Tea leaf cooling and impurity removing barrel

A technology for tea and greening, which is applied to the field of tea-airing and impurity removal cans, can solve the problems of difficulty in distributing the temperature of tea leaves, premature fermenting of tea leaves, and occupying room area, etc., and achieves simple structure, small footprint, and simplified processing. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

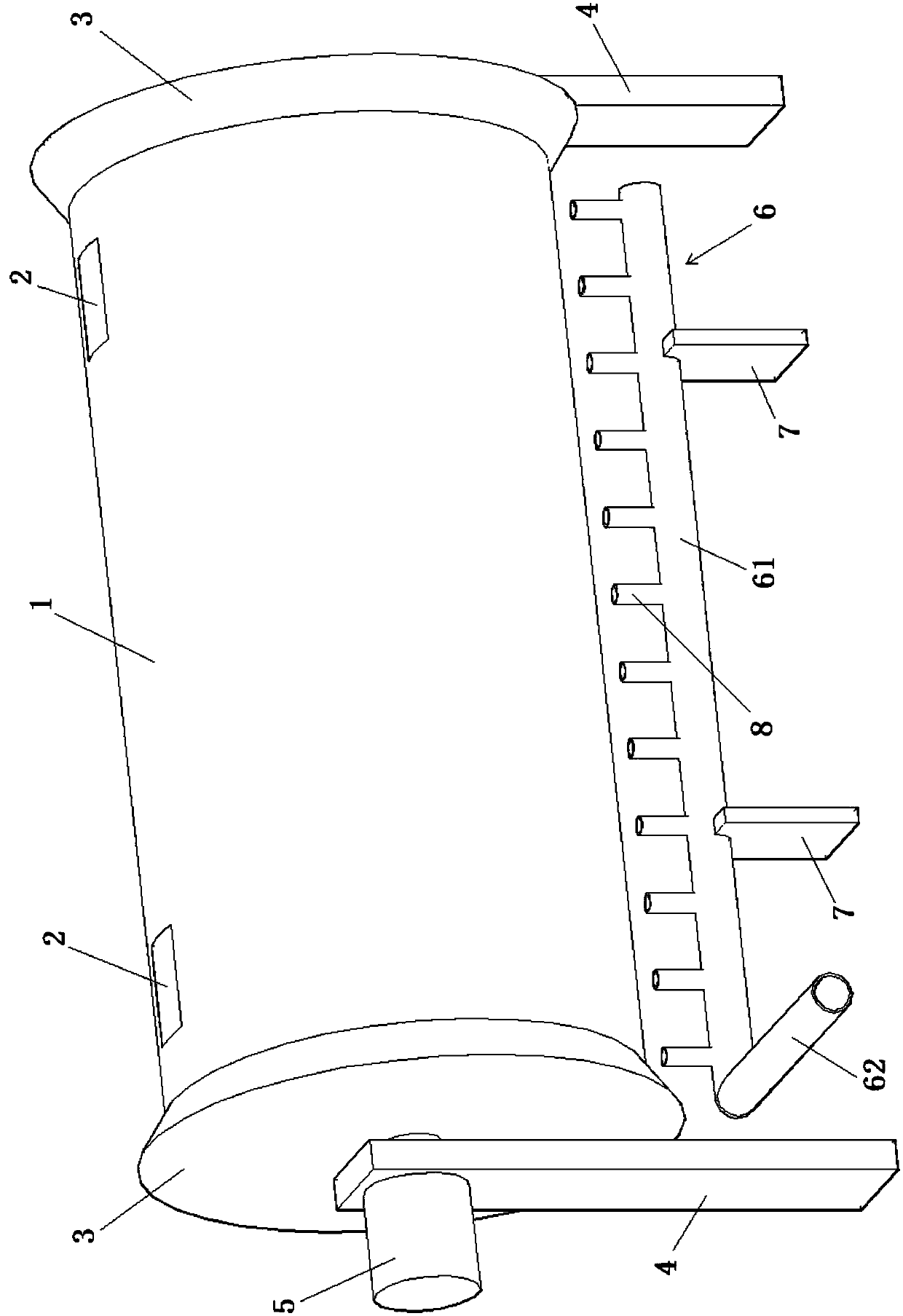

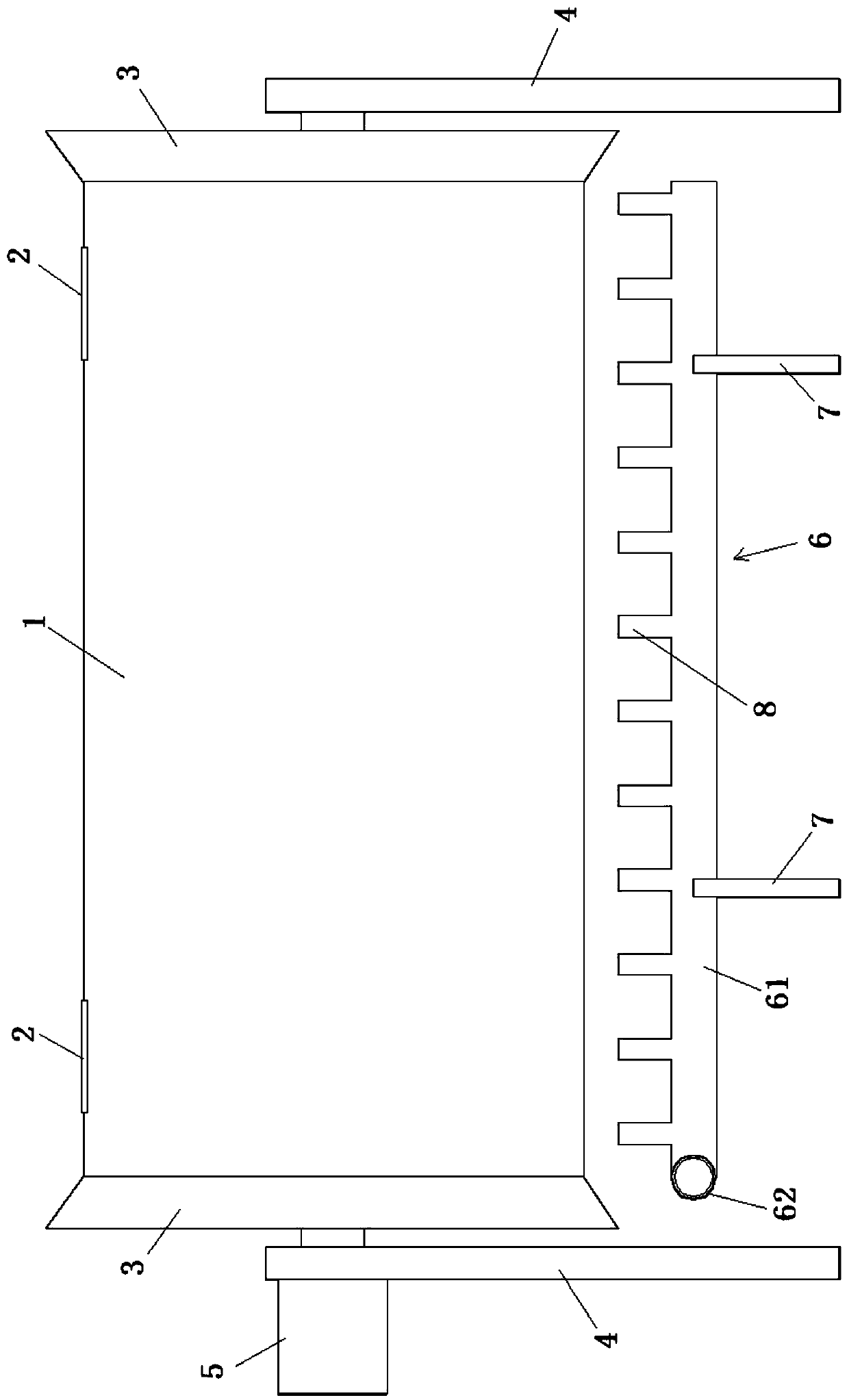

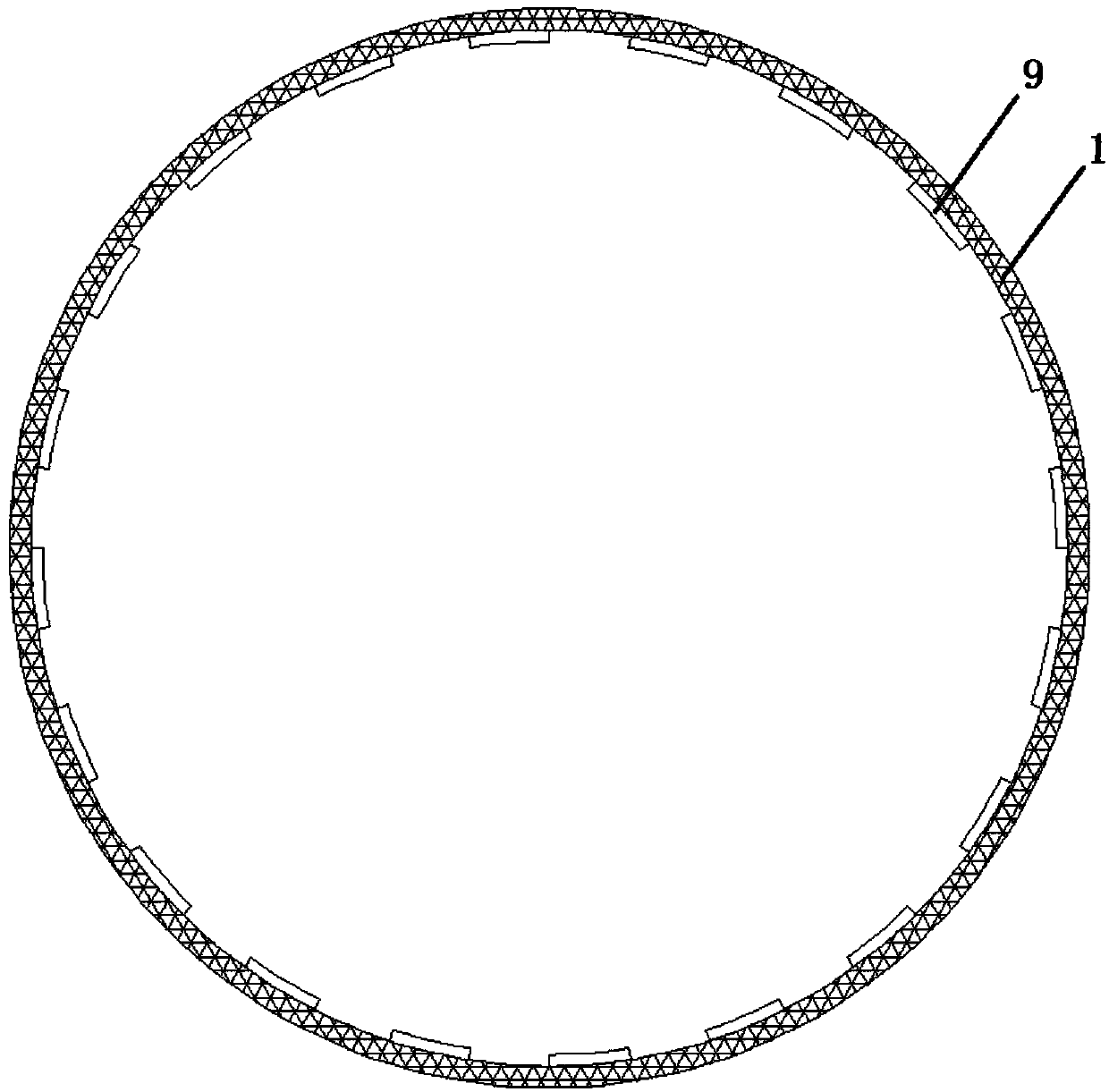

[0032] A barrel for airing and removing miscellaneous tea leaves, comprising a barrel body 1, the barrel body 1 is made of mesh stainless steel with a mesh number of 9 meshes, the barrel body 1 is provided with a material port 2, and the material port 2 is provided with a The material door can be opened and closed. The left and right sides of the cylinder body 1 are provided with frustum-shaped baffles 3. The baffles 3 are installed on the bracket 4 and rotated by the motor 5. The rotation of the baffles 3 drives the cylinder. The body 1 rotates to make the tea roll in the cylinder body 1, and the bracket 4 is fixed on the ground; an L-shaped