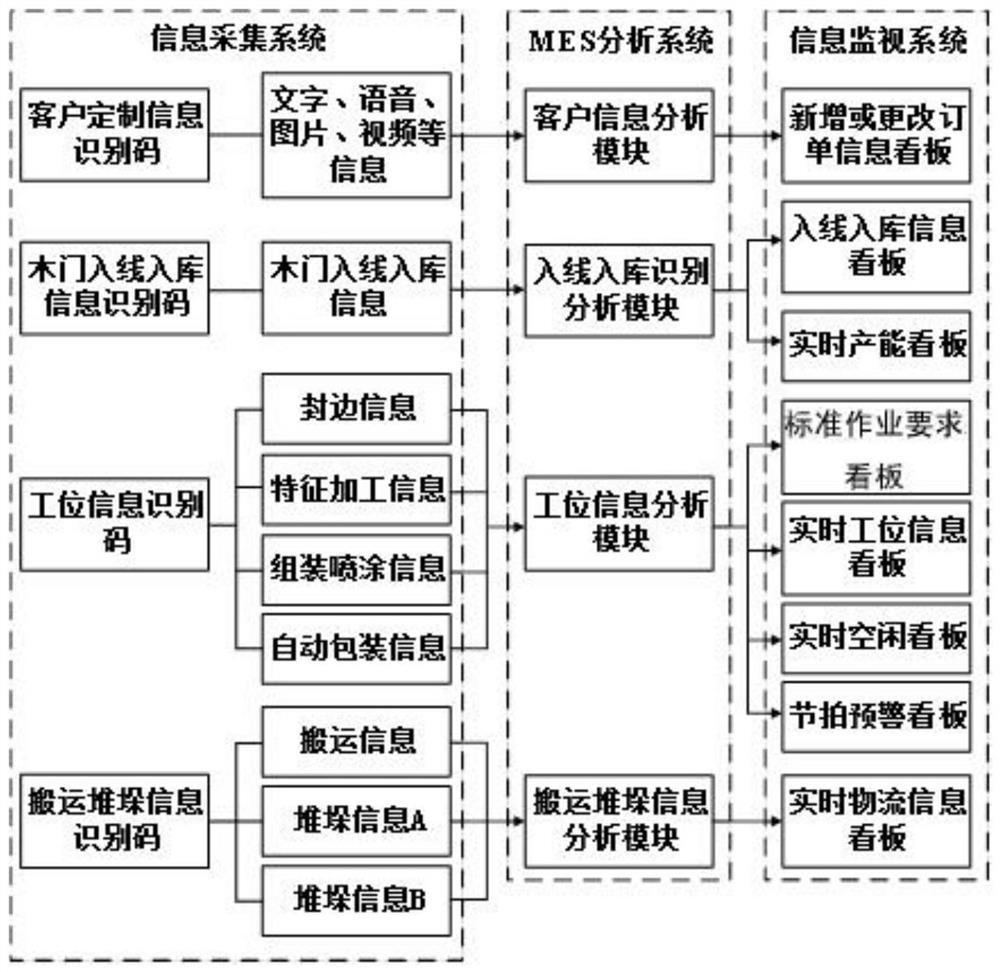

Automatic packaging integrated data processing system and method

ActiveCN113104463ATimely transmissionAccurate realization of circulationPackaging automatic controlTotal factory controlData processing systemPalletizer

The invention provides an automatic packaging integrated data processing system and method. The automatic packaging integrated data processing system comprises a bar code system, a scanning system, a stacking robot and a packaging robot. The bar code system comprises bar codes pasted on the products, and the bar codes record order information of the products along with generation of the products; the stacking robot fixes and confirms the effective position of the products with the bar codes, then places the products with the bar codes into a rolling conveying chain and conveys the products with the bar codes to the scanning system; the scanning system transmits data obtained by scanning the bar codes of the products to the bar code system and is used for performing data feedback on bar code data; and the packaging robot is used for packaging and boxing the products scanned by the scanning system. The whole-process automatic packaging of spunlace non-woven fabric is realized.

Owner:济南永信新材料科技有限公司

Express warehouse intelligent packaging robot

The invention relates to an express warehouse intelligent packaging robot. The express warehouse intelligent packaging robot intelligent comprises a bottom plate, a mounting frame, a conveying deviceand a cover closing device, wherein the mounting frame is mounted on the rear side of the bottom plate, the conveying device is mounted on the front side of the bottom plate, the cover closing deviceis arranged at the upper end of the conveying device, and the cover closing device is mounted at the lower end of the mounting frame. The cover closing device comprises a transverse sliding block, a longitudinal sliding block, a transverse moving plate, a longitudinal moving plate, a connecting frame, a driving mechanism and a pressing block. The conveying device comprises a supporting plate, a driving roller, a driven roller, a driving motor, a conveying belt and a positioning frame. Through cooperation of the conveying device and the cover closing device, the function of closing the cover ofa packaging carton loaded with cargoes is achieved, the traditional mode of closing the cover of the packaging carton manually is replaced, the labor cost is saved, the positioning frame arranged onthe conveying device can limit the packaging carton, the condition that the packaging carton slides accidentally, is avoided, and the stability in the subsequent operation process is guaranteed.

Owner:谢光辉

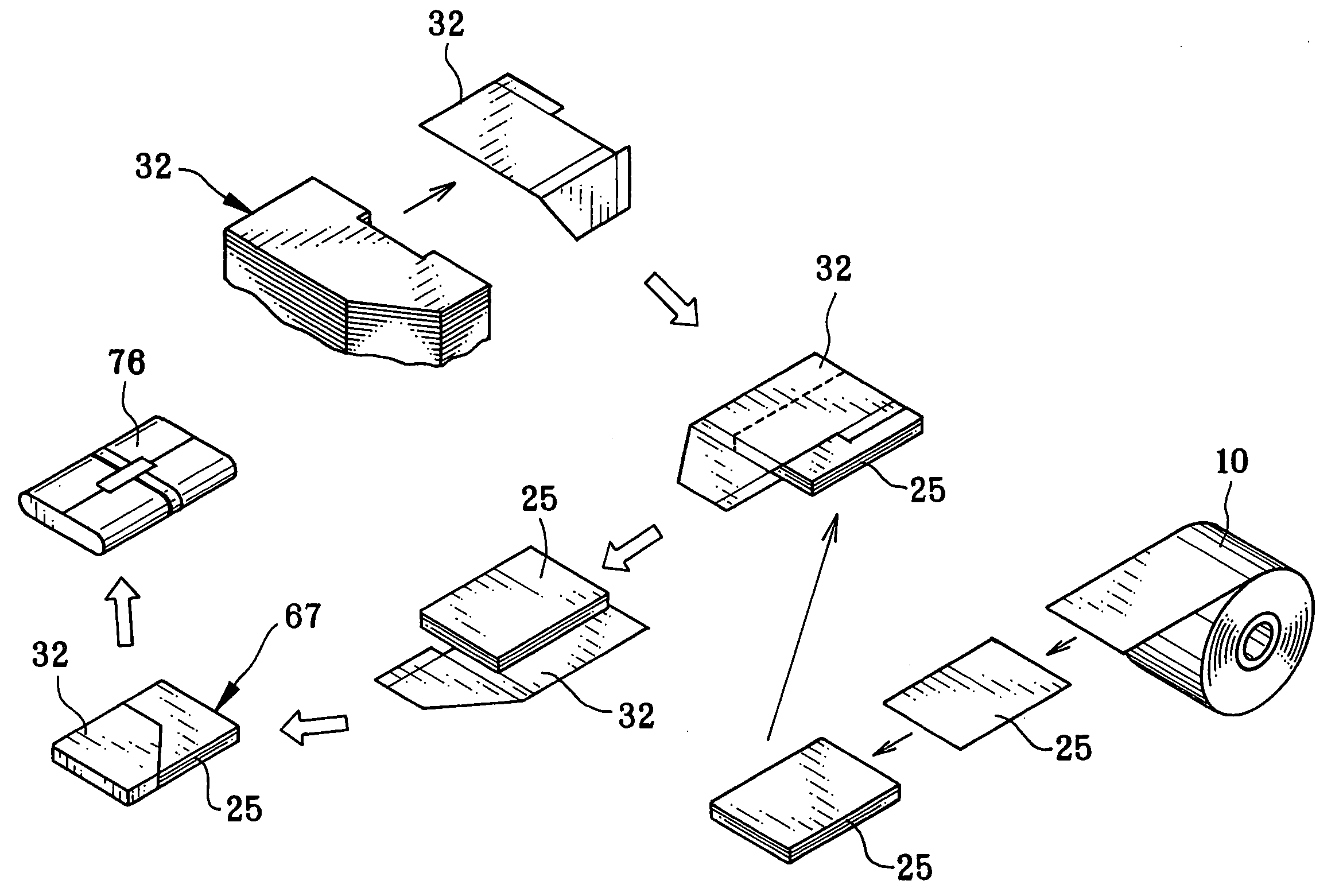

Sheet package producing system, sheet handling device, and fillet folding device

InactiveUS20050138900A1Efficient productionImprove efficiencyPaper article packagingWrapper folding/bending apparatusSynchronous controlX-ray

