Packaging film fixing device of winding packaging robot

A technology of fixing device and packaging film, which is applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of limited application range and place, low efficiency, low degree of automation, etc., and achieve the effect of improving the efficiency of wrapping packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

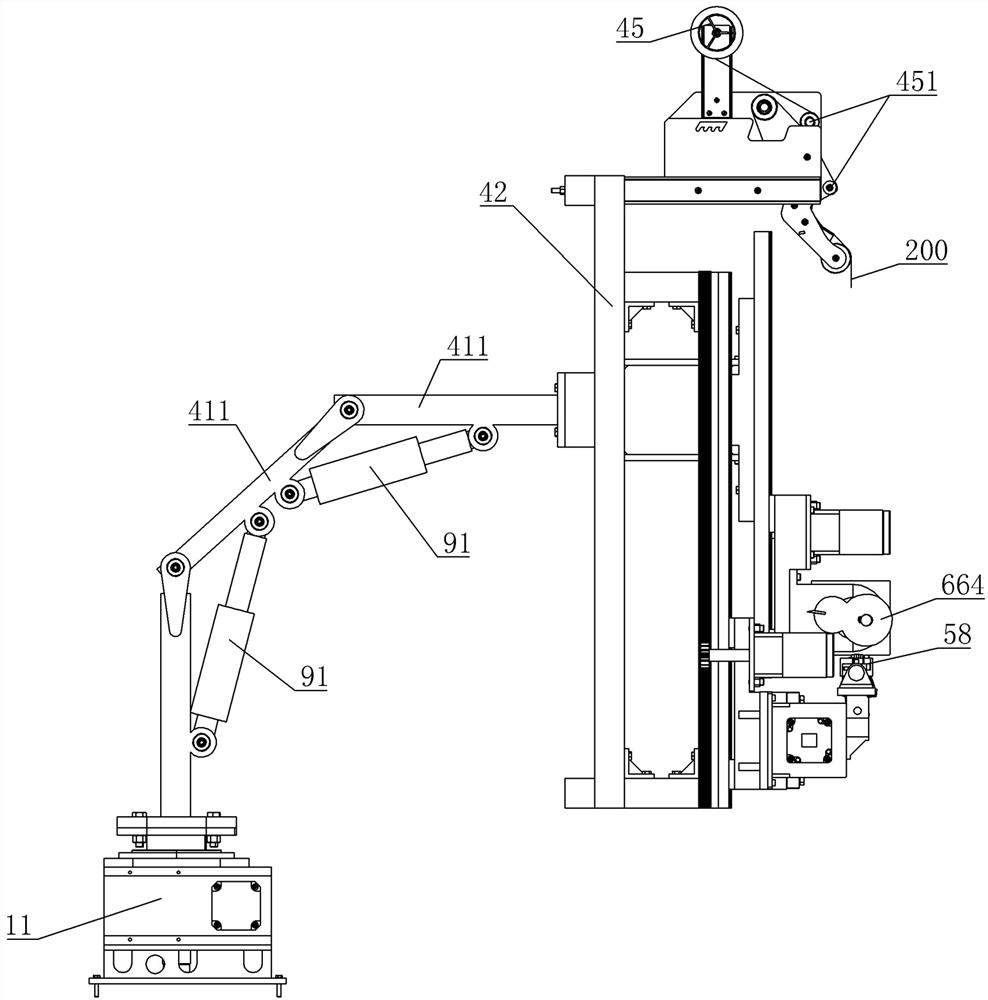

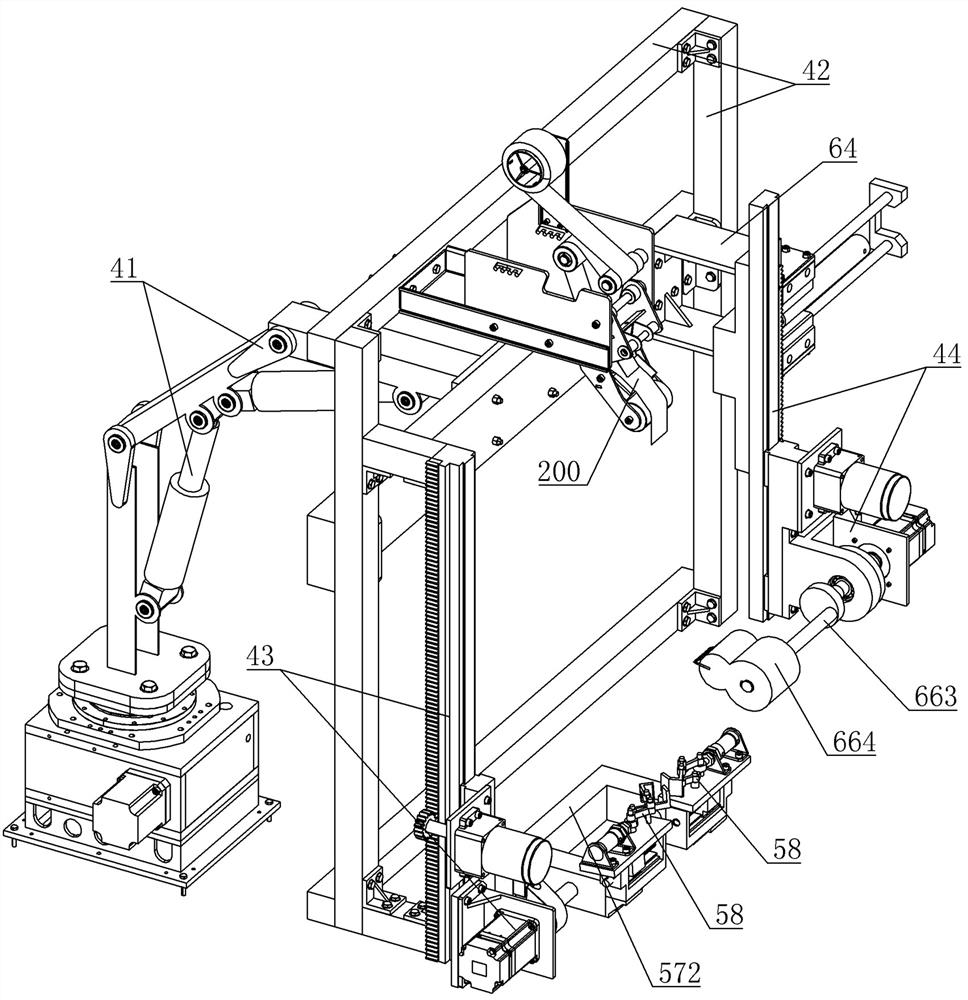

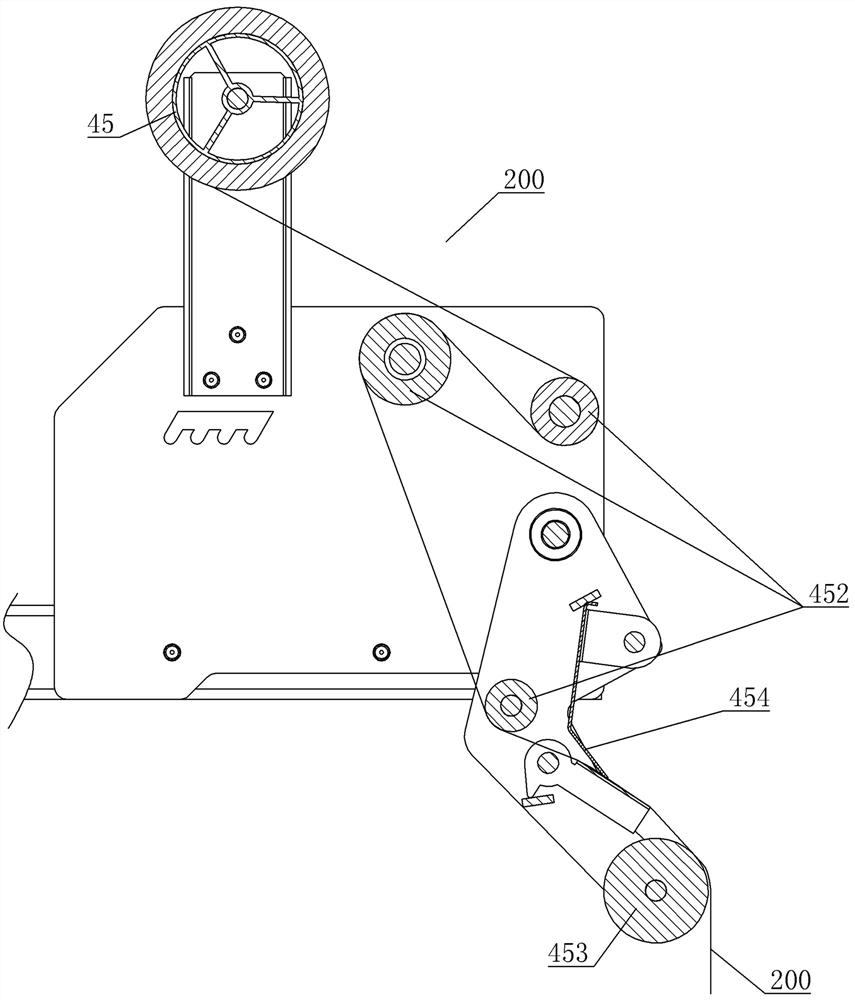

[0037] Embodiment one, refer to the description attached figure 1- 9. A packaging film fixing device for a wrapping packaging robot, characterized in that the device includes a rotating base fixed on the AGV, a multi-section arm armor with horizontal or vertical telescopic functions, a clamping and turning mechanism, and a pressing belt Cutting mechanism, tape wheel, the lower end of the multi-section arm armor is fixedly connected to the rotating base, the upper end is fixedly connected with a square bracket, and one side of the square bracket is vertically provided with a rail rack assembly A, which includes a rack rack and a guide rail A, used for lifting and clamping turning mechanism;

[0038] The inner side of the support A that clamps the turning mechanism is provided with a slider A and the guide rail A sliding connection, and the outer surface of the support A is provided with a gear motor A, and the shaft of the gear motor A is provided with a gear A and a rack A mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com