Automatic packaging integrated data processing system and method

A technology of integrated data and automatic packaging, applied in the field of packaging, can solve problems such as data transmission delay, complex overall structure, and errors in mutual cooperation, and achieve the effect of simplifying the packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment discloses an automatic packaging integrated data processing system, including:

[0039] Barcode system, scanning system, palletizing robot and packaging robot;

[0040] The barcode system includes the barcode pasted on the product, and the barcode records the order information of the product along with the generation of the product;

[0041] The palletizing robot fixes and confirms the effective position of the barcode product, puts it into the rolling conveyor chain, and sends it to the scanning system;

[0042] The scanning system sends the data obtained by scanning the product barcode to the barcode system for data feedback on the barcode data;

[0043] The packaging robot packages and packs the products scanned by the scanning system.

[0044] In the above scheme of the present disclosure, the barcode system produces the slitting barcode and sends it to the automatic packaging system. The barcode of each roll follows the goods and is transferred be...

Embodiment 2

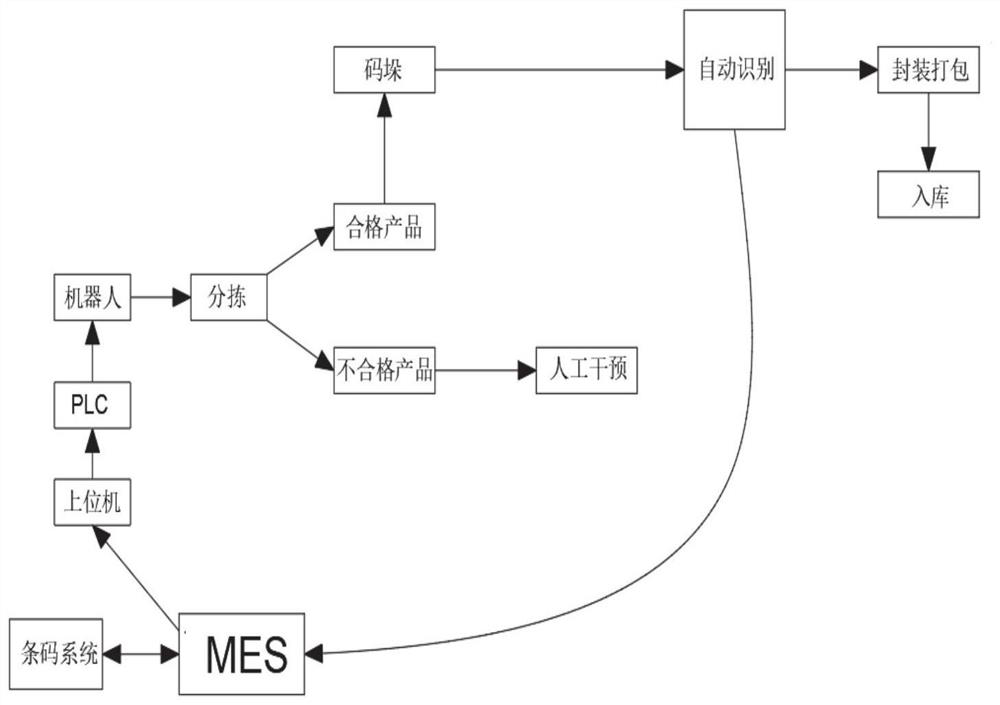

[0062] See attached figure 1 As shown, a control method of an automatic packaging integrated data processing system is provided, including:

[0063] The barcode records the order information of the product along with the generation of the product;

[0064] After the effective position of the barcode product is fixed and confirmed, the pallet is put into the rolling conveyor chain and sent to the scanning system;

[0065] The scanning system sends the data obtained by scanning the product barcode to the barcode system for data feedback on the barcode data;

[0066] Package and package the products scanned by the scanning system.

[0067] Before palletizing, it also includes sorting products, obtaining qualified products, and palletizing qualified products.

[0068] Automatic identification is required before packaging and packaging, and the palletized products are scanned again through the scanning system. If the data is consistent with the data to be packaged and packaged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com