Owner:FUJIFILM CORP

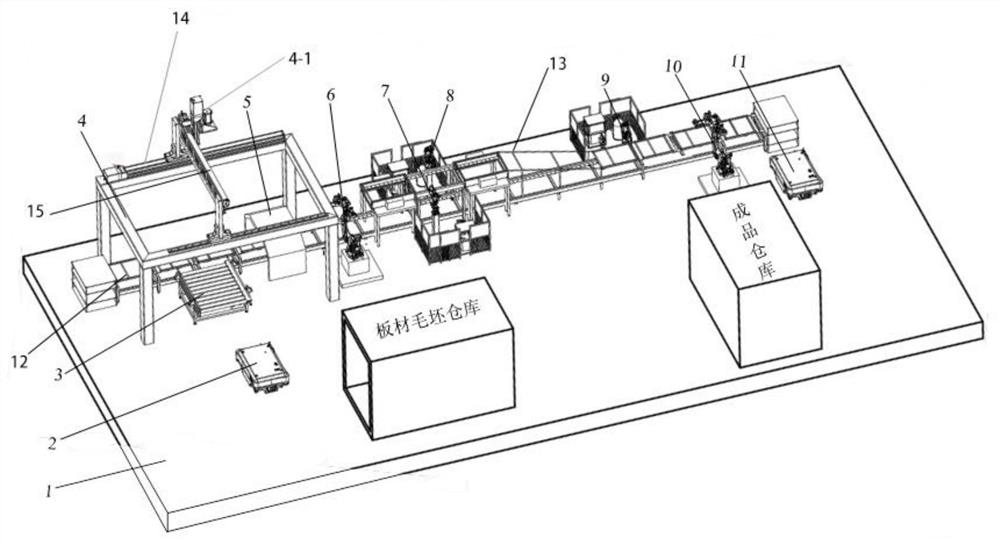

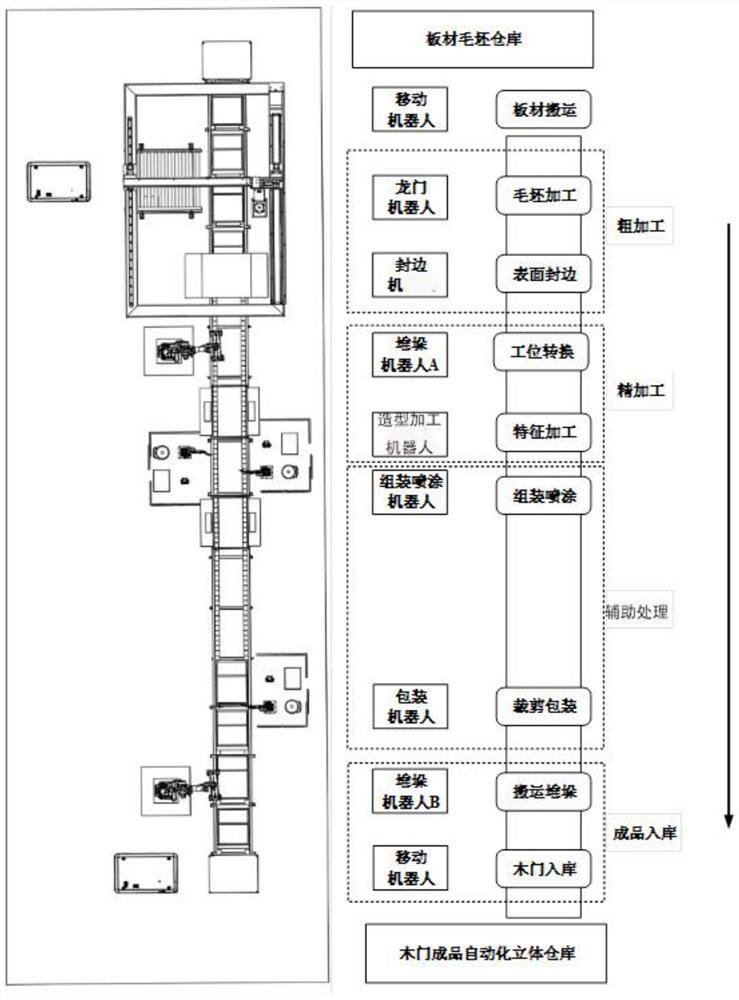

Wooden door production line and using method

ActiveCN114179185AIntelligent processingReduce manual operationsWood working apparatusMachineManufacturing line

The invention discloses a wooden door production line and a using method. Comprising a digital plate blank warehouse, a first conveying belt, a second conveying belt, a plate moving robot, a gantry robot, an edge sealing machine, a stacking robot A, a modeling machining robot, an assembling spraying robot, a packaging robot, a stacking robot B, a warehousing moving robot and a digital wooden door finished product warehouse. Wooden doors between the digital plate blank warehouse and the feeding position are conveyed through the plate moving robot, the gantry robot is arranged above the first conveying belt, a clamping device is arranged on the gantry robot and used for moving the wooden doors to the first conveying belt from the feeding position, and the edge sealing machine is connected with the stacking robot A through the first conveying belt. The first conveying belt and the second conveying belt are connected through the stacking robot A. The modeling machining robot, the assembling and spraying robot, the packaging robot and the stacking robot B are sequentially connected through the second conveying belt.

Owner:CHINA UNIV OF MINING & TECH

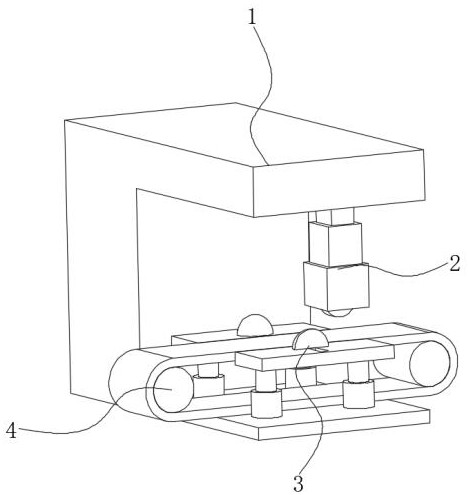

Packing Robot

An improved robot for packing produce such as fruit or other produce is provided. The robot includes a plurality of longitudinal carriage arms arranged in an array, and cantilevered off a support unit such that each longitudinal carriage arm is independently movable between an extended condition and retracted condition. Each arm includes a head connected to it that is independently movable in a vertical direction to pick up, hold and / or drop off an item of produce. Each longitudinal carriage arm is further independently movable in a lateral direction to alter the relative spacing between the plurality of heads such that the heads can move across lanes of the robot. The cantilevered arrangement of each carriage arm allows for compact set-out and other advantages.

Owner:ROBOTICS PLUS LTD

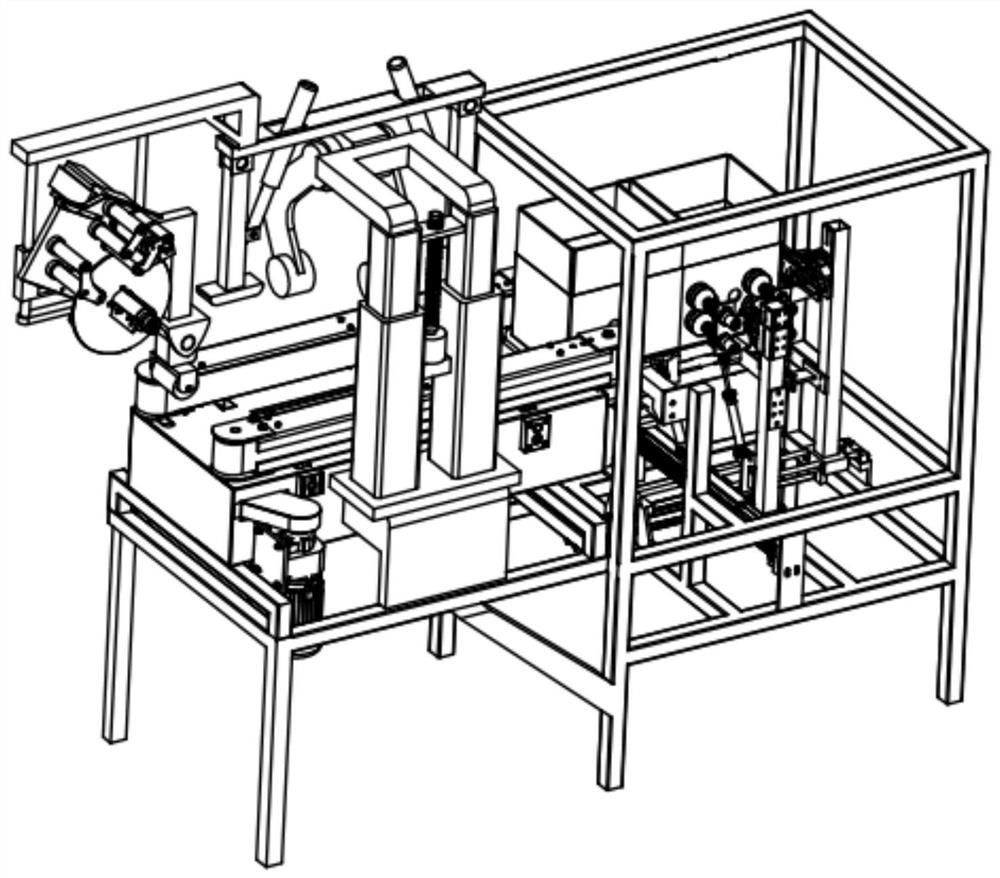

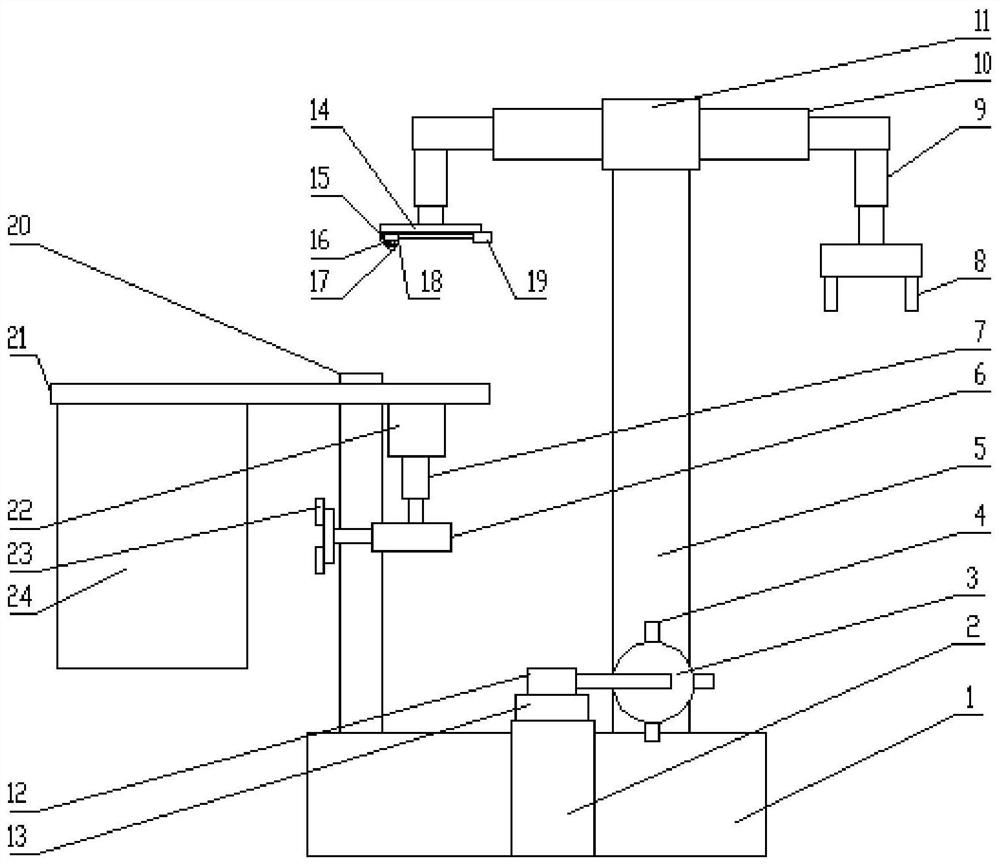

Cover shaking double insurance inserting-in type paper box packaging robot

ActiveCN107150829AImprove packaging efficiencyReduce labor intensityPackaging machinesRobot handStructural engineering

The invention discloses a cover shaking double insurance inserting-in type paper box packaging robot which comprises an upper cover shaking mechanical arm, a lower cover shaking mechanical arm, an in-box box opening module, a feeding and conveying module, a double side pushing and guide mechanism module and a packaging box output module. Through an upper cover shaking packaging gripper module and a lower cover shaking packaging gripper module which are arranged symmetrically, an opened paper box completes packaging of the cover shaking double insurance inserting-in type paper box through cover shaking of mechanical arm fingers; box taking, box opening, feeding, conveying, double side pushing, upper cover inserting-in, upper cover inserting opening double side guide, inserting of lower covers in upper cover inserting openings, box discharging conveying and other processes are concentrated into a compact robot operation platform, and the problem about automatic packaging of the cover shaking double insurance inserting-in type paper box is solved well; the problem about automatic packaging of disposable medical masks, gloves, operating coats and other irregular flexible materials is broken through; and the labor intensity and manual cost are greatly reduced, and the paper box packaging efficiency and the automation technology level of the complex paper box packaging industry are increased.

