An automated packaging robot

A technology of automatic packaging and robotics, applied in packaging machines, packaging, transportation and packaging, etc., can solve problems such as insufficient mobility and achieve the effect of preventing material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

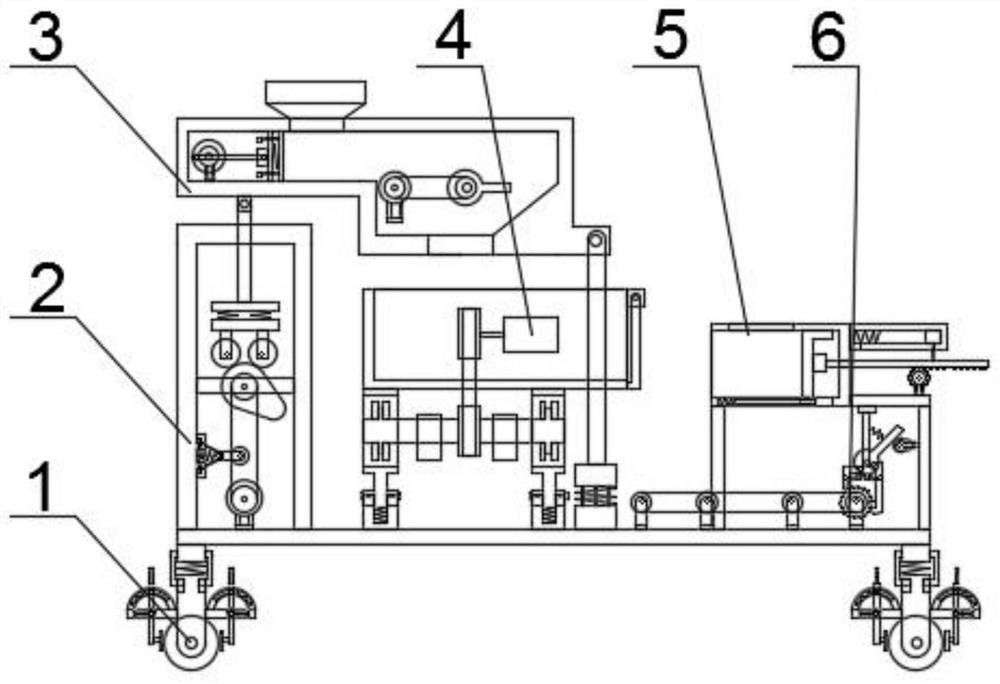

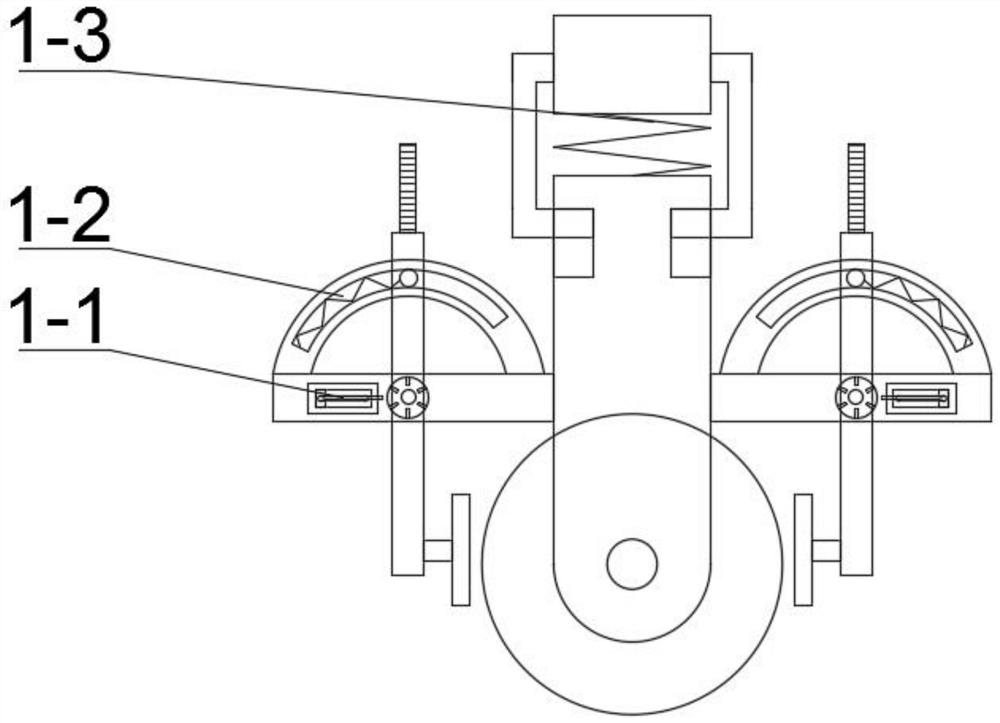

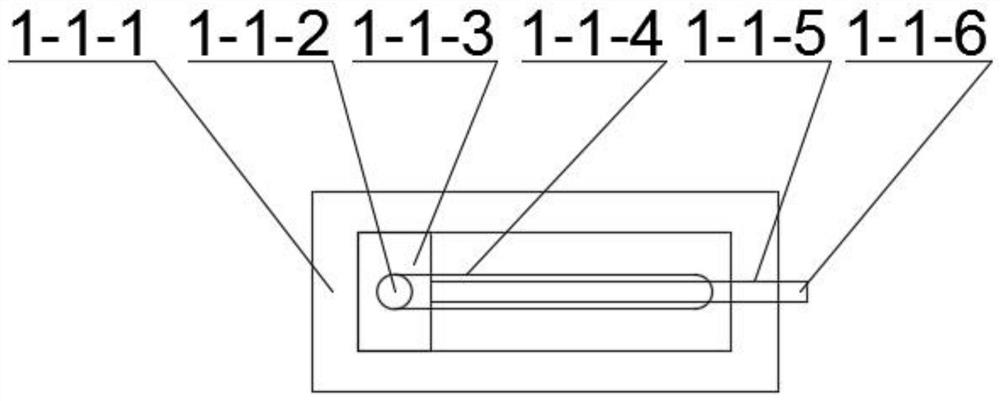

[0057] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 To illustrate this embodiment, the present invention relates to a packaging device, more specifically, an automated packaging robot, including a moving wheel mechanism 1, a tilting drive mechanism 2, a hopper mechanism 3, a vibrating feeding mechanism 4, and a packing box pushing mechanism 5. Loading and transportation mechanism 6, the device can move smoothly, the device can park, the device can tension the belt, the device can tilt the feeding, the device can prevent the accumulation of materials, the device can clean the accumulated materials through vibration, and the device can vibrate the feeding , the device can automatically send the box, and the device can tra...

specific Embodiment approach 2

[0081] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 This embodiment will be described. This embodiment will further describe the first embodiment, and the number of the moving wheel mechanisms 1 described above is four.

specific Embodiment approach 3

[0083] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 This embodiment will be described. This embodiment will further describe the first embodiment. The material of the collecting hopper 3-4 is high manganese steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com