Tea leaf withering process plant

A kind of processing equipment and tea technology, which is applied in the direction of tea processing before extraction, etc., to meet the requirements of large-scale production, improve quality, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

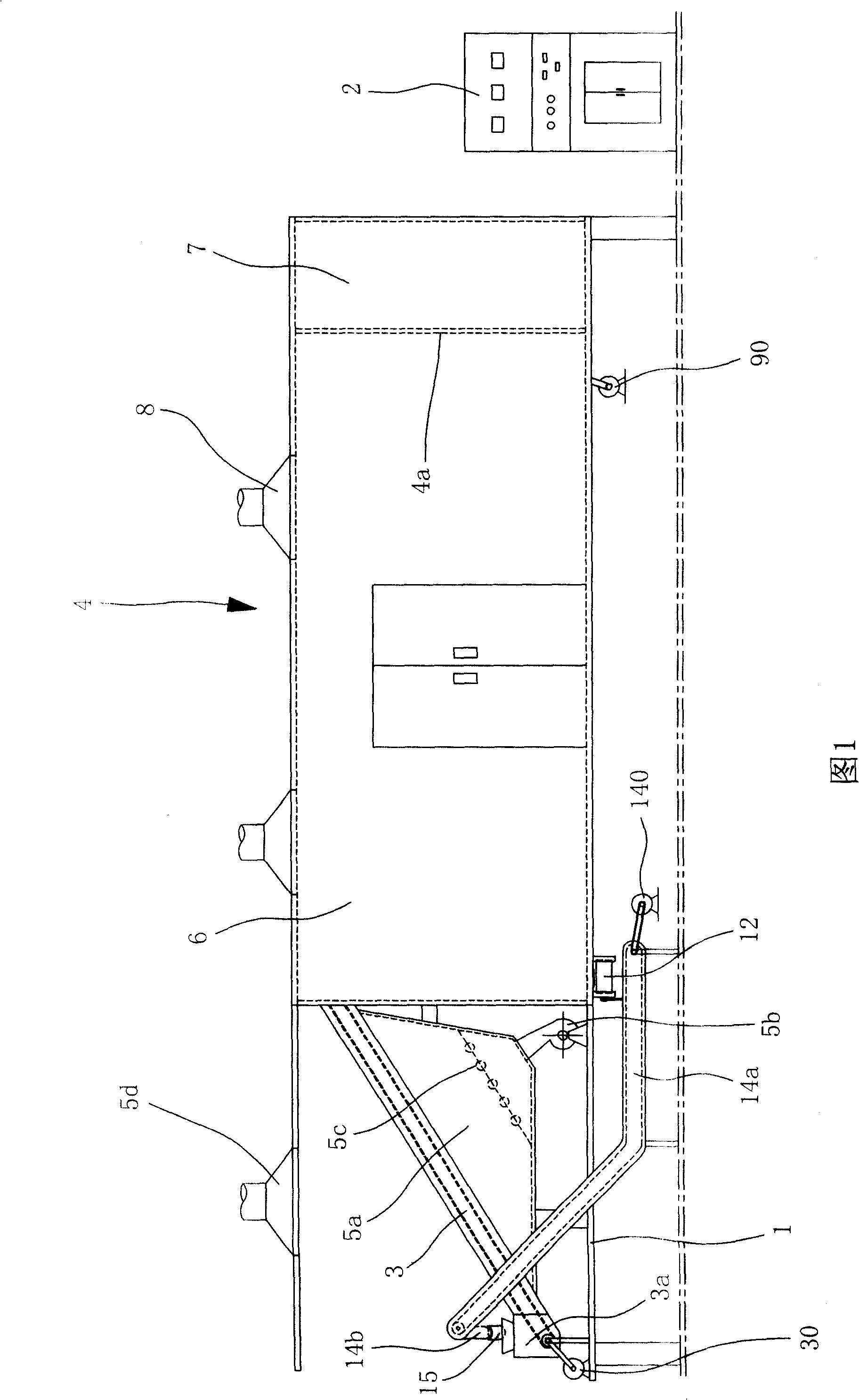

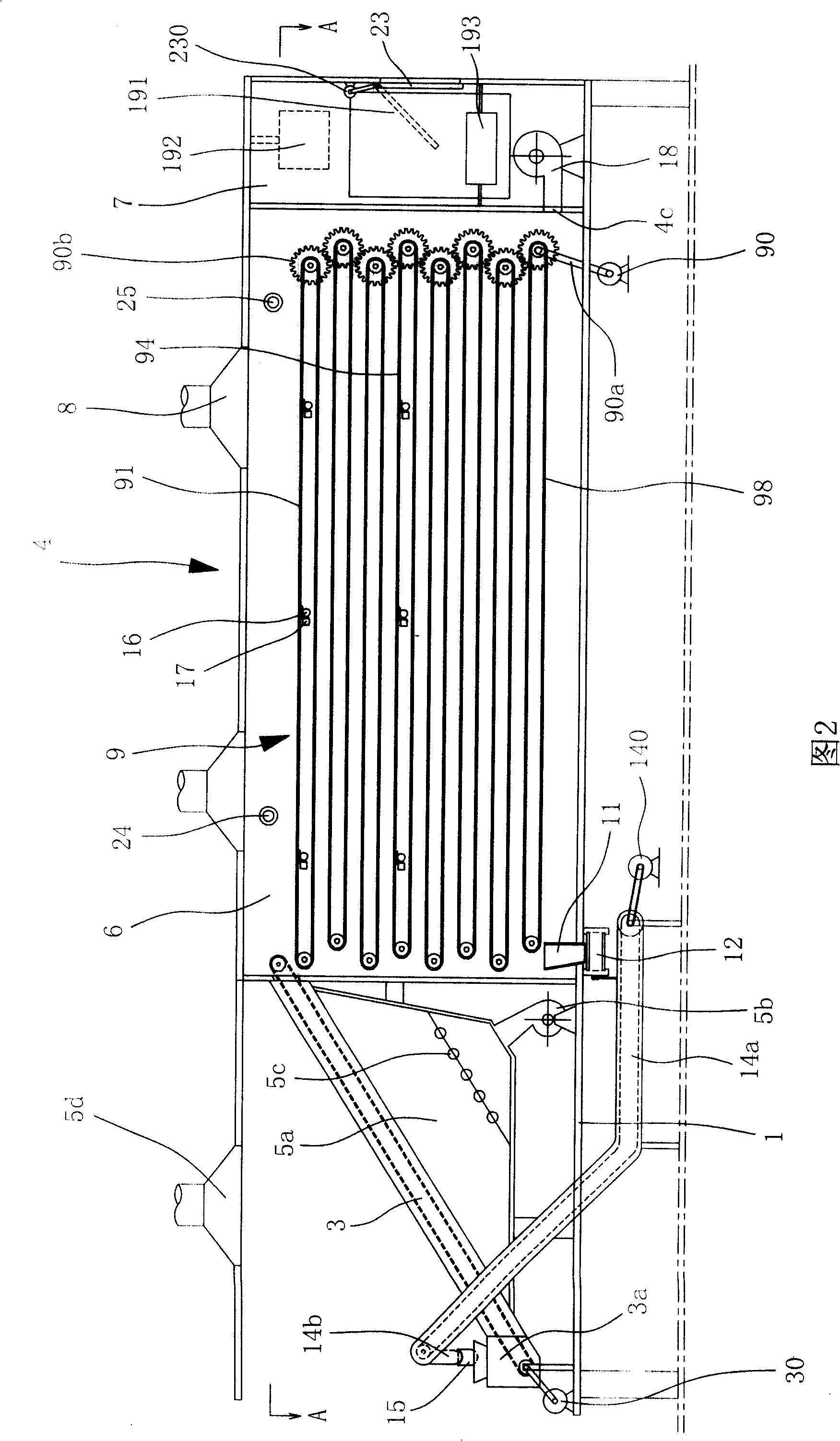

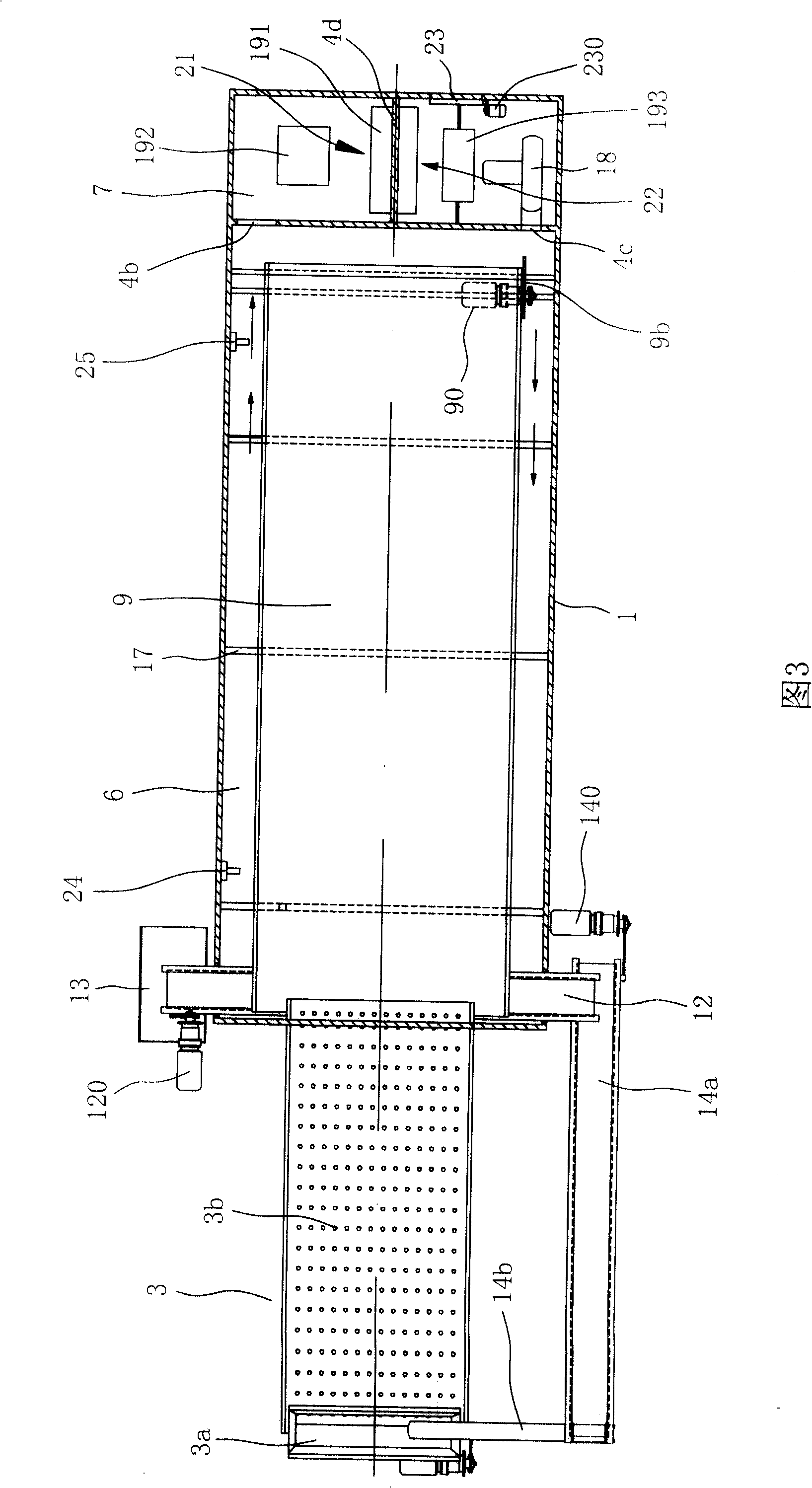

[0017] Embodiment 1: With reference to Fig. 1. The tea withering treatment equipment mainly includes a frame 1, an electric control box 2, a feeding conveyor belt 3 installed on the frame 1, a box body 4, a cold and hot air supply device, a discharge conveyor belt, and a loop return device. Below in conjunction with Fig. 1 to Fig. 3, the structure of this embodiment is described in detail:

[0018] Material lifting conveyor belt 3 is installed on the front upper part of frame 1 by support, and casing 4 is fixedly installed on the frame 1 of material lifting conveyor belt 3 rear portions. The driving motor 30 fixed on the frame 1 is connected with the transmission of the material lifting conveyor belt 3, and the driving motor 30 drives the material lifting conveyor belt 3 to rotate through the belt. The loading end of the material-lifting conveyor belt 3 is provided with a hopper 3a, and the discharge end passes through the side plate of the box body 4 and extends into the top...

Embodiment 2

[0027] Embodiment 2: as shown in Figure 5. The present embodiment is different from Embodiment 1 in that: the discharge conveyor belt 12 is directly arranged on the inner bottom of the tea green treatment chamber 6 below the discharge port end of the lowermost conveyor belt 98, and on the both sides of the tea green treatment chamber 6 Correspondingly, an opening 26 for the discharge conveyor belt 12 to pass through is provided, and the two ends of the discharge conveyor belt 12 protrude out of the dark green processing chamber 6 through the corresponding openings 26 . The tealeaves sent out by the lowermost conveyor belt 98 directly falls on the discharge conveyor belt 12, and the material passing port is no longer provided. The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com