Owner:何守印

An automated packaging robot

Owner:HENAN POLYTECHNIC

Automated packaging robot

The invention belongs to the technical field of packaging equipment, and relates to an automated packaging robot. The robot comprises the following parts of a base; a multifunctional arm arranged on the side of the base and comprising a first upright column which is vertically fixed to the base; a first turntable arranged on one end of the first upright column facing away from the base and used torealize transposition; a first support arm and a second support arm that have the same structure and are uniformly arranged on the first turntable; a claw part arranged at the end of the first support arm and used to bend a tongue part on the packaging box and grab a product to be packaged; and a packaging part arranged at the end of the second support arm and used for sealing the packaging box.The automated packaging robot provided by the invention has a reliable structure. The device provided by the invention for packaging can be used to consume less time and cost, produce more per unit time, obtain high work efficiency, reduce the total economic cost of the product, and obtain strong practicality as well as worth of promotion.

Owner:HENAN POLYTECHNIC

A packaging robot for home decoration board transportation

The invention discloses a packaging robot for home decoration plate transportation, and relates to the field of home decoration plates. The packaging robot comprises a robot body, an operating arm ismounted on the robot body, two movable driving units are arranged on the bottom side of the operating arm, and the driving units are mechanically connected with a driving motor; two driving units arefixedly connected with the tops of T-shaped conveying rods correspondingly; three containing tables are fixedly mounted on the side, close to each other, of the bottoms of the two T-shaped conveying rods; two supporting rods are fixedly arranged at the tops of the containing tables, and placing plates are fixedly connected to the top of the supporting rods; a pressure sensor is fixedly arranged inthe placing plates; and a control device is electrically connected with the driving motor and the pressure sensor. The packaging robot can be automatically pressed from the side surface, so that theplate does not shake in the transportation process, and the plate can be effectively prevented from falling and damaging or injuring personnel.

Owner:芜湖隆深机器人有限公司

An automated packaging robot

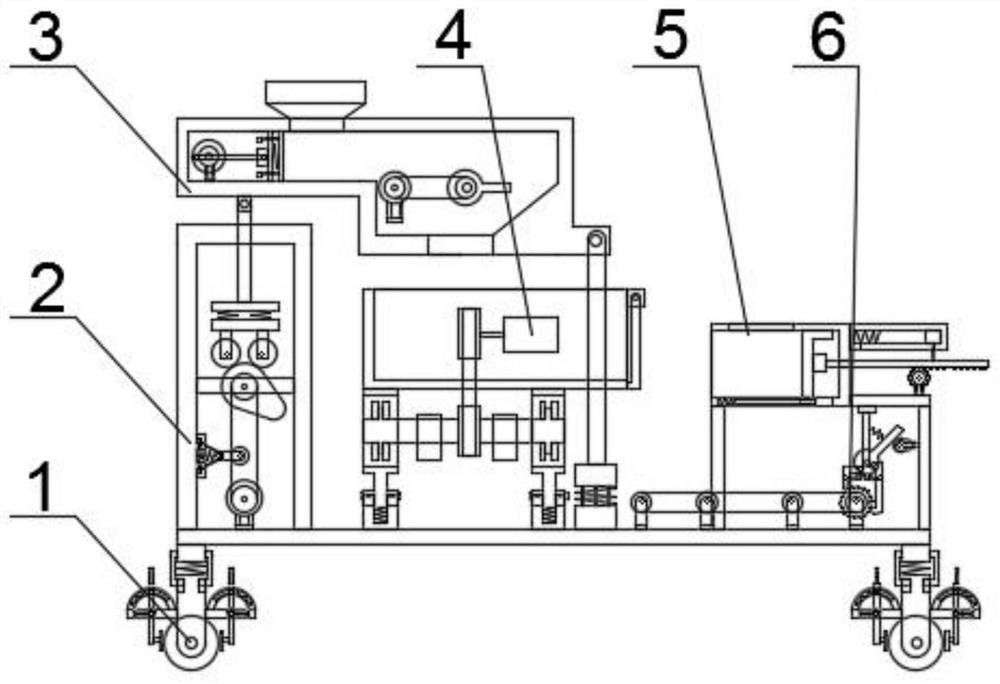

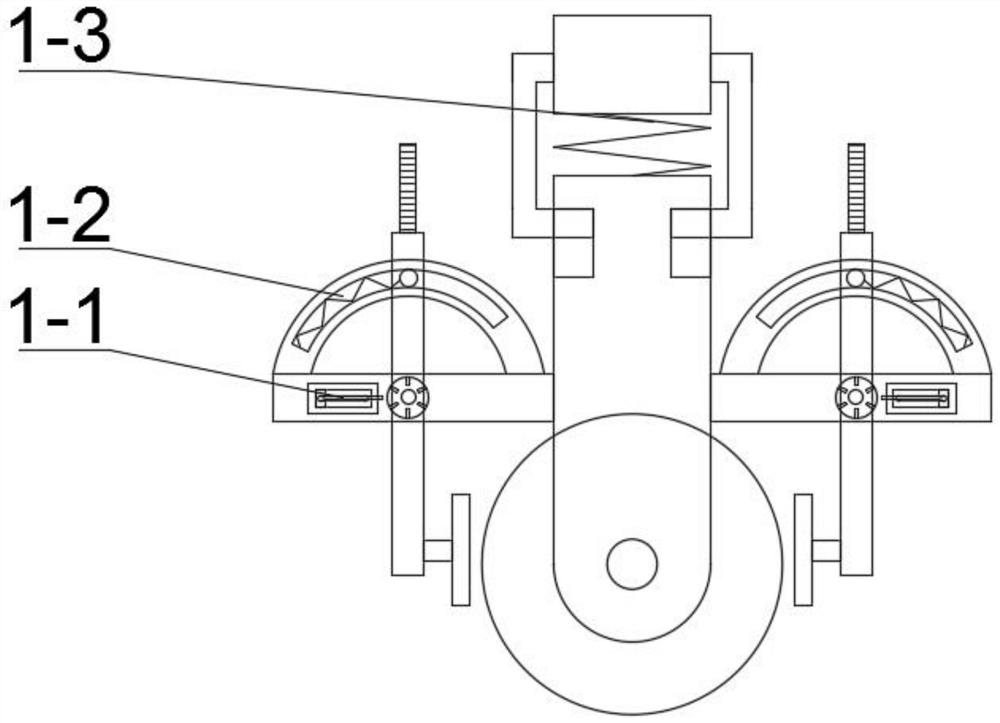

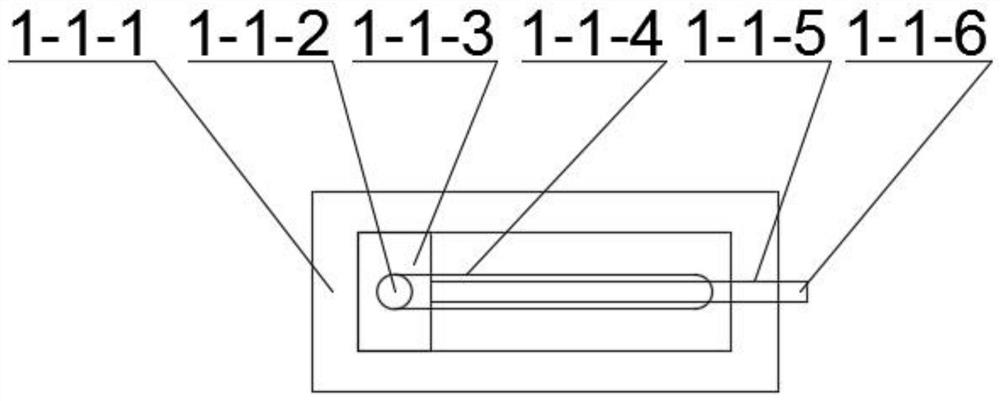

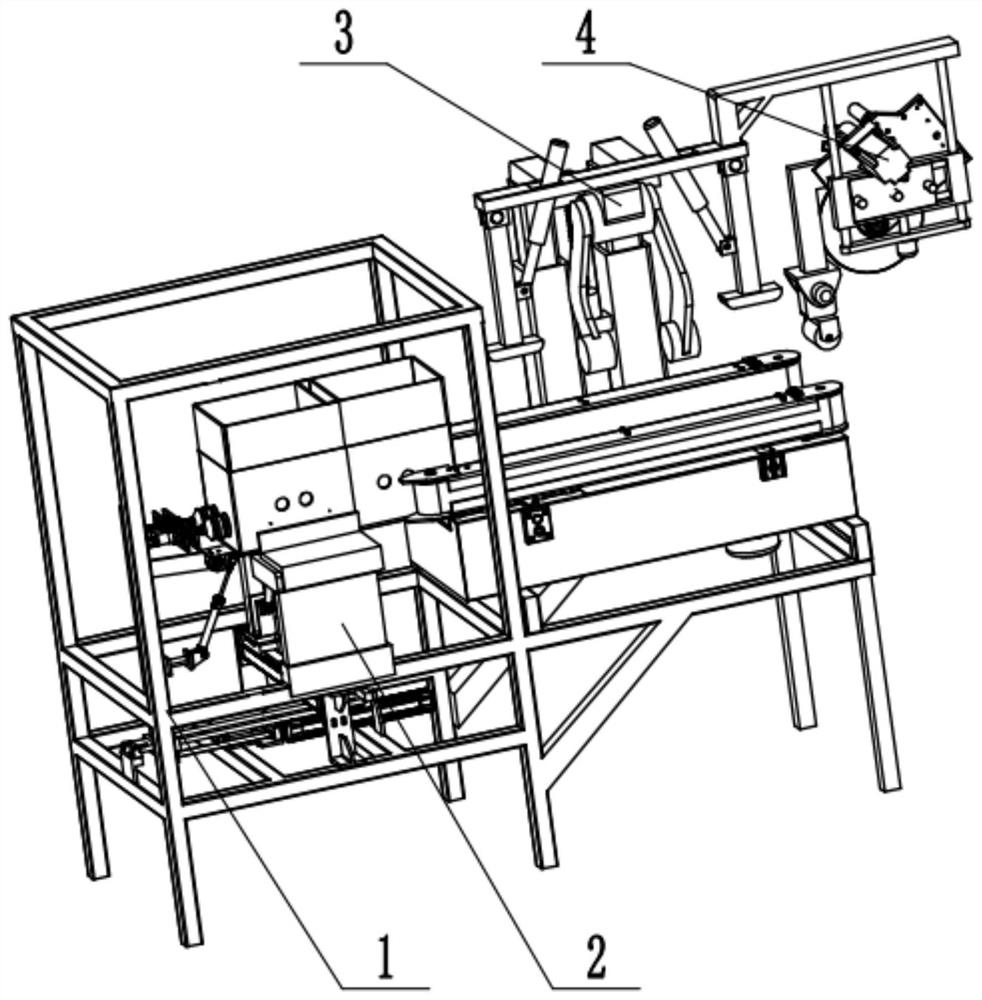

ActiveCN109987261BAvoid accumulationEasy to moveCastorsSolid materialClassical mechanicsMechanical engineering

The invention relates to a packaging device, in particular to an automatic packaging robot. The automatic packaging robot comprises a moving wheel mechanism, an inclined driving mechanism, a feeding hopper mechanism, a vibrating feeding mechanism, a packing box pushingmechanism and a loading and transporting mechanism. The packaging robot can move smoothly, park, tighten a belt, feed tipsily, prevent material accumulation, clean up the accumulated materials by vibration, feed through vibration, feed a box automatically, and transport the full box out. The moving wheel mechanism is arranged below the vibrating feeding mechanism; the inclined driving mechanism is connected with the vibrating feeding mechanism; the feeding hopper mechanism is matched with the inclined driving mechanism; the feeding hopper mechanism is connected with the vibrating feeding mechanism; the packing box pushing mechanism is arranged above the loading and transporting mechanism; and the loading and transportingmechanism is connected with the vibrating feeding mechanism.

