Self-propelled wrapping packaging robot and article wrapping method

A robot, self-propelled technology, applied in packaging/bundling items, packaging, wrapping items, etc., can solve the problems of limited use scope and place, low efficiency, low degree of automation, etc., to achieve strong promotion value and improve packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

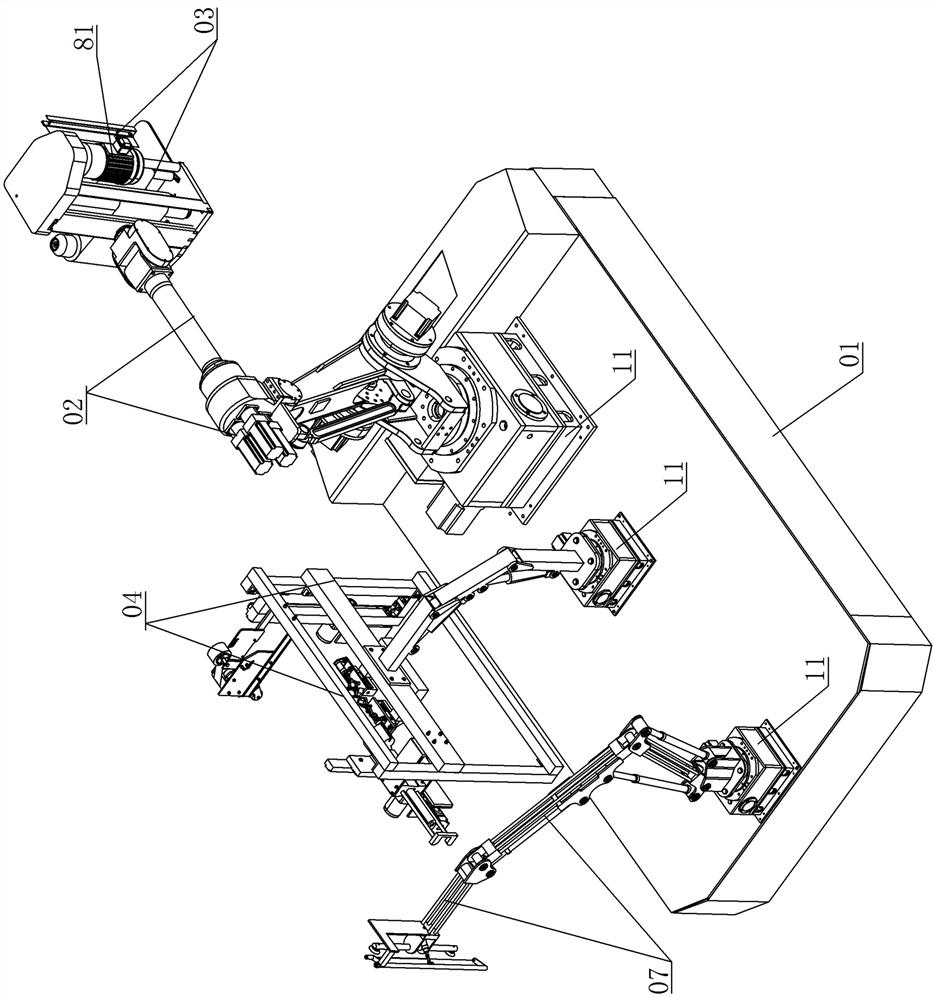

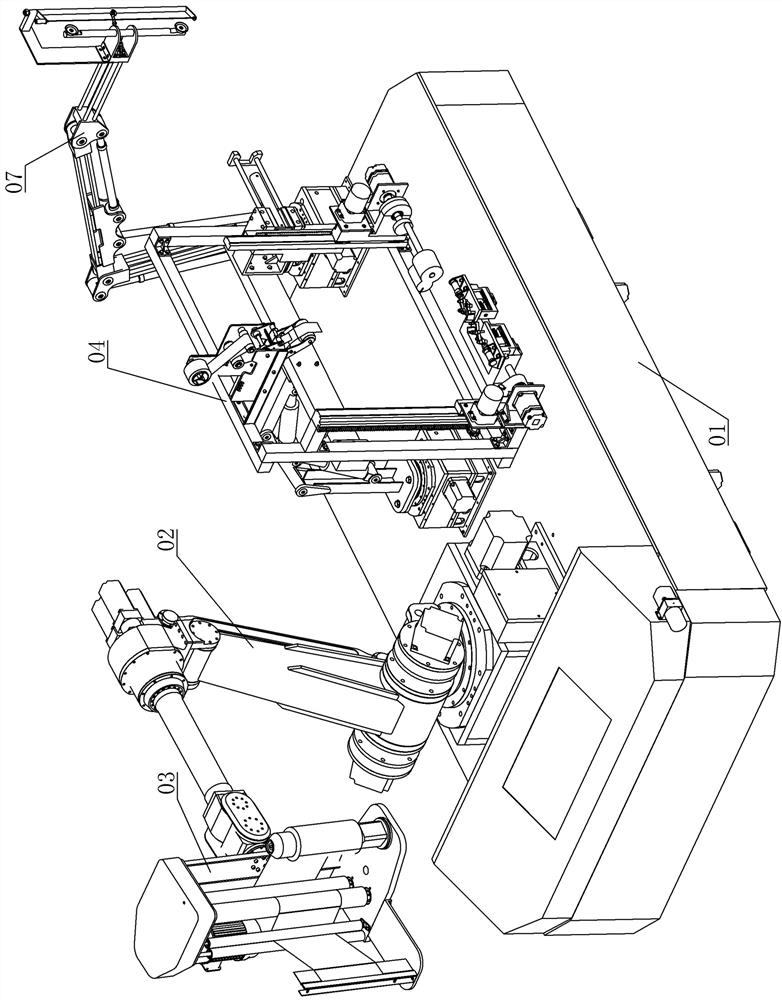

[0062] Embodiment one: refer to the appended Figure 1-22 , a self-propelled winding packaging robot, including an AGV vehicle and a mechanical arm installed at its front end, a film feeding device is provided on the mechanical arm, a tape fixing device is installed in the middle of the AGV vehicle, and a suction cup positioning device is installed at the rear end of the AGV vehicle;

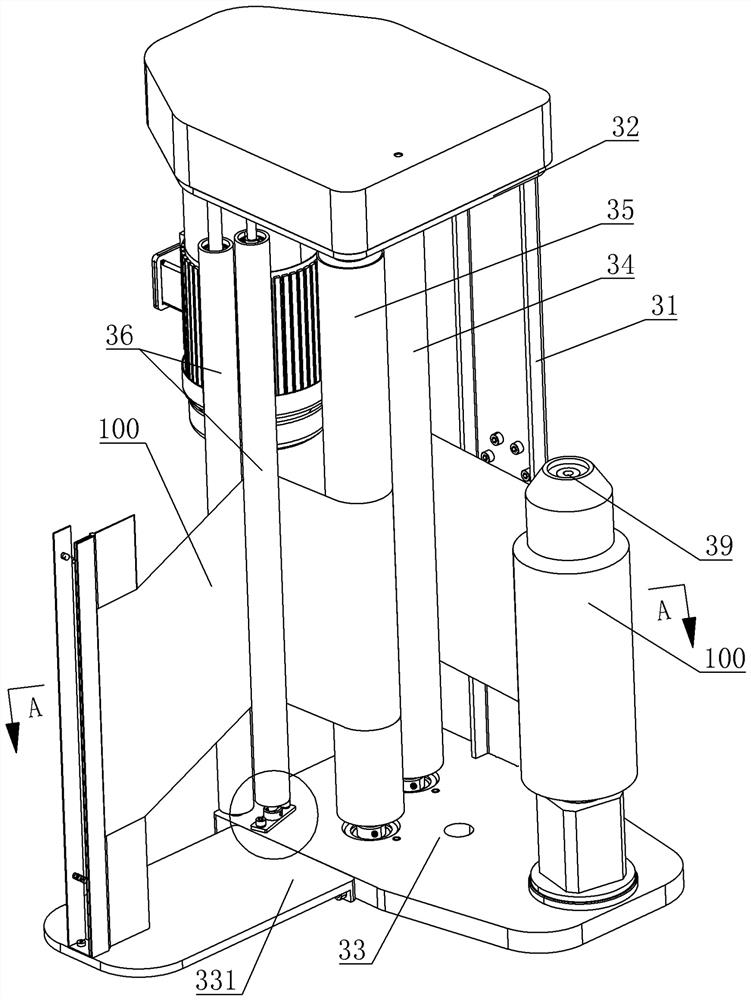

[0063] The film feeding device includes a top plate and a bottom plate fixedly connected by a support plate, a vertical roller shaft group, and a driving mechanism for driving the roller shaft group to rotate. The film feeding device is vertically fixedly connected to the end of the mechanical arm through a support plate. The roller shaft group includes Vertical staggered rotation arrangement, drive roller A, drive roller B, and two driven rollers installed between the top plate and the bottom plate at both ends, the two drive roller axes are located in the middle of the bottom plate and the top ...

Embodiment 2

[0073] Embodiment two, refer to the appended Figure 1-22 , a method for wrapping articles using the self-propelled wrapping packaging robot in Embodiment 1, comprising the following steps:

[0074] S1. The goods to be packaged are neatly arranged in the cargo yard, and the AGV vehicle receives the location information of the goods to be packaged (300), and traces to the location of the goods to be packaged by itself according to the location information and the yard map;

[0075] S2. The object camera forming module (12) equipped on the AGV vehicle itself obtains the image of the cargo, generates a digital 3D model of the cargo from the image according to the 3D visualization technology, and the control system automatically plans the winding path of the AGV vehicle according to the cargo model;

[0076] S3. The film (100) wrapped around the goods is pasted on the surface of the goods to be packaged (300) through the cooperation of the tape fixing device (04) and the suction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com