Cover shaking double insurance inserting-in type paper box packaging robot

A plug-in, robotic technology, applied in the direction of packaging machines, packaging, transportation and packaging, etc., can solve the problems of internal medical product contamination, reduce labor intensity and labor costs, and improve the efficiency of carton packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

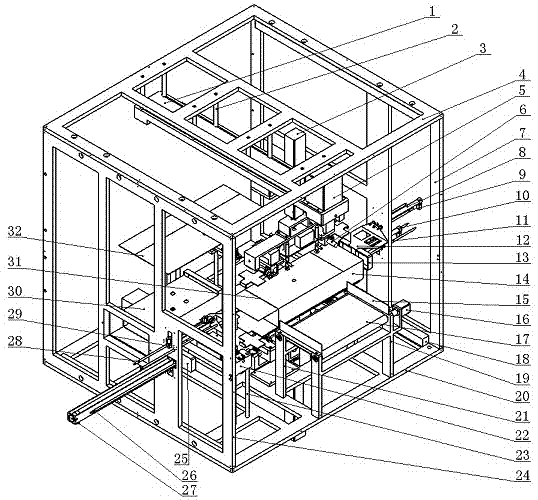

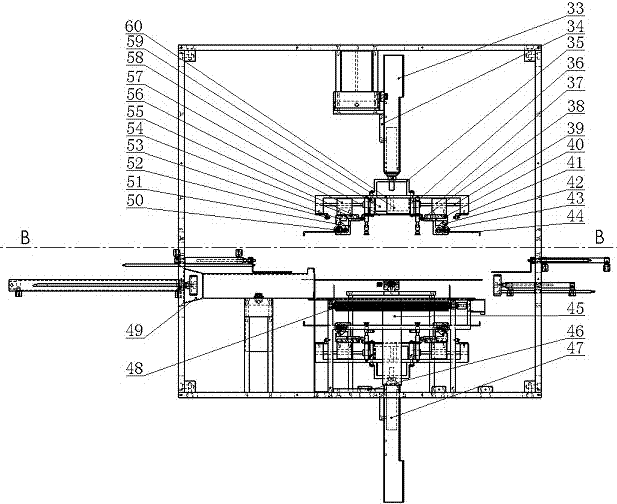

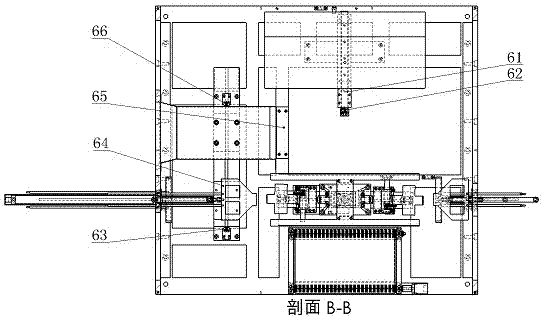

[0039] Such as figure 1 , figure 2 , image 3 As shown in the figure, a swing cover double-safety plug-in carton packaging robot includes an upper cover manipulator, a lower cover manipulator, a box input and opening module, a material feeding module, a double-side pushing and guiding mechanism module, and a box output module. The entire packaging and packaging process includes the process of taking out the box, opening the box, feeding, feeding, pushing the material on both sides, inserting the upper cover, guiding both sides of the upper cover socket, inserting the lower cover into the upper cover socket, and out of the box. . The following takes the packaging process of flexible and irregular materials (such as disposable medical masks, gloves, surgical gowns, etc.) as an example to illustrate the entire packaging process.

[0040] After the robot is powered on, it first self-checks the initial state of each component, including whether the initial state of each slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com