Owner:浏阳市恒信包装印刷有限公司

An automated packaging robot

InactiveCN111792072BRealize transportationHeight adjustableWrapper twisting/gatheringPackaging machinesCartonElectric machinery

Owner:中科未来世界科技(北京)有限公司

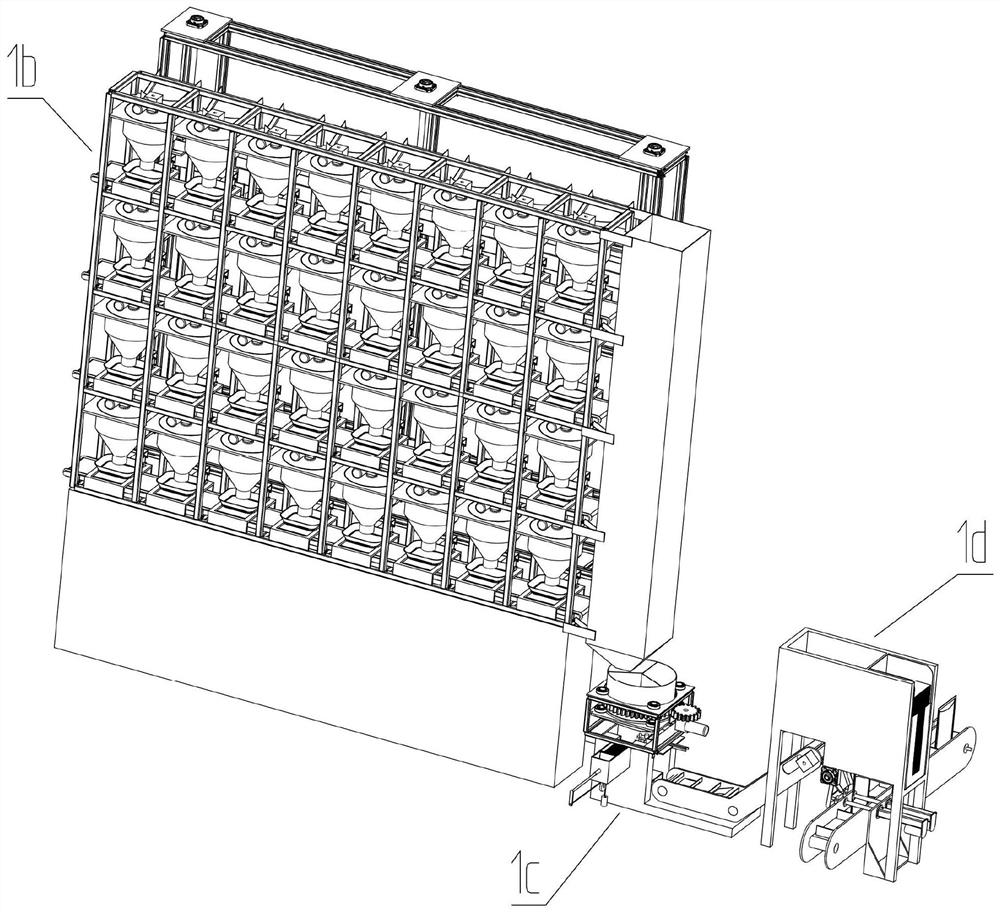

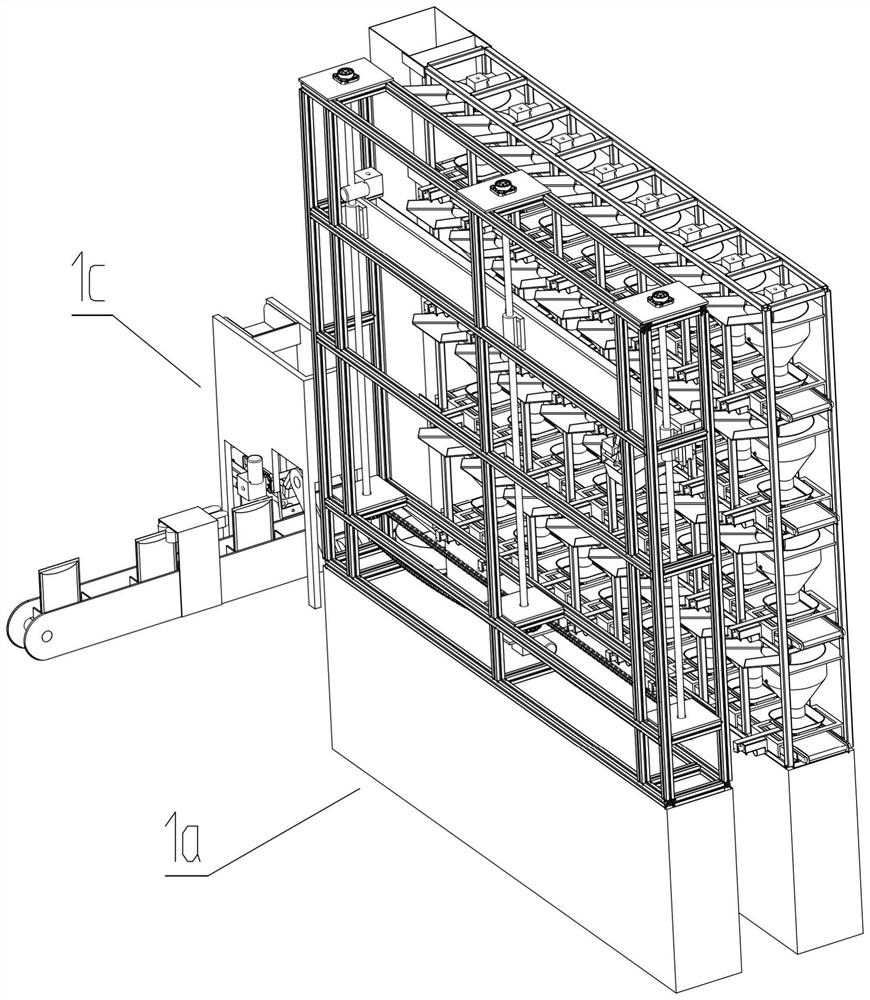

A traditional Chinese medicine automatic dispensing and packaging robot

ActiveCN109335118BReduce labor intensityReduce error rateMixer accessoriesWrapper twisting/gatheringProcess engineeringIndustrial engineering

The invention discloses an automatic dispensing and packaging robot for traditional Chinese medicine, which comprises an automatic feeding mechanism, an automatic feeding and weighing mechanism arranged on one side of the automatic feeding mechanism, and a small bag packaging arranged on one side of the automatic feeding and weighing mechanism Mechanism, a large bag packaging mechanism set at the output port of the small bag packaging mechanism; the automatic dispensing and packaging robot for traditional Chinese medicine is not only simple in structure, but also can quickly realize the feeding, grasping and packaging of traditional Chinese medicine, which solves the cumbersome steps of traditional Chinese medicine weighing , time-consuming and other issues.

Owner:山东禾起生物科技有限公司

Vertical automatic packaging robot

InactiveCN112623351ASuitable for useSmall footprintWrapper twisting/gatheringHeat sealerElectric machinery

The invention discloses a vertical automatic packaging machine. The vertical automatic packaging machine is mainly characterized in that a vertical rotating motor drives a main shaft to rotate so as to drive a material stirring disc to turn over materials; after material grabbing is completed, a rod piece carrying disc is driven by an external motor to move upwards, and a material grabbing rod is propped open; a material stirring stop disc and a clamping disc are driven by corresponding motors to move downwards; a material stirring stop plate of the material stirring stop disc blocks an opening in the side surface of a screening box body; a clamping jaw of the clamping disc clamps suction nozzle materials on the material grabbing rod; the material stirring stop disc and the clamping disc move upwards; the rod piece carrying disc restores to the station, and the material stirring action is repeated; and the clamping disc ascends to a heat sealing station, a cutting mechanism cuts packaging paper and pushes the packaging paper to a packaging bag operation platform, all actions are completed through bag opening of a bag opening suction rod and heat sealing of a heat sealing mechanism, and finally discharging is conducted. The vertical automatic packaging machine is high in yield, high in finished product rate, small in occupied area and high in automation degree.

Owner:阳平件

Packing robot

ActiveUS11034034B2Minimize timeProgramme-controlled manipulatorGripping headsEngineeringComputer vision

A produce packing robot is provided comprising a plurality of heads for picking up items of produce from a plurality of pick-up locations, and moving the items of produce and dropping them off at a plurality of drop-off locations. The plurality of heads move together in a first direction on a common rail. The robot may also comprise a range imaging camera and controller for sensing the location of the drop-off points dynamically.

