Vertical automatic packaging robot

An automatic packaging and robotic technology, applied in the field of robotics, can solve the problems of many manual participation links, low degree of automation, improper placement direction, etc., and achieve the effect of shortening the production process route, high degree of automation, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

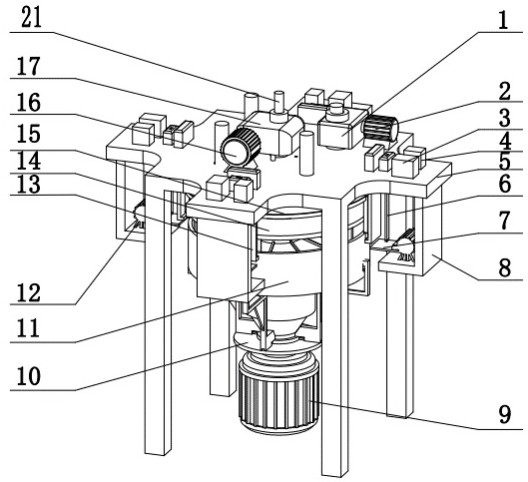

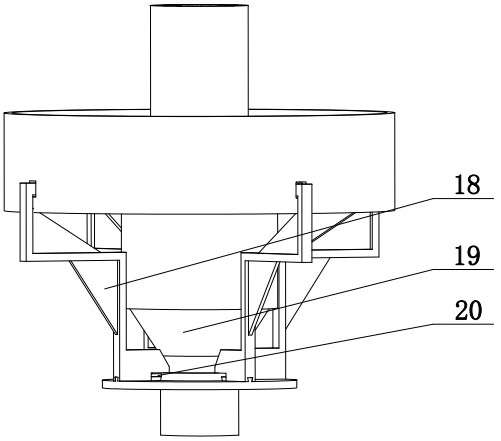

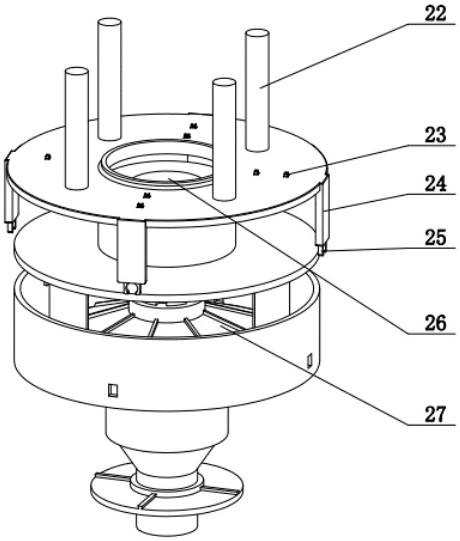

[0021] Examples, see Figure 1-7 As shown, a vertical automatic packaging robot includes a clamping disc screw lifter 1, a clamping disc lifting drive motor 2, a heat sealing machine power supply 3, a bag support suction rod air source 4, a packaging machine frame 5, a bag support Suction rod 6, packaging bag operation platform 7, cutting mechanism support platform 8, vertical rotating motor 9, rod mounting plate 10, screening box body 11, cutting mechanism 12, heat sealing mechanism 13, material dial stop plate 14, clip Holding plate 15, lifting drive motor 16 for material stop plate lifting, screw lifter for material stop plate 17, material grabbing rod 18, limit ring 19, return spring 20, material stop plate ejector rod 21, clamping plate lead screw 22 , wiring groove 23, clamping claw bearing rod 24,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com