Intelligent manufacturing production line for electric cylinders

An intelligent manufacturing and production line technology, applied in manufacturing tools, packaging automatic control, laser welding equipment, etc., can solve the problems that affect the yield of electric cylinder products, low production efficiency, high labor cost, etc., to improve production efficiency and reduce workload , The effect of increasing the output of the electric cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

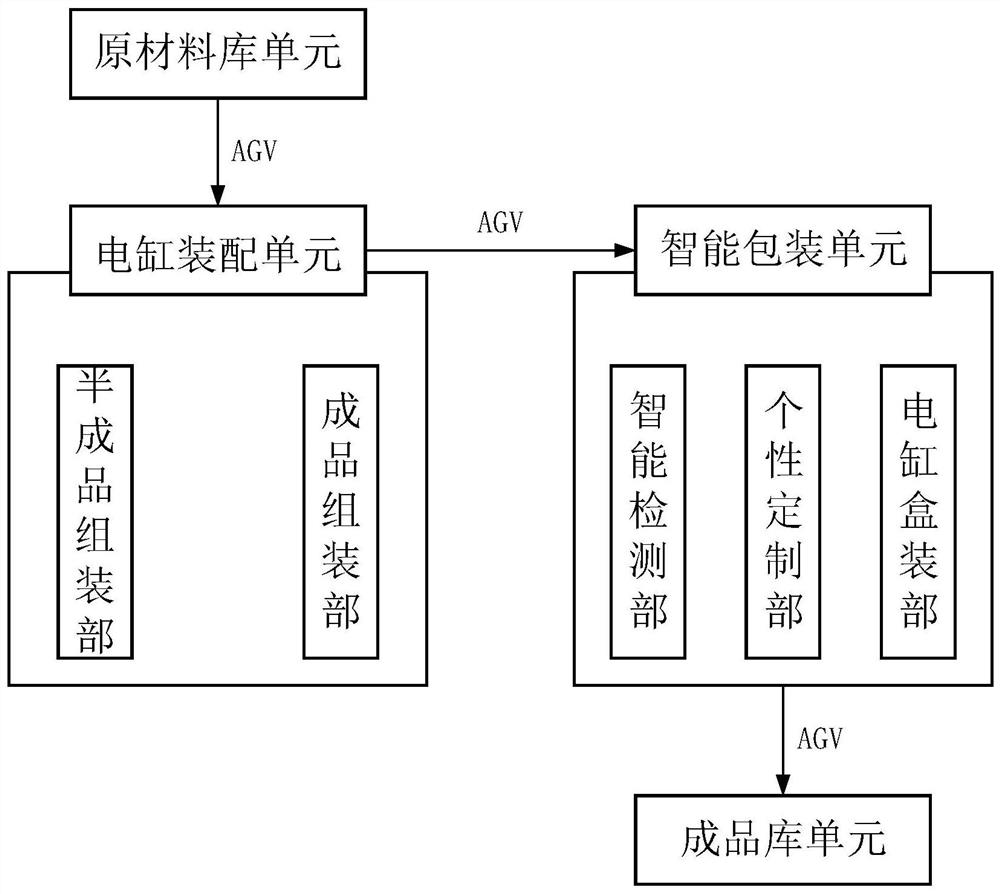

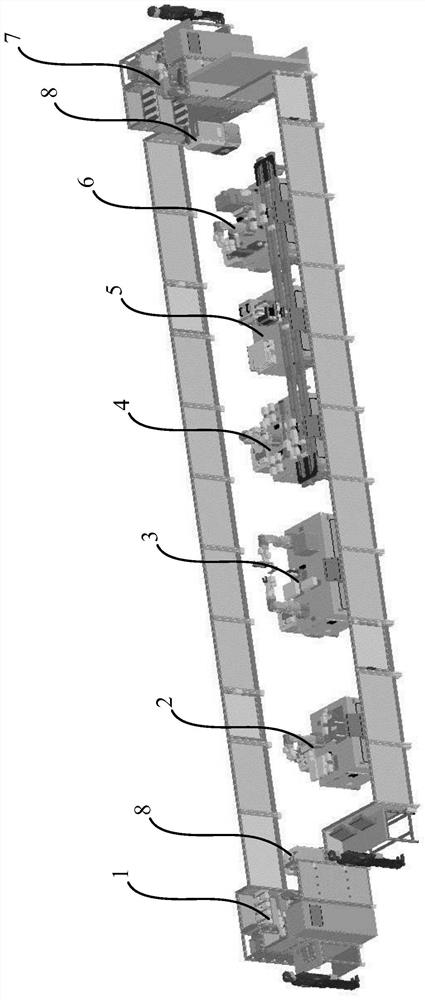

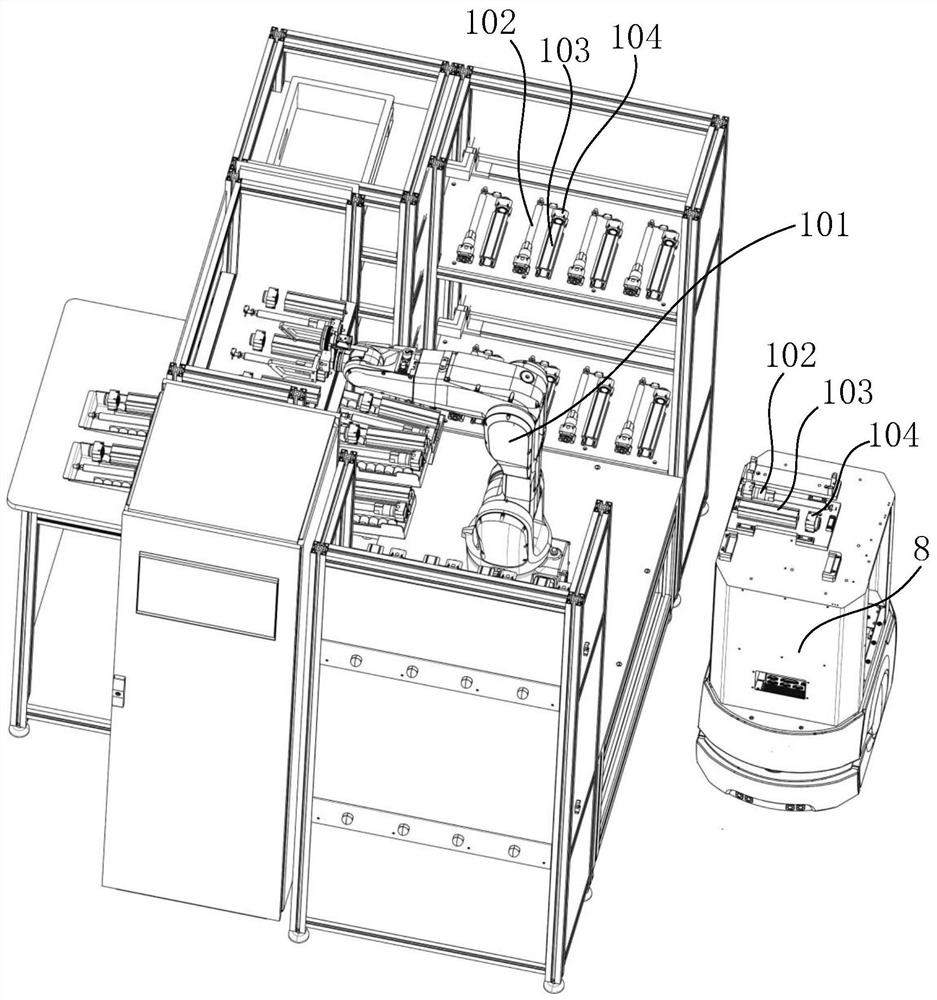

[0112] The present disclosure provides an electric cylinder intelligent manufacturing production line. The electric cylinder intelligent manufacturing production line realizes the coordinated control of robot automatic feeding and AGV automatic conveying device, and can produce electric cylinders in a more rapid and stable manner, effectively reducing the The workload of the workers is replaced by the traditional manual production method with the assembly line production method, and the intelligent production of the electric cylinder is realized, which greatly improves the production efficiency of the electric cylinder, further increases the output of the electric cylinder, and ensures the stability of the production quality of the electric cylinder. The finished product rate of electric cylinder production is improved, and the manufacturing cost is reduced. The main shortcomings and deficiencies of the existing electric cylinder manufacturing production line can be overcome. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com