Owner:ROBOTICS PLUS LTD

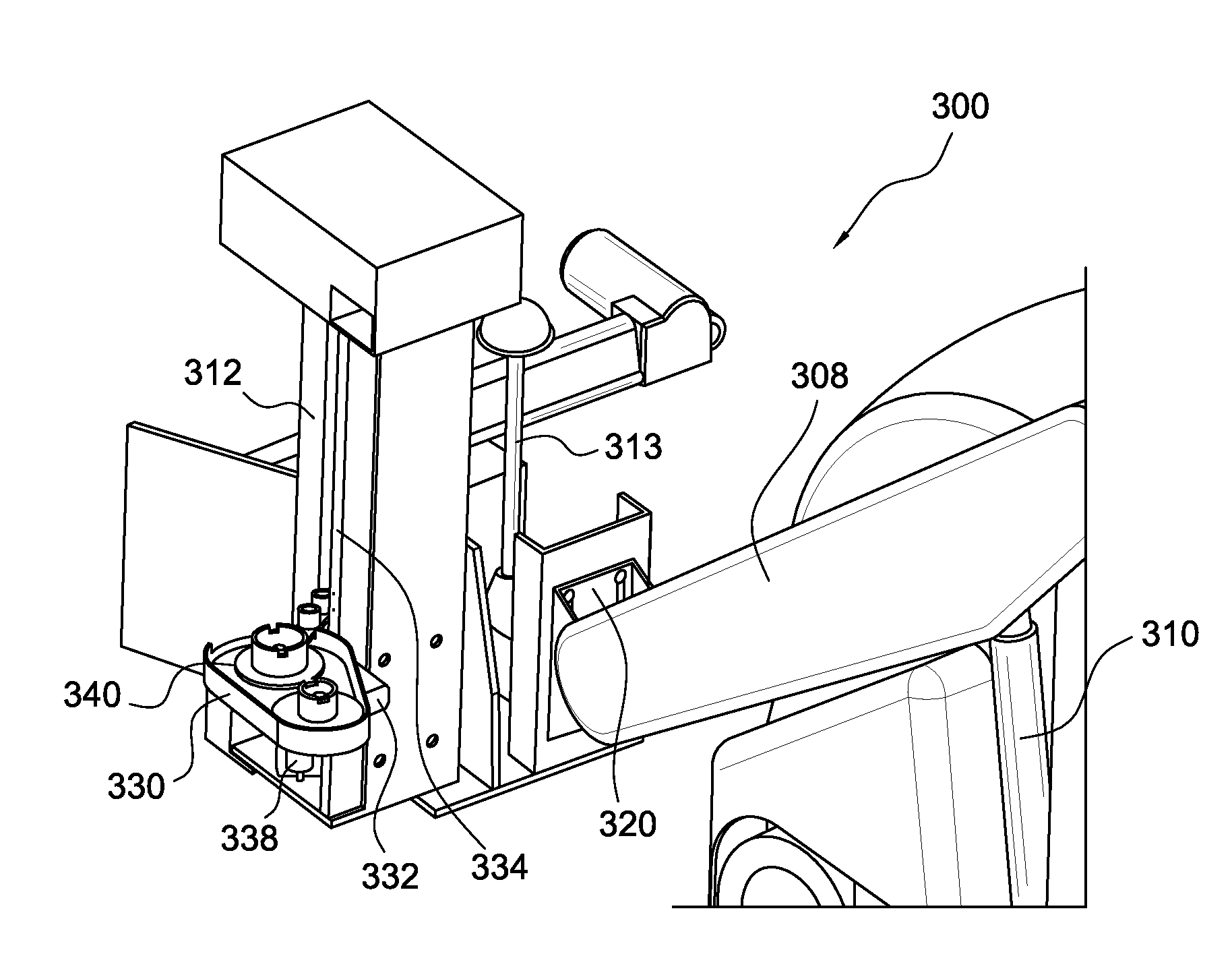

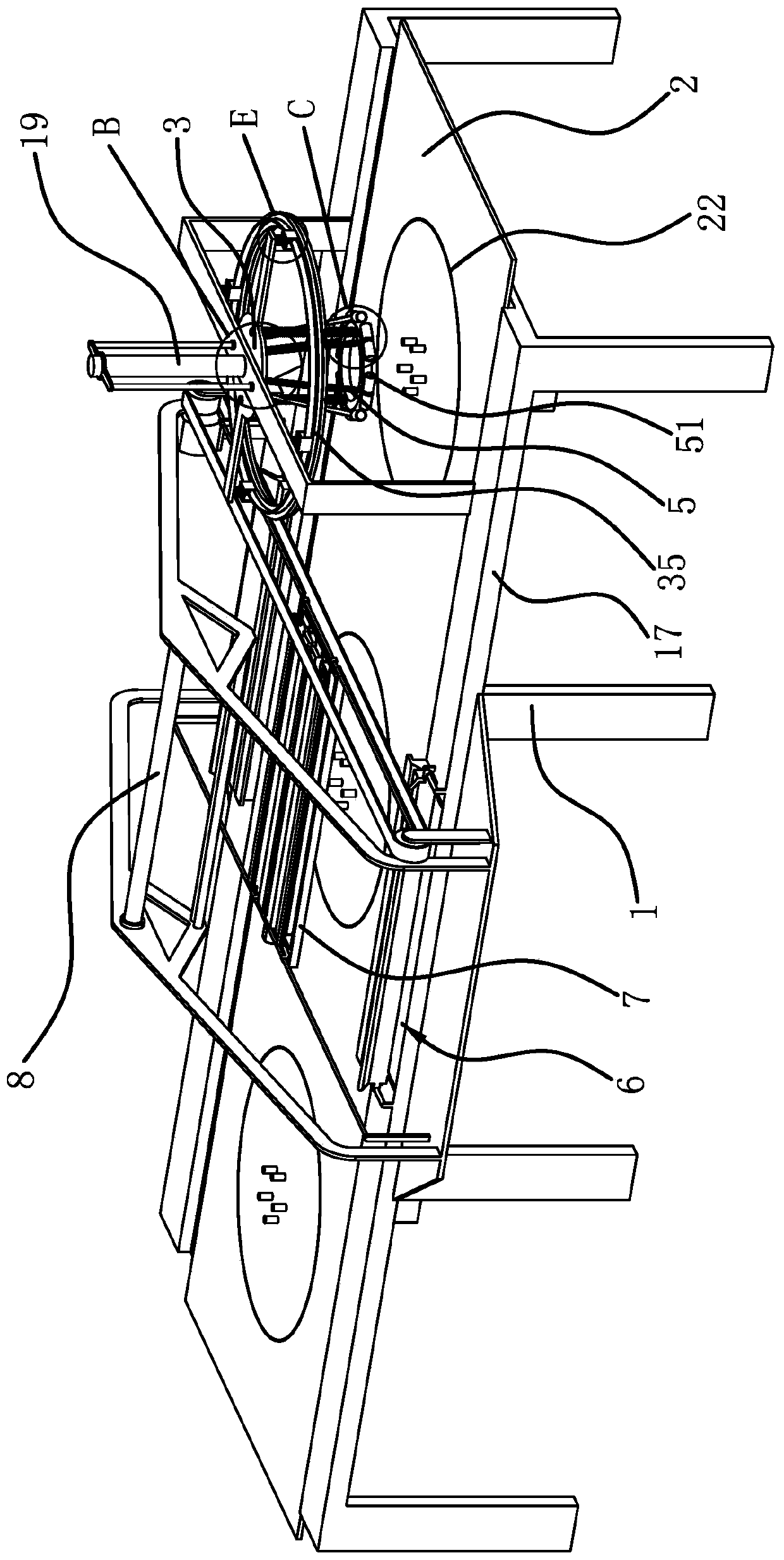

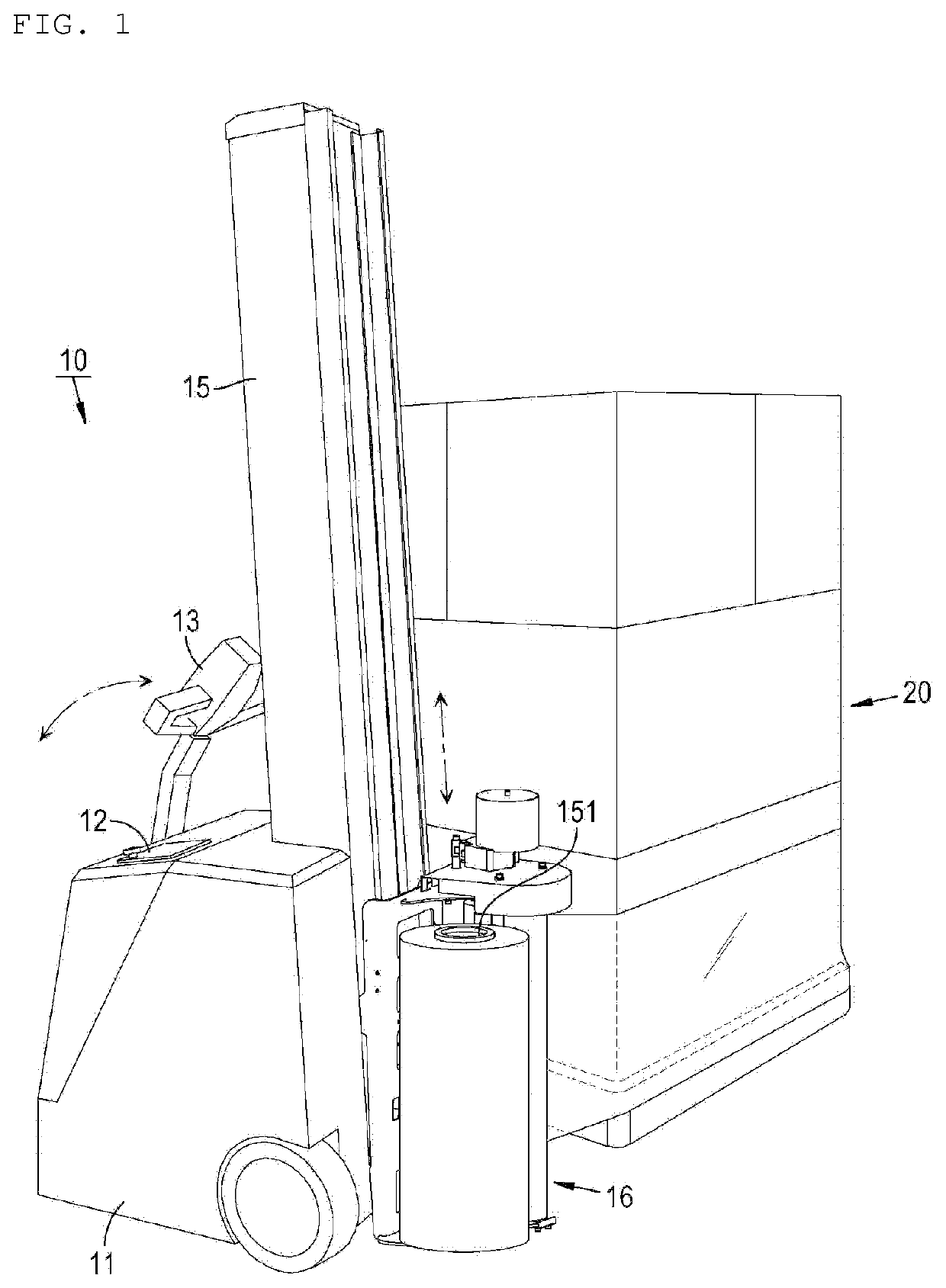

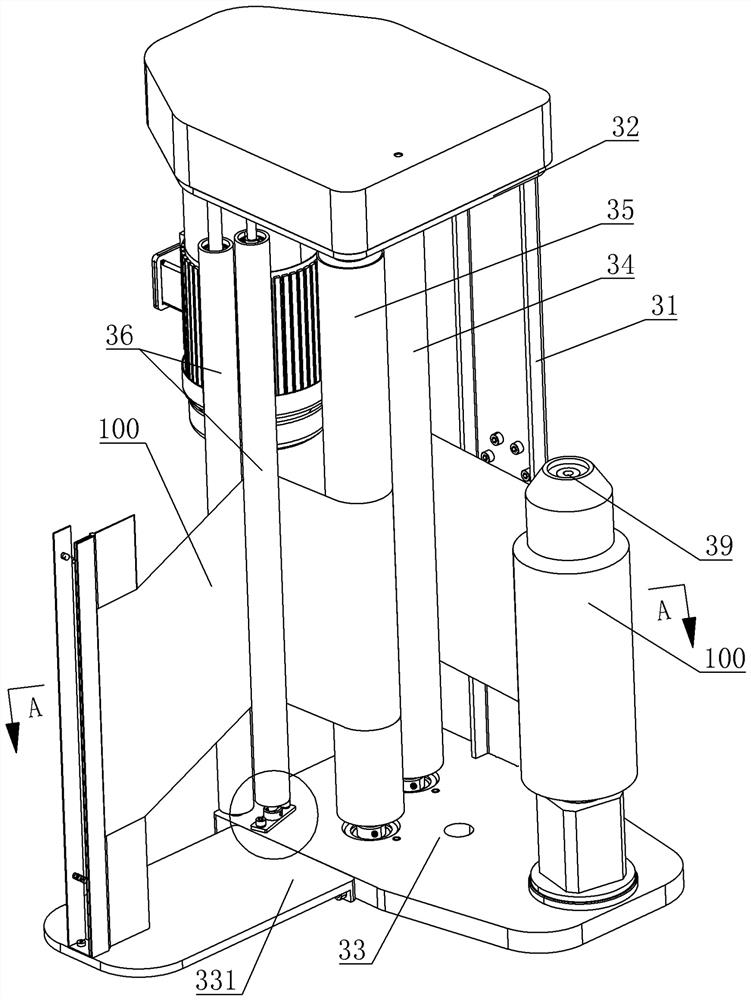

Wrapping robot with enhanced safety and reliability

ActiveUS20220348373A1Improve securityImprove reliabilityProgramme-controlled manipulatorPrestretching mechanismSimulationMechanical engineering

The present invention provides a wrapping robot with enhanced safety and reliability, the wrapping robot being able to prevent a safety accident that occurs when a worker or another object hits against a handle protruding outward from a robot body while the robot revolving around a product to perform wrapping by biasing the handle toward the product to be wrapped; and being able to improve reliability of wrapping by stopping operation of the wrapping robot when a wrap is loosened or cut during wrapping, using a sensor that senses loosening or cutting of a wrap.

Owner:YOON MYOUNG KOO

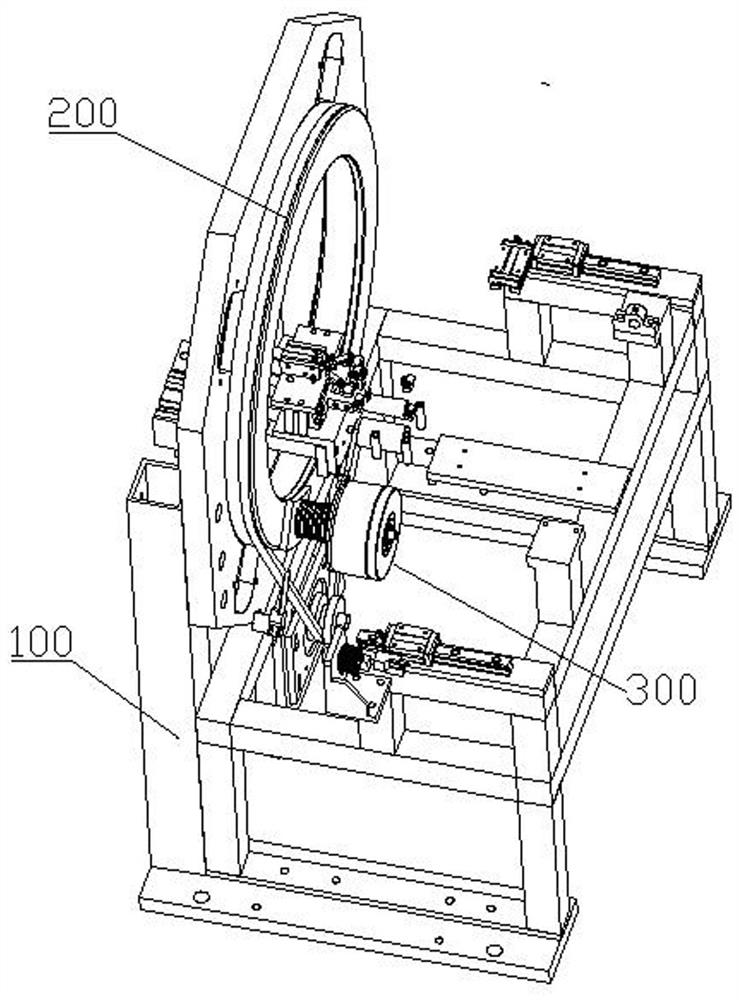

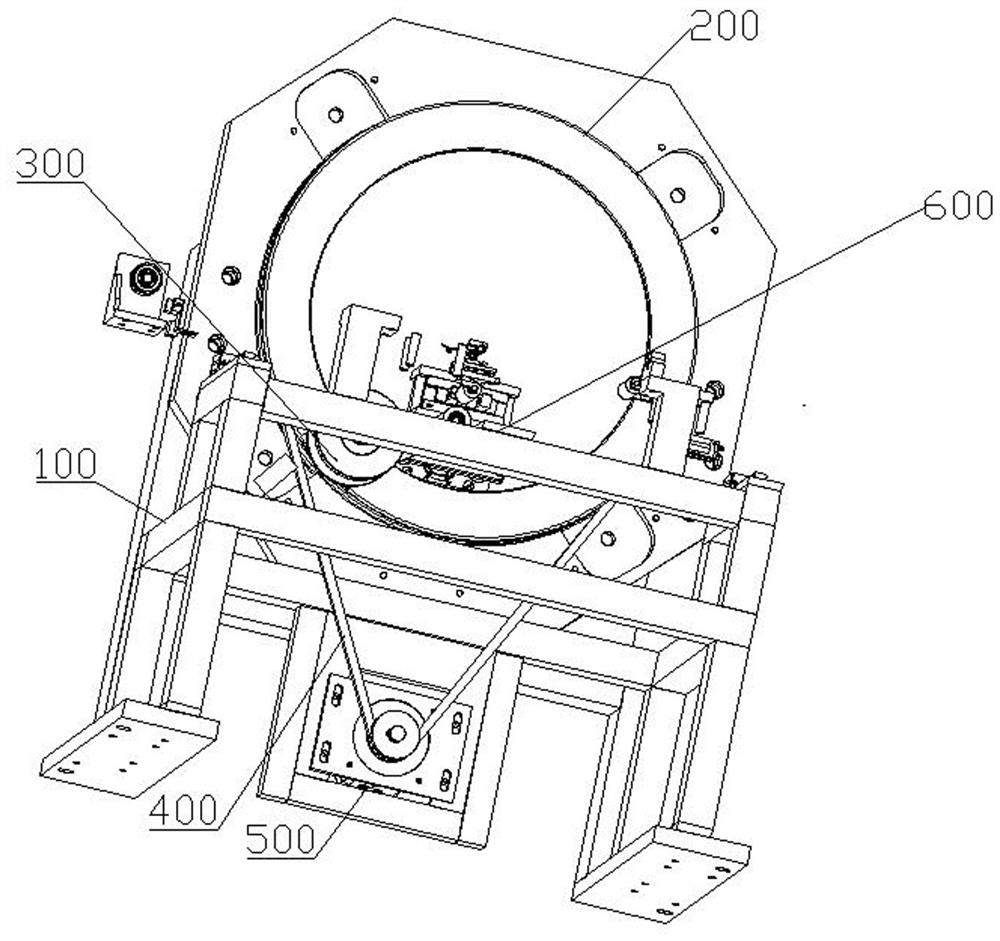

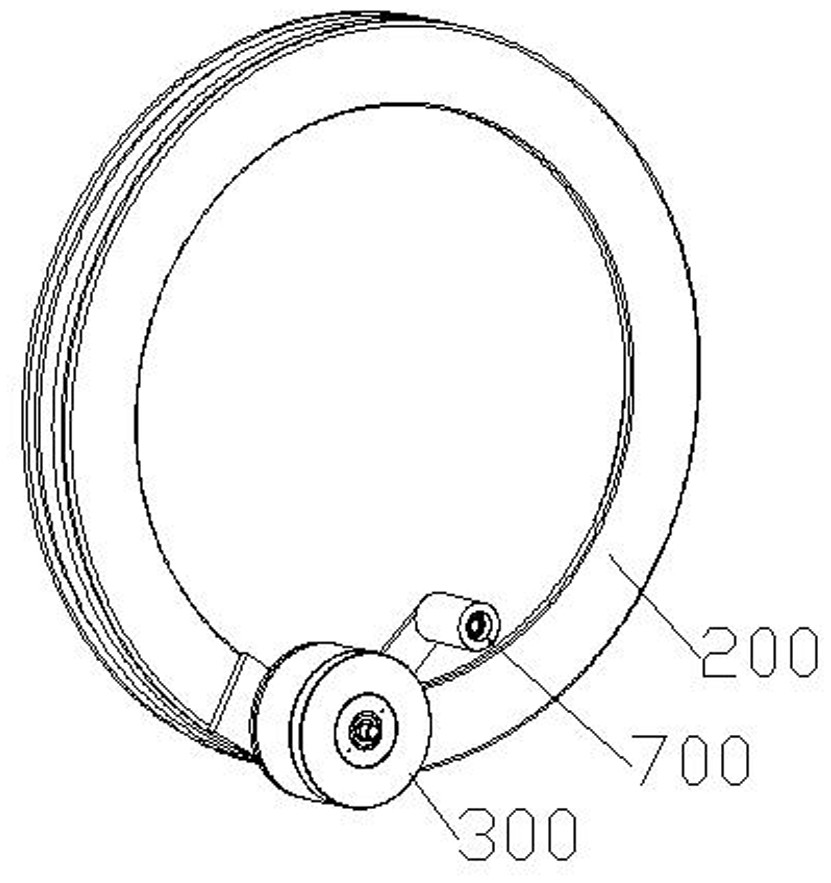

Winding packaging robot

The invention discloses a winding packaging robot, which belongs to the field of packaging, and comprises a machine body, a rotating wheel positioned on the machine body, a mounting wheel, a transmission belt, a driving machine and a fixing unit, a product to be packaged is fixed to the center position of the rotating wheel through the fixing unit, the rotating wheel is connected with the driving machine through the transmission belt, the driving machine drives the rotating wheel to rotate through the transmission belt, the edge of the rotating wheel is provided with an installation wheel, and the installation wheel is provided with a packaging film. The rotating wheel rotates to enable the mounting wheel to rotate so as to package a product on the fixing unit by a film, the mounting wheel comprises a central wheel body, the film for packaging is arranged on the edge of the central wheel body, wheel discs are respectively mounted at the two sides of the central wheel body, and the wheel discs and the central wheel body are coaxial.