air duct 6 is arranged under the cylinder body 1, and the L-shaped air duct 6 is composed of mutually perpendicular long The long pipe 61 and the short pipe 62 are composed of the long pipe 61 and the short pipe 62. The long pipe 61 is supported on the ground by several support plates 7. The long pipe 61 is located directly below the cylin...

Embodiment 2

[0038] A barrel for airing and removing miscellaneous tea leaves, comprising a barrel body 1, the barrel body 1 is made of mesh stainless steel with a mesh number of 9 meshes, the barrel body 1 is provided with a material port 2, and the material port 2 is provided with a The material door can be opened and closed. The left and right sides of the cylinder body 1 are provided with frustum-shaped baffles 3. The baffles 3 are installed on the bracket 4 and rotated by the motor 5. The rotation of the baffles 3 drives the cylinder. The body 1 rotates to make the tea roll in the cylinder body 1, and the bracket 4 is fixed on the ground; an L-shaped air duct 6 is arranged under the cylinder body 1, and the L-shaped air duct 6 is composed of mutually perpendicular long The long pipe 61 and the short pipe 62 are composed of the long pipe 61 and the short pipe 62. The long pipe 61 is supported on the ground by several support plates 7. The long pipe 61 is located directly below the cylin...

Embodiment 3

[0051] A barrel for airing and removing miscellaneous tea leaves, comprising a barrel body 1, the barrel body 1 is made of mesh stainless steel with a mesh number of 9 meshes, the barrel body 1 is provided with a material port 2, and the material port 2 is provided with a The material door can be opened and closed. The left and right sides of the cylinder body 1 are provided with frustum-shaped baffles 3. The baffles 3 are installed on the bracket 4 and rotated by the motor 5. The rotation of the baffles 3 drives the cylinder. The body 1 rotates to make the tea roll in the cylinder body 1, and the bracket 4 is fixed on the ground; an L-shaped air duct 6 is arranged under the cylinder body 1, and the L-shaped air duct 6 is composed of mutually perpendicular long The long pipe 61 and the short pipe 62 are composed of the long pipe 61 and the short pipe 62. The long pipe 61 is supported on the ground by several support plates 7. The long pipe 61 is located directly below the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com