Airing device for corn harvesting and using method of airing device

A drying device and corn technology, applied in lighting and heating equipment, drying, drying solid materials, etc., can solve the problems of low collection efficiency, labor-intensive, increased labor intensity, etc., to improve the effect of impurity removal, slow down the sliding speed, Guarantee the effect of impurity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

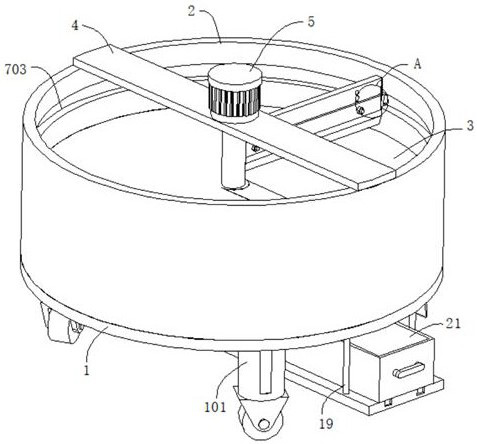

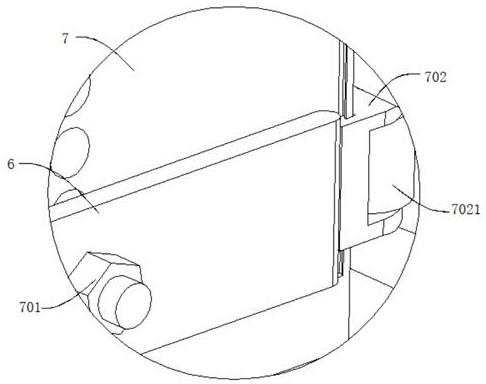

[0041] Refer figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 9 , A corn harvesting device, including the base 1, the top and bottom of the base 1, respectively connected to the annular frame 2 and the support seat 101, and the inner wall of the ring frame 2 is connected to the drying plate 3, and the top of the ring frame 2 is connected to the top plate 4, The outer wall of the top plate 4 is connected to the first motor 5. The output of the first motor 5 is connected to the first axis 501, and the first axis 501 is remote from one end of the first motor 5 through the top plate 4 and is rotated through the bearing 3, The outer wall of the first shaft 501 is connected to the fixing frame 6, and the inner wall of the fixing frame 6 is connected to the blade 7, and the blade 7 is placed above the drying plate 3, and the outer wall of the drying plate 3 is opened. 8, the bottom of the discharge groove 8 The wall is provided with a mesh plate 10, and...

Embodiment 2

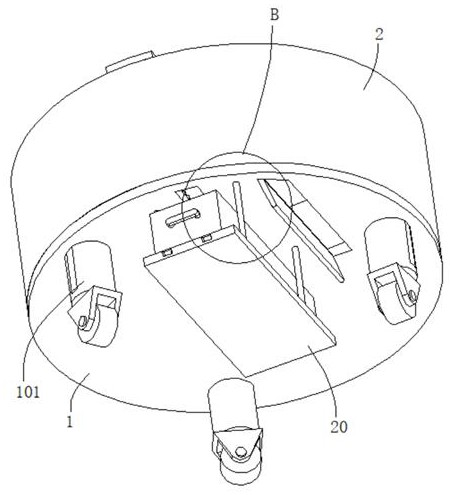

[0047] Refer Figure 3-7 One type of corn harvesting means is substantially the same as in Example 1, further, the outer wall of the connecting plate 9 is connected to the branch plate 15, and the bracket 15 is rotated and connected to the rotating lever 151, the rotor rod 151 outer wall connection is driven The cone gear 1511, and the outer wall of the second shaft 141 are connected to the active cone 1411 that is engaged with the slave gear 1511, and the rotating rod 151 is away from the slave plate 1511 and the first link 16 is connected. The outer wall of the first link 16 is rotated to be connected to the second link 161, and the second link 161 is connected to one end of the first link 16, and the moving rod 162 is fixedly connected to the mobile board 17, the moving plate 17 activity Connect to the discharge tank 8.

[0048] The bottom wall of the base 1 is connected to the connecting rod 19, and the connecting rod 19 is connected to one end of the base 1. The top plate 20 i...

Embodiment 3

[0051] Refer Figure 1-10 , A corn harvesting device is basically the same as that, further, the inner wall of the moving plate 17 is opened, and the inner wall of the groove 171 is connected to the first elastic member 172, the first elastic member 172 away from the concave One end of the inner wall of the groove 171 is connected to the top wall of the tablet 173 and the top wall of the drying plate 3 in the same plane; when the moving plate 17 is placed in the discharge groove 8, the flat plate 173 is in the action of the first elastic member 172. At the same plane with the drying plate 3, ensure the uniformity of the scraper 7 spread, avoiding the tank 8 due to the excess of the surface, causing the corn grain multi-layer coverage, cannot be directly contacted with the sun, affecting the drying effect of corn grains.

[0052] The outer wall of the mesh plate 10 is provided with a uniform distributed bump 18; it is convenient to slow the sliding speed of the corn granules on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com