Owner:XINGTAI POLYTECHNIC COLLEGE

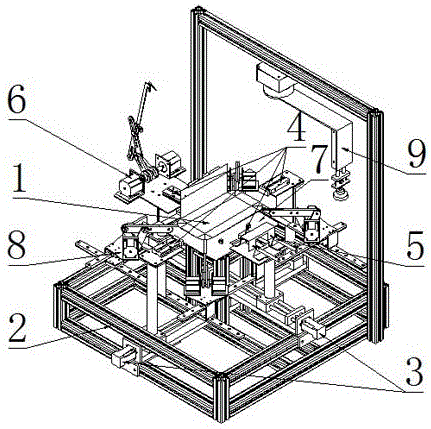

A Parts Mixing System for Combined Equipment

ActiveCN110371359BAutomate operationReduce labor costsPackaging automatic controlProcess engineeringMechanical engineering

Owner:王彪

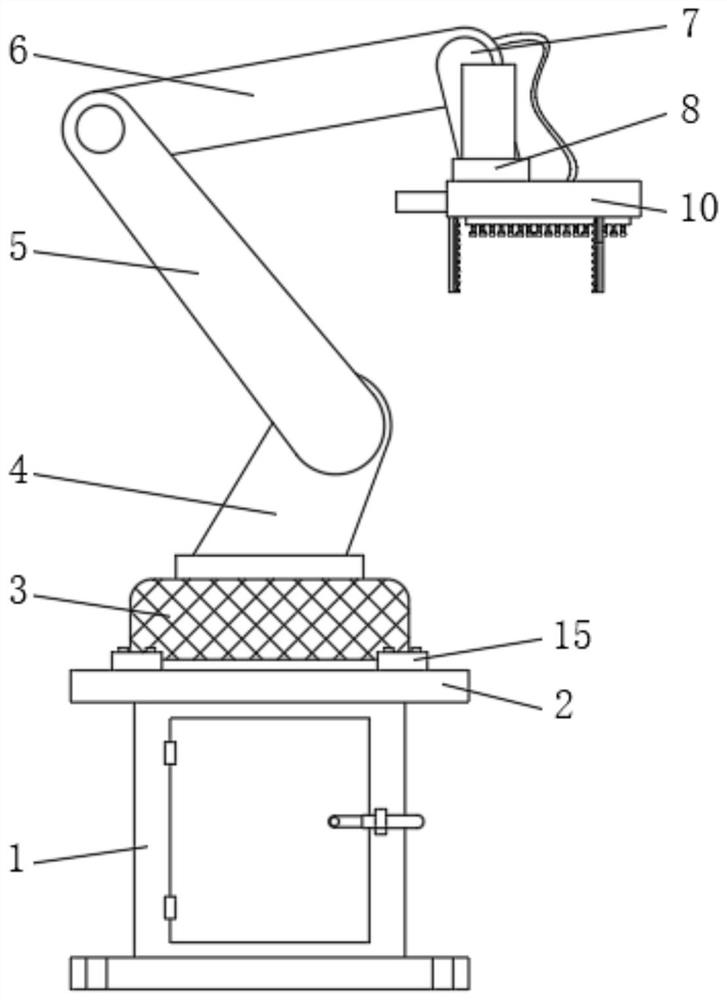

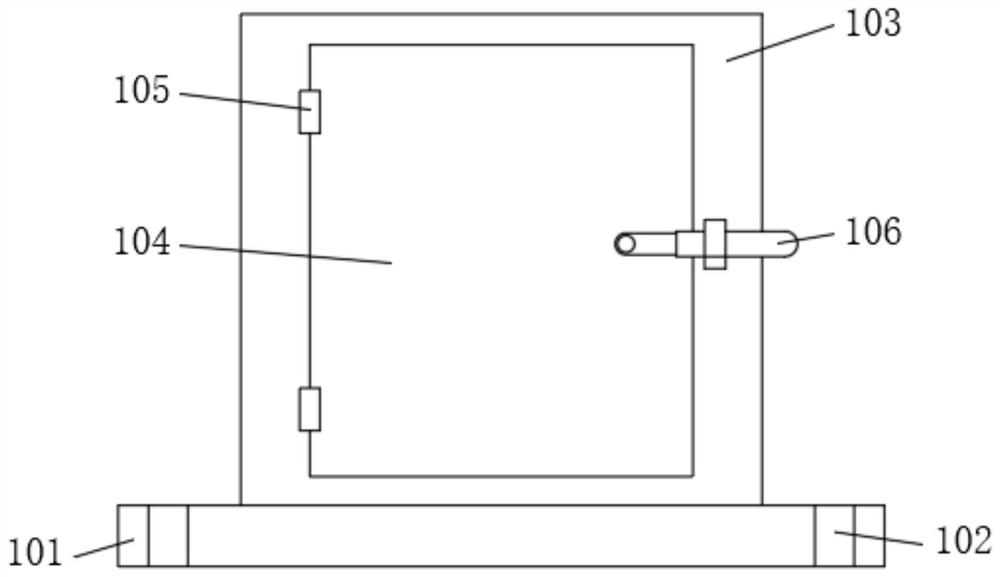

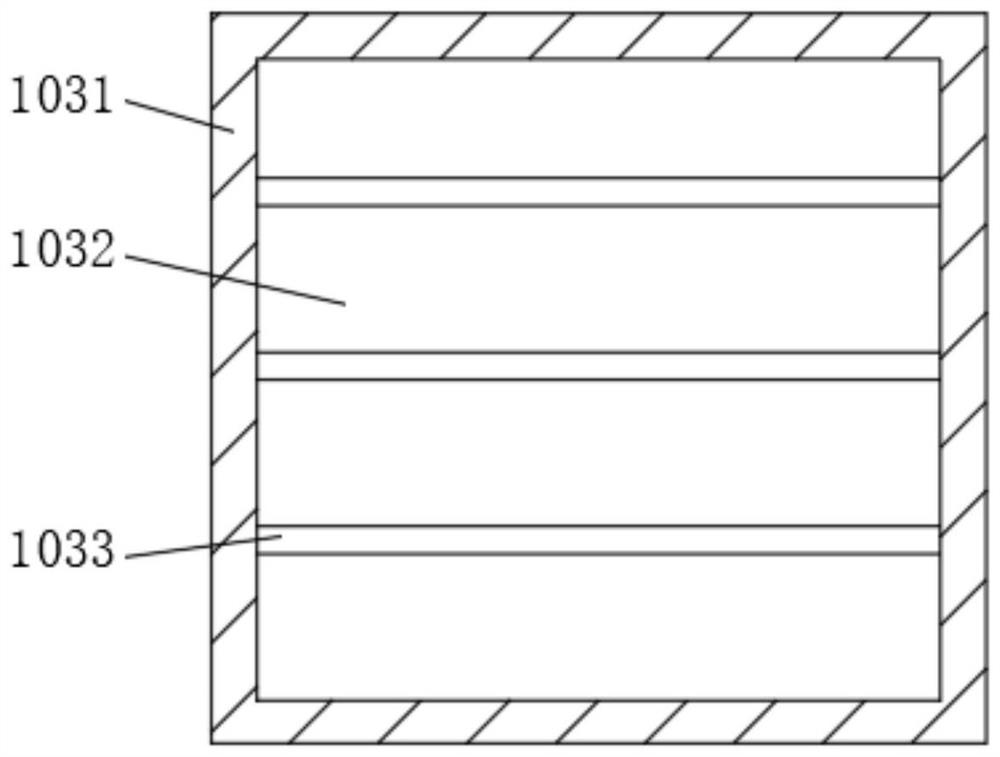

Automatic storage packaging robot for manufacturing industry

PendingCN112591199AEasy to transport for mobile workEasy to operatePackagingMechanical engineeringManufacturing sector

The invention discloses an automatic storage packaging robot for a manufacturing industry. The automatic storage packaging robot comprises a fixing base, wherein a supporting plate is fixedly arrangedat the upper end of the fixing base, an mounting seat is arranged on the supporting plate, and a rotating arm is arranged on the mounting seat. According to the automatic storage packaging robot forthe manufacturing industry, the fixing base is provided with two mounting modes, the mounting modes can be selected, transportation and moving work of the robot is facilitated, a connecting lock is adopted, opening and locking work of a movable door is facilitated, and meanwhile, a detachable rubber sleeve is arranged, impact between a rotating rod and a blocking rod can be reduced, disassembly and replacement are convenient, a suction structure can improve the clamping stability of an object and prevent the object from sliding down and being broken, springs are arranged, buffering can be carried out in the suction process, the use effect is improved, clamping pieces are arranged, the impact force on the object during clamping can be reduced while the clamping effect is ensured, and structures such as a rubber plate can be detached and are convenient to detach for replacement.

Owner:南京岱亿科技有限公司

Industrial object packaging robot

ActiveCN113635666ADoes not affect productivityImprove aestheticsInking apparatusRotary pressesAdhesive beltMechanical engineering

The invention belongs to the field of packaging, and particularly relates to an industrial object packaging robot. The robot comprises a fixing frame, box type limiting clamps are symmetrically arranged at the bottom of the inner wall of the fixing frame, the bottom ends of the box type limiting clamps are fixedly connected with the bottom of the inner wall of the fixing frame, and a conveying belt is slidably connected to the back of the outer surface of each box type limiting clamp. The lower surface of the conveying belt is slidably connected with the bottom of the inner wall of the fixing frame, a painting rod is fixedly connected to the top of the inner wall of the fixing frame, and the top end of the painting rod extends into an inner cavity of the fixing frame. The painting rod is shortened through the extrusion acting force, the bottom end of the painting rod makes contact with the upper surface of a box all the time, then the upper surface of the box is printed, and in the whole process, the product production efficiency is almost not affected by the added printing process; and according to the printed box, wrinkles of adhesive tape pasting can be covered by printed trademark patterns, so that the attractiveness of the product is further improved, and the product is more easily accepted by the market.

Owner:南通拂莱智能装备有限公司

Packaging robot for food production

PendingCN113277183AImprove cleanlinessFast cleaning effectPackaging automatic controlPump installationsHydraulic cylinderElectric machinery

The invention discloses a packaging robot for food production. The packaging robot for food production comprises a workbench, a storage groove, a material suction head and a hydraulic cylinder. The storage groove is fixedly formed in one side of the top of the workbench, a connecting plate is fixedly installed at one end of the top of the workbench, and the output end of a first motor is fixedly and rotationally connected with a threaded rod. A moving block is movably mounted on the surface of the threaded rod, a rotating rod is connected to the top of the moving block in a penetrating mode, a beam is fixedly connected to one side of the rotating rod, a material suction head is fixedly mounted at one end of the beam, and a hydraulic cylinder is fixedly arranged on the other side of one end of the beam. According to the packaging robot for food production, a metering plate is installed at the bottom end of the interior of the storage groove, whether to-be-packaged food exists in the storage groove or not can be accurately measured through a gravity sensor on the outer side of the storage groove, the two sides of the gravity sensor are connected with a reminding lamp and an operation panel through wires, the internal residual capacity is clear at a glance, and workers are more conveniently reminded to feed materials.

Owner:连云港市桂柳食品有限公司

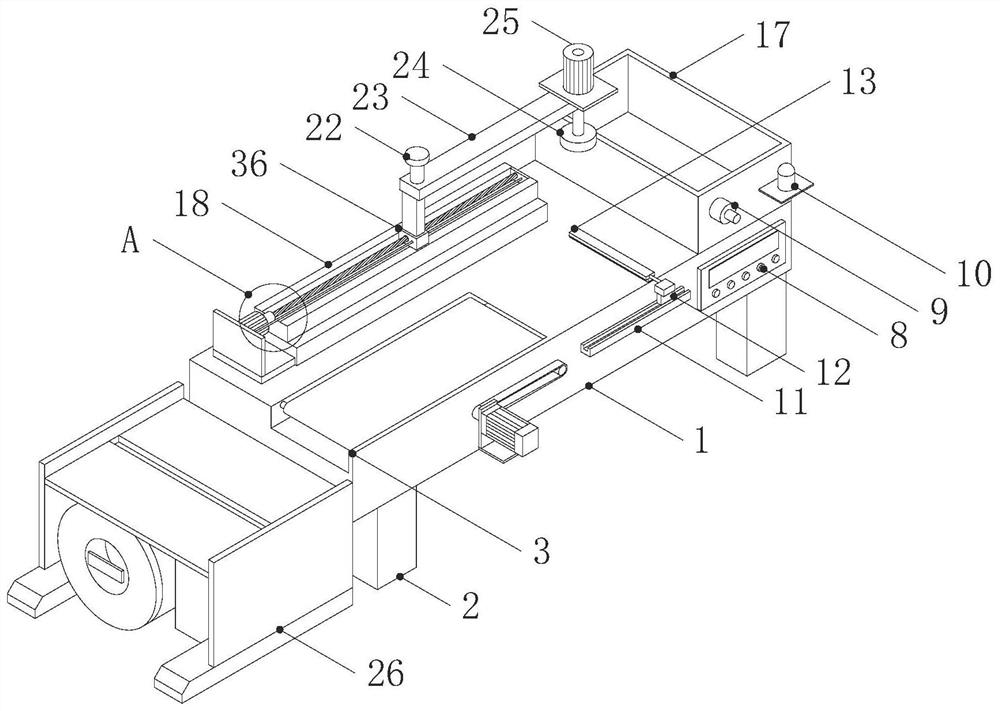

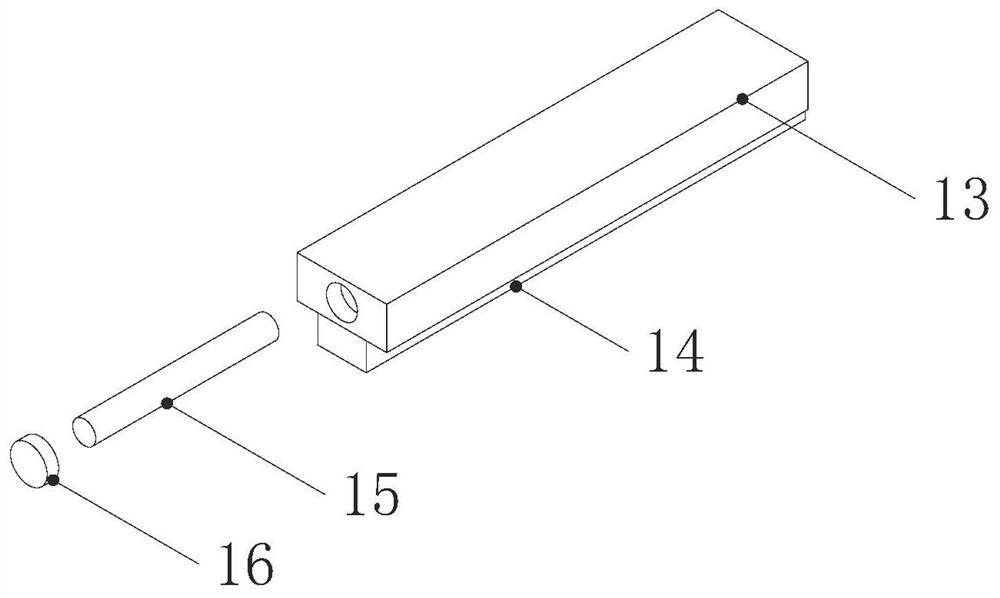

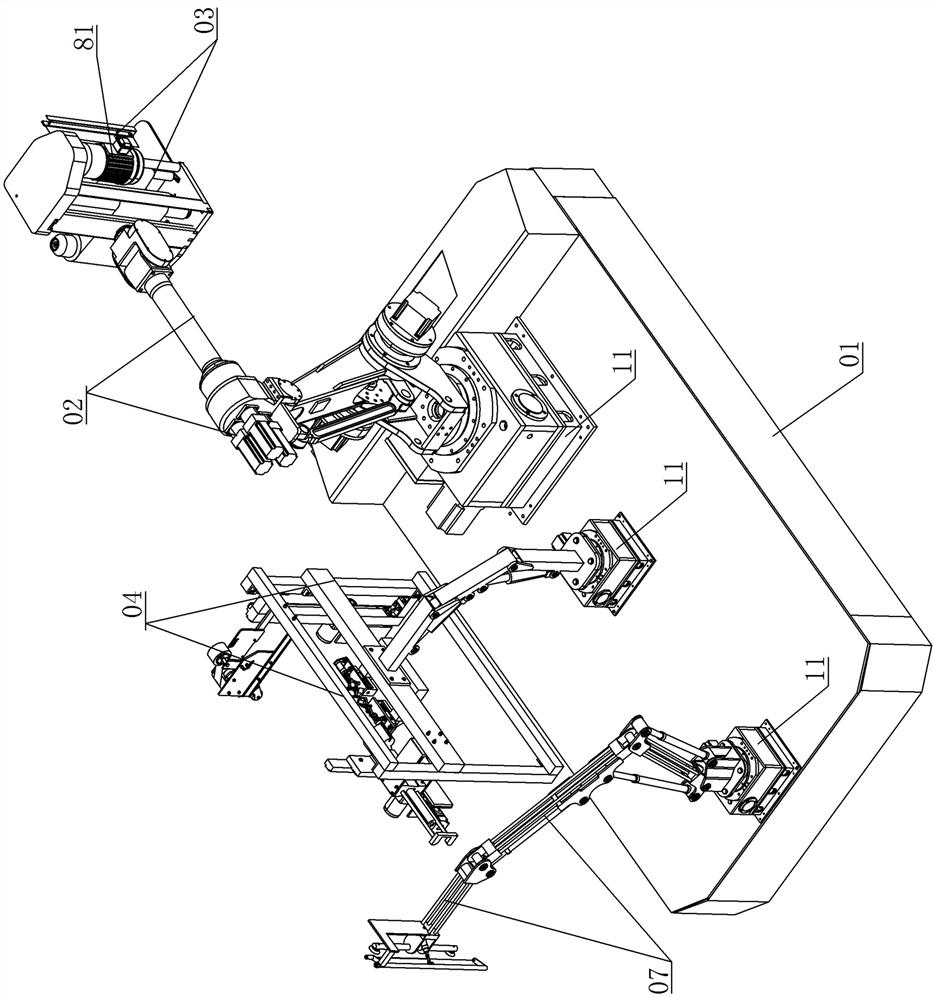

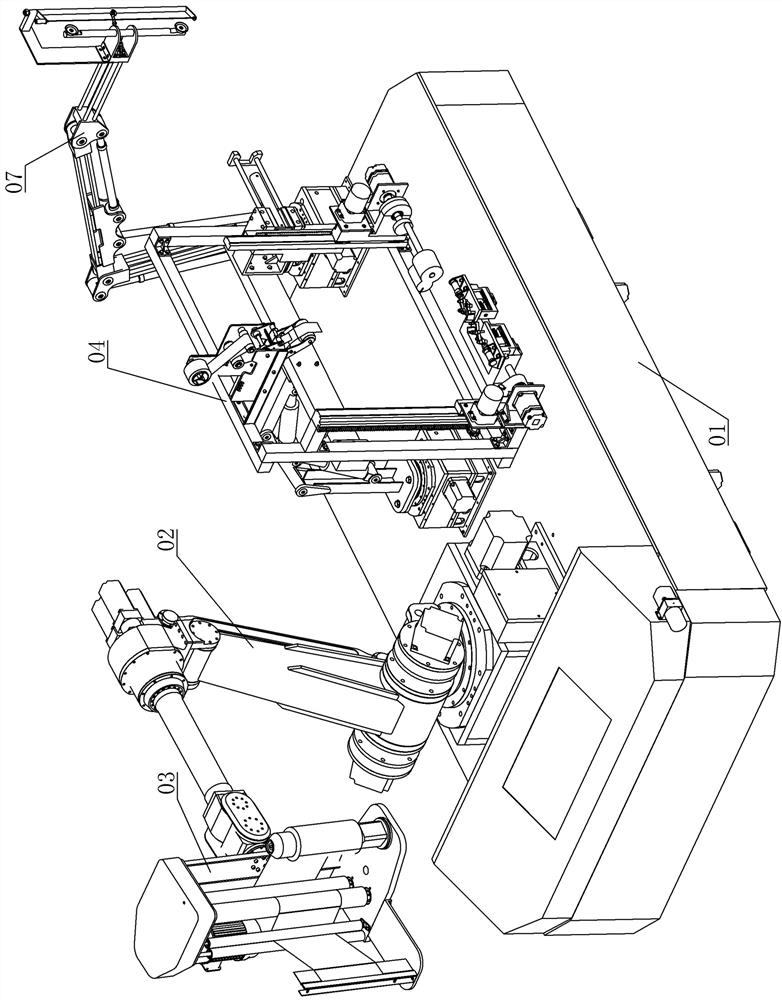

Self-propelled wrapping packaging robot and article wrapping method

ActiveCN112977916BNo manual operationFully automatedWeb rotation wrappingArticle deliveryWorking environmentEngineering

The invention relates to a self-propelled winding packaging robot and a method for wrapping articles. The robot completes the winding and packaging work of goods to be packaged by setting a film feeding device, a tape fixing device, and a suction cup positioning device on an AGV vehicle. The film feeding device can be The free movement corresponds to the suction cup positioning device. The suction cup of the suction cup positioning device sucks the film tightly and pulls it out from the film feeding device and presses it onto the goods to be packaged. The clamping and turning mechanism of the tape fixing device is used to pull out the tape and stick it onto the film and the object to be packaged, and then through the tape pressure head on the eccentric shaft of the tape cutting mechanism to complete the sticking and cutting of the tape, the AGV pulls the film and completes the wrapping of the goods to be packaged according to the preset winding path; this The invention realizes fully automated product wrapping packaging in the whole process, which improves packaging efficiency. The way of wrapping packaging can not only realize wrapping packaging of products of different shapes and sizes, but is not limited by the site and working environment, and has a strong promotion value.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com